Development and integration of an underground mining enterprise ventilation process simulations into the demand response

- 1 — Ph.D., Dr.Sci. Professor Perm National Research Polytechnic University ▪ Orcid

- 2 — Ph.D. Head of Center National Research University Higher School of Economics – Perm ▪ Orcid

Abstract

Controlling the ventilation in underground mining enterprises (UME), characterized by high inertia and numerous influencing external factors, based on real-time sensor data located in mine workings and on the surface, with a high level of accuracy in regulating air supply by the main ventilation unit (MVU), is feasible only under conditions of a pre-defined sequence of control actions. This task can be classified as an approximate dynamic programming (ADP) problem, which involves synthesizing a suboptimal control function for MVU operation in a predictive modeling mode of air distribution, given a known space of possible states and the selection of the optimal control strategy that meets a specified criterion. A simulation model of a digital twin subsystem for ventilation process control is presented, using the example of two types of UME (potash mines and oil shafts), which can be used to solve ADP tasks. For predictive modeling of air distribution and determining the energy efficiency criterion of the MVU, which consumes up to half of the total electricity of the UME, the digital twin is integrated with external data, based on which energy consumption is evaluated while maintaining the required volume of supplied air. This control approach enables not only safe and energy-efficient management of the ventilation process but also participation in the planning and implementation of measures for price-dependent electricity demand management.

Funding

The research was funded by the Ministry of Science and Higher Education of the Russian Federation (Project N FSNM-2024-0005).

Introduction

The mining industry is among the most energy-intensive sectors in Russia [1, 2] and abroad [3, 4], with the energy component accounting for 37-40 % of the production cost of finished products [5], which has a detrimental impact on the economy given the persistent trend of rising energy prices.

However, the methods and devices developed to reduce electricity consumption often do not allow for simultaneous efficient and safe management of underground mining enterprises (UME) [6, 7], necessitating the development of the company's energy policy. In addition to the complexity of implementing energy-saving programs at hazardous production facilities, there is the challenge of aligning generation and consumption patterns [8, 9]. This is because most power plants in industrial areas produce electricity continuously throughout the day, while energy consumption exhibits a pronounced cyclic pattern tied to a 24-hour time interval, i.e., there are periods of high and low electricity demand within a day [10, 11]. One solution to this second issue is price-dependent electricity demand management (Demand Response – DR) – a change in electricity consumption by end users relative to their normal profile in response to time-varying electricity prices or incentive payments provided for reducing energy consumption during peak demand hours.

The actual state of power grids in industrial regions, combined with the operating modes of energy consumers, weather conditions, and other factors, largely determines the imbalanced values of electricity generation and consumption indicators. The simultaneous activation of various equipment units throughout the day creates instantaneous energy demand, leading to a sharp increase in grid load and, consequently, a reduction in reliability. The practice of deploying and maintaining reserve grid capacities can address issues of high demand, including in energy-deficient regions, but it results in significant increases in capital expenditures and the cost of electricity transmission services.

The complexity of load balancing, including for overloaded substations, unpredictable consumption volumes, the inability to store electricity locally on an industrial scale, the need for more accurate forecasting (predictive analytics) and dynamic electricity distribution during peak load hours (preventive analytics), as well as the economically viable interpretation of modern energy market conditions, drive the demand for electricity demand management worldwide [12, 13] and in Russia [14-16]. To reduce financial costs in underground mining, it is necessary to develop mechanisms that not only reduce electricity consumption without compromising production safety but also do so at specific times to enable the enterprise to participate in DR.

Considering that the primary electricity consumption in UME is associated with ventilation (up to half [17-19], and according to some sources, up to 70 % [20]), the search for solutions in the areas of DR and energy conservation was focused on this domain. An essential condition was ensuring safety, as the critical ventilation process directly impacts it.

Despite the differences among enterprises based on the type of extracted raw material and mining methods, depending on the depth of the deposit, ventilation methods, the number of mine shafts, etc., a general action plan for process management can be developed, taking into account the most significant factors. This study examines two types of UME: potash mines (using the example of the Verkhnekamskoye deposit of potassium-magnesium salts – VKMKS) and oil shafts (Yaregskoye deposit).

Construction of the digital twin simulation subsystem for the ventilationcontrol

In recent years, digital technologies have been increasingly applied across all spheres of human activity, including the mining industry. In the mining sector, an example is the creation of digital twins (DT), i.e., virtual replicas of physical systems that enable monitoring, modeling, and managing the behavior of the simulated system in real time. This solution allows mining companies to optimize equipment performance and reduce downtime [21-23]. It is expected that the use of digital twins in Industry 4.0 and the Internet of Things (IoT) will grow in the coming years as more companies adopt this technology [24].

Implementing a digital twin requires a high level of integration of data and information from various sources and systems. A digital twin is typically created by integrating multiple technologies, including sensors, data analysis tools, and modeling tools. In the context of cyber-physical systems (CPS), a digital twin comprises several subsystems, with the simulation subsystem being one of the key components, used to model the behavior of the physical system and its interaction with the environment [25]. Developing the simulation subsystem of a digital twin requires a structure that accounts for the physical and cyber components of the system, as well as the interaction between these components. This structure may include co-simulation, where the digital twin and the physical system are modeled together, as well as hardware-in-the-loop testing, where the digital twin is integrated with physical equipment to simulate real-world scenarios.

The ventilation process, which is the most energy-intensive, in potash mines and oil shafts is carried out using the main ventilation unit (MVU). Unjustified changes to energy consumption, and thus the operating mode of the MVU, are prohibited, as it supplies the underground mining enterprise with the air necessary for the survival of miners and the safety of mining operations. Changes to the MVU's operating modes must be carried out based on a written order from the technical manager of the UME. Therefore, to utilize this resource for reducing energy consumption and participating in DR, it is necessary to provide justified recommendations for such actions.

The study [6] established that the most significant factor affecting the operation of the main ventilation unit (MVU) is the mine-wide natural draft – a phenomenon resulting from the difference in air densities in interconnected mine shafts [26, 27]. The primary parameter influencing the magnitude of the natural draft is the temperature of the outside air, as well as the air supplied to and exiting from the mine shafts [28]. The mine-wide natural draft can be negative, i.e., hindering ventilation, or positive, facilitating air supply and, consequently, the operation of the MVU [29, 30]. Based on this, it follows that when a positive natural draft is present, it becomes possible to reduce the MVU's output while still ensuring the supply of the required volume of air to the mine shafts [6, 31].

Previously derived mathematical relationships allow for determining the magnitude and direction of the mine-wide natural draft with a specified confidence probability, based on the parameters of the outside air, as well as the air supplied to and exiting from the mine shafts [32]. By knowing the technical characteristics of the underground mining enterprise, the parameters of the main ventilation unit, and the parameters of the outside air during the regulation of the ventilation process, it is possible to predetermine the magnitude and direction of the mine-wide natural draft and forecast the required operating mode of the MVU. In this case, changes to the MVU's operating mode are made based on changes in the outside air parameters, rather than relying on air flow sensor readings. The ventilation process is inertial, and after adjusting the MVU's output, air distribution between the mine shafts occurs only after a certain time interval, which for the considered potash mines and oil shafts is up to 6-7 min. Therefore, managing ventilation solely based on sensor readings, without accounting for the process's inertia, is not feasible.

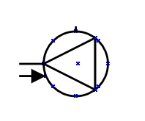

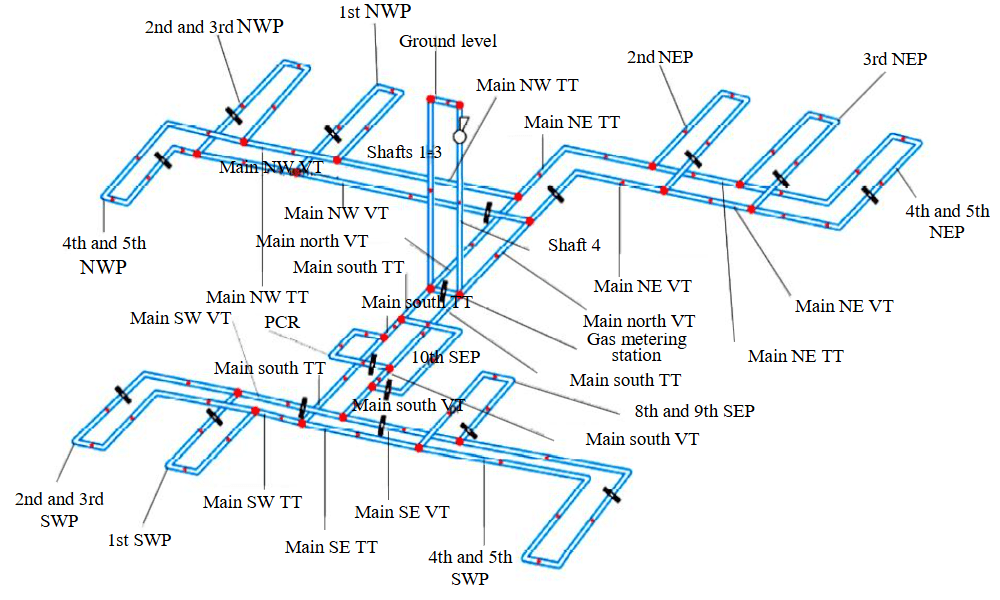

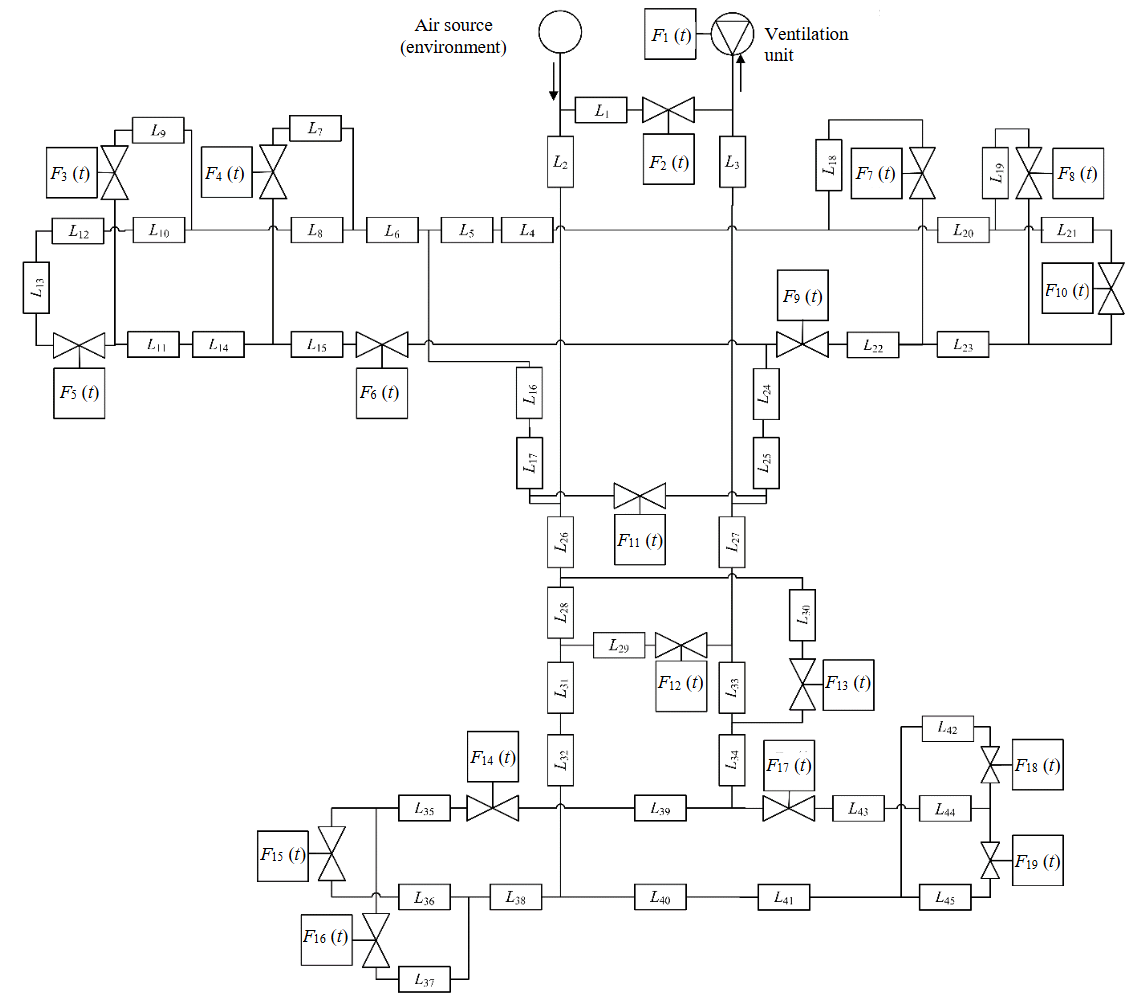

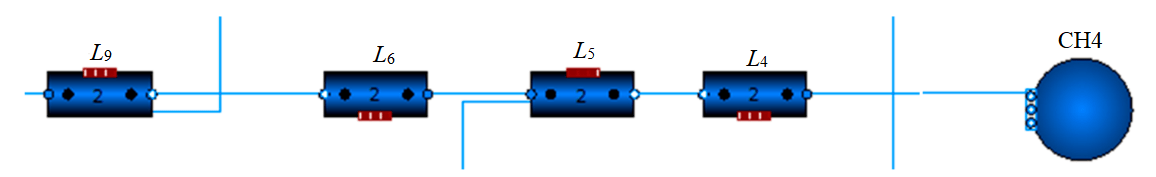

To predict air distribution between mine shafts and select the required operating mode of the main ventilation unit in real time based on the provided simplified ventilation scheme (Fig.1), a simulation subsystem of a digital twin (simplified model) for ventilation control was developed in OpenModelica using the example of the BKPRU-4 mine (Uralkali PJSC) (Fig.2).

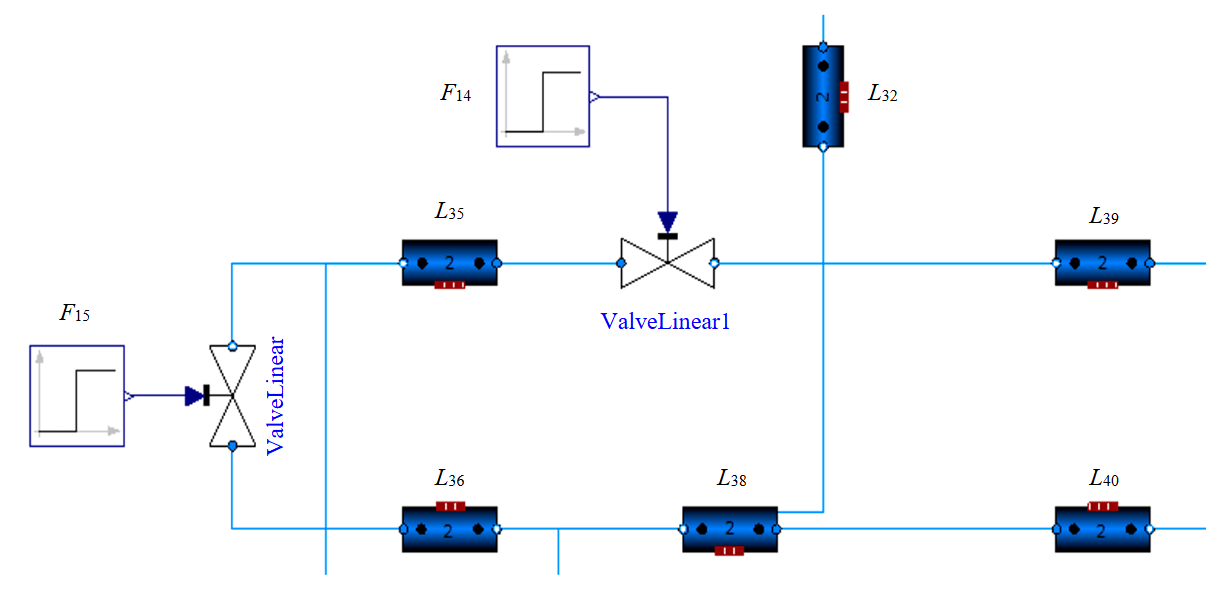

The presented graphical scheme of the ventilation control process for the digital twin simulation subsystem in OpenModelica includes components described in the Table. Each element is a software object from the Fluid library, which contains components for modeling air, liquid, and steam flows. Each software object implements specific physical behavior and has interfaces for interacting with other objects to receive and transmit computed values. The objects are described by corresponding differential equations, interconnected to form a system of 8170 equations, solved by the OpenModelica environment during the simulation of the ventilation process.

The Table provides information about the Pipe element of the Modelica.Fluid.Pipes.DynamicPipe software class, interpreted as a mine working. The parameters of this component correlate with the example of the BKPRU-4 mine scheme as follows: if the elevation parameters of the initial and final points are specified, the working is interpreted as horizontal if the values are the same, vertical if the values differ by the length of the section, and inclined in other cases. The cross-section of the mine working is assumed as circular, but an equivalent diameter is used, calculated according to the methodology [33].

Fig.1. Simplified ventilation scheme of the BKPRU-4 mine

TT – transport tunnel; VT – ventilation tunnel; NWP – north-west panel; NEP – north-east panel; SEP – south-east panel; SWP – south-west panel

Fig.2. Ventilation control model of a digital twin simulation subsystem

Technical description of the components of the digital twin simulation subsystem

|

Block type |

Notation |

Description |

|

|

Fig.2 |

OpenModelica |

||

|

FixedBoundary |

|

|

An air source with a specified temperature, pressure, density, specific enthalpy, and composition of gases in the form of impurities described by mass fractions |

|

Pipe |

|

|

A straight section of a mine workings with a specified length, cross-sectional area, wall unevenness, and the heights of the starting and ending points relative to the uniform horizontal level established for the entire mine |

|

MassFlowSource_T |

|

|

MVU fan simulating air supply with a specified mass flow rate per unit time, specified temperature, and impurity composition |

|

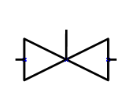

ValveLinear(valve with linear control) |

|

|

Valves that simulate various types of isolating devices, such as jumpers and ventilation doors, with a specified nominal mass air flow rate when fully open and a pressure drop when fully open |

|

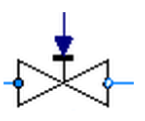

Step (step control function) |

|

|

Control element for valves with a set signal level and its time offset t relative to the start of ventilation simulation |

During the research, the results of the digital twin simulation subsystem were confirmed to be consistent with previously obtained experimental calculations [31].

To automatically “load” data on outdoor air parameters, a software was developed to connect to the digital twin simulation subsystem via its digital interface [34]. Examples of connections to the weather service, the block for reading and transferring data from .csv files, and the block for reading and writing data to the time series database have been developed. The software is launched by the user via the console and reads data on the outside air temperature from the weather service, data on the temperature at several points in the mine workings from files, fills in the gaps in the data, converts formats and exports the result to a measurement table in the database. In this case, it becomes possible to predict the value of the overall natural draft depending on the hydrometeorological forecast.

The simulation subsystem of the digital twin of the ventilation control process allows, based on the forecast values of outdoor air parameters using mathematical dependencies, to determine with high accuracy the value of the overall natural draft, which in this case will act between the mine shafts. This will allow the selection of the required mode of operation of the ventilation system, taking into account the inertia of the ventilation process, in which the required volume of air will be supplied to the mine air supply shafts. Also, when negative natural draft acts on the entire mine, there will be no unjustified increase in the air supply system's performance, but only compensation for its effect on the ventilation process. When positive natural draft acts on the entire mine, a decrease in performance is possible, and therefore, a decrease in the air supply system's energy consumption.

The second type considered in the UME study is oil mines, in which air is supplied by suction ventilation (similar to the ventilation scheme used in potash mines) – through two air supply shafts due to the vacuum created by the MVU located on the ventilation shaft. However, a sectional ventilation scheme is currently recommended [35, 36], in which, in addition to supplying air to the oil mine through mine shafts, air is supplied separately to each inclined block (production area) through air supply and ventilation wells. Through the air supply well, outside air enters the slope (air supply working), washes the drilling gallery where oil is produced, and is removed through the ventilation well drilled in the passage (air exhaust well) to the surface. With this ventilation scheme, natural draft will act not only between the mine shafts, but also between the inclined block wells. This makes it even more difficult to control the ventilation process, as it is necessary to take into account the effect of natural draft between each pair of inclined block wells on the operation of the ventilation system.

Using the air distribution between underground mine workings in a digital twin

The simulation subsystem allows determining the air distribution between mine shafts and selecting the MVU operating mode at which the required volume of air will be supplied to the UME. However, it should be noted that due to the constant growth in the volume of minerals extracted, the increase in the number of depleted mining areas and the distance between them and the air supply shafts, the process of supplying all working areas with fresh air is becoming more complicated and, consequently, there is no guarantee that the air will not be distributed throughout the mine workings, resulting in a shortage of air in the mining areas. In this case, the digital twin should consider the processes of air distribution between underground mine workings.

Since potash mines have low aerodynamic resistance [37], even slight temperature differences caused by heated sections of the conveyor belt or other heat sources will affect ventilation stability [33]. In addition, study [38] found that when light gases (mainly methane) are released in mined and mined chambers, additional natural draft occurs between mine workings due to the different specific weights of gas-air mixtures. In this regard, additional adjustments must be made to the digital twin to account for this effect.

In oil mines, air distribution between mining workings is an even more complex process, as there are heat sources in the production areas. Their presence is due to the unique method of extracting high-viscosity oil – thermal mining [39, 40]. When using this method, steam is injected into the oil reservoir, which reduces the viscosity of the oil and increases its fluidity. At the same time, the air temperature in the inclined block to high values – in the drilling gallery (the place where steam is injected into the reservoir) and in the outgoing mine workings. Solutions aimed at reducing the air temperature in the inclined block and outgoing mine workings have no significant effect.

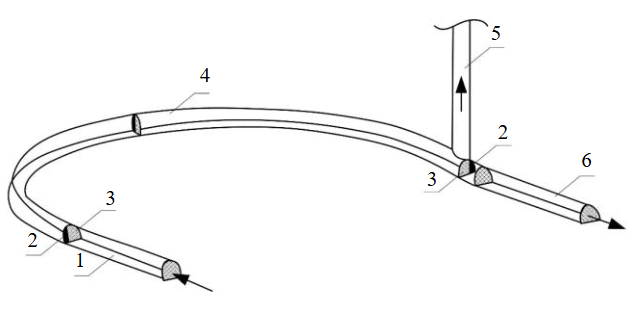

A method for reducing the air temperature in mountain oil mine workings while ensuring resource and energy conservation is described in [41]. A heat-insulating partition is installed in the inclined block in front of the heated oil layer (Fig.3), as a result of which the air supplied through the incline is divided into two streams – one stream passes between the heat-insulating partition and the oil layer (the non-working part of the drilling gallery), and the second enters the drilling gallery on the other side of the partition (the working part of the drilling gallery). In the non-working part of the drilling gallery, the air is heated and then removed to the surface through the ventilation well. The non-working part of the drilling gallery is limited by the heat-insulating partition to the base of the ventilation well. Air that meets the required sanitary standards enters the working part of the drilling gallery, i.e. it is possible to ensure comfortable working conditions in the inclined blocks and the oil shaft as a whole.

However, the presence of ventilation holes originating from inclined blocks, through which air of varying volumes and temperatures escapes, makes the ventilation process less stable and significantly complicates control.

When modelling the ventilation process in potash mines and oil wells, it is necessary to consider the release of harmful and hazardous gases in mine workings. For example, to account for methane, an additional FixedBoundary source with a specified air mixture composition describing a high methane content is installed in the simulation subsystem of the digital twin at one of the levels of the mine workings, which is connected to one of the transport workings (Fig.4).

Fig.3. Ventilation of the inclined block of an oil mine using a heat-insulating partition: 1 – slope; 2 – non-working part of the drill gallery; 3 – working part of the drill gallery; 4 – drill gallery; 5 – ventilation shaft; 6 – walkway

Fig.4. Example of adding a new source of gas-air mixture with excess methane content in OpenModelica

General natural draft can be incorporated into the simulation subsystem at the level of the valve control algorithm in the ventilation shaft (for oil wells – additionally in ventilation wells), as well as in adjacent branches. To simulate the action of general mine natural draft in a positive direction, i.e. when it promotes ventilation, the corresponding time delays and the level of air flow increase on the Step control device for the MVU must be set (see Table). To simulate the effect of natural draft in the mine in a negative direction, i.e. hindering ventilation, the corresponding air flow rate on the Step control device for the ventilation system must be reduced. To simulate a change in the direction of air between mine shafts, time delays for the damper must be set (Fig.5).

Fig.5. Example of damper control on a ventilation shaft (and ventilation well) to simulate the action of general natural draught in OpenModelica

The following parameters are specified with the model:

- temperature and atmospheric pressure of the outside air entering the mine shafts;

- location and/or inclination of mine workings, their cross-sectional area and length;

- condition of insulating devices, including those used to simulate the operation of mining machinery;

- MVU capacity, including for simulating unloading during demand management events.

Energy demand management system for underground mining operations

Energy flows and accompanying data between automation objects can be effectively used to regulate equipment operation and reduce load during periods of increased demand [13], but demand management strategies can vary significantly [42]. There are numerous publications by Russian scientists [43-46] describing the theoretical foundations of the functioning of such services and systems, including those based on the regulations of the Decree of the Government of the Russian Federation N 287 of 20 March 2019. It is known that the loads of a wide variety of electricity consumers can participate in demand management, including industrial equipment of mining enterprises, which can be combined into larger units with dispatch control. Due to the wide variety of current and potentially connectable industrial equipment units and the multitude of factors affecting their operation, avoiding energy consumption during peak demand hours in aggregated groups requires support from control room operators in terms of higher quality planning, which can be achieved through the development and implementation of digital twins.

Managing electricity demand during ventilation involves the following tasks:

- Planning energy consumption for the next day, i.e. planning tasks for the MVU control system. It is necessary to calculate the required amount of electricity per hour for the next day. Deviations from the plan lead to financial penalties. Determining energy consumption mainly depends on the performance of the MVU system, i.e. it is directly related to the volume of air supplied to the UME. Solving this problem using energy consumption forecasting methods allows you to take into account observation statistics, identify patterns and factors affecting the system, determine a planned energy consumption profile for the MVU system that is close to reality, and plan unloading operations taking into account the electricity tariff grid and possible time intervals, considering the effect of natural draft between the UME workings.

- Implementation of the declared energy consumption plan during the day. In real time, it is necessary to monitor the compliance of energy consumption with the declared plan and compensate for any deviations that arise. Deviations from the energy consumption plan may arise in the event of a mismatch between the predicted values of disturbances to the system during planning. For example, a significant error in the weather forecast and, as a result, a change in the value of the overall natural draft or interference caused by the movement of people, transport, and equipment within the UME, which leads to a change in air distribution between mine workings. Solving this problem using a digital twin simulation subsystem allows you to search for the optimal MVU control trajectory in simulation mode to minimize deviations from the declared energy consumption plan.

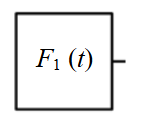

The optimal control problem is represented as a functional of the form:

where D – control actions set; Х – stateset; g(x) – constraints; J(x, u) – control criterion; x(t) – state vector; u(t) – control actions vector.

The constraints gk(x) ≥ 0, k = 1...N include requirements for ensuring the necessary air volume flow for each section of the mine and requirements for the concentration level of harmful gases. This problem can be solved using linear programming, which determines the time intervals for unloading and its magnitude.

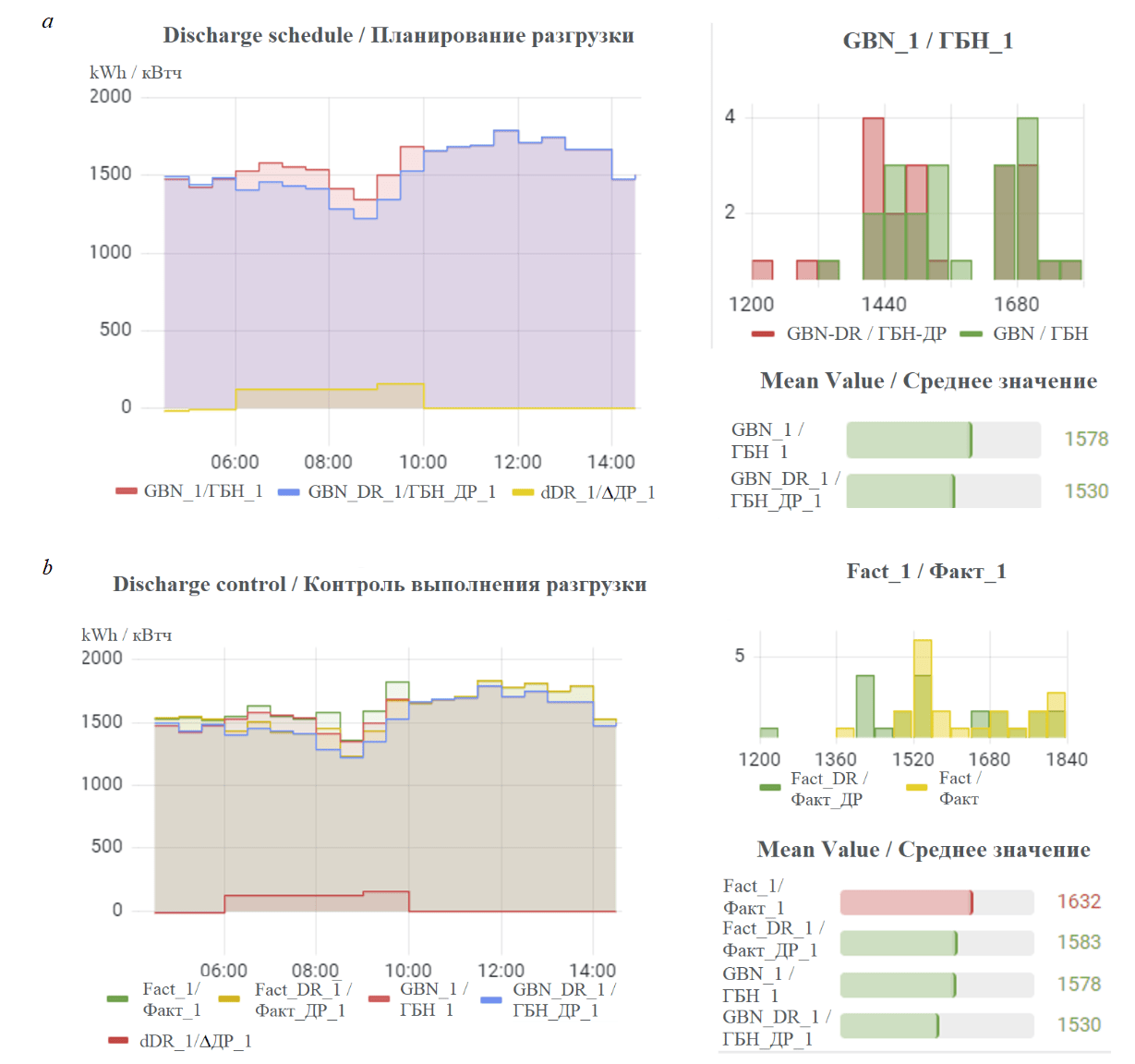

The results of calculations, daily energy consumption forecasting, and a simulation subsystem of a digital twin ventilation system in the OpenModelica environment were jointly integrated with the InfluxData Internet of Things platform based on the TICK technology stack. Instead of the built-in visualization unit, the external Grafana service was used to clearly display energy consumption values in the form of time series. As part of the integration, standard screen forms were implemented for UME demand response specialists, including an example of an operator panel for planning unloading and monitoring plan implementation, including the display of graphs, histograms, and average values (Fig.6).

The operator panel displays a widget with a base load graph (GBN), i.e. a calculated daily electricity consumption plan for the next day according to the System Operator's GBN calculation method (Fig.6, a). According to the action plan and weather conditions, OpenModelica estimates air distribution considering the effect of general natural draft and determines the permissible reduction value for a given unloading time. Based on the implemented models, the software calculates the cost of electricity for the month ahead for two profile states, namely the profile without power changes (“as is” according to the GBN) and after the change (“as will be” according to the GBN – the permissible power calculated in the digital twin), including a histogram and average values.

During testing, demand management event dates were selected at random in accordance with the accepted rules. After that, the necessary calculations were performed and unloading plans were obtained in accordance with the permissible values for each specific case. Figure 6, b also shows the difference between the GNB or actual values, as well as the GBN or actual values with unloading, respectively, including a histogram and average values. For example, unloading was simulated for 19 January 2022 from 06:00 to 10:00, including calculations of the base load of the GBN and power reduction in a given interval based on the parameters of the model in OpenModelica, assuming natural draft.The results presented show that during the specified four-hour period, the amount of power reduction that can be declared in advance and then guaranteed to be implemented is 171 kW, while in some hours the reduction potential may be significantly higher, for example 222 kW.

Fig.6. Operator panel to support the process of managing electricity demand during ventilation of the UME based on a digital twin simulation subsystem: a – GBN; b – difference between GBN and actual values

GBN / ГБН (orange); GBN_DR / ГБН _ДР (blue) – with a marked reduction plan; Fact / Факт (green) – electricity consumption without demand response events; Fact_DR / Факт_ДР (yellow) – electricity consumption, taking into account demand response events

The results of integrating and testing a simulation model as part of the InfluxData energy management platform using external meteorological data are demonstrated, allowing the possibility of reducing the load on the MVU system through natural ventilation to be assessed. Aligning the moments when draft is active with demand management events and controlled reduction of the load on the ventilation system allows maintaining the required level of air distribution, both in the case of a shaft and for a mine under conditions of perfectly accurate weather forecasting. The results of modelling permissible unloading showed a wide range of possibilities for reducing power from 51 to 224 kW at a nominal fan power of 2 MW (~ 11 % of the MVU power).

Conclusion

The solutions described allow natural processes to be used to reduce electricity consumption for the most energy-intensive process – ventilation of the UME. At the same time, air distribution, the operating mode of the MVU system and, consequently, energy consumption can be determined in advance based on hydrometeorological forecast data.

Currently, according to [47], the success rate (accuracy) of hydrometeorological forecasts and warnings about atmospheric phenomena reaches 85-90 %. Consequently, once meteorological data has been obtained, it is possible to calculate the value of the overall natural draft in advance and select the operating mode of the MVU system that will ensure the required ventilation mode.

In this case, it becomes possible not only to reduce the consumption of electricity for the operation of the ventilation system, but also to participate in the planning and implementation of DR. If energy consumption is reduced at a specified time, the mining company will receive financial compensation, thereby reducing the cost of mineral extraction.

Given that seasonal and daily changes in outdoor air parameters are stochastic in nature, when developing an electricity DR system, it is necessary to consider the conditions under which a reduction in electricity consumption will be possible if climatic changes do not allow the ventilation process to be controlled.

Other data can also be exported to the digital twin:

- daily electricity rates – potentially higher electricity consumption at a lower price;

- scheduled equipment shutdowns, inspections and repairs – these activities may be carried out during peak load hours.

The proposed model of electricity demand management using a digital twin simulation subsystem is an important technological solution that can be adapted to solve alternative problems in other industries. In particular, the technology can be used to implement energy consumption management algorithms with Model Predictive Control (MPC) predictive models, one of the modern methods of control theory used mainly in the management of production processes, for example in the chemical industry and oil refining [48]. In this case, the use of the service allows for more effective energy management strategies for technological processes and production facilities, implementing the concept of an intelligent power complex with a smart network (MicroGrid), which is particularly relevant for geographically distributed industrial sites and production facilities based on cyber-physical architectures [49, 50].

A key feature of the implementation of simulation modelling of the ventilation process is an object-oriented approach that allows the formation of model scenarios for related areas of knowledge, for example, to develop sequences of control commands to minimize environmental impact, to develop a management strategy considering personnel safety requirements, etc. A promising area of research is the introduction of elements of specialized intelligence (NarrowAI) into the energy consumption control loop, which, together with the proposed model, will allow the construction of hybrid forms of artificial intelligence (HybridAI) that use the strengths of machine learning together with the results of calculations based on accurate mathematical models [51].

The solutions developed in the study can be used to generate various energy consumption scenarios to obtain datasets that can be used to train more complex deep learning models for virtual energy managers, as well as, for example, to verify the results of generative artificial intelligence (GenAI), which together can be used to support decision-making on improving energy efficiency [52].

References

- Nevskaya M.A., Raikhlin S.M., Chanysheva A.F. Assessment of Energy Efficiency Projects at Russian Mining Enterprises within the Framework of Sustainable Development. Sustainability. 2024. Vol. 16. Iss. 17. N 7478. DOI: 10.3390/su16177478

- Dmitrieva D., Solovyova V. Russian Arctic Mineral Resources Sustainable Development in the Context of Energy Transition, ESG Agenda and Geopolitical Tensions. Energies. 2023. Vol. 16. Iss. 13. N 5145. DOI: 10.3390/en16135145

- Aramendia E., Brockway P.E., Taylor P.G., Norman J. Global energy consumption of the mineral mining industry: Exploring the historical perspective and future pathways to 2060. Global Environmental Change. 2023. Vol. 83. N 102745. DOI: 10.1016/j.gloenvcha.2023.102745

- Liu Xiaomeng, Meng Xiangrui. Evaluation and empirical research on the energy efficiency of 20 mining cities in Eastern and Central China. International Journal of Mining Science and Technology. 2018. Vol. 28. Iss. 3, p. 525-531. DOI: 10.1016/j.ijmst.2018.01.002

- Knyazkin E.A. Justification of parameters for energy-efficient drainage schemes for underground mines using hydropower: Avtoref. dis. … kand. tekhn. nauk. Moscow: Institut problem kompleksnogo osvoeniya nedr im. akademika N.V.Melnikova, 2021, p. 18.

- Nikolaev A.V., Lyalkina G.B., Kychkin A.V., Vöth S. Season-oriented mine ventilation modes analysis. Eurasian Mining. 2021. Vol. 36. N 2, p. 81-85. DOI: 10.17580/em.2021.02.17

- Zharikov I.F. Energy efficiency and energy-saving technologies in open-pit coal mining. Tendentsii razvitiya nauki i obrazovaniya. 2018. N 42-5, p. 38-41.

- Göransson L. Balancing Electricity Supply and Demand in a Carbon-Neutral Northern Europe. Energies. 2023. Vol. 16. Iss. 8. N 3548. DOI: 10.3390/en16083548

- Kiviluoma J., Rinne E., Helistö N. Comparison of flexibility options to improve the value of variable power generation. International Journal of Sustainable Energy. 2018. Vol. 37. Iss. 8, p. 761-781. DOI: 10.1080/14786451.2017.1357554

- Torriti J. Household electricity demand, the intrinsic flexibility index and UK wholesale electricity market prices. Environmental Economics and Policy Studies. 2022. Vol. 24. Iss. 1, p. 7-27. DOI: 10.1007/s10018-020-00296-1

- Sperber E., Frey U., Bertsch V. Reduced-order models for assessing demand response with heat pumps – Insights from the German energy system. Energy and Buildings. 2020. Vol. 223. N 110144. DOI: 10.1016/j.enbuild.2020.110144

- Eid C., Codani P., Perez Y. et al. Managing electric flexibility from Distributed Energy Resources: A review of incentives for market design. Renewable and Sustainable Energy Reviews. 2016. Vol. 64, p. 237-247. DOI: 10.1016/j.rser.2016.06.008

- Ugurlu U., Tas O., Kaya A., Oksuz I. The Financial Effect of the Electricity Price Forecasts’ Inaccuracy on a Hydro-Based Generation Company. Energies. 2018. Vol. 11. Iss. 8. N 2093. DOI: 10.3390/en11082093

- Dzyuba A.P., Solovyeva I.A. Prospects for Energy Demand Management in Russian Regions. Economy of Region. 2021. Vol. 17. Iss. 2, p. 502-519 (in Russian). DOI: 10.17059/ekon.reg.2021-2-11

- Afanasyev D.O., Fedorova E.A. On the impact of outlier filtering on the electricity price forecasting accuracy. Applied Energy. 2019. Vol. 236, p. 196-210. DOI: 10.1016/j.apenergy.2018.11.076

- Zhukovskiy Yu.L., Suslikov P.K. Assessment of the potential effect of applying demand management technology at mining enterprises. Sustainable Development of Mountain Territories. 2024. Vol. 16. N 3, p. 895-908 (in Russian). DOI: 10.21177/1998-4502-2024-16-3-895-908

- Sibo Nan, Ming Zhou, Gengyin Li. Optimal residential community demand response scheduling in smart grid. Applied Energy. 2018. Vol. 210, p. 1280-1289. DOI: 10.1016/j.apenergy.2017.06.066

- De Souza E. Improving the energy efficiency of mine fan assemblages. Applied Thermal Engineering. 2015. Vol. 90, p. 1092-1097. DOI: 10.1016/j.applthermaleng.2015.04.048

- Wallace K., Prosser B., Stinnette J.D. The practice of mine ventilation engineering. International Journal of Mining Science and Technology. 2015. Vol. 25. Iss. 2, p. 165-169. DOI: 10.1016/j.ijmst.2015.02.001

- de Vilhena Costa L., Margarida da Silva J. Cost-saving electrical energy consumption in underground ventilation by the use of ventilation on demand. Mining Technology. 2020. Vol. 129. Iss. 1, p. 1-8. DOI: 10.1080/25726668.2019.1651581

- Ting Yu Lin, Zhengxuan Jia, Chen Yang et al. Evolutionary digital twin: A new approach for intelligent industrial product development. Advanced Engineering Informatics. 2021. Vol. 47. N 101209. DOI: 10.1016/j.aei.2020.101209

- Aheleroff S., Xu X., Zhong R.Y., Lu Y. Digital Twin as a Service (DTaaS) in Industry 4.0: An Architecture Reference Model. Advanced Engineering Informatics. 2021. Vol. 47. N 101225. DOI: 10.1016/j.aei.2020.101225

- Steindl G., Stagl M., Kasper L. et al. Generic Digital Twin Architecture for Industrial Energy Systems. Applied Sciences. 2020. Vol. 10. Iss. 24. N 8903. DOI: 10.3390/app10248903

- Lo C.K., Chen C.H., Zhong R.Y. A review of digital twin in product design and development. Advanced Engineering Informatics. 2021. Vol. 48. N 101297. DOI: 10.1016/j.aei.2021.101297

- Saad A., Faddel S., Mohammed O. IoT-Based Digital Twin for Energy Cyber-Physical Systems: Design and Implementation. Energies. 2020. Vol. 13. Iss. 18. N 4762. DOI: 10.3390/en13184762

- Jianwei Cheng, Yan Wu, Xu H. et al. Comprehensive and Integrated Mine Ventilation Consultation Model – CIMVCM. Tunnelling and Underground Space Technology. 2015. Vol. 45, p. 166-180. DOI: 10.1016/j.tust.2014.09.004

- Fomin A.I., Grunskoy T.V. Improvement of the Working Conditions of Oil Miners During the Transition from the Thermoshaft Method of High-Viscosity Oil Production to the Modular Mine Method of the Yaregskoye Field Development. Occupational Safety in Industry. 2020. N 12, p. 58-65 (in Russian). DOI: 10.24000/0409-2961-2020-12-58-65

- Nie B.S., Peng B., Guo J.H. et al. Research on Characteristics of Air Flow Disorder in Inlet Shafts. Journal of Mining Science. 2018. Vol. 54. N 3, p. 444-457. DOI: 10.1134/S1062739118033846

- Hao Shao, Qingzi Lu, Shuguang Jiang. Effect of Frequency Conversion Ventilation on Coal Spontaneous Combustion. Combustion Science and Technology. 2021. Vol. 193. Iss. 10, p. 1766-1781. DOI: 10.1080/00102202.2020.1713769

- Fetri M., Shahabi R.S., Namin F.S. et al. Analyzing the effects of natural ventilation caused by excavating the waste pass on the ventilation network of Anguran mine. International Journal of Mining and Geo-Engineering. 2023. Vol. 57. Iss. 3, p. 231-240. DOI: 10.22059/IJMGE.2022.342133.594970

- Kychkin A.V., Nikolaev A.V. Architecture of a Cyber-Physical System for the Mining Enterprise Ventilation Control Based on the Internet of Things Platform. Mekhatronika, avtomatizatsiya, upravlenie. 2021. Vol. 22. N 3, p. 115-123 (in Russian). DOI: 10.17587/mau.22.115-123

- Lyalkina G.B., Nikolaev A.V. Natural Draft and Its Direction in a Mine at the Preset Confidence Coefficient. Journal of Mining Science. 2015. Vol. 51. N 2, p. 342-346. DOI: 10.1134/S1062739115020180

- Mokhirev N.N., Radko V.V. Engineering calculations for mine ventilation. Construction. Reconstruction. Operation. Мoscow: Nedra, 2007, p. 324.

- Nikolaev A.V., Zhebelev D.D., Presnyakov A.A. Certificate of state registration of computer program N 2023685311 MineVent DT-Connector. Program for integrating a simulation subsystem of a digital twin of an underground mining enterprise. Publ. 24.11.2023. Bul. N 12 (in Russian).

- Gendler S.G., Fazylov I.R. Application efficiency of closed gathering system toward microclimate normalization in operating galleries in oil mines. Mining Informational and Analytical Bulletin. 2021. N 9, p. 65-78 (in Russian). DOI: 10.25018/0236_1493_2021_9_0_65

- Rudakov M.L., Korobitsyna M.A. On the possibility of normalizing air temperature in the mine workings of the oil mines. Occupational Safety in Industry. 2019. N 8, p. 66-71 (in Russian). DOI: 10.24000/0409-2961-2019-8-66-71

- Alymenko N.I. Research and development of methods and means to improve the efficiency and reliability of ventilation in underground mines with large equivalent openings (using potash mines as an example): Avtoref. dis. ... d-ra tekhn. nauk. St. Petersburg: Sankt-Peterburgskii gosudarstvennyi gornyi institut im. G.V.Plekhanova, 1998, p. 44.

- Nikolaev А.V., Maksimov P.V., Fajnburg G.Z., Konotop D.А. Efficiency of a new ventilation method for a tilted block in an oil mine. Mining Informational and Analytical Bulletin. 2023. N 5, p. 83-98 (in Russian). DOI: 10.25018/0236_1493_2023_5_0_83

- Konoplev Yu.P., Buslaev V.F., Yagubov Z.Kh., Tskhadaya N.D. Thermomine development of oil fields. Moscow: Nedra, 2006, p. 288 (in Russian).

- Chertenkov M.V., Mulyak V.V., Konoplev Y.P. The Yarega Heavy Oil Field – History, Experience, and Future. Journal of Petroleum Technology. 2012. Vol. 64. Iss. 4, p. 153-160. DOI: 10.2118/0412-0153-JPT

- Nikolaev A.V., Maksimov P.V., Lialkina G.B., Konotop D.A. The effect of methane emission on air distribution in potash mine production units. News of the Higher Institutions. Mining Journal. 2021. N 6, p. 87-97 (in Russian). DOI: 10.21440/0536-1028-2021-6-87-97

- dos Santos S.A.B., Soares J.M., Barroso G.C., Prata B. de A. Demand response application in industrial scenarios: A systematic mapping of practical implementation. Expert Systems with Applications. 2023. Vol. 215. N 119393. DOI: 10.1016/j.eswa.2022.119393

- Savard C., Iakovleva E., Ivanchenko D., Rassõlkin A. Accessible Battery Model with Aging Dependency. Energies. 2021. Vol. 14. Iss. 12. N 3493. DOI: 10.3390/en14123493

- Senchilo N.D., Ustinov D.A. Method for Determining the Optimal Capacity of Energy Storage Systems with a Long-Term Forecast of Power Consumption. Energies. 2021. Vol. 14. Iss. 21. N 7098. DOI: 10.3390/en14217098

- Shabalov M.Yu., Zhukovskiy Yu.L., Buldysko A.D. et al. The influence of technological changes in energy efficiency on the infrastructure deterioration in the energy sector. Energy Reports. 2021. Vol. 7, p. 2664-2680. DOI: 10.1016/j.egyr.2021.05.001

- Zhukovskiy Y.L., Kovalchuk M.S., Batueva D.E., Senchilo N.D. Development of an Algorithm for Regulating the Load Schedule of Educational Institutions Based on the Forecast of Electric Consumption within the Framework of Application of the Demand Response. Sustainability. 2021. Vol. 13. Iss. 24. N 13801. DOI: 10.3390/su132413801

- Mukashev D., Abitova G., Uskenbayeva G., Shaikhanova A. Weather prediction with artificial intelligence in meteorology. The Bulletin of KazATC. 2024. N 1 (130), p. 414-425. DOI: 10.52167/1609-1817-2024-130-1-414-425

- Raimondi Cominesi S., Farina M., Giulioni L. et al. A Two-Layer Stochastic Model Predictive Control Scheme for Microgrids. IEEE Transactions on Control Systems Technology. 2018. Vol. 26. Iss. 1, p. 1-13. DOI: 10.1109/TCST.2017.2657606

- Razmi D., Lu T. A Literature Review of the Control Challenges of Distributed Energy Resources Based on Microgrids (MGs): Past, Present and Future. Energies. 2022. Vol.15. Iss. 13. N 4676. DOI: 10.3390/en15134676

- Blesslin S.T., Wessley G.J.J., Kanagaraj V. et al. Microgrid Optimization and Integration of Renewable Energy Resources: Innovation, Challenges and Prospects. Integration of Renewable Energy Sources with Smart Grid. Wiley, 2021, p. 239-262. DOI: 10.1002/9781119751908.ch11

- Corrigan C.C., Ikonnikova S.A. A review of the use of AI in the mining industry: Insights and ethical considerations for multi-objective optimization. The Extractive Industries and Society. 2024. Vol. 17. N 101440. DOI: 10.1016/j.exis.2024.101440

- Kaur S., Kumar R., Singh K., Yinglai Huang. Leveraging Artificial Intelligence for Enhanced Sustainable Energy Management. Journal of Sustainability for Energy. 2024. Vol. 3. Iss. 1, p. 1-20. DOI: 10.56578/jse030101