Development and research of backfill compounds with improved elastic and strength properties for oil and gas well lining

- 1 — Ph.D. Associate Professor Empress Catherine II Saint Petersburg Mining University ▪ Orcid

- 2 — Postgraduate Student Empress Catherine II Saint Petersburg Mining University ▪ Orcid

- 3 — Ph.D., Dr.Sci. Professor Empress Catherine II Saint Petersburg Mining University ▪ Orcid

- 4 — Ph.D. Associate Professor Empress Catherine II Saint Petersburg Mining University ▪ Orcid

Abstract

This article describes operations from the well construction cycle where the cement rock behind the casing is subjected to dynamic action (impacts of the drill stem during drilling and normalization of the cement sleeve, secondary drilling operations, hydraulic fracturing, etc.). The developed cement mortar compositions were tested following API 10B-2, API 10B-6, API STD-65-2, and GOST 28985-91 standards. The composition of the cement system without the use of imported components (CM-5) was developed, which improved elastic and strength properties compared to existing industry solutions. An improvement in the elastic and strength features and technological properties of cement rock when using epoxy resins was identified, the optimal composition of the cement-and-epoxy grout was determined, and the internal structure of the formed backfill rock, its permeability, and porosity were studied.

Introduction

In 2022, the volume of drilling in Russia exceeded 28 thousand km, which was the highest value in ten years, and the total number of wells had increased by 7 % and exceeded 7,800 [1-3]. According to industry data from Bloomberg, the increase in production drilling in 2022 in Russia was associated with deteriorating production conditions, i.e., with an equivalent level of annual production in 2021-2022, it was necessary to build more wells to maintain production levels [3-5].

One of the main factors ensuring efficient extraction of hydrocarbons from the well is the joint tightness of the casing and cementing. Currently, the most common technological solution for single-stage cementation is the joint use of two types of backfill solutions: cement mortar (CM) with a normal density of 1.8-2 g/cm3 (according to the requirements of regulatory documentation and well construction programs) is used to cover the intervals of productive formations, and lightweight CM with a density of 1.4-1.6 g/cm3 overlaps the overlying intervals in the open hole and the annulus [6-8].

According to industry standards and instructions of large field operators, CMs are tested for requirements for thickening time, water yield, strength, transition time, etc. However, the standards do not contain recommendations on the necessary elastic and strength properties of cement rock with normal density, which, located in the zone of productive formations, is subject to dynamic influences at various stages of drilling, completion, development, and production that result in cracking of the cementing (cement rock/ring) from dynamic loads and deteriorated cementing tightness behind the casing [9-11].

During the construction and completion of the well, the cementing is subject to dynamic loads. The following dynamic loads are particularly destructive:

- impact of the bottom hole assembly (BHA) during normalization of the cement sleeve and drilling for the next section;

- casing pressure test;

- cumulative perforation as the most frequent and cheapest method of secondary drilling, as well as hydraulic fracturing (HF) through cementing (including acid (AHF) and multistage hydraulic fracturing (MHF)) [12-14].

The analysis of the RPI report “The Russian market of MHF equipment: the current state and scenarios of development in 2021-2030” showed the following:

- until 2030, the number of HF operations at horizontal sidetrack wells will be increasing, and the number of HF stages will increase from 9-10 to 15 or more;

- in the short term (from one to three years), Western Siberia and the Volga region, where the total volume of hard-to-recover reserves is estimated at 200 billion tons, are most likely to become the most attractive regions for the application of HF/MHF technology [15-17].

The complication of drilling conditions and the replication of not environmentally friendly (explosive) secondary drilling methods, as well as production intensification methods, such as HF, to maintain the required level of annual production volume leads to an increase in operations that have a dynamic effect on the cementing in the well construction cycle [18, 19].

Considering the current trends in the life cycle of the well during construction and development, it is necessary to develop elastic cement systems capable of effectively maintaining the insulation of productive formations under dynamic conditions. The greatest potential in increasing the elastic properties of cement rock is the method of using epoxy resin as part of a backfill solution (development of cement-and-epoxy grout), which has a beneficial effect on the elastic and strength properties, permeability, and open porosity of cement rock. The use of epoxy resin in CM is primarily justified by the greater variability of concentrations compared with classical elastomers made of rubber, the reduction of risks associated with the colmatation of casing tooling elements (the shoe, the front collar) during cementation, and a greater degree of the cement system uniformity [20-22].

Methods

The cement mixtures were prepared following the API 10B-2 standard, and during sample preparation, the recommendations of the standard for sealing and conditioning time were followed. The thermal conditions of sample exposure for the formation of cement rock correspond to the temperature conditions of the production casing and shanks of the Nadym-Purskaya region of Western Siberia (the bottom-hole temperature of the layers Ach, Yu1, and Yu2 is 95-105 °C). As a result of modeling the cementation conditions using CemPro software, the circulation temperature (71 °C (160 °F)) and pressure (40.7 MPa (5,900 psi)) were determined to test the thickening time. The holding time of the samples for the subsequent determination of the elastic properties of the cement rock was 10 days since this time interval corresponds to the minimum time from the end of the cementation operation to the start of secondary drilling work on the object under consideration [23-25].

To determine the elastic properties of cement rock, samples were made with a length of 130±10 mm and a diameter of 58.6±1 mm (according to the State Standard (GOST) 28985-97). PVC pipes 63x2.2 mm were used as a casting mold [26].

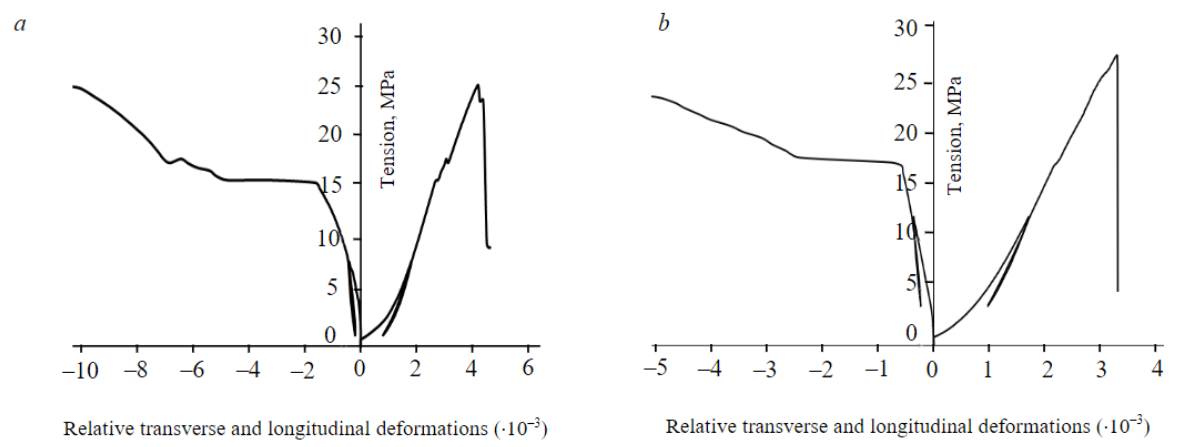

The elastic properties of cement rock were determined following GOST 28985-91 to identify the deformation characteristics, namely, the modulus of elasticity (Young modulus) and Poisson's ratio [26]. The tests were carried out at the MTS Direct Shear Test Systems installation to determine the mecha-nical properties.

The method provides for the determination of the tensile strength under uniaxial compression of the test sample since it is required to unload 50 % of the compressive strength of the sample, and then load 10 % of the tensile strength of the sample. As a rule, in this case, the phenomenon of hysteresis is observed, i.e., a mismatch of strain values during loading and unloading for the same values because the restoration of the shape and size of the body lags behind the load in time and does not obey Hooke's law.

To determine Poisson's ratio, it is necessary to measure the longitudinal and transverse deformations simultaneously. The sample is loaded continuously with a constant rate of load increase (0.6±0.2) MPa/s until its destruction. The built-in software allows one to analyze the collected data automatically and create a complete test report [26]. The strength properties of cement rock samples were determined using a Controls hydraulic press, and the test design met the requirements of API and ISO standards [9, 10, 27].

The tensile strength was determined using the method of destruction of cylindrical samples by compression according to the forming materials based on GOST 21153.3-85 “Rocks. Methods for determining the uniaxial tensile strength”, known worldwide as the Brazilian Test. The testing method implies applying a compressive load along the diameter of a cylindrical sample, leading to tensile stresses in the central part of the sample, which destroys the rock disk. According to research by many scientists, methods of intensification of production, for example, HF/MHF/AHF, create tensile stresses in cement rock. In this regard, it is necessary to pay special attention to the tensile strength when selecting CM compositions that are resistant to dynamic effects during secondary drilling operations and production intensification [18, 28-30].

Testing of the CM thickening time was carried out according to standardized API 10B-2 methods in thermobaric conditions of cementing production casing and shanks in the fields of Western Siberia using Fann 420 and Fann 290 high pressure and temperature consistometers. The thickening time is one of the main technological CM characteristics, as it regulates the permissible time of its injection and squeezing following clause 403 of the safety regulations in the oil and gas industry (PBNGP) and industry standards for well cementing implemented by the leading companies in Russia and globally [9-11].

The transition period of CMs (measurement of static shear stress from time) was studied (according to the recommendations of API 10B-6 and API Standard 65-Part 2) using the Fann MACS II multitasking CM analysis system. Thermobaric tests and simulation of the CM injection time were carried out following the average cementing conditions for production casing and shanks of the Nadym-Purskaya region of Western Siberia. CM testing to determine the transition period, according to API 10B-6, is mandatory when carrying out critical work, such as cementing shanks and production casing [11].

One of the industry requirements for normal density CM, according to RD 39-00147001-767-2000, is the permeability of cement rock. When separating the intervals of occurrence of productive formations from which extraction is planned, it is required that the permeability of cement rock to gas should not exceed 2 mD. The permeability of cement rock was tested using the PIK-PP gas permeability and porosity analyzer, designed to study the gas permeability coefficient and open porosity of rocks. The principle of operation of the device is based on the Boyle and Mariotte law, where the basic characteristic of the filtration and capacitance properties of the rock is determined by the consumption of helium passing through the rock sample; the operating range of measurement of the gas permeability coefficient is from 0.01 to 5,000 mD. The sample was placed in the receiving chamber of the analyzer, and then the permeability was automatically measured following the thermobaric conditions of the production casing and shanks [31-33].

Results

Well cementing is an established technological process in the well construction cycle; in the USA alone, cementing operations have been used since the end of the 19th century. An important role in the development of well cementing was played by E. Halliburton's invention of the JET Mixer, which made it possible to mix a dry cement mixture with a sealing liquid in a continuous mode and immediately pump it into the well without using a surge tank [28, 34].

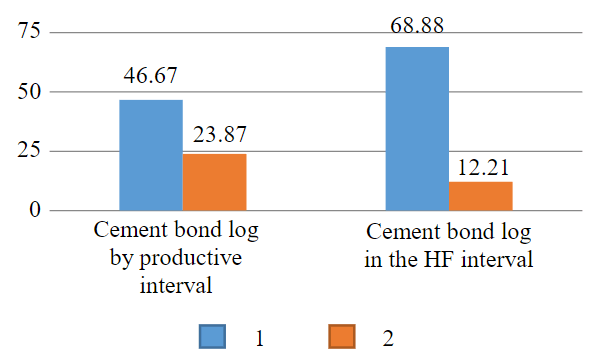

Fig.1. Cementing quality before (1) and after (2) HF, %

Well cementing is carried out by pumping special backfill solutions into the casing and then squeezing it into the annulus; most often CM is used as a grouting solution. Since the end of the 19th century, scientists, laboratory assistants, and cementing engineers have developed many variants of compositions for cementing wells and introduced and created an extensive range of additives to regulate the CM properties. However, the main disadvantage of CM as a backfill solution is the relatively small values of the elastic pro-perties of cement rock and its low ability to withstand dynamic loads [35-37].

The cumulative perforation method has been used since the late 1950s. However, in recent years, various technologies for intensifying production, such as HF (AHF, MHF), have become increasingly widespread. This is mainly due to the need to maintain the production level at a consistently high level to ensure contractual obligations for oil supply in conditions of depletion of field reserves of the existing fund. Besides, according to forecasts of analytical agencies, until 2030, there will be a trend of stable growth and an increase in the number of works on secondary drilling of HF/MHF, as well as an increase in the stages of MHF to 15 [14, 28, 38].

From the completion of the work on the well lining to the occurrence of loss of tightness, several technological operations take place (pressure test, perforation, inflow, etc.), the execution of which creates dynamic loads on the casing transmitted to the cement rock. These impacts worsen the quality of the cementing and lead to cracking, loss of adhesion (to the casing and rock), and the formation of micro-gaps when using inelastic cement rock. According to OOO KogalymNIPIneft, the quality of cementing after hydraulic fracturing decreases two to three times, and the probability of leakage increases, as a result of which flow channels can form in the annulus and the space behind the casing, the reservoir waters can break through in the perforation intervals, etc. The quality of casing cementing is determined using geophysical methods of well exploration, among which the most common is cement bond log (CBL) (Fig.1) [24, 39, 40].

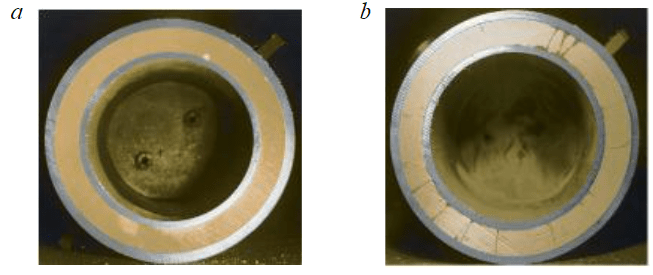

Figure 2 shows the typical effects of high overpressure on cement rock without special additives and on elastic cement rock. Cracking was recorded in the cement rock without special additives and the integrity of the cement sheath deteriorated, while the elastic cement rock withstood overpressure tests without consequences. The overpressure during testing of cement rock without special additives was 30.9 MPa, and the elastic cement composition withstood tests at a pressure of 61.8 MPa (according to Halliburton Incorporated) [22, 28, 29, 41]. According to the data cited in [42], when a micro gap of 0.38 microns is formed, cement loses adhesion to the casing, a micro gap of 25 microns is gas permeable, and a micro gap of 200 microns is fluid permeable.

To reduce the negative impact of dynamic action on the cementing and increase the tightness of the cementing, a CM with increased elastic properties should be used, i.e., a solution that forms cement rock with low values of Young's modulus and a high Poisson's ratio. Cement rock of normal density without special additives is character-rized by relatively low elastic properties (Young's modulus: 11-12 GPa, Poisson's ratio: 0.15-0.17) [15, 22, 43, 44].

To increase the elastic properties of cement rock, special additives like elasticizers are used. In this study, epoxy resin was used as an elasticizer. This is due to the significant variability in resin concentrations in the composition of the CM compared with classical elastomers from rubber processing products. Besides, the use of resin as an elastomeric additive is due to lower risks during cementing, since there is no likelihood of floating equipment clogging [20, 22].

Compositions of cement systems with different resin concentrations were developed. The reference samples were compositions of CMs with normal density and without special additives and the technological solution used was a CM with normal density and with the addition of elastomers from rubber processing products. In many ways, the CM properties depend on density. For this study, the density of CMs was determined as 1.84 g/cm3, which converges with the average density of normal-density CMs used for fastening production casing and shanks.

The CMs were created by upgrading the composition of the base CM, which did not contain special additives like elasticizers. This study considered that some additives change the output of the solution, and thus the water-cement ratio (W/C) can differ. The density of solutions was additionally checked on sealed lever scales, and the concentration of additives was calculated based on the weight of dry cement (Table 1).

Table 1

CM composition

|

Component |

СМ-1* |

СМ-2 |

СМ-3 |

СМ-4 |

СМ-5 |

СМ-6** |

|

Cement, % |

100 |

|||||

|

W/C |

0.47 |

0.47 |

0.44 |

0.43 |

0.47 |

0.44 |

|

Lignosulfonate inhibitor, % |

0.2 |

|||||

|

Water loss regulator, % |

0.25 |

|||||

|

Foam suppressant, % |

0.2 |

|||||

|

Resin, % |

4.11 |

4.11 |

7.92 |

11.90 |

4.11 |

– |

|

Firming agent % |

0.41 |

0.41 |

0.79 |

1.19 |

0.41 |

– |

|

Latex, % |

– |

– |

– |

– |

1 |

– |

|

Elastomer, % |

– |

– |

– |

– |

– |

5 |

* The basic CM composition.

** An industry-average solution for an elastic cement system.

Fig.2. Defects of cement rock when creating overpressure: a – is elastic cement rock after exposure to an overpressure of 61.8 MPa; b – is the cement rock without special additives after exposure to an overpressure of 30.9 MPa

With an increase in the concentration of epoxy resin compared to the presented formulations (CM-2, CM-3, CM-4, and CM-5), the cost of backfill solution increases, and, consequently, the profitability decreases.

Functions of the chemical reagents used:

- backfill Portland cement PCT 1-G-CC-1 – CM base (cement);

- CM inhibitor for moderate temperatures (lignosulfonate): an increase in thickening time;

- polymer of prop-2-enoic acid with 2-methyl-2-[(1-oxoprop-2-enyl) amino]-1-propanesulfonic acid – water loss regulator;

- a mixture of silicon dioxide, mineral oil, n-Decanol, and 1-Heptanol – foam suppressant;

- diglycidyl ether of bisphenol A – elastomer;

- polyethylene polyamine – firming agent;

- a mixture of rubber components – elastomer;

- latex (a copolymer of vinyl acetate and ethylene 3 %) – elastomer.

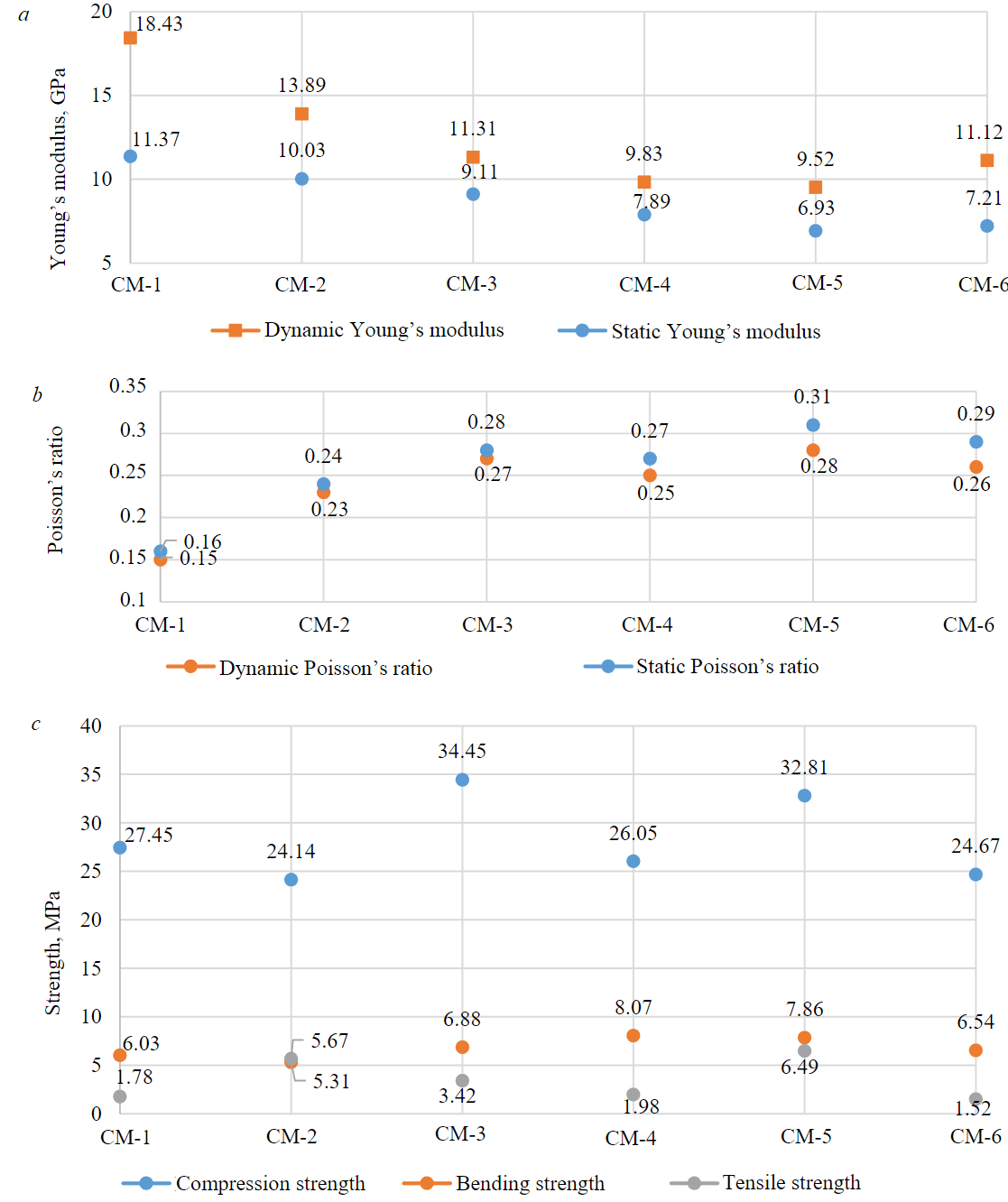

The results of the elastic strength studies were decisive in assessing the properties of elastic cement systems. The results of the experimental studies (changes in Young's modulus, Poisson's ratio, and strength properties of backfill rock) are shown in Fig.3.

Fig.3. The results of the experimental studies: change in Young's modulus (a); change in Poisson's ratio (b); strength properties of the backfill rock composition (c)

Fig.4. Test schedules for CM elastic properties: a – CM-1; b – CM-5

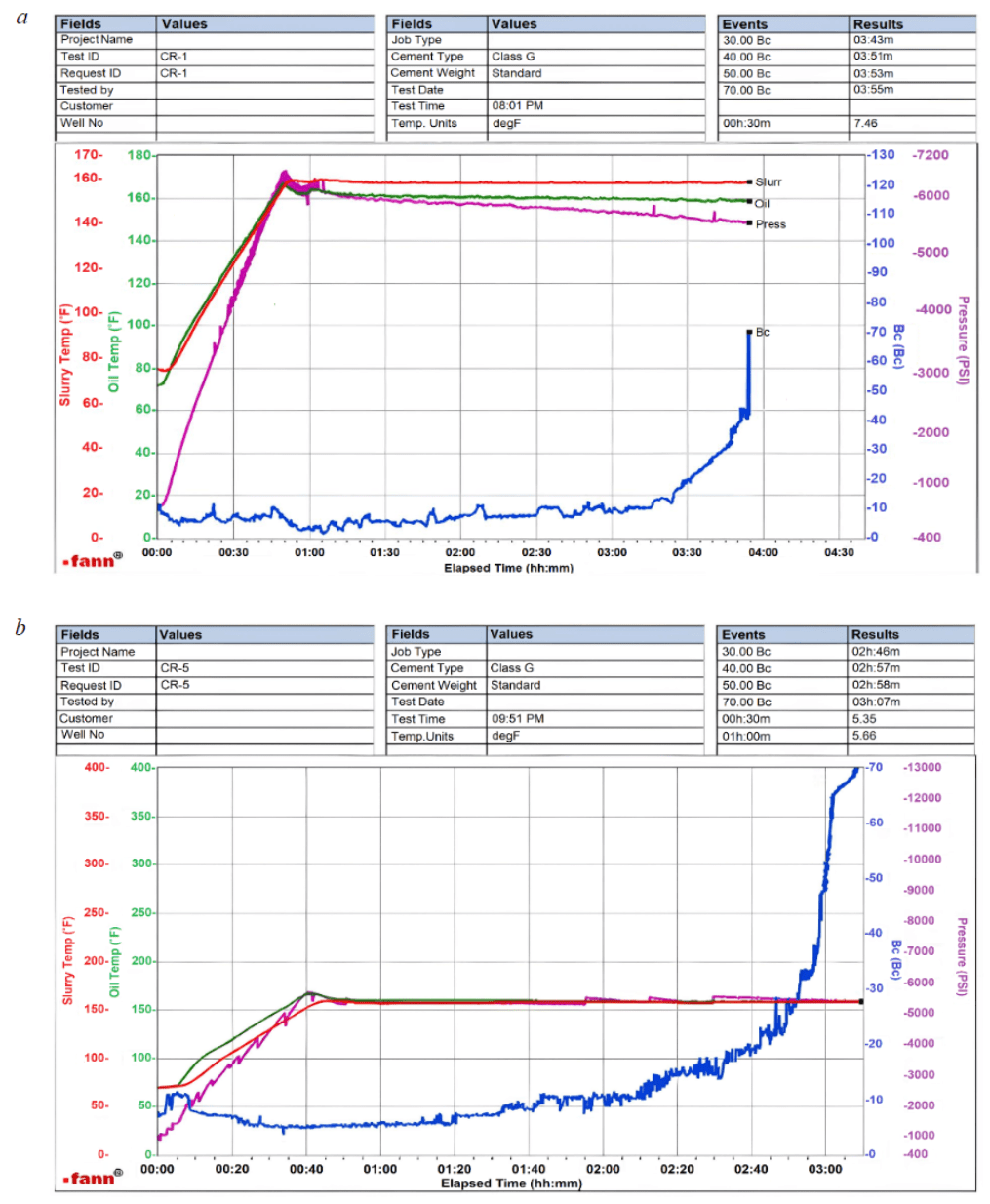

Fig.5. Determination of the thickening time for CM-1 (a) and CM-5 (b)

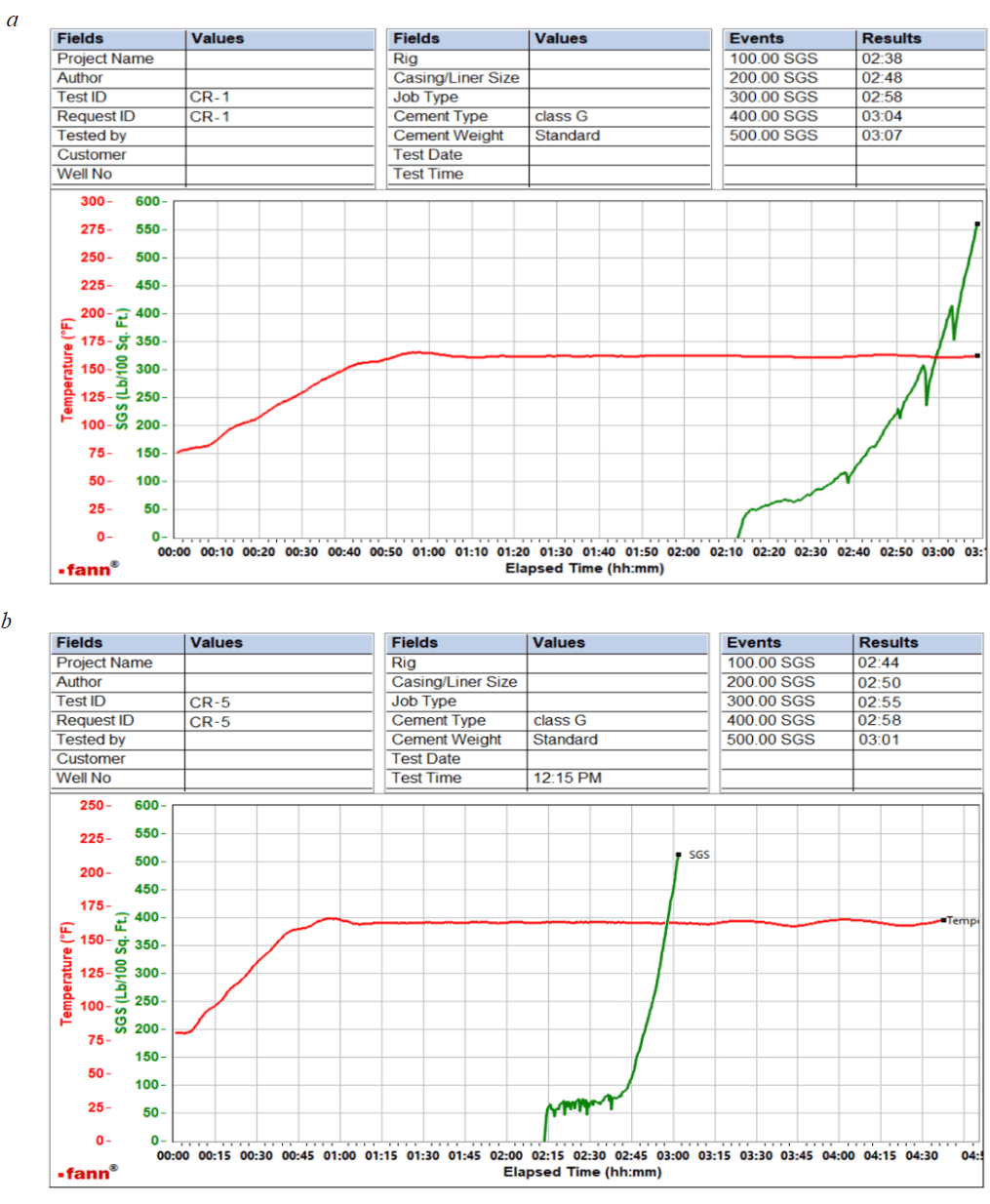

Fig.6. Definition of the transition period for CM-1 (a) and CM-5 (b)

According to the results of testing the CM elastic properties (Fig.4), the CM-5 solution has the best properties, therefore, CM-5 was chosen for further research, and the base solution CM-1 was used as a control sample.

To determine the applicability of the CM composition, tests for the thickening time (Fig.5) and the duration of the transition period (Fig.6) were carried out. The tests were carried out on certified Fann equipment based on API 10B-2, ISO 10426-2, and API 10B-6 standards [10, 11].

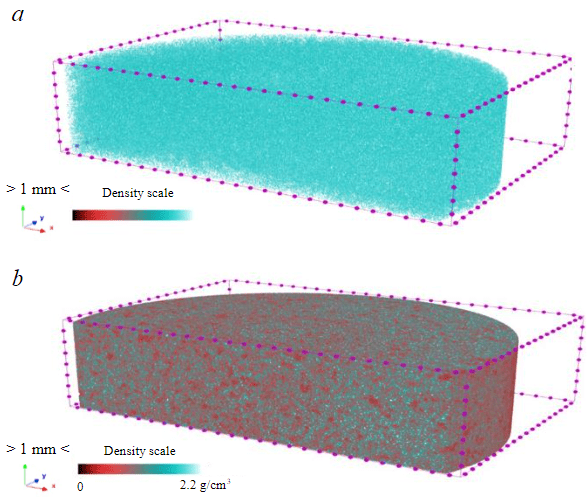

Studies of the permeability and porosity of cement rock were carried out for samples CM-1 (control) and CM-5 (which showed the best results when testing elastic and strength properties) on an automated PIC-PP device. According to RD 39-00147001-767-2000, the permeability of cement rock should be less than 2 mD. For CM-1, the permeability was 1.4 mD with an open porosity of 22.9 %, while for CM-5, the permeability was 0.011 mD with an open porosity of 0.008 % [21, 28].

The test results are presented in Table 2. The exposure time of the samples was 10 days (the minimum possible time from the working practice in the Nadym-Purskaya region of Western Siberia).

Table 2

Results of the experimental studies with an exposure time of 10 days

|

CM |

Density according to sealed lever scales, g/cm3 |

API water loss, ml |

Compression/bending/tensile strength, MPa |

Dynamic/static Young's module, GPa [20] |

Dynamic/static Poisson's ratio [20] |

|

CM-1 |

1.84 |

48 |

27.45/6.03/1.78 |

18.43/11.37 |

0.15/0.16 |

|

CM-2 |

1.84 |

51 |

24.14/5.31/5.67 |

13.89/10.03 |

0.23/0.24 |

|

CM-3 |

1.83 |

56 |

34.45/6.88/3.42 |

11.31/9.11 |

0.27/0.28 |

|

CM-4 |

1.83 |

55 |

26.05/8.07/1.98 |

9.83/7.89 |

0.25/0.27 |

|

CM-5 |

1.84 |

47 |

32.81/7.86/6.49 |

9,52/6.93 |

0.28/0.31 |

|

CM-6 |

1.83 |

49 |

24.67/6.54/1.52 |

11.12/7.21 |

0.26/0.29 |

Fig.7. The internal space of the CM samples based on the results of X-ray 3D scanning: a: CM-1; b: CM-5

The values of permeability and open porosity of CM-1 met the requirements of industry standards, and the results of 3D X-ray scanning showed a developed pore structure. As a result of 3D X-ray scanning of samples (Fig.7), it was observed that the inner space of CM-5 was uniformly filled with epoxy resin [36], which formed a cohesive mesh inside the cement rock, creating an additional barrier, and had a synergistic effect enhancing the elastic and strength properties of cement-and-epoxy rock. When visually evaluating cement rock samples, a change in the aggregate state of the epoxy resin from liquid to solid was noted, i.e., during the exposure time of the samples, epoxy resin particles had formed a solid substance.

Conclusion

When studying the properties of cement-and-epoxy systems, the technological properties of the compositions were analyzed, and a comparative assessment of the developed compositions with an industry solution and a basic additive-free CM was carried out. The composition of a cement-and-epoxy system made of Russian-made components with improved elastic, strength, and technological properties was developed.

The developed composition (CM-5), containing 4.52 % epoxy resin (resin: 4.11 %, firming agent: 0.41 %) and latex (3 % vinyl acetate and ethylene copolymer) 1 %, is characterized by the following:

- reduced Young’s modulus: 6.93 GPa (38 % lower than that of the additive-free CM-1 and 4 % lower than that of the industry-based CM-6 solution);

- increased Poisson's ratio: 0.31 (51 % higher than that of the additive-free CM-1 and 6 % higher than that of the industry-based CM-6 solution);

- increased compressive/bending/tensile strength: 32.81/7.86/6.49 MPa, respectively.

When using epoxy resin in a CM, the thickening time of the CM decreases, however, this effect can be reduced by increasing the concentration of the inhibitor and adjusting the concentration of the epoxy resin firming agent.

When the epoxy resin concentration reaches more than 10 % of the cement weight, there is a decrease in the compressive strength of the cement-and-epoxy rock.

Epoxy resin reduces the CM transition time by more than two times (see Fig.6): CM-1 had the time between 100 to 500 SGS from 2:38 to 3:07 equaling 29 min, while for CM-5 the time between 100 to 500 SGS from 02:44 to 03:01 equaled 16 min. The thickening time is acceptable for carrying out work on cementing production casing and shanks in Western Siberia.

The use of epoxy resin in the CM composition reduces the permeability of cement rock to 0.011 mD, as well as the open porosity to 0.008 %, favorably affecting the cementing tightness.

Based on laboratory studies of the sealing and then the preparation of cement-and-epoxy mixtures in the field, it is necessary to provide for the use of a surge tank for careful mixing and obtaining a homogeneous mixture and consider the use of an epoxy solvent for washing cementing equipment.

References

- Litvinenko V.S., Tsvetkov P.S., Dvoynikov M.V., Buslaev G.V. Barriers to implementation of hydrogen initiatives in the context of global energy sustainable development. Journal of Mining Institute. 2020. Vol. 244, p. 428-438. DOI: 10.31897/PMI.2020.4.5

- Inyakina E.I., Levitina E.E., Ryabikova K.O., Inyakin V.V. Investigation of Formation Fluid During the Development of Fields on the Kara Sea Shelf. Science. Innovations. Technologies. 2023. N 1, p. 155-174 (in Russian). DOI: 10.37493/2308-4758.2023.1.8

- Chertenkov M.V. Features of well construction in difficult mining and geological conditions in the European north of Russia. Petroleum Engineering. 2022. Vol. 20. N 5, p. 18-34 (in Russian). DOI: 10.17122/ngdelo-2022-5-18-34

- Litvinenko V.S. The Role of Hydrocarbons in the Global Energy Agenda: The Focus on Liquefied Natural Gas. Resources. 2020. Vol. 9. Iss. 5. N 59. DOI: 10.3390/resources9050059

- Hongwei Zhang, Zhenzhong Shen, Liqun Xu et al. Experimental and theoretical investigation on hydraulic fracturing in cement mortar exposed to sulfate attack. Materials & Design. 2022. Vol. 223. N 111226. DOI: 10.1016/j.matdes.2022.111226

- Savenok O.V., Gorpinchenko A.N. Analysis of the influence of the coefficient of anomaly high formation pressure on the development of oil and gas fields. Science. Engineering. Technology. 2022. N 2, p. 141-154 (in Russian).

- Litvinenko V.S., Tsvetkov P.S., Molodtsov K.V. The social and market mechanism of sustainable development of public companies in the mineral resource sector. Eurasian Mining. 2020. N 1, p. 36-41. DOI: 10.17580/em.2020.01.07

- Yongjin Yu, Jiawen Fu, Chi Zhang et al. Mechanical Properties and Enhancement Mechanism of Oil-Well Cement Stone Reinforced with Carbon Fiber Surfaces Treated by Concentrated Nitric Acid and Sodium Hypochlorite. International Journal of Polymer Science. 2020. Vol. 2020. N 8214549. DOI: 10.1155/2020/8214549

- Jianjian Song, Mingbiao Xu, Chunqin Tan et al. Study on an Epoxy Resin System Used to Improve the Elasticity of Oil-Well Cement-Based Composites. Materials. 2022. Vol. 15. Iss. 15. N 5258. DOI: 10.3390/ma15155258

- Salamanova M.Sh. Study of cement properties for plugging oil wells. Herald of Dagestan State Technical University. Technical Sciences. 2022. Vol. 49. N 1, p. 149-155 (in Russian). DOI: 10.21822/2073-6185-2022-49-1-149-155

- Bazrkar H., Lork A., Aminnejad B. Application of a Synthetic Polymer Nanocomposite Latex in a Wellbore Cement Slurry for Gas Blockage Functions. ACS omega. 2022. Vol. 7. Iss. 31, p. 27469-27478. DOI: 10.1021/acsomega.2c02507

- Agzamov F.A., Belousov A.O., Komlev Ya.K. Application of an elastic cement stone for increasing stability of well mount at shock and dynamic loads. Problems of Gathering, Treatment and Transportation of Oil and Oil Products. 2020. N 2 (124), p. 9-19 (in Russian). DOI: 10.17122/ntj-oil-2020-2-9-19

- Morozov V.A., Dvoinikov M.V., Blinov P.A. Investigation of steady work optimum range of the system “drill bit – screw downhole engine – drilling column”. Petroleum Engineering. 2018. Vol. 16. N 2, p. 35-43 (in Russian). DOI: 10.17122/ngdelo-2018-2-35-43

- Gubaidullin A.G., Moguchev A.I. Calculation of Elastoviscoplastic Displacement of Well Walls in Transversal and Isotropic Rocks. Journal of Mining Institute. 2019. Vol. 236, p. 180-184. DOI 10.31897/PMI.2019.2.180

- Miao He, Jianjian Song, Mingbiao Xu et al. Effect of Epoxy Resin Emulsion on the Mechanical Properties of Oil Well Cement-Based Composites. Advances in Civil Engineering. 2020. Vol. 2020. N 5344866. DOI: 10.1155/2020/5344866

- Chengzhang Cao, Yuhuan Bu, Leiju Tian et al. Epoxy Resin-Based Cementing Fluid Produces a Low Elastic Modulus

- Cementing Fluid System and Enhances the Cement–Formation Interface. Arabian Journal for Science and Engineering. 2022. Vol. 47. Iss. 9, p. 11987-11998. DOI: 10.1007/s13369-022-06750-4

- Belikov S.A., Salakhov T.R., Kardopoltsev A.S., Leskin F.Yu. Analysis of efficiency of horizontal wells with multi-stage hydraulic fracturing on the example of Kondinskoye field. Petroleum Engineering. 2023. Vol. 21. № 1, p. 39-50 (in Russian). DOI: 10.17122/ngdelo-2023-1-39-50

- Morozov V.A., Dvoynikov M.V. Rational choice of parameters of directional wells drilling mode when using screw downhole motor. Construction of oil and gas wells on land and sea. 2019. N 2, p. 15-18 (in Russian). DOI: 10.30713/0130-3872-2019-2-15-18

- Lima V.N., Silva Flávio de Andrade, Skadsem H.J. et al. Effects of confinement pressure on the mechanical behavior of an oil well cement paste. Journal of Petroleum Science and Engineering. 2022. Vol. 208. N 109769. DOI: 10.1016/j.petrol.2021.109769

- Blinov P.A., Sadykov M.I. Evaluation of elastic-strength properties of cement-epoxy systems. Bulletin of the Tomsk Polytechnic University. Geo Аssets Engineering. 2023. Vol. 334. N 1, р. 97-105 (in Russian). DOI: 10.18799/24131830/2023/1/3925

- Yakovleva A.A., Movchan I.B., Shaygallyamova Z.I. Dynamic response of multi-scale geophysical systems: waves and practical applications. Philosophical Transaction of Royal Society A. Mathematical, Physical and Engineering Sciences. 2022. Vol. 380.

- Iss. 2237. N 20210403. DOI: 10.1098/rsta.2021.0403

- Blinov P.A., Shansherov A.V., Cheremshantsev D.M. et al. Analysis and selection of a grouting mixture, resistant to dynamic loads, in order to improve the support tightness quality in the annulus. Bulletin of the Tomsk Polytechnic University. Geo Аssets Engineering. 2022. Vol. 333. N 11, p. 115-123 (in Russian). DOI: 10.18799/24131830/2022/11/3726

- Movchan I.B., Yakovleva A.A., Frid V. et al. Modelling of seismic assessment for large geological systems. Philosophical Transaction of Royal Society A. Mathematical, Physical and Engineering Sciences. 2022. Vol. 380. Iss. 2231. N 20210393. DOI: 10.1098/rsta.2021.0393

- Yizhao Wang, Bing Hou, Dong Wang, Zhenhua Jia. Features of fracture height propagation in cross-layer fracturing of shale oil reservoirs. Petroleum Exploration and Development. 2021. Vol. 48, p. 469-479. DOI: 10.1016/S1876-3804(21)60038-1

- Gendler S.G., Fazylov I.R., Abashin A.N. The results of experimental studies of the thermal regime of oil mines in the thermal method of oil production. Mining Informational and Analytical Bulletin. 2022. N 6-1, p. 248-262 (in Russian).

- DOI: 10.25018/0236_1493_2022_61_0_248

- Kozyrev A.A., Kasparyan E.V., Fedotova Yu.V., Kuznetcov N.N. Estimating the rockburst hazard of hard rocks based on laboratory test results. Vestnik of MSTU. 2019. Vol. 22. N 1, p. 138-148 (in Russian). DOI: 10.25018/0236_1493_2022_61_0_248

- Kurbatov Yu.E., Kashevarova G.G. Determination of elastic characteristics of cement stone to predict the fatigue life of concrete. Vestnik MGSU. 2022. Vol. 17. Iss. 4, p. 476-486 (in Russian). DOI: 10.22227/1997-0935.2022.4.476-486

- Moghadam А., Castelein K., ter Heege J., Orlic B. A study on the hydraulic aperture of microannuli at the casing–cement interface using a large-scale laboratory setup. Geomechanics for Energy and the Environment. 2022. Vol. 29. N 100269. DOI: 10.1016/j.gete.2021.100269

- Baklushin M., Velikaya N., Zyryanov V., Vologdin D. Applying a Resin-Cement System to Help Prevent Fluid Migration in the Annulus: Case Study, Western Siberia. SPE Russian Petroleum Technology Conference, 22-24 October 2019, Moscow, Russia. OnePetro, 2019. N SPE-196799-MS. DOI: 10.2118/196799-MS

- Chernyshov S.E., Popov S.N., Varushkin S.V. et al. Scientific justification of the perforation methods for Famennian deposits in the southeast of the Perm Region based on geomechanical modelling. Journal of Mining Institute. 2022. Vol. 257, p. 732-743. DOI: 10.31897/PMI.2022.51

- Yuhuan Bu, Mengran Xu, Huajie Liu. Mechanism of Cement Stone Porosity and Permeability Structures for Downhole Fluid Packing. Arabian Journal for Science and Engineering. 2022. Vol. 47. Iss. 9, p. 12223-12235. DOI: 10.1007/s13369-022-06943-x

- Feng Xu, Zhipeng Xu, Shengchuan Tang et al. Evolution of physical and mechanical properties of cementing materials during underground energy exploitation and storage. Journal of Energy Storage. 2022. Vol. 45. N 103775. DOI: 10.1016/j.est.2021.103775

- Shaojun Zheng, Tianle Liu, Guosheng Jiang et al. Effects of Water-to-Cement Ratio on Pore Structure Evolution and Strength Development of Cement Slurry Based on HYMOSTRUC3D and Micro-CT. Applied Sciences. 2021. Vol. 11. Iss. 7. N 3063. DOI: 10.3390/app11073063

- Ngoc Lan Mai, Nguyen-Hieu Hoang, Ha T. Do et al. Elastic and thermodynamic properties of the major clinker phases of Portland cement: Insights from first principles calculations. Construction and Building Materials. 2021. Vol. 287. N 122873. DOI: 10.1016/j.conbuildmat.2021.122873

- Lanka S.T., Niclas Galih Anak Moses, Suppiah R.R., Maulianda B.T. Physio-chemical interaction of Ethylene-Vinyl Acetate copolymer on bonding ability in the cementing material used for oil and gas well. Petroleum Research. 2022. Vol. 7. Iss. 3, p. 341-349. DOI: 10.1016/j.ptlrs.2021.10.003

- Xinpu Shen, Ping Zhang. A calculation method for the allowable fracturing injection pressure of preventing casing deformation. Natural Gas Industry B. 2019. Vol. 6. Iss. 4, p. 384-393. DOI: 10.1016/j.ngib.2019.01.014

- Popov S.N., Chernyshov S.E., Krivoshchekov S.N. Comparative analysis of the analytical and numerical methods for calculating the stress-strain state of the near-wellbore zone based on the elastic model taking into account the main structural elements of the well. Bulletin of the Tomsk Polytechnic University. Geo Аssets Engineering. 2023. Vol. 334. N 5, p. 94-102 (in Russian).

- DOI: 10.18799/24131830/2023/5/3961

- Shkryaba I.T., Mulyavin S.F., Kleshchenko I.I., Kusakin V.Yu. Analysis of efficency of multi-stage hydraulic fracturing in horizontal wells at Vyngapurovskoye gas field. Oil and Gas Studies. 2017. N 4, p. 89-92 (in Russian). DOI: 10.31660/0445-0108-2017-4-89-92

- Gorelikov V.G., Lykov Y.V. Gorshkov L.K., Uspechov A.M. Investigation of Thermal Operational Regimes for Diamond Bit Drilling Operations (TECHNICAL NOTE). International Journal of Engineering. 2019. Vol. 32. Iss. 5, p. 790-793. DOI: 10.5829/ije.2019.32.05b.21

- Agzamov F.A., Maskenov A.S., Shantasov N.N. Investigation of additives for self-healing of cement sheath. Problems of Gathering, Treatment and Transportation of Oil and Oil Products. 2019. N 2 (118), p. 30-38 (in Russian). DOI: 10.17122/ntj-oil-2019-2-30-38

- Bakirov D.L., Burdyga V.A., Fattakhov M.M. et al. Increase of a well cementing stability to dynamic influence. Oilfield engineering. 2020. N 1 (613), p. 65-70 (in Russian). DOI: 10.30713/0207-2351-2020-1(613)-65-70

- Jutten J.J., Hayman A.J. Microannulus Effect on Cementation Logs: Experiments and Case Historiesю SPE Asia Pacific Oil and Gas Conference, 8-10 February 1993, Singapore. DOI: 10.2118/25377-MS

- Fahretdinov I.V. integrated monitoring of horizontal wells with multistage hydraulic fracturing at the implementation stage within the Priobskiy oil field for their work effectiveness. Problems of Gathering, Treatment and Transportation of Oil and Oil Products. 2017. N 4 (110), p. 92-99 (in Russian). DOI: 10.17122/ntj-oil-2017-4-92-99

- Chernyshov S.E., Popov S.N., Savich A.D., Derendyaev V.V. Analysis of wells cement sheath stability during shaped charge perforating based on geomechanical modeling. Georesources. 2023. Vol. 25. N 2, p. 245-253 (in Russian). DOI: 10.18599/grs.2023.2.18