Scientific and methodological approaches in implementing the MGIS import substitution project at PJSC ALROSA

- 1 — Ph.D., Dr.Sci. Director Mining Institute, KSC of the RAS ▪ Orcid

- 2 — Ph.D., Dr.Sci. Deputy Director Mining Institute, KSC of the RAS ▪ Orcid

Abstract

This article examines the experience of strategic cooperation between a mining software developer and a large mining company in adapting the Mining and Geological Information System (MGIS) to the company’s corporate requirements. The market-out of foreign MGIS from Russia placed large companies in a particularly difficult situation, as they had been building solutions based on imported software products for many years. The task of software import substitution in the mining industry, which deals with complex geotechnical systems, should be considered as a managed interdisciplinary scientific and engineering process requiring a systematic methodological approach. We note the importance of assessing the level of digitalization of existing business processes for engineering support of mining operations in forming a rational plan for software adaptation and modification. Given the requirement for a quick solution to the import substitution issue, we must consider the internal development of MGIS when coordinating with the industrial partner a work plan for functionality modification. This ensures the development of a competitive digital system for engineering support of mining operations not only for the company but for the entire mining industry. We present the main directions for modifying the MGIS functionality in the fields of geology, mine surveying, and geotechnology, along with examples of developed digital tools. We note that experts have mostly resolved the tasks of developing MGIS to meet the requirements of PJSC ALROSA, and the priority has become the development of software tools for medium-term and short-term planning of open-pit and underground mining operations. We provide a functional diagram of the planning unit. For the development of MGIS, we consider building the Mining Geological Digital Platform (MGDP). This platform provides the ability to create working tools (units) through the use of API functions and dynamic attachment of units to the MGDP system core.

Introduction

As noted by many experts, the introduction of sanctions has had a dual impact [1, 2]. On the one hand, sanctions have restricted access to Western technologies, revealing the serious dependence of the domestic mining industry on imports. On the other hand, they have stimulated the development of Russian high-tech products that, for many years, were unable to compete equally with foreign counterparts due to the lack of investment in development. The situation in the domestic market of mining and geological information systems (MGIS) is particularly illustrative, where foreign developments dominate [3]. Large companies, which have been driving the adoption of digital technologies [4] and building their solutions based on imported software products for years, found themselves in a particularly difficult situation. One of the largest mining companies in Russia, PJSC ALROSA [5], is among the first in the industry to adopt a comprehensive digital solution for operational mining tasks. The company was required to quickly switch to domestic solutions. It should be noted that MGIS and other related digital solutions in the field of mining are rich in specific functionality, the development of which requires appropriate personnel and scientific support. These are tools built on the use of methods for optimizing engineering solutions [6-8], simulation modelling [9-11], geostatistics [12-14], machine learning [15, 16], and big data processing [17].

As a result of analysing the functionality of few Russian MGIS, PJSC ALROSA selected a solution developed by MINEFRAME Lab LLC [18] in close collaboration with the Mining Institute of the KSC RAS [19] as its corporate system. The choice was determined by the presence of sufficiently advanced functionality in the fields of geology, mine surveying, and procedure for both open-pit and underground mining operations, implemented on the basis of 3D graphics and multi-user work with the database. In the summer of 2022, a memorandum on strategic cooperation in the field of information technology was signed between PJSC ALROSA and MINEFRAME Lab LLC. In this partnership, ALROSA acted as an industrial partner, while MINEFRAME Lab LLC served as a developer of digital solutions on the MINEFRAME MGIS platform. Given that ALROSA deals both with open-pit and underground mining operations, and the company has experience in implementation and a well-formed understanding of digital business processes, a detailed plan for the adaptation and development of MGIS functionality was prepared. This plan meets the requirements of both the industrial partner and the mining industry as a whole.

The substantial scope of work, which included not only the MGIS functionality development but also the transition to a new technology stack, required a significant increase in MINEFRAME Lab LLC staff and close interaction with the customer. One of the main requirements for business processes of engineering support for mining operations was their implementation in a unified digital space of mining procedure targets, formed on the basis of the MINEFRAME MGIS. At the same time, the customer specified strict requirements for information security and the implementation of a role-based user access model to data. Another key requirement was the transition to cross-platform solutions that would allow, if necessary, to switch to national operating systems in the near future.

Methods

The solution to the issue of software import substitution in the mining industry (an industry dealing with complex geotechnical systems) should be considered not as a routine process organizational operation, but as a managed interdisciplinary scientific and engineering procedure requiring a systematic methodological approach. This approach should be implemented within the framework of a digital lifecycle, combining elements of hybrid management (Agile + Waterfall) and focusing on the phased satisfaction of functional, engineering, and organizational requirements. The task was solved under significant constraints: complexity and diversity of geotechnical data, thorough coordination of individual design specifications, necessity for uninterrupted operation of existing processes, as well as limited timeframe of 2.5 years for adaptation and implementation. The implementation included several key stages:

- Assessment of the mining enterprise digital infrastructure maturity and identification of critical engineering gaps.

- Development of an architectural model for import-substituting software, considering functional, non-functional, and integration requirements.

- Adaptation and replatforming based on open standards, cross-platform solutions (e.g., Vulkan, PostgreSQL), and web-oriented architectures.

- Integration and validation in a production environment, including development of interfaces with external systems (mining and geological data management systems, geomechanical monitoring, dispatching, and ERP), unification of directories and classifiers, as well as testing of algorithms on real geological and engineering data while solving typical business tasks.

- Organizational and engineering support, including personnel training, development of operational regulations, and continuous technical support.

This approach is based on the principles of systems engineering and procedure change management, which ensures not only the system operability in principle but also its sustainable operation in production. To evaluate the effectiveness of the methodological approach implementation at real mining enterprises, the following metrics are proposed: degree of substitution of imported solutions, reduction in cost of ownership, increase in productivity of geological, mine surveying, and engineering departments, level of user satisfaction, response time to changes in mining conditions. Thus, the methodological approach transforms import substitution from a process modernization task into a scientifically organized digital transformation. This process contributes to the formation of a sustainable, secure, and technologically independent digital landscape of mining production.

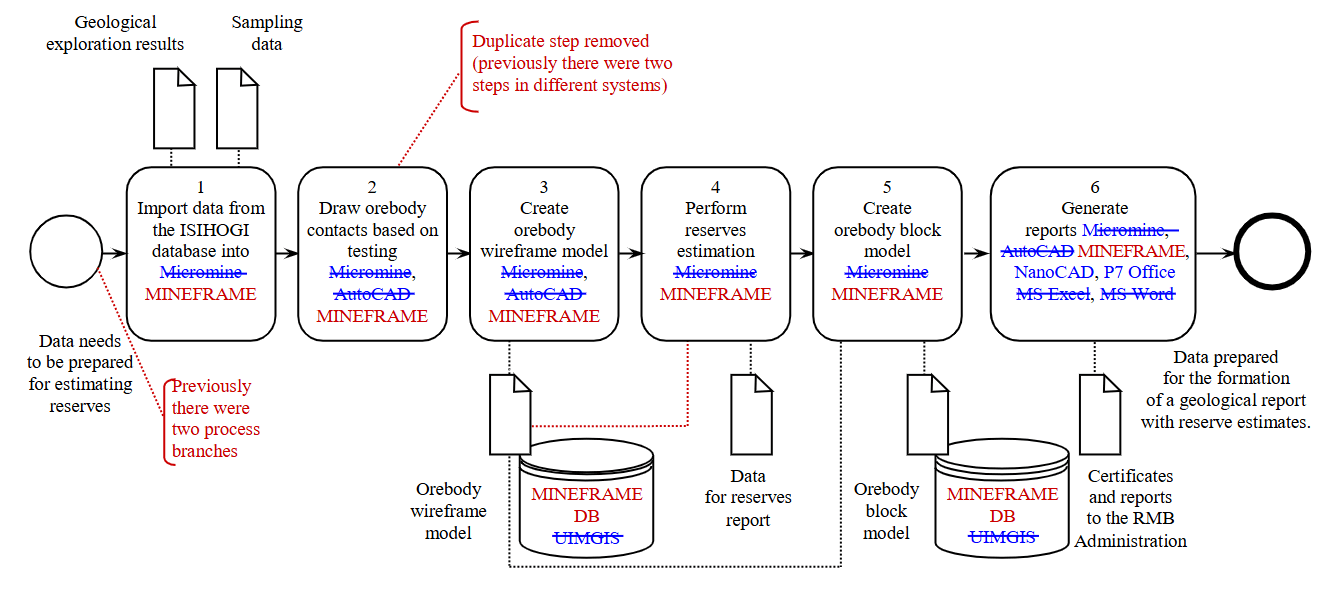

Following the provisions of this methodological approach, prior to initiating the integration of the national mining and geological information system (MGIS) into the engineering support for mining operations, experts from MINEFRAME Lab LLC assessed the level of digital enablement across various divisions of PJSC ALROSA. This assessment formed the basis for developing an adaptation and software modification plan. Transition and target diagrams (to be) were developed for the most critical business processes (Fig.1).

The software incorporated in the MGIS was adapted and modified to meet PJSC ALROSA requirements simultaneously in several areas:

- Migration to PostgreSQL DBMS, integration of user authorization procedures and data access with Active Directory service.

- Expansion of data import tools for the most common CAD and MGIS formats, as well as data exchange in MS Excel format.

- Migration of the geological database editor to a Web platform, accompanied by development of data filtering and validation tools, implementation of the State Commission for Reserves (GKZ) requirements for grade estimation, and introduction of capabilities for storing and processing geophysical data.

- Porting of the graphic editor (desktop application for solving mining and geological tasks in a 3D space) from DirectX API (Windows) to Vulkan (Windows, Linux).

- Enhancement of statistical and geostatistical research tools to a level capable of addressing most tasks encountered in the practice of prospecting and mining exploration [12, 20, 21].

- Implementation of functionality for working with block models containing hundreds of millions of blocks.

- Development of implicit (conditional) modelling functions [22, 12] for geological body surfaces based on a set of spatially distributed exploration data.

- Implementation of tools for working with point clouds [23-26] (based on results of laser scanning of underground workings, open pit slopes, and dumps), including construction of engineering facility models. A distinctive feature of MINEFRAME MGIS models is their structure, which is formed to solve engineering tasks rather than merely rendering their vector and wireframe models.

As an example of implementing functional requirements according to the MGIS adaptation plan, we can focus on the following tools.

Geology. Software was modified to provide experts with a set of tools capable of solving the entire range of geological tasks:

- Statistical data processing tools for geological exploration – statistical estimation for numerical components obtained from analytics and reserve estimation using block models; visualization of exploration data distribution, highlighting domains with high or top-cut grades on bar charts; emphasis of top-cut grades using multiple methods through various graphs, including decile analysis; construction of scatter plots for multiple components from a single data source; construction of box-and-whisker plots with estimation of median, quantiles, variance, and data asymmetry; Swath Plot displaying content distribution in multiple directions; formation of tonnage-average grade graphs based on cutoff grade variations in block models.

- Interactive tools for working with sample models to include or exclude them from the estimation of useful component content in a selected volume.

- Data comparison tools for adjacent exploration wells to identify and trace coeval complexes, horizons, beds, and interbeds.

- Spatial heterogeneity assessment tools (variography) using geostatistical methods and applying identified patterns during data interpolation with kriging techniques.

Fig.1. Fragment of the adaptation diagram of the business process “Deposit modelling, reserve assessment”

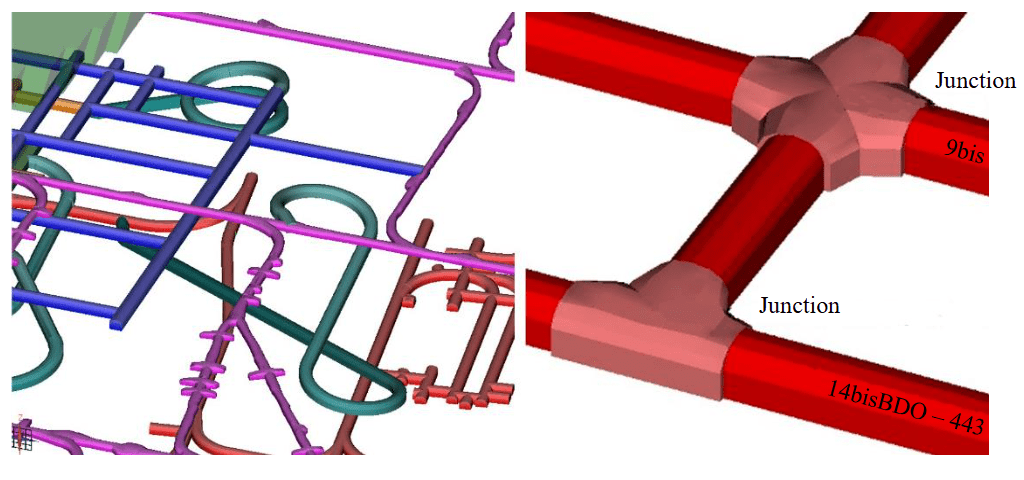

Fig.2. Automated design of workings and their junctions based on typical sections

Mine surveying. One of the critical tasks of mine surveying support for underground mining operations is the development of mine working models based on survey data. Several methods are used for this purpose. One of the primary methods is tacheometric surveying of the mine working surface, which results in a list of 3D coordinates for a relatively small number of points defining the mine working limits. To improve the accuracy of mine working models, an algorithm was developed that allows for automated fitting of design cross-sections of mine workings into survey contours while linking the sections to surveyed points. This significantly enhances the accuracy of estimating mine working volumes based on modelling data. The improved algorithm simultaneously solves the issue of forming the mine working axis (required for transportation tasks during mining planning) in the presence of niches, rock falls, one-sided narrowings, and expansions.

Tools for creating actual working models based on point clouds obtained through scanning were further developed. An algorithm was implemented for transitioning from a point cloud describing the mine working surface to a set of its cross-sections. This has significantly reduced the “weight” of vector and wireframe models while making them more informative in the field of engineering graphics.

Geotechnology. The evolution of methods for modelling underground mine workings indicates a transition to more detailed representation of their cross-sections and junctions. In both foreign and national MGIS systems, automation of the design process for workings is generally absent, which affects the speed of design and accuracy of models. To automate this process, a set of tools was developed in MINEFRAME that provides parametric modelling of workings and their junctions based on a set of cross-sections (Fig.2), for the creation of which standard or user formulas for estimation are used. Shape control for the selected type of cross-sections is implemented by setting the width and height of the working. Cross-sections are linked to the working axis and positioned along linear sections and curves through defining parameters of the generated models.

An important part of the design process for workings is the selection of support type and estimation of its parameters. An algorithm was developed for automated selection of working support passports based on mining, geological, and geomechanical conditions of mining operations. While developing the algorithm, we analysed instructions for supporting mine workings used at mining enterprises. This allowed generalizing existing experience and presenting it in the form of a set of digital solutions.

The range of tools for open-pit mining design was expanded, focusing on automated development of structural elements for the open-pit mine. To achieve this, we implemented an algorithm that allows creating brake platforms of specified length and width based on the edge line of the bench (upper or lower) and the outline of an already constructed ramp. The tool considers the possibility of connecting ramps with different and equal widths, allows for sequential construction of multiple ramps and platforms, automatically determines various elements of the open pit, and significantly reduces design time.

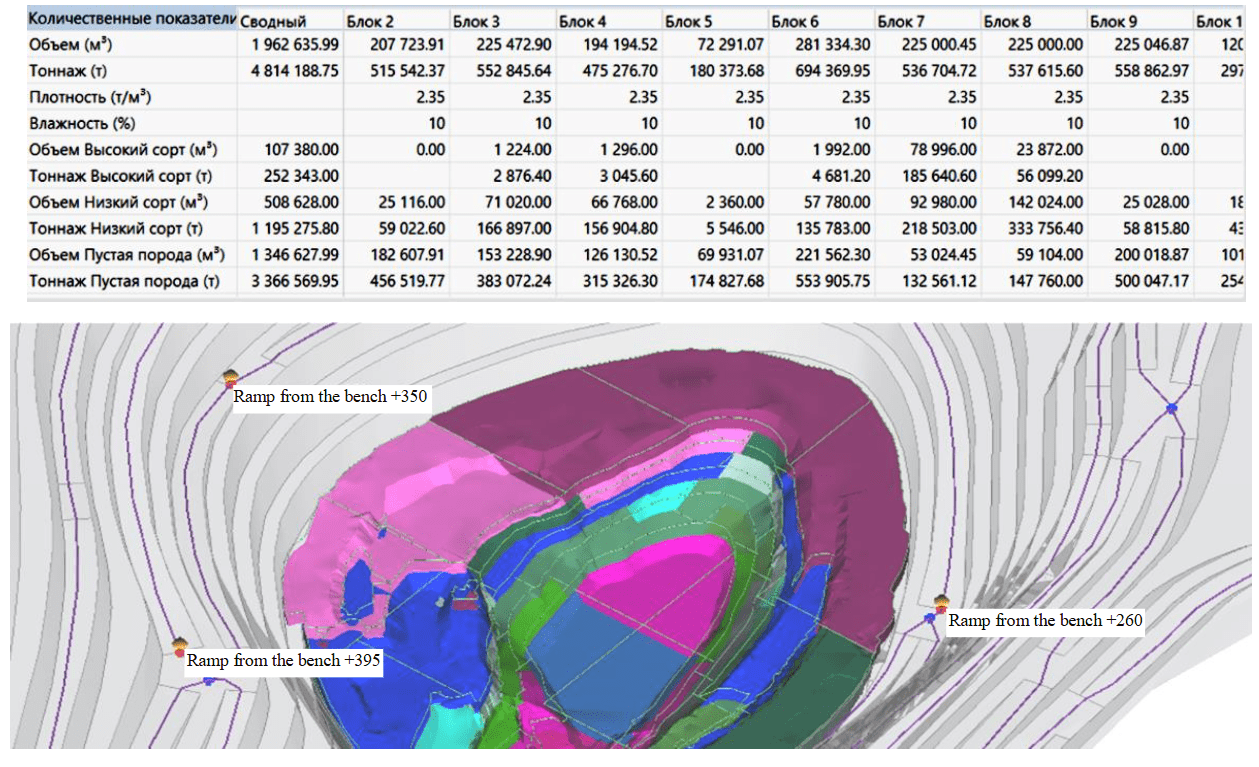

Tools for estimating tonnage based on volumetric and quality indicators in models of geological and engineering facilities were developed. The developed approaches allow for highly accurate estimation of volumetric and quality indicators based on attributes of block models in selected volumes of the simulated space. Such volumes can include reserves of horizons, blocks, individual extraction units. The modified functionality allows for operation with values of density and other properties of the massif, creating conditions for more accurate accounting of its characteristics.

As an example of interaction with third-party developer solutions, we can consider integration with specialized software [27]. This software is designed for 3D modelling and estimation of engineering indicators for mineral extraction using underground mining in a sublevel caving system with end drawing of ore. This integration allows for synchronization of data on deposit attitude, modelling results, estimation of recovery rates during rock mass drawing. This improves the accuracy of mining planning. Through integration, a data exchange solution was implemented to ensure uninterrupted mining design and planning processes.

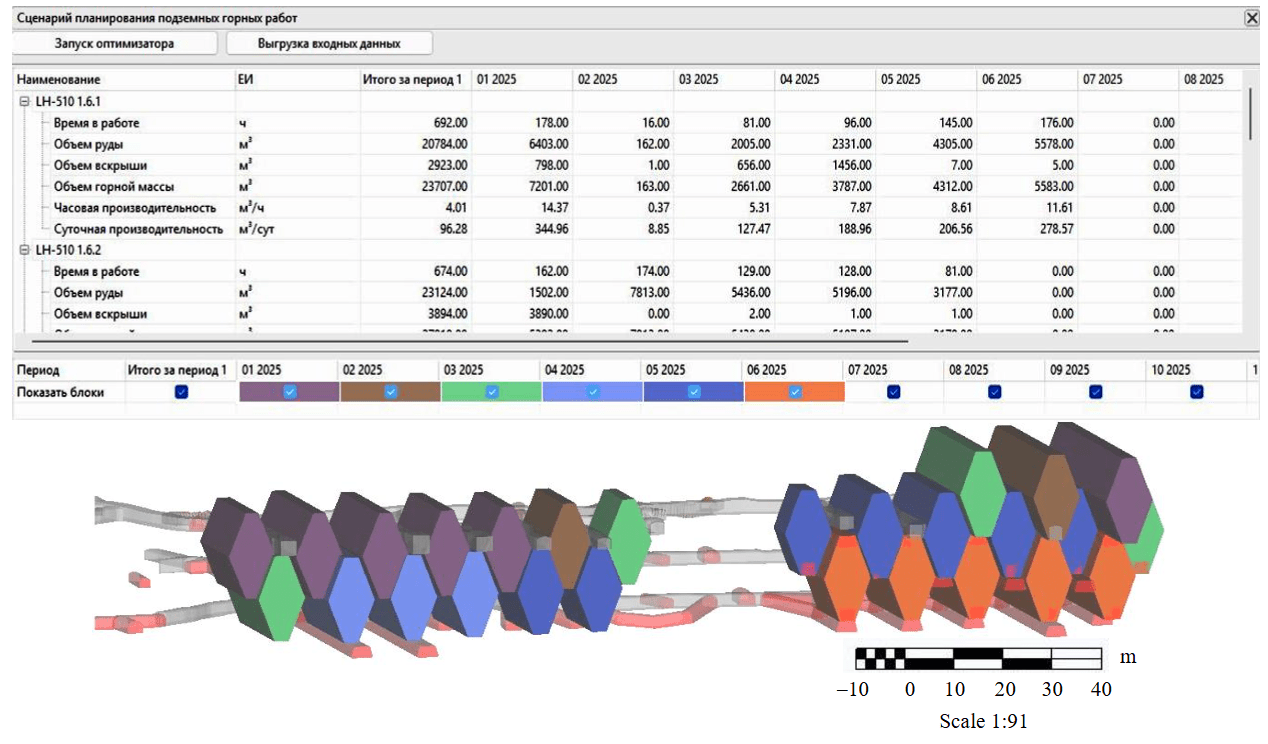

Mining operations planning. A separate major area is the development of units for medium- and short-time planning for both open-pit and underground mining methods. In close collaboration with the PJSC ALROSA working group, we formulated the requirements for functionality that should provide automated development of technologically sound plans for periods ranging from two years to weekly-daily schedules.

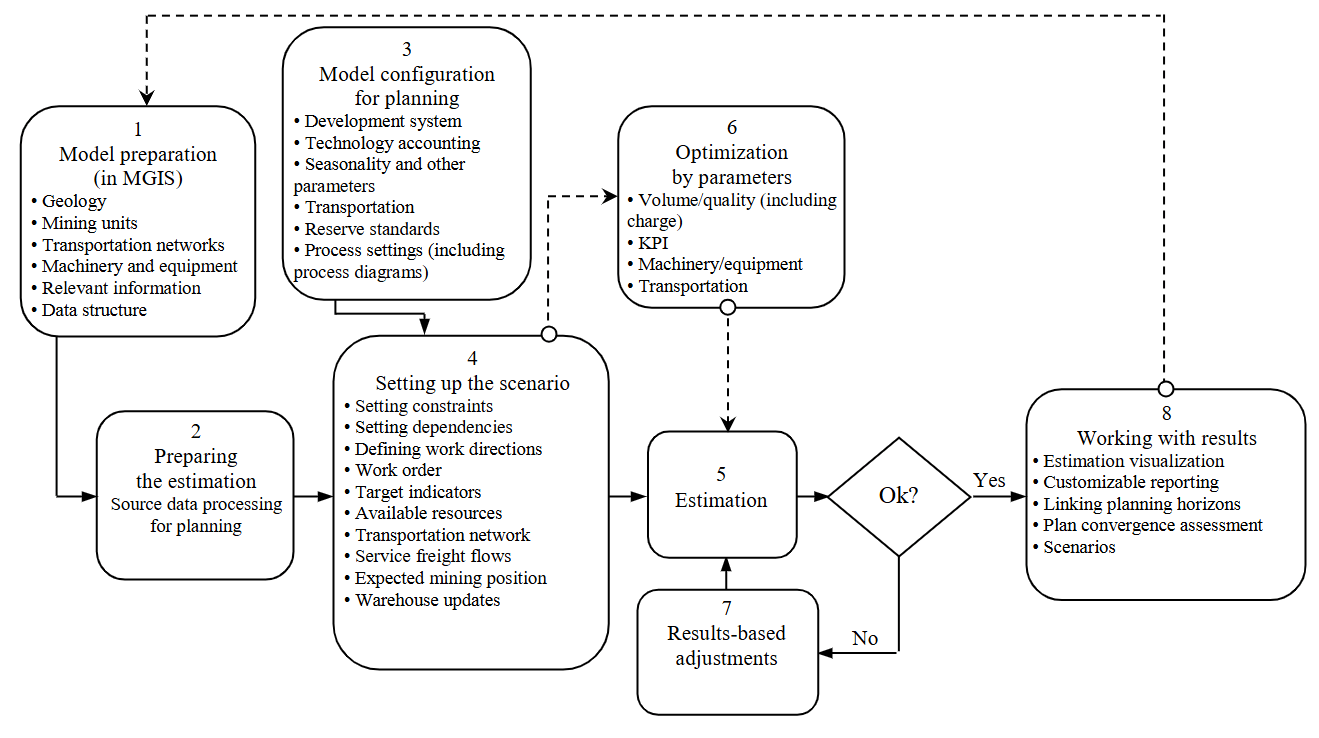

The planning unit for open-pit and underground mining operations is based on a unified optimization algorithm within the framework of constraint programming [28-32] and simulation modelling methods (Fig.3). The main principles of its operation are as follows:

- seamless integration with mining and geological models within the MGIS environment;

- automated generation of extraction units;

- calendar planning of mining operations for various time periods with the ability to divide them into time intervals: year, quarter, month, week, day;

- end-to-end planning procedure integrating medium- and short-term horizons, and in the future – the strategic level;

- estimation and visualization of mining operation scenarios based on limiting factors (extraction sequence, equipment productivity, repairs/downtimes, process constraints), with display/editing, comparison/analysis of scenarios;

- generation of user documentation, including equipment operation schedules, based on mining operation plan estimations.

Basic requirements for underground mining planning tools (Fig.4):

- duration accounting of process cycles (filling, second mining, driving, etc.);

- assessment of volumes of preparatory and cutting works based on planned ore volumes, considering the prepared reserves coefficient;

- determination of sequence of extraction volumes according to the development system regulations;

- planning scenario implementation based on specified conditions and driving speeds of mine workings, including near hazardous zones and faults;

- construction of transportation network with assignment of trafficability and storage capacity (e.g., ore pass) for its individual elements;

- evaluation of equipment productivity and its optimal quantity depending on operating conditions.

Basic requirements for open-pit mining planning tools (Fig.5):

- consideration of engineering features of stripping and mining operations when operating excavator-truck complexes, as well as bulldozer equipment;

- compliance with safety conditions for conducting mining operations;

- determination of sequence for extracting units at different levels;

- construction of transportation network including temporary ramps;

- accounting of mining and transportation equipment productivity based on traffic conditions in each section of the transportation network.

Fig.3. Design of the automated mining planning unit

Fig.4. Planning of underground mining operations with extraction unit modelling

Fig.5. Open-pit mining planning with cut modelling

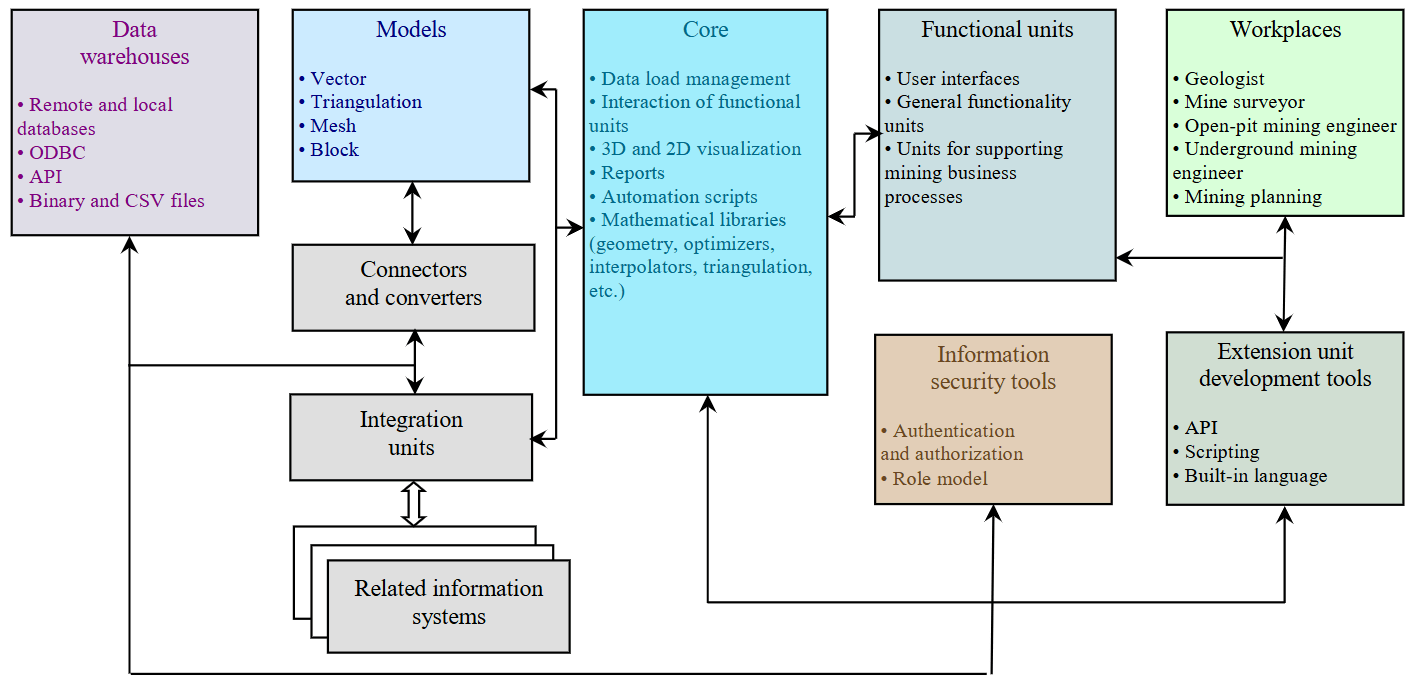

Development of a mining digital platform. One of the key development vectors of the MINEFRAME MGIS is a mining digital platform (MDP) based on it, which implements the following operation principles:

- separation of system tools (development, visualization, editing, saving, and loading of models) and working tools (solving specific mining and geological tasks), achieved through the development of a cross-platform core and dynamically connected units;

- simplification of new functionality development by providing developers with documented high-level API functions for accessing object model classes and system functions for working with them;

- increased stability of operation by restricting developers of working tools from making changes to the MDP core;

- enhanced database performance by reducing traffic associated with saving only modified parts of models;

- implementation of local (user) – remote (corporate) database connection to simplify the procedure for connecting and interaction between experts;

- provision of model development history display in a time-based perspective, achieved through saving all model changes in the database.

The MDP architecture (Fig.6) provides multi-user work with a collaborative controlled access database. The relational principle of database arrangement maintains data integrity, preservation, and quick response to requests requiring data transfer. Data import, export, and analysis tools are integrated with other programs at mining enterprises. The ability to use third-party digital data and models is even more relevant because, with foreign software vendors market-out from Russia, mining enterprises are extremely interested in preserving information they have been collecting over years [33]. For MINEFRAME, tools are developed that allow seamless data importing in formats of the most widespread in Russia foreign MGIS systems into the MDP environment.

Fig.6. MINEFRAME MDP architecture

Discussion

To date, adapting the MGIS to the PJSC ALROSA requirements has been mostly completed, with verification and refinement of individual working tools underway. The main focus shifted tothe development of open-pit and underground mining planning units, which, according to the functionality stated in the design specification, must meet the best foreign counterparts and surpass them in terms of universality.

The project scale can be assessed by several indicators: our team conducted over 1,500 working meetings between customer and developer employees. We assigned 106 major tasks, which were transformed into more than 3,000 elementary development tasks. As we implemented and presented the developed functionality to the customer, we identified and addressed over 150 comments.

Analysis of successful interaction practices with PJSC ALROSA and other representatives of the mining industry, which have requirements for deep software customization, allows formulating key theoretical and applied conclusions:

- Specificity of developing industry-specific MGIS software solutions. Software of this class is characterized by complex architecture formed under the influence of internal engineering and methodological processes of the developer. This is due to the need to adapt specialized algorithms and software units to the unique production conditions of the customer. It is critically important for the customer to consider the developer’s expert position during the stages of identifying design specification requirements and coordinating the project implementation schedule. Ignoring this aspect leads to an imbalance between the parties’ expectations, incorrect task formulation, and, consequently, reduced quality and functional stability of the final product.

- Role of communicative and creative components in software development management. Development of software solutions for the mining industry is a complex process combining elements of system design, research activities, and creative approach. Normalization of labour costs in such projects is complicated by the need to solve non-standard engineering tasks, as well as dependence on the level of involvement of customer’s experts in iterative development stages. Clear formulation of business goals, combined with a deep understanding of the process platform’s capabilities, allows minimizing risks of time and resource costs. This is achieved through early identification of critical project nodes, prioritization alignment, and implementation of advanced project management methodologies. This combination reduces software time-to-market and increases return on digitalization investments.

- Critical importance of documenting processes and requirements. Successful implementation of projects for adapting both MGIS and other complex digital systems is impossible without detailed recording of requirements, business logic, and engineering specifications. Neglecting the documentation stage leads to discrepancies between customer expectations and developer task interpretation and complicates system maintenance at the post-project stage. It is recommended to use combined approaches – supplement text descriptions with visual models, use cases, and examples of source data. This reduces the risk of ambiguity in design specifications.

- Necessity of training and knowledge transfer. Effective software implementation requires not only engineering adaptation but also training of customer employees. There is often a gap between the functional capabilities of the system and the competency level of its users. To minimize this gap, it is necessary to provide training sessions focused on practical tasks specific to the particular enterprise, develop instructions and video tutorials adapted to the customer’s business processes, as well as implement a feedback system for prompt response to training gaps and identified needs for software functionality improvements.

- Strategic role of post-project support and development. The cycle of interaction does not end with project completion. Mining companies facing dynamic external conditions (changes in legislation, engineering innovations, expansion of production capacities) require software flexibility. This implies building long-term partnership relations between the customer and the developer; incorporating into contractual obligations provisions for functionality updates, error corrections, and system scaling; use of modular software architecture allowing implementation of new components without reworking the entire system.

- Expectation management and balance of parties’ interests. Conflicts in projects often arise due to discrepancies between customer expectations and real process capabilities or resource limitations. To prevent them, it is necessary to conduct an audit of the customer’s digital maturity and infrastructure, analysis of analogous solutions at the project initiation stage; clearly differentiate mandatory and desirable functions for implementation; define intermediate acceptance stages for results (for example, the minimum viable product stage) to timely adjust the development direction.

- Consideration of industry specifics and regulatory requirements. The mining industry is characterized by strict safety standards, environmental regulations, and requirements of supervisory authorities. The developer needs to integrate into software tools for automated reporting in accordance with regional and international standards; provide functions for risk monitoring, including geomechanical and hydrogeological aspects; ensure data protection that complies with industry regulations and digital infrastructure of mining holdings.

- Risk analysis and flexibility in project management. The high complexity and probabilistic nature of geological data, elements of uncertainty in mining operations require developers to account for risks such as incomplete or contradictory initial data from the customer; technical limitations of the existing IT landscape; periodic changes in external conditions (e.g., adjustment of regulatory framework). To minimize consequences, it is necessary to apply risk management methodologies and incorporate backup mechanisms into schedule plans (buffer periods, budget reserve).

Conclusion

Effective collaboration between mining companies and developers of both MGIS and similar systems requires a systematic approach that combines engineering expertise, communication management, and adaptation to industry challenges. The success of projects is determined not only by engineering implementation but also by the ability of the parties to build a dialogue based on mutual trust, transparency, and readiness to jointly solve non-standard tasks.

The experience of practically implementing the MGIS import substitution project at PJSC ALROSA has allowed achieving the following indicators:

- information security requirements are fully implemented, data synchronization is configured according to a schedule, and data loss resulting from file access outside the user’s role is eliminated;

- more than 250 trained experts;

- seven network databases deployed, with 35 engineering projects organized across implementation sites;

- over 200 user accounts registered in the MGIS role-based model;

- foreign software replaced by 95 %.

Engineering support for mining operations was implemented at six deposits, with implementation underway at five more sites. Thus, the successful implementation of projects to adapt the MGIS required synergy between the technical experience of the developer and the engineering experience of the customer. This is confirmed both by IT project management models and by the practical results presented in the article.

References

- Tverdov A.A. Western sanctions policy’s impact on solid minerals sector. Nedropolzovanie XXI vek. 2022. N 6 (98), p. 14-17 (in Russian).

- Lyutyagin D.V., Zabaikin Yu.V., Bogachev M.Yu. et al. Transformation of approaches to efficiency management for mining enterprises facing risks of sanctions. Economics: Yesterday, Today and Tomorrow. 2019. Vol. 9. N 3B, p. 613-628 (in Russian).

- Lukichev S.V., Nagovitsyn O.V. Digital transformation and technological independence of the mining industry. Russian Mining Industry. 2022. N 5, p. 74-78 (in Russian). DOI: 10.30686/1609-9192-2022-5-74-78

- Barnewold L., Lottermoser B.G. Identification of digital technologies and digitalisation trends in the mining industry. International Journal of Mining Science and Technology. 2020. Vol. 30. Iss. 6, p. 747-757. DOI: 10.1016/j.ijmst.2020.07.003

- Bobova M. ALROSA experts: ignoring digitalization is running away from problem-solving. Dobyvayushchaya pro-myshlennost. 2024. N 4 (46), p. 156-160 (in Russian).

- Mai L., Saw Z. Chapter 10 – Optimization of large mining supply chains through mathematical programming. Applications of Artificial Intelligence in Mining and Geotechnical Engineering. Elsevier, 2024, p. 165-182. DOI: 10.1016/B978-0-443-18764-3.00022-9

- Furtado e Faria M., Dimitrakopoulos R., Pinto C. Stochastic stope design optimisation under grade uncertainty and dynamic development costs. International Journal of Mining, Reclamation and Environment. 2022. Vol. 36. Iss. 2, p. 81-103. DOI: 10.1080/17480930.2021.1968707

- Nelis G., Morales N. A mathematical model for the scheduling and definition of mining cuts in short-term mine planning. Optimization and Engineering. 2022. Vol. 23. Iss. 1, p. 233-257. DOI: 10.1007/s11081-020-09580-1

- Rylnikova M.V., Vlasov A.V., Makeev M.A. Justification of Conditions for Application of Automated Control Systems for Surface Mining during Construction of In Pit Crushing and Conveying System using Simulation Modeling. Russian Mining Industry. 2021. N 4, p. 106-112 (in Russian). DOI: 10.30686/1609-9192-2021-4-106-112

- Hadizadeh Ghaziani H., Monjezi M., Mousavi A. et al. Design of Loading and Transportation Fleet in Open-Pit Mines using Simulation Approach and Metaheuristic Algorithms. Journal of Mining and Environment. 2021. Vol. 12. Iss. 4, p. 1177-1188. DOI: 10.22044/jme.2022.11450.2131

- Manríquez F., Pérez J., Morales N. A simulation–optimization framework for short-term underground mine production scheduling. Optimization and Engineering. 2020. Vol. 21. Iss. 3, p. 939-971. DOI: 10.1007/s11081-020-09496-w

- Avalos S., Ortiz J.M. Recursive convolutional neural networks in a multiple-point statistics framework. Computers & Geosciences. 2020. Vol. 141. N 104522. DOI: 10.1016/j.cageo.2020.104522

- Madani N. Multi-collocated cokriging: An application to grade estimation in the mining industry. Mining goes Digital. Proceedings of the 39th International Symposium “Application of Computers and Operations Research in the Mineral Industry”, 4-6 June 2019, Wroclaw, Poland. CRC Press, 2019, p. 158-167. DOI: 10.1201/9780429320774

- Deveci M., Varouchakis E.A., Brito-Parada P.R. et al. Evaluation of risks impeding sustainable mining using Fermatean fuzzy score function based SWARA method. Applied Soft Computing. 2023. Vol. 139. N 110220. DOI: 10.1016/j.asoc.2023.110220

- Valencia J., Emami E., Battulwar R. et al. Blasthole Location Detection Using Support Vector Machine and Convolutional Neural Networks on UAV Images and Photogrammetry Models. Electronics. 2024. Vol. 13. Iss. 7. N 1291. DOI: 10.3390/electronics13071291

- Levinson Z., Dimitrakopoulos R. A reinforcement learning approach for selecting infill drilling locations considering long-term production planning in mining complexes with supply uncertainty. Mining Technology. 2024. Vol. 133. Iss. 2, p. 176-187. DOI: 10.1177/25726668241244930

- Badiezadeh T., Saen R.F., Samavati T. Assessing sustainability of supply chains by double frontier network DEA: A big data approach. Computers & Operations Research. 2018. Vol. 98, p. 284-290. DOI: 10.1016/j.cor.2017.06.003

- Laptev V.V., Gurin K.P. Automated Planning of Underground Mining Operations with Regard to Geological and Geo-technical Constraints. Journal of Mining Science. 2023. Vol. 59. N 3, p. 490-496. DOI: 10.1134/S106273912303016X

- Kornienko A.V., Gurin K.P., Stepacheva A.V. Application of modern approaches for software development on an example of mining-and-geological information system MINEFRAME. The North and the Market: Forming the Economic Order. 2019. N 1 (63), p. 153-160 (in Russian). DOI: 10.25702/KSC.2220-802X.1.2019.63.153-160

- Araújo C. da P., Bassani M.A.A., Koppe V.C. et al. Geostatistical simulations with heterotopic hard and soft data without modeling the linear model of coregionalization. REM – International Engineering Journal. 2021. Vol. 74. Iss. 2, p. 269-278. DOI: 10.1590/0370-44672020740075

- Chilès J.-P., Desassis N. Fifty Years of Kriging. Handbook of Mathematical Geosciences. Springer, 2018, p. 589-612. DOI: 10.1007/978-3-319-78999-6_29

- Huang L., Balamurali M., Silversides K.L. Machine learning classification of geochemical and geophysical data. Mining goes Digital. Proceedings of the 39th International Symposium “Application of Computers and Operations Research in the Mineral Industry”, 4-6 June 2019, Wroclaw, Poland. CRC Press, 2019, p. 101-105. DOI: 10.1201/9780429320774

- Vystrchil M.G., Baltyzhakova T.I., Savina A.V. Algorithm for assessing the accuracy of polygonal TIN surfaces, obtained from sparse point clouds. Vestnik of the Siberian State University of Geosystems and Technologies. 2024. Vol. 29. N 3, p. 5-19 (in Russian). DOI: 10.33764/2411-1759-2024-29-3-5-19

- Kolesatova O.S., Krasavin A.V. Enhancing the effectiveness of mine surveying measurements to determine the volumes of underground mined-out areas through mobile scanning systems. Globus. 2020. N 5 (64), p. 76-78 (in Russian).

- Ferrero A.M., Migliazza M.R., Umili G. Rock mass characterization by means of advanced survey methods. Rock Engineering and Rock Mechanics: Structures in and on Rock Masses. CRC Press, 2014, p. 17-27. DOI: 10.1201/b16955

- Buyer A., Schubert W. Calculation the Spacing of Discontinuities from 3D Point Clouds. Procedia Engineering. 2017. Vol. 191, p. 270-278. DOI: 10.1016/j.proeng.2017.05.181

- Shekhar G., Gustafson A., Hersinger A. et al. Development of a model for economic control of loading in sublevel caving mines. Mining Technology. 2019. Vol. 128. Iss. 2, p. 118-128. DOI: 10.1080/25726668.2019.1586371

- Van Hentenryck P., van Hoeve W.-J. Constraint Programming. Encyclopedia of Optimization. Springer, 2023. p. 16 DOI: 10.1007/978-3-030-54621-2_713-1

- Zuenko A.A., Fridman O.V., Zuenko O.N. Constraint programming paradigm in solving scheduling problems: an analytical survey. Proceedings of Voronezh State University. Series: Systems Analysis and Information Technologies. 2022. N 4, p. 156-179 (in Russian). DOI: 10.17308/sait/1995-5499/2022/4/156-179

- Morales N., Nancel-Penard P., Espejo N. Development and analysis of a methodology to generate operational open-pit mine ramp designs automatically. Optimization and Engineering. 2023. Vol. 24. Iss. 2, p. 711-741. DOI: 10.1007/s11081-021-09702-3

- Nancel-Penard P., Morales N., Rojas V., González T. A heuristic approach for scheduling activities with ‘OR’-precedence constraints at an underground mine. International Journal of Mining, Reclamation and Environment. 2020. Vol. 34. Iss. 10, p. 748-762. DOI: 10.1080/17480930.2020.1734152

- Rivera Letelier O., Espinoza D., Goycoolea M. et al. Production Scheduling for Strategic Open Pit Mine Planning: A Mixed-Integer Programming Approach. Operations Research. 2020. Vol. 68. Iss. 5, p. 1425-1444. DOI: 10.1287/opre.2019.1965

- Tsepina A. Mining industry digitalization – 2024: dreams and reality. Dobyvayushchaya promyshlennost. 2024. N 4 (46), p. 24-30 (in Russian).