Well killing with absorption control

- 1 — Ph.D. Acting Associate Professor S.Yessenov Caspian University of Technologies and Engineering ▪ Orcid

- 2 — Ph.D. Acting Associate Professor S.Yessenov Caspian University of Technologies and Engineering ▪ Orcid

- 3 — Ph.D. Acting Associate Professor S.Yessenov Caspian University of Technologies and Engineering ▪ Orcid

- 4 — Ph.D. Acting Associate Professor S.Yessenov Caspian University of Technologies and Engineering ▪ Orcid

- 5 — Ph.D. Acting Associate Professor S.Yessenov Caspian University of Technologies and Engineering ▪ Orcid

- 6 — Ph.D. Acting Associate Professor S.Yessenov Caspian University of Technologies and Engineering ▪ Orcid

- 7 — Ph.D. Doctoral Student S.Yessenov Caspian University of Technologies and Engineering ▪ Orcid

- 8 — Ph.D. Deputy Director for Research Institute of Petrochemistry and Catalysis, UFRC RAS ▪ Orcid

- 9 — Ph.D. Deputy Director for Research Ufa Scientific and Technical Center LLC ▪ Orcid

Abstract

The development of new fields with low-permeability reservoirs required the introduction of new production technologies, of which the most significant for well killing and underground repair were multi-ton hydraulic fracturing, the simultaneous operation of two or three development sites by one well grid, and an increase in the rate of fluid extraction. These global decisions in field development have led to the need to search for new effective materials and technologies for well killing. The article is devoted to the analysis of problems associated with the process of killing production wells in fields characterized by increased fracturing, both natural and artificial (due to hydraulic fracturing), with reduced reservoir pressure and a high gas factor. The relevance of the analysis is due to the increase in the number of development sites where complications arise when wells are killed. Particular attention is paid to technical solutions aimed at preserving the filtration and capacity properties of the bottomhole formation zone, preventing the absorption of process fluid, and blocking the manifestation of gas. The classification of block-packs used in killing is given, based on the nature of the process fluid. Suspension thickened water-salt solutions are considered, forming a waterproof crust on the surface of the rock, which prevents the penetration of water and aqueous solutions into the formation. This approach ensures the safety and efficiency of killing operations, especially when working with formations in which maintaining water saturation and preventing the ingress of the water phase are of critical importance. Modern trends in the development of technology are revealed, and promising areas for further improvement of well killing with absorption control are outlined.

Funding

The work was carried out with the support of the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (grant N AP19679430).

Introduction

The article is a review of scientific and technical literature devoted to the problem of well killing with absorption control for the period from the mid-1970’s to the present. The relevance of the work is the generalization of published materials and the determination of the possibility of using blocking compositions of different nature as process fluids for well killing in complicated mining and geological conditions. Particular attention is paid to polymer-based blocking fluids containing suspended particles with a solid phase, as the most universal and effective.

The global trend in oil field exploitation is a gradual deterioration in the structure of reser-ves [1-4]. Well operation is also accompanied by deterioration of the filtration and capacity characteristics of the bottomhole formation zone [5, 6], gas or water breakthroughs through highly permeable channels, mechanical wear of underground equipment. In order to effectively overcome these complications and maintain the target level of oil production, it is necessary to carry out routine and major repairs. One of the important stages of preparation for such work – well killing – includes the introduction of process fluid into the wellbore to create back pressure in order to prevent oil and gas shows. Analysis of the killing results showed that process fluids have a significant negative impact on the production potential of wells in formations with low permeability and low formation pressure due to the absorption of salt solutions into the productive formation [7, 8].

Killing of wells is the most common operation that accompanies a well throughout its entire period of operation. All underground and major repairs, as well as the treatment of the bottomhole zone of wells, begin with killing. The main causes of complications during well killing are well known. The first in importance is associated with a decrease in phase permeability for oil, which occurs due to an increase in water saturation in the bottomhole zone of the formation. When the water-based repair and technological fluid is absorbed at low reservoir pressures, an increase in water saturation occurs in the bottomhole zone, which is uncharacteristic for the formation as a whole at the current stage of development. This problem is especially acute in low-permeability hydrophilic reservoirs, and to eliminate it, hydrophobizers from among cationic surfactants are added to the killing fluid or mutual solvent treatments are carried out [9]. Such measures make it possible to return wells to their pre-repair operational parameters, but are accompanied by significant additional costs.

The second important reason for the complication is also associated with the penetration of salt solutions into the bottomhole zone – swelling of clay minerals and the formation of poorly soluble salts due to a violation of the salt balance [10]. In this case, permeability for liquid decreases and oil inflow decreases. To prevent these negative phenomena, clay swelling reducers and salt deposit inhibitors are added to the killing fluids, which help to remove the complication, but significantly increase the cost of the process.

There is another type of complications during killing, typical for wells with a high gas factor or development objects in the section of which there are gas interlayers [11]. Gas egress during repair is unacceptable, and to prevent it, surfactant solutions are injected into the bottomhole zone so that the escaping gas forms foam, which again means additional costs. The use of fluids with absorption control essentially eliminates all of the above problems. Absorption control is carried out when repair and technological fluids have properties that prevent them from escaping into the formation.

The objective of the review is to analyze technological solutions related to well killing with absorption control in the conditions of development of fields with low-permeability reservoirs, including natural and artificial fracturing, with a high gas factor and low reservoir pressure. The materials presented in the review work will be useful to field workers when performing well killing in complex mining and geological conditions.

Materials and methods of research

To obtain emulsion blocking compounds for killing, degassed oil, diesel fuel, condensate, mineralized water, emulsifiers, and microcalcites are used [12, 13]. To obtain thickened compositions, water-soluble polymers of synthetic nature (polyacrylamide, polyacrylic acid, polyvinylpyrrolidone, polyethylene oxide) and plant origin (carboxymethyl cellulose, hydroxyethyl cellulose, hyd-roxypropyl guar), biopolymers (xanthan, succinoglucan, scleroglycan), as well as viscoelastic surfactants (zwitterionic compounds) are used [13, 14]. Chalk, microcalcites, boiled halite, dolomite, and siderite are used as colmatants to obtain thickened dispersions [13, 14]. For fractured collectors, fibrous materials are used: asbestos, peat, water-swelling and degradable synthetic fibers [15-17].

The following acids are used as breakers after killing during well development: hydrochloric, formic, acetic, sulfamic; enzymes specific for the decomposition of bio- and plant polymers; peroxides (persulfates, peroxocarbonates, urea hydroperoxide); complexones (oxyethylidenediphosphonic, nitrilotrimethylphosphonic, oxalic acids) [14]. To determine the rheological parameters of blocking fluids (ultimate shear stress, elastic modulus and viscosity modulus), modern rotational viscometers are used, including those with an oscillatory rheometry option [18]. Filtration-blocking characteristics are studied on low- and high-pressure filter presses, as well as using filtration units: imported, for example FDES-645 (Coretest Systems Corporation), and domestic, for example SMP-PS/FES-2R (Kortekh LLC) [19, 20].

Industrial implementation of the preparation of blocking liquids is carried out in accordance with the provisions described in the article [21]. Blocking compounds are prepared at specialized mortar units [12, 22] or using a mobile mixing and averaging unit. The containers used must be equipped with paddle mixers that ensure uniform distribution of chemical reagents throughout the volume, eliminating the occurrence of “dead zones”. The reagent preparation unit or container of the required volume must be equipped with an external electric centrifugal pump, a paddle mixer, an ejector for feeding bulk products, piping to the pump, as well as a line for filling and unloading. It is possible to disperse the powder of the water-soluble reagent-thickener through a dry hydrofunnel of the ejector into a stream of water-salt base created by an electric centrifugal pump. It is allowed to disperse the polymer by pouring it into the water-salt solution in the mixing zone of the paddle mixer in the preparation container.

The piping of the tanks for preparing blocking fluids must have a design that provides for the possibility of flushing it in the event of the occurrence of “gel defects”. Blocking compositions of increased viscosity are prepared by dissolving a water-soluble polymer thickener in a water-salt base and are intended for temporary and reversible reduction of permeability at the boundary of the well wall – the entrance to the formation, control of the absorption of the killing fluid during underground repair of production and injection wells without hydraulic fracturing, including those with abnormally high reservoir pressure (AHRP).

The preparation of a blocking composition with a solid phase includes dissolving a water-soluble polymer thickener on a water-salt basis with subsequent dispersion of particles with a solid phase, which is used as microcalcite of different grades, boiled halite, dolomite. Suspension of solid particles in a polymer solution is intended for temporary and reversible reduction of permeability at the boundary of the well wall – the entrance to the formation, control of absorption of killing fluids during underground repair of production and injection wells, including those with hydraulic fracturing, wells with super-collector interlayers in the section, wells with slotted and gravel filters in conditions with abnormally low reservoir pressure (ALRP) and AHRP.

The preparation of an emulsion blocking composition for killing requires effective dispersion of degassed oil in a water-salt base and a chemical reagent-emulsifier. Emulsion blocking compositions are intended for temporary and reversible reduction of permeability at the boundary of the well wall – the entrance to the formation of producing wells, control of absorption of killing fluids during repair of wells without hydraulic fracturing, wells with a high gas factor (more than 400 m3/t), wells operating water-sensitive reservoirs. The technology for preparing emulsion blocking compositions includes a set of the calculated amount of degassed oil or hydrocarbon solvent in the reagent preparation unit. Then the emulsifier is dosed and mixed for at least 30 min with the electric centrifugal pump of the mixer and stirrer turned on. Then the required amount of water-salt base is added and mixed again for at least 2 h. The emulsion blocking composition can be stored in the preparation container before shipment for no more than 2 h. Before shipment after the specified period, this composition is mixed in the container using a centrifugal pump.

Discussion

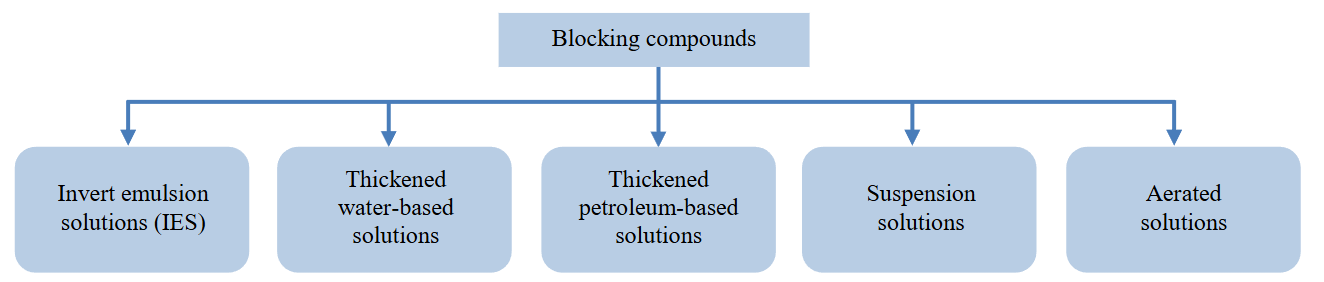

Absorption control during well killing is ensured by two main mechanisms: an increase in the viscosity of the process fluid, as well as crust formation on the surface of the rock, when a suspension of solid particles clogs the pores and filtration channels. In particular, thickened polymer solutions, hydrogels, and reverse emulsions operate according to the first mechanism, while suspension systems operate according to the second. There are several essentially similar classifications of blocking compositions [23, 24]. The scheme proposed in the article [24], based on the nature of blocking fluids seems to us more illustrative (Fig.1). Let us dwell in more detail on the main types of blocking compositions used in killing with absorption control. Historically, the mass introduction of reverse emulsions in well killing was first carried out at Tatneft PJSC in the 1970’s [12]. Special stationary solution units were built, where the reverse emulsion of the required density was prepared. This technology is successfully used at present [25], being a popular tool in capital and underground repair work. Service contractors use emulsifiers that allow creating reverse emulsions for different temperature ranges. Reverse emulsions have proven their effectiveness in killing wells in granular reservoirs. In the case of well killing in fractured reservoirs, as well as in wells with hydraulic fracturing, reverse emulsions do not always cope with their task, because natural and artificially created cracks are capable of absorbing viscous liquids.

An illustrative example of the change in the efficiency of the invert dispersion “Disin”, which is a reverse emulsion stabilized by calcium carbonate and calcium oxide hydrate, was demonstrated at Yuganskneftegaz PJSC. This reagent was proposed by G.S.Pop for killing wells at facilities in Western Siberia [26, 27]. At the beginning of its use, when wells with low-volume hydraulic fracturing were killed, the inverted dispersion “Disin”, which belongs to the class of Pickering emulsion stabilized by solid particles, coped with its task perfectly [28-30]. As the hydraulic fracturing method developed, when the mass of pumped proppant increased to 200-300 t, “Disin” as a block pack ceased to exhibit blocking properties. The fact is that during the operation of the multi-layer object of the Priobskoye field with a single filter, the highly permeable layer is produced more intensively and the formation pressure in it decreases more significantly. And, although “Disin” contained solid stabilizers, it was not possible to create a strong crust on the surface of the proppant packing, because the dispersed particles were submicron in size and were absorbed by the formation. During repair work, a significant amount of repair and technological fluid had to be added to the wells, and subsequently these wells took a long time to develop and did not reach the pre-repair production level. This problem was solved by specialists of RN-UfaNIPIneft LLC by using suspension blocking fluids based on xanthan polymer solutions with a suspended dispersion of microcalcite. Under the leadership of V.N.Gusakov, together with field engineers (O.V.Akimov and others), suspension killing fluids were developed, where xanthan polymer solutions were used as a dispersion medium, and microcalcites of different grades were used as a dispersed phase [31, 32].

Fig.1. Main types of well killing blocking compounds

More effective invert dispersions with a solid phase were proposed to be used by D.V.Mardashov and Sh.R.Islamov [33, 34]. These are reverse emulsions in which dispersions of microcalcite of different sizes are suspended depending on the degree of crack opening (for which an effective emulsifier was selected) for the purpose of killing wells in fractured-porous reservoirs with reduced formation pressure. The fractional composition of microcalcites was calculated purely geometrically according to the criteria of M.Kaeuffer or S.Vickers.

A significant advantage of the block composition based on inverse emulsions is the fact that their external phase is hydrocarbon and does not cause additional filtration resistance when inducing oil inflow after repair. Invert dispersions with granular and fibrous fillers have been successfully used in killing absorbing wells in carbonate reservoirs [35, 36]. This combined solution allows combining two important effects from the use of blocking fluids – not increasing the water saturation of the reservoir and forming a filter cake of solid colmatants. If we compare the effectiveness of invert dispersions with granular fillers and thickened water-based fluids with the same colmatants, then preference should be given to invert dispersions, since they do not introduce an additional water phase into the bottomhole formation zone [37]. The use of invert dispersion is especially relevant in water-sensitive low-permeability granular reservoirs, where the ingress of the aqueous phase into the bottomhole formation zone is unacceptable.

An interesting approach to the use of Pickering emulsion is shown in the work [38], in which emulsions were stabilized by hydrophobic and hydrophilic nanosilicas, which ensured their stability at high temperatures. In the article [39] the emulsion composition was obtained on the basis of “green chemistry”. In particular, biodiesel was used as the hydrocarbon phase – methyl esters of fatty acids obtained by transesterification of rapeseed oil.

The use of thickened water-based solutions for killing wells has also been known for a long time. B.A.Andreson (1976) proposed using salt solutions thickened with polyacrylamide with the addition of surfactants for killing wells at Bashneft PJSC. The surfactant-containing polymer solution “Chance” was successfully used at the fields of YUKOS Oil Company [40] with the introduction of refining additives.

Unlike polymer solutions, hydrogels used as block packs for well killing are more effective because, due to their cross-linked structure, they are practically not filtered into the formation. In particular, in order for a polysaccharide killing fluid based on xanthan or hydroxypropyl guar solutions cross-linked with a borate cross-linker to begin to filter into the formation, a pressure differential of more than 6.0 MPa is required [41, 42]. For killing wells in fractured-porous reservoirs with a high gas factor by D.V.Mardashov and A.V.Bondarenko [20, 43] proposed a hydrogel based on xanthan gum cross-linked with chromium acetate as a block pack. The advantage of such a hydrogel is that it successfully blocks cracks, while possessing high gas-retaining capacity.

The use of hydrogels as blocking fluids has been rapidly developing in recent years due to the possibility of flexible regulation of their properties depending on the conditions of use. Thus, when killing wells in fractured reservoirs, a viscoelastic gel based on oxyethylated cellulose cross-linked with copper sulfate was used. A peroxyhydrate-citric acid system was used as a breaker [44]. For the same purpose in the work [45] a hydrogel based on guar and xanthan gum crosslinked with a borate crosslinker is proposed. This technology is distinguished by a controlled gel decomposition time, which is achieved through the use of an encapsulated breaker – the same peroxyhydrate system with citric acid.

For killing wells in fractured reservoirs with high formation pressure, a sodium bromide-weighted nanocomposite hydrogel system cross-linked with covalent bonds with a density of 1.2-1.5 g/cm3 has been developed [46]. The heat resistance of the blocking composition is determined up to 160 °C, and the gelation time is regulated from 8 to 12 h.

Foam gel based on a double-crosslinked hydrogel (polyacrylamide + Cr3++ polyethyleneimine), foamed due to the release of CO2 during the reaction of acid with carbonates, and was used in the overhaul of wells in reservoirs with low formation pressure and low temperature [47, 48].

For killing wells containing toxic acid gases in associated gas, such as H2S, CO2, SO2, a gel based on plant resin with a crosslinker and pH regulator is proposed. At pH 8, the gel does not break down for 72 h at 150 °C with a concentration in water of H2S – 300 mg/l and CO2 – 100 mg/l. After gelation, the viscosity is 30 Pa∙s, and after the introduction of a breaker for 6 hours it decreases to 3 mPa∙s [49].

A block composition based on salt-resistant partially hydrolyzed polyacrylamide when killing highly watered wells in fractured reservoirs allows not only to carry out repair work without problems, but also to reduce water cut and increase oil production due to the effect of water insulation when gel leaks into cracks [50]. In the article [51] the use of a high-viscosity gel plug in well repair is described, which is convenient in that the viscosity of the gelled composition reaches 30,000 mPa∙s, and after exposure to an acid breaker after 4 h it decreases to 5 mPa∙s. Viscous gelled blocking compositions with adjustable gel decomposition time are used for routine and major repairs of wells in order to reduce the risk of gas manifestations [52].

It should be noted that hydrogels based on partially hydrolyzed polyacrylamide have been increasingly modified with nanoparticles in recent years. The fact is that under severe conditions of temperature and salt aggression, decomposition of block packs based on cross-linked polymer systems occurs. The destruction of hydrogels consists of rupture of the main polymer chains, rupture of cross-links, hydrolysis of the polymer and syneresis [53]. Nanosilica particles interact with their silanol groups with the carboxyl group of partially hydrolyzed polyacrylamide to form a hydrogen bond (proven by IR spectra) [54], thereby enhancing the interaction with water molecules and preventing dehydration and syneresis of the gel [55]; in this case, the nanoparticles are evenly distributed throughout the entire volume of the hydrogel. In the work [56] it has been shown that the introduction of 9 % nanosilica increases the strength of the hydrogel by 5000 %. From the images obtained using an electron microscope, it is evident that the nanoparticles reinforce the hydrogel during gelation in situ, which allows the temporarily blocking material to significantly better withstand temperature, salt and shear effects compared to the hydrogel without the addition of nanosilica. In fractured carbonate formations with low reservoir pressure, it is sufficient to introduce 5 % nanoparticles into the hydrogel, and at the same time, the increase in the structural and mechanical properties of such a nanocomposite allows for trouble-free repair work [57]. Data are provided that the addition of 8 % nanosilica to a gel based on partially hydrolyzed polyacrylamide and an environmentally friendly crosslinker – polyethyleneimine provides a 14-fold increase in the elastic modulus with a viscosity modulus of only 71 Pa, which is extremely favorable from the point of view of low damage to the granular collector [58]. For wells in high-temperature development objects, the nanocomposite gel is obtained from heat-resistant sulfonated polyacrylamide with the addition of secondary-modified laponite, thiourea, and a crosslinker – polyethyleneimine [59]. Authors of the article [60] noted that the linear dimensions of nanosilica significantly affect the properties of nanocomposites. Thus, a hydrogel based on partially hydrolyzed sulfonated polyacrylamide cross-linked with chromium acetate has maximum strength characteristics with nanoparticles of 20-30 nm in size compared to similar gels with the addition of nanosilica of 7-10 nm and 60-70 nm in size.

Specialists from different countries around the world pay much attention to self-destructing hydrogels. Thus, in the works [61, 62] self-destructing gels under the influence of temperature based on pre-formed gel particles are proposed. In the articles [63, 64] gels with an internal breaker with adjustable decomposition time are described. Safe repair time is determined based on laboratory experiments at reservoir temperature. In order to predict the time of thermal self-destruction of hydrogel block compositions in the work [65] kinetic experiments were conducted and a mathematical model was developed that coincided with the results of the study of temperature aging with a correlation coefficient of 0.988. This approach allows us to predict the time that block compositions will be in working condition and to estimate the safe period for carrying out repair work on wells.

Variants of using gel-fiber systems for temporary blocking of the formation are considered. Cellulose nanofibrils were added to the hydrogel based on heat-resistant sulfonated polyacrylamide cross-linked with polyethyleneimine [66]. At the same time, such a nanofibrous composite was superior in its structural-mechanical and heat-resistant properties to a nanocomposite with the addition of an equal amount of nanosilica. The fibrous synthetic filler was fed into a high-temperature well in a polymer solution, where, over a pre-calculated time, the synthetic fibers were hydrolyzed with the release of organic acids, which in turn destroyed the polymer [67]. Summarizing the analysis of the use of block compositions, we can note the review in the article [68], where the properties of gels obtained in situ, methods for increasing their thermal stability and structural-mechanical properties, regulating the rate of gelation, methods of destruction and self-destruction are summarized.

Viscoelastic surfactant compositions based on zwitterionic compounds are increasingly used as hydrogel block packs [69, 70], which have a significant advantage over hydrogels based on water-soluble polymers – they are destroyed upon contact with oil and water, causing an influx after repairs.

Thickened petroleum-based solutions (commercial thickened petroleum) [71] are used to kill wells with low reservoir pressure. Recently, their use has been very limited in accordance with fire safety regulations. Although in some production enterprises, for example in Slavneft-Megionneftegaz PJSC, hydrocarbon-based blocking fluids were once quite widely used [72]

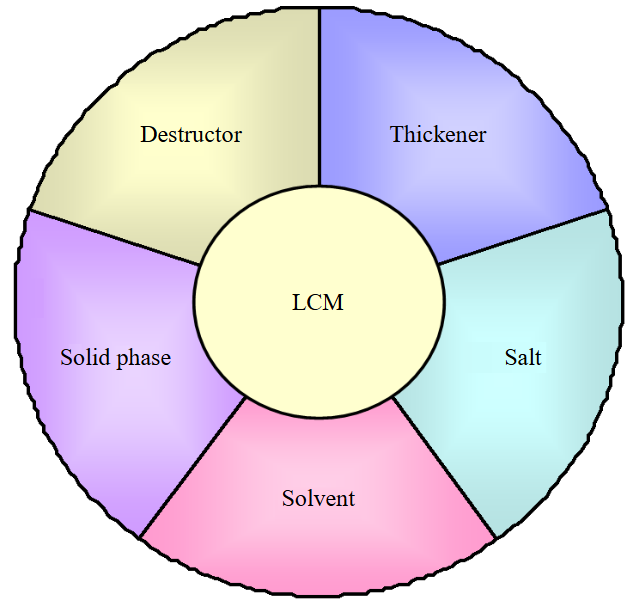

The use of water-based suspension blocking compositions has also been known for a long time. At first, clay solutions were used in this capacity, which, although they had a slight advantage over mineral salt solutions, were not effective enough due to the colmatation of the bottomhole formation zone. In particular, S.Z.Zaripov (1981) showed that killing wells with clay solutions (Bashneft PJSC) in the 1970s led to a significant decrease in well productivity. Research by the service company M-I Swako convincingly showed that it is most expedient to suspend the colmatant particles in thickened solutions of biopolymers. Since biopolymers of microbial origin have a branched structure and fairly high values of the viscoelastic component of complex viscosity, suspended particles do not settle. In addition, in the works [73, 74] the calculation of the optimal fractional composition of colmatating particles depending on the diameter of the pores of the rock is given. Implementation of technologies using absorption control materials (Liquid Control Materials – LCM), or LCM technologies, involves the use of such components as a water-salt base, a water-soluble polymer thickener, a breaker for breaking down the polymer and restoring permeability (Fig.2) [75]. Industrial water is used as a water-salt base, as well as solutions of mineral salts (water-soluble polymers used as thickeners).

The main technological disadvantages of polymer thickeners are the risk of obtaining “gel defects” [76] and a significant loss of viscosity with increasing temperature. Only systems thi-ckened with succinoglycan and erucylamidopropyl betaine (belongs to the class of high-viscosity surfactants) retain their viscosity up to 70 °С [75].

Fig.2. System of components for the implementation of LCM technologies

To maintain the production potential of wells and quickly bring them into operation after killing when using polymer blocking fluids, it is necessary to use breakers individually selected for each class of thickeners. Breakers affect the carbon chains of polymers, chemically modify the functional groups of macromolecules and destroy the network structure of hydrogels. Peroxides, enzymes, acids and complexones are used for these purposes. Breakers are used in two variants. In the first case, the breaker is a component of the process fluid. This variant is possible when the breaker action begins with a long induction period. By this time, the main operations of the current well repair should be completed, and after the destruction of polymer molecules when well is stimulated, the permeability coefficient is restored. According to the second variant, the breaker is pumped in after the main stages of well repair and also ensures permeability restoration. Polymer-free thickened fluids do not require the use of a breaker, since the viscosity of such a system is reduced upon contact with water or oil, causing an influx after repair [77, 78]. Due to the fact that the zwitterionic surfactants used for these purposes have good surface-active properties, after the destruction of cylindrical micelles with viscoelastic properties, an easier influx triggering is achieved. When using suspension blocking killing fluids, it is possible to use modifying additives from the glycol class, which reduce the adhesion of the colmatant crust to the surface of the rock [74].

Another method of forming a filter cake with a small depth of penetration of colmatants into the formation is carried out by selecting the fractional composition of the colmatant corresponding to the distribution of pores by size. If the particle size is much smaller than the average diameter of the pores, then undesirable penetration of these particles into the filtration channels will occur; particles with a diameter much larger than the pore sizes are not capable of forming a low-permeability cake, which leads to fluid absorption during repair.

Optimization of the colmatant size comes down to selecting the composition of dispersions of different sizes [79]. According to the Ideal Packing Theory (IPT, M.Kaeuffer), the selection is carried out by the method of approximating the dependence “integral fractional composition – square root of the particle diameter” to an ideal straight line. Another option for optimizing the particle size distribution (according to S.Vickers) is specified by a curve with parameters [79] at diameters: Dmax – particle fraction 90 %; 2/3Dmax – 75 %; 1/3Dmax – 50 %; 1/7Dmax – 25 %; Dmin – 10 %. To create the densest filter cake according to the A.Abrams criterion, a colmatant with a particle diameter of 1/7 to 1/3 of the pore diameter is required. The densest low-permeability and thin filter cake can be obtained by selecting particles by size according to the S.Vickers criterion (Table 1 [79]).

Table 1

Results of tests of filter cakes formed by well killing fluids

|

Disc pore size, µm |

Parameter |

Calculation of the fractional composition of the colmatant according to the criteria |

||

|

S.Vickers |

М.Kaeuffer |

A.Abrams |

||

|

5 |

Filtration efficiency, cm3/30 min |

21.0 |

22.0 |

30.0 |

|

Recovery coefficient, % |

93.8 |

49.5 |

61.5 |

|

|

20 |

Filtration efficiency, cm3/30 min |

20.0 |

42.0 |

23.0 |

|

Recovery coefficient, % |

85.7 |

69.5 |

80.9 |

|

|

60 |

Filtration efficiency, cm3/30 min |

20.8 |

31.0 |

19.0 |

|

Recovery coefficient, % |

86.2 |

78.1 |

93.5 |

|

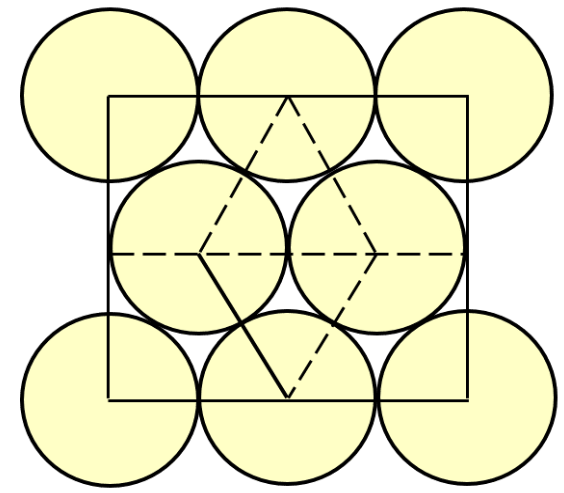

It should be noted that the justified composition of the colmatant can be determined with knowledge of the distribution of pore sizes in the porous medium. For the use of a blocking fluid with a solid phase in wells after hydraulic fracturing, finding the optimal size of dispersed particles is simplified, since the proppant size for each well is known (Fig.3). The algorithm of actions intended for the practical use of the technology of killing with absorption control is indicated in Table 2 [14]. The field experience of RN-Yuganskneftegaz LLC in killing wells with absorption control, carried out according to the algorithm given in Table 2, confirmed the correctness of the chosen solution [14, 31]. The use of microcalcite as a solid phase for suspension blocking fluids is safe, since this colmatant is easily soluble in acid when needed [80]. The use of polymer thickeners is characterized by the risk of the formation of so-called gel defects, which arise due to incomplete polymer dissolution in a

Fig.3. Graphical construction of calculation of proppant packing transparency

water-salt base. To prevent this phenomenon, dispersion of the polymer in non-aqueous polar solvents is used. Modern technologies of well killing with absorption control are developing rapidly, since they reduce the consumption of aqueous brines and, accordingly, reduce the number of complications caused by the intensive development of terrigenous and carbonate reservoirs. Thus, in 2008, RN-UfaNIPIneft LLC, together with employees of RN-Yuganskneftegaz LLC, deve-loped and patented an effective solution for killing multi-layer wells of the Priobskoye field with multi-tonnage hydraulic fracturing [32, 81]. In comparative tests with the technology of M-I Swaco (Seal-N-Peel), the Russian version using a block-composition of muffling

with microcalcite (BSG-MK) showed comparable efficiency.

Table 2

Algorithm for selecting a well killing design with absorption control

|

Required calculation parameter |

Source of information |

The characteristic being determined |

Algorithm of action |

|

Volume of blocking killing fluid V, m3 |

Oil and gas production workshop data |

Specific volume of the well in the zonefrom the current bottomhole to the upperperforation holes |

V = 0.001Vsp [hcrnt.btm – hup + 150] + + Vexc |

|

Excess volume of blocking killing fluid Vexc, m3 |

Oil and gas production workshop data |

Position of the upper perforations and the perforated interval |

Vexc = 0.0007hup + КhperfК = 0.05 и 0.01 m3/m for directional and horizontal wells |

|

Reservoir pressure P0 at the start of repairs, Pa |

Oil and gas production workshop data |

Excessive wellhead pressure Рexcby water at the beginning of repairs |

Р0 = ρgh + Рexc |

|

Reservoir pressure Prfor the duration of the repair, Pa |

Data from hydrodynamic studies of wells |

Pressure recovery curve for a well |

Pr = P0 + K(T)½ |

|

Density of the killing fluid at 20 оС taking into account thermal expansion at positive temperature ρ(t), kg/m3 |

Reference literature |

Thermal expansion coefficient of the kill solutiona ≈ 0.5838 kg/(m3·°С) |

ρ(t) = ρ(20) – α(t – 20) |

|

Daily forecast of change in density of kill fluid taking into account the pressure recovery curve |

Estimated data |

Reservoir temperature and pressure

|

Calculation of the density of the killing fluid with correction for the pressure recovery curve |

|

Proppant grain pore mouth diameter Dmax – Dmin, µm |

Well passport |

Fractional composition of proppant |

Proppant brand |

|

Fractional composition of a mixture of microcalcites for the formation of a filter cake |

Filling theory (according to S.Vickers criterion) |

Criterion according to S.Vickers:Dmax – 90 %2/3Dmax – 75 %1/3Dmax – 50 %1/7Dmax – 25 %Dmin – 10 % |

Minimization of deviation of the model curve of microcalcites from the curve according to S.Vickers (software product) |

|

Thickener concentration in the blocking killing fluid |

Experimental data |

Dependence of sedimentation stability of suspension on thickener concentration |

Visual observation of suspension stability |

|

Effective viscosity of blocking killing fluid |

Experimental data |

Flow time of 500 cm3 of blocking liquid on the VBR-2 viscometer in laboratory and field conditions |

Determination of the flow time of 500 cm3 of blocking liquid on the VBR-2 viscometer |

Notes: K – permeability, μm2; hcrnt.btm– distance from wellhead to current bottomhole, m; hup – distance from wellhead to upper perforation holes, m; hperf– perforation interval, m; hvert – vertical depth of upper perforation holes, m; g – acceleration of gravity, m/s2; T, t – formation temperature, °C.

In 2009, a number of production companies of Rosneft Oil Company introduced the technology of a suspension blocking fluid with a self-destructing colmatating solid phase – halite (BSG-halite) [82]. The main technological advantage of such a composition is the ability of solid shunting particles to completely dissolve when causing an influx of watered products after completion of underground well repair (UWR). This feature allows eliminating the risk of colmatation of the bottomhole formation zone, installing a block pack with squeezing onto the formation, carrying out flushing and normalization of the bottomhole in conditions of absorption. Due to the growth of the initial shear gradient when a free gas phase appears, this material can be successfully used for killing oil wells with a high gas factor and gas condensate wells [83]. A similar approach to the use of water-soluble salt dispersions is described in a later publication [84]. The use of a dispersion of polyethylene wax and oil-soluble phenolic resin with rosin is known as oil-soluble colmatants. The advantage of such materials is that when well is stimulated they completely dissolve in oil. According to core studies, they provide a permeability recovery coefficient from 0.90 to 0.95 [85].

Another typical example of the use of block packs is demonstrated during the killing of wells at Jurassic sites developed by Kharampurneftegaz LLC, where the work is complicated by a number of negative factors, such as low permeability of the hydrophilic reservoir, high gas factor, and low reservoir pressure. In order to eliminate the impact of these complications on the success of UWR, an approach to the killing technology was developed, which consists in combining several types of process fluid, which, when used together, allow to minimize the risks of reducing the production potential of wells [19]. Thus, to prevent gas leaks, a blocking liquid based on the polymer “Biopol” and surfactants (gas blocking composition – GazoBS) has been developed, which acts due to its viscoelastic properties (polymer) and foaming ability upon contact with gas (surfactant).

A spacer fluid designed to prevent swelling of clay cement, reduce interfacial tension and restore phase permeability to oil was developed on the basis of a 6 % HCl solution with the addition of a surfactant-hydrophobizing agent (spacer hydrochloric acid fluid – BufSK). The blocking killing compositions BSG-MK and BSG-halite were used to prevent absorption of the killing fluid at reduced formation pressure in wells with hydraulic fracturing. Pilot-field work was carried out on 23 wells, where the GazoBS block-packs were used 21 times, BufSK – 9 times, BSG-halite and BSG-MK – 14 and 9 times, respectively (Table 3). All wells underwent UWR to replace the electric centrifugal pump without changing its size, as well as to replace/review the tubing. Borehole normalization was performed on two wells. The observed slight increase in fluid flow rate after UWR is due to cleaning of perforation holes from calcite deposits due to the action of BufSK and abrasive cleaning of paraffin deposits – with BSG-halite and BSG-MK compositions.

Table 3

Results of pilot-field work tests of process fluids

|

Blocking liquid |

Number of tests |

Total relative flow rate, before UWR / after UWR (bringing to stable production), % |

||

|

Total |

With a decrease in oil flow rate during the well's commissioning |

Liquid |

Oil |

|

|

BSG-MK |

9 |

2 |

100/100.6 |

100/100.5 |

|

BSG-halite |

14 |

2 |

100/102.4 |

100/104.3 |

|

BufSK |

9 |

0 |

100/100.7 |

100/105.4 |

|

GazoBS |

21 |

3 |

100/102.7 |

100/101.6 |

|

Total wells |

23 |

3 |

100/102.5 |

100/102.8 |

The use of aerated fluids for well killing is necessary in fields with ALRP to avoid the absorption of the killing fluid into the formation. Back in the 1970s, A.V.Amiyan proposed using two- and three-phase foams for this purpose [86]. Subsequently, this technology was successfully extended to gas and gas condensate fields, which are very sensitive to the water phase in the bottomhole formation zone [87]. At the same time, the use of foam systems for well killing is complicated by their instability over time, as well as destruction upon contact with oil. Rapid restoration of the properties of foam systems in the wellbore is possible by their repeated circulation.

For the suppression of gas condensate objects with low reservoir pressure and high temperature, a foam-polymer composition with increased foam stability based on sodium dodecyl sulfonate and dodecyl methyl betaine, stabilized with xanthan gum [88] and polyurethane thickener [89] is proposed. The composition remains functional at mineralization up to 10,000 mg/l and temperature up to 150 °C for 24 h. If the well repair lasts longer, it is necessary to restore the foam system in the wellbore by pumping in new portions [88]. This article provides an example of a well repair to remove sand from the bottomhole, which lasted 58 h and went without complications. The work described [88] the technical solution involves the use of complex additional equipment – a tanker-pumper of liquid nitrogen or a mobile truck-generator of nitrogen, a foam generator. The use of self-generating foam gel systems as blocking liquids [90] allows for repair work at high temperatures without the risk of reducing the volume of nitrogen foam. This foam gel system consists of a gel-forming composition, a gas-generating mineral composition, and a surfactant. Due to its low density, the foam gel is easily removed from the wellbore when well is stimulated. The high stability of foam gels over time and at elevated temperatures is due to the fact that the foam lamellas are a cross-linked polymer composition with high structural and mechanical properties [91].

Another promising direction for objects with ALRP is the use of aphrons – microbubble systems stabilized from polymer and surfactant solutions, first proposed by M-I Drilling Fluids. Initially, these aerated fluids were used in drilling [92, 93].

Based on the materials presented in this review article, recommendations have been made for the use of various blocking compositions of killing fluids (Table 4). For killing in conditions of multiple complications, a combination of several types of blocking killing fluids is required, as well as the development of a selection matrix and application technology in the conditions of a specific research object, fixing the injection order, risks, and limitations of applicability.

Table 4

Selection of well killing fluids

|

Blocking fluid for well killing |

Basis for selection of blocking killing fluid |

|

IES |

Wells in granular and fractured reservoirs without hydraulic fracturing with normal reservoir pressure |

|

IES with dispersed or fibrous fillers |

Wells in granular reservoirs with hydraulic fracturing. Wells in fractured reservoirs with normal reservoir pressure and ALRP. Fact of gas shows for the previous UWR |

|

BSG-halite |

Wells in granular and fractured reservoirs with normal reservoir pressure and ALRP. The fact of excess of the kill solution consumption is 30 m3 higher than according to the technological plan of kill for the previous DPW (or excess of the kill solution filling rate by more than 1 m3/h) |

|

BSG-MK |

Wells in granular and fractured reservoirs with hydraulic fracturing with normal reservoir pressure, ALRP and AHRP. The fact of excess of the consumption of the killing solution is 30 m3 higher than according to the technological plan of killing for the previous UWR (or excess of the rate of adding the killing solution over 1 m3/h) |

|

BSG-MK |

Wells in multi-layer objects operated by a single filter, granular and fractured reservoirs with hydraulic fracturing with normal reservoir pressure, ALRP and AHRP. The fact of excess of the consumption of the killing solution is higher by 30 m3 than according to the technological plan of killing for the previous UWR (or excess of the rate of adding the killing solution over 1 m3/h) |

|

IES with dispersed or fibrous fillers |

Wells in multi-layer objects operated by a single filter, granular and fractured reservoirs with hydraulic fracturing with normal reservoir pressure, ALRP and AHRP. The fact of excess of the consumption of the killing solution is higher by 30 m3 than according to the technological plan of killing for the previous UWR (or excess of the rate of adding the killing solution over 1 m3/h) |

|

GazoBS |

Wells in granular and fractured reservoirs with normal reservoir pressure, ALRP and AHRP. Fact of gas shows for the previous UWR with a gas flow rate of at least 1000 m3/day |

|

BufSK |

Wells in granular low-permeability water-sensitive reservoirs. Water cut of produced fluid is less than 50 %. Requires combination with a second block-pack (IES, BSG-halite, BSG-MK) |

Conclusion

Let us note several main trends in the development of the technology of well killing with absorption control. In the perimeter of the post-soviet countries, the first trend is the implementation of scientific development of these technologies in oil universities and institutes. Thus, at the St. Petersburg Mining Institute, under the leadership of M.K.Rogachev and D.V.Mardashov, a range of modern well killing technologies has been developed that respond to almost all production challenges [94-97]. At the Russian Gubkin State University of Oil and Gas, under the supervision of L.A.Magadova and M.A.Silin, a method of killing using a polysaccharide liquid as a block pack was developed and implemented [98]. At the Ufa State Petroleum Technological University, under the leadership of Yu.V.Zeigman and V.Sh.Mukhametshin, this direction is also successfully developing [99].

The second trend is the development, adaptation and optimization of the technology of killing with absorption control in industry research institutes. Here, the undisputed leader is RN-BashNIPIneft LLC. This institute supports this direction in the perimeter of Rosneft Oil Company, where development objects, radically different from each other in their geological and physical characteristics, are geographically located in almost all regions of Russia. In this regard, universal technical solutions are impossible, and for each characteristic group of fields it is necessary to optimize the best technologies. It should be noted that the systematic approach of RN-BashNIPIneft LLC employees allowed them to first systematize technical solutions for well killing in different mining and geological conditions, clearly substantiate the criteria for the applicability of block packs of different nature [100], and then adapt and optimize the technologies of well killing for specific development objects. Thus, for the carbonate object of the Kuyumbinskoye oil and gas condensate field, suspension and foam gel block-packs were adapted [101]. For deposits in Eastern Siberia with low-temperature, highly permeable terrigenous reservoirs, suspension block packs with instant filtration are recommended, capable of quickly forming a strong crust and preventing the absorption of process fluid [102]. For killing gas wells exploiting Achimov deposits, RN-BashNIPIneft LLC recommended the use of suspension block packs, in which a heat-resistant polymer is used as a thickener, as well as a modified salt composition based on viscoelastic surfactants [103].

The third trend is the wide variety of technical solutions offered by service companies on the service market. Each service company has its own range of technical solutions, with which they present them to tender commissions of oil companies. In this type of business, it is necessary to note such service companies as Mirrico Group of Companies [104], Zirax Group of Companies [105].

The use of nanocomposite hydrogels is clearly visible in the development trend of absorption-controlled wellbore killing technologies abroad; moreover, the application options for hydrogel-based block compositions are quite diverse depending on reservoir conditions and the technical task of repair [68]. Comparing the technical level of Russian and foreign approaches, it can be noted that the development of the level of technology and engineering in this direction is proceeding in parallel courses without any obvious advancement or lag of either side. Publications by Russian specialists are regularly published in prestigious international journals of the Q1 level, which testifies to the worldwide recognition of the relevance and novelty of the published materials.

Thus, it is safe to state that today well killing technologies with absorption control in the oil industry are successfully used all over the world. In Russia, the production needs for adapting technical solutions to specific geological and physical conditions are met by industry institutes and service firms. A stable services market has formed, which undoubtedly contributes to progress in this area. Let us pay attention to aerated fluids for absorption control, in particular aphrons, the discussion of the structure and properties of which continues to this day [106]. However, they are already being used stably in drilling, and this direction is developing [107-110]. There is a mention of the use of aphron-like compounds for waterproofing [111], and there are only a few publications on their use for well killing, from which the potential of this approach is evident; for example, in the use of aphron-like foam plastic blocking fluids formed by the interaction of surfactants and polymers with a gas-liquid system, which are called fuzzy-balls [112, 113].

References

- Shmal G.I. The Problem of Developing Oil Difficult to Recover in Russia and Solution Approaches. Georesources. 2016. Vol. 18. N 4. Part 1, p. 256-260 (in Russian). DOI: 10.18599/grs.18.4.2

- Iskritskaya N.I., Makarevich V.N., Schepochkina A.A. Changes in the structure of the hard-to-recover oil reserves caused by transition to the new classification. Neftegazovaya Geologiya. Teoriya i praktika. 2016. Vol. 11. N 4, p. 12 (in Russian). DOI: 10.17353/2070-5379/44_2016

- Khafizov F.Z. Problems of development of hard-to-recover reserves. Nedropolzovanie XXI vek. 2014. N 3 (47), p. 68-73 (in Russian).

- Korotkevich A.I. The role of hard to recover reserves in conditions of deterioration of the structure of reserves. Neftegaz.RU. 2018. N 6 (78), p. 52-57 (in Russian).

- Fung Van Khay, Shamaev G.A., Nguen Khyu Nyan et al. Basic problems reducing permeability near wellbore of the lower oligocene (“White tiger” oilfield). Bashkir chemistry journal. 2008. Vol. 15. N 2, p. 135-139 (in Russian).

- Erofeev A.A., Mordvinov V.A. Changing the properties bottom-hole within the development of Bobrikovsky Unvinskogo deposit. Perm Journal of Petroleum and Mining Engineering. 2012. Vol. 11. N 5, p. 57-62 (in Russian).

- Dmitruk V.V., Rakhimov S.N., Boyarkin A.A., Shtakhov E.N. Improving the effectiveness of killing wells of Urengoyskoye field. Oil Industry Journal. 2010. N 5, p. 130-135 (in Russian).

- Vakhrushev S.A., Mikhailov A.G., Kostin D.S. et al. Production wells killing on R.Trebs high-temperature cavernous-fractured carbonate deposits. Oil Industry Journal. 2017. N 10, p. 41-45 (in Russian). DOI: 10.24887/0028-2448-2017-10-41-45

- Khakimov A.M., Makatrov A.K., Karavaev A.D. et al. Filtration testing of a new generation of domestic and foreign surfactants as additives to repair and technological fluids during underground repairs and wellbore maintenance in hydrophilic reservoirs. Neftepromyslovoe delo. 2005. N 12, p. 48-53 (in Russian).

- Atvinovskaya T.V. The role of killing fluid in the well repair process. Vestnik Gomel'skogo gosudarstvennogo tekhni-cheskogo universiteta imeni P.O.Sukhogo. 2018. N 2, p. 34-41 (in Russian).

- Kravtsov A.A., Mukhutdinov A.A., Gryadunov D.A. Killing wells in conditions of low production rates and high gas factor at the fields of JSC Orenburgneft. Inzhenernaya praktika. 2018. N 11 (in Russian).

- Orlov G.A., Kendis M.Sh., Glushchenko V.N. Применение обратных эмульсий в нефтедобыче. Moscow: Nedra, 1991, p. 224 (in Russian).

- Mardashov D.V. Justification of technologies for regulating the filtration characteristics of the bottomhole zone of wells during underground repairs: Avtoref. dis. ... kand. tekhn. nauk. St. Petersburg: Sankt-Peterburgskii gosudarstvennyi gornyi institut imeni G.V.Plekhanova, 2008, p. 20 (in Russian).

- Akimov O.V. Improving well killing technologies during intensification of development of low-permeability terrigenous reservoirs: Avtoref. dis ... kand. tekhn. nauk. Ufa: Ufimskii gosudarstvennyi neftyanoi tekhnicheskii universitet, 2011, p. 23 (in Russian).

- Bustos O., Ali S., Ngujen C. Patent N 2499131 RF. Application of degradable fibers in solutions of inverted emulsions for well killing. Publ. 20.11.2013. Bul. N 32 (in Russian).

- Perejma A.A., Cherkasova V.E., Gasumov R.R. Patent N 2330055 RF. Method of making polydisperse peat reagent for boring solutions and kill fluids. Publ. 27.07.2008. Bul. N 21 (in Russian).

- Gasumov R.A., Kostyukov S.V., Gasumov R.R. et al. Maintenance of filtration and capacitive reservoir properties during temporary isolation. Oil and Gas Studies. 2017. N 4, p. 58-66 (in Russian). DOI: 10.31660/0445-0108-2017-4-58-66

- Schramm G. A practical approach to rheology and rheometry. Moscow: KolosS, 2003, p. 312 (in Russian).

- Gusakov V.N., Korolev A.Yu., Yagudin R.A. et al. Well silencing technologies in conditions of multiple complications. Petroleum Engineering. 2023. Vol. 21. N 2, p. 17-24 (in Russian). DOI: 10.17122/ngdelo-2023-2-17-24

- Bondarenko A.V., Mardashov D.V., Islamov Sh.R. Assessing the Effective Implementation of Blocking Polymer Compositions for Well Control Operation in the Conditions of Carbonate Reservoir and High Gas-Oil Ratio. Petroleum Engineering. 2022. Vol. 20. N 1, p. 53-64 (in Russian). DOI: 10.17122/ngdelo-2022-1-53-64

- Silin M.A., Magadova L.A., Akimov O.V. et al. Advanced technologies for wells killing. Oil Industry Journal. 2015. N 1, p. 66-70 (in Russian).

- Mannapov G.M., Khazimuratov R.Kh., Smykov Yu.V., Safuanova R.M. Experience in organizing the work of the process fluid preparation unit. Neftepromyslovoe delo. 2006. N 4, p. 36-39 (in Russian).

- Mardashov D.V. Development of blocking compositions with a bridging agent for oil well killing in conditions of abnormally low formation pressure and carbonate reservoir rocks. Journal of Mining Institute. 2021. Vol. 251, p. 667-677. DOI: 10.31897/PMI.2021.5.6

- Kraevskiy N.N., Islamov R.A., Lind Yu.B. Selection of well killing technology for complex geological and technological conditions. Petroleum Engineering. 2020. Vol. 18. N 4, p. 16-26 (in Russian). DOI: 10.17122/ngdelo-2020-4-16-26

- Glushchenko V.N., Khizhnyak G.P. Directions for Improving the Compositions of Reverse Emulsions for Well Plugging. Perm Journal of Petroleum and Mining Engineering. 2023. Vol. 23. N 1, р. 44-50 (in Russian). DOI: 10.15593/2712-8008/2023.1.6

- Pop G.S. Causes of occurrence and methods of elimination of gas manifestations in wells. Moscow: VNIIEgazprom, 1991, p. 19 (in Russian).

- Pop G.S., Kucherovskii V.M., Zotov A.S., Bodachevskaya L.Yu. Killing wells in conditions of decreasing reservoir pressure at fields in Western Siberia. Neftepromyslovoe delo. 2002. N 11, p. 26-29 (in Russian).

- Kulikov A.N., Ismagilov T.A., Shadymukhametov S.A., Telin A.G. Development and application of new compositions for well killing at YUKOS oil fields. Vestnik Inzhiniringovogo tsentra YuKOS. 2002. N 4, p. 52-55 (in Russian).

- Kulikov A.N., Ismagilov T.A., Telin A.G., Khakimov A.M. Application of invert dispersion “Disin” for killing of absorption wells after hydraulic fracturing. Bashkir chemistry journal. 2001. N 3, p. 73-75 (in Russian).

- Lezov G.O., Yashin V.I., Ismagilov T.A. et al. Technology of combined killing and secondary opening of oil wells using inverted dispersion “Disin”. Oil Industry Journal. 1994. N 2, p. 48-51 (in Russian).

- Zdolnik S.E., Zgoba I.M., Telin A.G., Gusakov V.N. Problems of well killing at Priobskoye field and ways to solve them. Nauchno-tekhnicheskii vestnik OAO “NK “Rosneft”. 2006. N 1, p. 36-39 (in Russian).

- Akimov O.V., Zdolnik S.E., Khudyakov D.L. et al. Well kill technologies with fluid loss control for hydro-fractured wells under AHFP and ALFP Conditions. Oil Industry Journal. 2010. N 2, p. 92-95 (in Russian).

- Islamov Sh.R., Bondarenko A.V., Mardashov D.V. Substantiation of a well killing technology for fractured carbonate reservoirs. Youth Technical Sessions Proceedings. CRC Press, 2019, p. 256-264. DOI: 10.1201/9780429327070-35

- Mardashov D., Islamov S., Nefedov Yu. Specifics of well killing technology during well service operation in complicated conditions. Periódico Tchê Química. 2020. Vol. 17. N 34. p. 782-792. DOI: 10.52571/PTQ.v17.n34.2020.806_P34_pgs_782_792.pdf

- Islamov Sh.R. Justification of the technology of killing oil wells before underground repair in conditions of fractured-porous carbonate reservoirs: Avtoref. dis. ... kand. tekhn. nauk. St. Peterburg: Sankt-Peterburgskii gornyi universitet, 2021, p. 20 (in Russian).

- Shamsutdinov R.D. Application of fibrous fillers in invert emulsion solutions to improve the quality of well workovers: Avtoref. dis. ... kand. tekhn. nauk. Ufa: Ufimskii gosudarstvennyi neftyanoi tekhnicheskii universitet, 2002, p. 24 (in Russian).

- Islamov S., Islamov R., Shelukhov G. et al. Fluid-Loss Control Technology: From Laboratory to Well Field. Processes. 2024. Vol. 12. Iss. 1. N 114. DOI: 10.3390/pr12010114

- Sergeev V., Tanimoto K., Abe M. Innovative Emulsion-Suspension Systems Based on Nanoparticles for Drilling and Well Workover Operation. Abu Dhabi International Petroleum Exhibition & Conference, 11-14 November 2019, Abu Dhabi, United Arab Emirates. OnePetro, 2019. N SPE-197510-MS. DOI: 10.2118/197510-MS

- Uliasz M. Workover fluid for the reconstruction of wells with reduced reservoir pressure. Nafta-Gaz. 2020. Vol. 76. N 7, p. 457-465 (in Polish). DOI: 10.18668/NG.2020.07.04

- Shadymukhamedov S., Kulikov A. Development of work to improve the quality of well killing at YUKOS Oil Company. Nauchno-tekhnicheskii vestnik YuKOS. 2003. N 7, p. 30-32 (in Russian).

- Magadova L.A., Silin M.A., Gaevoy E.G. et al. Killing and washing fluids preserving reservoir characteristics of the formation. Coiled Tubing Times. 2009. N 3 (028), p. 72-80 (in Russian).

- Silin M.A., Magadova L.A., Ponomareva V.V. et al. Development of a non-filterable, high-density, water-based polysaccharide kill fluid. Territoriya ”Neftegaz”. 2010. N 8, p. 56-61 (in Russian).

- Bondarenko A.V., Islamov S.R., Ignatyev K.V., Mardashov D.V. Laboratory investigation of polymer compositions for well killing in fractured reservoirs. Perm Journal of Petroleum and Mining Engineering. 2020. Vol. 20. N 1, р. 37-48 (in Russian). DOI: 10.15593/2224-9923/2020.1.4

- Okromelidze G.V., Nekrasova I.L., Garshina O.V. et al. Well killing operation using viscoelastic gels – from theory to practice. Oil Industry Journal. 2016. N 10, p. 56-61 (in Russian).

- Martyushev D.A., Govindarajan S.K. Development and study of a Visco-Elastic Gel with controlled destruction times for killing oil wells. Journal of King Saud University – Engineering Sciences. 2022. Vol. 34. Iss. 7, p. 408-415. DOI: 10.1016/j.jksues.2021.06.007

- Hu Jia, Zheng Kang, Jinzhi Zhu et al. High density bromide-based nanocomposite gel for temporary plugging in fractured reservoirs with multi-pressure systems. Journal of Petroleum Science and Engineering. 2021. Vol. 205. N 108778. DOI: 10.1016/j.petrol.2021.108778

- Hu Jia, Xin-Yu Yang, Jin-Zhou Zhao. Development of a Novel In-Situ-Generated Foamed Gel as Temporary Plugging Agent Used for Well Workover: Affecting Factors and Working Performance. SPE Journal. 2019. Vol. 24. Iss. 4, p. 1757-1776. DOI: 10.2118/194215-PA

- Hu Jia, Hao Chen, Jin-Zhou Zhao. Development of a Highly Elastic Composite Gel through Novel Intercalated Crosslinking Method for Wellbore Temporary Plugging in High-Temperature Reservoirs. SPE Journal. 2020. Vol. 25. Iss. 6, p. 2853-2866. DOI: 10.2118/201090-PA

- Xu Yuan, Tang Yongfan. Development and Application of Temporary Plugging and Killing System Suitable for Sour Gas Field. Oilfield Chemistry. 2022. Vol. 39. N 3, p. 381-386. DOI: 10.19346/j.cnki.1000-4092.2022.03.001

- Hu Jia, Hao Chen. The Potential of Using Cr3+/Salt-Tolerant Polymer Gel for Well Workover in Low-Temperature Reservoir: Laboratory Investigation and Pilot Test. SPE Productions & Operations. 2018. Vol. 33. Iss. 3, p. 569-582. DOI: 10.2118/189460-PA

- Xiong Ying, Xi Yuan, Zhang Yadong, Fu Ziyi. Study of Gel Plug for Temporary Blocking and Well-Killing Technology in Low-Pressure, Leakage-Prone Gas Well. SPE Production & Operations. 2021. Vol. 36. Iss. 1, p. 234-244. DOI: 10.2118/204213-PA

- Shaydullin V.A., Vakhrushev S.A., Magzumov N.R. et al. Features of Killing Wells Operating Fractured Formations with Abnormally Low Formation Pressures and High Gas Factor. SPE Russian Petroleum Technology Conference, 26-29 October 2020. OnePetro, 2020. N SPE-202071-MS. DOI: 10.2118/202071-MS

- Chunming Xiong, Falin Wei, Weitao Li et al. Mechanism of Polyacrylamide Hydrogel Instability on High-Temperature Conditions. ACS Omega. 2018. Vol. 3. Iss. 9, p. 10716-10724. DOI: 10.1021/acsomega.8b01205

- Zhongliang Hu, Maje Haruna, Hui Gao et al. Rheological Properties of Partially Hydrolyzed Polyacrylamide Seeded by Nanoparticles. Industrial & Engineering Chemistry Research. 2017. Vol. 56. Iss. 12, p. 3456-3463. DOI: 10.1021/acs.iecr.6b05036

- Pan Xu, Zhijie Shang, Meiling Yao, Xinxue Li. Mechanistic insight into improving strength and stability of hydrogels via nano-silica. Journal of Molecular Liquids. 2022. Vol. 357. N 119094. DOI: 10.1016/j.molliq.2022.119094

- Zareie C., Bahramian A.R., Sefti M.V., Salehi M.B. Network-gel strength relationship and performance improvement of polyacrylamide hydrogel using nano-silica; with regards to application in oil wells conditions. Journal of Molecular Liquids. 2019. Vol. 278, p. 512-520. DOI: 10.1016/j.molliq.2019.01.089

- Hu Jia, Cheng-Cheng Niu, Xin-Yu Yang. Improved understanding nanocomposite gel working mechanisms: From laboratory investigation to wellbore plugging application. Journal of Petroleum Science and Engineering. 2020. Vol. 191. N 107214. DOI: 10.1016/j.petrol.2020.107214

- Hu Jia, Xin-Yu Yang. Environmental and strength-enhanced nanosilica-based composite gel for well temporary plugging in high-temperature reservoirs. Asia-Pacific Journal of Chemical Engineering. 2019. Vol. 14. Iss. 1. N e2270. DOI: 10.1002/apj.2270

- Hu Jia, Dong-Shan Xie, Zheng Kang. Secondary surface modified laponite-based nanocomposite hydrogel for gas shutoff in wellbore. Journal of Petroleum Science and Engineering. 2020. Vol. 191. N 107116. DOI: 10.1016/j.petrol.2020.107116

- Dijvejin Z.A., Ghaffarkhah A., Sadeghnejad S., Sefti M.V. Effect of silica nanoparticle size on the mechanical strength and wellbore plugging performance of SPAM/chromium (III) acetate nanocomposite gels. Polymer Journal. 2019. Vol. 51. N 7, p. 693-707. DOI: 10.1038/s41428-019-0178-3

- Dao-Yi Zhu, Xing-Yu Fang, Ren-Xian Sun et al. Development of degradable pre-formed particle gel (DPPG) as temporary plugging agent for petroleum drilling and production. Petroleum Science. 2021. Vol. 18. Iss. 2, p. 479-494. DOI: 10.1007/s12182-020-00535-w

- Hong-Jun Zhang, Dao-Yi Zhu, Yong-Long Gong et al. Degradable preformed particle gel as temporary plugging agent for low-temperature unconventional petroleum reservoirs: Effect of molecular weight of the cross-linking agent. Petroleum Science. 2022. Vol. 19. Iss. 6, p. 3182-3193. DOI: 10.1016/j.petsci.2022.07.013

- Bougha A., Ndukauba G., Okeke C., Abudu R. Restoring Integrity and Production on a Well with Compromised Barriers: Use of Crosslinked Polymer Gel to Prevent Fluid Loss Post Well Kill to Enable the Safe Repair of Compromised Christmas Tree Valves. Gas & Oil Technology Showcase and Conference, 13-15 March 2023, Dubai, United Arab Emirates. OnePetro, 2023. N SPE-214228-MS. DOI: 10.2118/214228-MS

- Zeeshan Ahmad, Abdullah Alhaj Al Hosini, Mohammed Ibrahim Al Janahi et al. Challenges of Gas Wells Killing Operation with Emphasis on Reservoir & Completion Integrity Issues. Abu Dhabi International Petroleum Exhibition & Conference, 15-18 November 2021, Dubai, United Arab Emirates. N SPE-208063-MS. DOI: 10.2118/208063-MS

- Hu Jia, Zheng Kang, Sanxi Li et al. Thermal degradation behavior of seawater based temporary plugging gel crosslinked by polyethyleneimine for fluid loss control in gas well: Kinetics study and degradation prediction. Journal of Dispersion Science and Technology. 2021. Vol. 42. Iss. 9, p. 1299-1310. DOI: 10.1080/01932691.2020.1740727

- Yang Yang, Xiaoxuan He, Dalong Sun et al. Pseudointerpenetrating network nanocomposite hydrogel for temporary plugging in fractured reservoirs. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2023. Vol. 656. Part A. N 130369. DOI: 10.1016/j.colsurfa.2022.130369

- Uguna G., Rachid R., Milne A., Ali S. Controlling Losses When Recompleting Low-Pressure Reservoirs. SPE European Formation Damage Conference and Exhibition. 2015. N SPE-174169-MS. DOI: 10.2118/174169-MS

- Zheng Kang, Yin-Tao Liu, Hu Jia et al. Progress and Prospects of In Situ Polymer Gels for Sealing Operation in Wellbore and Near-Well Zone. Energy & Fuels. 2024. Vol. 38. Iss. 5, p. 3539-3563. DOI: 10.1021/acs.energyfuels.3c04382

- Telin A., Lenchenkova L., Yakubov R. et al. Application of Hydrogels and Hydrocarbon-Based Gels in Oil Production Processes and Well Drilling. Gels. 2023. Vol. 9. Iss. 8. N 609. DOI: 10.3390/gels9080609

- Magadova L.A., Silin M.A., Malkin D.N., Krisanova P.K. Patent N 2746499 RF. Viscoelastic composition for use in oil and gas production techniques. Publ. 14.04.2021. Bul. N 11 (in Russian).

- Tokunov V.I., Saushin A.Z. Process fluids and mixtures for oil and gas well production increase. Moscow: Nedra-Biznestsentr, 2004, p. 711.

- Rjabokon S., Martinov B., Doctor S. Technological decisions at completion and workover of the wells, directed on preservation collected properties of productive layers. Burenie & neft. 2008. N 9, p. 4-7 (in Russian).

- Ross C.M., Williford J., Sanders M.W. Current Materials and Devices for Control of Fluid Loss. SPE Asia Pacific Oil and Gas Conference and Exhibition, 20-22 April 1999, Jakarta, Indonesia. OnePetro, 1999. N SPE-54323-MS. DOI: 10.2118/54323-MS

- Dick M.A., Heinz T.J., Svoboda C.F., Aston M. Optimizing the Selection of Bridging Particles for Reservoir Drilling Fluids. SPE International Symposium on Formation Damage Control, 23-24 February 2000, Lafayette, LA, USA. OnePetro, 2000. N SPE-58793-MS. DOI: 10.2118/58793-MS

- Svoboda C. Optimizing High-Temperature Kill Pills: The Åsgard Experience. SPE Drilling & Completion. 1999. Vol. 17. Iss. 1. N SPE-76639-PA. DOI: 10.2118/76639-PA

- Foks K.B. Patent N 2287549 RF. Stable liquid suspension compositions and the method of their production and application. Publ. 20.11.2006. Bul. N 32 (in Russian).

- Semyuel M., Marsinev R., Dzhun K.Zh. Patent N 2004120281 RF. Non-damaging fluid for reducing drilling mud losses and its method of application. Publ. 27.03.2005. Bul. N 9 (in Russian).

- Samuel M., Marcinew R., Al-Harbi M. et al. A New Solids-Free Non-Damaging High Temperature Lost-Circulation Pill: Development and First Field Applications. SPE Middle East Oil and Gas Show and Conference, 9-12 June 2003, Bahrain. OnePetro, 2003. N SPE-81494-MS. DOI: 10.2118/81494-MS

- Vickers S., Cowie M., Jones T. et al. A new methodology that surpasses current bridging theories to efficiently seal a varied pore throat distribution as found in natural reservoir formations. AADE Drilling Fluids Technical Conference, 11-12 April 2006, Houston, TX, USA. American Association of Drilling Engineers, 2006. N AADE-06-DF-HO-16.

- Araujo A., Calderon A. Field Use of Temporary Fluid-Loss Control Pill During Deepwater Completions in HighPermeability Formations. SPE Latin America and Caribbean Petroleum Engineering Conference, 21-23 April 1999, Caracas, Venezuela. OnePetro, 1999. N SPE-53924-MS. DOI: 10.2118/53924-MS

- Akimov O.V., Zdol’nik S.E., Gusakov V.N., Khudjakov D.L., Kraevskij N.N. Patent N 2380391 RF. Well process fluid with controlled absorption in thermo baric-reservoir conditions. Publ. 27.01.2010. Bul. N 3 (in Russian).

- Gusakov V.N., Kraevskiy N.N., Khakimov A.F. et al. Technology of absorption prevention during workover in conditions of low reservoir pressure. Oil Industry Journal. 2013. N 10, p. 50-51 (in Russian).

- Zdolnik S.E., Akimov O.V., Khudjakov D.L., Malyshev A.S., Gusakov V.N., Kraevskij N.N. Patent N 2482152 RF. Borehole process fluid with low damaging properties and controlled absorption in thermobaric formation conditions. Publ. 20.05.2013. Bul. N 14 (in Russian).

- Youssry Abd El-Aziz Mohamed, El-Gindy A.T., El-Agamy H.A. et al. Field Application of Newly Designed Non-Damaging Sealing Killing Fluid to Control Losses in Completion and Workover Operations in Western Desert, Egypt. SPE Trinidad and Tobago Section Energy Resources Conference, 28-30 June 2021. OnePetro, 2021. N SPE-200936-MS. DOI: 10.2118/200936-MS

- Cuixia Li, Xiaoping Qin, Liangchuan Li et al. Preparation and Performance of an Oil-Soluble Polyethylene Wax Particles Temporary Plugging Agent. Journal of Chemistry. 2018. Vol. 2018. Iss. 1. N 7086059. DOI: 10.1155/2018/7086059

- Amiyan V.A., Amiyan A.V. Increasing well productivity. Moscow: Nedra, 1986, p. 159 (in Russian).

- Tagirov K.M., Gasumov R.A., Pereima A.A., Minlikaev V.Z. Foam systems with filler for well killing. Gazovaya promyshlennost. 1999. N 8, p. 50-51 (in Russian).

- Lijuan Pan, Huifeng Liu, Wu Long et al. A Novel Foamy Well Killing Fluid for Low-Pressure Gas Reservoirs in Tarim Basin, China. International Petroleum Technology Conference, 23 March – 1 April 2021. OnePetro, 2021. N IPTC-21434-MS. DOI: 10.2523/IPTC-21434-MS

- Dongdong Liu, Renyuan Sun, Yunfei Zhang et al. A Low Density Micro-Foam Workover Fluid for Deep and Ultra-Deep Wells with Low-Pressure Coefficient and High Inorganic Salt. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2024. Vol. 682. N 132870. DOI: 10.1016/j.colsurfa.2023.132870

- Gurbanov А.G., Baspayev Е.Т. New kill method for gas producing wells. SOCAR Proceedings. 2022. N 2, p. 28-34 (in Russian). DOI: 10.5510/OGP20220200671

- Telin A., Karazeev D., Vezhnin S. et al. Use of Self-Generating Foam Gel Composition with Subsequent Injection of Hydrogel to Limit Gas Inflow in Horizontal Wells of Vostochno-Messoyakhskoye Field. Gels. 2024. Vol. 10. Iss. 4. N 215. DOI: 10.3390/gels10040215

- Vasilchenko C.V., Medentsev S.V. Solving the problems of opening up depleted formations: Aphron technology. Burenie & neft. 2003. N 6, p. 36-37 (in Russian).

- Usanov N.G., Andreson R.K., Gil’vanova E.A., Gusakov V.N., Telin A.G., Kalimullina G.Z. Patent N 2322472 RF. Technological liquid for damping oil and gas hole and method for its preparing. Publ. 20.04.2008. Bul. N 11 (in Russian).

- Bondarenko A.V., Islamov Sh.R., Mardashov D.V. Complex Algorithm for Developing Effective Well-Killing Fluids for Production Wells. Oil and Gas Territory. 2018. N 10, p. 42-49 (in Russian).

- Mardashov D.V., Rogachev M.K., Zeigman Y.V., Mukhametshin V.V. Well Killing Technology before Workover Operation in Complicated Conditions. Energies. 2021. Vol. 14. Iss. 3. N 654. DOI: 10.3390/en14030654

- Duryagin V.N., Limanov M.N., Onegov N.A., Shamsutdinova G.T. Offshore well killing. Burenie & neft. 2023. Special Issue 1, p. 44-47 (in Russian).

- Mardashov D., Duryagin V., Islamov S. Technology for Improving the Efficiency of Fractured Reservoir Development Using Gel-Forming Compositions. Energies. 2021. Vol. 14. Iss. 24. N 8254. DOI: 10.3390/en14248254

- Silin M.A., Magadova L.A., Gaevoy E.G. et al. Application of killing fluids on the polysaccharide base in wells with low pressure and after fracturing. Oil Industry Journal. 2010. N 4, p. 104-107 (in Russian).

- Zejgman J.V., Mukhametshin V.Sh., Khafizov A.R., Kharina S.B. Prospects of Application of Multi-Functional Well Killing Fluids in Carbonate Reservoirs. Socar Proceedings. 2016. N 3, p. 33-39 (in Russian). DOI: 10.5510/OGP20160300286

- Nikulin V.Yu., Mukminov R.R., Mukhametov F.Kh. et al. Overview of promising killing technologies in conditions of abnormally low formation pressures and risks of gas breakthrough. Part 1. Technology classification and experience with water-based and hydrocarbon-based thickened liquids. Petroleum Engineering. 2022. Vol. 20. N 3, p. 87-96 (in Russian). DOI: 10.17122/ngdelo-2022-3-87-96

- Grebenyuk A.N., Kurshev A.V., Korytko I.A. et al. Justification of effective well killing technologies in fractured carbonate reservoirs of Eastern Siberia. Inzhenernaya praktika. 2023. N 3 (in Russian).

- Nikulin V.Yu., Britov E.V., Mukminov R.R. et al. The utilization of composition with spurt loss for control absorptions during killing wells in low-temperature terrigenous reservoirs in Eastern Siberia. Exposition Oil Gas. 2023. Iss. 1, p. 76-80 (in Russian). DOI: 10.24412/2076-6785-2023-1-76-80

- Nikulin V.Yu., Mukminov R.R., Nigmatullin T.E. Reducing the negative impact of high density killing solutions on the productivity of gas wells operating Achimov reservoirs. Part 2. Rationale for the use of blocking compositions. Exposition Oil Gas. 2023. Iss. 4, p. 16-21 (in Russian). DOI: 10.24412/2076-6785-2023-4-16-21

- Demakhin S.A., Merkulov A.P., Kasyanov D.N. et al. Killing wells with block packs is an effective means of preserving the filtration properties of the productive formation. Neft. Gaz. Novatsii. 2015. N 1, p. 66-69 (in Russian).

- Merkulov A.P., Mershiev M.P. Well killing process in conditions of abnormal low formation pressure (ALFP) by the reagent of Zirax group of companies. Neft. Gas. Novacii. 2019. N 7, p. 13-15 (in Russian).

- Yong-li Yan, Yang Zhang, Christian-chibuike Una. On the nature of colloidal aphrons. Colloid and Interface Science Communications. 2020. Vol. 34. N 100232. DOI: 10.1016/j.colcom.2019.100232

- Usanov N.G., Andreson R.K., Gilvanova E.A., Zobov P.M., Andreev V.E., Kotenev Y.A., Khajredinov N.Sh., Poljakov V.N., Kuznetsov Y.S., Khuzin R.R. Patent N 2301822 RF. Drilling fluid. Publ. 27.06.2007. Bul. N 18 (in Russian).

- Natsepinskaja A.M., Grebneva F.N., Iljasov S.E., Okromelidze G.V., Garshina O.V., Khvoshchin P.A., Popov S.G., Klykov P.I. Patent N 2563856 RF. Method of drilling of wells complicated by absorbing horizons. Publ. 20.09.2015. Bul. N 26 (in Russian).

- Rabaev R.U. On the Question of Afron-containing Borehole Mud Application for Drilling Wells under Complicated Conditions on Black Sea Shelf Fields. Problems of Gathering, Treatment and Transportation of Oil and Oil Products. 2021. Iss. 5 (133), p. 9-23 (in Russian). DOI: 10.17122/ntj-oil-2021-5-9-23

- Jinliang Han, Jinsheng Sun, Kaihe Lv et al. Polymer Gels Used in Oil–Gas Drilling and Production Engineering. Gels. 2022. Vol. 8. Iss. 10. № 637. DOI: 10.3390/gels8100637

- Volkov V.A., Belikova V.G. Patent N 2332439 RF. Gas-filled composition for insulation of water-supply to hole. Publ. 27.08.2008. Bul. N 24 (in Russian).

- Xiaoyong Li., Lihui Zheng, Yuanbo Chen et al. Fuzzy-Ball Fluids Enhance the Production of Oil and Gas Wells: A Historical Review. Energies. 2023. Vol. 16. Iss. 18. N 6647. DOI: 10.3390/en16186647

- Fanghui Zhu, Lihui Zheng, Yang Zhao et al. Plugging Efficiency in Fractured Carbonate Gas Reservoirs Using Fuzzy-Ball Fluids Combined with Solid Plugging Agents. Energies. 2023. Vol. 16. Iss. 18. N 6688. DOI: 10.3390/en16186688