Environmental geotechnology for low-grade ore mining with the creation of conditions for the concurrent disposal of mining waste

- 1 — Ph.D., Dr.Sci. Director Institute of Mining, Ural Branch of the RAS ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Ph.D. Head of Laboratory Institute of Mining, Ural Branch of the RAS ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 3 — Ph.D. Senior Researcher Institute of Mining, Ural Branch of the RAS ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 4 — Researcher Institute of Mining, Ural Branch of the RAS ▪ Orcid

Abstract

Due to the constantly deteriorating environmental situation in the regions with mining enterprises, the article considers the topical issue of disposing the maximum possible volume of waste from the mining and processing of low-grade ferrous ores through the creation of an effective underground environmental geotechnology. Traditional procedure with descending mining of reserves with a caving system does not allow waste to be disposed of in a gob. The idea is to use geotechnology based on the ascending order of mining the ore body, room excavation, leaving truncated pillars, and staggered arrangement of adjacent rooms in height, which makes it possible to form containers for waste disposal in the form of a cementless backfill. The main characteristics of the proposed procedure are investigated and compared with the traditional procedure of low-grade iron ores mining. It was established that from the point of view of the complete extraction of reserves and the unit costs for the preparatory-development operations, the processes are comparable, while in terms of the mining quality, the proposed option is much more efficient. Evaluation of environmental geotechnology by the criterion of waste disposal, performed according to the proposed methodology, showed that the combination of these technical solutions ensures the placement in the formed gob from 80 to 140% of all waste generated during the mining and beneficiation of low-grade iron ores.

Introduction

The continuous accumulation of waste from mineral production, mining, and be-neficiation leads to a significant deterioration of the environmental situation in the regions where mining and processing enterprises are located [1-3]. Over the past decade, the growth of these wastes in Russia has increased from 3.8 to 7.9 billion tons per year [4]. It is obvious that the problem of waste disposal is becoming more and more relevant both in terms of the environmental consequences of mineral management [5-7] and in terms of the economic efficiency of enterprises in the face of tougher environmental requirements [8-10]. The target of study in this paper is geotechnological methods for the disposal of waste from the mining and processing of mineral raw materials during underground mining, which would reduce the share of geoenvironmental measures, such as reclamation and neutralization.

All geotechnological methods of waste disposal are primarily based on their placement in the gob. In open pit mining, the main disposal methods are internal dumping, the use of the entire quarry bowl or its part for storing liquid and pasty waste, the preparation of man-made containers inside the quarry space or in dumps using overburden, dams, and gabion structures, etc. [11-13]. In underground mining, waste disposal is possible by using it as backfill material for infilling the gob [14, 15]. While remaining an integral part of underground geotechnology, backfill operations are mainly considered from the point of view of controlling rock pressure and increasing the completeness of the working excavation. In modern conditions, the need to apply an integrated approach to the development of deposits is obvious, when geotechnology with backfilling of gob should be considered in the aspect of providing favourable conditions for the disposal of mining and beneficiation waste, in other words, as an environmental geotechnology [16-18].

Thus, the development of an effective underground environmental geotechnology with the purposeful creation of conditions for the disposal of the maximum possible amount of waste is an urgent scientific and technical task.

Methodology

Due to the low content of the useful component with large volumes of mining, the issue of waste disposal is most acute in the development of high-output deposits. During the mi-ning of non-ferrous metal ores, the backfill mass, as a rule, is formed by hardening mixtures based on a cement binder, and significant costs for backfill operations are justified by the complete and qualitative extraction of the mineral and the high recoverable value of the mined and beneficiated ore [19]. The disadvantages of the hardening backfill, in addition to the high cost, include the staged procedure for mining reserves, due to the significant period of strength gain of the backfill mass [20, 21]. To reduce the cost of the hardening backfill in the development of copper pyrite deposits, mixture compositions based on lime-slag binders were sought, which made it possible to abandon the use of cement and reduce the cost of backfill by 20-30 % [22]. Studies were carried out on the construction of a combined backfill mass from a dry and hardening backfill, which made it possible to reduce costs and intensify the process. However, it complicated the organization of backfilling [23]. There are developments on the partial strengthening of a dry backfill mass by injecting hardening solutions through special wells and its subsequent compaction by breaking the reserves of the adjacent room onto the compressed environment of the backfill mass [24].

Another direction was the construction of high-density man-made masses with a small proportion of hardening backfill (10-15 %) and mechanical compaction of rock fill by analogy with road construction. The disadvantage of the procedure is the need to use heavy road rollers in underground conditions and a certain procedure for erecting a backfill mass with an accurate layout, alternating parapets of certain sizes at a certain distance. It should be noted that the use of hardening mixtures, even in small quantities and regardless of their composition, entails organizational and technical complication and an increase in the cost of the entire geotechnology as a whole. However, the economic effect obtained during the mining of non-ferrous metal ores or rich ores makes it possible to use working systems with a hardening backfill for the development of high-output deposits with virtually no alternative.

In the mining of poor and ordinary ores of ferrous metals, in particular iron, the low recoverable value makes the use of a hardening backfill impractical. Such deposits, as a rule, are mined by working systems with the caving of ores and host rocks. The traditional procedure has significant advantages such as high labour productivity at the working excavation and low production costs; however, it is characterized by low ore recovery rates (losses and impoverishment to 20-30 %) and a large specific volume of preparatory-development operations (PDO) [25-27]. These factors affect its efficiency but make it possible to profitably develop low-grade iron ore deposits in modern economic conditions. The potential of this geotechnology in terms of waste disposal in the gob is practically zero [28]. Thus, the only way to increase the environmental potential of the geotechnology in such deposits is the use of workings systems with cementless backfill.

The use of a cementless backfill involves the formation of insulating interlevel (ILP) and interchamber (ICP) pillars, since the backfill does not have the necessary stability properties in the presence of lateral outcropping planes. ICPs can be either kept or worked out by mining systems with caving. The use of the ascending order of reserves mining makes it possible to withdraw from the ILP [29]. A significant part of the ore body is left in the form of remnant pillars or is mined using caving procedure that does not imply the conditions for waste disposal in the gob.

Thus, when designing an environmentally oriented mining system, one should be guided by the following principles:

- application of a room excavation, which allows to form a gob as a container for waste disposal;

- use of ascending order of reserves mining;

- the design of the system should provide the possibility of placing the maximum volume of waste in the form of a cementless backfill with a minimum volume of formed ore pillars;

- provision of recovery rates comparable with conventional procedure with ore and host rocks caving.

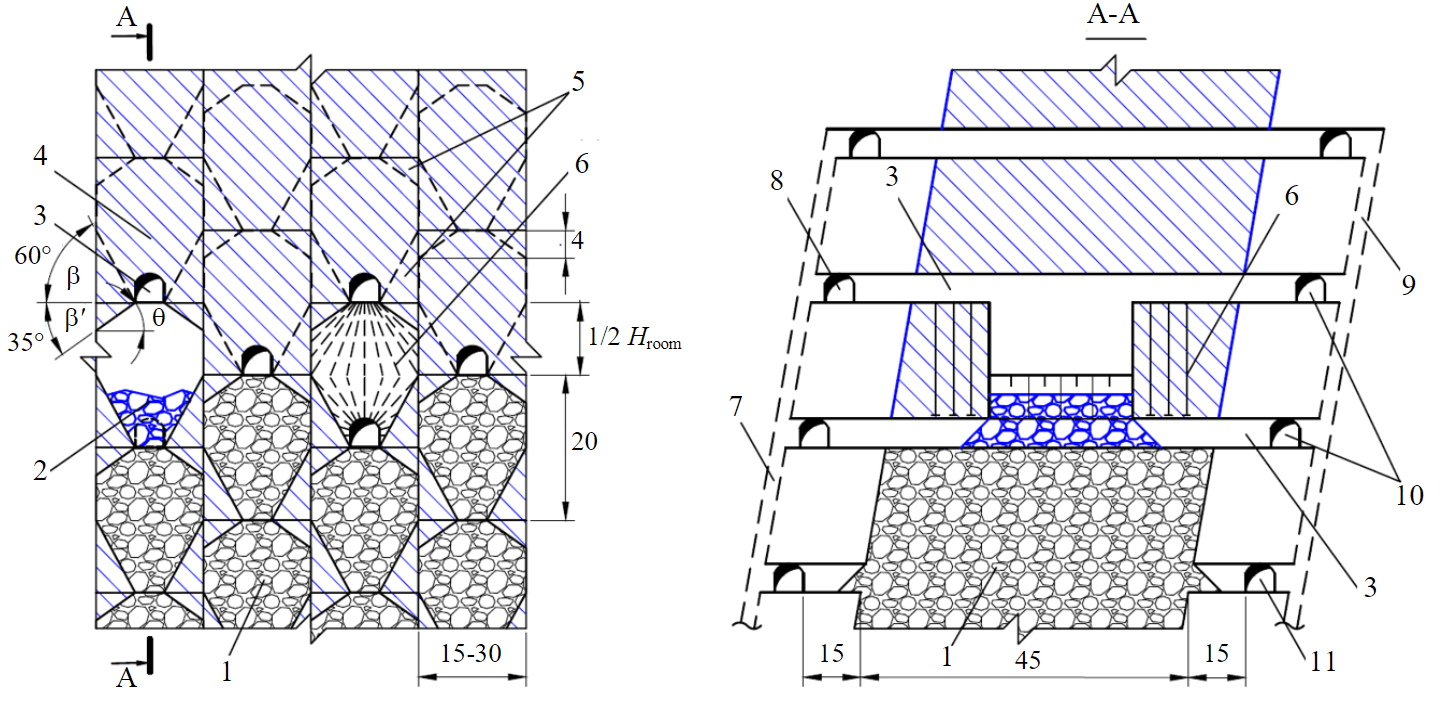

As a result, a variant of a sublevel-room mining system with cementless backfill was designed, which meets the main trends in improving underground ore mining as part of the development of environmental geotechnologies. The procedure provides for the division of the level into sub-levels, which are mined in ascending order by rooms located relative to neighbouring rooms with an offset in the vertical plane by half of the sublevel height and leaving remnant insulating pillars of a triangular or trapezoidal shape with a minimum width of the upper base (Fig.1).

Two faces carry out extraction of room reserves by sectional breaking of ore with opposite fans of holes and subsequent end withdrawal using load-haul-dump machines (LHD) with remote control (RC). After mining out the room, it is filled with backfill material. Mining dump trucks are used to transport cementless backfill to the room. The backfill mass formed by a mine bulldozer with RC by distributing and planning the rock over the entire area of the room, which makes it possible to create a drawing-off level of the overlying room.

The ascending order of mining the ore body, the staggered arrangement of the rooms in height and the leaving of insulating triangular pillars make it possible to isolate the mined room from the adjacent gob filled with waste, thereby forming a container for the construction of a cementless backfill mass, and the truncated shape of the remnant pillars minimizes their sizes.

Fig.1. Sublevel-room mining system with ascending extraction and cementless backfill 1 – cementless backfill; 2 – broken ore; 3 – drill haulage ort; 4 – room; 5 – insulating pillar; 6 – blastholes; 7 – ascending ventilation hole; 8 – ventilation drift; 9 – ore pass; 10 – sublevel drift; 11 – level drift

Discussion of the results

The proposed option should not be inferior to the traditional procedure in terms of completeness and quality of extraction of subsoil reserves. Another important factor in any underground geotechnology is the specific volume of PDO, which has a significant impact on the cost of driving preparatory-development workings. These factors and the volume of the emerging container for waste disposal significantly depend on the geometric parameters of the rooms, determined considering specific mining, geological, and geomechanical conditions. It is known that with an increase in the size of the stope rooms, technical and economic factors improve. Since the study is methodical in nature, we considered the range of change in the width of the room from 15 to 30 m at a constant height of 20 m. With an increase in the height of the rooms, it is very difficult to qualitatively design the pillars of a truncated shape, which ensure the stability of the cementless backfill mass [30].

The factors of the traditional system were determined with a rational ratio of the width and height of the panel, 15×20 m, 20×25, and 25×30 m [31] according to the generally accepted method [32]. With the proposed procedure, ore losses in truncated insulating pillars make up the bulk of the total operational losses during excavation of reserves. With an increase in the width of the room from 15 to 30 m, the losses in the pillars are halved (from 25 to 13 %), the losses of broken ore remain within 2-3 %.

Calculation of the specific volume of PDO, considering the increase in the width of the room or panel, was carried out as follows

where ΣVpdo is the total volume of PDO in the room (panel), m3; Qmin are mineable reserves of the room, t; Sd.h.o., Se, Savh, Sop, Ssd – areas of the drill haulage ort, entry into the room, ascending ventilation hole, ore pass, and sublevel drift, m2; m is the thickness of the ore body, m; le is the length of entry into the room, m; ne is the number of entries to the room, pcs.; Lop is the distance between the ascending ventilation hole and the ore pass along the strike of the ore body, m; hsl is the sublevel height, m; B is the room width, m; nsd is the number of sublevel drifts, pcs.; γo – ore density, t/m3; L – ore loss index, mon. units; I– ore impoverishment index, mon. units.

Comparison of indicators of losses and specific volume of PDO, characterizing the traditional (1) and the proposed option (2) depending on the width of the mining unit (panel or room), is shown in Fig.2.

An analysis of the graphs in Fig.2 shows that, in terms of the complete extraction of reserves and the unit costs for preparatory-development operations, the options are comparable. With an increase in the width of the mining units, the factors of losses and the specific volume of PDO for both options improve. The specific consumption of PDO is reduced due to the greater increase in the mineable reserves of the room (panel) to the increase in the PDO volume. Impoverishment during room excavation of a thick steeply dipping ore body in ascending order will be several times lower than during descending mining by a sublevel caving system with an end withdrawal (5-7 % vs. 25-30) due to the minimal admixture of waste rocks of the hanging side and the working excavation under the ore mass, and not the collapsed rocks.

As noted above, the traditional procedure with the caving of ore and host rocks does not have an environmental potential, since no cavities suitable for filling with waste are formed. To assess the environmental potential of the developed underground geotechnology, an appropriate criterion is proposed, the factor of waste disposal in the gob, which is the ratio of the filled volume of the room to the volume of waste generated during its mining

Fig.2. Comparison of ore recovery and specific consumption of PDO with traditional (1) and proposed (2) process options

where Vop is the operating volume of the room, m3; kfil is the filling factor of the room, mon. units; kshr is the factor of waste shrinkage, mon. units; Vw is the volume of waste generated during the mining of the room, m3.

The operating volume of the room is determined considering the triangular shape of the pillars

where a is the room width, m; h is the room height, m; b is the pillar base width, m; β is the tilt angle of the triangular pillar in the lower part of the room, deg; β′ is the tilt angle of the triangular pillar in the upper part of the room, deg; m is the thickness of the steeply dipping ore body, m.

The angle β is determined by the pillar width, the sublevel height and is limited to half of this height. The angle β' is equal to the angle θ, which is assumed to be 1-2 degrees greater than the repose angle of the backfill mass being formed in the roof of the room.

The volume of waste generated during the mining of the room is determined considering the specific consumption of PDO and the procedure of two-stage beneficiation of iron ores using dry and wet magnetic separation methods [33, 34]:

where Vrock is the volume of rock from the preparatory-development operations, m3; Vdms is the volu-me of dry magnetic separation waste, m3; Vwms is the volume of wet magnetic separation waste, m3.

As an example of assessing the environmental potential of the proposed procedure, a steeply dipping ore body with an average thickness of 45 m and an iron content in low-grade ores from 25 to 45 % is considered.

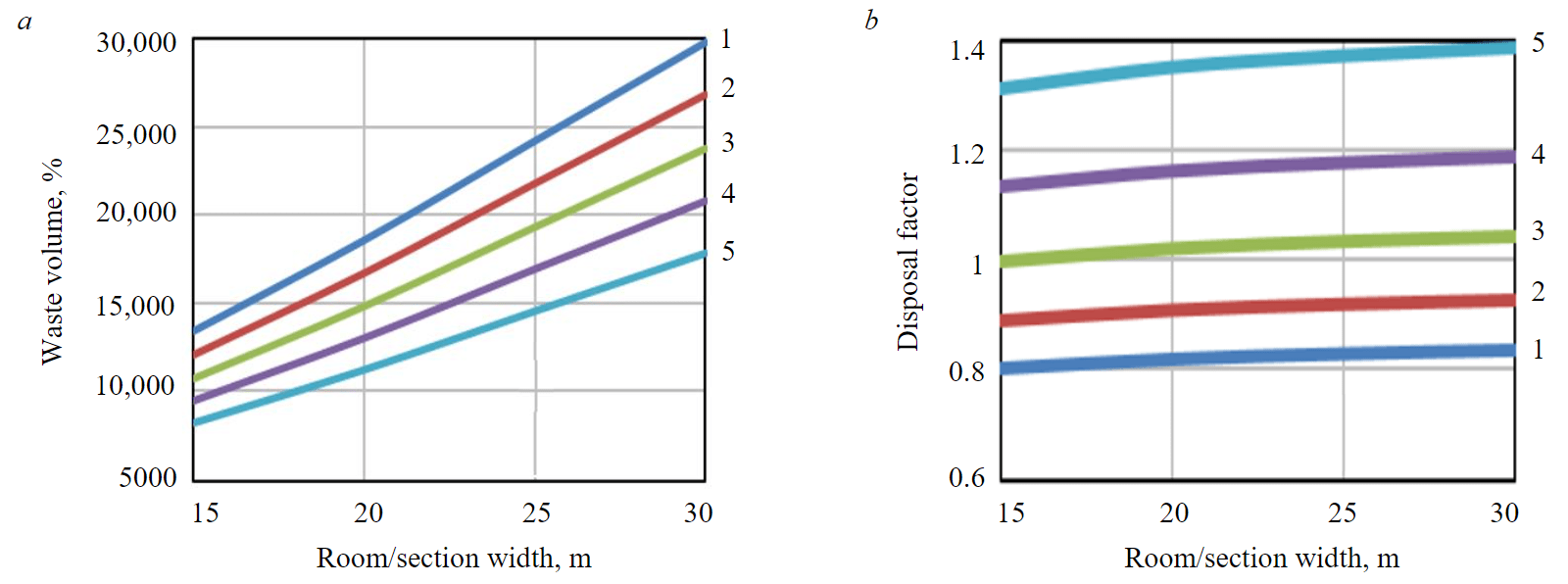

Approximate volumes of waste are presented as a function of the width of the room and the content of the useful component (Fig.3, a).

The graphs in Fig.3, a show that the volume of disposed waste grows with an increase in the room width due to an increase in the volume of mineable reserves in the extraction unit and decreases with an increase in the metal content in the ore. An increase in the intensity of the function with an increase in the width of the room occurs due to a decrease in the influence of the share of waste from drifting, and a decrease in the intensity of the function with an increase in the content of the useful component is due to an increase in impoverishment and a decrease in the quality gain in the beneficiation process at the stage of dry magnetic separation [35].

Fig.3. Dependence of the volume of waste generated during the mining of the room (a) and the disposal factor (b) on the width of the room and the content of the useful component in the ore 1 – Fe = 25 %; 2 – 30; 3 – 35; 4 – 40; 5 – 45

The values of the waste disposal factor determined for the developed environmental geotechno-logy depending on the width of the mining unit in the considered range of the content of the useful component in the ore are shown in Fig.3, b.

Figure 3, b shows that the factor values increase with the room width and the content of the useful component in the ore due to an increase in the volume of reserves and a decrease in the proportion of waste rock in the ore mass. A decrease in the intensity of the function with an increase in the room width occurs due to an improvement in the loss factor and a deterioration in the impoverishment factor.

The results of the study show that it is possible to use a significant amount of waste from the mining and processing of low-grade iron ores in specially formed storage rooms without a binder to consolidate and hold backfill material in a stable state (from 80 % in the worst to 140 % in the best of the considered cases). Also, when the iron content in the ore is more than 35 % (η > 1), the backfilled rooms may dispose more dry and solid waste than is generated as a result of their mining, which additionally enables to dispose the rock from the permanent workings or other mining waste already existing at the enterprise.

Conclusion

As part of the creation of environmentally oriented underground geotechnologies for the mining of low-grade ores, an environmental geotechnology was developed based on the working of a deposit in an ascending order, room extraction of reserves with a staggered arrangement of rooms in height, the formation of insulating pillars of a truncated shape, and the placement of mining waste in a gob in the form of cementless backfill. In addition to iron ore deposits, the developed procedure can be promising for deposits with low-grade ores of non-ferrous metals and apatite-nepheline raw materials similar in occurrence conditions.

Studies of the main factors of the proposed procedure and their comparison with the traditional procedure for mining low-grade iron ore, the system for developing sublevel caving, determined that in terms of the complete extraction of reserves and unit costs for drifting of preparatory-development workings, the procedures are comparable, while in terms of extraction quality, the developed version is much more efficient.

Evaluation of environmental geotechnology according to the criterion of waste disposal, performed according to the proposed methodology, showed that the sublevel-room working system with ascending excavation of rooms and cementless backfill provides placement in the formed gob from 80 to 140 % of all waste generated during the mining and beneficiation of low-grade iron ores with iron content alternating from 25 to 45 %.

Improvement of underground environmental geotechnologies and development of the methodo-logy for their assessment with access to an integral environmental and economic criterion is the direction of further research by the authors.

References

- Pashkevich M.A. Classification and Environmental Impact of Mine Dumps. Assessment, Restoration and Reclamation of Mining Influenced Soils. London: Academic Press, 2017, p. 1-32. DOI: 10.1016/B978-0-12-809588-1.00001-3

- Lima A.T., Mitchell K., O'Connell D.W. et al. The legacy of surface mining: remediation, restoration, reclamation and rehabilitation. Environmental Science & Policy. 2016. Vol. 66, p. 227-233. DOI: 10.1016/j.envsci.2016.07.011

- Agboola O., Babatunde D.E., Fayomi O.S. et al. A review on the impact of mining operation: Monitoring, assessment, and management. Results in Engineering. 2020. Vol. 8. N 100181. DOI: 10.1016/j.rineng.2020.100181

- Antoninova N.Yu., Shubina L.A. To the Question about the Features of Integrated Environmental Analysis Areas Experienced Local Technical Burden of Mining and Smelting Complex Enterprises. Ecology and Industry of Russia. 2017. Vol. 21. N 2, p. 52-56. DOI: 10.18412/1816-0395-2017-2-52-56

- Arratia-Solar A., Svobodova K., Lèbre É., Owen J.R. Conceptual framework to assist in the decision-making process when planning for post-mining land-uses. The Extractive Industries and Society. 2022. Vol. 10. N 101083. DOI: 10.1016/j.exis.2022.101083

- Boldy R., Santini T., Annandale M. et al. Understanding the impacts of mining on ecosystem services through a systematic review. The Extractive Industries and Society. 2021. Vol. 8. Iss. 1, p. 457-466. DOI: 10.1016/j.exis.2020.12.005

- Kornilkov S.V., Antoninova N.Yu., Shubina L.A., Slavikovskaya Yu.O. Ecological Aspects of Choosing a Recultivation Scenario in Mineral Mining. Mining Informational and Analytical Bulletin. 2021. N 5-2, p. 218-230 (in Russian). DOI: 10.25018/0236_1493_2021_52_0_218

- Onimisi A.H., Olanrewaju I.O. Environmental impacts of iron ore mining on quality of surface water andits health implication on the inhabitants of Itakpe. International Journal of Current Multidisciplinary Studies. 2016. Vol. 2. Iss. 6, p. 318-321.

- Pashkevich M.A., Alekseenko A.V., Petrova T.A. Assessment and control of environmental and economic risk in the Novorossiysk industrial agglomeration. Izvestiya Tulskogo gosudarstvennogo universiteta. Nauki o zemle. 2018. N 1, p. 23-35 (in Russian).

- Antoninova N.Yu., Rybnikova L.S., Slavikovskaya Yu.O., Shubina L.A. Environmental and Economic Aspects of Selecting Reclamation Directions for Industrial Mining and Metallurgical Waste Disposal Sites. Russian Mining Industry. 2022. N S1, p. 71-77 (in Russian). DOI: 10.30686/1609-9192-2022-1S-71-77

- Trubetskoy K.N. Solution of the problem of ecological balance in open pit mineral mining. Gornyi zhurnal. 2018. N 6, p. 71-76 (in Russian). DOI: 10.17580/gzh.2018.06.15

- Zoteev O.V., Kravchuk T.S., Pytalev I.A., Yakshina V.V. Study of the possibility of using gabion structures in the complex development of mining systems. Izvestija Tulskogo gosudarstvennogo universiteta. Nauki o zemle. 2020. N 4, p. 179-189 (in Russian). DOI: 10.25635/h3068-0098-9195-n

- Sakantsev G.G., Perekhod T.M., Sveshchinskaya N.A. Theoretical Bases of Waste-Free Technologies for Opencast Mining of Ore Deposits. Problems of Subsoil Use. 2019. N 3 (22), p. 86-94 (in Russian). DOI: 10.25635/2313-1586.2019.03.086

- Kaplunov D.R., Yukov V.A. Principles of a Mine Transition to Sustainable and Environmentally Sound Development. Mining Informational and Analytical Bulletin. 2020. N 3, p. 74-86 (in Russian). DOI: 10.25018/0236-1493-2020-3-0-74-8615

- Khayrutdinov M.M., Kuziev D.A., Kopylov A.B., Golovin K.A. Man-Made Waste in Backfill Mixtures – A Way to Reduce Environmental Impact. Izvestija Tulskogo gosudarstvennogo universiteta. Nauki o Zemle. 2022. N 1, p. 152-164 (in Russian). DOI: 10.46689/2218-5194-2022-1-1-152-164

- Kaplunov D.R., Rylnikova M.V., Radchenko D.N. Scientific and Methodological Bases of Design of Ecologically Balanced Cycle of Comprehensive Exploitation and Conservation of the Earth's Reserves. Mining Informational and Analytical Bulletin. 2015. N S 4-2, p. 5-11 (in Russian).

- Galchenko Yu.P. The Creation and Use of Ekogeo-Tehnology – As the Prospect of Environmental Engineering. Mining Informational and Analytical Bulletin. 2014. N S1, p. 211-227 (in Russian).

- Litvinenko V., Naumov I., Bowbriсk I., Zaitseva Z. Global guidelines and requirements for professional competencies of natural resource extraction engineers: Implications for ESG principles and sustainable development goals. Journal of Cleaner Production. 2022. Vol. 338. N 130530. DOI: 10.1016/j.jclepro.2022.130530

- Danilov A.S., Horttanainen M.V., Matveeva V.A., Korelskiy D.S. Backfill of a mined-out gold ore deposit with the cemented rubber-cord and waste rock paste: environmental changes in aqueous media. Journal of Ecological Engineering. 2021. Vol. 22. Iss. 7, p. 190-203. DOI: 10.12911/22998993/138870

- Wu D., Fall M., Cai S.J. Coupling temperature, cement hydration and rheological behaviour of fresh cemented paste backfill. Minerals Engineering. 2013. Vol. 42, p. 76-87. DOI: 10.1016/j.mineng.2012.11.011

- Yowa G.G., Sivakugan N., Tuladhar R., Arpa G. Strength and rheology of cemented pastefill using waste pitchstone fines and common pozzolans compared to using portland cement. International Journal of Geosynthetics and Ground Engineering. 2022. Vol. 8. N 56. DOI: 10.1007/s40891-022-00400-3

- Kalmykov V.N., Petrova O.V., Yanturina Yu.D. Assessment of technological reserves of sustainable development of mining engineering systems in underground development of ore deposits. Mining Informational and Analytical Bulletin. 2014. N S1-1, p. 69-78 (in Russian).

- Allaberdin A.B., Mazhitov A.M., Pytalev I.A., Gavrishev S.E. analysis and evaluation of formation schemes of a combined artificial array for the storage-chamber development system. Sustainable Development of Mountain Territories. 2020. Vol. 12. N 3 (45), p. 436-443. DOI: 10.21177/1998-4502-2020-12-3-436-443

- Mazhitov A.M., Volkov P.V., Krasavin A.V., Allaberdin A.B. Developing the Technology for the Formation of an Artificial Array with Specified Geotechnical Characteristics. Izvestiya vysshikh uchebnykh zavedenii. Gornyi zhurnal. 2019. N 2, p. 51-58 (in Russian). DOI: 10.21440/0536-1028-2019-2-51-58

- Savich I.N. Application of systems with forced collapse in underground mining of ore deposits. Mining Informational and Analytical Bulletin. 2014. N S1, p. 366-373 (in Russian).

- Sokolov I.V., Antipin Yu.G., Nikitin I.V. et al. Survey on Underground Geotechnology during Transition to the Development of Deep Reserves of Inclined Copper Pyrite Deposits. News of the Ural State Mining University. 2016. N 2 (42), p. 47-53 (in Russian). DOI: 10.21440/2307-2091-2016-2-47-53

- Ross I.T. Benchmarking and its application for caving projects. Caving 2018: Proceedings of the Fourth International Symposium on Block and Sublevel Caving, 15-17 October 2018, Perth, Australia. Australian Centre for Geomechanics, 2018, p. 473-486. DOI: 10.36487/ACG_rep/1815_36_Ross

- Falorni G., Del Conte S., Bellotti F., Colombo D. InSAR monitoring of subsidence induced by underground mining operations. Caving 2018: Proceedings of the Fourth International Symposium on Block and Sublevel Caving, 15-17 October 2018, Perth, Australia. Australian Centre for Geomechanics, 2018, p. 705-712. DOI: 10.36487/ACG_rep/1815_54_Falorni

- Antipin Yu.G., Baranovsky K.V., Rozhkov A.A., Klyuyev M.V. Overview of Combined Underground Mining Systems for Ore Deposits. Problems of Subsoil Use. 2020. N 3 (26), p. 5-22 (in Russian). DOI: 10.25635/2313-1586.2020.03.005

- Antipin I.G., Rozhkov A.A., Baranovskii K.V. Substantiation of the parameters of open stoping mining method with abandonment of unrecoverable pillars. Izvestiya vysshikh uchebnykh zavedenii. Gornyi zhurnal. 2021. N 4, p. 15-23 (in Russian). DOI: 10.21440/0536-1028-2021-4-15-23

- Noriega R., Pourrahimian Y., Victor W.L. Optimization of the undercut level elevation in block caving mines using a mathematical programming framework. Caving 2018: Proceedings of the Fourth International Symposium on Block and Sublevel Caving, 15-17 October 2018, Perth, Australia. Australian Centre for Geomechanics, 2018, p. 363-372. DOI: 10.36487/ACG_rep/1815_25_Noriega

- Mijalkovski S., Despodov Z., Mirakovski D., Adjiski V. Methodology for optimization of coefficient for ore recovery in sublevel caving mining method. Podzemni radovi. 2017. Vol. 30, p. 19-27. DOI: 10.5937/podrad1730019S

- Pelevin A.E. Iron ore beneficiation technologies in Russia and ways to improve their efficiency. Journal of Mining Institute. 2022. Vol. 256, p. 579-592. DOI: 10.31897/PMI.2022.61

- Feiwang Wang, Zhiqiang Zhao, Song Zhang et al. Performance assessment of an innovative precise low-intensity magnetic separator. Minerals Engineering. 2022. Vol. 187. N 107774. DOI: 10.1016/j.mineng.2022.107774

- Tripathy S.K., Singh V., Rama Murthy Y. et al. Influence of process parameters of dry high intensity magnetic separators on separation of hematite. International Journal of Mineral Processing. 2017. Vol. 160, p. 16-31. DOI: 10.1016/j.minpro.2017.01.007