Mathematical modelling of displacement during the potash ores mining by longwall faces

Abstract

In favourable mining conditions, in particular at the Starobinskoye potash deposit (Belarus), longwall mining systems are used. They cause a high human-induced load on the subsoil, including intense deformation of the ground surface. The presented investigations are aimed at studying the dynamics of the ground surface displacement during the longwall face advance. Mathematical modelling was carried out in an elastic-plastic formulation with numerical implementation by the finite element method. The condition for the roof rocks collapse was opening of the contact between the seams when its boundaries were reached by shear fractures or formation of the tensile stresses area at the outcrop. With the working front advance, an increase in subsidence is observed, followed by its stabilization to a value determined by the process parameters of mining operations and the physical and mechanical properties of collapsed rocks. In this case, each point of the ground surface experiences sign-alternating horizontal deformations: when the front approaches, it causes tension, and when it moves away, compression. The obtained results of mathematical modelling are in good agreement with the data of instrumental measurements of the ground surface displacements, which indicates the adequate description of the rock mass deformation during the slice excavation of sylvinite seams by longwall faces.

Introduction

Potash and salt mineral deposits are developed by a room-and-pillar method. This is due to the need to ensure the safety of the water-protective layer and prevent the breakthrough of fresh water into mine workings [1-4]. Only in favourable mining conditions, in particular at the Starobinskoye potash deposit (Republic of Belarus), various options for pillar methods are used [5-7], which are typical for coal basins. In this regard, targeted studies of displacement during long-pillar mining are associated with coal deposits [8-10], and the engineering methods developed for them to predict the ground surface subsidence are based on long-term instrumental observations. The results of these studies formed the basis of the regulatory framework for the protection of the ground surface targets from the harmful effects of underground coal mining. At the same time, modern experience in the development of coal deposits and the transition to deeper horizons shows that the normative engineering methods for predicting subsidence differ significantly from the results of actual observations [11-13]. To level these discrepancies, empirical correction factors [11, 14, 15], transition to statistical estimates [16, 17], and mathematical modelling methods are used [11, 18, 19], which make it possible to consider structural features of the undermined massif and physical and mechanical properties of the rocks that make it up [20-22] in the ground surface deformation estimates.

The prediction of ground surface displacements during sylvinite seams mining by longwall faces is based on empirical approaches and ratios typical for coal deposits. By analogy, the maximum subsidence of the ground surface is determined by the following formula [23]:

where Nx, Ny are indices depending on the ratio of the gob dimensions and the mining depth; m is the recoverable seam thickness; ω – ore recovery factor.

Field studies of displacement at the Starobinskoye deposit, related to the study of the undermined massif stratification and the formation of a zone of water-conducting fractures, are given in [24, 25]. Attempts were also made to mathematically model the displacement process [26], based on the use of analytical approaches, which did not allow adequately describing the dynamics of the ground surface deformations.

The purpose of the presented investigations was to study the dynamics of the ground surface displacement when advancing the longwall face. Numerical simulation was carried out in the elastic-plastic formulation by the finite element method.

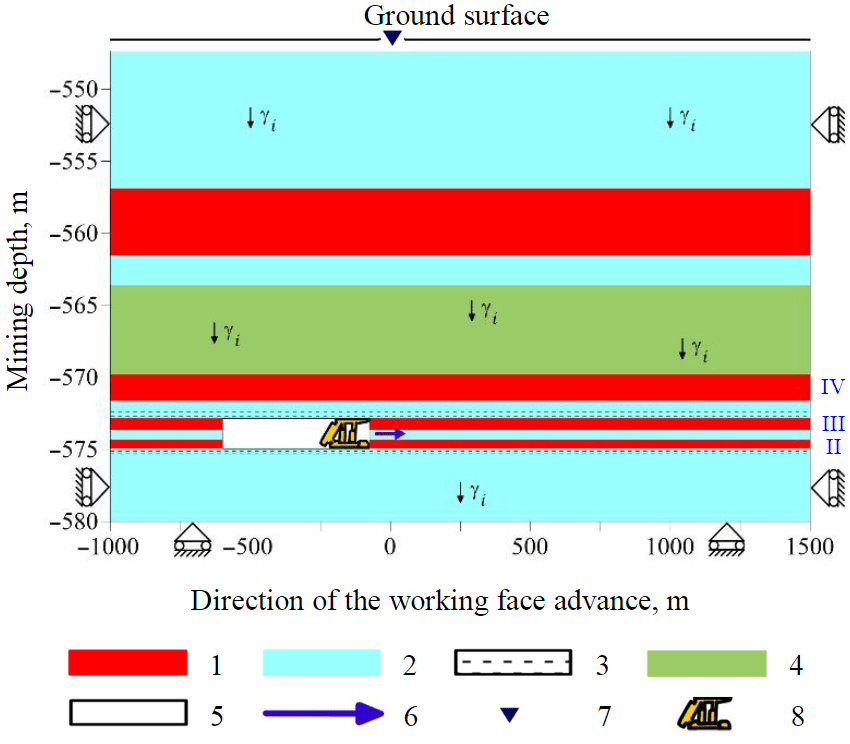

Fig.1. Schematic diagram of the SSS calculation for undermined massif 1 – sylvinite; 2 – rock salt; 3 – clay interlayers; 4 – clay-carnallite member; 5 – gob space; 6 – longwall advance direction; 7 – observation point; 8 – bottomhole support

Methodology

The change in the stress-strain state (SSS) of the rock mass was assessed in relation to the bulk mining of three seams in the Third potassium horizon. The corresponding estimation scheme, built towards the longwall advance, is shown in Fig.1. It was assumed that the estimated area experiences the action of body forces with intensity (where is the specific gravity of the rocks of the ith element in the geological section); horizontal displacements are limited on the lateral boundaries, and vertical displacements are limited on the lower one. The upper boundary (ground surface) is free. The geomechanical model reflected the main structural features of the undermined massif. Mechanical properties of the rocks that make up the geological section were taken in accordance with the laboratory test results [27, 28].

Determination of the stress-strain state of rocks was based on the model of an ideal elastic-plastic medium, which, in the area of compressive stresses, was implemented in the variant of the parabolic Coulomb – Mohr criterion [29]:

and in the area of tensile stresses, elastic deformation was limited by the tensile strength

where τmax = (σ1 – σ3)/2 – maximum shear stress; σ = (σ1 – σ3)/2 – normal stress; σ1, σ3 – principal stresses estimated from the results of mathematical modelling; r = σс/σt – ratio of uniaxial compressive strength σс to uniaxial tensile strength σt;

In physical terms, plastic deformation zones in the areas of compression and tension are associated with fracturing due to the development of shear and rupture fractures.

The problem was solved numerically according to the standard procedure of the finite element method [30], within which the plastic nature of rock deformation was considered by the secant matrix method [31]. The interaction of the seams lying in the roof and the foot of the gob was modelled by Goodman contact elements [32-34] in the modification of the full deformation diagram [35]. The mechanical properties of the contacts were taken according to the results of laboratory tests of contacts in the “shear with compression” mode [36].

The criterion for the roof rocks collapse was opening of the contact between the seams when shear fractures reached its boundaries or formation of a zone of tensile stresses at the outcrop [37]. In numerical calculations, it was implemented within the framework of an iterative procedure by localizing and then excluding from the estimate of the elements in which the collapse criterion is satisfied. The estimation scheme of mathematical modelling in the form of a geomaterial included destroyed rocks filling the gob, the deformation properties of which were taken an order of magnitude lower than the corresponding indicators of the rock mass [38].

Discussion of the results

Destruction of rocks during the longwall advance

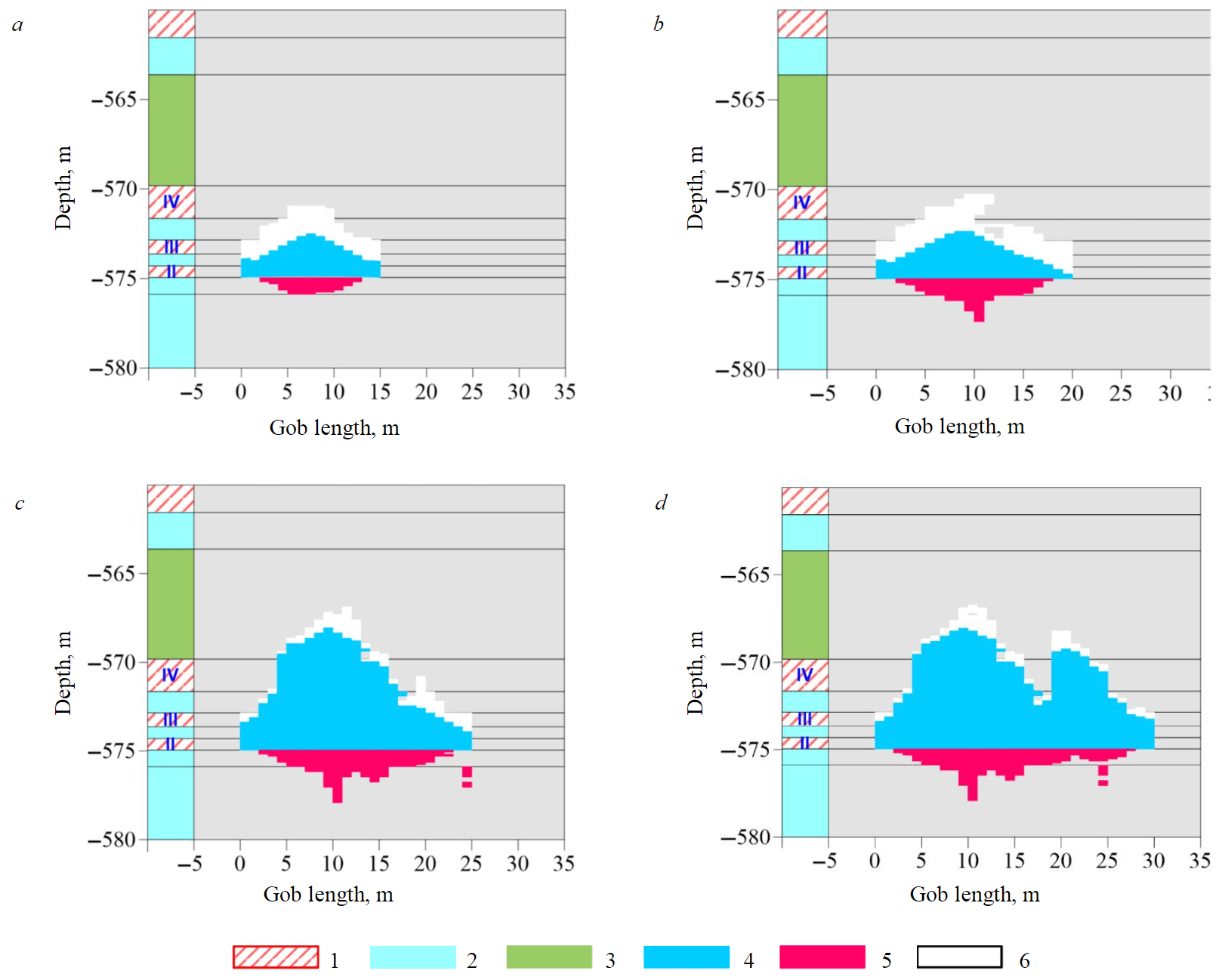

The results of mathematical modelling show that when the longwall face advances, the area of plastic deformations associated with the formation of rupture fractures is localized in the sole. The collapse of the roof rocks begins to occur when the longwall advances to a distance of about 5 m (Fig.2, a).

As the working front advances further (Fig.2, b-d), an expansion of the fracturing area in the sole and an increase in the volume of collapsed roof rocks are observed. With a gob length of more than 25 m (Fig.2, c, d), the fracturing area in the sole stabilizes and only its lateral increase is further recorded. The accepted decompaction index determines the complete filling of the gob with destroyed rocks, which prevents further development of fracture zones in the roof. Thus, rocks up to the clay-carnallite member, inclusive, are subject to collapse. With a significantly greater length of the gob, fracturing and possible collapse of the roof can also affect the overlying seams. At the same time, a non-homogeneous technogenic geo-environment is formed in the gob.

Periodicity is observed in the nature of the rock mass destruction in the vicinity of the gob. First, an increase in fracture zones in the sole and an increase in the volume of collapsed rocks in the roof are recorded. Then the gob is filled with geomaterial, which prevents further increase in fracture zones in the vertical direction. After that, the process repeats.

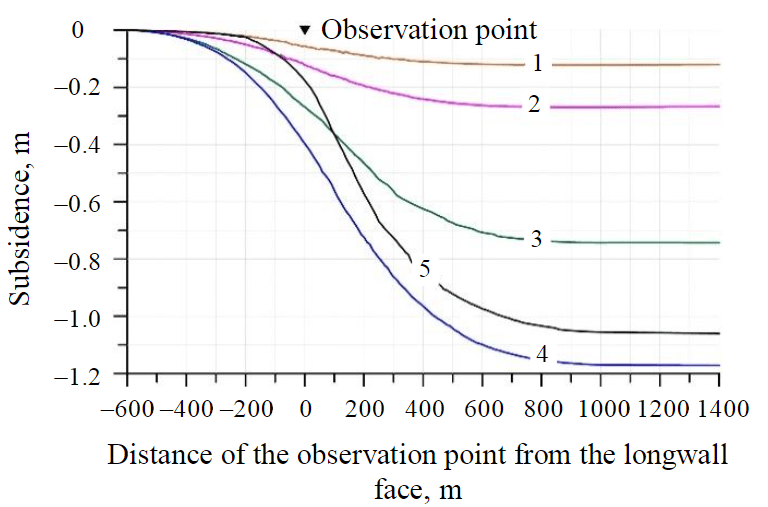

As the performed estimates show, the properties of destroyed rocks have a determining influence on the deformation of the undermined massif. Depending on the deformation properties adopted in the estimate, the magnitude of the ground surface subsidence changes significantly (Fig.3). An increase in these indicators sharply reduces the maximum ground surface subsidence at the stage of longwall advance, which affects the change in the gradient of vertical displacements at the measurement point (reference point, Fig.3).

Fig.2. Nature of the rock mass destruction when advancing the working front at a distance 15 (a), 20 (b), 25 (c), 30 (d) m 1 – sylvinite; 2 – rock salt; 3 – clay-carnallite member; 4 – collapsed rock; 5 – fracturing area; 6 – longwall gob

Fig.3. Curves of dependence of the ground surface subsidence at the observation point on the level of reduction in the modulus of collapsed rocks deformations relative to the initial indicators 1 – 5 times; 2 – 15 times; 3 – 25 times; 4 – 35 times; 5 – gradual decrease from 5 to 30 times

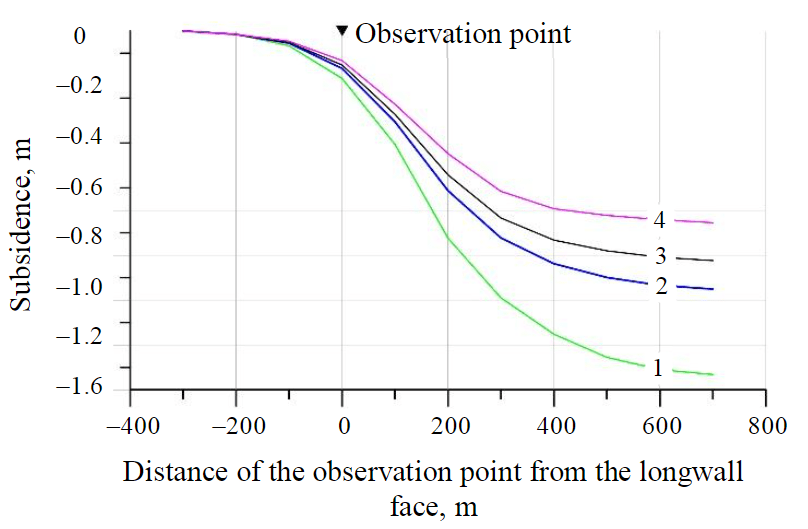

Fig.4. Curves of dependence of the ground surface subsidence at the point of observation on the rate of working face advance 1 – 1; 2 – 2; 3 – 3; 4 – 10 m/day

In Fig.3-6, the X-axis determines the distance between the point of mine surveying observations of the ground surface displacement (reference point) and the projection of the longwall working face onto it. Negative values of the distance correspond to the longwall advance to the point of mine surveying observations 0, positive values correspond to the removal from it. The variation in the deformation properties of collapsed rocks makes it possible to calibrate the geomechanical model according to the data of mine surveying measurements, but it is not possible to achieve an acceptable agreement in the area where significant gradients are formed. It can be assumed that the decrease in the deformation properties of destroyed rocks occurs gradually, as the working front advances. With this in mind, relatively high gradients of the ground surface subsidence are provided in the active stage of displacement (Fig.3, curve 5).

Dynamics of shear development

The ground surface subsidence within the dynamic part of the shear trough is significantly affected by the advance rate of the working face: the higher the rate, the greater the subsidence. The fact of the proportional dependence of the rate of the observation point subsidence on the rate of advancement of mining operations for coal deposits was noted by H.Kratzsch [8]. For the conditions at the Starobinskoye potash deposit, according to the results of processing mine surveying observations, this dependence is described in the form of a linear expression

where Vface is the rate of working face advance, m/day; X, V – indices depending on the mining and engineering conditions of mining.

The main difficulty in using expression (2) is to determine the indices X, B in the absence of mine survey data. However, a general analysis of the ratio shows that at a significant distance of the working face from the observation point, the ground surface subsidence will decrease with increasing longwall advance rate. This is also confirmed by the results of mathematical modelling (Fig.4). When the face is 700 m away from the observation point and the longwall rate increases from 1 to 10 m/day, the subsidence will decrease from 1.51 to 0.85 m, or by 45 %. Thus, the higher the face advance rate, the smaller part of the final ground surface subsidence is in the dynamic part of the shear trough. A sharp decrease in subsidence occurs in the range of 1-4 m/day, and a further increase in the working face advance rate does not lead to such a significant decrease in subsidence.

Mathematical modelling of the massif deformation was carried out on the example of mining longwall N 102 in mine 1 RU of OAO Belaruskali. The advance rate of the working face was assumed to be constant, 2 m/day. During geomechanical modelling, the gob gradually increased evenly, simulating the working face advance, and the deformation properties of collapsed roof rocks decreased in a linear relationship. The maximum “weakening” of the deformation properties of collapsed rocks was supposed to ensure the shear transition to a damping stage and the achievement of the ground surface subsidence corresponding to the chosen face rate.

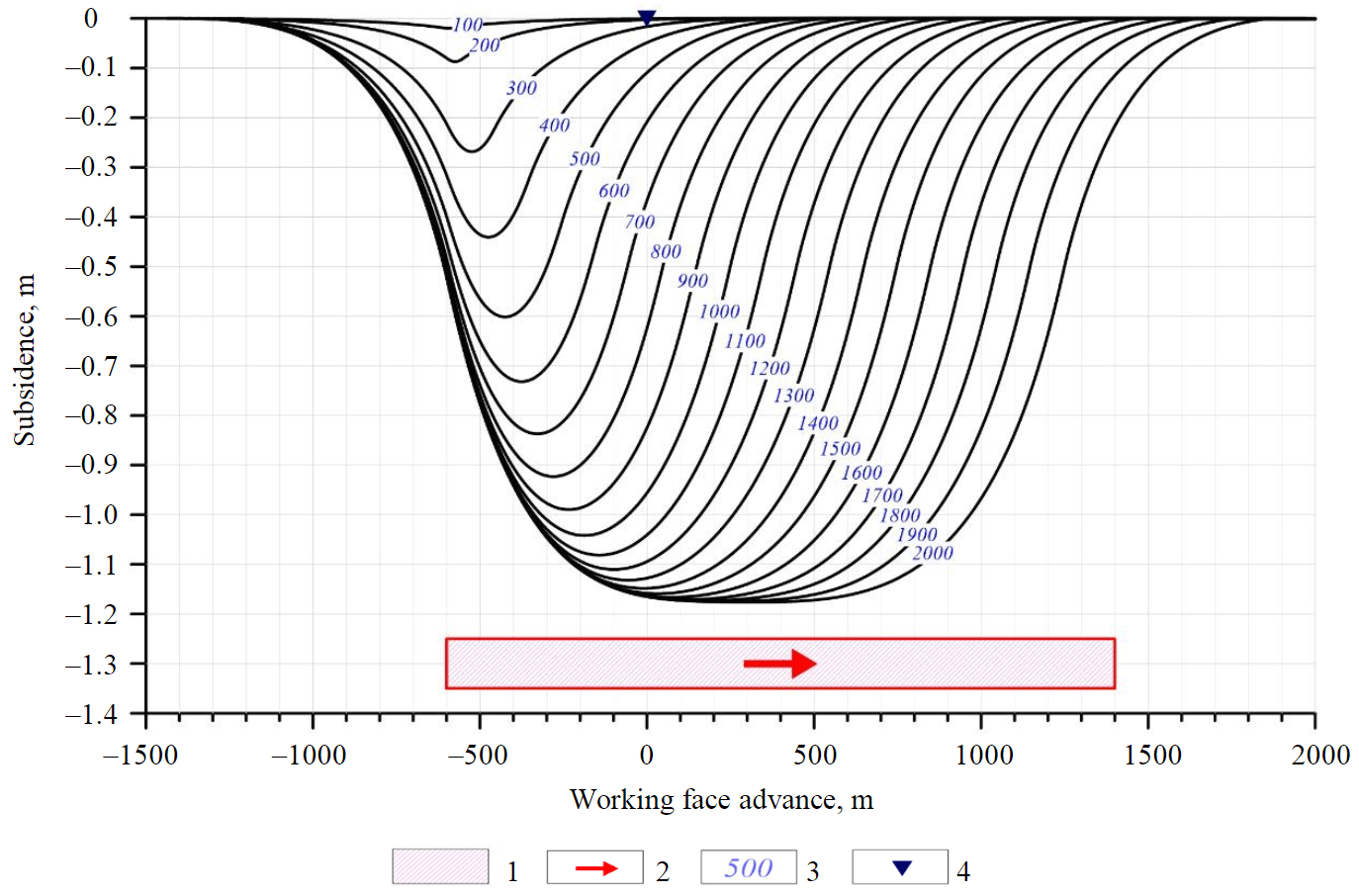

Figure 5 shows the development dynamics of the ground surface subsidence during the working front advance, built on the basis of the mathematical modelling. As the gob increases at a constant rate, at first, an increase in subsidence is observed, followed by its stabilization to a value determined by the process parameters of mining operations (mining rate, mineable thickness, etc.) and the physical and mechanical properties of the collapsed rocks. Then there is only an expansion of the lateral shear trough following the working front advance. After longwall mining, the ground surface subsidence will increase to the final values determined by expression (1) in a damping mode.

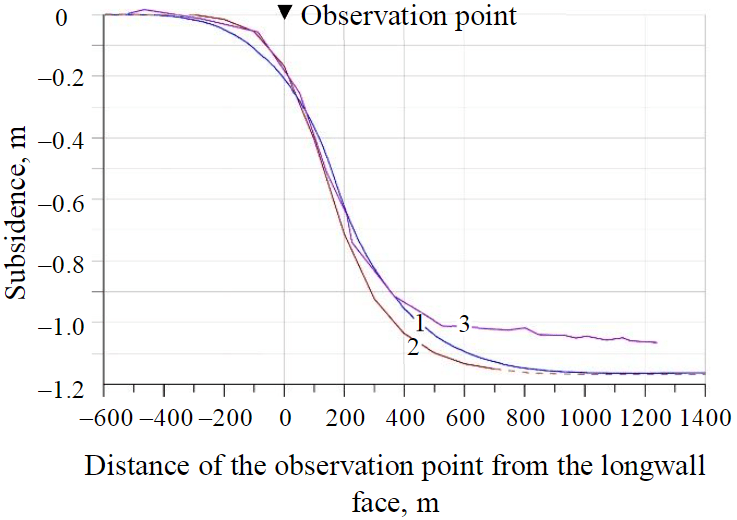

Figure 6 shows the curves of the increase in vertical shears of the ground surface at the observation point during working excavation (curve 1); also, for comparison, subsidence is shown, constructed according to the empirical formula (2) at a rate of working face advance of 2 m/day (curve 2), and actual subsidence (curve 3). It can be seen that there is a good correspondence between the ground surface subsidence both in magnitude and in the rate of its increase. Some difference between the actual subsidence (curve 3) and the estimated one after the completion of the active stage of shear is apparently due to the fact that the real longwall rate was variable and varied in the range of 0.9-5.2 m/day.

Fig.5. Dynamics of the shear trough formation during the working front advance 1 – gob; 2 – face advance direction; 3 – size of the gob; 4 – observation point

Fig.6. Curves of the ground surface subsidence at the observation point during the working face advance 1 – results of mathematical modelling; 2 – calculated according to the empirical formula (2) at the face advance rate of 2 m/day; 3 – actual (benchmark 1, longwall N 102 of mine 1 RU)

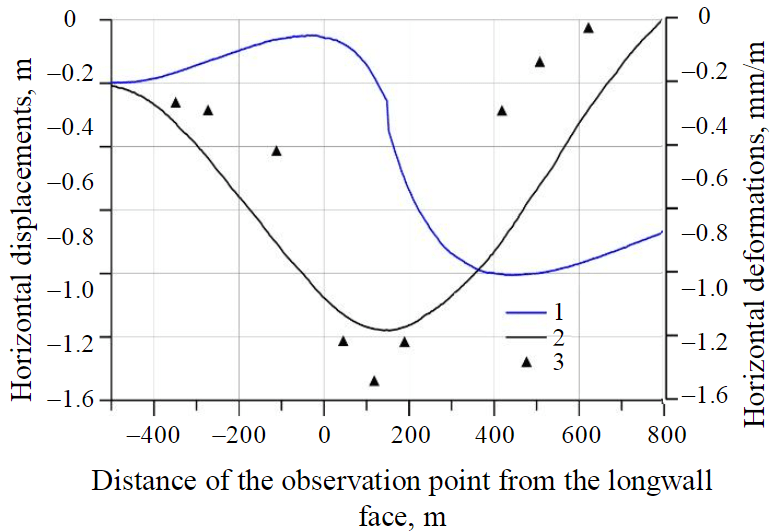

Fig.7. Horizontal displacements and ground surface deformations at the observation point 1 – deformations; 2 – estimated displacements; 3 – actual displacements

Usually [39, 40] during the longwall face advance, horizontal displacements are recorded on the ground surface along with its subsidence. At first there is a direct movement towards the advancing face, and then the observation point returns back (Fig.7). If the observation point is on the longitudinal axis of the extraction column, and there are no other influencing factors (heterogeneous structure of the undermined massif, the presence of neighbouring gob areas, undermining, overmining, etc.), then the forward and reverse trajectories of the observation point will coincide in direction, but the reverse, as a rule, turns out to be longer. In other words, the observation point does not return to its original position. This trend is reflected in the mathematical modelling results. Some deviation of the actual measurements from the estimated ones (Fig.7) can be explained by the influence of a group of mining, geological, and engineering factors that are not considered in the estimate.

It is of interest to change the horizontal deformations of the ground surface at the observation point, which determine the level of negative impact of mining operations on industrial and civil facilities (Fig.7, positive values are tensile deformations, negative values are compressive deformations). As can be seen, during the working front advance, the observation point experiences sign-alternating deformations: when advancing, there is tension, and when removing, compression. Zero horizontal deformations are recorded approximately 100 m behind the longwall face.

Conclusion

The constructed geomechanical model of the rock mass fully reflects the main structural features of the massif, the longwall face advance, and the process parameters of mining operations. The model includes the roof rocks collapse in the mined seam. Its implementation makes it possible to study the change in the stress-strain state of the undermined rock mass and identify the main patterns of the ongoing geomechanical processes, including the nature of the ground surface deformations development.

It is shown that it is possible in principle to achieve a correspondence between the estimated subsidence and field observations of the ground surface displacement by varying the properties of collapsed rocks formed during the longwall face advance. In this case, it becomes possible to predict the ground surface displacement during the slice mining of sylvinite seams by longwall faces.

References

- Baryakh А.А., Smirnov E.V., Kvitkin S.Y., Tenison L.O. Russian potash industry: Issues of rational and safe mining. Russian Mining Industry. 2022. Vol. 1, p. 41-50 (in Russian). DOI: 10.30686/1609-9192-2022-1-41-50

- Zubov V.P., Kovalski E.R., Antonov S.V., Pachgin V.V. Improving the safety of mines in developing verkhnekamsk potassium and magnesium salts. Mining informational and analytical bulletin. 2019. N 5, p. 22-33 (in Russian). DOI: 10.25018/0236-1493-2019-05-0-22-33

- Belyakov N.A., Belikov A.A. Prediction of the integrity of the water-protective stratum at the Verkhnekamskoye potash ore deposit. Mining informational and analytical bulletin. 2022. N 6-2, p. 33-46 (in Russian). DOI: 10.25018/0236_1493_2022_62_0_33

- Podlesnyi I.A., Getmanov V.N., Petrovskiy B.I., Nosulya I.E. Multi-slice mining technology for potash seam III at the Starobinsk deposit. Gornyi zhurnal. 2018. N 8, p. 59-64 (in Russian). DOI: 10.17580/gzh.2018.08.08

- Kovalev O.V., Mozer S.P., Mozer I.Yu., Leisle A.V. Substantiation of rational technologies for mining horizon IV in the conditions of the Starobinskoye potash salt deposit. Journal of Mining Institute. 2011. Vol. 190, p. 9-15 (in Russian).

- Kovalev O.V., Koval'skii E.R., Sirenko Yu.G., Tkhorikov I.Yu. Development of process schemes for selective excavation of potash seams of complex structure in the conditions of the Starobinskoye deposit. Journal of Mining Institute. 2011. Vol. 190, p. 16-21 (in Russian).

- Kratzsch H. Mining Subsidence Engineering. Berlin, Heidelberg, New York: Springer-Verlag, 1983, p. 558.

- Viktorov S.D., Goncharov S.A., Iofis M.A., Zakalinskii V.M. Mechanics of displacement and destruction of rocks. Moscow: Institut problem kompleksnogo osvoeniya nedr im. akademika N.V.Melnikova RAN, 2019, p. 360 (in Russian).

- Galvin J.M. Ground Engineering – Principles and Practices for Underground Coal Mining. Switzerland: Springer International Publishing, 2016, р. 684.

- Kulibaba S., Miletenko N. Influence of the mining depth factor on accuracy of the forecast of the earth’s surface subsidence in Kuzbass. E3S Web of Conferences. VIII International Scientific Conference “Problems of Complex Development of Georesources”. 2020. Vol. 192. N 04009. DOI: 10.1051/e3sconf/202019204009

- Averin G.A., Dotsenko O.G., Koretskaya E.G. Consideration of the influence of sandstones and limestones on the maximum ground surface subsidence caused by mining. Sbornik nauchnykh trudov Donbasskogo gosudarstvennogo tekhnicheskogo instituta. 2021. N 22 (65), p. 21-27 (in Russian).

- Ghabraie B., Ghabraie K., Ren G., Smith J.V. Numerical modelling of multistage caving processes: insights from multi-seam longwall mining-induced subsidence. International Journal for Numerical and Analytical Methods in Geomechanics. 2017. Vol. 41. Iss. 7, p. 959-975. DOI: 10.1002/nag.2659

- Larchenko V.G., Kovalenko E.V., Matalkina Yu.A. Prediction of probable subsidence of the earth’s surface during its undermining at great depths. Sbornik nauchnykh trudov Donbasskogo gosudarstvennogo tekhnicheskogo instituta. 2021. N 24 (67), p. 40-44 (in Russian).

- Tao Xu, Tian-hong Yang, Chong-feng Chen et al. Mining induced strata movement and roof behavior in underground coal mine. Geomechanics and Geophysics for Geo-Energy and Geo-Resources. 2015. Vol. 1, p. 79-89. DOI: 10.1007/s40948-015-0010-2

- Gordienko M.E., Kolesnik N.A., Kozlovsky G.I., Nazimko V.V. Development of the method for calculation of buildings and constructions deformation during their undermining. Problemy hirskoho tysku. 2013. N 1-2 (22-23), p. 137-166 (in Russian).

- Zhixian Hou, Keming Yang, Yanru Li et al. Dynamic prediction model of mining subsidence combined with D-InSAR technical parameter inversion. Environmental Earth Sciences. 2022. Vol. 81 (11). N 307. DOI: 10.1007/s12665-022-10423-8

- Koretskaia E.G. Modeling of the earth crust subsidence under the conditions of longwall undermining N 35east layer h8 of Frunze mine. Sbornik nauchnykh trudov Donbasskogo gosudarstvennogo tekhnicheskogo instituta. 2018. N 12 (55), p. 23-28 (in Russian).

- Makeeva T.G., Trofimov V.A. Estimate of the ground surface subsidence of mining facilities (on the example of coal deposits in Donbass). Geoekologiya. Inzhenernaya geologiya, gidrogeologiya, geokriologiya. 2022. N 1, p. 69-76 (in Russian). DOI: 10.31857/S086978092201009X

- Jiránková E., Waclawik P., Nemcik J. Assessment of models to predict surface subsidence in the Czech part of the Upper Silesian Coal Basin – Case study. Acta Geodynamica et Geomaterialia. 2020. Vol. 17. N 4 (200), p. 469-484. DOI: 10.13168/AGG.2020.0034

- Tajduś K. Numerical simulation of underground mining exploitation influence upon terrain surface. Archives of Mining Sciences. 2013. Vol. 58. N 3, p. 605-616. DOI: 10.2478/amsc-2013-0042

- Hongwei Wang, Yaodong Jiang, Yixin Zhao et al. Numerical investigation of the dynamic mechanical state of a coal pillar during longwall mining panel extraction. Rock Mechanics and Rock Engineering. 2013. N 46 (5), p. 1211-1221. DOI: 10.1007/s00603-012-0337-8

- Novokshonov V.N., Danilova A.F., Usova N.M. Dependence of horizontal shifts of a terrestrial surface on subsidence in a displacement trough. Gornaya mekhanika i mashinostroyeniye. 2015. N 1, p. 5-8 (in Russian).

- Novokshonov V.N., Danilova A.F., Deshkovskiy V.N., Zeytts V.E. Research of process of development of anthropogenic fractures in underworked rock massif at Starobinsky deposit. Gornyy zhurnal. 2014. N 2, p. 19-22 (in Russian).

- Novokshonov V., Danilova A., Deshkovsky V., Bogdan S. Development of deformations in underworked rock massive in case of pillar mining of potassium strata. Rudnik budushchego. 2011. N 2 (6), p. 17-20 (in Russian).

- Zhuravkov M.A., Krupoderov A.V. On the problem of modeling the ground surface movements in a region of large-scale mining. Vestnik Belorusskogo gosudarstvennogo universiteta. Seriya 1. Fizika. Matematika. Informatika. 2008. N 3, p. 52-55 (in Russian).

- Proskuryakov N.M., Antonov A.A., Livenskii V.S. Study of the physical and mechanical properties of salt rocks of the Starobinskoye deposit. Journal of Mining Institute. 1972. Vol. 61 (1), p. 101-104 (in Russian).

- Petrovsky A.B., Prushak V.Ya., Lutovich E.A. Physical and mechanical properties of the rocks of the Starobinsky deposit forming the third potash layer and its roof. Doklady of the National Academy of Sciences of Belarus. 2021. Vol. 65. N 4, p. 484-494 (in Russian). DOI: 10.29235/1561-8323-2021-65-4-484-494

- Ding-Jian Wang, Huiming Tang, Peiwu Shen, Yi Cai. A Parabolic Failure Criterion for Transversely Isotropic Rock: Modification and Verification. Mathematical Problems in Engineering. Vol. 2019. N 8052560, p. 1-12. DOI: 10.1155/2019/8052560

- Zienkiewicz O.C., Taylor R.L., Zhu J.Z. The Finite Element Method: Its Basis and Fundamentals. Oxford: Butterworth-Heinemann, 2013, p. 756. DOI: 10.1016/C2009-0-24909-9

- Huang C., Lu R., Hsu W. Power Flow Analysis Based on the Secant Method in the Environment of the Offshore Wind Farm. Journal of Physics: Conference Series. 2020. Vol. 1583. N 012007. DOI: 10.1088/1742-6596/1583/1/012007

- Goodman R.E. The Mechanical Properties of Joints. Advanced Rock Mechanics. 1974. Vol. 1. Part. A, p. 127-140.

- Hatzor Y., Ma G., Shi G.-H. Discontinuous Deformation Analysis in Rock Mechanics Practice. London, UK: Taylor & Francis Group, 2017. Vol. 5, p. 410. DOI: 10.4324/9781315687032

- Delong Huang, Aiping Tang, Zhongyue Wang. Analysis of pipe-soil interactions using Goodman contact element under seismic action. Soil Dynamics and Earthquake Engineering. 2020. Vol. 139. N 106290. DOI: 10.1016/j.soildyn.2020.106290

- Baryakh A.A., Pankov I.L. Interaction of seams in a salt massif. Message 2: Mathematical modeling of geomechanical processes considering the deformation of contacts. Fiziko-tekhnicheskie problemy razrabotki poleznykh iskopaemykh. 1992. N 3, p. 21-27 (in Russian).

- Baryakh A.A., Dudyrev I.N., Asanov V.A., Pan'kov I.L. Interaction of seams in a salt massif. Message 1. Mechanical properties of contacts. Fiziko-tekhnicheskie problemy razrabotki poleznykh iskopaemykh. 1992. N 2, p. 7-11 (in Russian).

- Baryakh A.A., Andreiko S.S., Fedoseev A.K. Gas-dynamic roof fall during the potash deposits development. Journal of Mining Institute. 2020. Vol. 246, p. 601-609. DOI: 10.31897/PMI.2020.6.1

- Baryakh A.A., Andreyko S.S., Fedoseev A.K. About the mechanism of localization of gas dynamic phenomena focuses in the bedrock of sylvinite formations. Perm Journal of Petroleum and Mining Engineering. 2017. Vol. 16. N 3, p. 247-254 (in Russian). DOI: 10.15593/2224-9923/2017.3.5

- Tajduś K., Misa R., Sroka A. Analysis of the surface horizontal displacement changes due to longwall panel advance. International Journal of Rock Mechanics and Mining Sciences. 2018. Vol. 104, p. 119-125. DOI: 10.1016/j.ijrmms.2018.02.005

- Barbato J., Hebblewhite B., Mitra R., Mills K. Prediction of horizontal movement and strain at the surface due to longwall coal mining. International Journal of Rock Mechanics and Mining Sciences. 2016. Vol. 84, p. 105-118. DOI: 10.1016/j.ijrmms.2016.02.006