Development of an engineering methodology for determining the standard consumption of electricity by air coolers

- Ph.D. Leading Specialist GCE-energo LLC ▪ Orcid

Abstract

The issue of reducing electricity consumption costs is becoming relevant for industrial enterprises, taking into account the growing demand for electricity every year. The electricity consumption of air coolers at a gas processing plant was considered in the framework of this study. The change in ambient temperature (during the day and depending on the season) is the main disturbing factor affecting the performance of air coolers. With such significant seasonal changes in air temperature, its density changes, which causes fluctuations in the power consumed by the electric motor by up to 30 %. The issues of increasing energy efficiency, forecasting and determining the power consumption rate of air coolers, depending on changing external conditions, therefore become important. A methodology has been developed to determine the standard power consumption of air coolers depending on two factors – the ambient temperature and the load of the gas processing plant. A two-factor power-law approximation of the values was carried out due to nonlinear dependencies on plant loading and ambient temperature. The dependence of power consumption on ambient temperature and the loading of the installation on raw materials for any type of air cooler is determined with high accuracy (the root-mean-square error of the calculated and approximating values does not exceed 1 %). The formula for calculating the standard consumption of electric power of the air cooler at the considered installation was determined based on the results of the study. The methodology can be used by employees of gas processing enterprises to determine the standard electricity consumption of air coolers under changing climatic and technological factors.

Introduction

One of the priorities for all types of production in Russia and the world due to the high energy intensity [1] is the reduction and optimization of fuel and energy resources costs [2], including electrical energy, which is highlighted in one of the trends of the 4D concept [3]. Thus, the “decrease” trend means a reduction in the consumption of all types of resources and materials, including the amount of waste produced. At the same time, industrial electricity consumption in the world is projected to increase by 83 % in 2022-2050.

There has been a decrease in gas production and transportation due to external factors in recent years. The development of the industry depends both on foreign supplies of equipment (which makes it difficult to introduce new capacities) and on the demand for energy resources, while the cost of electricity increases [4, 5]. In this regard, a lot of research is being conducted in the direction of peak load coverage by means of electricity storage systems to reduce costs at gas industry facilities [6-8].

A significant amount of electrical energy costs at gas production, transportation and processing facilities is determined by the operation of pumps [9], compressors [10], various traction, ventilation and air coolers [11], which are the objects of this study, as well as their design features and degree of wear. The operating mode of the specified equipment may depend on many factors that affect energy consumption to varying degrees. Thus, air coolers are operated on the territory of the Russian Federation in a wide temperature range: from –45 to +50 °С [12]. Changes in ambient temperature (during the day and depending on the season) are the main disturbing factor affecting the operation of air coolers and their operability [13, 14]. The heat flow changes with such significant seasonal changes in ambient temperature and there is a need to increase air consumption, which causes corresponding fluctuations in the power consumed by the electric motor – up to 30 % [15, 16]. At the same time, at subzero ambient temperatures (in winter in the northern regions), air coolers may not be switched on at all.

On the other side, the electrical consumption of the air cooler is affected by the loading of the gas processing plant, which includes the air cooler. Depending on the technological process (volume of transported or pumped gas), the need to turn on the air cooler occur in stages, even in summer. In this regard, at the next stage of the work, it is necessary to take into account and classify industrial facilities as typical according to several parameters combined (technological process, location of the region, type of technology, etc.).

According to the article [17], the efficiency of each type of air cooler is not constant during operation, but is characterized by a certain dynamics, which is caused by a change in the operating mode of the technological site/plant, as well as changes in climatic conditions. Reducing unit costs per unit of produced and processed products, i.e. gas or gas condensate, including in the transportation and distribution sector (at gas transportation facilities – compressor stations) [18-20], is an important scientific and technical research area for the development of the gas industry [21].

One of the relevant directions is the use of digital twins of technological equipment at oil and gas industry facilities [22, 23]. The digital twin of an air cooler is a virtual model that is an exact copy of a real device used for modeling, analyzing, and optimizing its operation. The digital twin of an air cooler can include physical parameters, heat transfer characteristics, aerodynamics and other important factors and be used for the following purposes:

- optimization of operation – modeling of various scenarios of operation of the air cooler, determining optimal operating modes to increase efficiency and reduce energy consumption [24];

- fault prediction based on data collected from real equipment, the digital twin can predict possible breakdowns and malfunctions, which allows for preventive maintenance and avoiding equipment downtime [25];

- design improvement – testing new design solutions and optimizing the shape and size of the air cooler elements to increase its efficiency;

- staff training to work with air coolers without putting real equipment at risk;

- lifecycle management – monitoring the condition of the air cooler from design to disposal.

The methodology presented in this study can serve as a basis for the creation, implementation, and use of modern solutions in the field of digitalization at enterprises.

The issue of increasing energy efficiency [26, 27], modeling [28-30], forecasting [31, 32] and determining the rate of power consumption by air coolers, depending on changing external conditions such as ambient temperature and plant loading, is becoming relevant. However, in the research of Russian authors, for example in [33, 34], mathematical models are proposed that describe the operation of air coolers and are designed to develop methods for controlling the operating modes of air coolers to reduce electricity consumption, in which only one factor (ambient temperature) is reflected as influen-cing fluctuations in the power consumption of air coolers. The influence of wind speed on the cooling process by air coolers, in addition to temperature, is taken into account in the studies of foreign authors [35, 36].

The purpose of this study is to develop a methodology for determining the standard electricity consumption of air coolers depending on two changing factors – ambient temperature and the load of the gas processing plant.

The research methodology includes solving the following tasks:

- determination of the availability of initial data, such as the technical characteristics and parameters of air coolers, the thermal load of air coolers based on the results of preliminary modeling of the gas processing plant;

- calculation of the mass air flow through the air cooler;

- calculation of the standard power consumption of the air cooler, taking into account the efficiency of the engines;

- approximation of values by the smallest polynomial function of standard electricity consumption with a deviation of the approximated and calculated values of no more than 5 %;

- determination of the coefficients of two-factor approximation for the formation of the final dependence of the standard of electricity consumption by the air cooler on the ambient temperature and the loading of the gas processing plant.

Methods

The consumption of fuel and energy resources by technological and auxiliary equipment of industrial enterprises depends on several factors, the main of which is the volume of production.

The initial data for the development of formulas for calculating the standard consumption of fuel and energy complex by technological equipment is a list of equipment, as well as statistical data on its operating modes. This data is recorded at the enterprises and used when planning production volumes. The following can be used as initial data on the operating modes of technological equipment: unloading from the accounting system, time sheets, maps, technological regulations, design data. Statistical data in the development of formulas for calculating the standard consumption of fuel and energy complex are used only to determine the technological parameters that affect the energy consumption of production and equipment.

One of the tasks in developing this methodology for determining standard consumption values is to use simple formulas for calculating that do not require the use of specialized equipment or software, with the possibility of further application of the methodology by specialists of gas processing enterprises. Mathematical modeling of technological plants and processes using specialized software is a laborious process and is not the optimal solution to achieve the objectives of this study. For this reason, upon completion of the calculation of the theoretically required volume of fuel and energy resources consumption, depending on the volume of output/processing of raw materials and ambient temperature, the results of the calculations are approximated to develop formulas for calculating consumption without using specialized tools.

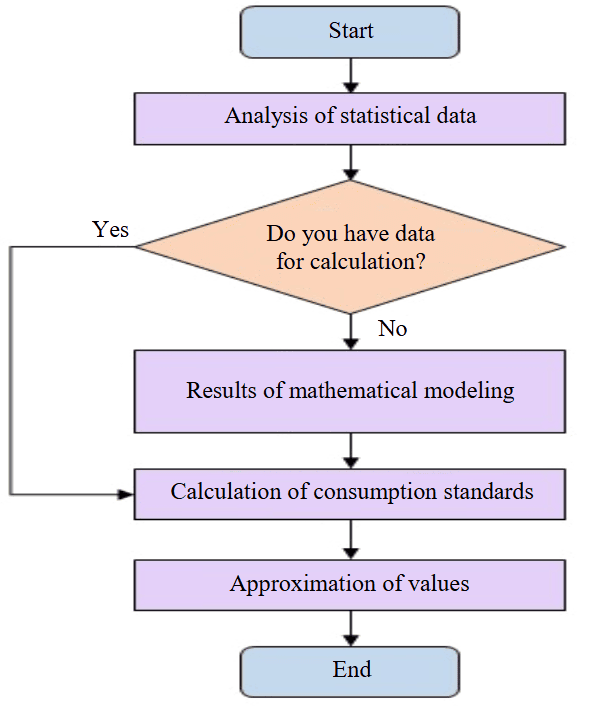

Approximation is a scientific method that consists in replacing some mathematical objects with others that are close to the original ones [37]. In particular, it is the basis for the analytical representation of tabular data by a function of a given type with unknown parameters, the values of which are determined so that the graph of the functions is as close as possible to the specified points. To simplify the calculation formulas, minimum degree polynomials are used in the approximation, which ensures the necessary calculation accuracy. The algorithm for developing calculation formulas for the absolute consumption of technological equipment is shown in Fig.1. The above algorithm is applied for each piece of equipment.

Fig.1. An algorithm for developing calculation formulas for electricity consumption standards

It is possible to use two methods for determining the thermal load of air coolers, depending on the availability of initial data and the scope of application of each equipment item:

- according to the mathematical modeling of technological plants;

- according to the flow rate, the temperature of the cooled medium at the inlet and the maximum allowable temperature at the outlet of the air cooler.

The article discusses a technique based on mathematical modeling of technological plants, suitable for use by engineering and technical personnel and using two variable parameters, which allows to obtain the most accurate result. The methodology for developing calculation formulas for the standard consumption of electric energy by air coolers is presented using the example of a gas condensate stabilization unit (GCSU) at a gas processing plant. Further calculations were performed in the Microsoft Office Excel software, which is sufficient to complete the task.

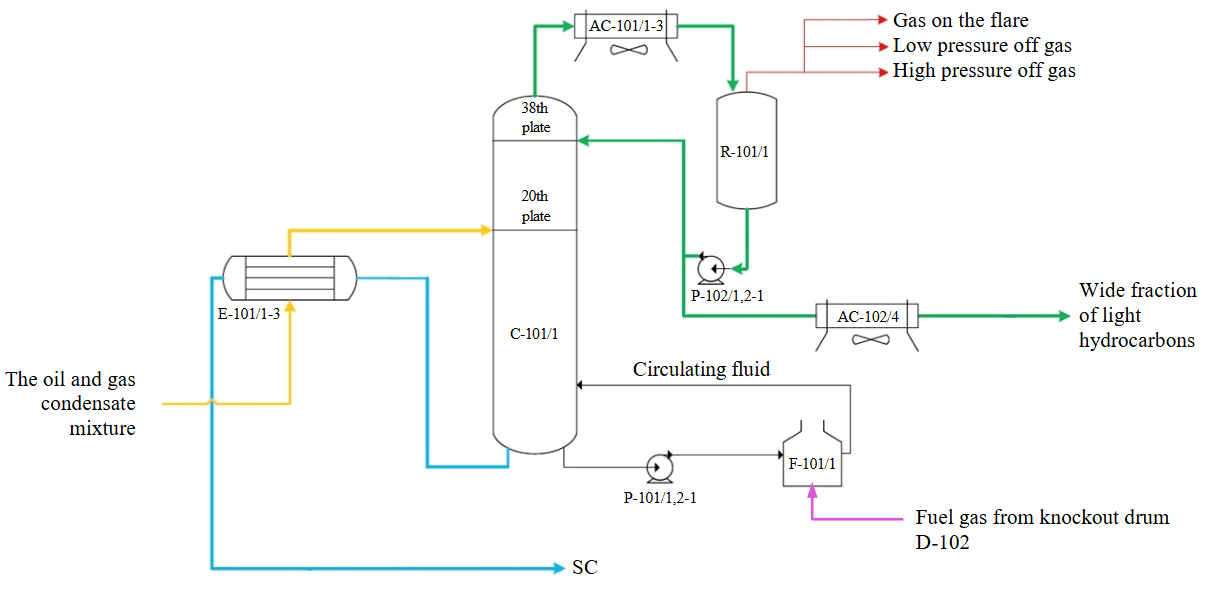

The AC-101 air cooler, which is located as part of the GCSU of the condensate stabilization plant, was considered as the object under study. The main parameter determining the performance of the GCSU is the volume of raw materials – the processed oil and gas condensate mixture. Figure 2 shows a block diagram of a gas condensate stabilization unit.

The oil and gas condensate mixture enters the processing train of the plant from a common collector and passes sequentially through the tube space of the Е-101/1-3 heat exchangers, where it is heated to a temperature of 80-120 °С by a reverse flow of stable condensate coming out of the cubic part of the С-101/1 stabilization column. The oil and gas condensate mixture, heated to a temperature of 80-120 °C, enters the 20th plate in the middle part of the C-101/1 stabilization column. The C-101/1 stabilization column is designed for separating an oil and gas condensate mixture into stable condensate (SC) and a wide fraction of light hydrocarbons by rectification. The С-101/1 column is a vertical cylindrical apparatus of variable cross-section, inside which 38 mass-exchange valve plates are located. The SC is withdrawn to the raw materials park or to the substandard product line.

Fig.2. Technological block diagram of a gas condensate stabilization unit

Vapors of a wide fraction of light hydrocarbons from the top of the С-101/1 stabilization column are sent to the parallel-operating air coolers AC-101/1-3, where they are cooled to a temperature of 25-60 °C, partially condensed and fed into the reflux drum R-101/1.

An reflux system for tube bundles with chemically purified water is installed on the air coolers in the summer to reduce the amount of waste gases. A partially condensed wide fraction of light hydrocarbons from the reflux drum R-101/1 is supplied to the pumps P-102/1,2-1, with which a portion of the wide fraction of light hydrocarbons is supplied to the upper plate of the stabilization column C-101/1 as live reflux to maintain the temperature regime of the top of the stabilization column. The balance amount of a wide fraction of light hydrocarbons passes through the AC-102/4 air cooler, where it is pre-cooled to a temperature of no more than 40 °C and sent for further processing or output as finished products to the parks of the raw material base or to the line of substandard product.

A constant amount of cubic liquid is circulated by pumps Р-101/1-1, Р-101/2-1 through the furnace F-101/1 and the return of the vapor-liquid mixture to the lower part of the stabilization column under the lower plate to maintain the required temperature regime of the stabilization column С-101/1. A balanced amount of stable condensate is removed from the cube of the C-101/1 stabilization column under its own pressure, which sequentially passes through the shell side of the E-101/1-3 heat exchangers, gives off heat to the oil and gas condensate mixture and cools to a temperature not exceeding 40 °C, enters the common collector, through which it is discharged. Stable condensate is discharged into the line of substandard product during start-up and stop operations of technological lines, as well as if the quality of stable condensate does not meet the requirements.

The АС-101/1-3 air cooler is a condenser of the upper product of the column. An air cooler of type AVZ-20-2.5-B1/8-4-6 is installed at the specified position. Zigzag type AVZ air coolers are designed for condensation and cooling of vaporous, gaseous and liquid media [38]. The main parameters of the air cooler are in accordance with the data of the technological regulations for the condensate stabilization unit, as well as OST 26-02-537-79, necessary for the development of a standard for electricity consumption (initial data): type – AVZ-20-2,5-B1/8-4-6; heat exchange surface of a tubes area – 440 m2, finned – 5300 m2; size – 6.0×6.47 m; number of sections – 3; fan power – 90 kW.

The consumption of air coolers includes the consumption of electrical energy for the fan drive, which is determined by the required air flow through the fan. The required air consumption is determined by the thermal load of the air cooler (heat output into the atmosphere), as well as the temperature difference between the cooled medium and the ambient air.

Results

When developing a methodology for rationing basic indicators, it is necessary to ensure that calculations are linked to these factors, i.e. to identify the dependence of the productivity of individual equipment, such as a furnace [39, 40] or a column reboiler, on the volume of output or processing of raw materials by a technological plant. Mathematical modeling of technological installations in Aspen Hysys software can be used to calculate the theoretically required amount of energy consumption by technological equipment of enterprises.

During the simulation, the operating modes of plants and individual equipment are assumed in accordance with the available statistical data. The simulation is carried out under operating conditions of installations and individual equipment at several performance values, which makes it possible to determine the theoretically required energy consumption. The result of the mathematical modeling of technological installations is the elementwise theoretically necessary loads of technological equipment.

An additional calculation is carried out based on the results of mathematical modeling, depending on the type of equipment under study, the purpose of which is to determine the dependencies of the theoretical consumption of fuel and energy resources on the plant's performance and ambient temperature, taking into account the characteristics of the equipment. Thus, for air coolers, an assessment of the electricity consumption by fans is carried out to ensure the necessary heat removal.

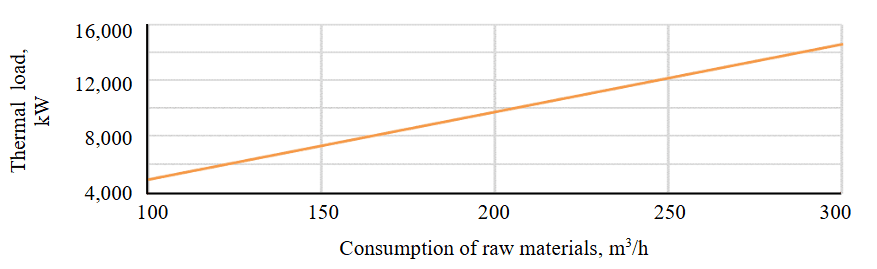

The estimated power consumption for the fan motor at the design stage should be increased by 10 % to ensure engine start-up. The design documentation calculates the maximum load of the installation, so there is no calculation of the power consumption of air coolers depending on the load of the installation. In this study, the obtained dependence allows us to determine the value of power consumption by the air cooler at a certain load of the installation at a specific time. The thermal load on the air cooler was determined based on the results of mathematical modeling of the column at different plant loads taking into account the use of a two-phase cooled medium (Fig.3). At a raw material consumption of 100 m3/h, the thermal load is 252.9 (4860) kJ/kg (kW); at 150 m3/h, the thermal load is 252.8 (7290) kJ/kg (kW); at 200 m3/h, the thermal load is 252.8 (9718) kJ/kg (kW); at 250 m3/h, thermal load 252.7 (12,145) kJ/kg (kW); at 300 m3/h, thermal load 252.97 (14,570) kJ/kg (kW).

The temperatures of the cooled medium at the inlet and outlet of the air cooler, in accordance with the analysis of statistical data, are assumed to be equal to constant values for the operating mode of the plant. The temperature values of the cooled medium (the upper product of the columns) averaged for the operating mode of the installation are 70.0 °C at the inlet and 52.6 °C at the outlet.

The possibility of heat exchange of one section of the air cooler (heat release into the atmosphere) is calculated using the heat transfer equation

where K1 is the coefficient of normative deterioration of the technical condition of the air cooler over the period of operation; K is the heat transfer coefficient of this type of air cooler, J/kg ·°С; F is the area of the finned heat exchange surface, m2; θt is the average logarithmic temperature difference.

Average logarithmic temperature difference

where T1 is the outside air temperature, °C; T2 is the air temperature behind the air cooler, °C,

n is the number of installed sections of the air cooler; Ga is the air flow rate through one section of the air cooler, kg/s; Сhc is the heat capacity of the air, J/kg·°С.

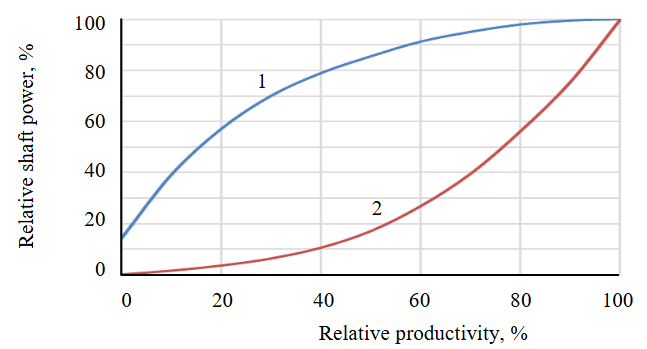

Based on the presented dependencies, the required air flow through the air cooler was calculated (Table 1). Based on the data in Table 1 and the typical dependence of the power consumption of the air cooler on the air flow (Fig.4), the calculation of the standard power consumption for the drive of the air cooler was carried out.

Fig.3. The calculated value of the thermal load of the air cooler, depending on the load and operating mode of the condensate stabilization plant

Fig.4. Typical dependence of the fan power consumption on its performance

1 – throttling; 2 – frequency control

Table 1

Air consumption through the air cooler, kg/s

|

Consumption of raw materials, m3/h |

Tа, °С |

||||

|

–40 |

–20 |

0 |

20 |

30 |

|

|

100 |

50.7 |

64.2 |

87.6 |

137.6 |

192.6 |

|

150 |

76.0 |

96.3 |

131.3 |

206.4 |

288.9 |

|

200 |

101.4 |

128.4 |

175.1 |

275.1 |

385.2 |

|

250 |

126.7 |

160.4 |

218.8 |

343.8 |

481.3 |

|

300 |

152.0 |

192.5 |

262.5 |

412.5 |

577.5 |

Note. Тa – ambient temperature.

The power of the electric drive of the fans of the air cooler is determined by the typical dependence in Fig.4 in the absence of a frequency-controlled drive. The power consumption of the electric fan drive of the air cooler in the presence of a frequency-controlled drive is calculated by the formula

where N0 is the rated power of the air cooler according to the passport documentation, kW; ηem is the efficiency of the electric motor; ηfc is the efficiency of the frequency converter; ра is the barometric pressure, MPa; рst, Тst are pressure and temperature under standard conditions, respectively, рst = = 101,325 Pa, Тst = 293.15 K; nnom, n is the nominal and actual rotation speed of the electric motor shaft, respectively, rpm.

The following parameters were taken into account in the subsequent calculations:

- typical dependence of the fan power consumption on its performance;

- type of air flow control (no regulation, blinds, variable frequency drive);

- electric motor power of one section;

- number of sections;

- engine load factor in nominal mode (assumed to be 0.8);

- the method of turning on the fans (in parallel or in series).

The rated efficiency of the engine was determined according to the international IEC standard.

The results of the calculation of the standard power consumption for the drive of the air cooler are presented in Table 2.

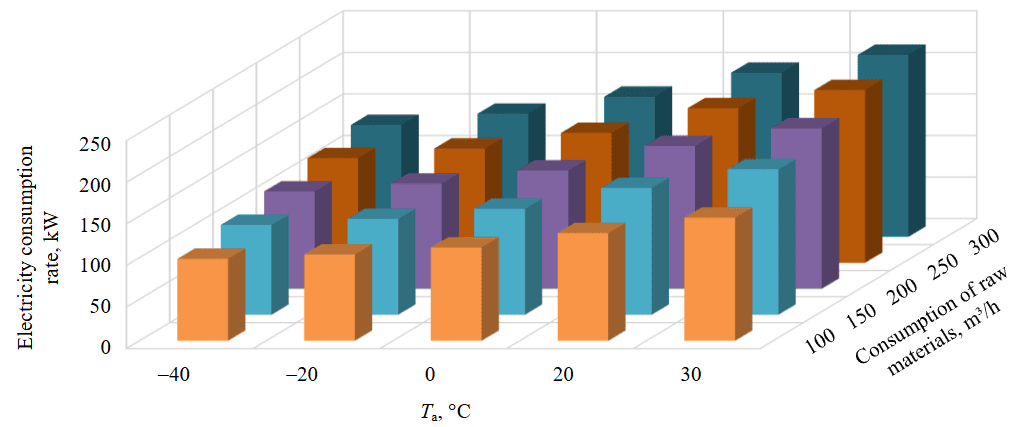

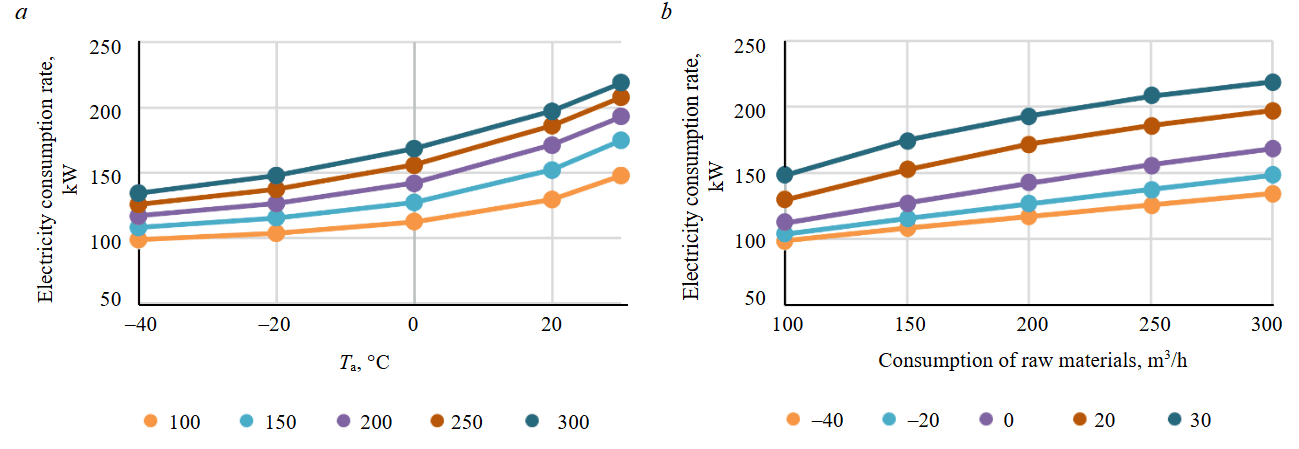

The dependence of the power consumption of the air cooler is nonlinear both on the ambient temperature and on the loading of the installation (Fig.5), in Fig.6 the dependencies are presented in two-dimensional form.

Fig.5. The dependence of the power consumption of the air cooler on the load of the installation and the ambient temperature

Fig.6. The dependence of the power consumption of the air cooler on the ambient temperature at different plant loads (a), on the plant load (b)

The study calculated the operating modes of the air cooler at 25 points. Since the calculations are complex, their use directly at the enterprise in this form is impractical. Therefore, a polynomial two-factor approximation of the values of electricity consumption by an air cooler was carried out. Due to non-linear dependencies both in terms of installation load and ambient temperature, a power-law approximation of the values was carried out using the least squares method implemented in Microsoft Office Excel software. The degree of the polynomial was chosen to be minimal (to reduce the complexity of the function), giving an error of no more than 5 % at any of the calculated points.

Table 2

Standard power consumption depending on performance and ambient temperature

|

Consumption of raw materials, m3/h |

Tа, °С |

||||

|

–40 |

–20 |

0 |

20 |

30 |

|

|

Mechanical power of the fan drive, taking into account alternate loading, kW |

|||||

|

100 |

63.42 |

71.73 |

85.15 |

109.34 |

130.77 |

|

150 |

78.70 |

89.81 |

106.61 |

135.54 |

159.08 |

|

200 |

92.41 |

105.30 |

124.36 |

155.74 |

177.64 |

|

250 |

104.53 |

118.74 |

139.64 |

170.47 |

192.57 |

|

300 |

115.34 |

130.72 |

152.49 |

182.02 |

203.40 |

|

The standard of power consumption of the air cooler, taking into account the efficiency of the engines, kW |

|||||

|

100 |

98.67 |

103.81 |

112.28 |

129.63 |

148.09 |

|

150 |

108.15 |

115.35 |

127.48 |

152.47 |

174.89 |

|

200 |

117.11 |

126.46 |

142.33 |

171.65 |

193.06 |

|

250 |

125.87 |

137.43 |

156.29 |

186.02 |

207.88 |

|

300 |

134.55 |

148.05 |

168.51 |

197.37 |

218.91 |

The minimum degrees of the polynomial obtained from the results of the analysis are as follows: in terms of loading Q, m3/h – the 2nd degree, in terms of ambient temperature Tа, °C – the 2nd degree. The results of the selection of approximate values of the power consumption of the air cooler are presented in Table 3.

Table 3

The results of the selection of approximate values of the power consumption of the air cooler

|

Consumption of raw materials, m³/h |

Ta, °С |

||||

|

–40 |

–20 |

0 |

20 |

30 |

|

|

Electricity consumption rate, kW |

|||||

|

100 |

98.67 |

103.81 |

112.28 |

129.63 |

148.09 |

|

150 |

108.15 |

115.35 |

127.48 |

152.47 |

174.89 |

|

200 |

117.11 |

126.46 |

142.33 |

171.65 |

193.06 |

|

250 |

125.87 |

137.43 |

156.29 |

186.02 |

207.88 |

|

300 |

134.55 |

148.05 |

168.51 |

197.37 |

218.91 |

|

Approximate value of the standard of power consumption, kW |

|||||

|

100 |

99.78 |

101.50 |

112.51 |

132.80 |

146.42 |

|

150 |

108.97 |

113.18 |

128.42 |

154.68 |

171.95 |

|

200 |

117.89 |

124.70 |

143.06 |

172.99 |

192.29 |

|

250 |

126.54 |

136.04 |

156.44 |

187.72 |

207.45 |

|

300 |

134.92 |

147.22 |

168.54 |

198.88 |

217.43 |

|

Deviation of the approximated and calculated values, % |

|||||

|

100 |

1.117 |

–2.226 |

0.209 |

2.438 |

–1.128 |

|

150 |

0.753 |

–1.880 |

0.740 |

1.453 |

–1.682 |

|

200 |

0.663 |

–1.397 |

0.518 |

0.782 |

–0.397 |

|

250 |

0.532 |

–1.010 |

0.095 |

0.914 |

–0.203 |

|

300 |

0.274 |

–0.559 |

0.017 |

0.761 |

–0.676 |

|

Root-mean-square error (RMSE) – 0.301 % |

|||||

Based on the results of comparing the approximating curves and the calculated values of the electricity consumption standards, it was concluded that the approximation polynomial and the calculated values are satisfactorily convergent (the standard deviation at all points does not exceed 1 %). According to the approximation results, the resulting dependence will have the form:

where Q – consumption of raw materials, m3/h; a, b, с – coefficients of two-factor approximation, relative units (Table 4).

Table 4

Coefficients of two-factor approximation, rel. u.

|

Designation |

Meaning |

The physical meaning of coefficients |

|

a2.1 |

–3.012· 10–7 |

The coefficient at x2 (the coefficient at higher powers of x) reflects nonlinear components that may indicate the presence of curvature, fluctuations, or other complex dependencies in the process |

|

b2.1 |

1.189· 10–4 |

|

|

c2.1 |

2.724· 10–3 |

|

|

a1.1 |

–1.706· 10–5 |

The coefficient at x1 (linear coefficient) determines the rate of change of the function (slope) relative to the variable x (dependence of the consumption of the air cooler with proportional changes in the plant load and ambient temperature) |

|

b1.1 |

9.369· 10–3 |

|

|

c1.1 |

0.01598 |

|

|

a0.1 |

–2.542· 10–4 |

The free term (coefficient at x0) is the initial value of the function at the point x = 0 or the base level (the base value of the consumption of the air cooler according to the initial technical parameters and equipment data) |

|

b0.1 |

0.3818 |

|

|

c0.1 |

76.87 |

It is necessary to take into account the context of the problem, the physical meaning of variables and units of measurement when interpreting coefficients. Not all coefficients may have an obvious physical meaning in each particular case, some of them may simply be mathematical artifacts reflecting the complexity of the process being approximated. A formula for calculating the standard power consumption for the air cooler AVZ-20-2.5-B1/8-4-6 was formed based on the results of determining the coefficients of two-factor approximation

The obtained dependence allows us to calculate the value of the power consumption of the air cooler at a specific time. Additionally, the sensitivity of the model to the input data is analyzed. When checking the model based on test values for plant loading (raw material consumption) and changes in ambient temperature for the calculation period, it was found that with various combinations of errors in setting the ambient temperature by ±2 °C and/or raw material consumption by ±5 %, the change in the calculated value of the power consumption standard was up to 1.5 %.

The resulting solution can be the basis (source data) for the formation of a database of statistical data for determining the standard of electricity consumption and subsequently used for the following purposes:

- planning the volume of electricity consumption and reducing energy consumption in the planning and economic processes of enterprises;

- identification of equipment and nodes with increased electricity consumption in order to develop plans for replacement, reconstruction, and modernization of installations;

- analysis of electric energy costs as part of the development of schedules for preventative and predictive maintenance and future energy conservation and energy efficiency programs;

- creation and implementation of digital twins at production facilities, models for forecasting electricity and power consumption, energy management systems with the integration of IoT sensors and other intelligent devices.

Conclusion

The issue of reducing the cost of electricity consumption for industrial enterprises with an annual growing demand for electricity and, as a result, the introduction of energy-saving and energy efficiency-enhancing measures is becoming urgent. However, the development of such measures is impossible without an accurate assessment of the power consumption of various types of equipment involved in the production process.

The electrical consumption of air coolers at a gas processing plant was considered in the framework of this study. A methodology has been developed that makes it possible to determine with high accuracy the standard consumption of electric power by an air cooler, depending on two changing factors – the ambient temperature and the load of the gas processing plant (the RMSE of the calculated and approximating values according to the results of the study does not exceed 1 %). The formula for calculating the standard electric power consumption for a specific air cooler in the installation under consideration was determined based on the results of the study.

The methodology can be used by employees of gas processing enterprises to determine the standard electricity consumption of air coolers under changing external and technological factors. This technique, developed and implemented in the Microsoft Office Excel software, allows its use by administrative, technical and production personnel without the use of specialized equipment or software, which would be a laborious process. In particular, it is possible to use the methodology in the R7-Office software for enterprises that have switched to the Russian office application package.

The further direction of the research work is to test the developed calculation methodology at gas processing and/or transportation enterprises, namely, comparing the obtained standard values with real statistical data recorded at the enterprise, conducting field measurements, assessing the factors affecting electricity consumption and the degree of their influence.

Such factors may include the following:

- geographical location and microclimate of the facility;

- physical obsolescence and deterioration of equipment;

- the absence or presence of seasonal changes in the fan blades impinging angle in spring and autumn due to changes in air density (the effect of temperature on the operating mode of the air cooler is only partially compensated because the adjustment is discrete, as a result, inaccurate maintenance of gas temperature and increased energy costs, since turning on the fans of the air cooler does not lead to the required temperature reduction, however, the possible savings in electrical energy are up to 10 %);

- irregular or untimely cleaning of the finned surface of the heat exchange pipes of the air cooler (hydrates form on the walls of the pipes of the heat exchange sections at low outdoor temperatures, as a result of which the gas cooling efficiency deteriorates, pressure losses in the heat exchange sections increase, mechanical deformation and destruction of the pipes of the heat exchange sections occur);

- design and operational features of the air cooler (lifting the structures of the units above ground level, the use of heat exchange pipes with a maximum finning coefficient, or, for example, the use of composite materials in the design of impellers, which will increase the efficiency of fans due to a more advanced aerodynamic shape of the blades and ensure the possibility of reducing the power consumption of the air cooler by up to 40 %);

- fan activation method (fans can be loaded in different ways depending on the switching method – in parallel, when all fans are turned on at the same time and work the same way, or sequentially, when one fan is loaded to 100 % first, then the next, etc.);

- air flow control, the degree of engine load (lack of regulation, regulation by means of blinds or a frequency-controlled drive, for example, reducing the power of a drive not designed to operate as part of a frequency-controlled drive, with frequency control by more than 30 % leads to overheating of the windings and reduced service life, while the presence of a frequency-controlled drive provides energy savings of up to 20 %);

- the quality of the source data (requires statistics on the electricity consumption of each piece of equipment installed at the research facility, in addition to the working documentation and equipment passports), etc.

Based on the results of testing the methodology at gas processing plants, studies can be conducted aimed at developing predictive analytics methods to identify signs of equipment wear at an early stage, and measures can be developed to save energy and increase energy efficiency, reduce electricity costs.

References

- Zhukovskiy Y.L., Batueva D.E., Buldysko A.D. et al. Fossil Energy in the Framework of Sustainable Development: Analysis of Prospects and Development of Forecast Scenarios. Energies. 2021. Vol. 14. Iss. 17. N 5268. DOI: 10.3390/en14175268

- Khasanov I.I., Arduganov A.I. Modernization of fans of gas air cooling unit at compressor stations of main gas pipelines. Transport and storage of Oil Products and hydrocarbons. 2022. N 1-2, p. 29-34 (in Russian). DOI: 10.24412/0131-4270-2022-1-2-29-34

- Zhukovskiy Y., Koshenkova A., Vorobeva V. et al. Assessment of the Impact of Technological Development and Scenario Forecasting of the Sustainable Development of the Fuel and Energy Complex. Energies. 2023. Vol. 16. Iss. 7. № 3185. DOI: 10.3390/en16073185

- Morenov V. Advances in Oil and Gas Production: A Viewpoint. Energies. 2023. Vol. 16. Iss. 3. N 1379. DOI: 10.3390/en16031379

- Zhukovskiy Y., Tsvetkov P., Koshenkova A. et al. A Methodology for Forecasting the KPIs of a Region’s Development: Case of the Russian Arctic. Sustainability. 2024. Vol. 16. Iss. 15. N 6597. DOI: 10.3390/su16156597

- Tokarev I.S. Development of parameters for an industry-specific methodology for calculating the electric energy storage system for gas industry facilities. Journal of Mining Institute. 2025. Vol. 272, p. 171-180.

- Senchilo N.D., Ustinov D.A. Method for Determining the Optimal Capacity of Energy Storage Systems with a Long-Term Forecast of Power Consumption. Energies. 2021. Vol. 14. Iss. 21. N 7098. DOI: 10.3390/en14217098

- Tokarev I.S., Yugay V.F., Tolmachev V.N. et al. Use of electric power storage systems as part of power generating equip-ment of PJSC Gazprom production facilities power supply systems. Gas Industry. 2023. Iss. S3 (853), p. 34-40 (in Russian).

- Dubinina N.A., Michurina O.Y., Kudryavtseva O.V., Kushner A.A. The main directions of increasing energy efficiency at the enterprises of the oil and gas industry. Engineering and Construction Bulletin of the Caspian Region. 2021. N 4 (38), p. 80-85 (in Russian). DOI: 10.52684/2312-3702-2021-38-4-80-85

- Pronin V.A., Tsvetkov V.A., Kovanov A.V. et al. Methods for regulating the performance of screw compressors. Journal of International Academy of Refrigeration. 2021. N 2 (79), p. 28-38 (in Russian). DOI: 10.17586/1606-4313-2021-20-2-28-38

- Abakumov A.M., Zubkov Yu.V., Abakumov O.A. Electric drives control of gas cooling units taken into account of indi-vidual characteristics air cooling apparatus. News of the Tula State University. Sciences of Earth. 2024. Iss. 8, p. 567-571 (in Russian). DOI: 10.24412/2071-6168-2024-8-567-568

- Yanvarev I.A., Vanyashov A.D., Krupnikov A.V. Improving Gas Cooling Technology at its Compression in the Booster Compressor Station. Procedia Engineering. 2016. Vol. 152, p. 233-239. DOI: 10.1016/j.proeng.2016.07.696

- Kudina H.F., Prihodzko I.V., Karpenko V.V., Kuritsyn P.A. Influence of climatic factors on performance of electrical equipment. Mining Mechanical Engineering and Machine-Building. 2021. N 2, p. 55-64 (in Russian).

- Ermishov K.V., Zharov A.Yu., Kopycheva U.N. Implementation of digital models for increasing of the efficiency of gas-processing enterprises: Simulation of air-cooling units. Oil & Gas Chemistry. 2021. N 3-4, p. 60-62 (in Russian). DOI: 10.24412/2310-8266-2021-3-4-60-62

- Khvorov G.A., Yumashev M.V. Analysis of energy-saving technologies for gas cooling based on air cooling units for gas transport at Gazprom PJSC. Oil and Gas Territory. 2016. N 9, p. 127-132 (in Russian).

- Arslanova А.F., Farukhshina R.R. Evaluation of the thermal efficiency of air-cooled gas devices of the “Iceberg” type. Transport and Storage of Oil Products and Hydrocarbons. 2023. N 2, p. 59-65 (in Russian). DOI: 10.24412/0131-4270-2023-2-59-65

- Kalinin A.F., Merkuryeva Yu.S., Hallyev N.H. Operational Efficiency Estimate of Gas Air Coolers of New Generation. Oil and Gas Territory. 2018. N 9, p. 74-80 (in Russian).

- Eremenko O.V. Towards the effectiveness of innovation in the selected sectors of activity of oil and gas producing enterprises. Bulletin of Buryat State University. Economy and Management. 2018. Iss. 1, p. 33-43 (in Russian). DOI: 10.18101/2304-4446-2018-1-33-43

- Shoghl S.N., Pazuki G. Compressor/pump stations in natural gas transmission pipelines. Advances in Natural Gas: Formation, Processing, and Applications. Elsevier, 2024. Vol. 6: Natural Gas Transportation and Storage, p. 177-236. DOI: 10.1016/B978-0-443-19225-8.00006-8

- Jiawei Zhang, Lin Li, Qizhi Zhang, Yanbin Wu. Optimization of Load Sharing in Compressor Station Based on Improved Salp Swarm Algorithm. Energies. 2022. Vol. 15. Iss. 15. N 5720. DOI: 10.3390/en15155720

- Maskov L.R., Kornilov V.Yu. Development of a model of an electrical complex for gas air cooling devices of gas field N 1 Gazprom dobycha Yamburg LLC with a centralized power supply system in the MATLAB/SIMULINK program. Power engineering: research, equipment, technology. 2022. Vol. 24. N 2, p. 50-71 (in Russian). DOI: 10.30724/1998-9903-2022-24-2-50-71

- Knebel F.P., Trevisan R., do Nascimento G.S. et al. A study on cloud and edge computing for the implementation of digital twins in the Oil & Gas industries. Computers & Industrial Engineering. 2023. Vol. 182. N 109363. DOI: 10.1016/j.cie.2023.109363

- Egbumokei P.I., Dienagha I.N., Digitemie W.N. et al. The role of digital transformation in enhancing sustainability in oil and gas business operations. International Journal of Multidisciplinary Research and Growth Evaluation. 2024. Vol. 5. Iss. 5, p. 1029-1041. DOI: 10.54660/.IJMRGE.2024.5.5.1029-1041

- Semenov P.V., Semishkur R.P., Diachenko I.A. Conceptual model of digital twin technology implementation for oil and gas industry. Gas Industry. 2019. N 7 (787), p. 24-30 (in Russian).

- Yun J., Kim S., Kim J. Digital Twin Technology in the Gas Industry: A Comparative Simulation Study. Sustainability. 2024. Vol. 16. Iss. 14. N 5864. DOI: 10.3390/su16145864

- Abakumov A.M., Antropov V.E., Vedernikov A.S., Abakumov O.A. The energy efficiency of cooling the natural gas with variable frequency drive fans. Vestnik of Samara State Technical University. Technical Sciences Series. 2019. N 3 (63), p. 94-104 (in Russian).

- Kalinin A.F., Merkuryeva J.S., Fomin A.V. Performance Assessment of Variable Speed Electrical Drive for Gas Air Cooling Units on Trunk Pipeline Compressor Station. Oil and Gas Territory. 2019. N 11, p. 68-75 (in Russian).

- Enbin Liu, Liuxin Lv, Yang Yi, Ping Xie. Research on the Steady Operation Optimization Model of Natural Gas Pipeline Considering the Combined Operation of Air Coolers and Compressors. IEEE Access. 2019. Vol. 7, p. 83251-83265. DOI: 10.1109/ACCESS.2019.2924515

- Angjun Xie, Gang Xu, Chunming Nie et al. Operation Data Analysis and Performance Optimization of the Air-Cooled System in a Coal-Fired Power Plant Based on Machine Learning Algorithms. Energies. 2024. Vol. 17. Iss. 22. N 5571. DOI: 10.3390/en17225571

- Mehrpooya M., Ghorbani B., Mousavi S.A., Zaitsev A. Proposal and assessment of a new integrated liquefied natural gas generation process with auto-Cascade refrigeration (exergy and economic analyses). Sustainable Energy Technologies and Assess-ments. 2020. Vol. 40. N 100728. DOI: 10.1016/j.seta.2020.100728

- Klyuev R.V., Morgoev I.D., Morgoeva A.D. et al. Methods of Forecasting Electric Energy Consumption: A Literature Re-view. Energies. 2022. Vol. 15. Iss. 23. N 8919. DOI: 10.3390/en15238919

- Babanova I.S., Prokhorova V.B., Tokarev I.S. Management of electricity consumption by oil and gas companies, taking into account the assessment of the technical condition of consumers and regulators. Moscow: Gornaya kniga, 2022, p. 372 (in Russian).

- Shalygin A.V., Fetisov V.G., Karyakina I.V. Research of air cooler working in a main gas pipeline system. Transport and Storage of Oil Products and Hydrocarbons. 2023. N 2, p. 29-32 (in Russian). DOI: 10.24412/0131-4270-2023-2-29-32

- Fahmy M.F.M., Nabih H.I. Impact of ambient air temperature and heat load variation on the performance of air-cooled heat exchangers in propane cycles in LNG plants – Analytical approach. Energy Conversion and Management. 2016. Vol. 121, p. 22-35. DOI: 10.1016/j.enconman.2016.05.013

- Lei Chen, Lijun Yang, Xiaoze Du, Yongping Yang. A novel layout of air-cooled condensers to improve thermo-flow per-formances. Applied Energy. 2016. Vol. 165, p. 244-259. DOI: 10.1016/j.apenergy.2015.11.062

- Yonghong Guo, Tongrui Cheng, Xiaoze Du, Lijun Yang. Anti-Freezing Mechanism Analysis of a Finned Flat Tube in an Air-Cooled Condenser. Energies. 2017. Vol. 10. Iss. 11. N 1872. DOI: 10.3390/en10111872

- Nelyubin A.P., Podinovski V.V. Approximation of Functions Defined in Tabular Form: Multicriteria Approach. Computa-tional Mathematics and Mathematical Physics. 2023. Vol. 63. N 5, p. 730-742. DOI: 10.31857/S0044466923050174

- Silkina T.S., Lyamina N.F. Increasing energy efficiency of air cooler in associated petroleum gas disposal in oilfields. Oil and gas technologies and environmental safety. 2023. N 1, p. 51-58 (in Russian). DOI: 10.24143/1812-9498-2023-1-51-58

- Arabov M.Sh., Arabov S.M. Energy efficiency of technological processes at the Astrakhan gas processing plant. Equipment and technologies for oil and gas complex. 2023. N 3 (135), p. 10-19 (in Russian). DOI: 10.33285/1999-6934-2023-3(135)-10-19

- Arabov M.Sh., Gamzatova A.H., Arabova Z.M., Arabov S.M. Tubular furnace efficiency in the process of hydrocarbon condensate stabilization at the Astrakhan Gas Processing Plant. Oil and gas technologies and environmental safety. 2023. N 4, p. 62-69 (in Russian). DOI: 10.24143/1812-9498-2023-4-62-69