Determination of impact hazard potential of rocks in the Norilsk Industrial Region

- 1 — Ph.D., Dr.Sci. Head of Department Empress Catherine II Saint Petersburg Mining University ▪ Orcid ▪ Scopus

- 2 — Ph.D. Associate Professor Empress Catherine II Saint Petersburg Mining University ▪ Orcid

- 3 — Ph.D. Senior Researcher Gipronikel Institute LLC ▪ Orcid ▪ Scopus

Abstract

The deeper the mineral deposits developments are, the worse the mining and geological conditions become. Significant growth of stress level in the rock mass contributes to possible manifestation of rock pressure in dynamic form. The resulting task of assessment of rock impact hazard is closely related to the task of obtaining more accurate results of compression tests of samples in rigid or servohydraulic test presses using graphs of their full deformation. This approach requires special expensive equipment, considerable time resources, and sufficient core material. Therefore, it is important to have an approach that allows to assess the propensity of rocks to brittle fracture with research methods simple enough not to result in the loss of quality and reliability of the obtained results. This paper presents the results of laboratory tests of rocks from the Norilsk Industrial Region to determine their tensile and compressive strengths. Test methods involved both domestic and foreign standards for determining the value of the brittleness coefficient. The impact hazard potential of rocks was determined using the Kaiser criterion. It is found that the tested lithological types (rich sulfide ores, hornblende, disseminated ores, and gabbro-dolerite rocks), with the exception of anhydrite, have a low impact hazard potential.

Introduction

Development of mineral deposits at great depths generally leads to more complicated geomechanical conditions [1-3] such as increased rock pressure, as well as increased risk of its dynamic manifestation [4-6]. For example, the depth of the Talnakh mine development in some areas today reaches more than 1000 m at the known critical depth of the impact hazard of 700 m [7-9]. At such great depths and consequently high stress values, the rock mass is characterized by the fracturing of its edge part, potentially manifested in brittle form with the release of elastic energy, i.e. in the form of a rock impact [10-12].

According to the recommended practices, it is necessary to identify areas in a rock mass where the possibility of rock impact is the highest, i.e. it is necessary to assess the propensity of rocks to brittle fracture [13-15]. One of the most accurate ways to assess the propensity of rocks to brittle fracture is the ratio of the elasticity modulus E to the decrease of material modulus M. Given the ratio (E/M) > 1, the test specimen is assumed as not vulnerable to impact, and in the case of (E/M) £ 1, the test specimen is assumed as vulnerable to impact. Such an assessment requires compression tests on specimens to obtain full deformation diagrams. This approach can be carried out on either rigid or servohydraulic test presses, taking into account the increase in the transverse strain rate [16-18]. Such tests require specialized equipment, a large time frame both for the tests and for logistics, and quality core material in sufficient quantity.

A rather simplified method for assessing the brittle fracture susceptibility of rocks is the method of Ya.A.Bich [19, 20], which consists in comparing the values of elastic and total deformations. In this case, the impact hazard coefficient is determined by the formula

where εel is deformations in the elastic zone; εtot is total deformations (before fracture).

A rock is considered impact hazardous at kimp > 0.7. According to the recommended practices*, when determining the correlation between the value E/M and the impact hazard coefficient kimp, it is allowed to carry out the number of tests for the sixth and subsequent specimens at pre-limit loads [21, 22].

Due to the large number of tests, the possibility of applying the well-known Kaiser criterion [23], which consists in determining the value of the impact hazard potential of rocks [24], seems quite promising. Application of this criterion requires only the results of the determination of the compressive and tensile strength of rocks. Thus, in this case, the propensity of rocks to brittle fracture is determined in a rather simple way, which allows us to obtain a quick assessment of the impact hazard potential of the studied rocks [25-27].

Research method

Studies of the rock impacts in Canadian mines have shown that the rock impact hazard can be estimated quite accurately using the indicator of rock impact hazard potential [23]. This indicator takes into account such parameters as UCS (uniaxial compressive strength) and the ratio of the compressive strength of rocks to their tensile strength UCS/UTS, defined as their brittleness coefficient [28].

It is known that the compressive strength of rocks is characterized by the energy accumulated in the rock mass up to the moment of its fracture: the higher limit of rock strength corresponds to large values of potential energy of elastic deformations and kinetic energy, which leads to dynamic destruction of the mass in the form of ejection of rock mass and distribution of individual rock pieces. Another important indicator of the propensity of rock to fracture as a result of thin plate detachment is the brittleness coefficient defined as the ratio of the compressive strength to the tensile strength of the examined rock samples (core material) [29].

While studying impact hazard of deposits located in the territory of the Russian Federation, this approach was successfully applied to ores and rocks of deposits of the Khibiny massif the and Novoshirokinskoe polymetallic ore deposit located in the Zabaikalsky Krai [30-32].

When carrying out underground mining operations at great depths in rocks with the potential for impact hazard, rock impacts are possible, and if there is no such potential, the probability of dynamic manifestation of rock pressure is close to zero [27, 28].

It should be noted that after obtaining the test results for determining the compressive and tensile strength of rocks, it is possible, by increasing the scale of the work performed, to obtain more reliable and statistically significant results. For this purpose, the results of laboratory tests for determining the physical and mechanical properties of ores and rock mass of two deposits of the Norilsk Industrial Region in 2018-2023 were used.

Several types of ores and rocks of the Norilsk Industrial Region were considered for the assessment of the impact hazard potential (Table 1). These ores and rocks have been chosen because the first four lithological types for the Talnakh mines were classified as brittle fracture-prone rocks, according to the Federal Industrial Safety Standards and Regulations. It should be noted that anhydrite is not classified as an impact-prone rock in the Talnakh mines [33, 34].

Data obtained from uniaxial compression and tensile tests was used for assessment of the impact hazard potential of rocks and ores. The results according to GOST and ASTM (ISRM) were compared. Sample preparation and testing were performed according to GOST 21153.2-84 “Rocks. Methods of Determining Uniaxial Compressive Strength” and GOST 21153.3-85 “Rocks. Methods of Determining Uniaxial Tensile Strength”. Determination of tensile strength is regulated by standards “ASTM D7012-14. Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures” and “ISRM Suggested Methods for Determining Tensile Strength of Rock Materials” [35, 36].

In the tests carried out according to the GOST regulated methods, the specimens had a ratio of height to diameter of 2:1 for compression and 1:1 for tension. For tests carried out according to foreign standards, the ratio of height to diameter for compression specimens was 2:1 and 2.5:1, for tensile specimens – 0.5:1. For the first sample, a series of tests was performed, including six specimens for compression, six specimens for tension, according to GOST, and four specimens for tension (as per ASTM). The obtained test results were averaged.

Laboratory test results

The experimental studies resulted in determining of the strength properties of five lithological types of ores and rocks of the Norilsk Industrial Region. The obtained results concerning the determination of the impact hazard potential of rocks and ores are summarized in Table 1.

Table 1

Distribution of the impact hazard potential of rocks and ores of the Norilsk Industrial Region

|

Indicator |

Rich ores |

Hornblende |

Disseminated ores |

Rock gabbro-dolerites |

Anhydrites |

||||||

|

I |

II |

I |

II |

I |

II |

I |

II |

I |

II |

||

|

Total samples |

51 |

96 |

140 |

144 |

47 |

29 |

|||||

|

Nopotential, % |

80.4 |

68.6 |

54.2 |

76.0 |

60.0 |

70.0 |

57.6 |

61.8 |

0.0 |

0.0 |

|

|

Low potential, % |

15.7 |

27.5 |

40.6 |

23.0 |

33.6 |

27.1 |

36.1 |

34.0 |

0.0 |

0.0 |

|

|

Medium potential, % |

3.9 |

3.9 |

5.2 |

1.0 |

6.4 |

2.9 |

5.6 |

4.2 |

0.0 |

0.0 |

|

|

High potential, % |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

0.7 |

0.0 |

0.0 |

0.0 |

|

|

Very high potential, % |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

0.7 |

0.0 |

0.0 |

|

Note. Method I – GOST, method II – ASTM.

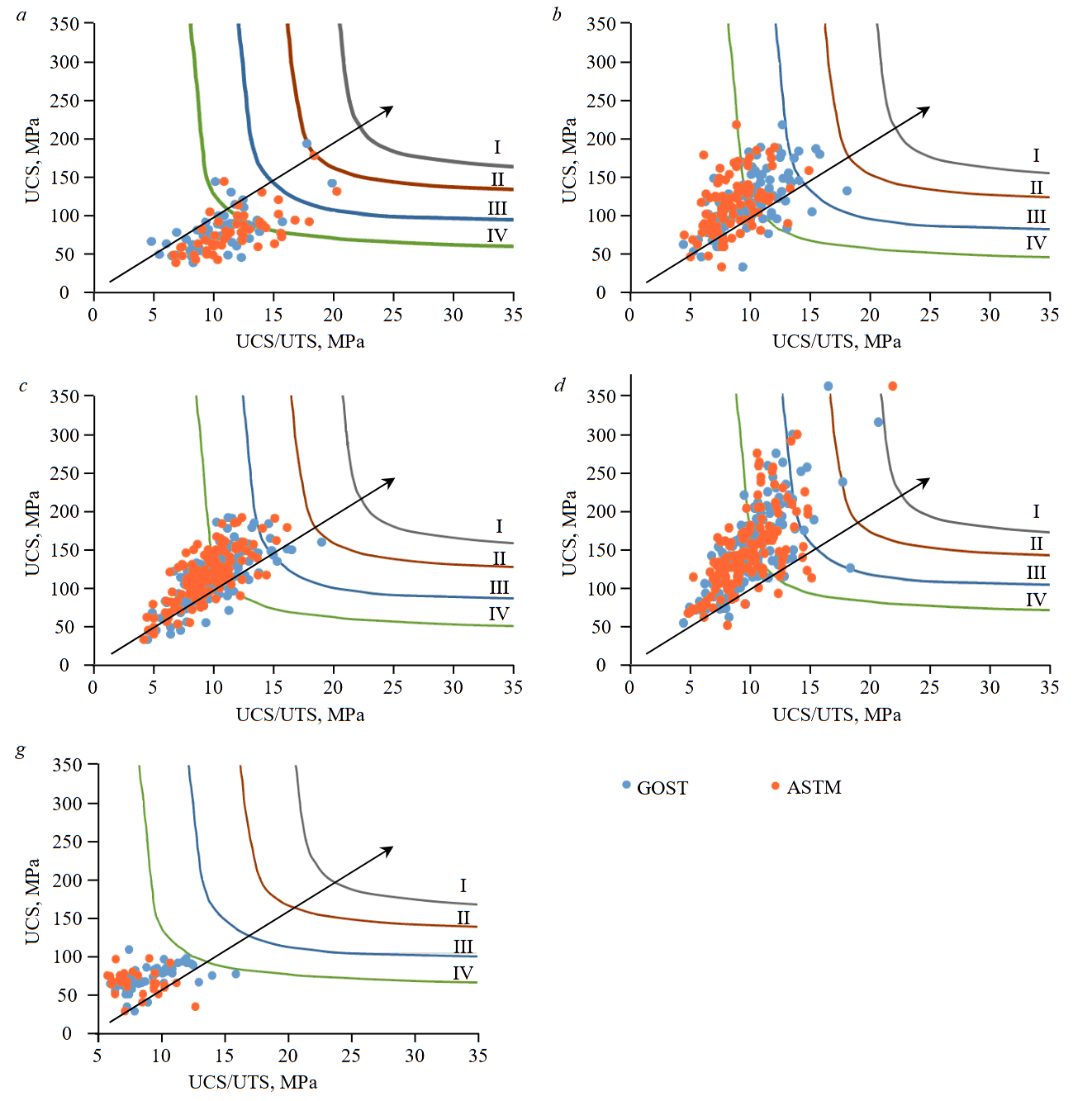

Graphic distribution of samples is shown on Fig.1.

According to the obtained results, samples of all lithological types with the exception of anhydrite have a low level of impact hazard potential [37, 38]. At the same time, the ratio of non-impact-prone samples ranged from 54 to 80 %, depending on the lithology type and test methodology. These percentages are quite sufficient to classify these lithological types as impact-prone, since, according to the recommended practices, the minimum percentage of impact-prone rocks should be at least 10 %. The best matching of results from different methods is observed in the testing of rock gabbro-dolerites. Thus, in the case of rich ores, the number of samples with impact hazard potential was 12 % higher when tested by foreign methods compared with domestic ones. For disseminated ores and hornblende, the highest percentage of impact-prone samples was obtained when tested as per domestic methods. However, despite some discrepancies in the obtained proportions, no significant differences were observed [39, 40].

- Impact hazard potential of the main lithological types: a – rich ore; b – hornblende; c – disseminated ores; d – gabbro-dolerite intrusion; e – anhydrite [41] I – very high; II – high; III – medium; IV – low

The impact hazard of hornblende and gabbro-dolerites is conditioned mainly by their high compressive strength which can reach up to 300 MPa in a sample, while rich ores are characterized by a higher value of the brittleness coefficient (Table 2) compared to other rocks, which indicates the propensity of such rocks to spalling in thin plates as a result of their detachment (pressing off).

Table 2

Average value of brittleness coefficient of the studied lithological types

|

Method |

Rich ore |

Hornblende |

Disseminated ores |

Rock gabbro-dolerites |

|

GOST |

10.57/13.73* |

9.85/11.98 |

9.63/11.93 |

9.29/11.59 |

|

ASTM |

11.73/14.81 |

8.49/10.93 |

8.95/11.53 |

9.10/11.63 |

|

* All samples/impact hazardous samples. |

||||

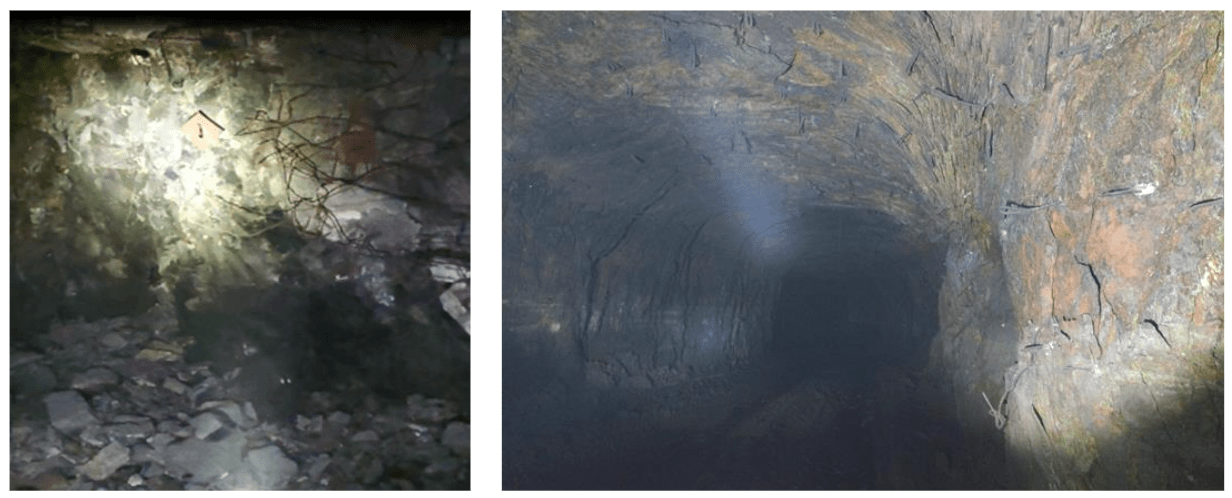

-

Fig.2. Examples of ore delamination in the border zone under the action of high level stresses

Such a characteristic feature (high value of brittleness coefficient) is manifested in rich ores and in rock mass.Thus, during the development of mineral deposits at deep horizons, the border zone of the ore massif is pressed off, forming characteristic delaminations (Fig.2), while in other geological varieties such effect usually does not occur [42].

The average brittleness coefficient of anhydrites is not shown in Table 2, it amounted to 8.75; compressive strength did not exceed 105 MPa.

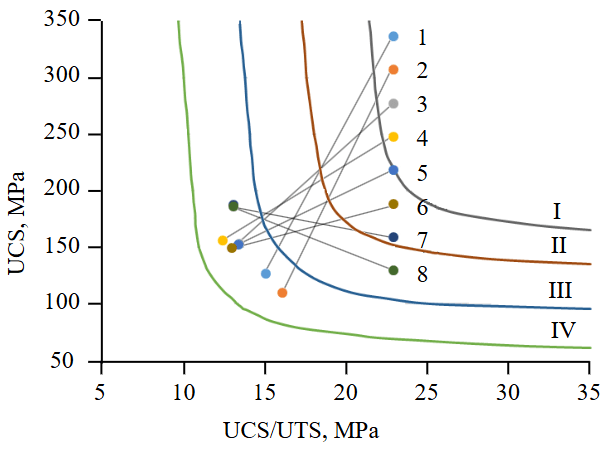

The same conclusion about the lower brittleness coefficient in the strongest rocks was also made in [30] when investigating the impact hazard potential of rocks at apatite-nepheline deposits.This is clearly presented in Fig.3, which shows the distribution of lithological types in the diagram according to the average values of brittleness coefficients and compressive strength (samples without impact hazard potential were not considered in this sample).

Thus, taking into the account the rock test results it can be determined that, despite the different nature of possible impact hazard, all the rocks considered with the exception of anhydrite are assigned a low level of impact hazard.

-

Fig.3. Average values of impact hazard potential of the studied lithological types: rich ore (1 – GOST, 2 – ASTM); hornblende (3 – GOST, 4 – ASTM); disseminated ores (5 – GOST, 6 – ASTM); rock gabbro-dolerites (7 – GOST, 8 – ASTM)

I-IV – see Fig.1

Laboratory studies carried out to assess the impact hazard of rich ores of the Norilsk Industrial Region by means of compression tests of samples in the mode of controlling the growth rate of transverse deformation [19], showed that they are impact hazardous. This confirms the possibility of using the Kaiser criterion to assess the impact hazard potential in the considered conditions.

Conclusion

- As a result of tests using domestic and foreign methods, the strength properties of various rocks and ores of the Norilsk Industrial Region have been determined and the values of their brittleness coefficients have been calculated.

- Using the Kaiser criterion, it was found that the percentage of non-impact-prone samples varied from 54 to 80 % depending on the type of lithology and testing methodology, which confirms the propensity to dynamic fracture of rocks of the Norilsk Industrial Region. The highest percentage of impact-prone samples obtained during hornblende testing according to Russian methods amounted to almost half of the tested samples. The best matching between the methods used was observed when testing rock gabbro-dolerites. The obtained research results reflected a sufficient qualitative convergence between domestic and foreign methods.

- It is noted that rich ores have the lowest compressive strength than other impact-prone rock types, but at the same time have the highest brittleness coefficient, which indicates their tendency to spalling in the form of thin plates. The latter fact is confirmed by the results of field studies in mines, where ore plates were pressed off under high stress levels from the border zone of the rock mass.

- It is determined that the studied lithological types with the exception of anhydrite have a low impact hazard potential. There is no impact hazard potential of anhydrites, i.e. they are non-impact-prone.

- To assess the impact hazard of rich ores of the Norilsk Industrial Region using the Kaiser criterion, a broad comparison with the results of compression tests of samples in the mode of controlling the growth rate of transverse deformation was carried out. The comparison confirmed that the rich ore is impact hazardous.

References

- Rybak J., Khayrutdinov M.M., Kuziev D.A. et al. Prediction of the geomechanical state of the rock mass when mining salt deposits with stowing. Journal of Mining Institute. Vol. 253. p. 61-70. DOI: 10.31897/PMI.2022.2

- Hongpu Kang, Pengfei Jiang, Yongzheng Wu, Fuqiang Gao. A combined “ground support-rock modification-destressing” strategy for 1000-m deep roadways in extreme squeezing ground condition. International Journal of Rock Mechanics and Mining Sciences. 2021. Vol. 142. N 104746. DOI: 10.1016/j.ijrmms.2021.104746

- Jian Zhou, Chao Chen, Kun Du et al. A new hybrid model of information entropy and unascertained measurement with different membership functions for evaluating destressability in burst-prone underground mines. Engineering with Computers. 2022. Vol. 38. Iss. 1 Suppl, p. 381-399. DOI: 10.1007/s00366-020-01151-3

- Konicek P., Schreiber. Rockburst prevention via distress blasting of competent roof rocks in hard coal longwall mining. Journal of the Southern African Institute of Mining and Metallurgy. 2018. Vol. 118. N 3, p. 235-242. DOI: 17159/2411-9717/2018/v118n3a6

- Tyupin V.N. Estimation of Critical Depth of Deposits by Rock Bump Hazard Condition. Journal of Mining Institute. Vol. 236, p. 167-171. DOI: 10.31897/PMI.2019.2.167

- Sidorov D.V., Potapchuk M.I., Sidlyar A.V., Kursakin G.A. Assessment of Rock-Burst Hazard in Deep Layer Mining at Nikolayevskoye Field. Journal of Mining Institute. Vol. 238, p. 392-398. DOI: 10.31897/PMI.2019.4.392

- Pleshko M.S., Davydov A.A., Silchenko Yu.A., Kaledin O.S. Effective lining solutions for super-deep shaft SKS-1 in Skalisty mine in difficult geomechanical conditions. Gornyi zhurnal. N 6, p. 57-62 (in Russian). DOI: 10.17580/gzh.2020.06.08

- Sergunin M.P., Alborov A.E., Andreev A.A., Buslova M.A. Stress assessment ahead of stoping front with widening stress relief zone – A case study of the Oktyabrsky and Talnakh deposits. Gornyi zhurnal. N 6, p. 38-41 (in Russian). DOI: 10.17580/gzh.2020.06.06

- Balandin V.V., Leonov V.L., Kuranov A.D., Bagautdinov I.I. Application of generalized Hoek – Brown criterion to selection and design of mine support systems for the Oktyabrsky copper-nickel deposit: Case study. Gornyi zhurnal. N 11, p. 14-18 (in Russian). DOI: 10.17580/gzh.2019.11.01

- Zakalinsky V.M., Mingazov R.Y., Shipovskii I.E. The influence of mining and technological factors on drilling and blasting operations during the development of deposits at great depth. Problems of Subsoil Use. N 2 (33), p. 46-54 (in Russian). DOI: 10.25635/2313-1586.2022.02.046

- Aleksandrova T.N., Afanasova A.V., Kuznetsov V.V., Babenko T.A. Process analysis of selective disintegration of Zapolyarny copper–nickel ore. Mining Informational and Analytical Bulletin. N 12, p. 73-87 (in Russian). DOI: 10.25018/0236_1493_2021_12_0_73

- Aleksandrova T.N., Chanturiya A.V., Kuznetsov V.V. Mineralogical and technological features and patterns of selective disintegration of ferruginous quartzites of the Mikhailovskoye deposit. Journal of Mining Institute. Vol. 256, p. 517-526. DOI: 10.31897/PMI.2022.58

- Pershin G.D., Pshenichnaya E.G., Mazhitov A.M. Energy criteria for quasi-brittle fracture of rocks in technological processes of mining and primary processing. Russian Mining Industry. N 2, p. 84-89 (in Russian). DOI: 10.30686/1609-9192-2022-2-84-89

- Korchak P.A., Karasev M.A. Geomechanical prediction of the brittle fracture zones in rocks in the vicinity of the excavation junction of Ltd “Apatit” mines. Sustainable Development of Mountain Territories. Vol. 15. N 1 (55), p. 67-80 (in Russian). DOI: 10.21177/1998-4502-2023-15-1-67-80

- Sonnov M.A., Trofimov A.V., Rumyantsev A.E., Shpilev S.V. Application of Numerical and Block Geomechanical Modelling to Determine Parameters of Large-Section Chambers. Russian Mining Industry. N 2, p. 127-131 (in Russian). DOI: 10.30686/1609-9192-2021-2-127-131

- Ulusay R., Hudson J.A.The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974-2006. International Society for Rock Mechanics, Commission on Testing Methods, 2007, p. 628.

- Protosenya A.G., Belyakov N.A., Bouslova M.A. Modelling of the stress-strain state of block rock mass of ore deposits during development by caving mining systems. Journal of Mining Institute. Vol. 262, p. 619-627.

- Morozov K.V., Demekhin D.N., Bakhtin E.V. Multicomponent strain gauges for assessing the stress-strain state of a rock mass. Mining Informational and Analytical Bulletin. N 6-2, p. 80-97 (in Russian). DOI: 10.25018/0236_1493_2022_62_0_80

- Gospodarikov A.P., Trofimov A.V., Kirkin A.P. Evaluation of deformation characteristics of brittle rocks beyond the limit of strength in the mode of uniaxial servohydraulic loading. Journal of Mining Institute. Vol. 256, p. 539-548. DOI: 10.31897/PMI.2022.87

- Bich Ya.A., Melkov A.D., Dyakonov Yu.Ya. Prevention of rock impacts in development of anthracite seams. Moscow: Nedra, 1993, p. 159 (in Russian).

- Subrahmanyam D.S. Evaluation of Hydraulic Fracturing and Overcoring Methods to Determine and Compare the In Situ Stress Parameters in Porous Rock Mass. Geotechnical and Geological Engineering. 2019. Vol. 37. Iss. 6, p. 4777-4787. DOI: 10.1007/s10706-019-00937-7

- Krietsch H., Gischig V., Evans K. et al.Stress Measurements for an In Situ Stimulation Experiment in Crystalline Rock: Integration of Induced Seismicity, Stress Relief and Hydraulic Methods. Rock Mechanics and Rock Engineering. 2019. Vol. 52. Iss. 2, p. 517-542. DOI: 10.1007/s00603-018-1597-8

- Ming Cai, Kaiser P.K. Rockburst Support. Reference Book. In 2 volumes. Vol. 1: Rockburst Phenomenon and Support Characteristics. Sudbury: Laurentian University, 2018, p. 284.

- Aynbinder I.I., Ovcharenko O.V. Potential rockburst hazard research at the project mining depth at the Valunistoe deposit. Mining Informational and Analytical Bulletin. N 6, p. 35-45 (in Russian). DOI: 10.25018/0236_1493_2022_6_0_35

- Aleksandrova T., Nikolaeva N., Afanasova A. et al. Selective Disintegration Justification Based on the Mineralogical and Technological Features of the Polymetallic Ores. Minerals. 2021. Vol. 11. Iss. 8. N 851. DOI: 10.3390/min11080851

- Winn K. Multi-approach Geological Strength Index (GSI) Determination for Stratified Sedimentary Rock Masses in Singapore. Geotechnical and Geological Engineering. 2020. Vol. 38. Iss. 2, p. 2351-2358. DOI: 10.1007/s10706-019-01149-9

- Samsonov A.A. Assessment of rock mass state of Oleniy Ruchey rock burst deposit based on the results of stress measurements. Herald of the Kola Science Centre of RAS. N 1 (11), p. 62-67 (in Russian). DOI: 10.25702/KSC.2307-5228.2019.11.1.62-67

- Závacký M., Štefaňák J. Strains of rock during uniaxial compression test. The Civil Engineering Journal. 2019. Vol. 28. N 3, p. 398-403. DOI: 14311/CEJ.2019.03.0032

- Biryuchev I.V., Makarov A.B., Usov A.A. Geomechanical model of underground mine. Part II. Application. Gornyi zhurnal. N 2, p. 35-44 (in Russian). DOI: 10.17580/gzh.2020.02.04

- Kuznetcov N.N., Kondrashov L.Yu. Rockburst hazard potential assessment of rocks of the Khibiny massif deposits according to the Kaiser criterion. Vestnik of MSTU. Vol. 26. N 2, p. 170-179 (in Russian). DOI: 10.21443/1560-9278-2023-26-2-170-179

- Eremenko A.A., Shaposhnik Yu.N., Filippov V.N., Konurin A.I. Development of scientific framework for safe and efficient geotechnology for rockburst-hazardous mineral deposits in Western Siberia and the Far North. Gornyi zhurnal. N 10, p. 33-39 (in Russian). DOI: 10.17580/gzh.2019.10.03

- Bertuzzi R. Revisiting rock classification to estimate rock mass properties. Journal of Rock Mechanics and Geotechnical Engineering. 2019. Vol. 11. Iss. 3, p. 494-510. DOI: 1016/j.jrmge.2018.08.011

- Marysyuk V.P., Shilenko S.Yu., Trofimov A.V., Kuzmin S.V. Risk assessment in main ore chute construction in difficult geological conditions based on integrated geotechnical research. Gornyi zhurnal. N 1, p. 62-66 (in Russian). DOI: 10.17580/gzh.2020.01.12

- Marysyuk V.P., Shilenko S.Yu., Andreev A.A., Shabarov A.N. Interwell area design procedure to generate safe zones in rockburst-hazardous conditions of Talnakh deposits. Gornyi zhurnal. N 1, p. 106-112 (in Russian). DOI: 10.17580/gzh.2023.01.18

- Saadatmand Hashemi A., Katsabanis P. Tunnel face preconditioning using destress blasting in deep underground excavations. Tunnelling and Underground Space Technology. 2021. Vol. 117. N 104126. DOI: 1016/j.tust.2021.104126

- Kozyrev A.A., Kuznetsov N.N., Fedotova Iu.V., Shokov A.N. The determination of rockburst hazard degree of hard rocks by the test results under uniaxial compression. News of the Higher Institutions. Mining Journal. N 6, p. 41-50 (in Russian). DOI: 10.21440/0536-1028-2019-6-41-50

- Kovalevsky V.N., Mysin A.V. Performance of tubular elastic charges in natural stone production. Mining Informational and Analytical Bulletin. N 1, p. 20-34 (in Russian). DOI: 10.25018/0236_1493_2023_1_0_20

- Zubov V.P., Than Van Duy, Fedorov A.S. Technology of underground mining of thick coal seams with low strength Ugol. 2023. N (5), p. 41-49 (in Russian). DOI: 10.18796/0041-5790-2023-5-41-49

- Verbilo P., Karasev M., Belyakov N., Iovlev G. Experimental and numerical research of jointed rock mass anisotropy in a three-dimensional stress field. Rudarsko-geološko-naftni zbornik. 2022. Vol. 37. N 2, p. 109-122. DOI: 17794/rgn.2022.2.10

- Vennes I., Mitri H., Chinnasane D.R., Yao M. Effect of Stress Anisotropy on the Efficiency of Large-Scale Destress Blasting. Rock Mechanics and Rock Engineering. 2021. Vol. 54. Iss. 1, p. 31-46. DOI: 1007/s00603-020-02252-7

- Kirkin A.P. Impact hazard management of solid sulfide ore mass by drilling and blasting in conditions of complex stress state: Avtoref. dis. … kand. tekhn. nauk. St. Petersburg: Saint Petersburg Mining University, 2023, p. 22 (in Russian).

- Marinin M.A., Karasev M.A., Pospekhov G.B. et al. Engineering and geological parameters for heap leaching of gold from low-grade sandy clay ores: a feasibility study. Mining Informational and Analytical Bulletin. N 9, p. 22-37 (in Russian). DOI: 10.25018/0236_1493_2023_9_0_22

* Recommended practices for assessment of the propensity of ore and nonmetallic mineral deposits to rock impact. Approved by the Order 216 of the Federal Service for Environmental, Technological and Nuclear Supervision dated 23.05.2013.

References

- Rybak J., Khayrutdinov M.M., Kuziev D.A. et al. Prediction of the geomechanical state of the rock mass when mining salt deposits with stowing. Journal of Mining Institute. 2022. Vol. 253. p. 61-70. DOI: 10.31897/PMI.2022.2

- Hongpu Kang, Pengfei Jiang, Yongzheng Wu, Fuqiang Gao. A combined “ground support-rock modification-destressing” strategy for 1000-m deep roadways in extreme squeezing ground condition. International Journal of Rock Mechanics and Mining Sciences. 2021. Vol. 142. N 104746. DOI: 10.1016/j.ijrmms.2021.104746

- Jian Zhou, Chao Chen, Kun Du et al. A new hybrid model of information entropy and unascertained measurement with different membership functions for evaluating destressability in burst-prone underground mines. Engineering with Computers. 2022. Vol. 38. Iss. 1 Suppl, p. 381-399. DOI: 10.1007/s00366-020-01151-3

- Konicek P., Schreiber. Rockburst prevention via distress blasting of competent roof rocks in hard coal longwall mining. Journal of the Southern African Institute of Mining and Metallurgy. 2018. Vol. 118. N 3, p. 235-242. DOI: 10.17159/2411-9717/2018/v118n3a6

- Tyupin V.N. Estimation of Critical Depth of Deposits by Rock Bump Hazard Condition. Journal of Mining Institute. 2019. Vol. 236, p. 167-171. DOI: 10.31897/PMI.2019.2.167

- Sidorov D.V., Potapchuk M.I., Sidlyar A.V., Kursakin G.A. Assessment of Rock-Burst Hazard in Deep Layer Mining at Nikolayevskoye Field. Journal of Mining Institute. 2019. Vol. 238, p. 392-398. DOI: 10.31897/PMI.2019.4.392

- Pleshko M.S., Davydov A.A., Silchenko Yu.A., Kaledin O.S. Effective lining solutions for super-deep shaft SKS-1 in Skalisty mine in difficult geomechanical conditions. Gornyi zhurnal. 2020. N 6, p. 57-62 (in Russian). DOI: 10.17580/gzh.2020.06.08

- Sergunin M.P., Alborov A.E., Andreev A.A., Buslova M.A. Stress assessment ahead of stoping front with widening stress relief zone – A case study of the Oktyabrsky and Talnakh deposits. Gornyi zhurnal. 2020. N 6, p. 38-41 (in Russian). DOI: 10.17580/gzh.2020.06.06

- Balandin V.V., Leonov V.L., Kuranov A.D., Bagautdinov I.I. Application of generalized Hoek – Brown criterion to selection and design of mine support systems for the Oktyabrsky copper-nickel deposit: Case study. Gornyi zhurnal. 2019. N 11, p. 14-18 (in Russian). DOI: 10.17580/gzh.2019.11.01

- Zakalinsky V.M., Mingazov R.Y., Shipovskii I.E. The influence of mining and technological factors on drilling and blasting operations during the development of deposits at great depth. Problems of Subsoil Use. 2022. N 2 (33), p. 46-54 (in Russian). DOI: 10.25635/2313-1586.2022.02.046

- Aleksandrova T.N., Afanasova A.V., Kuznetsov V.V., Babenko T.A. Process analysis of selective disintegration of Zapolyarny copper–nickel ore. Mining Informational and Analytical Bulletin. 2021. N 12, p. 73-87 (in Russian). DOI: 10.25018/0236_1493_2021_12_0_73

- Aleksandrova T.N., Chanturiya A.V., Kuznetsov V.V. Mineralogical and technological features and patterns of selective disintegration of ferruginous quartzites of the Mikhailovskoye deposit. Journal of Mining Institute. 2022. Vol. 256, p. 517-526. DOI: 10.31897/PMI.2022.58

- Pershin G.D., Pshenichnaya E.G., Mazhitov A.M. Energy criteria for quasi-brittle fracture of rocks in technological processes of mining and primary processing. Russian Mining Industry. 2022. N 2, p. 84-89 (in Russian). DOI: 10.30686/1609-9192-2022-2-84-89

- Korchak P.A., Karasev M.A. Geomechanical prediction of the brittle fracture zones in rocks in the vicinity of the excavation junction of Ltd “Apatit” mines. Sustainable Development of Mountain Territories. 2023. Vol. 15. N 1 (55), p. 67-80 (in Russian). DOI: 10.21177/1998-4502-2023-15-1-67-80

- Sonnov M.A., Trofimov A.V., Rumyantsev A.E., Shpilev S.V. Application of Numerical and Block Geomechanical Modelling to Determine Parameters of Large-Section Chambers. Russian Mining Industry. 2021. N 2, p. 127-131 (in Russian). DOI: 10.30686/1609-9192-2021-2-127-131

- Ulusay R., Hudson J.A.The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974-2006. International Society for Rock Mechanics, Commission on Testing Methods, 2007, p. 628.

- Protosenya A.G., Belyakov N.A., Bouslova M.A. Modelling of the stress-strain state of block rock mass of ore deposits during development by caving mining systems. Journal of Mining Institute. 2023. Vol. 262, p. 619-627.

- Morozov K.V., Demekhin D.N., Bakhtin E.V. Multicomponent strain gauges for assessing the stress-strain state of a rock mass. Mining Informational and Analytical Bulletin. 2022. N 6-2, p. 80-97 (in Russian). DOI: 10.25018/0236_1493_2022_62_0_80

- Gospodarikov A.P., Trofimov A.V., Kirkin A.P. Evaluation of deformation characteristics of brittle rocks beyond the limit of strength in the mode of uniaxial servohydraulic loading. Journal of Mining Institute. 2022. Vol. 256, p. 539-548. DOI: 10.31897/PMI.2022.87

- Bich Ya.A., Melkov A.D., Dyakonov Yu.Ya. Prevention of rock impacts in development of anthracite seams. Moscow: Nedra, 1993, p. 159 (in Russian).

- Subrahmanyam D.S. Evaluation of Hydraulic Fracturing and Overcoring Methods to Determine and Compare the In Situ Stress Parameters in Porous Rock Mass. Geotechnical and Geological Engineering. 2019. Vol. 37. Iss. 6, p. 4777-4787. DOI: 10.1007/s10706-019-00937-7

- Krietsch H., Gischig V., Evans K. et al.Stress Measurements for an In Situ Stimulation Experiment in Crystalline Rock: Integration of Induced Seismicity, Stress Relief and Hydraulic Methods. Rock Mechanics and Rock Engineering. 2019. Vol. 52. Iss. 2, p. 517-542. DOI: 10.1007/s00603-018-1597-8

- Ming Cai, Kaiser P.K. Rockburst Support. Reference Book. In 2 volumes. Vol. 1: Rockburst Phenomenon and Support Characteristics. Sudbury: Laurentian University, 2018, p. 284.

- Aynbinder I.I., Ovcharenko O.V. Potential rockburst hazard research at the project mining depth at the Valunistoe deposit. Mining Informational and Analytical Bulletin. 2022. N 6, p. 35-45 (in Russian). DOI: 10.25018/0236_1493_2022_6_0_35

- Aleksandrova T., Nikolaeva N., Afanasova A. et al. Selective Disintegration Justification Based on the Mineralogical and Technological Features of the Polymetallic Ores. Minerals. 2021. Vol. 11. Iss. 8. N 851. DOI: 10.3390/min11080851

- Winn K. Multi-approach Geological Strength Index (GSI) Determination for Stratified Sedimentary Rock Masses in Singapore. Geotechnical and Geological Engineering. 2020. Vol. 38. Iss. 2, p. 2351-2358. DOI: 10.1007/s10706-019-01149-9

- Samsonov A.A. Assessment of rock mass state of Oleniy Ruchey rock burst deposit based on the results of stress measurements. Herald of the Kola Science Centre of RAS. 2019. N 1 (11), p. 62-67 (in Russian). DOI: 10.25702/KSC.2307-5228.2019.11.1.62-67

- Závacký M., Štefaňák J. Strains of rock during uniaxial compression test. The Civil Engineering Journal. 2019. Vol. 28. N 3, p. 398-403. DOI: 10.14311/CEJ.2019.03.0032

- Biryuchev I.V., Makarov A.B., Usov A.A. Geomechanical model of underground mine. Part II. Application. Gornyi zhurnal. 2020. N 2, p. 35-44 (in Russian). DOI: 10.17580/gzh.2020.02.04

- Kuznetcov N.N., Kondrashov L.Yu. Rockburst hazard potential assessment of rocks of the Khibiny massif deposits according to the Kaiser criterion. Vestnik of MSTU. 2023. Vol. 26. N 2, p. 170-179 (in Russian). DOI: 10.21443/1560-9278-2023-26-2-170-179

- Eremenko A.A., Shaposhnik Yu.N., Filippov V.N., Konurin A.I. Development of scientific framework for safe and efficient geotechnology for rockburst-hazardous mineral deposits in Western Siberia and the Far North. Gornyi zhurnal. 2019. N 10, p. 33-39 (in Russian). DOI: 10.17580/gzh.2019.10.03

- Bertuzzi R. Revisiting rock classification to estimate rock mass properties. Journal of Rock Mechanics and Geotechnical Engineering. 2019. Vol. 11. Iss. 3, p. 494-510. DOI: 10.1016/j.jrmge.2018.08.011

- Marysyuk V.P., Shilenko S.Yu., Trofimov A.V., Kuzmin S.V. Risk assessment in main ore chute construction in difficult geological conditions based on integrated geotechnical research. Gornyi zhurnal. 2020. N 1, p. 62-66 (in Russian). DOI: 10.17580/gzh.2020.01.12

- Marysyuk V.P., Shilenko S.Yu., Andreev A.A., Shabarov A.N. Interwell area design procedure to generate safe zones in rockburst-hazardous conditions of Talnakh deposits. Gornyi zhurnal. 2023. N 1, p. 106-112 (in Russian). DOI: 10.17580/gzh.2023.01.18

- Saadatmand Hashemi A., Katsabanis P. Tunnel face preconditioning using destress blasting in deep underground excavations. Tunnelling and Underground Space Technology. 2021. Vol. 117. N 104126. DOI: 10.1016/j.tust.2021.104126

- Kozyrev A.A., Kuznetsov N.N., Fedotova Iu.V., Shokov A.N. The determination of rockburst hazard degree of hard rocks by the test results under uniaxial compression. News of the Higher Institutions. Mining Journal. 2019. N 6, p. 41-50 (in Russian). DOI: 10.21440/0536-1028-2019-6-41-50

- Kovalevsky V.N., Mysin A.V. Performance of tubular elastic charges in natural stone production. Mining Informational and Analytical Bulletin. 2023. N 1, p. 20-34 (in Russian). DOI: 10.25018/0236_1493_2023_1_0_20

- Zubov V.P., Than Van Duy, Fedorov A.S. Technology of underground mining of thick coal seams with low strength properties. Ugol. 2023. N (5), p. 41-49 (in Russian). DOI: 10.18796/0041-5790-2023-5-41-49

- Verbilo P., Karasev M., Belyakov N., Iovlev G. Experimental and numerical research of jointed rock mass anisotropy in a three-dimensional stress field. Rudarsko-geološko-naftni zbornik. 2022. Vol. 37. N 2, p. 109-122. DOI: 10.17794/rgn.2022.2.10

- Vennes I., Mitri H., Chinnasane D.R., Yao M. Effect of Stress Anisotropy on the Efficiency of Large-Scale Destress Blasting. Rock Mechanics and Rock Engineering. 2021. Vol. 54. Iss. 1, p. 31-46. DOI: 10.1007/s00603-020-02252-7

- Kirkin A.P. Impact hazard management of solid sulfide ore mass by drilling and blasting in conditions of complex stress state: Avtoref. dis. … kand. tekhn. nauk. St. Petersburg: Saint Petersburg Mining University, 2023, p. 22 (in Russian).

- Marinin M.A., Karasev M.A., Pospekhov G.B. et al. Engineering and geological parameters for heap leaching of gold from low-grade sandy clay ores: a feasibility study. Mining Informational and Analytical Bulletin. 2023. N 9, p. 22-37 (in Russian). DOI: 10.25018/0236_1493_2023_9_0_22