Predicting the permeability of the near-bottomhole zone during wave impact

- 1 — Ph.D., Dr.Sci. Dean Beijing University of Civil Engineering and Architecture ▪ Orcid

- 2 — Ph.D., Dr.Sci. Chief Researcher Perm National Research Polytechnic University ▪ Orcid

- 3 — Ph.D. Dean Perm National Research Polytechnic University ▪ Orcid

- 4 — Ph.D. Associate Professor Perm National Research Polytechnic University ▪ Orcid

Abstract

The research reveals that during selection of a method to increase oil recovery it is necessary to take into account rheological features of fluid movement through the formation, effect of capillary forces and heterogeneity of reservoir properties of the productive formation in thickness and along the bedding. Low-frequency wave impact, which is used to increase production in oil fields, is considered. At low-frequency impact new fractures appear and existing fractures in rocks increase in size. The greatest increase in porosity and permeability of rocks occurs at an impact frequency up to 10 Hz. Dynamics of oscillation amplitude during wave's movement in saturated porous medium is studied in the paper: essential attenuation of amplitude occurs at distance up to 1 m from borehole axis. With increase of frequency from 1 to 10 Hz the intensity of amplitude's attenuation decreases. The technology was tested on a well in Perm region (Russia). The actual permeability value was 50 % higher than the predicted value. According to the results of hydrodynamic investigations processing, it was noted that the greatest increase of permeability took place near the wellbore, while away from the wellbore axis permeability remained almost unchanged. In order to refine the mathematical model for prediction of wave impact on rock permeability it is necessary to take into account interconnection of pore space structure, change of adhesion layer, as well as to study transfer of particles during vibration.

Introduction

The development of oil fields is accompanied by various artificial stimulation measures aimed at improving oil recovery. The use of modern technologies ensures that the oil recovery factor is maintained at 0.35-0.40.

One of the widely used methods for stimulating rocks in the bottomhole zone is the wave impact. Results of research show that low-frequency vibration reduces the compressive strength and modulus of elasticity for rocks by up to 55 % [1]. Numerous fractures form in the rock [2-4], dividing the crystalline core into smaller blocks [5-7]. Under prolonged impact of low frequency and high amplitude, plastic deformation of rocks is possible [8, 9]. At low amplitudes rock strength and modulus of deformation decrease exponentially with increasing loading cycles [10]. At the same time, the specific energy of the rock increases with increasing number of loading cycles and decreases with increasing frequency of impact [11]. The development of fracturing under wave impact increases the connectivity of pores and channels in the rock, which also increases its permeability.

This paper investigates the possibilities for predicting rock permeability under wave impact and compares calculated values with field data using the field of Perm region as an example.

Methodology

Evaluating the optimum frequency and amplitude of the wave impact

Investigations show that loading frequency and amplitude have a significant influence on the behaviour of the rock under dynamic cyclic loading conditions. The dynamic fatigue strength and dynamic axial rigidity of the rock decrease with increasing frequency and amplitude of loading in the region of low frequency values. The dynamic modulus of elasticity increases with loading frequency but decreases with increasing amplitude. Rock is more easily decompressed at low frequencies and amplitudes than at high frequencies and amplitudes, all other conditions being equal [12].

Work [13] defines equations for estimating the Young's modulus E and Poisson's ratio ν under full (triaxial) loading (σ3=σ2; ε3=ε2)

where σ – applied stress; ε – strain; indices 1, 2 and 3 – axes, along which the corresponding stresses are applied and the corresponding strains are manifested.

For the samples considered in work [13], the maximum applied stress has the most significant effect on unstrengthening.

Relation between fatigue strength and stress amplitude under dynamic cyclic loading can be expressed [14] as

where N – fatigue strength; X – stress amplitude; a and b – constants.

The relationship between stress amplitude and dynamic strength under dynamic cyclic rock loading can be represented by the expression [14]

where σ𝑑 – dynamic strength; σ0 – static compressive strength; с and d – constants.

For saturated samples under cyclic loading, it was observed that the rock strength decreased by an average of 30 %, while the average value of dynamic Young's modulus decreased by 20 % [12]. According to works [15, 16], the length and rate of microfractures propagation under ultrasonic excitation depends on the type of rock. The propagation mechanism shows that the creation of fractures is caused by tensile destruction [17].

As the frequency of applied load increases, the rocks strengthen, but microfractures that facilitate fluid filtration have not been considered [18-20].

Differential filtration equation for a plane-parallel fluid filtration through a porous medium under wave treatment conditions is obtained in the work [21]:

where F(x)=k(x)/μ(x); k(x) – permeability of the porous medium as a function of distance, m2; μ(x) – viscosity of the filtered fluid as a function of distance, Pa∙s;P – pressure, Pa; m – porosity; Kfpm – volumetric compression modulus of the fluid with respect to the strain of the porous medium, Pa; t – time, s.

As a result of numerical solution of this equation, it is proved that in elastic wave fields the ratio of porous medium permeability to viscosity of fluid increases by three times or more [21]. Considering that the filtered fluid consists of immiscible water and oil phases, each filling the pore space with its own saturation, the average density and viscosity of the fluid, as well as rock permeability, will depend on the ratio of fluid saturations, distributed unevenly over x. Since the distribution of water and oil saturations in the formation is not known, it is difficult to apply formula (1).

The reservoir properties of the filter medium are affected not only by the frequency of the wave impact, but also by the amplitude. According to research results [22, 23], an increase in the amplitude of oscillations contributes to an increase in porosity.

Rock porosity changes are caused by rock strain under the influence of vibration. Oscillation waves affect rock structure and texture by rearranging the rock grains.

Researchers note that wave impact with a continuous longitudinal wave can increase porosity by 6 % and permeability by 7 %, while discontinuous longitudinal waves increase porosity by 6 % and permeability by 31 %. Circular waves can increase porosity by 5 and permeability by 41 % [24].

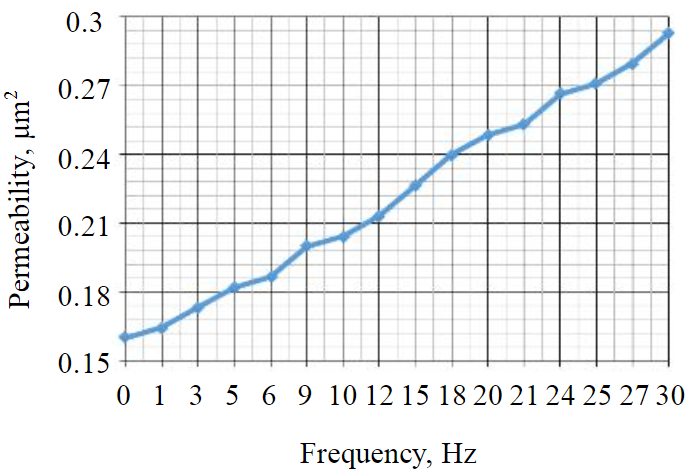

The article [25] notes an increase in rock permeability when the impact frequency is increased up to 10 Hz and a decrease in permeability when the frequency is further increased. Reference [26] confirms the efficiency of impact on formation with frequencies up to 30 Hz. At frequencies up to 10 Hz porosity can increase up to 45 % [27], which will entail an increase in permeability. A further increase in frequency up to 50 Hz reduces the value of porosity increase by up to 15 %.

It has been noted that low-frequency impact on rocks can be used to create microfractures [28], which can increase rock permeability and increase fluid flow in the impact area. Wave impact also helps to clean rocks from sediments: asphaltenes, salts, mechanical impurities [29]. Wave stimulation improves water absorption in both water-saturated and oil-saturated rock samples. The acceleration of capillary impregnation in hydrophilic rock samples is a consequence of a change in rock wettability under the action of applied vibration [30].

The analysis of research has shown that it is most rational to impact the formation by low-frequency waves. A review of works by scientists and researchers shows similar trends in the properties of media (sandstone, granite, limestone) under loading.

Predicting changes in permeability under wave impact

During vibrational treatment of an oil-saturated reservoir, production enhancement is achieved through local changes in pore pressure [31]. When a formation is heterogeneous in terms of permeability, a pore pressure difference arises between adjacent rock layers. This creates a pressure difference and leads to fluid movement from a zone with low permeability to a zone with high permeability. Amplitude difference of the pore pressure oscillations caused by rock stress fluctuations is described by the following equation [31]:

where indices 1 and 2 – high and low permeability layers respectively; Pa – pressure amplitude; σa – normal stress amplitude; ω – oscillation frequency; h – thickness of the rock layer; sw – water saturation; sо – oil saturation; Kw, Kо – volumetric moduli of elasticity for water and oil respectively; DT – effective total permeability across the two layers; ϕ – porosity; ρs – rock density; Vp – velocity of the pressure wave propagating through the porous medium.

The change in rock deformation during elastic wave propagation in a saturated formation is described by the following equation [31]:

where ε' – oscillatory displacement of rock grains; λw, λ0 and λT – mobility of water, oil and total fluid mobility respectively, λT = λw+λ0 ; D – reservoir depth.

Equations (2) and (3) do not take into account the attenuation of the wave and assume a constant wave velocity, which leads to a significant error in predicting the permeability of the bottomhole zone.

Experimental investigations [32, 33] have established empirical relationships between permeability and viscosity changes in the field of high-frequency elastic waves

where k0 – initial permeability of the porous medium; K = 0.02 – empirical coefficient; α – sound attenuation coefficient (the effect of oscillation frequency is calculated through the sound attenuation coefficient); ρ – saturated porous medium density; c – sound velocity in a saturated medium; µ– formation fluid viscosity; P0– vibration amplitude; grad P – pressure gradient;

μ0 – initial oil viscosity; Pw – oscillation amplitude.

Some scientists have noted the low penetration capability of high-frequency waves in the bottomhole zone of the formation, which reduces the efficiency of their application for enhanced oil recovery.

Equation for predicting permeability after wave impact has been derived in [34]

where Δk=ka-kref; ka – effective medium permeability; kref – initial medium permeability; B – amplitude of pressure fluctuation; ΔP – pressure drop; f – constant (equal to 1.67 in a confidence interval of 1.5 to 1.8).

Equation (5) is applicable at amplitudes not exceeding 0.3 MPa, in real wells the amplitudes during wave impact reach tens of megapascals. To broaden the scope of the equation it is presented in the following form:

where a = 0.7; b = 1.7 – experimental constants.

When propagating in a porous formation, the wave amplitude is intensely attenuated. To estimate changes in signal amplitude during wave propagation through a formation, the following equation can be used

where P0 – initial acoustic pressure value; r – distance from the oscillation source to the point, at which the amplitude is determined; n – power index (n = 0 for plane, n = 1 – spherical, n = 0.5 – cylindrical waves).

Expression for the attenuation coefficient:

where ω – angular frequency; Q – quality factor; с – longitudinal wave velocity.

Fig.1. Field plan

Practical application of low-frequency impact is implemented in production wells of Perm region in the form of dilatation-wave impact (DWI) technology. This technology consists in creation of rock dilatation (decompaction) zone around well

in perforation interval by weight of tubing string when it is lowered on borehole bottom via special liner. Then low-frequency elastic oscillations, created in liner and through it in rock by pumped fluid column during operation of sucker-rod pump, are excitated in formation rock. In this case, the use of the DWI technology can cause the formation of new fractures in the rock.

Let us consider the results of applying the DWI technology on a well operating a carbonate-type reservoir. The limestones in the reservoir are predominantly clotted and pitted. Pores in the formation are interformational of secondary leaching with size 0.05-0.25 mm, communicating by means of interformational channels with opening 0.01-0.03 mm. The formation is extensively fractured. The reservoir contains 1-2 permeable interlayers between 0.4 and 1.8 m thick, with a total thickness of up to 2 m.

Physical properties of the oil formation and formation fluids: average oil-saturated thickness 7.5 m; porosity 19 %; rock sample permeability 0.4 μm2; partition coefficient 7.70 units. Temperature of formation is 28 °С, initial formation pressure is 16.75 MPa, oil viscosity under formation conditions is 48.8 mPa∙s, oil density under formation conditions is 0.922 t/m3, absolute height of WOI is 1412 m, oil saturation pressure is 10 MPa, gas content is 10 m3/t .

The location of the wells at the field is shown in Fig.1.

A pump is lowered into the well to the depth Нp = 1083 m; liner length for bottomhole contact is 406 m; polished rod stroke is 2.1 m; number of double strokes 6.1 min–1; dynamic level Нd is 608 m; average bottomhole pressure is 9.5 MPa.

For the conditions considered, the velocity of the elastic waves in the fluid can be determined by the formula

where Gf – elasticity modulus of the fluid, kg/m2; γf – specific weight of the fluid, kg/m3; g = 9.8 m/s2.

Considering the theory of N.E.Zhukovskii for the case of hydroshock in metal pipes, the velocity of elastic waves in the fluid can be found using the equation [35]:

where Gp – elastic strain modulus of the pipe material, Pa; D, δ – inside diameter and wall thickness of the pipe respectively, cm.

The following parameters are obtained: water compression modulus Gw = 23·107 kg/m2, oil Goil = 14·107 kg/m2, elastic strain modulus of pipes Gp = 20.6·109 kg/m2, fluid density ρf = 764 kg/m3, inner diameter and wall thickness of pipes are 62 and 5.5 mm, watercut of product is 40 %.

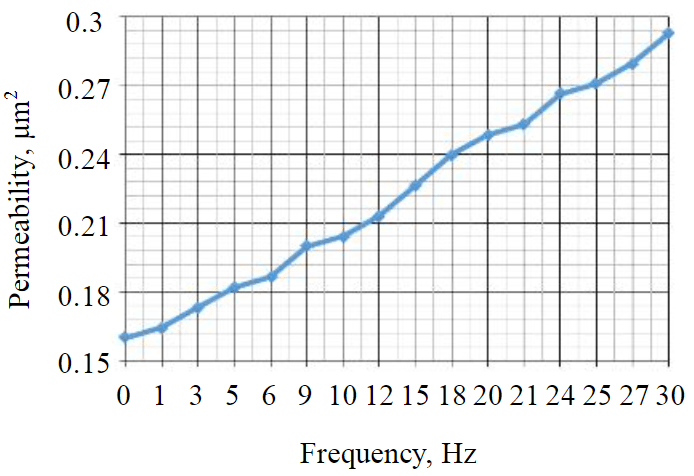

Fig.2. Changes in formation permeability as a function of the impact frequency

Then the elasticity modulus for the fluid

elastic wave velocity

in the case of hydraulic fracturing

natural oscillation period of the fluid column in the well

oscillation period of the tubing string

The oscillation period of the liner to the borehole bottom is determined by the value of the double strokes of the polished rod in the sucker-rod pump and is

then the oscillation frequency

The wave impact on the near-bottomhole zone is carried out by the pressure fluctuations created by the column of pumped fluid. The expected amplitude is equal to the weight of the fluid column from the dynamic level to the wellhead. The average density of the gas-liquid mixture in this interval is 764 kg/m3,

To estimate the possibility of applying the methods of permeability prediction presented in [33] and [34], it is required to calculate the permeability changes in the near-bottomhole zone (NBHZ) under conditions of ultrasonic impact on the formation for the pilot well by equation (4) for the conditions of Permian region fields.

Wave attenuation coefficient in the formation

Formation permeability during wave treatment

The predicted change in permeability from equation (4) is shown in Fig.2.

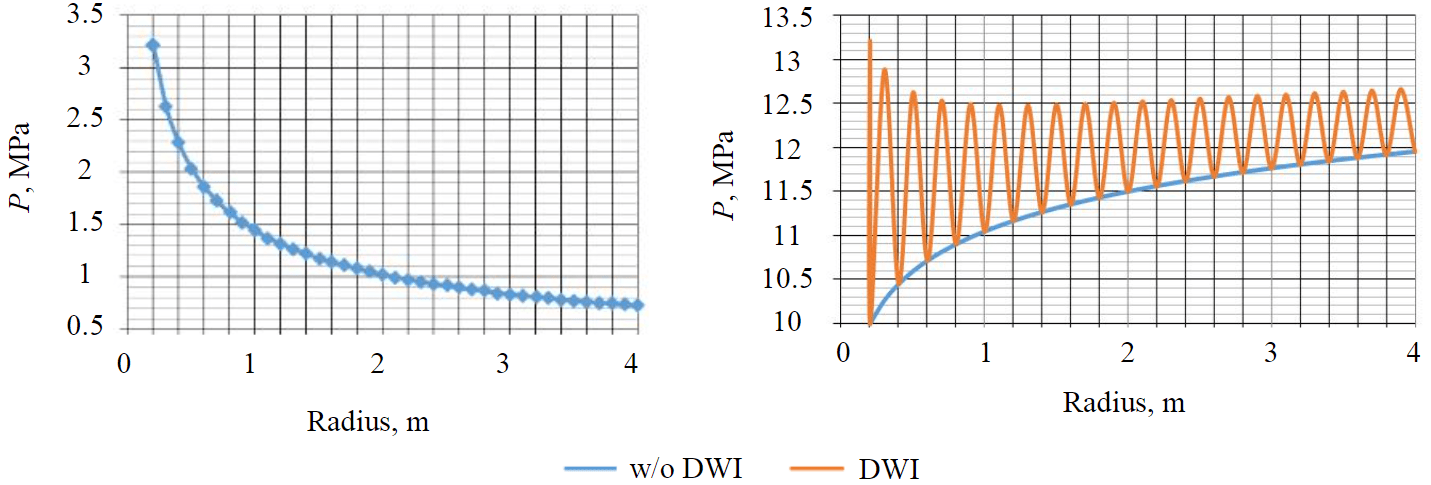

Fig.3. Changes in amplitude and pressure as a function of distance at 0.1 Hz

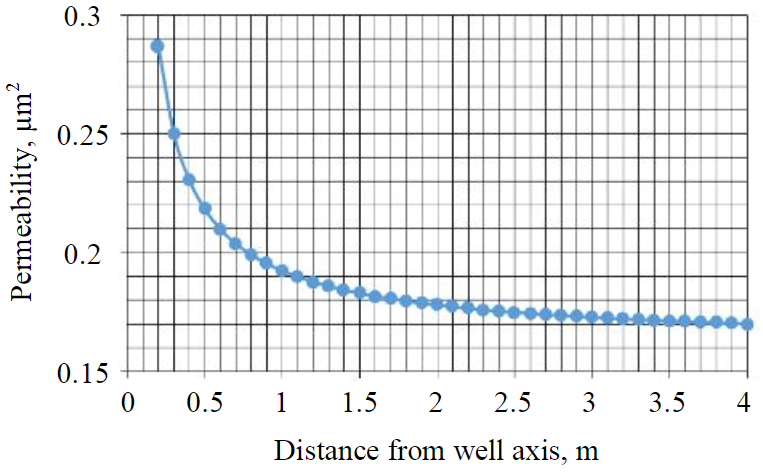

Fig.4. Change in the NBHZ permeability at 0.1 Hz

Fig.5. Change in formation permeability as a function of impact frequency (distance 0.2 m from the well axis)

Changes in reservoir properties under the influence of elastic waves are calculated using the methodology proposed in [34]. Cylindrical wave propagation from the well is determined by transforming equation (6):

where distance r changes in the range from rс to Rk.

Taking into account the wave attenuation coefficient

Using equation (7), the oscillation amplitude and pressure dynamics in the formation were evaluated (Fig.3).

The amplitude of the oscillations decreases significantly with distance from the wellbore, with the pressure at the moment of wave passage tending to 12.5 MPa.

Predictive assessment of permeability changes in the formation is made:

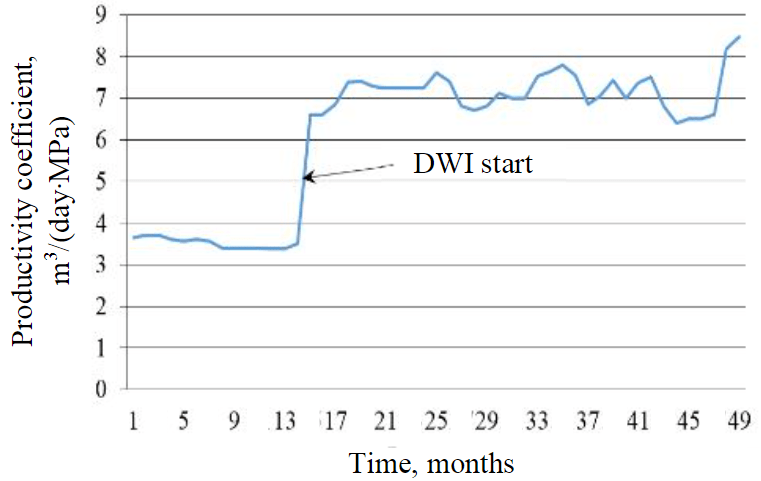

Fig.6. Dynamics of the well productivity coefficient

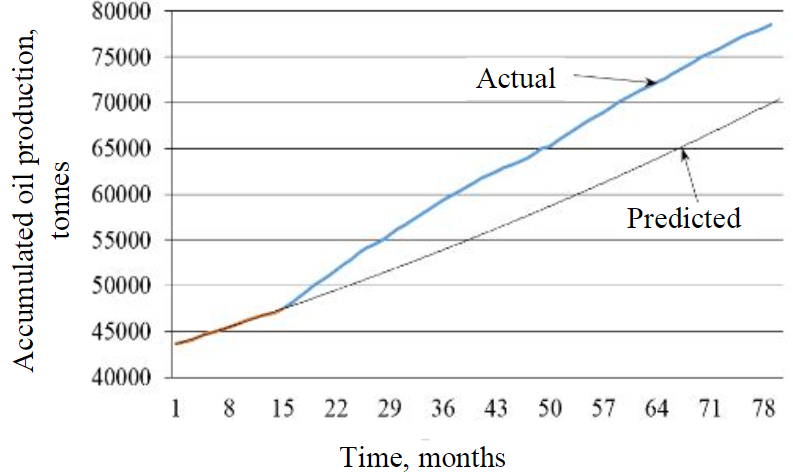

Fig.7. Dynamics of accumulated oil production by well

The main permeability change occurs in the immediate vicinity of the wellbore, within 1m of the well axis (Fig.4). As the impact frequency increases to 10 Hz, the predicted permeability of the reservoir increases (Fig.5).

One month after the start of wave impact, hydrodynamic investigations were carried out on the pilot well and the dynamics of pressure recovery after the use of DWI technology was determined. Processing of the hydrodynamic investigations data (pressure recovery curves) shows a significant increase in NBHZ permeability after the use of DWI.

Permeability of NBHZ prior to DWI was 0.16, RBHZ – 0.11 μm2, after DWI the permeability of NBHZ reached 0.31 and permeability of RBHZ – 0.12 μm2. At the same time, the permeability coefficient in the NBHZ increased more significantly than in the remote zone, which corresponds to the theoretical investigations. The permeability of the reservoir in the NBHZ according to the actual measurements increased more than according to the predicted calculations. This is due to the fact that the thickness of oil and water adsorption layers on the rock walls decreased and fluid viscosity changed during wave impact.

After the use of the DWI technology, the well productivity coefficient almost doubled and did not decrease during the 70 months of observation (Fig.6).

The dynamics of accumulated oil production indicate an increase in oil production in the well drainage area (Fig.7). The difference between the actual oil production and the predicted value at the considered site 60 months after the implementation of the wave impact is 8.5 thousand tons of oil.

According to the results of hydrodynamic investigations processing, the permeability increase after DWI was 93.7 %, according to method [34] – 79.1 %, technology [33] – 0.63 %. Calculations according to method [33] showed low correlation due to the fact that the main area of its application is ultrasonic impact. Consequently, for the considered rock and geological bedding conditions, the greatest correlation of results is achieved when using the methodology presented in [34]. The technology has a number of related disadvantages, which will not be considered in detail within the framework of this article. First, cyclic pressure fluctuations have negative influence on the state of wellbore lining, which may affect integrity and continuity of contact between cement stone and adjacent media. Second, there is no total possibility to control boundaries and parameters of wave field propagation. Third, it is difficult to realize this technology in horizontal sections of the wellbore. Fourth, research on NBHZ cleaning by the wave field is insufficient. Despite these disadvantages, the technology of wave impact on the NBHZ in practice has proved its efficiency.

Conclusion

The formation of fractures in rocks under wave impact will increase permeability and hence oil production. This paper investigated the possible frequencies of wave impact on rock formations. According to literature sources, the greatest efficiency of the impact can be achieved at low frequencies. The methods of rock permeability change prediction under wave impact were studied for field conditions of Perm region. A part of oil formation, where the technology of dilatation-wave impact with frequency of 0.1 Hz is realized, was chosen. The prediction of permeability under wave impact and estimation of the results according to the data from the oil field were carried out. Hydrodynamic investigations showed increase of permeability after the impact of 93.7 %, according to method [34] – 79.1 %, according to method [33] – 0.63 %. For the considered rock and geological bedding conditions the greatest correlation of results is achieved when using the methodology presented in [34]. The results of wave impact show the possibility of effective application of this technology to increase oil production in carbonate reservoirs.

References

- Lei Zhang, Xufeng Wang, Jiyao Wang, Zhanbiao Yang. Mechanical characteristics and pore evolution of red sandstone under ultrasonic high-frequency vibration. AIP Advances. 2021. Vol. 11. Iss. 51. N 055202. DOI: 10.1063/5.0051640

- Cardoni A., Harkness P., Lucas M. Ultrasonic rock sampling using longitudinal-torsional vibrations. Ultrasonics. 2010. Vol. 50. Iss. 4-5, p. 447-452. DOI: 10.1016/j.ultras.2009.09.036

- Fernando P.K.S.C., Meng Zhang, Pei Z. Rotary ultrasonic machining of rocks: An experimental investigation. Advances in Mechanical Engineering. 2018. Vol. 10. Iss. 3. DOI: 10.1177/1687814018763178

- Wiercigroch M., Wojewoda J., Krivtsov A.M. Dynamics of ultrasonic percussive drilling of hard rocks. Journal of Sound and Vibration. 2005. Vol. 280. Iss. 3-5, p. 739-757. DOI: 10.1016/j.jsv.2003.12.045

- Ning Li, Ping Zhang, Yunsheng Chen, Swoboda G. Fatigue properties of cracked, saturated and frozen sandstone samples under cyclic loading. International Journal of Rock Mechanics and Mining Sciences. 2003. Vol. 40. Iss. 1, p. 145-150. DOI: 10.1016/S1365-1609(02)00111-9

- Fernando P.K.S.C., Pei Z.J., Meng Zhang. Mechanistic cutting force model for rotary ultrasonic machining of rocks. International Journal of Advanced Manufacturing Technology. 2020. Vol. 109. Iss. 1-2, p. 109-128. DOI: 10.1007/s00170-020-05624-z

- Da-jun Zhao, Peng Yuan. Research on the Influence Rule of Ultrasonic Vibration Time on Granite Damage. Journal of Mining Science. 2018. Vol. 54. Iss. 5, p. 751-762. DOI: 10.1134/S1062739118054856

- Kozhevnikov E.V., Turbakov M.S., Riabokon E.P., Poplygin V.V. Effect of Effective Pressure on the Permeability of Rocks Based on Well Testing Results. Energies. 2021. Vol. 14. Iss. 8. N 2306. DOI: 10.3390/en14082306

- Kozhevnikov E., Riabokon E., Turbakov M.A. Model of Reservoir Permeability Evolution during Oil Production. Energies. 2021. Vol. 14. Iss. 9. N 2695. DOI: 10.3390/en14092695

- Momeni A.A., Karakus M., Khanlari G.R., Heidari M. Effects of cyclic loading on the mechanical properties of a granite. International Journal of Rock Mechanics & Mining Sciences. 2015. Vol. 77, p. 89-96. DOI: 10.1016/j.ijrmms.2015.03.029

- Yi Liu, Feng Dai, Lu Dong et al. Experimental Investigation on the Fatigue Mechanical Properties of Intermittently Jointed Rock Models Under Cyclic Uniaxial Compression with Different Loading Parameters. Rock Mechanics and Rock Engineering. 2018. Vol. 51. Iss. 1, p. 47-68. DOI: 10.1007/s00603-017-1327-7

- Bagde M.N., Petroš V. Fatigue properties of intact sandstone samples subjected to dynamic uniaxial cyclical loading. International Journal of Rock Mechanics and Mining Sciences. 2005. Vol. 42. Iss. 2, p. 237-250. DOI: 10.1016/j.ijrmms.2004.08.008

- Lin-jian Ma, Xin-yu Liu, Ming-yang Wang et al. Experimental investigation of the mechanical properties of rock salt under triaxial cyclic loading. International Journal of Rock Mechanics and Mining Sciences. 2013. Vol. 62, p. 34-41. DOI: 10.1016/j.ijrmms.2013.04.003

- Mingming He, Ning Li, Yunsheng Chen, Caihui Zhu. Strength and Fatigue Properties of Sandstone under Dynamic Cyclic Loading. Shock and Vibration. 2016. Vol. 2016. N 9458582. DOI: 10.1155/2016/9458582

- Xiao X., Pan Y., Lu X., Yang X. Mechanism of methane permeability enhance through ultrasonic irradiating on low permeable coal seam. Chinese Journal of Geophysics. 2013. Vol. 56, p. 1726-1733. DOI: 10.6038/cjg20130530

- Yin Songyu, Zhao Dajun, Zhai Guobing. Investigation into the characteristics of rock damage caused by ultrasonic vibration. International Journal of Rock Mechanics and Mining Sciences. 2016. Vol. 84, p. 159-164. DOI: 10.1016/j.ijrmms.2015.12.020

- Dajun Zhao, Shulei Zhang, Meiyan Wang. Microcrack Growth Properties of Granite under Ultrasonic High-Frequency Excitation. Advances in Civil Engineering. 2019. N 3069029. DOI: 10.1155/2019/3069029

- Guzev M.A., Kozhevnikov E.V., Turbakov M.S. et al. Experimental Investigation of the Change of Elastic Moduli of Clastic Rocks under Nonlinear Loading. International Journal of Engineering. 2021. Vol. 34. Iss. 3, p. 750-755. DOI: 10.5829/ije.2021.34.03c.21

- Guzev M., Kozhevnikov E., Turbakov M. et al. Experimental Studies of the Influence of Dynamic Loading on the Elastic Properties of Sandstone. Energies. 2020. Vol. 13. Iss. 23. N 6195. DOI: 10.3390/en13236195

- Guzev M., Riabokon E., Turbakov M. et al. Modelling of the Dynamic Young’s Modulus of a Sedimentary Rock Subjected to Nonstationary Loading. Energies. 2020. Vol. 13. Iss. 23. N 6461. DOI: 10.3390/en13236461

- Marfin E., Gavrilov A., Abdrashitov A., Kadyirov A. Pressure build-up test under elastic-wave action on the reservoir. CMMASS 21st International Conference, 24-31 May 2019, Crimea, Russian Federation. Computational Mechanics and Modern Applied Software Systems. 2019. Vol. 2181. N 020018, p. 020018-1-020018-7. DOI: 10.1063/1.5135678

- Xiaodong Han, Liming Zheng, Cunliang Chen, Hongfu Shi. Velocity and attenuation of elastic wave in a developed layer with the initial inner percolation in the pores. Journal of Petroleum Exploration and Production Technology. 2018. Vol. 8. DOI: 10.1007/s13202-018-0468-x

- Liming Zheng, Hao Wang. Numerical study on the variation of single phase flow in three-dimensional layer under low-frequency artificial vibration of seismic production technique. Energy Sources. Part A: Recovery, Utilization, and Environmental Effects, 2020. DOI: 10.1080/15567036.2020.1840668

- Louhenapessy S.C., Ariadji T. The effect of type waves on vibroseismic implementation of changes properties of rock, oil viscosity, oil compound composition, and enhanced oil recovery. Petroleum Research. 2020. Vol. 5. Iss. 4. p. 304-314. DOI: 10.1016/j.ptlrs.2020.05.001

- Ariadji T. Effect of Vibration on Rock and Fluid Properties: On Seeking the Vibroseismic Technology Mechanisms. SPE Asia Pacific Oil and Gas Conference and Exhibition, 5-7 April 2005, Jakarta, Indonesia. Society of Petroleum Engineers, 2005, p. 161-168. DOI: 10.2118/93112-ms

- Liming Zheng, Chaoxiang Pu, Li Y.-J. et al. Biot's consolidation with variables for influence of low-frequency vibration stimulation on radial flow in low-permeability developed reservoir. Chinese Journal of Geotechnical Engineering. 2017. Vol. 39. Iss. 4, p. 752-758. DOI: 10.11779/CJGE201704022

- Liming Zheng, Pu C., Jiaxiang Xu et al. Modified model of porosity variation in seepage fluid-saturated porous media under elastic wave. Journal of Petroleum Exploration and Production Technology. 2016. Vol. 6. Iss. 4, p. 569-575. DOI: 10.1007/s13202-015-0217-3

- Li S.Q., Yan T., Li W., Bi F.Q. Modeling of vibration response of rock by harmonic impact. Journal of Natural Gas Science and Engineering. 2015. Vol. 23, p. 90-96. DOI: 10.1016/j.jngse.2015.01.025

- Shedid S.A. An ultrasonic irradiation technique for treatment of asphaltene deposition. Journal of Petroleum Science and Engineering. 2004. Vol. 42. Iss. 1, p. 57-70. DOI: 10.1016/j.petrol.2003.11.001

- Abaa K., Ityokumbul M.T., Adewumi M. Effect of Acoustic Stimulationon Aqueous Phase Trapping in Low-Permeability Sandstones. Journal of Energy Resources Technology, Transactions of the ASME. 2017. Vol. 139. Iss. 61. N 062905. DOI: 10.1115/1.4037156

- Chun Huh. Improved Oil Recovery by Seismic Vibration: A Preliminary Assessment of Possible Mechanisms. SPE 1st International Oil Conference and Exhibition in Mexico, 31 August – 2 September, 2006, Cancun, Mexico. Society of Petroleum Engineers, 2006, p. 358-373. DOI: 10.2118/103870-ms

- Fasfiev B.R., Marfin E.A., Khusnullina A.А. The Change in the Temperature Dependence of the Viscosity of Oil under Ultrasonic Action. European Association of Geoscientists & Engineers 20th Conference on Oil and Gas Geological Exploration and Development – Geomodel 2018, 10-14 September 2018, Gelendzhik, Russian Federation. 2018, p. 1-5. DOI: 10.3997/2214-4609.201802359

- Mardegalyamov M.M., Marfin E.A., Vetoshko R.A. Change in Permeability of a Porous Medium at Ultrasonic Action. EAGE 8th International conference and exhibition – Innovations in Geosciences-Time for Breakthrough, 9-12 April 2018, Saint Petersburg, Russian Federation. European Association of Geoscientists & Engineers, 2018, p 1-5. DOI: 10.3997/2214-4609.201800258

- Elkhoury J.E., Niemeijer A.R., Brodsky E.E., Marone C. Laboratory observations of permeability enhancement by fluid pressure oscillation of in situ fractured. Journal of Geophysical Research. 2011. Vol. 116, p. 2-16. DOI: 10.1029/2010JB007759

- Zhukovskii N.E. About hydroshock in water pipes. Moscow-Leningrad: Gosudarstvennoe izd-vo tekhniko-teoreticheskoi literatury, 1949, p. 105 (in Russian).