Methodology for managing energy development of production facilities in the gas industry

- Ph.D. Head of Department PAO Gazprom

Abstract

The current stage of Russia's development is characterized by dynamic changes in the operating conditions of gas industry enterprises, which leads, among other things, to significant adjustments in approaches to the development of energy production facilities. The article examines on the system level the ways to improve energy supply, taking into account the goals and objectives of the development of production facilities from the conditions of solving a single technological problem of the gas industry – high-quality gas supply to consumers. The optimal functioning of energy supply systems, taking into account the peculiarities of technological processes at production facilities, presupposes the development models coordination of production facilities energy complexes with the gas industry enterprises parameters based on an integrated unified information space at all stages of their life cycle. The structure of production facility energy complex and the connections of its elements with related systems are justified taking into account the purposes of their creation and the requirements for production facilities. Problem solving for each system element as well as the exchange of information between equivalent systems is done on the basis of a developed hierarchy of optimization problems adjusted depending on the type of tasks of energy supply improvement of a production facility. Determining the values of parameters and indicators of energy complexes, as well as optimizing the lists and content of work to improve the energy supply of production facilities, is planned to be carried out in accordance with the methodology under consideration using a set of mathematical models.

Introduction

Energy supply systems are an integral and important infrastructure component that ensures the functioning of gas industry production facilities for various purposes, located throughout the Russian Federation, including remote areas of the Arctic zone.

The gas industry has accumulated a wealth of experience in improving the energy supply of production facilities based on the developed general conceptual approach to their development. The following components are carried out on a permanent basis: analysis of the functioning and implementation of energy-saving measures in energy supply systems; search for innovative solutions, participation in testing and installation of prototype samples of modern power equipment for trial operation at production facilities; research and development work in terms of updating and developing industry standards and standard solutions to improve the efficiency of facilities energy supply.

The transformation of the global economy and energy, the introduction of various types of sanctions, significant changes in the nature of the supply of products, diversification of production lead to dynamic changes in the operating conditions of gas industry enterprises in our country, changes in the nature of development, reconstruction and technical re-equipment (R&TR) of production facilities [1], make a number of issues relevant, including:

- assessment, using the apparatus of a risk-based approach (RBA), of the impact on the target indicators of enterprises in the production, transportation, underground storage and processing of natural gas and liquid hydrocarbons in the gas industry of the pace and quality of maintenance and repair (M&R), as well as R&TR of energy supply facilities;

- use of this assessment data to develop measures to minimize the consequences of the application of RBA to management in the gas industry;

- development of measures to minimize resource costs at various stages of improving the energy supply of production facilities group and the gas industry as a whole.

The greatest efficiency in solving the problems of developing production facilities energy supply is achieved by creating energy complexes that are optimally functioning, taking into account the peculiarities of technological processes at production facilities, integrated into a single infrastructure and information space of gas industry enterprises. At the same time, the production facility energy complex (PFEC) is understood as a set of technical and software means of general facility energy supply systems and industrial air conditioning systems of structures with installations of electricity external networks, heat-, water supply and sanitation systems, which, through the implementation of an integrated technical solution and optimal control algorithms, including the use of elements of artificial intelligence in management, allows you to obtain the maximum value of the TCI of the PFEC under conditions of applying RBA to management in the gas industry (аn integrated indicator of the technical condition (“Technical Condition Index”) combines the values of other technical indicators into a value that is used for comparison and evaluation). To determine the indicator of the technical condition of electric power facilities, the physical wear rate is used, manifested in the forms of mechanical wear, corrosion and fatigue of metals, deformation and destruction, changes in the physical and chemical properties of the substance.

The optimal solution to the problems of improving the production facilities energy supply is associated with the joint consideration of a significant number of issues with significant uncertainty in the initial information and the inability, in some cases, of using formalized methods for determining individual indicators of energy complexes. In problems of this class, the methodology of system analysis [1-3] using RBA is usually used. As part of the transition to RBA in development management in the gas industry, the Risk Management Policy and the PAO Gazprom Internal Control Policy were developed and approved by the Board of Directors on December 25, 2018. This policy serves as the basis for the formation of the methodology for managing the development of the gas industry energy sector.

To obtain the maximum technical and economic effect in the process of improving energy supply to production facilities in the gas industry, it seems necessary to solve a number of scientific and practical problems in order to develop a methodology for managing energy development:

- Justify the concept for the development of energy supply systems for production facilities of enterprises on the scale of the gas industry, taking into account the provision of target indicators when applying RBA to industry management.

- Develop, as part of a decision support system development, a comprehensive (adaptive) model for determining and forecasting the energy complexes technical indicators for various organizational and financial scenarios for carrying out work to improve the production facilities energy supply.

- Develop standard lists of measures to improve energy supply, allowing obtaining a synergistic effect from optimizing technical solutions and operating modes of energy supply systems of jointly operating production facilities.

- Develop methods that allow you to effectively solve the problems of improving energy supply on the scale of a production facility, enterprise and industry as a whole in the context of applying RBA to management in the gas industry.

Overview of the problem

Currently, in world practice, the use of various methods of analysis and the theory of a systems approach for making economic and technical decisions in the oil and gas sector has significantly intensified. In particular, works numbered [4-6] highlight issues related to risk management in energy markets. Articles [7, 8] discuss the advantages and disadvantages of various approaches to risk modeling and management for practical use, as well as tools and strategies for manufacturers, wholesale consumers, investors and specialized participants in risk management in commodity markets.

The ways and political consequences for ensuring sustainable energy development are outlined in some works [9, 10], and in the given investigation [11] a comprehensive methodology of a systematic approach to energy saving processes at an industrial enterprise is considered. The results of the discussion of particular problems of energy saving are presented in works [12-14], and the effectiveness of the implementation of measures to improve energy efficiency is touched upon in works [15, 16].

In scientific work number [17], a fuzzy multi-criteria decision-making structure for assessing the risks of an integrated energy system is considered, sixteen risk factors from economics, technology, politics, society and management are identified, the proposed method is compared with other risk assessment methods, and its advantages are shown. Features of the application of risk management at the stage of digital transformation of industrial enterprises are analyzed in the research work number [18]. The main aspects of decision-making for assessing the risks of energy companies are given in works number [19-21].

An assessment of the consequences of the energy transition for the activities and business models of the oil and gas industry is considered in article number [22], risks during gas production and transportation are given in the following investigations [23-25]. Article [24] substantiates the relevance of risk management in oil and gas companies in modern conditions. Based on the systematization of types of risks, the main risks in the oil and gas business are identified: political, socio-economic, environmental, scientific, and technical ones.

Research works [26-28] contain information on the experience of applying a systematic approach to optimizing the production infrastructure of enterprises. Work [28] outlines the case for proactively managing energy procurement costs and discusses five key levers that support energy optimization and risk management.

The results of modern research on the use of artificial intelligence in the oil and gas industry and its contribution to the development of recommendations for increasing the sustainability of oil and gas projects are presented in the work of [29]. The paper provides information about the most promising applications and methodologies of artificial intelligence that can help solve problems for the sustainable development of the oil and gas industry.

In article [30], the relevance of conducting research in the field of energy efficiency of mineral resource complex facilities due to their specific nature and high-energy intensity is shown, including the use of the function of determining the effectiveness of energy-saving measures based on certain energy efficiency indicators.

The results of research on the development of predictive models based on retrospective data on planned electricity consumption in a region with a significant share of enterprises in the mineral resource complex are presented in the investigation of [31]. Models were obtained based on ensemble machine learning methods (random forest algorithms, gradient boosting XGBoost and CatBoost), as well as a recurrent neural network of long short-term memory (LSTM), which make it possible to create short-term forecasts of power consumption (for a period from one day to a week) with sufficiently high accuracy.

Article [32] is devoted to the development of a SCADA component for the compressor shop of a main gas pipeline. The developed component allows monitoring the characteristics of the gas pumping process selected by the operator. The development is based on the Windows operating system and the integrated environment TRACE MODE (SCADA/HMI).

Work [33] presents the theoretical basis for identifying the features of the use of neural networks at electric power enterprises in the context of digital transformation, as well as an analysis of methods for formalizing artificial intelligence systems for their use as part of automated systems.

In [34], the results of an analysis of the functioning features of autonomous electrotechnical complexes (ETC) are presented, based on the results of which a mathematical model of the ETC of a drilling rig with combined backup power sources was developed.

The main directions of energy development and modernization of power supply systems for technological facilities of the fuel and energy complex are considered in works [35-37]. Issues of improving the operation of the energy sector and ways to improve the quality of energy supply to production facilities in the gas industry are presented in works [38, 39].

It is necessary to develop a methodology for managing the development of the energy sector of production facilities to increase the efficiency of improving the energy sector of the gas industry in the conditions of applying RBA to industry management.

Methodology for managing the production facilities energy development in the gas industry

Optimization of the improving energy supply process is carried out on the basis of an analysis of the goals and objectives of the development of a set of production facilities (enterprises) in the gas industry, solving a single technological problem – high-quality gas supply to consumers – in the following sequence:

- The identification of industrial facilities which the development of energy supply is planned for is carried out on the basis of an analysis of the composition and functional purpose of production facilities (gas field facilities, main gas pipeline facilities, underground gas storage facilities, gas processing plant, gas industry facilities within a business process, etc.), affecting the solution of a single technological problem.

- Boundaries delimitation of the developed (reconstructed) PFEC is carried out on the basis of ensuring the requirements for energy supply from process equipment in all modes of operation of a group of production facilities while ensuring the required level of quality of external communications. Energy supply requirements mean the quantity and quality of energy resources, the level of reliability, safety and economic efficiency of operation, ease of use of PFEC equipment. External connections of PFEC are understood as connections with external systems of power supply, heat supply, water supply and sanitation, with existing and designed components of the facility automation system. The quality of external relations is determined by the composition of the technical and software tools responsible for the functioning of these tools. Depending on the developed requirements and features of the technological problems being solved and the composition of the objects, the set of functions implemented by the PFEC and their boundaries may change.

- The assessment of prospects for the development of PFEC is determined based on the results of a feasibility study, during which the condition and technical level of existing energy supply systems, the effects of the development (reconstruction) of energy complexes for a specific group of production facilities, the costs of their creation, etc. are assessed.

- Formulation of optimization problems for PFEC parameters and development of corresponding optimality criteria. Optimization is carried out according to a complex technical and economic indicator in order to minimize the costs of achieving a given value of the index of the technical condition of energy supply systems during the development of energy supply. The optimization process should involve taking into account the inverse influence of the technical level during the creation and operation of PFEC on the performance of a group of production facilities in the conditions of application of risk-based management principles in the gas industry by determining the individual components of the resulting effect at the pace of technological processes and (or) decision-making processes in order to prepare information for making a comprehensively informed decision on managing the improvement of energy supply.

Determination of the structure of the production facility energy complex and the connection of its elements with adjacent systems based on the formulated goals of creation and requirements for PFEC.

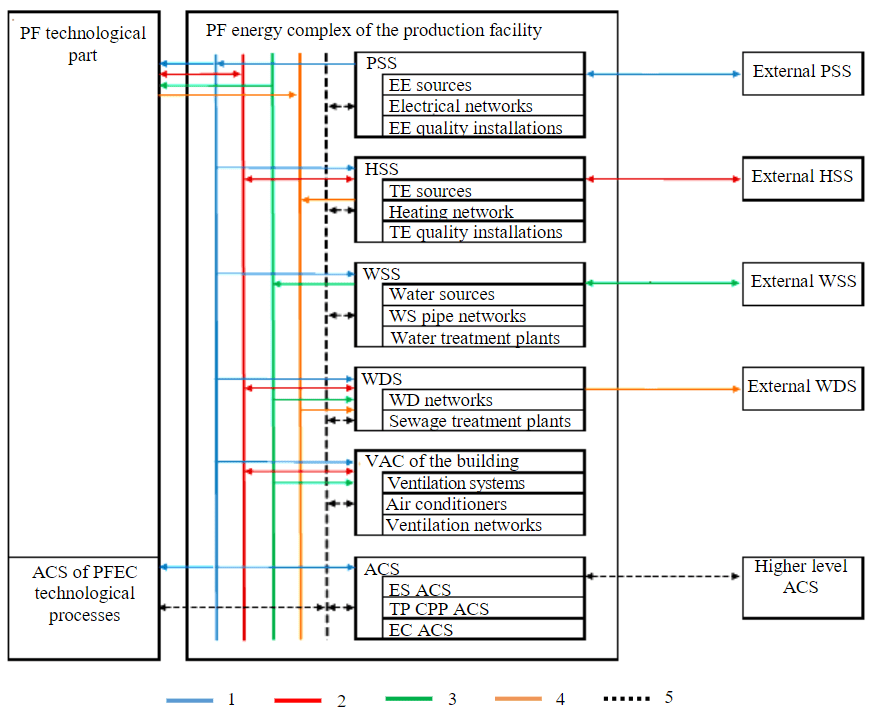

As components of the structure of energy complexes of production facilities, general facility power supply systems (PSS), heat supply (HSS), water supply (WSS), water disposal (WDS), ventilation and air conditioning systems of industrial and household buildings (VAC), including automated sources, network structure, installations for ensuring the quality of energy resources, purification of source water and wastewater, as well as means of interface with automated systems of a production facility and gas industry enterprise.

It is advisable to divide the PFEC into structural components taking into account the groups of functions they perform for a specific purpose. The composition of structural components and their technical implementation, depending on the requirements for PFEC, the technical level of the existing control system, etc., may vary. An example of the structure and connections of the energy complex of a production facility with the full composition of energy supply systems is shown in Fig.1.

Reducing the dimension of the optimization problem associated with the development of energy supply to a group of production facilities

Taking into account the variety of technical solutions of existing and energy supply facilities under formation, as well as the fact that changes in individual technical parameters have different effects on the efficiency indicators of energy complexes, the task of optimizing the process of managing their development becomes multidimensional and multicriteria. Reducing the dimension of the optimization problem is possible by replacing the set of real elements of energy complexes and their connections with equivalent systems, models of aggregated PFEC, which retain only those properties of the real system that need to be determined when solving problems of its functioning and optimization.

The number of levels of the equivalent systems hierarchy and their number at each level of the hierarchy for different scenarios for improving groups of production facilities energy supply depends on the complexity of the real group of energy complexes under study, as well as on the scenario conditions for financing the process of improving energy supply.

Units (as opposed to the structural components of individual subsystems) can be implemented both within a separate PFEC, and within a group of energy complexes of jointly functioning production facilities of a gas industry enterprise or on the scale of the gas industry as a whole. The latter depends on the requirements for the goals, structure and operation, reliability, safety, maintenance and repair of components of the PFEC, etc. The aggregation of the PFEC is carried out due to the order of measures implementation for the energy supply development.

Determination of the composition of tasks for equivalent systems

The hierarchy of optimization problems is built on the basis of a hierarchy of equivalent systems. It is created with the aim of streamlining optimization problems at each stage of improving the production facilities energy supply. At the same time, optimization problems for each stage differ in depth and detail of development. From the point of view of the hierarchy of tasks to be solved, the process of using PFEC is divided into stages: research, creation, operation (due to possible combinations of operating modes of a group of production facilities and external power supply systems).

The optimal distribution of functions between structural components and the possibility of their redistribution depending on the stage of reconstruction (creation) and the operating mode of the PFEC within the framework of improving energy supply makes it possible to create redundant groups of energy complexes.

This is necessary in cases of improving energy supply in several stages, significant changes in energy supply requirements, changes in the composition of operating sources, networks of a production facility, and external energy supply systems, and among others can be implemented by means of intelligent automation systems.

Determination of the composition of indicators and methods of exchange of energy resources and information between equivalent systems

The structural components of the PFEC exchange with each other and external systems (power supply, higher-level automation, etc.), energy resources and information, which under certain condition can be divided into initial, intermediate, sought and reverse; into external and internal [3].

Fig.1. Structure of the production facility energy complex with a complete set of energy supply systems 1 – electrical energy (EE); 2 – thermal energy (TE); 3 – source water (W); 4 – sewer drains (WD); 5 – information flows; ES ACS – energy supply automated control system; ACS TP CPP – ACS for technological processes of a captive power plant

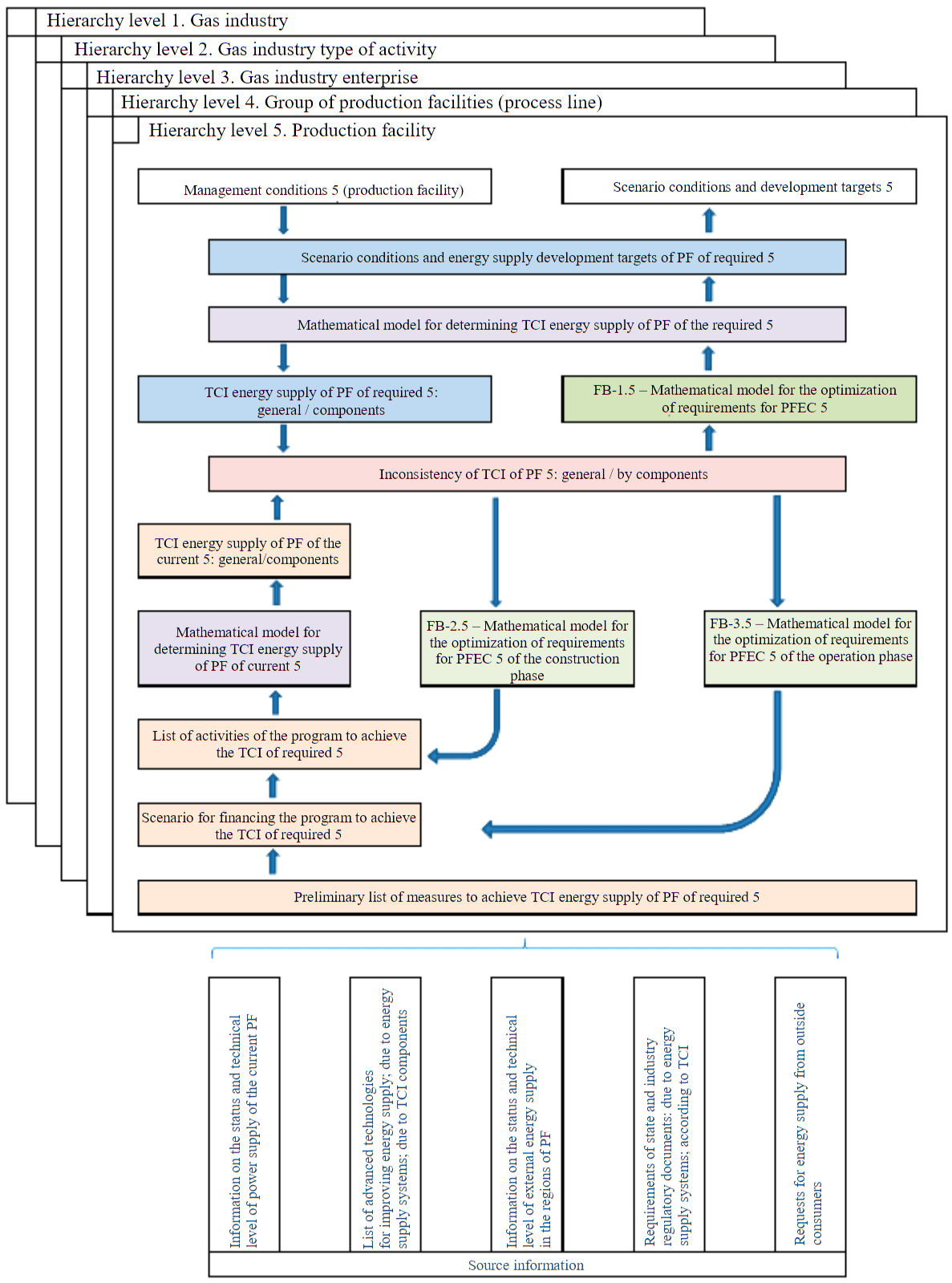

At the stages of the PFEC life cycle, three groups of optimization problems are solved:

- the task of optimizing the requirements for power supply of the PF, depending on the current TCI and achievable by means of reconstructing the TCI with the allocated amount of funding. The solution to the problem is provided by information on level 1 feedback (FB-1) for each level of the hierarchy of optimization problems of PFEC from hierarchy level 1 (gas industry FB-1.1) to hierarchy level 5 (production facility FB-1.5);

- the task of optimizing the list and scope of work for measures to develop the energy supply of PFEC in the conditions of given restrictions on financing the program to achieve the required level of TCI (general and/or for individual components) at the stage of creating the PFEC. The solution to the problem is provided by information on level 2 feedback (FB-2.1 – FB-2.5);

- the task of optimizing the list and scope of work for measures to develop the energy supply of PFEC under the given restrictions on financing the program to achieve the required level of TCI (general and (or) individual components) at the stage of operation of the PFEC. The solution to the problem is provided by information on level 3 feedback (FB-3.1 – FB-3.5).

In conditions of significant uncertainty in the initial information and the lack of strict formalization in determining a number of indicators, optimization problems in the process of managing the development of energy supply to production facilities in the gas industry are solved using combined methods – methods of narrowing Pareto-optimal outcomes and expert methods. The hierarchy of optimization problems at the stages of development of energy complexes of production facilities in the gas industry is shown in Fig.2.

Analysis of balances of production and consumption of energy resources and information that individual units must exchange between each other and external systems at various stages of the life cycle of PFEC will allow in the future to more reasonably solve the optimization problem of determining priorities in the implementation of measures to improve energy supply and the distribution of functions between units and individual structural components of energy complexes.

The search for the optimal list and scope of work for development activities of PFEC is associated with determining the current value of TCI PFEC for various levels of the hierarchy with combinations of the composition and content of activities that can be implemented using the allocated funds for the program to achieve the required level of TCI energy supply.

Fig.2. Hierarchy of optimization problems at the stages of development of PFEC of the gas industry

Extreme values of individual indicators of PFEC and energy supply as a whole, in most cases, are not the sum of extreme values of indicators of individual elements and subsystems [3]. If there are several irreducible criterion indicators, it is necessary to rank the criteria, highlighting one of them as the main one, and using the rest as restrictions.

The composition of mathematical models for determining the values of parameters and indicators of energy complexes, as well as optimizing the lists and content of work on the development of energy supply to production facilities

The set of mathematical models must correspond to the list of problems solved as part of the development of energy supply to the PF. The general model should make it possible to transform the values of the specified production facilities target indicators (PFTI) into the required target indicators of energy supply PF (TIES) and then into the value of the required index of the technical condition of the energy supply of a group of production facilities (ITCESgr.pr.f), the functioning of which directly affects achieving the specified PFTIs.

With the help of the model it is possible to assess the value of an integral indicator of energy supply for a given level of the ITCESgr.pr.f hierarchy and the value of its component indicators: the availability of energy resources; energy quality; reliability of energy supply; safety of energy supply; energy efficiency of energy supply; ease of operation (economical operation) of energy complexes.

The basis for the energy supply development process should be the following mathematical models:

- a model for determining the current TCI power supply of a given group of PF, as a function of the totality of initial information presented in Fig.2;

- a model for optimizing the list and scope of work to achieve the required level of TCI energy supply in the conditions of application of RBA to management in the gas industry (stage of creating an PFEC). This model should make it possible to build families of trends in the integral indicator and components of the energy supply TCI for the analyzed group of PF for various combinations of lists and scope of work, as well as capital investments in the program to achieve a given level of TCI PF for all levels of the hierarchy, taking into account the design and actually received in the creation process indicators of energy supply facilities;

- a model for optimizing the list and scope of work to achieve the required level of TCI energy supply in the conditions of application of RBA to management in the gas industry (operation stage of the created PFEC). In contrast to the models of the creation stage, models of the operation stage of PFECs evaluate various options for achieving the required level of TCI energy supply, including taking into account the optimization of the joint functioning of the created PFEC at a certain level of their operation.

The complex should include adaptive mathematical models that require the minimum required amount of initial information and allow:

- justify the level of requirements for the distribution of the balance of production and ensuring the quality of energy resources between sources and installations of PFEC and external energy supply systems, as well as to the information properties of individual structural components of PFEC;

- determine the necessary communication capabilities of the structural components of PFEC to ensure distributed generation and ensure the quality of energy resources at the required level;

- predict the implementation of given scenario conditions, loads on individual energy supply systems, etc. in order to make informed decisions on optimizing the list and scope of work to improve energy supply.

The results of modeling energy supply development processes are the basis for developing a structured proposal from a decision support system in order to optimize the process of improving the energy supply of industrial facilities in the industry.

Discussion

Using the principles of the methodology described above, the Development Concept and the Comprehensive Target Program for the reconstruction and technical re-equipment of the energy sector of production facilities in the gas industry were developed.

The methodology was a tool for the logical organization of research and a means of calculating indicators, which made it possible, based on solving a multi-criteria optimization problem, to formulate a general vision of the vector of energy supply development in the context of dynamic changes in business conditions and restrictions on financing development programs, as well as to formulate an optimal list and sequence of implementation of reconstruction measures energy of production facilities in order to achieve the maximum value of the index of technical condition of energy facilities on an industry scale.

Previously, the main tool for developing comprehensive programs was only methods for determining indicators of the economic efficiency of reconstruction measures, which did not take into account important technical aspects of the functioning of energy complexes.

To date, the problems of developing mathematical models for finding correspondence between target production indicators of various levels and the minimum required technical level of energy supply for groups of production facilities of industry enterprises have not been solved, which is the subject of further scientific research.

Conclusion

Dynamic changes in business conditions and the use of RBA in the gas industry have led to the need to develop a methodological approach to improve the efficiency of managing the energy development of production facilities, based on a comprehensive analysis of the parameters of jointly functioning technological installations and energy complexes of production facilities in order to solve business problems.

The methodology developed by the author for managing the development of the energy sector of production facilities is based on the provisions of system analysis and allows optimizing, at the pace of changing operating conditions, the process of improving energy supply by solving a multi-criteria optimization problem when determining the technical condition index of PFEC under conditions of restrictions.

The use of the provisions of the developed methodology made it possible to substantiate at the system level the optimal list and priority of implementation of measures to improve the energy sector of production enterprises in the gas industry as part of the development of a program for the reconstruction and technical re-equipment of the industry’s energy supply.

Further scientific research is associated with the development, based on the provisions of the proposed methodology, of a decision support system, which allows, by structuring heterogeneous information about the current state and possible options for improving the energy sector of the gas industry, to optimize the process of solving business problems of production facilities within the framework of the implementation of various scenario conditions for the development of the industry.

References

- Nikiforov S.I., Medvedev K.A., Gitarskiy M.L. Russian oil and gas industry under fourth energy transition and climate change. Fundamental and Applied Climatology. 2022. Vol. 8. N 3, p. 74-87 (in Russian). DOI: 10.21513/2410-8758-2022-3-74-87

- Markelov V.A., Bronnikov A.N., Shapovalo A.A. et al. Concept of developing the power system of production facilities under dynamically changing conditions applied to business activities of gas industry companies. Gas Industry Journal. 2023. N S3 (853), p. 8-11 (in Russian).

- Voropai N.I., Podkovalnikov S.V., Trufonov V.V. et al. Justification for the development of power systems: methodology, models, methods, their use. Novosibirsk: Nauka, 2015, p. 448 (in Russian).

- Ishutina T.A. Risk management in energy companies of the Russian Federation. Developing the energy agenda for the future: Sbornik dokladov Mezhdunarodnoi nauchno-prakticheskoi konferentsii dlya predstavitelei soobshchestva molodykh inzhenerov TEK, 10-11 dekabrya 2021, Sankt-Peterburg, Rossiya. St. Petersburg: Sankt-Peterburgskii gosudarstvennyi elektrotekhnicheskii universitet “LETI” im. V.I.Ulyanova (Lenina), 2021, p. 339-343 (in Russian).

- Handbook of Risk Management in Energy Production and Trading. Ed. by R.M.Kovacevic, G.Ch.Pflug, M.T.Vespucci. New York: Springer, 2013, p. 505. DOI: 10.1007/978-1-4614-9035-7

- Swindle G. Valuation and Risk Management in Energy Markets. Cambridge: Cambridge University Press, 2014, p. 487. DOI: 10.1017/CBO9781139568302

- Burger M., Graeber B., Schindlmayr G. Managing Energy Risk. A Practical Guide for Risk Management in Power, Gas and Other Energy Markets. Wiley, 2014, p. 448. DOI: 10.1002/9781118618509

- Kamchatova E. Risk management of generating energy companies. Vestnik Universiteta. 2018. N 2, p. 50-56 (in Russian). DOI: 10.26425/1816-4277-2018-2-50-56

- Bakhteeva N.Z., Shatskikh Z.V. Some aspects of risk management in the electric power industry. Bulletin of the Kazan State Energy University. 2015. N 1 (25), p. 111-124 (in Russian).

- Xianlei Chen, Manqi Wang, Bin Wang et al. Energy Consumption Reduction and Sustainable Development for Oil & Gas Transport and Storage Engineering. Energies. 2023. Vol. 16. Iss. 4. N 1775. DOI: 10.3390/en16041775

- Sucic B., Peckaj M., Tomsic Z., Uranic J. Systematic approach for improving energy efficiency in industrial facilities, from energy audit to practical implementation – case study production of autoclaved aerated concrete. E3S Web of Conferences. 2019.

- Vol. 116. N 00083. DOI: 10.1051/e3sconf/201911600083

- Kelchevskaya N.R., Shirinkina E.V., Atlasov I.V. Assessing energy efficiency factors in industrial companies. IOP Conference Series: Materials Science and Engineering. 2020. Vol. 862. N 042001. DOI: 10.1088/1757-899X/862/4/042001

- Tarasenko V.N., Denisova Y.V. The problem of energy conservation in Russia. Bulletin of Belgorod State Technological University named after V.G.Shukhov. 2016. Vol. 1. N 11, p. 63-68 (in Russian). DOI: 10.12737/22375

- Ulyasheva V.M., Ponomarev N.S., Martyanova A.Yu., Sukhanova I.I. Energy saving at oil and gas production and transportation facilities. St. Petersburg: Sankt-Peterburgskii gosudarstvennyi arkhitekturno-stroitelnyi universitet, 2022, p. 216.

- Hashim K.M., Hassim Mimi H., Ng D.K.S., Ten J.Y. Leading Energy Performance Indicator: Tracking of Energy Management Systems in Oil and Gas Companies. ASM Science Journal. 2019. Vol. 12, p. 16. DOI: 10.32802/asmscj.2019.312

- Arriola-Medellín A.M., López-Cisneros L.F., Aragón-Aguilar A. et al. Energy efficiency to increase production and quality of products in industrial processes: case study oil and gas processing center. Energy Efficiency. 2019. Vol. 12. Iss. 6, p. 1619-1634. DOI: 10.1007/s12053-019-09803-0

- Gasumov E., Gasumov R., Suleymanov G., Gurbanov K. Risk management in the production and transportation of natural gas under the conditions of the economic crisis in the energy market. Reliability: Theory & Applications. The Fourth Eurasian Risk Conference and Symposium, 11-13 October 2022, Baku, Azerbaijan. 2022. Vol. 17. Special Issue 4 (70), p. 502-508.

- Pashchenko D.S., Komarov N.M. Risk Management as a Key Element in the Digital Transformation of an Industrial Enterprise. The World of New Economy. 2021. Vol. 15. N 1, p. 14-27. DOI: 10.26794/2220-6469-2021-15-1-14-27

- Sterev N., Biolcheva P. Market Mechanisms for Risk Management in Energy. Economic Alternatives. 2022. Iss. 1, p. 132-141. DOI: 10.37075/EA.2022.1.08

- Nazarova F., Voropayeva T., Horobets N., Sokolova O. Energy risk management in urban projects management. International Journal of Human Capital in Urban Management. 2023. Vol. 8. Iss. 2, p. 143-160. DOI: 10.22034/IJHCUM.2023.02.01

- Rahmani J. The main approaches to evaluating the effectiveness of applying the risk analysis and management methodology at energy company. T-Comm. 2022. Vol. 16. N 9, р. 46-55. DOI: 10.36724/2072-8735-2022-16-9-46-55

- Mastepanov A.M. Energy transition: what should the oil and gas world get ready for. Problems of economics and management of oil and gas complex. 2019. N 10 (178), p. 5-14 (in Russian). DOI: 10.33285/1999-6942-2019-10(178)-5-14

- Londoño A.A., Velásquez J.D. Risk Management in Electricity Markets: Dominant Topics and Research Trends. Risks. 2023. Vol. 11. Iss. 7. N 116. DOI: 10.3390/risks11070116

- Lenkova O.V. Risk management of oil and gas company in terms of strategic transformations. Espacios. 2018. Vol. 39. N 6, p. 30.

- Babakov A.V., Saulin A.D. Identification and classification of risks gas transmission companies. Voprosy ekonomiki i prava. 2018. N 10 (124), p. 75-83 (in Russian).

- Groten M., Gallego-García S. A Systematic Improvement Model to Optimize Production Systems within Industry 4.0 Environments: A Simulation Case Study. Applied Sciences. 2021. Vol. 11. Iss. 23. N 11112. DOI: 10.3390/app112311112

- Anthony Paul, Lawrence Kelvin, Kelvin Brown. Optimizing IT Growth: Strategies for Building and Scaling Robust Infrastructure Systems. Ladoke Akintola University of Technology. URL: https://www.researchgate.net/publication/377447014 17.01.2024 (accessed 16.02.2024).

- Bryan G., Carlson Ch., Gaponenko S., Mitra Sh. The Benefits of Modeling and Optimizing Production Systems: An Application on Civil Infrastructure Projects. URL: https://www.curt.org/2023/10/30/the-benefits-of-modeling-and-optimizing-production-systems-an-application-on-civil-infrastructure-projects/ (accessed 16.02.2024).

- Waqar А., Othman I., Shafiq N., Mansoor M.S. Applications of AI in oil and gas projects towards sustainable development:

- a systematic literature review. Artificial Intelligence Review. 2023. Vol. 56. Iss. 11, p. 12771-12798. DOI: 10.1007/s10462-023-10467-7

- Shklyarsky J.E., Zamyatina E.N., Zamyatin E.O. Evaluation of the energy efficiency of the electrotechnical complex. News of the Tula state university. Technical sciences. 2020. Iss. 3, p. 339-347 (in Russian).

- Klyuev R.V., Morgoeva A.D., Gavrina O.A. et al. Forecasting planned electricity consumption for the united power system using machine learning. Journal of Mining Institute. 2023. Vol. 261, p. 392-402.

- Ilyushin Yu.V., Afanaseva O.V. Development of Scada-model for trunk gas pipeline’s compressor station. Journal of Mining Institute. 2019. Vol. 240, p. 686-693. DOI: 10.31897/PMI.2019.6.686

- Unizhaev N.V. Particularities of the introduction of neural networks and artificial intelligence systems at power companies. Russian Journal of Innovation Economics. 2023. Vol. 13. № 1, p. 215-232 (in Russian). DOI: 10.18334/vinec.13.1.116945

- Chervonchenko S.S., Frolov V.Ya. Research of the operation of an autonomous electrical complex with a combined composition of backup power sources. Power engineering: research, equipment, technology. 2022. Vol. 24. N 4, p. 90-104 (in Russian).

- DOI: 10.30724/1998-9903-2022-24-4-90-104

- Bogachkov I.M., Khamitov R.N., Valiev M.K. The Choice of the Optimal Voltage Class of Gas Field Electricity Supply System. Electrotechnical Systems and Complexes. 2020. N 4 (49), p. 35-41 (In Russian). DOI: 10.18503/2311-8318-2020-4(49)-35-41

- Saushev A.I., Erazumov M.I., Romanov L.R. et al. Intelligent control electric power system oil fields. Avtomatizatsiya i IT v neftegazovoi oblasti. 2023. N 4 (54), p. 30-40 (in Russian).

- Tokarev I.S., Yugay V.F., Tolmachev V.N. et al. Use of electric power storage systems as part of power generating equipment of PJSC Gazprom production facilities power supply systems. Gas Industry Journal. 2023. N S3 (853), p. 34-40 (in Russian).

- Chekanskiy A.V., Shirshov D.N., Markova V.N. et al. Prospects for the use of nuclear power generation sources at PJSC Gazprom facilities. Gas Industry Journal. 2024. N 3 (862), p. 74-83 (in Russian).

- Shapovalo A.A., Konoplev T.F., Averyanov V.K. et al. Ways to improve the quality of energy supply for production facilities of PAO Gazprom in modern conditions. Nauka i tekhnika v gazovoi promyshlennosti. 2022. N 2 (90), p. 93-101.