Investigation of the effectiveness of the use of various substances for dust suppression during the transshipment of granular sulfur

- 1 — Labor Protection and Environmental Specialist Stevedoring and Shipping Company Limited ▪ Orcid

- 2 — Ph.D. Associate Professor Empress Catherine ΙΙ Saint Petersburg Mining University ▪ Orcid ▪ Scopus ▪ ResearcherID

- 3 — Ph.D. Associate Professor Empress Catherine ΙΙ Saint Petersburg Mining University ▪ Orcid

- 4 — Ph.D., Dr.Sci. Professor Lublin University of Technology ▪ Orcid

Abstract

The article is devoted to the problem of dusting during the transshipment of granular sulfur and existing methods of dust suppression. The analysis of various methods for reducing dust emission at granulated sulfur storage and transportation facilities is presented. The necessity of using special reagents to increase the efficiency of dust suppression and re-granulation of sulfur crushed by abrasion is noted. The sulfur dust obtained from the port terminal during the transshipment of technical sulfur was analyzed for granulometric composition. The results of experimental studies of the effectiveness of the use of various substances for sulfur dust suppression (alkyl polyglycosides, sodium silicate, starch) are presented. The laboratory installation was a hopper, inside which a test sample of dusty material was placed. The sample was subjected to an aerodynamic effect by an air flow at a given speed. The concentrations of suspended solids were measured with a dust meter-nephelometer with a sampling tube placed in the geometric center of the hopper. The effectiveness of dust suppression agents was determined based on a comparison of the concentration values obtained on dry and treated samples. For dust suppression at granulated sulfur treatment facilities, it is proposed to use a composition based on nonionic surfactants represented by a mixture of C12-14-alkylglycosides oligomers (1-1.5 %), additionally containing a mixture of amylose and amylopectin polysaccharides in the form of soluble starch (1-2.5 %) and water. The dust suppressor showed consistently high dust suppression efficiency both when measured immediately after irrigation (98.3 %) and after the expected time (99.7 %). The developed composition provides an increase in the dust-suppressing ability of the solution and the elimination of the possibility of repeated dusting due to the formation of a polymer film on the surface, as well as the regranulation of the product crushed by abrasion.

Funding

The work was carried out within the framework of the State assignment of the Ministry of Science and Higher Education of the Russian Federation (FSRW-2024-0005).

Introduction

Sulfur is one of the main resources of the chemical industry and is extracted in large quantities as a by-product during the purification of oil and natural gas. Sulfur compounds present in significant amounts in hydrocarbon raw materials cause a wide range of negative consequences, for example, lead to a decrease in engine efficiency and corrosion of pipelines. To improve the quality of the product and reduce the risk of emergencies, desulfurization or removal of sulfur from the produced fuel is carried out [1-3]. Applications of sulfur are the production of mineral fertilizers (simple superphosphate, ammonium sulfate, ammonium-sodium sulfate, potassium sulfate, kalimagnesium, magnesium sulfate, nitrosulfate, sulfoammophos, etc.) [4, 5], sulfuric acid [6], oil production (dilution of drilling and oil solutions) [7], production of explosives [8]. Work on flowability modeling is in demand and requires the use of modern software [9-11].

Technical sulfur is produced in three commercial forms: liquid, block, and granular. Granular sulfur is especially common because of its properties and uniform granulometric composition [12]. Emissions and losses of sulfur are a factor in the deterioration of the components of the natural environment [13], the processes of storage, transportation and transshipment of granular sulfur are accompanied by intense dusting, which can negatively affect both the health of workers and the state of the environment. Currently existing measures to reduce dust emission show low efficiency [14, 15]. The clean water irrigation systems most often used in enterprises are simple and economical to implement [16], but have an efficiency of less than 50 % due to the strong hydrophobicity of dust and high surface tension of water [17].

To improve the wettability of solutions, research is being conducted on dust suppression technologies using surfactants, which are able to form an insulating layer between the surface of the solution and the air [18-20]. Surfactants are a class of chemicals whose concentration in solution is higher on the surface than in the volume of a liquid. This means that the surfactant concentrates on the surface where it should function, which makes it very economical to use, since in this way it is possible to preserve most of the properties of water and improve wetting at low cost. This phenomenon is known as adsorption and occurs at the liquid – solid, liquid – liquid and liquid – air interfaces [21].

At the micro level, the characteristics of dust suppression foam are closely related to morphology, which can be characterized by the size of foam droplets and their distribution. As a rule, smaller and more homogeneous foam bubbles are more suitable for dust suppression, since they allow for stable dust suppression [22]. In fact, when foam hits a dust source and captures its particles, the number, average size, distribution and uniformity of bubbles in a large area foam will greatly affect the effectiveness of dust suppression by foam. If the size of the foam bubbles is too large or their distribution is uneven, the dust suppression stability is low. The size of the bubbles and their distribution depend to a certain extent on the properties of the foaming agent solution system, such as viscosity, surface tension, etc. [23]. Thus, in order to improve the morphology of foam and increase the efficiency of dust suppression, it is possible to change the properties of solutions of foaming agents [24].

In addition to surfactants, various wetting reagents can be used to increase the efficiency of dust suppression, which are fatty alcohols with the addition of sodium hydroxide, calcium chloride, ethyl alcohol, bischofite, sodium chloride, and water [25]. However, most wetting reagents have such disadvantages – unsanitary and unhygienic properties, strong corrosive effects on equipment, complex preparation methods, high cost, uncertainty about human health effects and low biodegradability, therefore their use may be limited [26].

The article analyzes the scientific literature on existing and developing dust suppression formulations that could be used to reduce dusting during the transshipment of technical sulfur. One such means of dust suppression is a composition for coating elemental sulfur in order to protect against atmospheric exposure [27], which is a mixture of silicone and an aqueous solution of sodium silicate. The composition in question is prepared with a ratio of silicone and sodium silicate from 25:75 to 75:25 wt.% and may additionally contain a coloring additive. The composition may also differ in that the sodium silicate is in water. The composition has high heat and frost resistance, adheres well to sulfur, is resistant to penetration of water and sulfur bacteria, is fire-resistant and relatively inexpensive. Sodium silicate is a highly effective sealant. There is a low efficiency of dust suppression of previously settled dust, which, when blown up, becomes a source of secondary air pollution by dust.

The composition [28] is known, which is a mixture of polysaccharide and boric acid, which, when mixed, turn into a gel with the formation of a stable elastic crust when applied to the surface. The resulting coating increases the stability of the substrate and prevents the loss of solid particles, i.e. dust formation. The first main component of the stabilizing composition is a mixture containing from 0.5 to 5 % polysaccharide, for example, starch. As soon as the two components combine to form a stabilizing compound, polysaccharide molecules, especially glucose molecules, begin to bind to borate at a controlled speed. This process, called complexation, forms weak covalent bonds comparable to weak cross-bonds in a polymer inside a polysaccharide matrix. The use of this composition may be limited, since boric acid has a negative impact on the environment and human health.

The use of polysaccharides as dust suppressants is also noted in the article [29] describing the use of a composition based on organic and rapidly decomposing substances with a ratio of the constituent components (water and a mixture of flax and starch) 98:2, which has a high adhesive ability.

There are known studies of compositions for suppressing dust formation using aqueous solutions of higher alkylglycosides [30-32]. Compositions of higher alkylglycosides are well-known materials with surface-active properties. Alkylglycosides are usually present in an aqueous solution to about 1 % by weight of an aqueous solution. With the help of such compositions, a long-lasting dust suppression effect is achieved. In addition, the composition is completely biodegradable and is not harmful to humans or the environment.

Alkylglycosides (R−(O−C6H10O5)nH) belong to the class of nonionic surfactants and are obtained from a reaction occurring in the presence of sulfonic acids and glucose at temperatures up to 140 °C or from butyl esters followed by interesterification. Nonionic surfactants are highly resistant to alkalis, acids and salts. Aqueous solutions of alkyl polyglycosides have the highest wetting ability compared to other surfactants and wetting agents [33].

Methods

The sulfur dust collected at the terminal for the transshipment of granular sulfur from railway wagons in a commercial seaport was studied. The granulometric composition of the dust under study was carried out using the HORIBA LA-950 particle size analyzer.

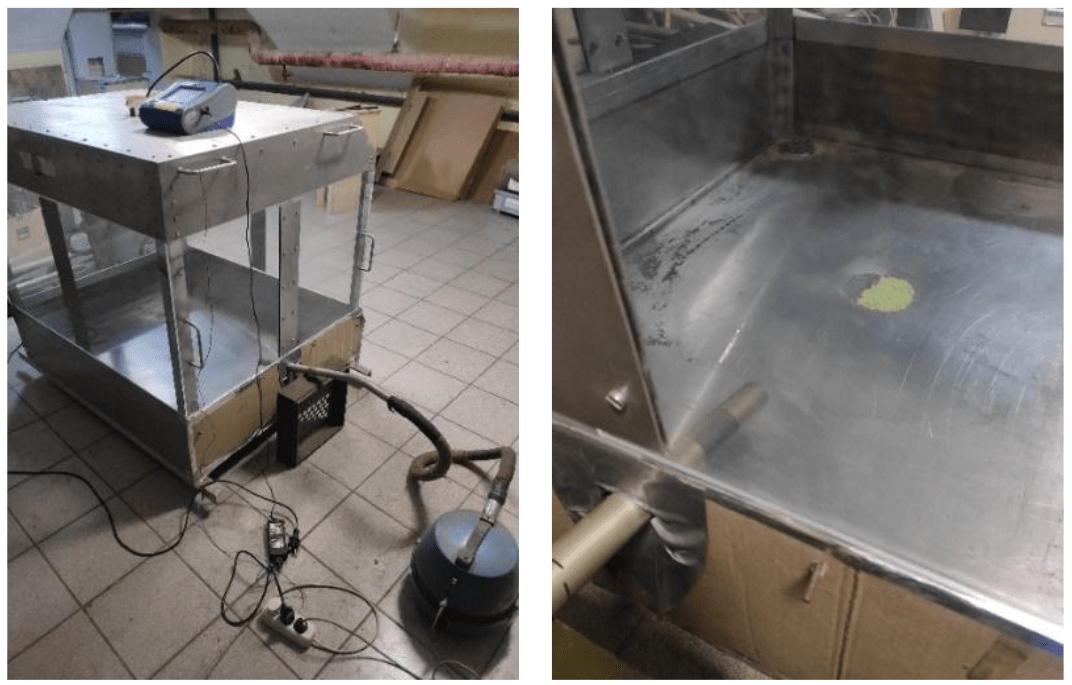

The effectiveness of reducing dust emission during irrigation of sulfur with various reagents was determined at a laboratory installation designed by St. Petersburg Mining University, which is a dust suppression hopper BPP 001 and a dust meter-nephelometer DustTrak 8533 (Fig.1).

The DustTrak DRX Model 8533 dust meter is a desktop analyzer with interchangeable impactors for measuring the mass concentration and fractional composition of dust in real time. This model of dust meter has an external pump that allows continuous monitoring of the concentration of suspended particles. The DustTrak dust analyzer measures the fractions PM10, PM4, PM2.5 and PM1 set by the standards, as well as the total dust content simultaneously, by combining an optical meter and a nephelometer in one housing. The measurement range of the aerosol mass concentration is 0.1-150 mg/m3.

Before conducting the experiment in the dust suppression hopper, the main meteorological characteristics were measured using the MES-200A meteometer: air temperature, relative humidity and air flow speed.

The method [34] for determining the effectiveness of dust suppression was implemented as follows:

- For testing in BPP 001, the optimal weight of the suspension of the studied sulfur dust was determined – 15 g. Such a mass was selected by performing preparatory experiments taking into account the current aerodynamic conditions formed in the dust suppression hopper of dust concentrations and the measurement limits and errors of the dust meter.

- Prior to testing with dusty samples, the dust suppression hopper was disassembled and vacuumed. The use of wet cleaning was limited in order to prevent changes in the formed experimental conditions, in particular, air humidity.

- A compressor nozzle was installed and fixed in the front part of the hopper and the air supply was started. At the location of the dust samples at the bottom of the dust suppression hopper, the air speed was measured and adjusted. After setting the desired wind speed (in the ongoing work, the wind speed in the surface layer of the considered area of the Ust-Luga MTP is 7 m/s), the air blower nozzle was turned off.

- The installation was completely assembled. A holder with an air intake tube was inserted into a special hole on the lid of the hopper, the opposite end of which was connected to the DustTrak 8533 dust meter. In order to prevent the accumulation of static electricity, the hopper was grounded with a special wire.

- At the same time, the air supply to the hopper was turned on at a fixed speed and the measurement of dust concentrations was started using a dust meter. The duration of measurements in the work carried out was 2 min, which is due to the unevenness of the dust concentrations created at the point where the concentrations were recorded by the dust meter. As a result of this test, the background dust concentration was obtained before placing dusty samples in the hopper.

- Next, all devices and grounding were disconnected, the air intake tube was dismantled, and the hopper was completely disassembled. An oval mold with an area of 110 cm2 was placed at the bottom of the hopper in a specially marked place in the center. The test sample of sulfur dust was poured into a mold and evenly distributed over the surface using a spatula. Thus, an ellipse-shaped dust sample was formed at the bottom of the hopper.

- The hopper was completely assembled in the same way as paragraph 4.

- With the launch of the air blower and the dust meter-nephelometer, dust concentrations in the dust suppression hopper were measured. In addition to the background concentration, dust particles were thrown up from the surface of the sample placed at the bottom of the hopper. The duration of the measurements was 2 min.

- The hopper was disassembled again and vacuumed. The remains of the analyzed dust sample were removed using a vacuum cleaner.

Fig.1. Laboratory dust suppression unit in the laboratory of the Mining University

Discussion of the results

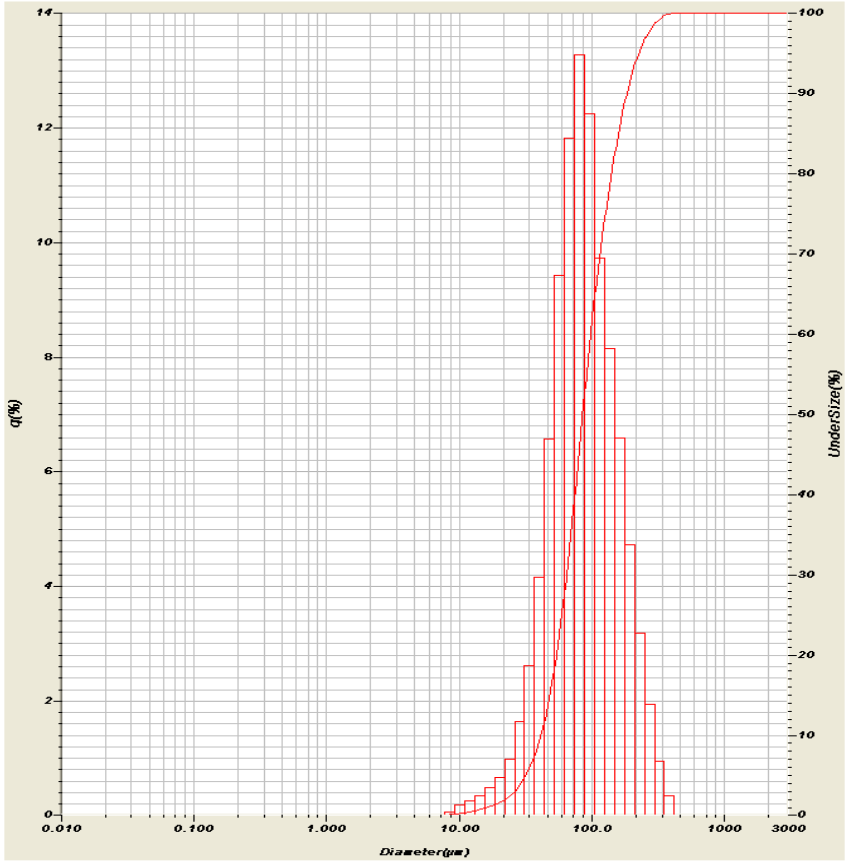

According to the obtained results of granulometric analysis on the HORIBA LA-950V2 device (Fig.2) it was found that the average size of dust particles collected at the sulfur processing unit is 101 microns. At the same time, the highest content in the sample (about 13 %) falls on particles with a diameter of 88 microns, and the proportion of particles of the dusty fraction (less than 10 microns), which is of the greatest interest, is about 0.2 %.

Based on the results of the analysis of scientific publications on the development of compositions for suppressing dust during the transshipment of bulk materials, the following chemicals were selected for research:

- a mixture of oligomers of C12-14-alkyl polyglycosides (APG);

- sodium silicic acid meta 5-aqueous Na2SiO3·5H2O (sodium silicate);

- soluble starch (С6H10O6)n.

Aqueous solutions with three different concentrations wt.% were prepared with these substances:

- alkyl polyglycosides 0.5/1/1.5 %;

- sodium silicate 0.5/1/1.5 %;

- starch 1/2.5/5 %.

A visual experiment was conducted with the obtained aqueous solutions to determine the possibility of these substances to contribute to the granulation of sulfur dust particles to ensure the prevention of further dusting. Sulfur samples of 15 g were scattered on paper, the studied solutions were sprayed onto dust samples using a spray gun in an amount of about 3.6 g and mixed.

Fig.2. Histogram of the particle size distribution of dust taken at the enterprise

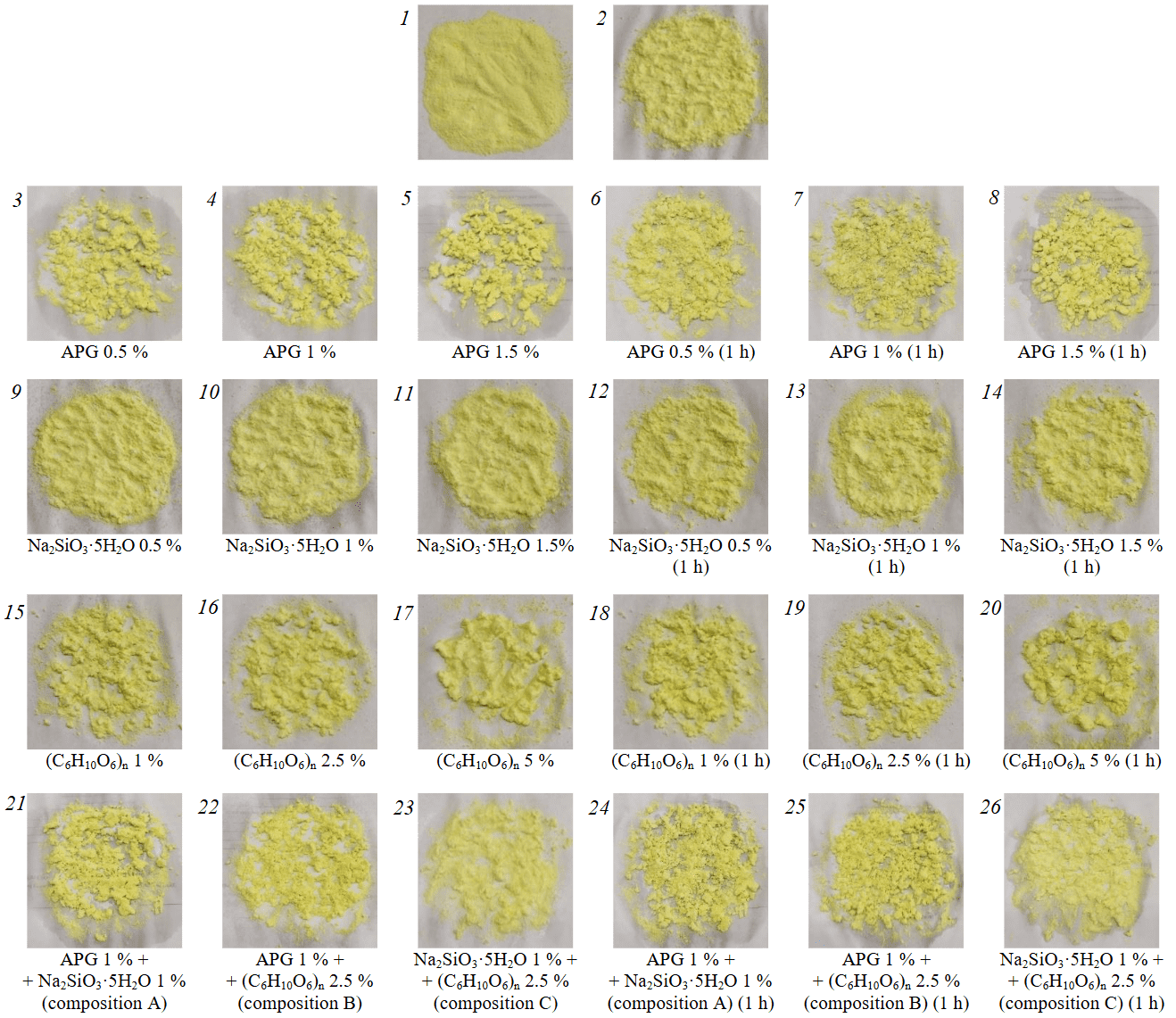

Photos of sulfur before irrigation, as well as after irrigation with clean water are shown in Fig.3 (1, 2).

Fig.3 (3-5, 9-11, 15-17) shows dust samples after irrigation with aqueous solutions of alkyl polyglycosides, sodium silicate, and starch. The observations show that nonionic surfactants and starch solution contribute to the greatest granulation of sulfur.

Fig.3 (6-8, 12-14, 18-20) shows the results of a visual experiment to determine the properties of granulation of the studied substances 1 h after irrigation. It can be seen that the granulation of sulfur particles under the influence of solutions of alkyl polyglycosides and starch decreases, but remains quite high compared with a solution of sodium silicate and pure water.

In addition to single-component aqueous solutions, binary compositions from mixtures of the substances in question were tested in the following ratios, wt.%:

- composition A – alkyl polyglycosides 1 %, sodium silicate 1 %;

- composition B – alkyl polyglycosides 1 %, starch 2.5 %;

- composition C – sodium silicate 1 %, starch 2.5 %.

The results are shown in Fig.3 (21-26). The greatest effect of granulation is shown by compositions A and B.

Tests were carried out in the dust suppression hopper to determine the effectiveness of irrigation of sulfur with water and various substances. Sulfur was treated with dust suppression agents by surface spraying with a spray gun. 1.8 g of water or an aqueous solution of a dust suppressor was applied to the dry sample. A series of three experiments was carried out with each reagent under consideration, in which the concentration of dust particles was measured instantly. In addition, three experiments were conducted with measuring the dust concentration after 20 min.

Fig.3. Visual determination of sulfur samples granulation: 1 – without dust suppression in air-dry condition; 2 – after water irrigation; 3 – when treated with an aqueous 0.5 % solution of alkyl polyglycosides; 4 – by 1 % solution;

5 – by 1.5 % solution; 6 – by 0.5 % solution after 1 h; 7 – by 1 % solution after 1 h; 8 – by 1.5 % solution after 1 h; 9 – when treated with an aqueous 0.5 % sodium silicate solution; 10 – by 1 % solution; 11 – by 1.5 % solution; 12 – by 0.5 % solution after 1 h; 13 – by 1 % solution after 1 h; 14 – by 1.5 % solution after 1 h; 15 – when treated with an aqueous 1 % starch solution; 16 – by 2.5 % solution; 17 – by 5 % solution; 18 – by 1 % solution after 1 h; 19 – by 2.5 % solution after 1 h; 20 – by 5 % solution after 1 h; 21 – when treated with a water-based formulation containing 1 % alkyl polyglycosides and 1 % sodium silicate (composition A); 22 – composition with 1 % alkyl polyglycosides and 2.5 % starch (composition B); 23 – composition with 1 % sodium silicate and 2.5 % starch (composition C); 24 – by composition A after 1 h; 25 – by composition B after 1 h; 26 – by composition C after 1 h

Tests in the dust suppression hopper were carried out with aqueous solutions of the following concentrations, wt.%: alkyl polyglycosides – 1 %, sodium silicate – 1 %, starch – 2.5 %, compositions A, B, and C.

The effectiveness of reducing dust emission was estimated by the formula:

where Coi – concentration without dust suppression, mg/m3; Cli – concentration when using dust suppression agents, mg/m3; n – number of measurements.

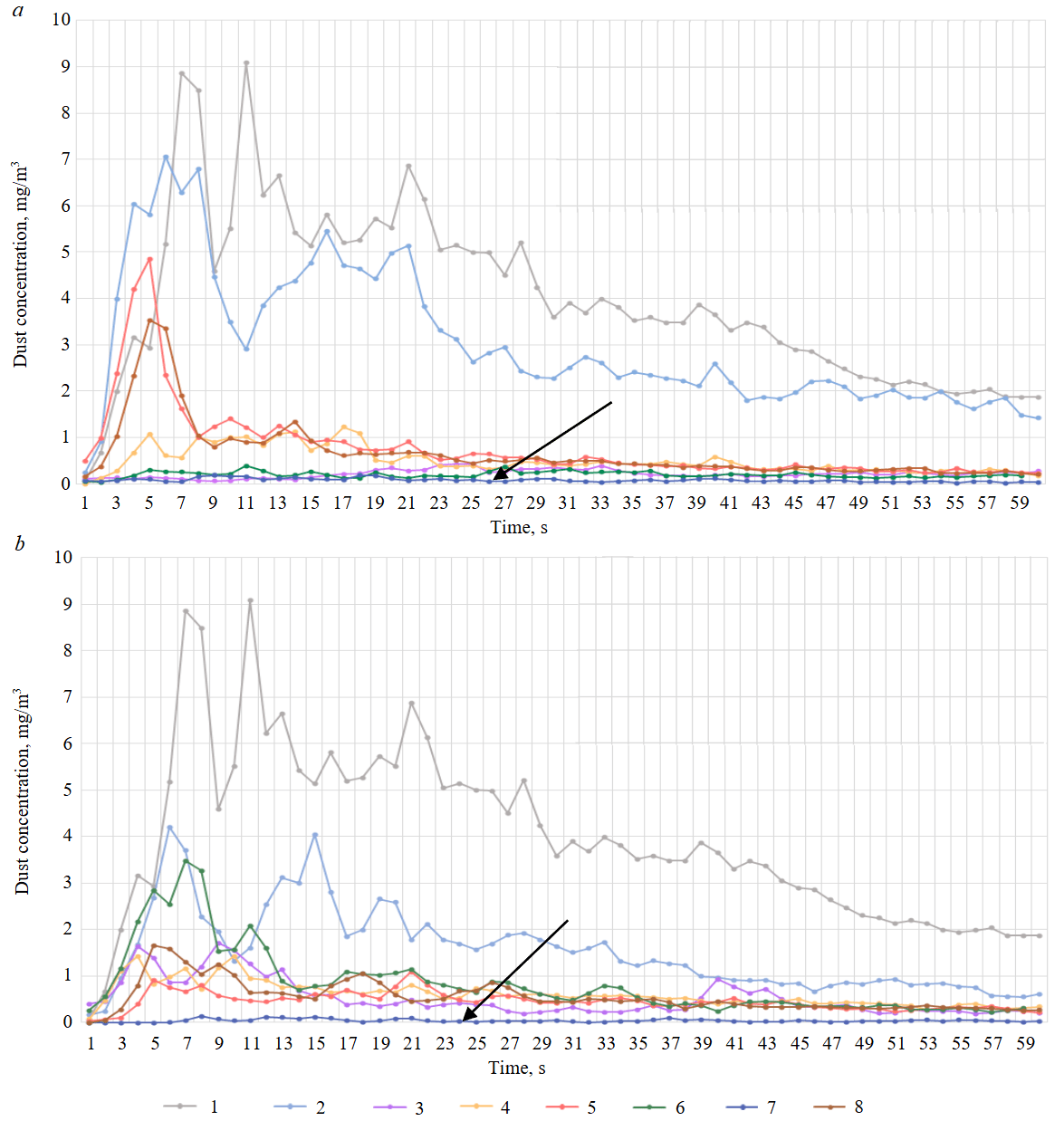

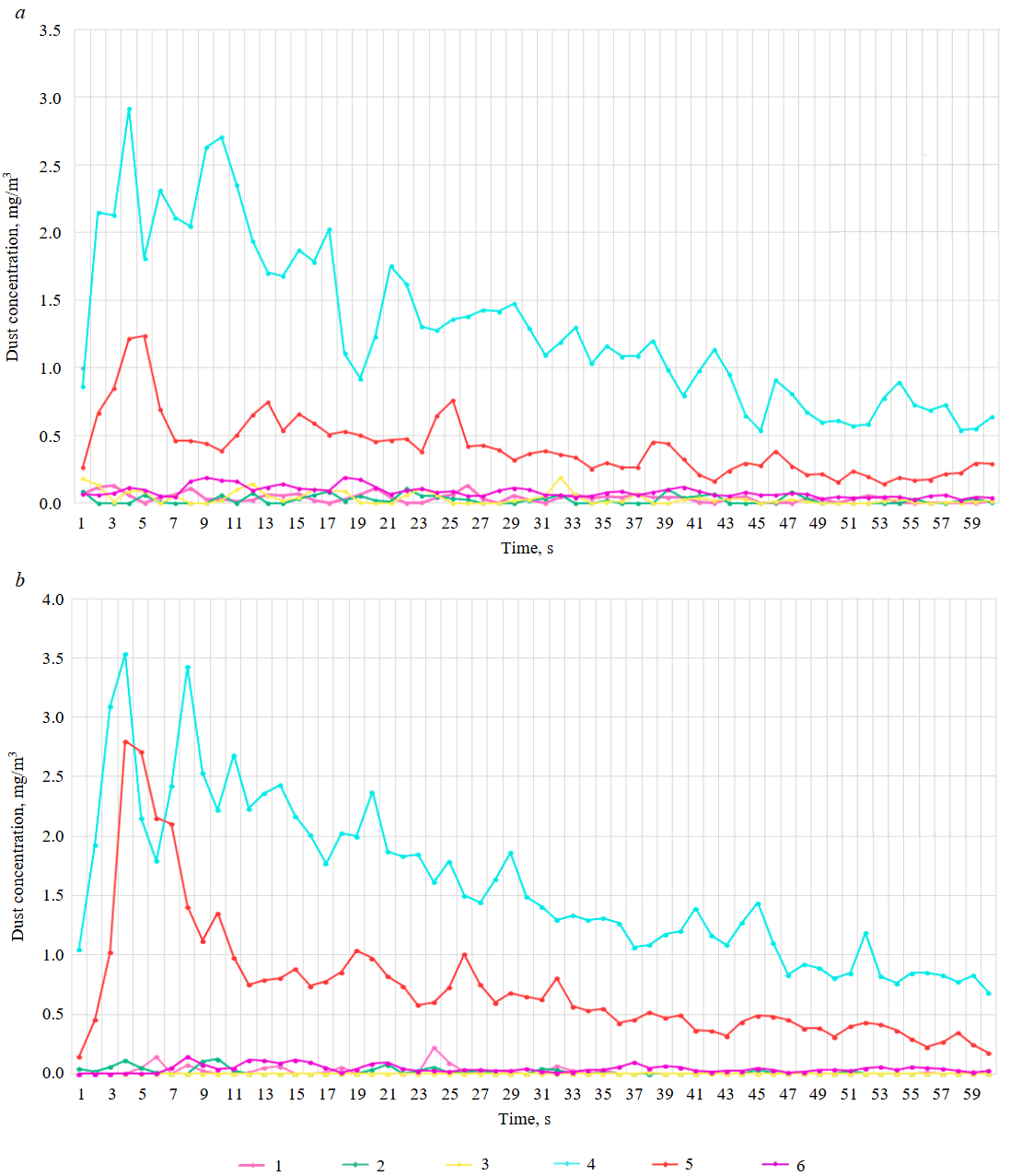

Graphs of the dependence of dust concentrations on time are shown in Fig.4. The results of calculating the dust suppression efficiency are presented in Table 1.

Table 1

The results of measuring the dust concentration using various means of dust suppression

|

Dust suppression agent |

Average concentration at a time, mg/m3 |

Air temperature, °С |

Air |

Average dust efficiency, % |

|

|||

|

10 s |

30 s |

75 s |

120 s |

|

||||

|

Without dust suppression |

9.085 |

3.594 |

1.409 |

0.557 |

18.1 |

29 |

– |

|

|

Water |

3.487 |

2.273 |

1.226 |

0.471 |

17.9 |

31 |

30.5 |

|

|

Water after 20 min |

1.322 |

1.648 |

0.529 |

0.124 |

18.4 |

33 |

64.4 |

|

|

Alkyl polyglycosides |

0.075 |

0.357 |

0.198 |

0.124 |

18.0 |

28 |

87.4 |

|

|

Alkyl polyglycosides after 20 min |

1.548 |

0.268 |

0.148 |

0.083 |

17.7 |

25 |

86.2 |

|

|

Sodium silicate |

0.999 |

0.999 |

0.213 |

0.099 |

18.0 |

28 |

86.2 |

|

|

Sodium silicate after 20 min |

1.432 |

0.590 |

0.217 |

0.077 |

18.4 |

28 |

83.6 |

|

|

Starch |

1.402 |

0.420 |

0.206 |

0.061 |

17.5 |

26 |

83.9 |

|

|

Starch after 20 min |

0.515 |

0.425 |

0.142 |

0.059 |

17.5 |

26 |

87.3 |

|

|

Composition А |

0.207 |

0.282 |

0.087 |

0.029 |

18.0 |

28 |

93.2 |

|

|

Composition А after 20 min |

1.575 |

0.525 |

0.196 |

0.083 |

18.0 |

28 |

82.6 |

|

|

Composition B |

0.165 |

0.100 |

0.021 |

0.023 |

17.5 |

28 |

97.5 |

|

|

Composition B after 20 min |

0.039 |

0.044 |

0.013 |

0.006 |

17.5 |

28 |

98.9 |

|

|

Composition C |

0.979 |

0.457 |

0.196 |

0.062 |

17.7 |

33 |

85.0 |

|

|

Composition C after 20 min |

1.024 |

0.452 |

0.149 |

0.061 |

17.7 |

33 |

86.6 |

|

Fig.4. Graph of the dependence of the total concentration of dust particles on time during instantaneous measurement (a) and 20 minutes later (b) after irrigation of sulfur with water and other substances

1 – without dust suppression; 2 – water; 3 – alkyl polyglycosides; 4 – sodium silicate; 5 – starch; 6 – composition А; 7 – composition B; 8 – composition C

The results show that composition B, which is a mixture of alkyl polyglycosides and starch, is the most effective. The dust suppression efficiency is 97.5 % with instantaneous measurement and reaches 98.9 % after 20 min, which indicates a decrease in the possibility of repeated dusting of the material.

To clarify the concentrations of the components of the developed composition, additional experiments were conducted to evaluate the effectiveness of dust suppression of a composition based on nonionic surfactants and starch with the following component ratios, wt.%:

- composition 1 – alkyl polyglycosides 0.5 %, starch 2.5 %;

- composition 2 – alkyl polyglycosides 1.5 %, starch 1 %;

- composition 3 – alkyl polyglycosides 1.5 %, starch 2.5 %;

- composition 4 – alkyl polyglycosides 0.5 %, starch 1 %;

- composition 5 – alkyl polyglycosides 1 %, starch 1 %;

- composition 6 – alkyl polyglycosides 1 %, starch 2.5 %;

The use of starch in a concentration of 5 % was excluded based on the results of a visual experiment for determining granulation due to the high content of the substance in question and the possibility of its negative effect on the physico-chemical properties of the product.

Dust concentrations were measured for all experiments at a temperature of 19.6 °C and an air humidity of 41 %. The results of calculating the efficiency of dust suppression using different compositions of alkyl polyglycosides and starch are presented in Table 2. Graphs of the dependence of sulfur dust concentrations on time are shown in Fig.5.

The experiments show that the proposed composition achieves the highest efficiency of sulfur dust suppression with the following content of components in an aqueous solution: a mixture of C12-14-alkyl polyglycosides oligomers – 1-1.5; soluble starch – 1-2.5 wt.%.

Table 2

The results of measuring the dust concentration using different compositions of alkyl polyglycosides and starch

|

Dust suppression agent |

Average concentration at a time, mg/m3 |

Average dust suppression efficiency, % |

Efficiency compared |

|||

|

10 s |

30 s |

75 s |

120 s |

|||

|

Composition 1 |

2.211 |

1.212 |

0.383 |

0.131 |

86.5 |

68.2 |

|

Composition 1 after 20 min |

0.142 |

0.045 |

0.023 |

0.012 |

97.1 |

96.8 |

|

Composition 2 |

0.056 |

0.021 |

0.024 |

0.004 |

98.1 |

97.2 |

|

Composition 2 after 20 min |

0.124 |

0.019 |

0.013 |

0.009 |

99.7 |

96.1 |

|

Composition 3 |

0.019 |

0.023 |

0.002 |

0.003 |

98.3 |

98.6 |

|

Composition 3 after 20 min |

0.008 |

0.013 |

0.001 |

0.005 |

99.7 |

99.3 |

|

Composition 4 |

2.707 |

1.290 |

0.436 |

0.165 |

66.3 |

56.5 |

|

Composition 4 after 20 min |

2.219 |

1.492 |

0.380 |

0.177 |

63.2 |

38.2 |

|

Composition 5 |

0.385 |

0.366 |

0.184 |

0.029 |

88.3 |

86.7 |

|

Composition 5 after 20 min |

1.353 |

0.651 |

0.288 |

0.062 |

81.5 |

64.8 |

|

Composition 6 |

0.165 |

0.100 |

0.021 |

0.023 |

97.1 |

97.2 |

|

Composition 6 after 20 min |

0.039 |

0.044 |

0.013 |

0.006 |

98.9 |

97.1 |

Fig.5. Graphs of the dependence of the total concentration of dust particles on time during instantaneous measurement(a) and 20 min (b) after irrigation of sulfur with the tested compounds

1-6 – compositions 1-6

The proposed composition can be used in existing water aerosol dust suppression systems at sulfur transportation facilities. In seaports and railway terminals, the first transshipment operation is the transshipment of sulfur from a gondola car to a conveyor belt by means of a car dump device located in an isolated room. As a rule, at this stage of transshipment, the first stage of the dust suppression system is implemented – a network of nozzles oriented to the pouring front. Repeated dust suppression (subsequent stages) is carried out by nozzle networks in closed transfer hoppers between conveyor sections. The operation of such a system using the proposed composition will allow granulation to reduce dust emission during all further sulfur transshipment operations, this is provided in two ways: humidification, coagulation, precipitation of blown sulfur dust in the air and humidification of the surface of the transported sulfur containing dusty fractions. The proposed composition can be used for spraying with different types of nozzles, and the conditions created in the BPP 001 dust suppression hopper are similar to those created in isolated rooms and closed overflow hoppers.

Conclusion

An experimental assessment of the effectiveness of various dust suppression methods conducted in the laboratories of Saint Petersburg Mining University has allowed to establish that the use of clean water as a working medium for the dust suppression process at granulated sulfur treatment facilities really shows low efficiency (30.5 %), which can lead to contamination of territories with sulfur dust formed as a result of transshipment.

As is known, sulfur is hydrophobic, i.e. it is not wetted with water. Surfactant molecules, having a diphilic nature, are adsorbed on the water – sulfur interface, which leads to a decrease in the surface tension of water. Nonionic surfactants, represented by alkyl polygligosides, added to water to increase the wettability of the processed material, are characterized not only by high efficiency, but also by good biodegradability. Alkyl polyglycosides are characterized by the highest emulsifying ability among industrial surfactants, which effectively reduces their consumption when used as a working medium for dust suppression [35, 36].

Polysaccharides are one of the most affordable and cheap resources, whose reserves are continuously replenished due to photosynthesis in plants. Starch is a high molecular weight organic compound represented by a mixture of amylose and amylopectin. Starch macromolecules are elongated and branched chains consisting of D-glucose residues in amylosis, interconnected by glycoside bonds. In addition to carbohydrates, starch contains a certain amount of fatty acids, which determine its ability to form a number of esters and ethers [37].

Starch hydrogels (paste) are widely used in various industries. There are known studies [38] confirming the ability of amylose in starch to form non-stoichiometric compounds with alcohols and other hydrocarbons. The reason for the steady thickening and increase in viscosity of starch hydrogels is the formation of complexes between starch amylose and highly mobile surfactant

molecules.

For dust suppression at granulated sulfur treatment facilities, it is proposed to use a composition based on nonionic surfactants represented by a mixture of C12-14-alkylglycosides oligomers, additionally containing a mixture of amylose and amylopectin polysaccharides in the form of soluble starch and water in the following component ratio, wt.%: a mixture of C12-14-alkylpolyglycosides oligomers – 1-1.5; soluble starch – 1-2.5.

The proposed highly dispersed sulfur dust suppressor showed consistently high dust suppression efficiency both when measured immediately after irrigation (98.3 %) and after the expected time (99.7 %). The developed composition provides an increase in the dust-suppressing ability of the solution and the elimination of the possibility of repeated dusting due to the formation of a polymer film on the surface, as well as the regranulation of the product crushed by abrasion. The treatment of highly dispersed sulfur with this dust suppressor guarantees an effective reduction in the surface tension of water at such concentrations of the components used that eliminate negative effects on other physical-chemical properties of the finished product, such as flowability, hygroscopicity and caking.

References

- Saleh T.A. Characterization, determination and elimination technologies for sulfur from petroleum: Toward cleaner fuel and a safe environment. Trends in Environmental Analytical Chemistry. 2020. Vol. 25. N e00080. DOI: 10.1016/j.teac.2020.e00080

- Rongrong Yang, Zhirong Wang, Juncheng Jiang et al. Cause analysis and prevention measures of fire and explosion caused by sulfur corrosion. Engineering Failure Analysis. 2020. Vol. 108. N 104342. DOI: 10.1016/j.engfailanal.2019.104342

- Naiyan Zhang, Zhi Zhang, Zhenhua Rui et al. Comprehensive risk assessment of high sulfur-containing gas well. Journal of Petroleum Science and Engineering. 2018. Vol. 170, p. 888-897. DOI: 10.1016/j.petrol.2018.07.016

- Shakhparonova T., Sobianina D., Karapetyan K. Development of a dissolution model of a vitreous phosphorus-containing fertilizer concerning interdiffusion applied for calculation of fertilizer doses. Research on Crops. 2021. Vol. 22. Iss. 2, p. 279-284. DOI: 10.31830/2348-7542.2021.069

- Kameshkov A.V., Kondrasheva N.K., Gabdulkhakov R.R., Rudko V.A. Comparison of coking additives obtained from different types of oil stock. Tsvetnye metally. 2020. N 10, p. 35-42 (in Russian). DOI: 10.17580/tsm.2020.10.05

- Rodionov V.A., Karpov G.N., Leisle A.V. Methodological approach to the need to assess the explosion and fire hazard properties of sulfide-containing polymetallic ores. Mining Informational and Analytical Bulletin. 2022. Iss. 6-1, p. 198-213 (in Russian). DOI: 10.25018/0236_1493_2022_61_0_198

- Dvoynikov M.V., Nutskova M.V., Blinov P.A. Developments Made in the Field of Drilling Fluids by Saint Petersburg Mining University. International Journal of Engineering. 2020. Vol. 33. Iss. 4, p. 702-711. DOI: 10.5829/IJE.2020.33.04A.22

- Kovalevsky V.N., Mysin A.V. Performance of tubular elastic charges in natural stone production. Mining Informational and Analytical Bulletin. 2023. N 1, p. 20-34 (in Russian). DOI: 10.25018/0236_1493_2023_1_0_20

- Zhukovskiy Y.L., Batueva D.E., Buldysko A.D. et al. Fossil Energy in the Framework of Sustainable Development: Analysis of Prospects and Development of Forecast Scenarios. Energies. 2021. Vol. 14. Iss. 17. N 5268. DOI: 10.3390/en14175268

- Boikov A., Savelev R., Payor V., Potapov A. Universal Approach for DEM Parameters Calibration of Bulk Materials. Symmetry. 2021. Vol. 13. Iss. 6. N 1088. DOI: 10.3390/sym13061088

- Kantyukov R.R., Zapevalov D.N., Vagapov R.K. Analysis of the application and impact of carbon dioxide media on the corrosion state of oil and gas facilities. Journal of Mining Institute. 2021. Vol. 250, p. 578-856. DOI: 10.31897/PMI.2021.4.11

- Khuzhakulov A.Kh. The use of sulfur in agriculture in Uzbekistan and training in safety requirements. Problemy nauki. 2021. N 6 (65), p. 96-102. DOI: 10.24411/2413-2101-2021-10601

- Ivanov A.V., Smirnov Y.D., Lisay V.V., Borowski G. Issues of the Impact of Granulated Sulfur Transportation on the Environmental Components. Journal of Ecological Engineering. 2023. Vol. 24. Iss. 6, p. 86-97. DOI: 10.12911/22998993/162558

- Bazhin V., Masko O. Monitoring of the Behaviour and State of Nanoscale Particles in a Gas Cleaning System of an Ore-Thermal Furnace. Symmetry. 2022. Vol. 14. Iss. 5. N 923. DOI: 10.3390/sym14050923

- Zyryanova O.V., Kireeva E.V., Abramova A.E. Development of Dust-suppressing Compositions to Ensure Environmental Safety in Open-pit Mining. Ecology and Industry of Russia. 2022. Vol. 26. N 10, p. 22-28 (in Russian). DOI: 10.18412/1816-0395-2022-10-22-28

- Cong Zhang, Shuo Yuan, Ningning Zhang et al. Dust-suppression and cooling effects of spray system installed between hydraulic supports in fully mechanized coal-mining face. Building and Environment. 2021. Vol. 204. N 108106. DOI: 10.1016/j.buildenv.2021.108106

- Qun Zhou, Botao Qin. Coal dust suppression based on water mediums: A review of technologies and influencing factors. Fuel. 2021. Vol. 302. N 121196. DOI: 10.1016/j.fuel.2021.121196

- Chaohang Xu, Hetang Wang, Deming Wang et al. Improvement of Foaming Ability of Surfactant Solutions by Water-Soluble Polymers: Experiment and Molecular Dynamics Simulation. Polymers. 2020. Vol. 12. Iss. 3. N 571. DOI: 10.3390/polym12030571

- Hetang Wang, Xiaobin Wei, Yunhe Du, Deming Wang. Effect of water-soluble polymers on the performance of dust-suppression foams: Wettability, surface viscosity and stability. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2019. Vol. 568, p. 92-98. DOI: 10.1016/j.colsurfa.2019.01.062

- Smirnyakov V.V., Rodionov V.A., Smirnyakova V.V., Orlov F.A. The influence of the shape and size of dust fractions on their distribution and accumulation in mine workings when changing the structure of air flow. Journal of Mining Institute. 2022. Vol. 253, p. 71-81. DOI: 10.31897/PMI.2022.12

- Guang Xu, Yinping Chen, Jacques Eksteen, Jialin Xu. Surfactant-aided coal dust suppression: A review of evaluation methods and influencing factors. Science of the Total Environment. 2018. Vol. 639, p. 1060-1076. DOI: 10.1016/j.scitotenv.2018.05.182

- Xiaobin Wei, Hetang Wang, Ying Xie, Yunhe Du. An experimental investigation on the effect of carboxymethyl cellulose on morphological characteristics of dust-suppression foam and its mechanism exploration. Process Safety and Environmental Protection. 2020. Vol. 135, p. 126-134. DOI: 10.1016/j.psep.2019.12.009

- Zidong Zhao, Ping Chang, Guang Xu et al. Comparison of the coal dust suppression performance of surfactants using static test and dynamic test. Journal of Cleaner Production. 2021. Vol. 328. N 129633. DOI: 10.1016/j.jclepro.2021.129633

- Ping Chang, Zidong Zhao, Guang Xu et al. Evaluation of the coal dust suppression efficiency of different surfactants: A factorial experiment. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2020. Vol. 595. N 124686. DOI: 10.1016/j.colsurfa.2020.124686

- Yen-Yi Lee, Chung-Shin Yuan, Po-Hsuan Yen et al. Suppression Efficiency for Dust from an Iron Ore Pile Using a Conventional Sprinkler and a Water Mist Generator. Aerosol and Air Quality Research. 2022. Vol. 22. Iss. 2. N 210320. DOI: 10.4209/aaqr.210320

- Huitian Peng, Wen Nie, Peng Cai et al. Development of a novel wind-assisted centralized spraying dedusting device for dust suppression in a fully mechanized mining face. Environmental Science and Pollution Research. 2019. Vol. 26. Iss. 4, p. 3292-3307. DOI: 10.1007/s11356-018-3264-8

- Friesen D.E., Radok A. Patent N CA 2640857 A1. Methods and compositions for coating sulfur blocks. Publ. 10.04.2009.

- Weagle G., Horvath T. Patent N CA 2645851 A1. Method and composition to form a flexible crust on a substrate. Publ. 04.06.2010.

- Katsubin A.V., Kovshov S.V., Ilyashenko I.S., Marinina V.M. Study of Organic Compounds for Reduction of the Aerotechnogenic Load from the Coal Mines Highways. Occupational Safety in Industry. 2020. N 1, p. 63-67 (in Russian). DOI: 10.24000/0409-2961-2020-1-63-67

- Winstanley R.A., Swartzlander M.W., Cooke T.W. Patent N US 5223165 A. Use of alkyl glycosides for dust suppression. Publ. 29.06.1993.

- van der Galiën M. Patent N NL 2011049 C2. Dust-suppressing composition and method there for. Publ. 05.01.2015.

- Beeksma W.J. Patent N NL 1027690 C2. Antidusting composition for treating dust-producing materials comprises alkyl glucoside, nonionic surfactant and water. Publ. 01.08.2006.

- Korneva M.V. Development and justification of measures to reduce the concentration of fine fractions in the dust aerosol of coal mines: Avtoref. dis. … kand. tekhn. nauk. Saint Petersburg: Saint Petersburg Mining University, 2020, p. 20.

- Ivanov A.V., Smirnov Yu.D., Chupin S.A. Development of the concept of an innovative laboratory installation for the study of dust-forming surfaces. Journal of Mining Institute. 2021. Vol. 251, p. 757-766. DOI: 10.31897/PMI.2021.5.15

- Skorobogatko D.S., Golovkov A.N., Kudinov I.I., Kulichkova S.I. Revisiting the ecotoxicity and efficiency of different classes of industrial nonionic surfaces used for cleaning metal surfaces in the process of capillary control of details of the aviation technology (review). Aviation Materials and Technologies. 2021. N 4 (65), p. 98-106 (in Russian). DOI: 10.18577/2713-0193-2021-0-4-98-106

- Nureev R.R., Pashkevich M.A., Kharko P.A. Assessment of the impact of copper ore processing waste on surface and groundwater. Geology and Geophysics of Russian South. 2022. Vol. 12. N 4, p. 169-179 (in Russian). DOI: 10.46698/VNC.2022.37.95.013

- Mozheyko F.F., Shevchuk V.V., Potkina T.N., Voytenko A.I. Using mixtures of non-ionic surfactants and polyvalent metal salts use for sylvinite ore flotation. Proceedings of the National Academy of Sciences of Belarus, Chemical Series. 2014. N 1, p. 113-117 (in Russian).

- Yusova A.A., Lipatova I.M., Moryganov A.P. Influence of Surfactants on the State of Starch Hydrogels under High Shear Stresses. Russian Journal of Applied Chemistry. 2003. Vol. 76. N 3, p. 434-438. DOI: 10.1023/A:1025609003041