Comprehensive study of filtration properties of pelletized sandy clay ores and filtration modes in the heap leaching stack

- 1 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid

- 2 — Ph.D., Dr.Sci. Professor Saint Petersburg Mining University ▪ Orcid

- 3 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid

- 4 — Postgraduate Student Saint Petersburg Mining University ▪ Orcid

- 5 — Postgraduate Student Saint Petersburg Mining University ▪ Orcid

- 6 — Laboratory Research Assistant Saint Petersburg Mining University ▪ Orcid

Abstract

There are the results of a study of the factors determining the formation and changes in the filtration properties of a heap leaching stack formed from pelletized poor sandy-clay ores. An analysis of methods of investigation of filtration properties of ore material for different stages of heap leaching plots functioning is carried out. Influence of segregation process during stack dumping on formation of zones with very different permeability parameters of ore has been established by experimental and filtration works. The construction and application of a numerical model of filtration processes in pelletized ores based on laboratory experiments is shown. By means of solution percolation simulation at different irrigation intensities the justification of optimal stack parameters is provided in terms of the geomechanical stability and prevention of solution level rise above the drainage layer.

Introduction

The concept of sustainable development of mining enterprises involves the deve-lopment of technologies aimed at low-waste development of solid mineral deposits [1, 2] and the maximumextraction of metals from poor off-balance ores [3-5], taking into account the required environmental standards [6, 7]. In practice, various technologies have been tested for extracting noble metals from ores [8-10], including heap leaching (HL), which is a promising and relatively cheap technology for processing poor and off-balance ores containing gold, silver and other useful components [11]. The effective extraction of useful components in this technology depends on the conditions of solution percolation through the ore stack [12, 13]. These conditions are defined by the particle size distribution and material composition of the material in the stack [14, 15]. Heap leaching does not depend as much on temperature as bioleaching of ores [16-18].

The initial granulometric composition of poor sandy-clay ores makes the leaching process very slow and unprofitable [14]. For example, the low percolation rate of solutions does not allow to carry out leaching during the period of positive temperatures in the Far North conditions, which requires continuation of works at negative temperatures at the expense of extra costs on solutions heating and pile insulation. In case of conservation of the ore stack for the winter period, it is necessary to take into account the influence of cycles of freezing and thawing of the material on the composition and geotechnological properties of raw materials [19].

The sandy-clay poor ores with a low filtration coefficient are pelletized by adding cement. This produces pellets that must provide the necessary percolation of solutions through the stack and withstand the pressure of the overlying ore masses. However, the filtration properties of a heap leaching pad are affected by many factors from the formation stage of the stack to the end of operation.

Filtration processes, in addition to influencing the leaching process itself, also determine the stability of the heap as a slope structure [20]. When irrigated, solutions, similar to water in pit walls or dumps, are responsible for the stress state, physico-chemical interaction and the nature of deformation development over time [21]. Therefore, the knowledge of filtration properties formation in the heap leaching stack will not only ensure effective extraction of gold from pelletized ores, but also determine the optimal and safe parameters of heap leaching piles in terms of layer height and their amount.

Many researchers have considered the application of computational methods and, in particular, numerical simulation methods for solving filtration problems during irrigation of pelletized ore with solutions. The works [22-24] present a modeling method of filtration through pelletized ores based on the theory of incompletely water-saturated media. A number of works [25-27] are devoted to the problems of filtration during operation of heap leaching piles, where the issues of applying the volumetric element method, stability of the pile during its irrigation, as well as solutions of filtration problems with regard to negative ambient air temperatures are considered. However, in spite of a sufficiently good theoretical development of the issue under consideration, the existing studies pay little attention to the validation of the adopted filtration models and their parameters according to large-scale laboratory studies or field investigations.

The aim of the study is to characterise and analyse the factors, which determine the formation and change of filtration properties in a pelletized sandy-clay ore massif during heap leaching of gold.

The characteristic conditions of Kuranakh gold ore cluster in Yakutia in Russia [28, 29] have been taken as an object for studying filtration properties and filtration modes in the heap leaching stack. The choice of the site is conditioned by intensive implementation of heap leaching in this territory and great potential for application of this technology for many years ahead, which is caused by several factors, among which the main ones are:

- low gold grade of 1.36 g/t, with large proven reserves in the area – 530 t;

- large volume of low-grade waste and tailings accumulated over 55 years of mining in the region, which could potentially be considered as promising anthropogenic raw materials;

- sandy-clay composition of ores with inclusions of coarse clastic material, formed as a result of hypergenic processes;

- possibility of achieving a high percentage (86.7-92.9 %) of gold recovery through direct cyanidation;

- short period of the year without sub-zero temperatures – less than 4.5 months, usually only in the summer months due to the harsh continental climate.

The Kuranakh gold mineralisation type was formed in weathering crusts by primary epithermal gold-sulphide-karst ores. The ores of the deposits are sandy-clay masses of quartz-limonite-hydrosludite-montmorillonite composition with the inclusion of coarse- grained clastic material. Due to its genesis in the territory of the Kuranakh cluster, gold is unevenly distributed in the contours of ore-bearing deposits, with high-grade areas alternating with poorly-graded ores [30, 31].

Experimental tests of gold heap leaching process from sandy-clay Kuranakh ores started in 1974-1975 by Irgiredmet Institute. As a result, it was found that the efficiency of the process, apart from gold content, depends on the scale of heap leaching unit, content of clay minerals, stack height, ore stack ing method and a number of other factors. The main role is played by the content of clay fraction, which prevents the filtration of solutions, as well as trapping already dissolved gold [32-34].

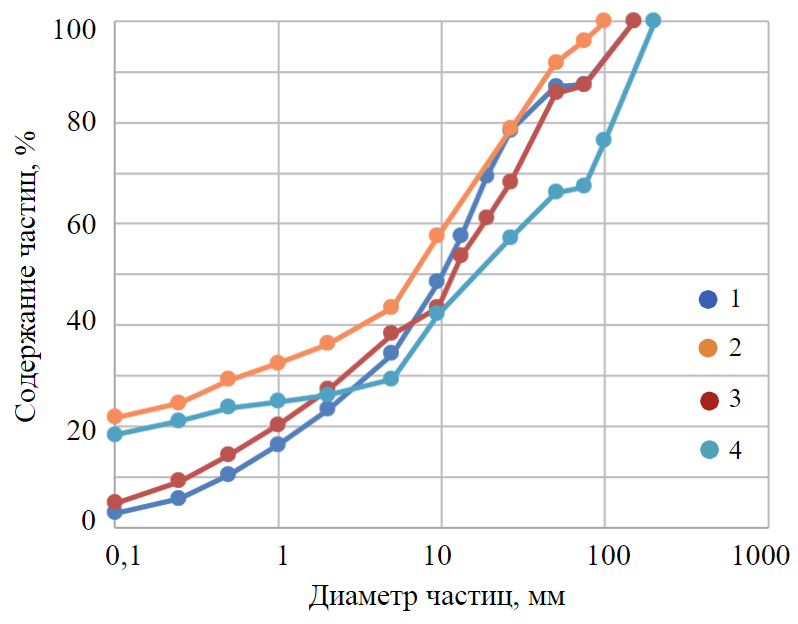

Fig.1. Granulometric composition of pelletized ores 1 and 2 – fresh pelletized ores N 1 и N 2; 3 and 4 – removed from irrigationores N 3 и N 4

Industrial heap leaching of pelletized sandy-clay Kuranakh ores was first implemented by AO “Aldanzoloto” in 1996 [25]. At the enterprise, ore crushed to –125 mm grade was pelletized with cement additives and stack ed for drip irrigation. At present, it is planned to intensify the process of implementation of heap leaching technology in the territory of Kuranakh gold ore cluster, which determines the relevance of substantiation of optimal parameters of heap leaching: stack height, number of layers, necessity of inter-layer drains, etc.

As a part of the investigation, the samples of fresh pelletized ores were obtained from the heap leaching pilot area prior to stack ing, as well as material from the areas already removed from irrigation. The material was irrigated for 30 to 50 days. The results of determining the particle size distribution of the samples taken by dry sieving are shown as integral curves (Fig.1).

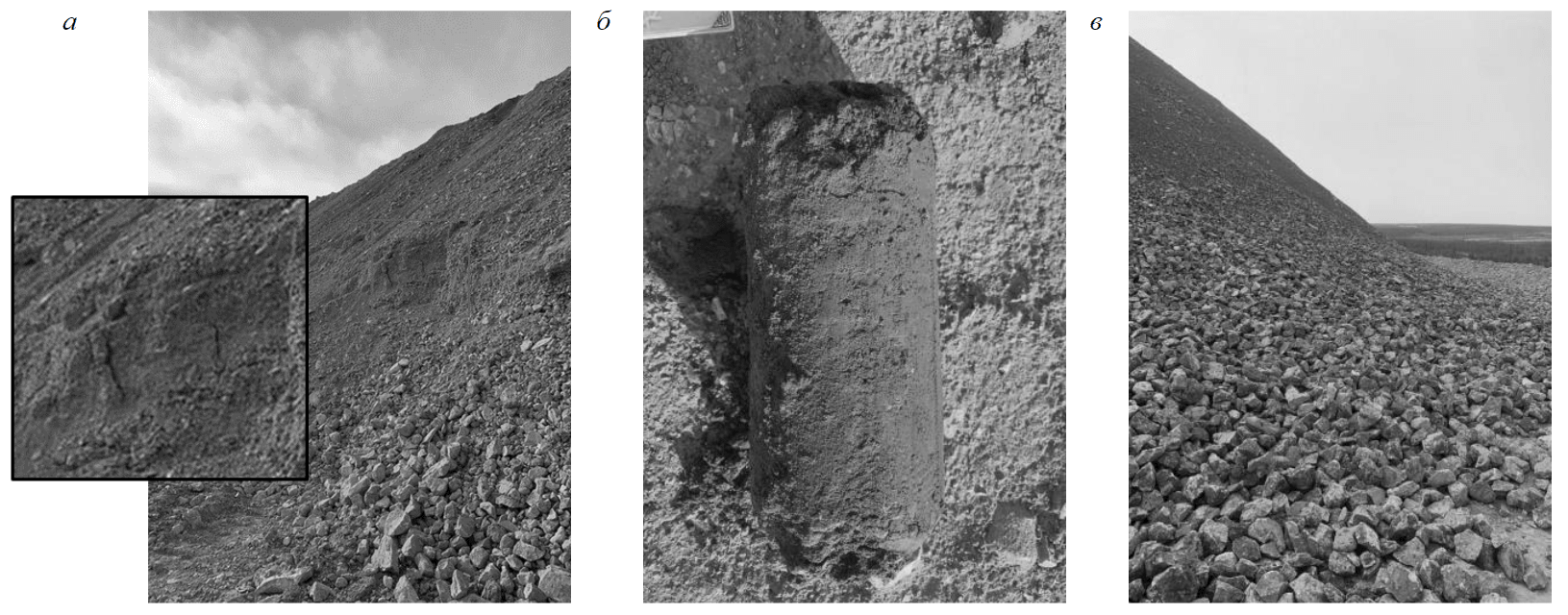

The differences in particle size distribution can be explained by the fact that after stack ing and irrigation, some of the pellets are broken up and the rock fragments are crushed by the solutions and the mechanical pressure of the overlying ores. The difference in particle size distribution means that the irrigation process also changes the filtration properties in the ore mass. At the same time, the breakdown of pellets leads to a return of the material to a state close to before the pelletizing, which also deteriorates the filtration parameters of the stack. Together with the effect of compositional segregation during stack formation, this can lead to the formation of lenses like sandy clay soils within the stack, which will reduce the efficiency of the gold recovery process. Figure 2 shows the evidence of the heterogeneous structure of the stack: the images of the uncovered slope surface at the test site (Fig.2, a), the core from the borehole (Fig.2, b) drilled through the de-irrigated stack, and the slope composed almost entirely of coarse-grained clastic material (Fig.2, c).

Fig.2. Segregation of ore material in the stack at the pilot site

In terms of particle size distribution in accordance with GOST 25100-2020 “Soils. Classification”, the presented materials by analogy with natural soils can be classified as: the material with drawn from irrigation to coarse-grainedcobble soils; freshly pelletized ore to coarse-grained silt soils. For these soils the value of the filtration coefficient can vary within a wide range. For example, in the hydrogeologist's handbook edited by V.M.Maximov, the average values of filtration coefficient for permeable pebbles and gravel with fine sand and clay are given in the range of 1-10 m/day. Approxi-mately the filtration coefficient of such materials can also be estimated according to P 56- 90/VNIIG “Recommendations on design of backflow filters for hydraulic structures” under the schedule of experimental values of filtration coefficients of sand-gravel-pebble and crushed stone soils.

If the particle diameter of 17 % by mass in the soil is taken as 0.1 mm, then the filtration coefficient will be: with loose structure 0.003-0.02 cm/s or 2.6-17.3 m/day; with dense structure 0.0005-0.003 cm/s or 0.4-2.6 m/day.

Thus, based on the granulometric composition, the studied materials can be characterized by the filtration coefficient in the range from 0.4 to 17.3 m/day, which requires further specification by laboratory and field studies of filtration properties of the pelletized ore.

Methods

The filtration characteristics of the pelletized ore were investigated in the laboratory on samples, on bench-scale equipment simulating a part of the massif on the heap leach pad, and in the field. This comprehensive approach allowed us to determine correlations between the different methods of studying the filtration characteristics of ores.

In the first stage of the study, the filtration characteristics of the pelletized ores were determined inlaboratory conditions. The ore was pre-compacted in compression devices to values of vertical stresses corresponding to the weight of the overlying ore mass. The test was carried out to loads of 0.6 MPa corresponding to a stack height of 40 m. Patterns of changes in filtration characteristics of pelletized ore were obtained for two types of particle size distribution depending on the stack height: the first type of pelletized ore was represented by a particle size class up to –20 mm, the second by a particle size class up to –125 mm.

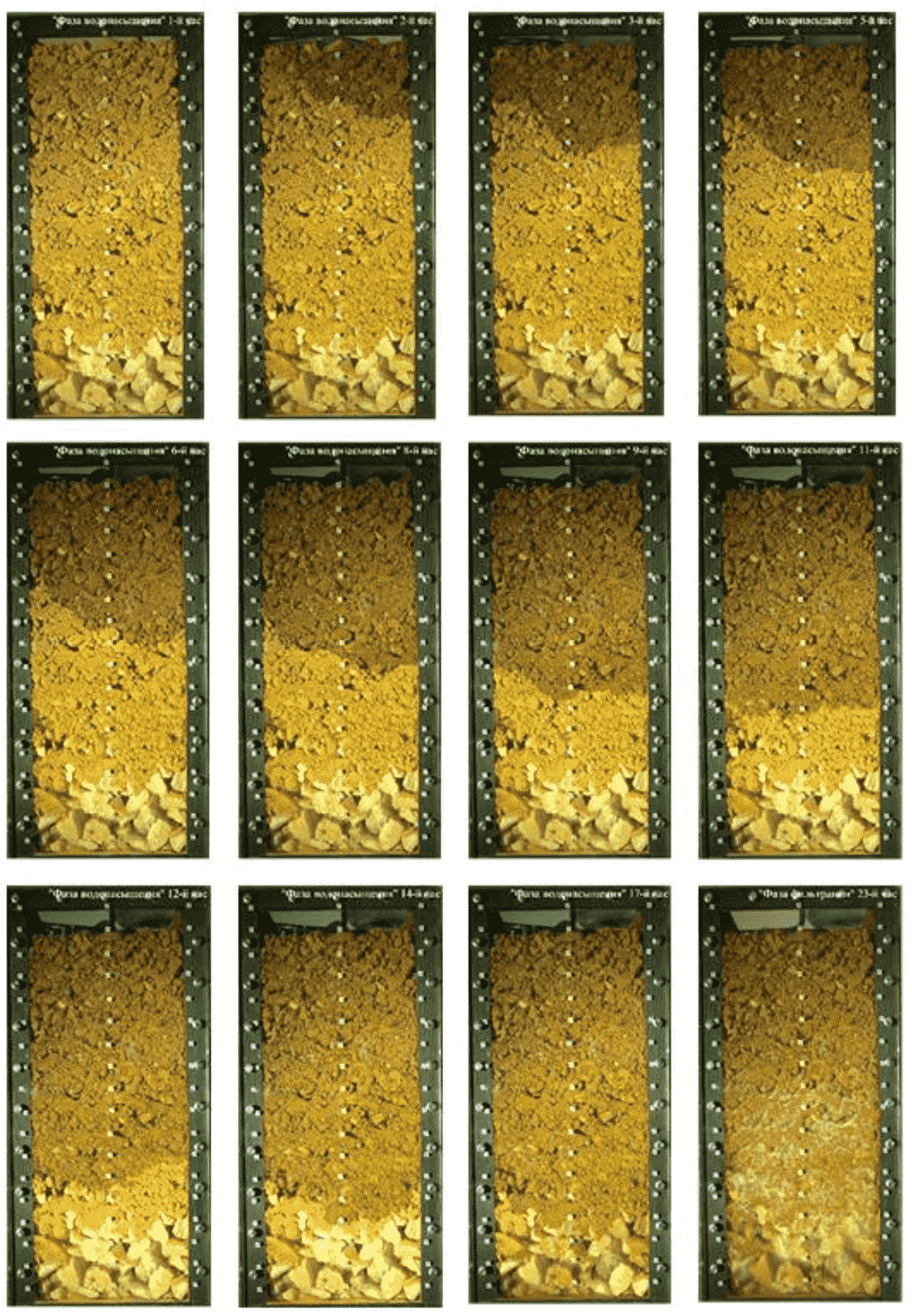

In the second stage of the study, the screening of pelletized ores was carried out with a characteristic distribution in the stack of grain size composition. The screenings were pre-stack ed in a prepared stand with dimensions of 450×450×1000 mm with a height of 1000 mm. In the first experiment, saturation of the pelletized ore at natural moisture was carried out with a solution and the saturation process was studied, while in the second experiment, the filtration process through the pelletized ore in a fully water-saturated state was studied.

The flow of a fluid through a porous medium of varying degrees of water saturation is usually considered through Richard's equations. Generally, this equation can be written in terms of two unknown variables of the degree of water saturation (relative humidity) S and head h:

where k – filtration coefficient.

For filtration calculations, the Van Genuchten – Mualem model, which is most widely used in practice, is adopted to describe the process of fluid filtration through porous bodies in fully water- saturated or partially water-saturated states. The adopted model allows to consider the change of filtration characteristics of a porous medium depending on the degree of its water saturation.

The filtration characteristics of porous medium are controlled through a characteristic relationship between the degree of water saturation (moisture content) of the soil and the negative pore pressure, which characterizes the ability of the soil to store liquid in the porous space at different pore pressure values.

The Van Genuchten – Mualem filtration model [35, 36] relates water saturation degree to head:

where pw – negative pore pressure; γw – liquid density in the pore space; Sres – residual value of degree of water saturation of porous medium by solution in the pore space; Ssat – value of total water saturation of the porous space by the solution; ga, gn, gc – parameters of Van Genuchten – Mualem equation.

The relative index of the filtration coefficient is determined by the following formula

where Seff – effective degree of water saturation of the porous medium by the solution.

The actual filtration coefficient is determined by the formula

where ksat – filtration coefficient of the porous medium in its fully saturated liquid state.

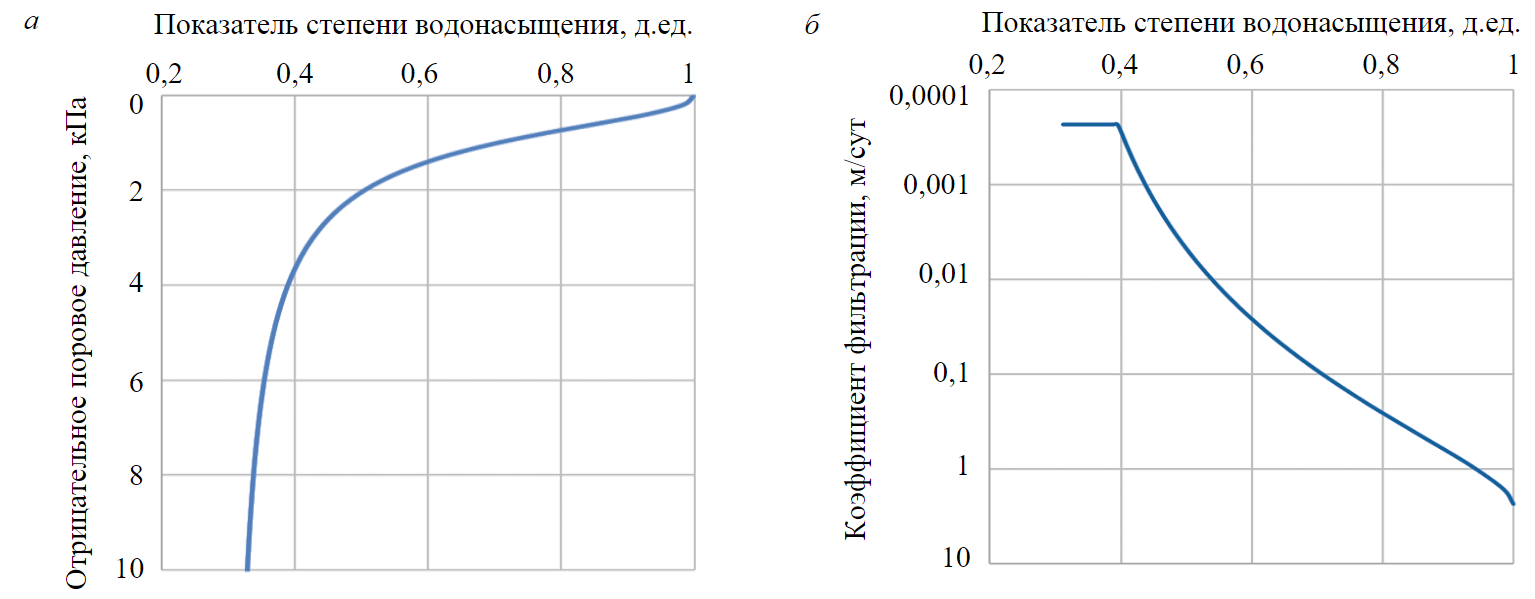

The adopted model allows taking into account change of filtration coefficient of pelletized ore depending on degree of its water saturation that will considerably increase reliability of forecast of filtration processes development in the zone of full and incomplete water saturation. When perfor-ming filtration calculations, it is assumed that the filtration coefficient is determined by granulometric composition taking into account the large inclusions. Filtration model parameters of incompletely saturated medium are determined for particle size distribution from 0.002-0.25 m. Parameters of filtration model are summarized in Table and for pelletized ore are represented as patterns of negative pore pressure and filtration coefficient change with the degree of water saturation (Fig.3).

Fig.3. Dependencies of negative pore pressure (a) and filtration coefficient (b) change on water saturation index

Parameters of the Van Genuchten – Mualem filtration model

|

Material |

ksat, m/day |

Sres |

Ssat |

ga, 1/m |

gn |

gc |

gl |

|

Pelletized ore |

2.35 |

0.139 |

1.0 |

12.4 |

2.28 |

–0.56 |

0.5 |

|

Gravel layer |

7.0 |

0.105 |

1.0 |

14.5 |

2.68 |

–0.62 |

0.5 |

|

Sandy layer |

3.5 |

0.105 |

1.0 |

14.5 |

2.68 |

–0.62 |

0.5 |

The numerical model was calibrated based on the results of filtration tests obtained on the benchtop equipment. During creation of the filtration numerical model, the main stages of the experiment, including initial water saturation of the pelletized ore, as well as subsequent stages of fluid filtration through the porous space, were taken into account. The numerical model geometrically repeated the physical model: pellet ore layer thickness 70 cm; drainage layer thickness 30 cm; cross- sectional dimensions 0.45×0.45. While performing model calibration it was accepted that irrigation intensity is 300 l/(m2·dai). The calculations show that saturation of pelletized ore occurs in 17 h, which generally corresponds to the data obtained by physical modeling. After full water saturation, the rate of fluid filtration through the porous medium is 20 min, which was also observed in the experiment. The moisture content of pelletized ore reaches 0.32, which corresponds to water saturation of 76 %. Based on the calculations performed, the filtration characteristics of the pelletized ore were calibrated.

The resulting parameters of the pelletized ore filtration model are adopted for parametric studies of solution saturation of the porous ore space.

Discussion of results

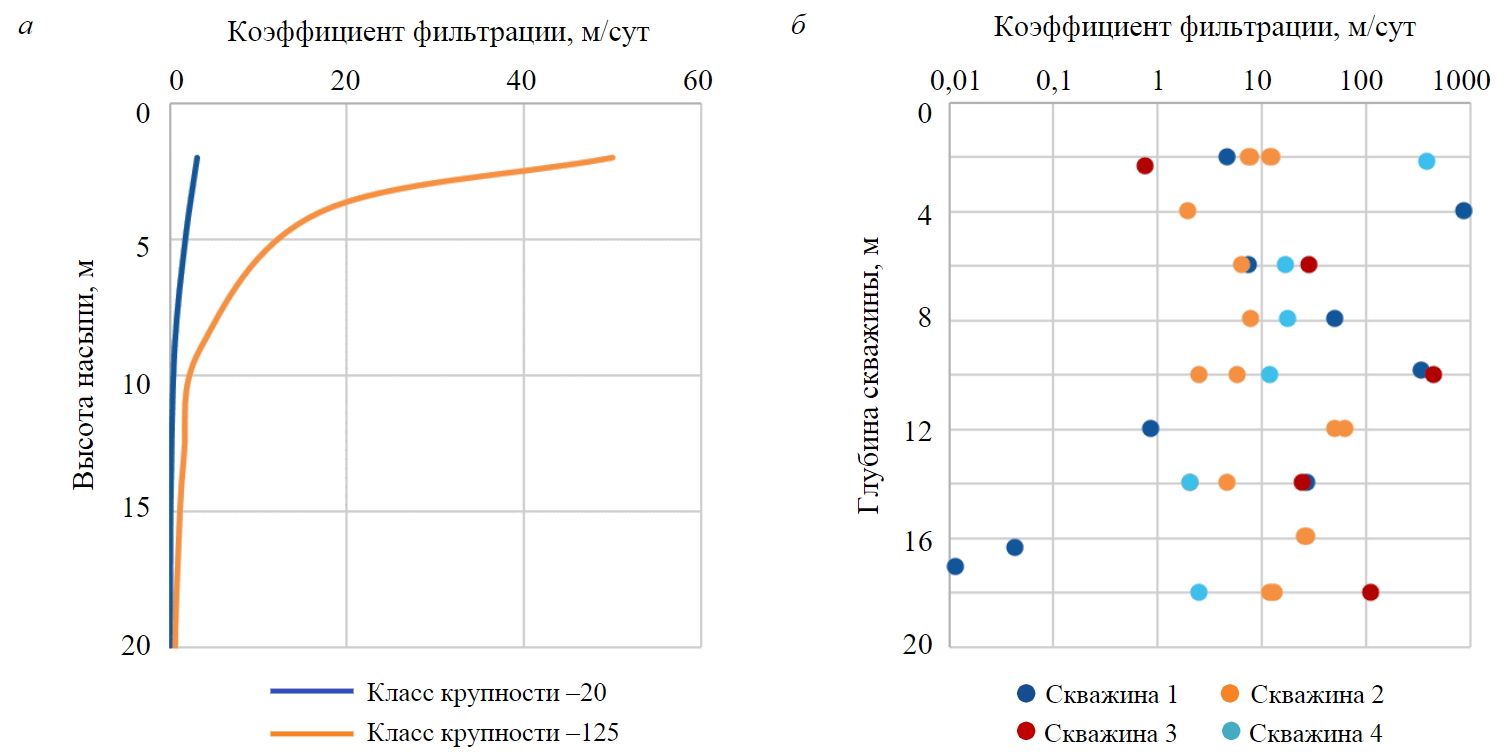

The laboratory studies to determine the filtration characteristics of the stack rocks (Fig.4, a) obtained at different size classes of pelletized ore have provided patterns of change in filtration characteristics with depth. The dependencies for the two ore grades are of the same nature. As can be seen from the presented patterns, filtration coefficient decreases as ore density increases and its porosity decreases, which is characteristic of porous media. It should be noted that the absolute values of the filtration coefficient are significantly different. Thus, the initial value of filtration coefficient of pelletized ore with the size class –20 is 3.1 m/day, while with the size class 125 the value of filtration coefficient is 50 m/day. That is, the studied ore size class has a significant impact on the filtration coefficient value and to a lesser extent affects the character of its change under the load.

Fig.4. Regularities of changes in filtration characteristics as a function of its degree of compaction and selection of granulometric composition, obtained inlaboratory conditions (a), and the results of determining changes in filtration coefficients by well depth according to field test data (b)

Fig.5. Self-compaction of ore material under irrigation

The study of the filtration characteristics of the stack rocks on the bench equipment (Fig.5) showed that the first stage of the laboratory experiment simulated the water saturation phase of 700 mm high ore material without compaction. The time for partial water saturation of the material was 18 h at an irrigation rate of 2.5/3.5 l/h, i.e. during this period water passed to the drainage layer. The ore material was further irrigated with the set intensity in order to complete water saturation. In the process of water saturation, the ore material settled by 5 cm, which amounts to 7 %. At the second stage of the experiment, additional irrigation was carried out on ore, which was already completely water saturated (65 cm). Under water supply with an intensity of 12 l/h the ore started to give up water after 10 min, and after 43 min from the beginning of irrigation reached an intensity of 12 l/h. Thus, the filtration coefficient of the material was 2 m/day. It was noticed that water solutions wash out the channels in the body of ore material and water mainly escapes through washouts. The pellet cannot withstand the flowing watering and collapses, so the channels in the body of the ore material are composed of primary rocks. At the third stage of the experiment, the water- saturated ore material was completely flooded with water for 1 h (with 66.5 l supplied and 64 l out). This experiment simulated the rise of solutions above the drainage layer. During the experiment, significant destruction of ore pellets was observed when they were flooded.

The field test data have shown (see Fig.4, b) that the filtration coefficient varies over a wide range (depending on the location of the test area) but that the filtration coefficient rarely falls below 2 m/day. Generally, the filtration coefficient varies between 2 and 10 m/day. In some local areas, the filtration coefficient value falls well below 2 m/day, but it is difficult to relate this drop in filtration characteristics to the general compaction of the stack rock, it is possibly related to the peculiarities of the heap leaching stack formation. Interestingly, the depth of the pelletized ores has little effect on the average filtration characteristics of these ores.

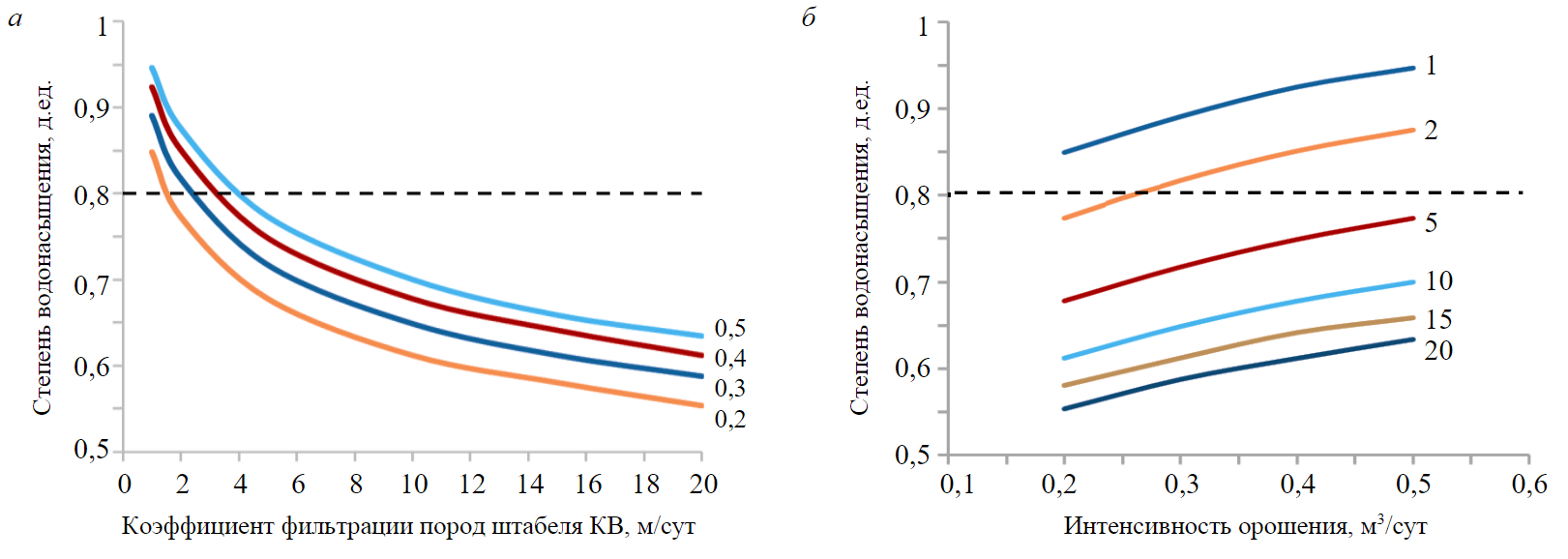

In order to assess the influence of filtration characteristics of the medium on the formation of an area of incompletely water-saturated rocks, a number of calculations were carried out where the value of the filtration coefficient varied in the range from 2 to 20 m/day. In the calculations, the minimum values of the filtration coefficient were taken without considering its change in plan at each depth interval investigated based on the results of the test-filtration works.

Fig.6. The regularities of changes in the degree of water saturation of HL stack depending on the filtration coefficient (a) and irrigation intensity (b) of HL stack at a given value of irrigation intensity (0.2, 0.3, 0.4, 0.5 m3/day) and ore filtration coefficient (1, 2, 5, 10, 15, 20 m/day); the dashed line (limiting value) – the maximum value of water saturation of HL stack rocks

The characteristics of the incompletely water-saturated model were taken from large-scale laboratory studies. For the actual particle size distribution of the pelletized ore, patterns of change in the degree of water saturation of the stack rocks depending on the intensity of solution pouring were obtained. The boundary value of water saturation degree was taken as 0.8. At values above 0.8, as shown in laboratory tests, the mechanical characteristics of the rocks begin to decline sharply due to solution saturation, this water saturation of the ores is assumed to be extreme.

On the basis of the performed calculations for the accepted filtration parameters of pelletized ores the regularities of change of a maximum degree of water saturation of rocks of a stack from a factor of filtration (Fig.6, a) and intensity of irrigation (Fig.6, b) have been received. The results show that as the filtration coefficient increases, the degree of water saturation of the stack rocks decreases, which allows to increase the intensity of irrigation of the stack surface with solutions. Thus, at filtration factor of 5 m/day the irrigation intensity can be increased up to 0.5 m3/h (500 l of solution per 1 m2), at 4 m/day – up to 0.4 m3/day, at 2 m/day irrigation intensity should not exceed 0.3 m3/day. According to the results of calculations the limiting values of intensity of irrigation of rocks at which inside the stack the water-bearing horizon will not form, and mechanical characteristics of rocks of a stack change in admissible limits are received. The limit value of water saturation of the stack rocks can lead to a sharp change in its mechanical characteristics.

The consideration of possible variation of filtration characteristics depending on actual particle size distribution of pelletized ore has shown that the value of limiting values of irrigation intensity varies within 20 %. It can be noted that the actual distribution pattern of filtration characteristics of HL stack rocks is more favourable in relation to the data obtained on the basis of laboratory studies, which allows to potentially increase the intensity of solution irrigation of rocks.

The proposed method of forecasting filtration processes in the heap leaching stack, based on determining filtration indices of the environment according to large-scale laboratory studies on bench equipment and their variability along the stack depth based on field tests, allows to qualitatively increase the reliability of the results of filtration rate calculations, determination of allowable irrigation intensity and possibility of aquifer formation inside the stack body. Subsequent studies will focus on a more detailed study of the segregation of pelletized ores within the heap leaching pile body and the impact of the deviations of filtration characteristics, recorded by field test data, from the average value on the indicators under investigation.

Conclusion

The paper presents the results of laboratory, field and indirect (based on particle size distribution) methods for determining filtration characteristics of ores. An analysis of methods for determining filtration parameters of pelleted sandy-clay ores at the experimental heap leaching site in the Kuranakh gold mining cluster is performed. It has been established that the design parame-ters characterising the filtration capacity of the ore stack can be guided by the particle size distribution composition of the pelletized ores.

The methods for laboratory determination of the filtration coefficient imply a state of complete water saturation of the material, which should not occur during operation in heap leaching plots.

In this regard, it is necessary to perform simulation of the ore irrigation process on stands, which will also allow to select the optimal irrigation intensity.

The most reliable information about the filtration coefficient value can be obtained by performing pilot filtration works at the pilot stack dumping area. The difference in the design and actual filtration values is due to the segregation of the composition during the formation of the ore stack.

The process of material segregation leads to the formation of a heterogeneous structure of the ore stack with zones of sharply different granulometric composition, which directly affects the anisotropy of the massif in terms of the filtration coefficient. This results in the formation of areas composed of the finest fractions, which are subjected to solution soaking and form, during compaction, zones with the filtration coefficient characteristic of clayey soils. These poorly permeable areas affect the movement of solutions in the stack and can affect the reduction of gold recovery.

Numerical modelling of filtration processes in the ore stack allows to take into account filtration heterogeneity of the massif and to determine the most effective parameters of heap leach operating modes.

References

- Argimbaev K.R., Ligotsky D.N., Mironova K.V., Loginov E.V. Investigations on material composition of iron-containing tails of enrichment of combined mining and processing in kursk magnetic anomaly of Russia. International Journal of Engineering, Transactions. 2020. Vol. 33. Iss. 7, p. 1431-1439. DOI: 10.5829/IJE.2020.33.07A.31

- Marinina O.A., Kirsanova N.Y., Nevskaya M.A. Circular economy models in industry developing a conceptual framework. Energies. 2022. Vol.15. Iss. 24, p. 9376-9386. DOI: 10.3390/en15249376

- Burakov A.M., Kasanov I.S. Appraisal Procedure for Probable Resources of Mining-Generated Placers in Yakutia. Mining Informational and Analytical Bulletin. 2019. N 9, p. 168-183 (in Russian). DOI: 10.25018/0236-1493-2019-09-0- 168-183

- Bragin V.I., Kharitonova M.Y., Matsko N.A. A probabilistic approach to the dynamic cut-off grade assessment. Journal of Mining Institute. 2021. Vol. 251, p. 617-625. DOI: 10.31897/PMI.2021.5.1

- Fomin S.I., Ivanov V.V., Semenov A.S., Ovsyannikov M.P. Incremental open-pit mining of steeply dipping ore deposits. Asian Research Publishing Network Journal of Engineering and Applied Sciences. 2020. Vol. 15. N 11, p. 1306-1311.

- Argimbaev K.R., Yakubovskiy M.M., Ivanova M.A. Design justification of drainage and antifilter facilities of the tailings at various methods of their constructions. International Journal of Ecology and Development. 2015. Vol. 30. N 2, p. 76-85.

- Petrova T.A., Rudzisha E., Alekseenko A.V. et al. Rehabilitation of Disturbed Lands with Industrial Wastewater Sludge. Minerals. 2022. Vol. 12. Iss. 3. N 376. DOI: 10.3390/MIN12030376

- Shumilova L.V., Khatkova A.N., Cherkasov V.G. Alternative Preparation of Mining Waste for Metal Leaching. Mining Informational and Analytical Bulletin. 2021. N 3-2, p. 173-181 (in Russian). DOI: 10.25018/0236_1493_2021_32_0_173

- Ivanik S.A., Ilyukhin D.A. Flotation extraction of elemental sulfur from gold-bearing cakes. Journal of Mining Institute. 2020. Vol. 242, p. 202-208. DOI: 10.31897/PMI.2020.2.202

- Aleksandrova T.N., Nikolaeva N.V., Lvov V.V., Romashev A.O. Ore processing efficiency improvements for precious metals based on process simulations. Obogashchenie rud. 2019. N 2, p. 8-13 (in Russian). DOI: 10.17580/or.2019.02.02

- Thenepalli T., Chilakala R., Habte L. et al. A Brief Note on the Heap Leaching Technologies for the Recovery of Valuable Metals. Sustainability. 2019. Vol. 11. Iss. 12. N 3347. DOI: 10.390/SU11123347

- McBride D., Croft T.N., Cross M. et al. Optimization of a computational fluid dynamics model – Heap leach model and sensitivity analysis of process operation. Minerals Engineering. 2014. Vol. 63, p. 57-64. DOI: 10.1016/J.MINENG.2013.11.010

- Van Genuchten M.Th. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil science society of America journal. 1980. Vol. 44. Iss. 5, p. 892-898. DOI: 10.2136/SSSJ1980.03615995004400050002x

- Aleksandrova Т., Nikolaeva N., Afanasova A. et al. Selective Disintegration Justification Based on the Mineralogical and Technological Features of the Polymetallic Ores. Minerals. 2021. Vol. 11. Iss. 8. N 851. DOI: 10.3390/min11080851

- Tataurov S.B. Justification of geotechnological processes of gold heap leaching with cryogenic transformation of mineral raw materials: Avtoref. dis. ... d-ra tekhn. nauk. St. Petersburg: Sankt Peterburgskii gornyi universitet, 2011, p. 41 (in Russian).

- Popov V.I., Kaimonov M.V. Determination of the Optimal Parameters of the Process of Leaching In Stack of Ore with Negative Temperatures of the Environment. Mining Informational and Analytical Bulletin. 2017. N 24, p. 292-298 (in Russian). DOI: 10.25018/0236-1493-2017-11-24-292-298

- Leahy M.J., Davidson M.R., Schwarz M.P. A model for heap bioleaching of chalcocite with heat balance: Bacterial tempera-ture dependence. Minerals. Engineering. 2005. Vol. 18. Iss. 1, p. 1239-1252. DOI: 10.1016/j.hydromet.2006.07.004

- Tataurov S.B. Study of variability of technological properties of gold-bearing raw materials in conditions of cryolithozone. Mining Informational and Analytical Bulletin. 2008. N 8, p. 45-50 (in Russian)..

- Pacheco P.G.M., Purizaga M., Huertas J., Romanel C. Flow analysis and dynamic slope stability in a copper ore heap leach. 14th Pan-American Conference on Soil Mechanics and Geotechnical Engineering 64th Canadian Geotechnical Conference, 2-6 October, 2011, Toronto, Ontario, Canada. SIMSG, 2011, p. 1-7.

- Lushnikov Ya.V., Bagazeev V.K. Definition of Physical and Mechanical Properties of Ore Pellets When Forming A Stack of Heap Leaching. Izvestiya vysshikh uchebnykh zavedenii. Gornyi zhurnal. 2013. N 8, p. 124-127 (in Russian).

- Kutepov Yu.I., Kutepova N.A. Methodology of Engineering Geological Study of Geotechnical Processes within Technogenically Disturbed Rockmass at Exploitation of Mineral Deposits. Mining Informational and Analytical Bulletin. 2014. N 8, p. 123-131 (in Russian).

- Xiuxiu Miao, Narsilio G.A., Aixiang Wu, Baohua Yang. 3D dual pore-system leaching model. Part 1: Study on fluid flow. Hydrometallurgy. 2017. Vol. 167, p. 173-182. DOI: 10.1016/J.HYDROMET.2016.11.015

- McBride D., Gebhardt J.E., Croft T.N., Cross M. Modeling the hydrodynamics of heap leaching in sub-zero temperatures. Minerals Engineering. 2016. Vol. 90, p. 77-88. DOI: 10.1016/J. MINENG.2015.11.005

- McBride D., Cross M., Gebhardt J.E. Heap leach modeling employing CFD technology: A “process” heap model. Minerals Engineering. 2012. Vol. 33, p. 72-79. DOI: 10.1016/J. MINENG.2011.10.003

- Boitsov V.E., Pilipenko G.N., Dorozhkina L.A. Model of formation of complex gold-uranium deposits of the Central Aldan ore district. Izvestiya vuzov. Geologiya i razvedka. 2006. N 2, p. 23-31 (in Russian).

- Cariaga E., Concha F., Sepúlveda M. Flow through porous media with applications to heap leaching of copper ores. Chemical Engineering Journal. 2005. Vol. 111. Iss. 2-3, p. 151-165. DOI: 10.1016/MIN.2005.02.019

- McBride D., Gebhardt J., Croft N., Cross M. Heap Leaching: Modelling and Forecasting Using CFD Technology. Minerals. 2018. Vol. 8. Iss. 1. N 9. DOI: 10.3390/MIN8010009

- Kovlekov I.I., Sherstov V.A., Varlakov P.S., Dmitriev A.A. Experience of heap leaching of ores in Yakutia. Nauka i obrazovanie. 2005. N 1, p. 21-24 (in Russian).

- Molchanov A.V., Terekhov A.V., Shatov V.V. et al. Gold Ore Districts and Ore Clusters of the Aldanian Metallogenic Province. Regional Geology and Metallogeny. 2017. N 17, p. 93-111 (in Russian).

- Tatarinov A.P., Dementyev V.Y., Tsykunova G.V. Development and introduction of heap leaching. 26th International Mineral Processing Congress: Innovative Processing for Sustainable Growth, 24-28 September 2012, New Delhi, India. IMPC, 2012, p. 5539-5542.

- Fedotov P.K., Senchenko A.E., Fedotov K.V., Burdonov A.E. Studies of enrichment of sulfide and oxidized ores of gold deposits of the Aldan shield. Journal of Mining Institute. 2020. Vol. 242, p. 218-227. DOI: 10.31897/PMI.2020.2.218

- Dementev V.E., Tatarinov A.P., Gudkov S.S. Main aspects of heap leaching technology for gold-bearing raw materials. Izvestiya vuzov. Gornyi zhurnal. 2001. N 5, p. С. 53-55 (in Russian).

- Dementev V.E., Druzhina G.Ya., Mineev G.G. Кучное выщелачивание золотосодержащего сырья. Izvestiya vuzov. Gornyi zhurnal. 2000. N 2, p. 74-78 (in Russian).

- Robertson S.W., van Staden P.J., Cherkaev A., Petersen J. Properties governing the flow of solution through crushed ore for heap leaching. Hydrometallurgy. 2022. Vol. 208. N 105811. DOI: 10.10165/J.HYDROMET.2021.105811

- Mostaghimi P., Tollit B.S., Neethling S.J. et al. A control volume finite element method for adaptive mesh simulation of flow in heap leaching. Journal of Engineering Mathematics. 2014. Vol. 87, p. 111-121. DOI: 10.1007/S10665-013-9672-3

- Tataurov S.B., Shesternev D.M., Myazin V.P., Cherepanov A.N. Changes in filtration coefficients and granulometric composition of gold-bearing pelletized loamy ore during construction and water saturation of heap leach stack. Mining Informational and Analytical Bulletin. 2006. N 12, p. 286-294 (in Russian).