Drilling of deep and ultra-deep wells for prospecting and exploration of new raw mineral fields

- 1 — Ph.D., Dr.Sci. Head of Department Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Ph.D. Head of Scientific Center “Arctic” Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 3 — Leading Engineer Saint Petersburg Mining University ▪ Orcid

- 4 — Head of Department Saint Petersburg Mining University ▪ Orcid

- 5 — Laboratory Assistant Saint Petersburg Mining University ▪ Orcid

Abstract

Scientific and technological progress over the last century has led to an enormous increase in the consumption of minerals, including energy resources. Most of the exploited oil and gas fields are already considerably depleted, so it is necessary to search for new hydrocarbon resources, particularly at great depths. Deep drilling plays a special role in solving this problem. The article considers the world and Russian experience of ultra-deep wells drilling. The methods and technologies used in the construction of wells, as well as complications and accidents occurring during their drilling were analyzed. The analysis revealed that the existing limitations for drilling parameters of deep and ultra-deep wells are caused by the technical characteristics of surface and bottomhole drilling equipment, which do not meet the extreme drilling conditions. The directions for development of deep and ultra-deep well drilling machinery and technologies are suggested. The notion of extreme rock and geological drilling conditions is introduced, which describes drilling in conditions of hydrostatic pressure of flushing fluid column and high bottomhole temperature both at stable and unstable wellbore conditions, coming close to the upper limit of operating technical characteristics of bottomhole assembly, the drill string and flushing fluid.

Introduction

The twentieth century will always be remembered as a time of new discoveries, the rapid development of science, technology and industry, the growth of production and consumption. The implementation of new ideas, developments and technologies requires the use of mineral resources. The extraction of traditional minerals, including hydrocarbon fuels, has intensified consi-derably – from the middle of the 20th century up to the present, the extraction of oil and gas has increased by an order of magnitude or more depending on the region. The 21st century, despite the development of green and renewable energy, as well as the introduction of numerous environmental programs, is characterized by a continuing increase in the consumption of mineral and energy resources. Due to the introduction of new technologies, human demand for mineral resources will only increase from year to year, and new discoveries, technologies for extraction of hard-to-recover reserves and development of old fields, the development of which was impossible before due to technical and technological constraints, will be able to satisfy its growth [1].

Currently, new sources of hydrocarbons are either small in size or require major improvements in exploration and production technology. Meanwhile, most of the operated fields are already signi-ficantly depleted, so the search for new hydrocarbon resources, including at great depths, and the introduction of new ultra-deep drilling technologies are needed. This will significantly expand the mineral resource base of our country.

Deep and ultra-deep wells are defined as wells with a depth significantly greater than the commercially developed drilling depth. In this article, the term “depth” is understood as the vertical distance from the wellhead to the bottomhole of the well. Thus, extended horizontal wells are not considered. According to the International Continental Scientific Drilling Program (ICDP) adopted in 1997, ultra-deep wells are wells with the depth of more than 8 km. There are more than 15 such wells in the world, including offshore wells (Table 1). However, the number of deep wells (<8 km) is much higher – more than a thousand and a half.

Table 1

Deep and ultra-deep wells

|

Number |

Well |

Region |

Actual depth, m |

Drilling period, years |

|

1 |

Kolskaya SG-3 |

Russia |

12262 |

1970-1990 |

|

2 |

Tiber |

USA |

10692 |

2009 |

|

3 |

Deep Water |

USA |

10500 |

1985 |

|

4 |

Blackbird West |

USA |

10064 |

2008 |

|

5 |

KTB-Oberpfalz |

Germany |

9 901 |

1987-1995 |

|

6 |

Berta Rogers |

USA |

9583 |

1973-1974 |

|

7 |

Baden Unit |

USA |

9159 |

1970-1971 |

|

8 |

Hauptborung |

Germany |

9100 |

1990-1994 |

|

9 |

53-2N |

China |

8874 |

2020 |

|

10 |

Luntan-1 |

China |

8882 |

2018-2019 |

|

11 |

University |

USA |

8668 |

1970-1980 |

|

12 |

Zisterdorf |

Austria |

8553 |

1990-1994 |

|

13 |

Saatlinskaya SG-1 |

Azerbaijan |

8340 |

1977-1990 |

|

14 |

En-Yakhinskaya SG-7 |

Russia |

8250 |

2000-2006 |

|

15 |

Tyumenskaya |

Russia |

7502 |

1987-1996 |

|

16 |

Timano-Pechorskaya |

Russia |

6904 |

1984-1993 |

|

17 |

Aralsorskaya |

Russia |

6800 |

1962-1971 |

|

18 |

Biikrzalskaya |

Russia |

6700 |

1962-1971 |

|

19 |

Gydanskaya 130 |

Russia |

6126 |

2017 |

|

20 |

Uralskaya |

Russia |

6015 |

1985-2004 |

|

21 |

Krivorozhskaya |

Ukraine |

5382 |

1984-1993 |

|

22 |

Dneprovsko-Donetskaya |

Ukraine |

5691 |

1983 |

|

23 |

Arakaevskaya |

Russia |

5207 |

2013 |

|

24 |

Tsekertinskaya 8 |

Russia |

5138 |

2007 |

|

25 |

Vostok, N 4 |

Russia |

5105 |

2005-2007 |

|

26 |

Yarudeyskaya, N 38 |

Russia |

5010 |

2005-2010 |

|

27 |

Vostok, N 1 |

Russia |

5010 |

2005-2007 |

|

28 |

Vostok, N 3 |

Russia |

5002 |

2005-2007 |

|

29 |

Vostochno-Yaskinskaya 1 |

Russia |

5000 |

2004 |

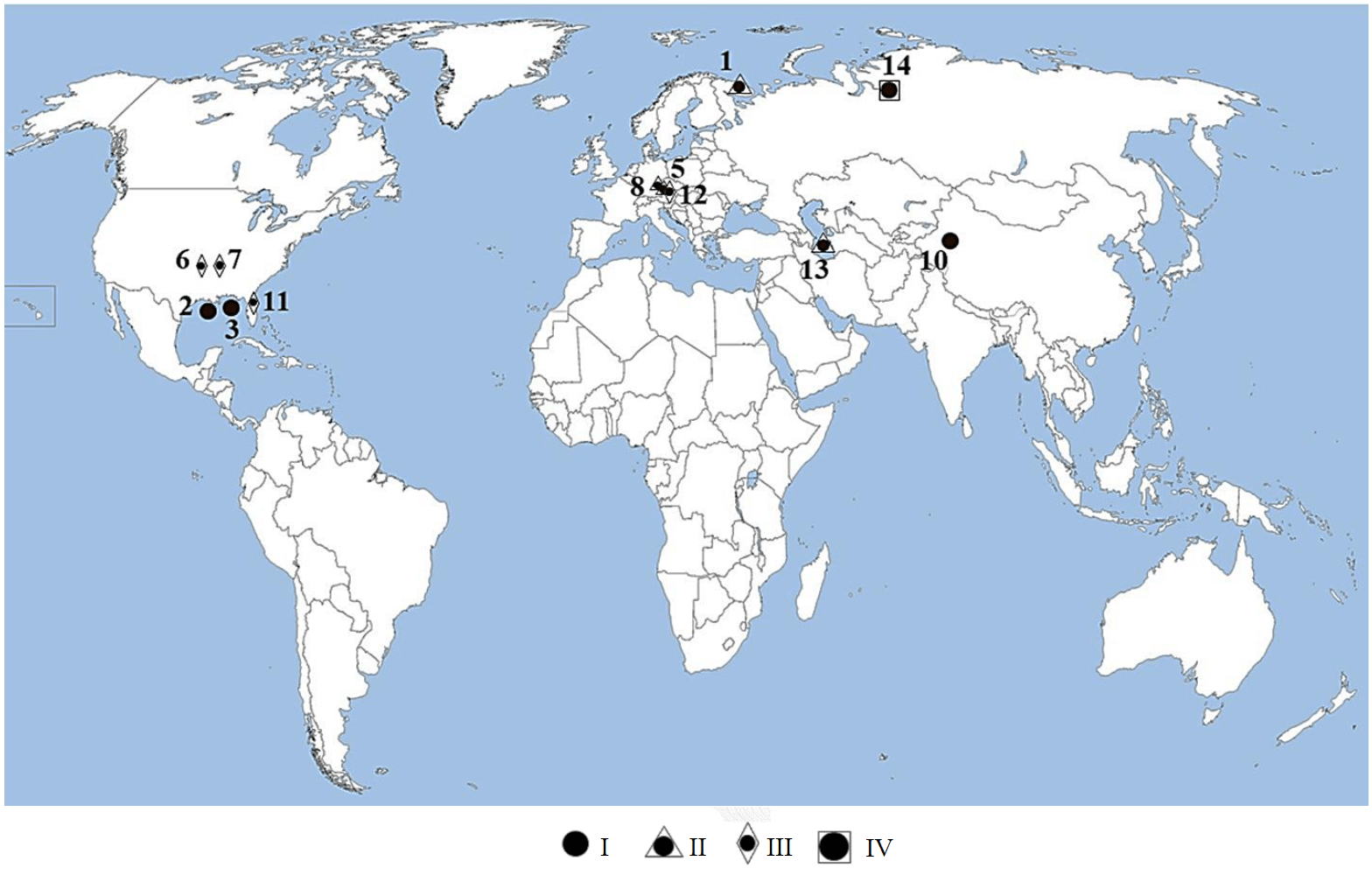

Deep and ultra-deep drilling is the only way of penetrating into the Earth’s depths, which will be the key to many fundamental geological problems (Fig.1). The article [2] notes that “the results of scientific drilling have been unexpected in many ways and have forced a reconsideration of theoretical notions that previously seemed obvious and inviolable. None of the deep or ultra-deep wells fully confirmed the geological section that had been assumed before drilling began. In many cases, the discrepancies were dramatic”.

The study of rock samples and geophysical logging data from deep (DW) and ultra-deep (UDW) wells has scientifically proved the presence of rock decompaction zones [2, 3], zones of rare metals concentration and mineral formations at considerable depths. Fluid migration by downward filtration mechanism has been established and the pattern of heat flow propagation has been clarified.

Exploration and production of oil from great depths has been growing rapidly over the past decade. This trend began in 2009 with discovery of one of the largest oil fields offshore the Gulf of Mexico by “Chevron”. The oil volume amounted to 15 billion barrels but was located at a depth of around 8.8 km. The same year, “British Petroleum” announced the discovery of a large field at a depth of 10.5 km offshore the Gulf of Mexico. The discovery of oil at depths of more than 10 km questioned the organic theory of oil origin, according to which the hydrocarbon cannot persist at great depths because of the high temperature and the ongoing process of decomposition. New horizons have emerged in the exploration of natural gas, which is generated at even greater depths than the oil. The search for new mineral deposits, for hydrogen at great depths is also not to be neglected.

Fig.1. Ultra-deep wells on the world map I – production well; II – appraisal well; III – prospecting well; IV – parametric well; well numbers (1-29) correspond to Table 1

The experience of ultra-deep drilling and the large hydrocarbon discoveries in recent decades demonstrate the need for further exploration of the continental Earth’s crust, both for scientific and commercial purposes. In this regard, deep and ultra-deep drilling should be increased [4-6].

Discussion

Looking at the history of deep and ultra-deep drilling in the Soviet Union and modern Russia, four main stages can be distinguished:

Stage I – work carried out between the early 1920s and the late 1930s.

Stage II – work from the mid-1940s to the 1960s.

Stage III – work carried out from the early 1960s to the 1990s. During this period, the main provisions of the integrated scientific and technical program of ultra-deep continental drilling “Exploration of the Earth’s interior and ultra-deep drilling” were formulated and adopted at the governmental level. Apart from Kolskaya SG-3 and En-Yakhinskaya SG-7, eight deep wells were drilled under the ultra-deep index (Table 2). The ultra-deep drilling program of the USSR was

a response to the US Ocean Drilling Program [7].

State research and production enterprise “Nedra”, now AO “NPC “Nedra”, was established in Yaroslavl in 1966. The enterprise carried out work under the program to study the Earth’s interior and ultra-deep drilling, in particular, drilling ten research wells (4-9 km depth), including the famous ultra-deep Kolskaya, Saatlinskaya and Tyumenskaya.

Table 2

Ultra-deep wells in the USSR and Russia

|

Number |

Well |

Region |

Actual depth, m |

Drilling period, years |

|

SG-1 |

Aralsorskaya |

Caspian lowland |

6 800 |

1962-1971 |

|

SG-2 |

Biikzhalskaya |

Caspian lowland |

6 700 |

1962-1971 |

|

SG-4 |

Uralskaya |

Verkhnyaya Tura, Sverdlovsk region |

6 015 |

1985-2004 |

|

SG-5 |

Timano-Pechorskaya |

Komi Republic, Vuktyl district |

6 904 |

1984-1993 |

|

SG-6 |

Tyumenskaya |

Western Siberia, Korotchaevo |

7 502 |

1987-1996 |

|

SG-8 |

Krivorozhskaya |

Ukraine, Krivoy Rog |

5 382 |

1984-1993 |

|

SG-9 |

Dneprovsko-Donetskaya |

Eastern Ukraine |

5 691 |

1983-N/A |

|

SG-10 |

Muruntauskaya |

Uzbekistan |

4 290 |

1984-N/A |

Stage IV – work carried out from the early 1990s till present.

In 1994, drilling of parametric and ultra-deep wells in the main oil and gas provinces was adopted as the main method of work for general geological and special purposes.

Geological and geophysical research from this moment has received a new branch of development, the modern stage of geological work began. Since then and up to the present time, work has been carried out on most of the Russian continental territory and water area (shelf). Currently, drilling work by division NPC “Nedra” is being carried out at seven sites: Novoyakimovskaya 1, Chambenskaya 1, Kanandinskaya 278, Severo-Ketskaya 1 (Krasnoyarsk Territory), Chumpalovskaya 1 (Kabardino-Balkaria), Zabaikalskaya and Gydanskaya 118 (YaNAO).

The Federal Agency for Subsoil Use has developed a program to drill new deep and ultra-deep wells and carry out additional special research using modern methods on sections of previously drilled deep and ultra-deep wells in order to clarify the geodynamic mode and tectonic development of the Earth, with an associated search for mineral deposits.

The implementation of this program, as well as the process of drilling wells deeper than 5 km, entails a number of technical and technological peculiarities of a natural (mining and geological conditions) and technical (equipment limitations) nature. There are single regulatory documents reflecting only some factors complicating the process of drilling at great depths. The authors have analyzed and summarized literature data on possible reasons of complications, resulting in introduction of new concept for drilling of deep and ultra-deep wells – “extreme rock and geological drilling conditions”.

The current well construction works are subject to different climatic, mining and geological conditions [8]. In the north-west, north, north-east and east of the country these are poorly explored, undeveloped areas without adequate infrastructure, located in harsh climatic conditions on the continental part and on the sea shelf with relatively shallow hydrocarbon deposits. In the west, south-west, south, south-east and central parts of the country there are favorable climatic conditions, developed areas with appropriate infrastructure, but with complex mining and geological conditions with the occurrence of hydrocarbons at great depths. But these conditions do not constrain large-scale drilling of deep and ultra-deep wells to implement this program.

Main constraints are the following [9]:

- Extremely complex mining and geological conditions. Drilling operations have to be carried out at high bottomhole temperature and pressure, with the use of high-density flushing fluids. According to works [2, 10] the temperature at the bottomhole bottom of some deep and ultra-deep wells varies from 100 to 300 °C (Table 3). This difference in temperature may be due to the presence of deep heating sources in the areas of deep tectonic faults or physical and chemical properties of rocks along the sedimentary cover section.

Table 3

Bottomhole temperature in some deep and ultra-deep wells [2]

|

Well |

Region |

Actual depth, m |

Bottomhole temperature, °С |

|

Aralsor |

Russia |

6800 |

163 |

|

Kolskaya |

Russia |

12262 |

212 |

|

Vorotilovskaya |

Russia |

5374 |

96 |

|

Tyrnyauzskaya |

Russia |

4001 |

223 |

|

Uralskaya |

Russia |

5355 |

81 |

|

Timano-Pechorskaya |

Russia |

6904 |

129 |

|

Tyumenskaya |

Russia |

7502 |

230 |

|

Krivorozhskaya |

Ukraine |

5382 |

85 |

|

Saatlinskaya |

Azerbaijan |

8324 |

148 |

|

Berta Rogers |

USA |

9583 |

260 |

|

Solton C |

USA |

3220 |

355 |

|

KTB-Oberpfalz |

Germany |

9 901 |

300 |

- Maximum technical capabilities of the mechanisms and actuators of the onshore drilling equipment. The main stock of drilling rigs BOZ D86-2 for deep well drilling has allowable hook load of 3260 kN, and rig BU 6200/450 BMCh – 4500 kN at allowable drilling depth of 5000 m and 6500 m respectively, with rotor rotation frequency of 350 rpm and drilling pumps with maximum developed pressure at the outlet of 35 MPa [11]. Uralmash-15000 is an ultra-deep drilling rig, manufactured and tested in single units.

- Durability characteristics of the borehole assembly (BHA), the drill string itself, the coring assembly [12].

- Maximum technical capabilities of rock destruction tools: in terms of rotational frequency – for roller cone bits up to 600 rpm, for PDC bits up to 440 rpm, for diamond bits up to 150 rpm; in terms of maximum allowable load – for roller cone bits up to 15 t, for PDC bits up to 10 t, for diamond bits up to 10 t.

- Limitations determined by the thermal stability of the drilling mud. Modern drilling fluid formulations successfully operate at temperatures up to 150 °C [13].

- The immediate destruction process of strong, very strong and extremely strong rocks that make up the Earth's crust [14]. Such rocks on Protodiakonov scale include rocks of the following categories I, II, III and IIIa.

Category I, extremely hard rocks, includes the strongest, most ductile and dense quartzites and basalts, as well as other rocks of exceptional hardness.

Category II – very hard rocks, includes very hard granites, quartz porphyries, siliceous shales, the hardest sandstones and limestones. Rocks in this category are less strong than in category I.

Category III – hard rocks, includes dense granite, very hard limestone and sandstone, very hard iron ores, hard conglomerate, quartz ore veins.

Category IIIa – hard rocks, includes hard limestone, hard sandstone, dolomite, pyrite, hard marble, soft granite.

It should be noted that rocks of category I, II, III and IIIa (degrees of hardness) correspond to the VI-XII categories of rock drillability [15].

Extreme drilling conditions are characterized by drilling under conditions of high hydrostatic pressure of the flushing fluid column and high bottomhole temperature, both at steady and unsteady wellbore states, approaching the upper limit of the performance specifications for the bottomhole assembly, the drill string itself and the flushing fluid.

Analyzing Table 3, works [16-19] and introducing the notion of extreme geological conditions for DW and UDW drilling process it can be concluded that for successful drilling the design specifications of bottomhole drilling equipment, logging tools and bottomhole instrumentation should meet the following limit values of operational parameters: rotation of bit in working mode with not less than 2000 rpm; temperature up to 400 °С; bottomhole pressure – 150 MPa; specific weight of drilling mud up to 2.5 g/cm3.

Drilling of DW and UDW mainly involves the use of existing, most proven and widely used technologies and types of mechanical rotation drilling technique only up to a certain depth. At depths where the technical capabilities of well and bottomhole equipment reach critical values in thermobaric conditions, drilling is problematic and sometimes impossible. The article considers the drilling of deep and ultra-deep onshore wells, but the described problems, technologies and development prospects also apply to deep offshore wells because of the similarity in technologies.

As a rule, the drilling of DW and UDW is carried out along the sedimentary cover and along the crystalline basement. The technology of sedimentary cover drilling is identical to that of conventional production wells. The process of drilling along the crystalline basement is of particular interest. The most indicative in this respect is well SG-3, where the basement starts practically from the surface and is composed of Precambrian crystalline rocks of the “granite” layer.

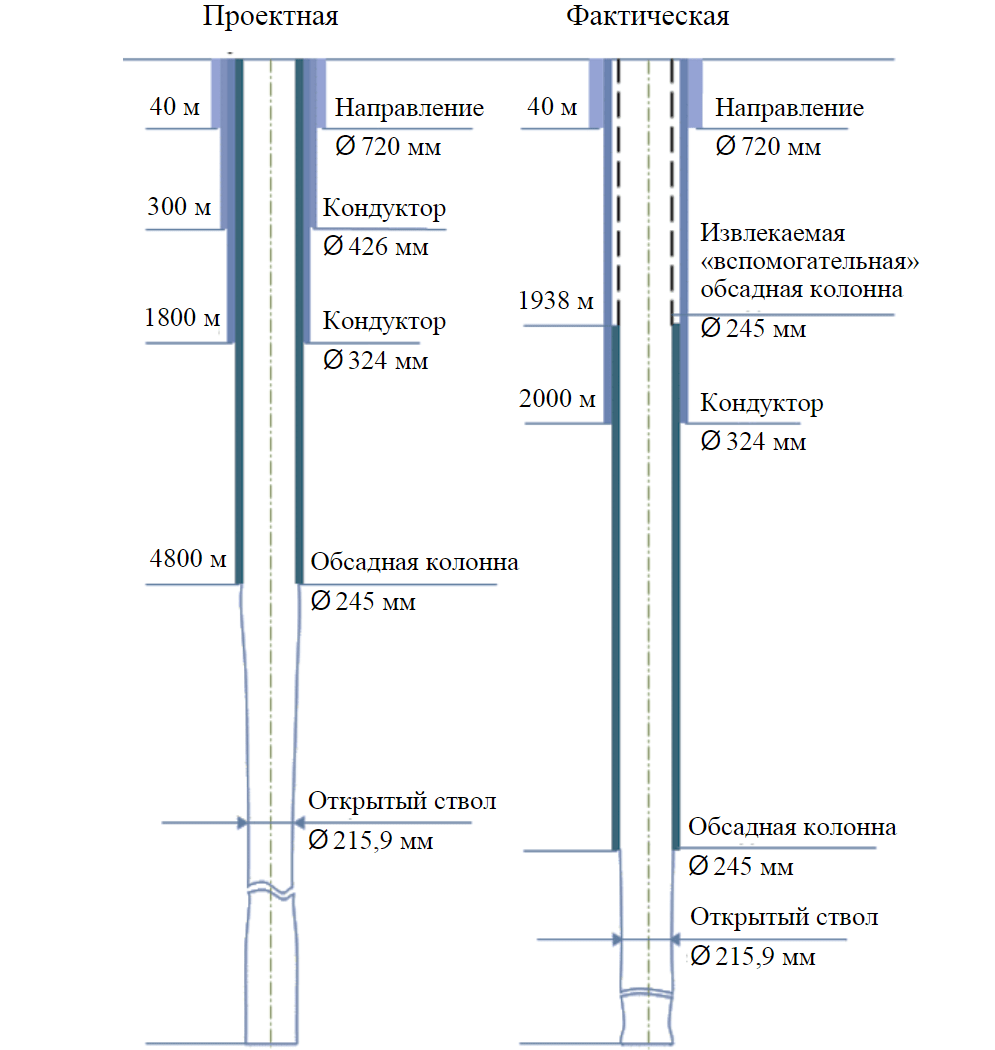

The design of all DW and UDW is conventional (from larger casing diameter to smaller one with final wellbore diameter of 190.0-215.9 mm) with covering the zones of incompatible drilling conditions and zones of possible complications. As an example, Figure 2 shows the design and actual structure of SG-3 well. The drilling technology of Kolskaya ultra-deep well gave a basis for development of further deep and ultra-deep drilling. The technique involved the following features: the well was drilled with advancing diameter until insurmountable complications emerged, and then, if necessary, the well was enlarged and cemented. During the drilling process turbodrills were used in combination with light-alloy drill pipes.

Fig.2. Structure of Kolskaya ultra-deep well

The temperature inside the well and the acting rock stresses determined the use of different aluminum alloys as the drill pipe material. In addition to aluminum alloys, alloyed high-strength steels were used as drill pipe and tool joint material [20]. A typical drill string design for 12000 m bottomhole is shown in Table 4.

Deepening the well from the 40 m mark was carried out with an advanced wellbore

using coring cone bits. A 195 mm diameter coring tool was positioned on the turbodrill shaft and collected 60 mm diameter rock sample. For coring, there were cone reamers with diameter 215-217 mm over drill head and coring tool. If necessary, the advancing wellbore was enlarged and secured with casing pipes. Such a need arose when the bottomhole reached 5363 m and a dangerous cavernosity started to appear at the depth of about 1800 m. The wellbore was enlarged under the retrievable casing by a reamer. Wellbore extension to diameter 215.9 mm was carried out with drill bits III215.9TKZ-GNU, reamer RD-445/640 was used for surface casing, RD-920 was used for conductor.

Table 4

Borehole assembly for SG-3 drilling

|

Drill pipes |

Pipe material |

Section length, m |

Mass in the air, t |

Yield strength, MPa |

Heat resistance, °С |

|

KNBK |

Steel |

50 |

7.0 |

– |

250 |

|

LBTVK-147 |

Alloy АК4-1 |

3000 |

58.0 |

280 |

220 |

|

LBTVK-147 |

Alloy D16Т |

2500 |

50.0 |

330 |

150 |

|

LBTVK-147 |

Alloy 01953 |

5000 |

110.0 |

490 |

110 |

|

TBVK-140 |

Steel |

1450 |

65.0 |

1000 |

300 |

|

Total |

– |

12000 |

290.0 |

– |

– |

The Kolskaya UDW was drilled to a depth of 8.5 km using the A7H4S high-torque and spindleless turbodrill with inclined pressure line. Spindle-type A7Sh turbodrills were also used [20].

From a depth of 8.5 km, the well was drilled by one-section reducer turbodrill of TRM series with the following operational characteristics: reduction ratio – 3.69; number of turbines – 109; liquid flow rate – 24-28 l/s; rotation frequency of reducer output shaft – 120-150 rpm; torque –2.2-3.02 kN∙m; maximum power – 35-55 kW; differential pressure – 2.2-2.9 MPa.

The heat resistance of the TRM reducer is up to 250 °C. The main operational characteristics of turbine assemblies with reducer insert are shown in Table 5.

Table 5

Main characteristics of turbine assemblies

|

Assembly |

Number |

Assembly length, m |

Assembly mass, kg |

Reduction ratio |

Liquid flow rate, l/s |

Rotation frequency of shaft, rpm |

Torque, kN·m |

Maximum power, kW |

Differential pressure, MPa |

Efficiency, % |

||

|

Turbodrill sections |

Number of turbines |

Reducers |

||||||||||

|

I |

1 |

109 |

1 |

13.7 |

2600 |

3.69 |

24-28 |

150-175 |

2.2-3.02 |

35-55 |

2.2-2.9 |

64 |

|

II |

2 |

218 |

1 |

21.2 |

4000 |

3.69 |

20-28 |

125-175 |

3.08-6.04 |

41-110 |

3.1-6.1 |

64 |

|

III |

3 |

327 |

1 |

28.6 |

5400 |

3.69 |

18-20 |

115-125 |

3.74-4.62 |

45-61 |

3.7-4.6 |

64 |

|

IV |

1 |

109 |

2 |

17.2 |

3260 |

11.76 |

20-28 |

35-48 |

5.23-10.25 |

20-52 |

1.6-3.2 |

59 |

|

V |

3 |

327 |

– |

25.9 |

4740 |

– |

24-30 |

560-700 |

1.96-3.06 |

115-225 |

6.5-10.0 |

70 |

Three types of turbodrill with removable and non-removable samplers were used for coring: KTD4S-195-214/60-80, KDM-195-214/60, coring tool with hydraulic rock sample transport MAG-195-214/60.

An aqueous clay solution with lubricating agents (density 1100-1200 kg/m3) was used as the drilling mud.

Sufficient time to restore thermal conditions in the well was not more than 50 h, the temperature difference between the upstream and downstream mud flows kept below 40 °C.

The “Uralmash-15000” drilling rig with two UNB-1250 pumps (working pressure up to 40 MPa) with load capacity of 4 MN was used for SG-3 drilling. During drilling fluid flow rate was kept about 30 l/s, at that pressure on pumps was less than 26 MPa.

The rig is driven electrically from a DC power source. Section length – 37 m, rigging – 6×7, hoist rope diameter – 38 mm.

Kolskaya UDW average values of drilling: rate of penetration per trip – 8 m; mechanical drilling rate – 2 m/h; drilling time – 4 h; reduced tripping rate – 0.32 m/s; duration of one trip at a depth of 12,000 m – 21 h.

Low values of drilling parameters are explained by the fact that more than 70 % of the wellbore by depth has been drilled with coring at the corresponding drilling mode with limitation of in terms of load and number of drill head revolutions.

Drilling of deep and ultra-deep wells, such as Kolskaya, Kolvinskaya, Timano-Pechorskaya, Krivorozhskaya, Dneprovsko-Donetskaya in Russia and CIS, Berta Rogers in USA, KTB-Oberpfalz in Germany and others shows a variety of complications associated with drilling deeper than 5-6 km [21]. The main complications are presented in Table 6.

Table 6

The main complications arising during drilling of deep and ultra-deep wells [21]

|

Well |

Bottomhole, m |

Main complications |

|

Kolskaya SG-3 (Russia) |

12 262 |

Wellbore curvature, increased rock sample fragmentation (self-sealing), |

|

En-Yakhinskaya SG-7 (Russia) |

8 250 |

Wellbore curvature, rockslides, rockfalls, sticking |

|

Tyumenskaya SG-6 (Russia) |

7 502 |

Wellbore curvature, rockslides, rockfalls, cavern formation |

|

Kolvinskaya (Russia) |

7 052 |

Wellbore curvature, increased hydrogen sulphide content at the bottomhole |

|

Timano-Pechorskaya (Russia) |

6 904 |

Wellbore curvature |

|

Uralskaya (Russia) |

6 100 |

Wellbore curvature, rockslides, rockfalls |

|

Berta Rogers (USA) |

9 583 |

Molten sulphur inflows into the wellbore |

|

Big Horn (USA) |

7 583 |

Borehole wall cavings, wellbore curvature |

|

KTB-Oberpfalz (Germany) |

9 101 |

Wellbore curvature, cavern formation |

|

Siljan Ring (Sweden) |

6 800 |

Wellbore curvature, cavern formation |

Most of the wells shown in Table 6 have not been drilled to their design depths. This is primarily due to the multiple complications encountered during drilling [21].

DW and UDW drilling accidents were mainly related to sticking and jamming of the DS, BHA and drill bit accidents. The statistics of complications and accidents during SG-3 drilling are shown in Table 7. It should be noted that most of the accidents were related to cavings and cavern formation in the wellbore.

Table 7

Statistics of complications and accidents during SG-3 drilling

|

Accident location |

Jamming |

BHA |

DS |

Drill bit |

Others |

|

Wellbore 1 (0-12066 m) |

89 |

33 |

15 |

93 |

6 |

|

Wellbore 2 (7010-12262 m) |

19 |

– |

5 |

7 |

2 |

|

Wellbore 3 (9649-10200 m) |

5 |

1 |

3 |

2 |

1 |

|

Wellbore extension (0-2000 m) |

9 |

26 |

3 |

11 |

– |

|

Wellbore extension (2000-8870 m) |

15 |

11 |

1 |

1 |

– |

|

TOTAL |

137 |

71 |

27 |

114 |

9 |

The current technologies and drilling equipment do not allow efficient drilling under extreme conditions at the bottomhole because of multiply increasing loads on drill string, hydraulic bottomhole motor and drill bit. There are no developed and tested heat-resistant flushing fluids. Specially designed and custom-built surface drilling equipment is required.

Various indicators are used to assess the technical and economic efficiency of drilling techno-logy. Technical indicators of the drilling rate include mechanical, trip, commercial, technical and cyclic rates, which are determined by the duration of individual operations [22].

The main economic indicator evaluating the efficiency of drilling is the cost per meter of penetration, which includes absolutely all costs of well construction (depending on penetration and time). This indicator determines the cost of constructing the well as a whole.

The cost of one meter penetration for deep and ultra-deep wells exceeds the cost of penetrating a production well, as a rule, by 3-5 times. It is caused by low rate of mechanical drilling, continuous coring, high volume of well surveys, use of very powerful, energy-consuming drilling rigs with carrying capacity up to 1 100 t and complicated well design.

Improving the efficiency of DW and UDW drilling, reducing construction time and lowering costs can be achieved by addressing the following tasks:

- Drilling of a “pilot” well in the sedimentary cover up to the basement using standard technology and design in the planned area of DW or UDW construction with maximum possible coring and volume of geophysical surveys. Trialing and testing elements of the proposed technology and techniques for drilling the planned DW and UDW [23].

- Development of well designs for specific rock and geological conditions with casing and cementing of the maximum possible wellbore diameter in the sedimentary cover up to the basement based on the data obtained during the drilling of a “pilot” well. Drilling with a continuous bottomhole to the basement, without coring in the sedimentary cover and with a minimum set of geophysical surveys being carried out. The use of “auxiliary” casing [24-26].

- Development of high-rotation diamond impregnated (≥2000 rpm in working mode) heat resistant drill heads of 215.9 mm diameter for coring and the same drill bits for continuous drilling, which will exclude reamers of 215-217 mm diameter from BHA.

- Development of new high-rotation (≥2000 rpm in working mode) coring tools with increased length (up to 36 m) with interchangeable rock samplers for extreme drilling conditions, which will reduce the number of tripping operations with coring tool [27].

- Development of medium- and low-volume high-rotation (≥2000 rpm in working mode) turbodrills [28] for extreme drilling conditions, the use of which will increase the mechanical drilling rate and penetration rate per drill bit and consequently reduce well construction time.

- Development of special technologies and bottomhole assembly equipment to prevent spontaneous borehole curvature in deep and ultra-deep wells [29].

- Development of heat resistant flushing fluids or drilling technology using coolant flushing fluids [30-32].

- Development of drill pipes design for technology of “self-floating” drill string during tripping operations to reduce drill string lifting resistance forces at high flushing fluid weight and great depths [33-35].

Conclusions

- The needs of Russian modern economy clearly dictate the need to find and develop new oil and gas fields, including those at great depths with complex rock and geological conditions.

- The existing drilling technology of DW and UDW inherently implies limitation of drilling parameters (bit load, bit rpm, penetration during drilling interval) due to technical characteristics of drilling equipment and extreme drilling conditions, which causes low drilling efficiency.

- The notion of “extreme rock and geological drilling conditions” is introduced, characterized by drilling in conditions of high hydrostatic pressure of the flushing fluid column and high bottomhole temperature, approaching the upper limit of the technical and technological characteristics of the BHA, the drill string and flushing fluid properties, both at stable and unstable condition of the wellbore.

- In order to estimate drilling costs it is necessary to understand the order of drilling time. Determining the tripping rate and mechanical drilling rates will define the cost of drilling one well over a number of years. This is the cost of pure drilling alone, without auxiliary operations, when the well is drilled in moderately complex geological conditions.

- Reducing the construction time of the DW and UDW by regulating the technical parameters of drilling, which is now possible with improved energy-efficiency of the drilling process.

- Complete rock sample and cuttings should be taken during the drilling process for comprehensive mineral exploration, including rare earth minerals.

- In order to scientifically substantiate the theory of chemical elements formation, it is necessary to equip the bottomhole assembly with high-tech sensors to identify mineral deposits located in extreme thermobaric conditions, including free hydrogen, taking into account the experience of ultra-deep wells drilled.

References

- Han Liexiang. New progress of drilling and completion technologies for ultra-deep wells in the Sichuan-Chongqing Area. Oil Drilling & Production Technology. 2019. Vol. 41. Iss. 5, p. 555-561 (in Chinese). DOI: 10.13639/j.odpt.2019.05.001

- Popov V.S., Kremenetskii A.A. Deep and Superdeep Scientific Drilling on Continents. Sorosovskii obrazovatelnyi zhurnal. 1999. N 11, p. 61-68 (in Russian).

- Xusheng Guo, Dongfeng Hu, Yuping Li et al. Theoretical progress and key technologies of onshore ultra-deep oil/gas exploration. Engineering. 2019. Vol. 5. Iss. 3, p. 458-470. DOI: 10.1016/j.eng.2019.01.012

- Tianle Liu, Leusheva E.L., Morenov V.A. et al. Influence of polymer reagents in the drilling fluids on the efficiency of deviated and horizontal wells drilling. Energies. 2020. Vol. 13. N 18. N 4704. DOI: 10.3390/en13184704

- Li Long, Yin Da, Li Lei et al. Application of Innovative High Density High-Perfomance Water-Based Drilling Fluid Technology in the Efficient Development and Production of Ultra-Deep Complicated Formations in the Tian Mountain Front Block in China. Offshore Technology Conference Asia, 20-23 March 2018, Kuala Lumpur, Malaysia. OnePetro, 2018. N OTC-28413-MS. DOI: 10.4043/28413-MS

- Li Ning, Zhou Xiaojun, Zhou Bo et al. Technologies for Fast Drilling Ultra-Deep Wells in the HLHT Block, Tarim Oilfield. Petroleum Drilling Techniques. 2017. Vol. 45. Iss. 2, p. 10-14 (in Chinese). DOI: 10.11911/syztjs.201702002

- Lobanov K.V., Chicherov M.V., Sharov N.V. The 50th Anniversary of the Start of Drilling the Kola Superdeep Well. Arctic and North. 2021. N 44, p. 267-284 (in Russian). DOI: 10.37482/issn2221-2698.2021.44.267

- Litvinenko V.S., Kudryashov B.B. Current problems of rocks destruction during well drilling. Journal of Mining Institute. 2001. Vol. 148, p. 14-21 (in Russian).

- Vasiliev N.I., Podoliyk A.V., Dmitriev A.N. et al. Controlled directional drilling of boreholes in glacial mass using carrying cable tool. Topical Issues of Rational Use of Natural Resources 2019: Proceedings of the XV International Forum-Contest of Students and Young Researchers under the auspices of UNESCO, 13-17 May 2019, St. Petersburg Mining University, Russia. London: CRC Press, 2019. Vol. 1, p. 245-252.

- Kucherov V.G., Bessel V.V. Challenges and Risks of Deep and Super Deep Drilling. Burenie i neft. 2020. N 3, p. 12-17(in Russian).

- Kadochnikov V.G., Dvoynikov M.V. Development of Technology for Hydromechanical Breakdown of Mud Plugs and Improvement of Well Cleaning by Controlled Buckling of the Drill String. Applied Science. 2022. Vol. 12. Iss. 3. N 6460. DOI: 10.3390/app12136460

- Tretyak A.A. Vibration Impact on the Strength Properties of Drill Bits, Tipped By Diamond Hard-Alloy Plates. Construction of Oil and Gas Wells on Land and Sea. 2016. N 10, p. 20-24 (in Russian).

- Ma Hongyan, Zheng Bangxian, Chen Jingwang et al. Optimized, safe and fast drilling technologies used in the ultra deep and high temperature wells in Yangshuiwu buried hill. Oil Drilling & Production Technology. 2020. Vol. 42. Iss. 5, p. 573-577 (in Chinese). DOI: 10.13639/j.odpt.2020.05.008

- Petrakov D., Kupavykh K., Kupavykh A. The effect of fluid saturation on the elastic-plastic properties of oil reservoir rocks. Curved and Layered Structures. 2020. Vol. 7. N 1, p. 29-34. DOI: 10.1515/cls-2020-0003

- Litvinenko V.S. Digital Economy as a Factor in the Technological Development of the Mineral Sector. Natural Resources Research. 2020. Vol. 29, p. 1521-1541. DOI: 10.1007/s11053-020-09716-1

- Simonyants S.L. The turbodrills era: results and prospects. Bulatovskie chteniya. 2020. Vol. 3, p. 336-341 (in Russian).

- Sklyanov V.I., Perepelkin M.A. Influence of rotation frequency of diamond cutting tool on the technical characteristics of exploratory drilling. Gornaya promyshlennost. 2017. N 5 (135), p. 96-97 (in Russian).

- Khlebnikov D., Myalitsin N. Turbodrills Improvement Methods for Drilling in Hard Rocks. Burenie i neft. 2013. N 6, p. 47-52 (in Russian).

- Shulga D.K. Comparative analysis of technical characteristics of domestic and imported bottomhole motors for oil and gas drilling. Trudy XX Mezhdunarodnogo simpoziuma im. M.A. Usova, 4-8 aprelya 2016, Tomsk, Rossiya. Izd-vo Tomskogo politekhnicheskogo universiteta, 2016. Vol. 2, p. 812-814 (in Russian).

- Povalikhin A.S. 50 years of scientific breakthroughs in Earth exploration. Kolskaya ultra-deep well: a path to energy and raw material supply for humanity. Inzhener-neftyanik. 2020. N 1, p. 5-16 (in Russian).

- Karasev D.V., Shcherbinina N.E., Karaseva T.V. Features Complications during Drilling Operations at Great Depths. Oil and Gas Business. 2015. N 4, p. 19-31 (in Russian). DOI: 10.17122/ogbus-2015-4-19-31

- Archegov V.B., Nefedov Y.V. Oil and gas exploration strategy in evaluation of fuel and energy potential of Russian arctic shelf. Journal of Mining Institute. 2015. Vol. 212, p. 6-13 (in Russian).

- Haige Wang, Hongchun Huang Wenxin Bi et al. Deep and ultra-deep oil and gas well drilling technologies: Progress and prospect. Natural Gas Industry B. 2022. Vol. 9. Iss. 2, p. 141-157. DOI: 10.1016/j.ngib.2021.08.019

- Haige Wang, Yunhua Ge, Lin Shi. Technologies in deep and ultra-deep well drilling: Present status, challenges and future trend in the 13th Five-Year Plan period (2016-2020). Natural Gas Industry B. 2017. Vol. 4. Iss. 5, p. 319-326. DOI: 10.1016/j.ngib.2017.09.001

- Yuan Guodong, Wang Hongyuan, Chen Zongqi et al. Key Drilling Technologies for the Ultra-Deep Well Manshen 1 in the Tarim Basin. Petroleum Drilling Techniques. 2020. Vol. 48. Iss. 4, p. 21-27. DOI: 10.11911/syztjs.2020067

- Dvoynikov M., Sidorov D., Kambulov E. et al. Salt Deposits and Brine Blowout: Development of a Cross-Linking Composition for Blocking Formations and Methodology for Its Testing. Energies. 2022. Vol. 15. Iss. 19. N 7415. DOI: 10.3390/en15197415

- Zhang Hua, Ding Zhiwei, Xiao Zhenhua et al. Liner Cementing in Ultra-deep Wells with Narrow Drilling Window and Small Annular Clearance. Drilling Fluid & Completion Fluid. 2018. Vol. 35. Iss. 4, p. 87-91. DOI: 10.3969/j.issn.1001-5620.2018.04.016

- Dvoynikov M.V., Sidorkin D.I., Kunshin A.A., Kovalev D.A. Development of hydraulic turbodrills for deep well drilling. Applied Sciences. 2021. Vol. 11. Iss. 16, p. 134-154. DOI: 10.3390/app11167517

- Youhong Sun, Feiyu Zhang, Qingyan Wang, Ke Gao. Application of “Crust 1” 10k ultra-deep scientific drilling rig in Songliao basin drilling project (CCSD-SKII). Journal of Petroleum Science and Engineering. 2016. Vol. 145, p. 222-229. DOI: 10.1016/j.petrol.2016.04.003

- Dvoynikov M.V., Budovskaya M.E. Development of a hydrocarbon completion system for wells with low bottomhole temperatures for conditions of oil and gas fields in Eastern Siberia. Journal of Mining Institute. 2022. Vol. 253, p. 12-22.DOI: 10.31897/PMI.2022.4

- Gomaa I., Elkatatny S., Abdulraheem A. Real-time determination of rheological properties of high over-balanced drilling fluid used for drilling ultra-deep gas wells using artificial neural network. Journal of Natural Gas Science and Engineering. 2020. Vol. 77. N 103224. DOI: 10.1016/j.jngse.2020.103224

- Koteleva N., Buslaev G., Valnev V., Kunshin A. Augmented Reality System and Maintenance of Oil Pumps. International Journal of Engineering. 2020. Vol. 33. Iss. 8, p. 1620-1628. DOI: 10.5829/ije.2020.33.08b.20

- Niu Xinming, Zhang Jinshuang, Zhou Haobo. Technological Challenges and Countermeasures in Well Control of Ultra-Deep Ultra-High Temperature and Ultra-High Pressure. Oil and Gas Wells. 2017. Vol. 45. Iss. 4, p. 1-7. DOI: 10.11911/syztjs.201704001

- Nutskova M.V., Kuchin V.N., Kovalchuk V.S. Prevention and elimination of issues well completion. Perm Journal of Petroleum and Mining Engineering. 2020. Vol. 20. N. 1, p. 14-26 (in Russian). DOI: 10.15593/2224-9923/2020.1.2

- Arsenev A.A., Aleksandrov V.M., Mulyavin C.F. To the 70th anniversary of the drilling of Tyumen appraisal well N 1-R. History of the thorny path to the discovery of Tyumen oil. Bulatovskie chteniya. 2020. Vol. 7, p. 29-36 (in Russian).