Development of a new assessment system for the applicability of digital projects in the oil and gas sector

- 1 — Ph.D. Saint Petersburg Mining University, ▪ Orcid

- 2 — Postgraduate Student Saint Petersburg Mining University ▪ Orcid

Abstract

Digital transformation is one of the global trends that has covered most sectors of the economy and industry. For oil and gas companies, the introduction of digital technologies has become not just a trend, but one of the factors for ensuring competitiveness and maintaining a stable position in the market in a rapidly changing macro environment. At the same time, despite the positive effects achieved, digital transformation is a complex process from the point of view of implementation and is associated with high technological, financial, and economic risks. The work aims to develop and test a new system for evaluating the applicability of digital projects in the oil and gas sector. The research methodology includes the application of the Gartner curve, methods of expert assessments, and tools for assessing the economic efficiency of investment projects. The developed assessment system is based on a comprehensive accounting of four components: the level of digital maturity of the company; compliance of the implemented technology with the goals and objectives of the organization; the level of reliability of the implemented technology; the level of innovation of the implemented project. Particular attention is paid to the practical testing of the proposed methodology based on the evaluation of a digital project implemented by a Russian oil and gas company.

Introduction

The development of the oil and gas sector is associated with a number of constraints [1, 2]. The oil and gas industry cannot fully rely on the stability of markets and prices, which have shown high volatility over the past decade. One of the important factors that predetermined stagnation in global markets, including the oil and gas sector, was the consequences of COVID-19 [1, 3]. A further decline in the oil and gas market is believed to maintain pressure on the market value of hydrocarbons and encourage energy companies to focus more on reforming their portfolio of projects and assets [4]. Most industry experts say the time for “plain” oil is over.

Nearly half of the oil (~43 %) comes from fields that have been in production for over 25 years. The economic situation in the hydrocarbon market and the increase in costs in the development of new assets have changed the orientation of oil and gas companies from the development of new fields to the maximum optimization of the operation of already developed assets. R.M.Lance, CEO of ConocoPhillips, summed up the current situation very accurately, noting that “low capital intensity is a CFO’s best friend”.

Another problem is that traditional hydrocarbon reserves are gradually being depleted. In view of this, the development of unconventional reserves and the resource potential of the Arctic oil and gas fields (including offshore reserves) is of particular relevance [4-7]. The efficient development of deposits with unconventional reserves requires special approaches and determines the relevance of the introduction of digital technologies [8, 9].

Every year, the industry will face more and more challenges related to physical and chemical properties of oil, reservoir parameters, difficult natural conditions, lack of personnel and competencies, and strict environmental standards [10-12]. The only way to close the gap between the heyday of the oil and gas industry and what the industry has now is to improve the efficiency of all business processes, “fighting for every drop of oil”. Only a comprehensive digital transformation of companies in the industry will be able to address this request [8, 13, 14].

The forecast published by International Data Corporation (IDC) suggests that the volume of investment in digital projects will show a gradual increase every year. The share of investments of oil and gas companies in digitalization projects varies between 25-40 % depending on the strategies being implemented, which allows us to conclude that they are interested in creating modern, high-tech industries [15]. According to Technology Outlook BP (2018), technologies will reduce production costs by more than 30 % by 2050 and increase the volume of recoverable oil reserves in the world [16].

The benefits of digital technologies usage cover a combination of economic, technological, environmental, and management aspects [17-20]. New technologies can either succeed or fail. The introduction of a new technology usually requires many pilot projects, and even this does not guarantee success. Considering the degree of the capital intensity of oil and gas enterprises, the issue of combining the principle of rapid prototyping and maintaining the maximum stability of production indicators, as well as the state of the company as a whole, is acute [21]. However, the main problem is that most companies do not take a comprehensive approach to digitalization: often digital solutions are used to strengthen weaknesses, for marketing purposes, or locally and at the request of production departments. This approach is wrong and contradicts the very meaning of using digital technologies. In this case, a detailed and clearly defined roadmap for digital business transformation can help the companies [22].

The fragmented approach to information exchange results in petabytes of data generated by drilling platforms that are either used inefficiently or not used at all, which is a negative aspect both from the point of view of the overall digitalization of the sector and the formation of a large number of lost benefits. Deloitte's analysis of 5,000 feature articles from the five largest oil and gas magazines confirms that the market is oversaturated with new technology names and that most new technologies do not reach the stage of their industrial application, fading at the very beginning of the journey – this applies to the entire types of technologies, not individual digital initiatives[4]. In this regard, the management of oil and gas companies faces the serious task of selecting digital projects based on integrated assessment systems.

The purpose of the study is to develop a new system for evaluating the applicability of digital projects in the oil and gas sector. To achieve the goal of the work, it is necessary to answer a number of research questions: Why is digital transformation important for the oil and gas complex and this process is associated with high risks? What methods can be used to evaluate projects aimed at introducing digital technologies into the activities of companies? How to evaluate the applicability of digital projects in the oil and gas sector? What indicators and methods should be used?

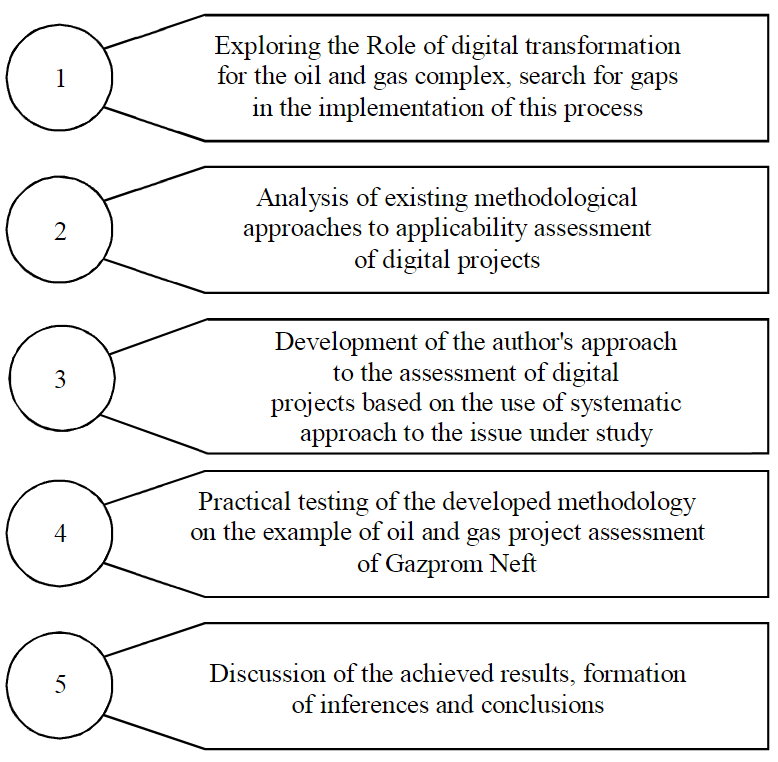

Fig.1. General research algorithm

Methodology

The keystone of the study is the information and analytical basis. To obtain relevant information about the key trends in digital transformation and the current state of the oil and gas sector, a content analysis of not only of academic literature but also of industry-specific international and national reports was carried out.

The result of the study was the conclusion about the almost complete absence of scientific research on the topic of evaluating digital projects in the oil and gas sector. In this regard, it seems appropriate to create a tool that will take into account the criteria that are significant for digital projects in the oil and gas sector or are not sufficiently used in classical project selection methods. Figure 1 shows the basic research algorithm.

Digital transformation is a process of integrating digital technologies into business processes, which is gradually penetrating into all areas of activity, and the oil and gas sector is no exception [7, 20, 23, 24].

S.Whitfield raises a reasonable question in his research “Digital transformation: great risk or great opportunity?”. This thesis actually reflects the inconsistency of the subject under study. On the one hand, oil and gas companies are forced to adapt to the ever-changing macro environment, improve efficiency and maintain a stable position in the market. On the other hand, the process of digital transformation itself is associated with high risks and a high degree of uncertainty.

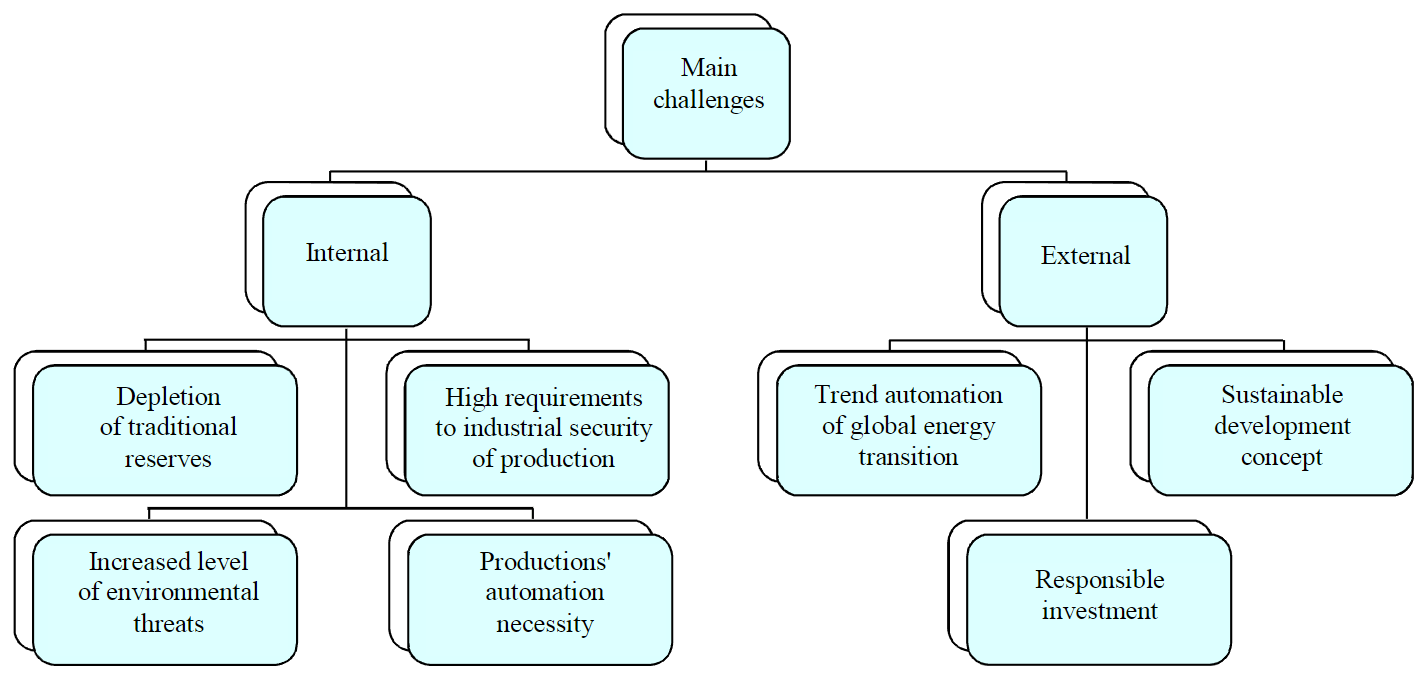

Energy companies face a significant number of different problems and threats, both internal and external (Fig.2). To overcome them effectively, it is necessary to introduce fundamentally new approaches to organizing production processes and making managerial decisions. All this actualizes the need to introduce digital technologies and solutions [11, 25-27].

The use of digital technologies allows to reduce the costs and increase productivity, which has been proven more than once by the example of foreign companies. For instance, the use of the “Field of the Future” technology allowed BP to increase production by 1-2 % [15]. Australian oil and gas company Woodside was able to increase productivity by 10-15 % by introducing advanced digital technologies into the production process [28]. Furthermore, the experience of oil and gas companies indicates the possibility of increasing the economic efficiency of activities through digitalization and intellectualization. For instance, Halliburton achieved a 20 % reduction in Capital Expenditure (CAPEX) by implementing a state-of-the-art Real time operation technology suite.

Digital technologies are also used in the activities of the largest national oil and gas companies, however, in terms of digital maturity, the country still lags behind international partners, which has been repeatedly noted by the Ministry of Natural Resources and Ecology of the Russian Federation.

Fig.2. Main challenges for oil and gas companies

Rosneft National Company assesses the current level of development and implementation of digital solutions in production and technological activities as low. At the same time, digitalization is defined by the company as one of the main priorities for future business development.

In the work [29] it was found that, despite all the difficulties of digital transformation, the implementation of this process is justified. The authors argue that the introduction of digital technologies opens up new opportunities not only in the upstream segment but also in the downstream segment. They allow reducing the time costs associated with the processing of information at the stages of geological exploration (GE) by more than 50-60 %. The introduction of such technologies can reduce costs by 20-30 % and increase productivity by up to 5 % directly at the stages of project implementation [29].

The size of the possible economic effects of digital transformation is of increasing interest from the business side. Digital transformation in the industry could bring about 640 billion dol. in benefits: ~170 billion dol. due to resource savings; ~10 billion dol. – productivity improvements; 30 billion dol. – reductions in water consumption; 430 billion dol. – emission reductions. Moreover, the use of digital technologies can lead to climate effects and the possibility of reducing total CO2 emissions by more than 1,300 million tons, saving water resources by 3 billion dol. liters, and preventing oil spills [5, 30].

It is obvious, that digital transformation is a complex process. Industry companies refer to this process as a complex of high-risk activities. According to research conducted by Deloitte, the list of the most common risks identified by companies as part of the topic of digitalization includes concerns about data privacy; lack of standardization of information data and processes; the complexity of integrating technology and management solutions; shortage of qualified staff [31]. These factors complicate the process of making managerial decisions.

To choose the right strategy in the field of digitalization, companies need to make complex investment decisions. Any investment in digital technology must be justified. This requires specific approaches to evaluate projects and technologies, taking into account not only potential advantages but also disadvantages. The academic literature practically does not reflect comprehensive approaches to assessing the applicability of new technologies (digital). To eliminate the formed gap, it is advisable to propose an integrated approach to solving the designated problem, which determines the relevance and significance of the study.

Approaches to evaluation of digital projects

In order to conduct a comprehensive assessment of the project, technological calculations are required [32]. For the reflection based on the example of the chain of implemented projects’ interconnections, the changes in business processes caused by them, as well as the emerged economic effects, with the support of industry experts, a list of relevant examples was compiled (Table 1).

Таble 1

Technological and economic effects of the implementation of digital technologies [12, 18, 32]

|

Project |

Changes in business processes |

Possible economic effects (including avoided damages) |

|

Creation of the drill pipes identification system |

Reduction of the drill pipes accidents and downtime |

To assess the economic effect (EE), it is necessary to calculate the losses for one day of downtime in the drilling process, evaluate the costs associated with the elimination of the accident, and predict the percentage of accidents that can be avoided through the implementation of the project:EE = (number of days of downtime avoided) × (cost of a day of downtime) + + (cost of accident elimination) |

|

Implementation of a system for intelligent interpretation of seismic data |

Reduction of the required time for the business process of interpreting seismic data |

Due to the fact that the function of interpreting seismic data is taken over by the information system, the management of the organization can reduce the number of specialists in this profile, thus saving on the wage fund. Also, the acceleration of this process increases the passage of the entire cycle of preparation for the development of the field (site), which entails an economic effect that increases the speed of project development, faster reaching the design capacity, which will reduce the return on investment |

|

Implementation of predictive analytics in the drilling process |

Automatic change of the axial load on a bit, inclination angle, and other drilling parameters in real time based on the assessment and analysis of many external factors |

Due to the use of the full potential of drilling rigs and the characteristics of the rocks being drilled, the time of penetration, wear of the bit, the number of accidents, failures, and operations not performed in full accordance with the technical specifications will be significantly reduced. As a result, the cost of drilling will significantly decrease and the quality of the work performed will increase. To assess the economic effect, it is necessary to analyze the technological parameters declared by the contractor, evaluate them in terms of cost and compare with the total cost of work performed without the use of the technology |

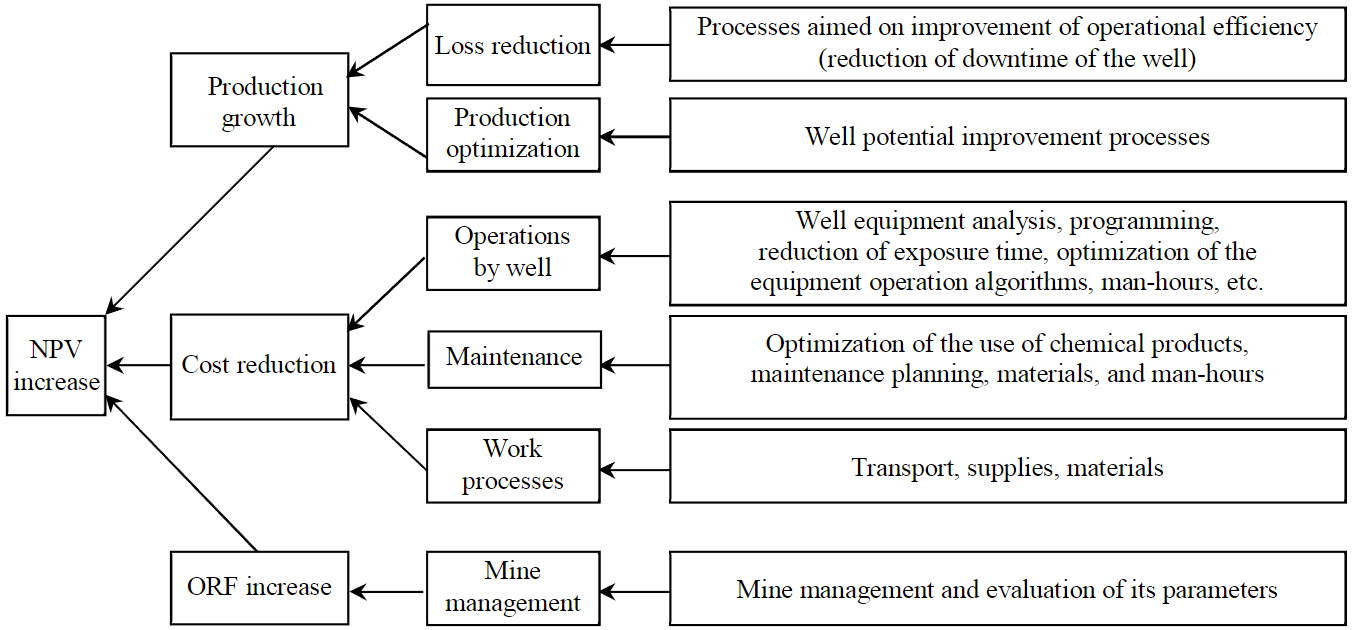

All the benefits from the introduction of digital technologies in the activities of oil and gas companies can be reflected through a number of basic criteria that affect business processes (Fig.3).

At the same time, economic efficiency is not the only parameter that is important to consider. Based on the systematization of data on the methods used by foreign and Russian companies for evaluating digital projects, as well as taking into account the specifics of digital solutions in the oil and gas sector, a list of parameters has been formed that could improve the efficiency of managerial decision-making: compliance of the project with the goals and objectives of the company; digital maturity of the company; the degree of reliability and innovativeness of the implemented technologies.

Fig.3. The measurement chain for the impact of changing business processes on the NPV project for oil and gas production

The first parameter reflects the basic ability to implement projects, the second – is the level of preparedness of the company to implement a digital project, and the third is the value of the technology. Thus, there is a transition from the strategic to the operational level of company management. The parameters complement each other and allow you to form a complete picture not only of the technologies themselves, but also of how the company can use them, and how the effect of their use will correspond to the company's activities. At the same time, in order to move to a quantitative assessment, it is important to determine the methods and approaches to its implementation.

Assessment of project compliance with the goals and objectives of the company is one of the most important steps in decision-making management process. The project should not contradict the stated target priorities, otherwise, its implementation will not lead to positive results (expected), but will cause a set of negative consequences.

The management of the company must define the goals of each business unit and identify key performance indicators to monitor the implementation of each task, as well as identify links between them [33-37].

The implementation of any digital project is a tool for influencing a number of indicators linked to the strategic goals of the company, and therefore, the success of the implementation of a digital project depends on changing these indicators to the desired level [38]. The main difficulty of this methodology is the time-consuming process of selecting representative indicators that are measurable and demonstrate the achievement of the specified goals.

In order to use this model in further calculations of the final indicator, the development of which is the main goal of the work, it is necessary to find ways to digitize the results of its application. To do this, as part of the application of the proposed assessment system, the organization needs to create a standard table of its goals and objectives (example in Table 2).

To get an indicator Cg, necessary for conducting a comprehensive multi-parameter assessment, the following formula can be used

if the goal is to increase a certain indicator; if the goal is to reduce the actual value of the indicator, then the next formula is used

where Cg – is the coefficient of compliance with the goals and objectives of the organization; Vf – is the predicted value of the indicator reflecting the achievement of the set goal or task, which will be achieved in the event of the implementation of a digital project; Vg – the target value of the indicator, reflecting the achievement of the goal or task.

Таble 2

Assessment of the compliance of the implemented project with the goals and objectives of the company

|

Goal |

Indicator |

Actual value |

Target value |

Predicted value after project implementation |

|

Production increase |

Annual oil production, mil/t |

32.5 |

36.7 |

34.2 |

|

Increasing the oil recovery factor (ORF) |

ORF, % |

23.4 |

31 |

27.2 |

|

Reducing the overhaul period of wells |

Downtime, day |

13 |

6 |

8 |

|

Reducing the cost of geological exploration work |

Expenses for exploration, billions of rub. |

12.5 |

10 |

9 |

Unlike the assessment of project performance based on the use of relative profitability indicators, the assessment of the project's compliance with the goals and objectives implies a clear relationship with the approved target priorities and cannot be universal for all companies at the level of the oil and gas industry considered in the study.

Assessment of the digital maturity of a company

Important factors in assessing the applicability of a digital project: the level of development of the company's digital infrastructure; degree of qualification of the staff in the field of new technologies; the state of corporate culture [34]. The organization is forced to develop in an evolutionary and complex way, otherwise, new digital projects introduced into the company's activities will not be able to be carried out effectively (with the achievement of the expected results). There should be a progressive systematic development of business process hardware, the level of competence of employees, and the adaptability of the corporate culture – only in this case the company will be able to meet modern market challenges and systematically introduce elements of the progressive industry 4.0 [39-41].

There are various methods that allow assessing both the degree of digitalization of a company and the level of its competencies when working with specific and applied tasks for the introduction of innovative technologies. Each method has its own advantages and disadvantages.

Some of the most popular models for assessing the digital maturity of an organization are models developed by Forrester, IDC, and Erricson. These models comply with Capability Maturity Model Integration (CMMI) standards and quite fully reveal the essence of the organization's digitalization, they also consider it in all main areas: corporate culture; management; business processes; technologies; learning [42].

Forrester’s methodology is available on the open access source, therefore, its comprehensive evaluation is possible. The assessment methodology is based on a questionnaire that consists of 28 questions in four key areas and has four digitizable answer options: 0 – strongly disagree; 1 – relatively disagree; 2 – relatively agree; 3 – totally agree. Based on the results of the survey filled by the experts of the organization, the total scores for all questions are summed up, and the company is assigned to one of four groups in accordance with the level of its digital maturity. This methodology is based on the use of expert opinion, therefore it is not objective. For a more accurate assessment of the digital maturity of an organization, a checklist has been developed based on leading methods, divided into three main sections: the level of technological equipment; personnel qualification; structure of business processes. Each section has a specific set of questions and answers that have a specific weight in the final assessment of the level of digital maturity. The maximum number of points is 100. The digital maturity coefficient is determined by dividing the score obtained as a result of filling out the checklist by 100 points. The assessment algorithm consists of the following stages: collection of key data; assessment according to the indicators presented in the checklist; calculation of the total score; assignment to one of four groups according to the level of digital maturity (high, average, below the average, low). The checklist-based methodology is qualitatively different from the existing tools on the market in that all the answer options are based on a factual basis and do not depend on expert opinion; only facts related to the activities of the organization in the field of digital technologies are checked. Groups of companies by digital maturity, formed according to the developed methodology, are presented in Table 3.

Таble 3

Classification of digital maturity levels

|

Level of digital maturity |

Digital maturity group |

Behavioral characteristic |

Total score |

|

High |

Innovators |

Demonstrate market dominance |

80-100 |

|

Average |

Advanced |

Complex but not innovative actions |

64-79 |

|

Below the average |

Testers |

Situational use in operation processes |

42-63 |

|

Low |

Sceptics |

Ignoring digitalization |

0-41 |

A value of 100 indicates a high level of digital maturity of the company and the presence of competitive advantages associated with the digitalization process. If the value of the indicator varies between 0-41, then this indicates a complete disregard for digitalization and unavailability (inertia) for the implementation of digital projects by the company.

Assessment of innovation and reliability of technology

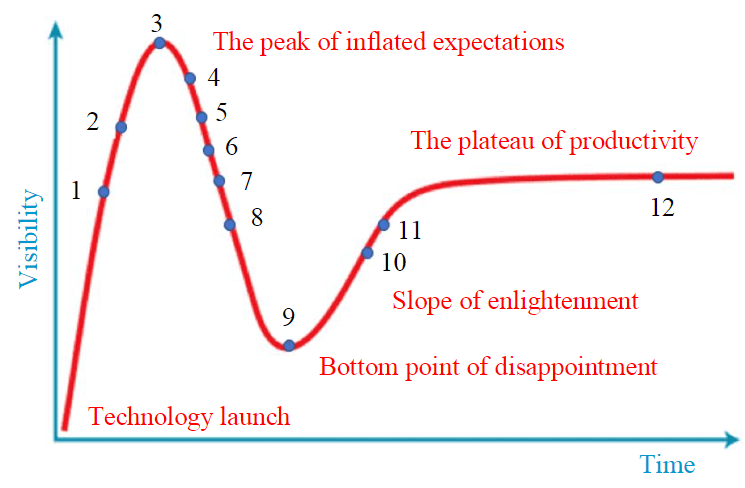

The next important aspect is the assessment of the degree of innovation and reliability of the implemented digital technology. To assess the relevance of the implemented digital technologies, it is proposed to use existing and authoritative systems for tracking current technology trends, one of which is the Gartner curve. This is a leading research organization, which activities are aimed at studying the situation in the field of digital technologies. It is best known for introducing the concept of ERP (Enterprise Resource Planning) and regular research reports in Magic Quadrant and Hype Cycle formats. The hype cycle reflects the degree of technology relevance [43, 44]. The Gartner curve is divided into several zones: innovative triggers; the peak of inflated expectations; the trough of disappointment; the slope of enlightenment; productivity plateau. Also, this curve reflects modern technologies marked with a special symbol, which means the predicted time to achieve technologies of a sufficient level of development for widespread use in the economic activities of organizations.

To conduct a comprehensive multi-parametric assessment, we will introduce two coefficients – the reliability of technology and the relevance of innovation. The measurement range for each parameter lies in the set of numbers from 0 to 1, where 0 in the case of the technology reliability coefficient means the complete absence of statistical information and successfully implemented projects based on this technology; 1 means that the technology has a case of successful industrial application in a time interval of at least a year after it passes the “productivity plateau” boundary. In the case of the relevance coefficient, 1 means the presence of technology in the zone of innovative triggers and has a positive effect on the overall value of the final indicator, since the early development of a promising technology can provide the leadership of an organization in this area; 0 is assigned to technologies that have received a more modern replacement in the market, allowing a change in the previous business model. These coefficients are proposed to be determined by internal or external experts of the company or based on the Gartner curve. Canon values of the relevance coefficient: innovative trigger – 1.0; the peak of inflated expectations – 0.8; depression of disappointment – 0.6; enlightenment slope – 0.4; productivity plateau – 0.2; obsolescence of technology – 0. Reference values of the coefficient of reliability: the complete absence of statistical information – 0; creation of a minimum viable product (MVP) based on technology – 0.2; feedback and statistics on the first use of the MVP, making appropriate adjustments – 0.4; the first successful experience of applying the technology in real business processes of companies – 0.5; the beginning of the industrial application of technology – 0.7; the beginning of industrial use by large companies – 0.85; successful industrial application during the year after passing the border of the productivity plateau – 1. For outdated technologies, the value of the coefficient will be equal to zero, and for the most relevant and innovative – to one.

These assessments are systematized based on the results of surveys of experts from “Gazprom Neft”, “Rosneft”, and Deloitte.

The scale for evaluating the reliability factor has similar meanings. In the absence of statistical information, the coefficient will be equal to zero. If the technologies have experience of successful industrial use, then the coefficient is equal to one.

Integrated multivariate assessment

To assess the effectiveness and applicability of digital projects, traditional investment indicators (NPV, IRR, ROI, PI, DPP) can be used. Their use allows you to form the basis for making an effective management decision. Nevertheless, digital technologies differ significantly from the technologies of Economy 3.0, therefore, in addition to the classical methods of investment analysis, the use of special tools that can take into account the specifics of such technologies and projects is required. To ensure an integrated approach to assessment, it is important to consider the readiness of the organization to introduce innovations, the relevance of technologies, their reliability, etc.

The relevance of the methodology lies in the integration of the most significant indicators into a single system to provide a systematic approach to making management decisions regarding the implementation of digital investment projects. The methodology being formed provides a reduction in the level of uncertainty and allows to overcome the gaps caused by the lack of methods for the systematic evaluation of digital projects. To solve these problems, it is proposed to use the following indicator:

where Cdm – is the coefficient of digital maturity of the organization; Crel – isthe coefficient of technology relevance; Cr – isthe technology reliability coefficient.

Within the framework of the study of a certain set of projects, it was concluded that the critical value, which is a barrier to the adoption of the project, is 0. With this value of the final indicator, the implementation of the project is inappropriate. Let us consider the indicator: it consists of four multipliers and takes the value 0 at the time when one of the parameters included in the final indicator of the complex multivariate assessment turns to 0.

With Crel = 0, it can be concluded that the technology under consideration has a more efficient analogue on the market, integrated with the overwhelming amount of existing infrastructure. An example would be a proposal to introduce a lighting system based on kerosene lamps, with LED substitutes that are ahead of this technology in all technological and economic indicators. When the reliability coefficient of a technology turns to 0, it makes sense to talk about working with a project that is based only on an idea and does not have a sufficient array of practical tests under it. Due to the high cost of a mistake, which is inherent in the oil and gas complex, the introduction and use of such technologies is impossible.

With Cg = 0 the implemented technology does not solve the tasks and goals of the organization, does not affect the technological and economic indicators that are important for it, and the proposals for the introduction of such technology are caused by momentary emotional outbursts that can be seen in the first zone of the Gartner curve. When the value of Cdm is identical to 0, it is necessary to talk about the complete unwillingness of the company to implement a project based on digital technologies in its activities due to the lack of the necessary technical conditions, competencies, and established business processes. Тhus, the proposed resulting indicator Cint,is intended not to replace existing project evaluation methods, but to supplement the list of relevant tools, which will reduce the degree of uncertainty in the management decision-making process for the implementation of digital projects. Its use will improve the efficiency of management decisions related to the introduction of digital technologies at the level of companies in the oil and gas sector.

Results

The proposed methodology requires practical testing. In the course of the study, a special case of the introduction of digital technologies was considered – a project tested in 2020 by Gazprom Neft to implement a record of the state of drill pipes using Blockchain technology.

The essence of the project is to verify the history of drilling equipment. The operating time of the drilling tool is not always sufficiently controlled, as a result of which the permissible level of operating time is exceeded, which leads to accidents (including fatal) and long downtime. The implementation of the project is aimed at recording the operating time of equipment and monitoring its inspections to prevent accidents and their consequences. The point is to apply special marks to the drilling equipment, which, when read, provide up-to-date information about the operating time of the tool. Binding the project with Blockchain technology ensures transparency and immutability of data.

An alternative to this technology is to carry out a complete flaw detection of drilling equipment, which on average can take several days, which is unacceptable given the cost of downtime of the drilling crew.

Evaluation of the compliance of the project with the goals and objectives of the company

Primarily, it is necessary to understand whether the implemented project corresponds to the goals and objectives of the company. To calculate the compliance coefficient, which is included in the final indicator of a comprehensive multi-parameter assessment, it is necessary to describe the goals and objectives of PAO “Gazprom Neft”. According to the developed approach, the implementation of the project should correspond to at least one goal or task set by the company's management. If there are several goals or objectives, then the assessment is carried out according to the indicator on which the implementation of the project has the greatest impact. In this case, a similar indicator is an increase in the economic effect due to the optimization of the drilling process:

The value of the coefficient above one indicates the compliance of the digital project with the goals and objectives of the organization (Table 4).

Таble 4

Goals and objectives of PAO “Gazprom Neft” in the context of the project assessment

|

Goal |

Index |

Actual value |

Target value |

Predicted value after project implementation |

|

Downtime reduction for other contractors |

Non-production time, days/year |

279.62 |

220 |

128.42 |

|

Reduction of the number of accidents and incidents per year |

Number of accidents, pcs. |

376.5 |

300 |

194.22 |

|

Increase of economic effect based on drilling optimization |

NPV, thousand rub. |

1 |

50000 |

118070 |

Fig.4. Gartner curve for oil and gas technologies [6] 1 – Edge Al; 2 – devices for volumetric display; 3 – smart workplace; 4 – IIoT platforms; 5 – Blockchain; 6 – virtual assistants; 7 – mixed reality; 8 – digital twins; 9 – augmented reality; 10 – predictive analytics while drilling; 11 – machine learning; 12 – computer simulation

Assessment of the digital maturity of a company

The next step is to assess the digital maturity of the company in question. “Gazprom Neft” is currently one of the leaders in digital transformation in the world. The organization has built an effective regulatory framework that allows you to quickly test various hypo-theses and quickly introduce various digital technologies into the company’s work.

When it comes to corporate culture, then digital transformation is one of the key vectors of development that permeates the company at all levels, from management to line staff. From the point of view of technological efficiency, “Gazprom Neft” can also be called a benchmark in the industry, as it has a developed digital infrastructure: from powerful data processing centers to advanced telemetry installed on wells [45].

According to the result of the developed questionnaire on the state of PAO “Gazprom Neft”, the organization received 89 points; therefore, its digital maturity coefficient is 0.89, which allows us to classify the company as an “innovator” and indicates its efficiency for the project.

Assessment of technology reliability

Blockchain technology has been actively used since 2008, has managed to accumulate a sufficient amount of data on its application, and has confirmed its viability in many areas – from financial transactions to government document management. For instance, Deutsche Bank is using product innovation in investment, while Amazon is using it in health insurance [46]. Due to the large number of proven cases of successful use and adoption of technology at the level of many states, it is assigned a reliability coefficient with a value of 1.

Assessment of technology innovation

According to the author's methodology, it is necessary to determine the level of technology innovation. To calculate the technology innovation ratio, we transform the curve and plot the most relevant technologies for the oil and gas sector on it in accordance with the data given in the Gartner study (Fig.4).

As can be seen from the presented diagram (Fig.4), the technology under consideration is in the “trough region” of disappointment on the Gartner curve, therefore, its innovation coefficient takes the value Crel = 0.6.

Calculation of the applicability indicator for the digital project

To ensure a systematic approach to a comprehensive multi-parameter assessment, it is necessary to calculate the final indicator, which includes all the described elements. None of the coefficients took a value equal to 0 (Crel > 0). Therefore, the technology has no modern substitutes and is relevant. Cg > 1 means that the implementation of the project fully coincides with the goals and objectives set by the organization, having a beneficial effect on important indicators for the economic activity of the oil and gas company. Cdm > 0.8 indicates a sufficient level of digital transformation of an oil and gas company, which allows it to implement the technology being evaluated. Indicator Cr > 0 signals that the technology is proven and sufficiently studied for its risk-free use in the activities of an oil and gas-producing organization. Respectively, Cint > 0, which means the absence of barriers to project implementation in terms of non-economic indicators inherent in digital projects:

Based on the results of using the developed system of criteria on a real digital project implemented in the activities of an oil and gas company, we can conclude that this methodology can be applied to provide a systematic approach to making and implementing management decisions at the level of oil and gas companies.

Comparison of the proposed assessment methodology with traditional approaches

One of the main approaches used to assess the effectiveness of investment projects is the calculation and interpretation of investment indicators – NPV, IRR, ROI, PI, and DPP. Net present value (NPV) measures how feasible the project is from an economic point of view. At the same time, the use of this indicator does not allow reflecting the specifics of individual projects, including in the field of digital solutions. In view of this, an assessment of additional parameters is required, which implies the improvement of approaches to its implementation and substantiates the significance of the developed methodology.

The simultaneous application of the designated traditional approach and the methodology proposed in the study can give different results. In the considered case, NPV (≥ 0) and the value of the final indicator indicate the feasibility of the project, but situations may be different. Table 5 compares the proposed assessment methodology with the traditional approach in the context of interpreting the obtained results and making managerial decisions.

The conducted analysis proves the incompleteness of the information obtained when using exclusively traditional approaches to assessing the applicability of digital projects in the oil and gas sector and justifies the need to use the proposed indicator to improve the quality and efficiency of accepted and implemented management decisions.

Discussion

Requirements calculated for one project have no value to the management of companies that use the methodology to evaluate digital projects. The final indicator calculated as part of a comprehensive multi-parameter assessment is as representative as possible when comparing several projects. The main competitive advantages of the developed assessment system of the applicability for digital projects in the oil and gas sector (compared to analogs) lie in the consideration of all key aspects specific to digital technologies; low degree of dependence on the human factor, expressed in expert assessments of various criteria. The main disadvantages of the developed methodology are dependence on other analytical systems (Gartner Hype Cycle) and the need to use expert assessments to determine the reliability and relevance of the implemented digital technology, which negatively affects the accuracy of estimating these parameters.

Further research will be aimed at analyzing additional sets of information on digital projects in the oil and gas sector, necessary to improve the accuracy of evaluating applicability criteria, as well as improving the methodology for evaluating each of the criteria included in the presented system in order to minimize the level of uncertainty and take into account the maximum number of factors.

Conclusion

One of the key challenges for the oil and gas industry at this time, characterized by an unstable economic and geopolitical environment, is to find ways to increase efficiency and reduce costs. The solution is the use of new technological solutions, most of which are digital technologies that have moved from the status of “image projects” to effective tools to increase the profitability of the development and operation of oil and gas fields. This fact is confirmed by a sharp increase in demand for innovative solutions in all areas of the industry, each of which needs to be evaluated in detail and properly selected. It should be taken into account that digital technologies are not only an opportunity for oil and gas companies, but also a certain challenge, since in addition to updating the technological infrastructure, they require organizations to actively develop the competencies of employees and even partially change business models.

In order to reduce uncertainty when making effective management decisions as part of the selection of digital projects in the oil and gas sector, a system of criteria for evaluating such projects has been developed, based on four key components: the level of digital maturity of the company; compliance of the implemented technology with the goals and objectives of the organization; the level of reliability of the implemented technology; the level of innovation of the implemented project.

Таble 5

Comparison of the proposed method of complex multi-parametric assessment with traditional approaches

| Conditions

|

Characteristic |

Interpretation of results |

Management decision-making process |

|

|

NPV indicator |

Final indicator Сint |

|||

|

NPV ≥ 0 |

Сint > 0 |

Both indicators are positive |

The obtained results indicate the feasibility and efficiency of the project implementation both in terms of economics and the innovativeness and effectiveness of the project itself |

In the context of the proven effectiveness of the project, its implementation is considered rational |

|

NPV < 0 |

Сint > 0 |

NPV provides a negative result, the final indicator is positive |

The obtained results indicate that the implementation of the declared project is inefficient from an economic point of view, but the used technologies are progressive, and their implementation corresponds to the company's target priorities |

It is necessary to refer to the results of the economic assessment, consider the possibilities of supporting the digital project and justify the significance of its implementation for the company |

|

NPV ≥ 0 |

Сint = 0 |

NPV provides a positive result, the final indicator is negative |

From the point of view of economic efficiency, the project is productive. To draw a conclusion about the value of the final indicator, it is necessary to evaluate the values of each coefficient: Сg= 0 – the implementation of the project does not correspond to the established goals of the company, it needs to be adapted to the implemented priorities; Cdm = 0 – the current level of digital maturity of the company does not allow to realize the existing potential, which conditions the adoption of the appropriate measures; Crel = 0 – the proposed technology has a more efficient analogue on the market, which is why the list of options under consideration should be expanded (more advanced and competitive technological solutions should be considered); Cr = 0 – the absence of relevant data on the implementation of the proposed technology, which leads to the presence of increased production, technological, and financial and economic risks |

The management decision-making process for the implementation of the project should be reviewed depending on which aspect of the final indicator is the gap. If there are more advanced analogues of the proposed technology, it is necessary to evaluate the possibilities of their implementation. If the implementation of the project as a whole contradicts the goals of the company, then, regardless of the economic effect, the issue of accepting it for implementation should be reviewed |

|

NPV < 0 |

Сint = 0 |

Both indicators are negative |

The obtained results indicate the inefficiency of the project from the economic side, its potential non-viability in terms of innovation, reliability, compliance with the goals and objectives of the company |

In the context of proven negative economic efficiency and inefficiency of the project implementation, it is advisable to reject the project (or postpone the implementation in the event of a revision of the technological component or a change in the priorities of the company) |

The ratio of the project's compliance with the goals and objectives of the company is calculated using the ratio of the technological effect brought by the implementation of the project and the existing goals of the organization relative to the measured metric. The value of the digital maturity coefficient is determined using the method of expert assessments or using a special questionnaire. Technology relevance is assessed through the use of existing technology of trend-tracking systems. The reliability of the technology used in the project is determined based on information about the history of its use.

All the developed metrics are taken into account when calculating the final criterion – the final indicator. It is with its help that one can compare diverse digital projects implemented in the activities of an oil and gas company. The final indicator, like the entire developed system of criteria for evaluating the applicability of digital projects, is intended not to replace, but to supplement the existing economic indicators of the effectiveness of projects to take into account the specifics of such business initiatives.

Within the framework of the study, the developed system of applicability criteria was tested on a real digital project of an oil and gas company. Testing of the methodology showed its practical applicability and made it possible to determine growth points for further development of the system of criteria. Thus, within the framework of the conducted scientific research, a comprehensive approach has been developed to assess the applicability of digital projects in the oil and gas sector, aimed at minimizing the level of uncertainty in making managerial decisions and, as a result, maximizing the technological and economic efficiency of digital projects implemented at the company level.

References

- Kuzemko C., Bradshaw M., Bridge G. et al. Covid-19 and the Politics of Sustainable Energy Transitions. Energy Research & Social Science. 2020. Vol. 68. N 101685. DOI: 10.1016/j.erss.2020.101685

- Jinfang Tian, Longguang Yu, Rui Xue et al. Global low-carbon energy transition in the post-COVID-19 era. Applied Energy. 2021. Vol. 307. N 118205. DOI: 10.1016/j.apenergy.2021.118205

- Anh Tuan Hoang, Nižetić S., Olcer A.I. et al. Impacts of COVID-19 pandemic on the global energy system and the shift progress to renewable energy: Opportunities, challenges, and policy implications. Energy Policy. 2021. Vol. 154. N 112322. DOI: 10.1016/j.enpol.2021.112322

- Ilinova A., Chanysheva A. Algorithm for assessing the prospects of offshore oil and gas projects in the Arctic. Energy Reports. 2020. Vol. 6. S. 2, p. 504-509. DOI: 10.1016/j.egyr.2019.11.110

- Ilinova A.A., Romasheva N.V., Stroykov G.A. Prospects and social effects of carbon dioxide sequestration and utilization projects. Journal of Mining Institute. 2020. Vol. 244, p. 493-502. DOI: 10.31897/PMI.2020.4.12

- Romasheva N., Dmitrieva D. Energy Resources Exploitation in the Russian Arctic: Challenges and Prospects for the Sustainable Development of the Ecosystem. Energies. 2021. Vol. 14. Iss. 24. N 8300. DOI: 10.3390/en14248300

- Samylovskaya E., Makhovikov A., Lutonin A. et al. Digital Technologies in Arctic Oil and Gas Resources Extraction: Global Trends and Russian Experience. Resources. 2022. Vol. 11. Iss. 3. N 29. DOI: 10.3390/resources11030029

- Alekseev A.D., Zhukov V.V., Strizhnev K.V., Cherevko S.A. Research of hard-to-recovery and unconventional oil-bearing formations according to the principle “in-situ reservoir fabric”. Journal of Mining Institute. 2017. Vol. 228, р. 695-704. DOI: 10.25515/PMI.2017.6.695

- Maizi Y., Bendavid Y., Belarbi T. Evaluation of RFID technology for real time drill pipes efficient management in harsh environments: A discrete event simulation model. Proceedings of the International Conference on Modeling and Applied Simulation 2018, 17-19 September 2018, Budapest, Hungary. Rende, 2018. Vol. 17, p. 83-88.

- Hassani H., Silva E.S., Al Kaabi A.M. The role of innovation and technology in sustaining the petroleum and petrochemical industry. Technological Forecasting and Social Change. 2017. Vol. 119, p. 1-17. DOI: 10.1016/j.techfore.2017.03.003

- Matkovskaya Ya.S., Vechkinzova E., Petrenko Y., Steblyakova L. Problems of Innovative Development of Oil Companies: Actual State, Forecast and Directions for Overcoming the Prolonged Innovation Pause. Energies. 2021. Vol. 14. Iss. 4. N 837. DOI: 10.3390/en14040837

- Navarro J., Sanchidrian J.A., Segarra P. et al. On the mutual relations of drill monitoring variables and the drill control system in tunneling operations. Tunnelling and Underground Space Technology. 2018. Vol. 72, p. 294-304. DOI: 10.1016/J.TUST.2017.10.011

- Beloglazov I.I., Petrov P.A., Bazhin V.Yu. The concept of digital twins for tech operator training simulator design for mining and processing industry. Eurasian Mining. 2020. N 2, p. 50-54. DOI: 10.17580/em.2020.02.12

- Clemens T., Viechtbauer-Gruber M. Impact of Digitalization on the Way of Working and Skills Development in Hydrocarbon Production Forecasting and Project Decision Analysis. SPE Reservoir Evaluation & Engineering. 2020. Vol. 23. Iss. 4, p. 1358-1372. N SPE-200540-PA. DOI: 10.2118/200540-PA

- Kozlova D.V., Pigarev D.Yu. Smart mining. Why Russia needs to change its approach to government incentives for the industry. Neftegas.RU. 2018. N 7 (79), p. 32-39 (in Russian).

- Abdrakhmanova G.I., Bykhovskii K.B., Veselitskaya N.N. et al. Digital transformation of industries: starting conditions and priorities. Doklad k XXII Aprelskoi mezhdunarodnoi nauchnoi konferentsii po problemam razvitiya ekonomiki i obshchestva, 13-30 aprelya 2021, Moskva, Rossiya. Мoscow: Natsionalnyi issledovatelskii universitet “Vysshaya shkola ekonomiki”, 2021, p. 239 (in Russian).

- Dmitrievskiy A.N., Eremin N.A., Stolyarov V.E. Digital transformation of gas production. IOP Conference Series: Materials Science and Engineering. 2019. Vol. 700. Iss. 1. N 012052. DOI: 10.1088/1757-899X/700/1/012052

- Linnik Yu.N., Kiryukhin M.A. Digital technologies in the oil and gas complex. Vestnik Universiteta. 2019. Vol. 1. N 7, p. 37-40 (in Russian). DOI: 10.26425/1816-4277-2019-7-37-40

- Kyunghwan Oh, Hyeongseog Kho, Youngjin Choi, Seogjun Lee. Determinants for Successful Digital Transformation. Sustainability. 2022. Vol. 14. Iss. 3. N 1215. DOI: 10.3390/su14031215

- Pereira C.S., Durão N., Moreira F., Veloso B. The Importance of Digital Transformation in International Business. Sustainability. 2022. Vol. 14. Iss. 2. N 834. DOI: 10.3390/su14020834

- Litvinenko V.S. Digital Economy as a Factor in the Technological Development of the Mineral Sector. Natural Resources Research. 2019. Vol. 29. Iss. 3, p. 1521-1541. DOI: 10.1007/s11053-019-09568-4

- Van Looy A. On the Synergies Between Business Process Management and Digital Innovation. Business Process Management. Cham: Springer, 2018, p. 359-375. DOI: 10.1007/978-3-319-98648-7_21

- Shiqian Wang. Shale gas exploitation: Status, problems and prospect. Natural Gas Industry B. 2018. Vol. 5. Iss. 1, p. 60-74. DOI: 10.1016/j.ngib.2017.12.004

- Tewari S., Dwivedi U.D. Ensemble-based big data analytics of lithofacies for automatic development of petroleum reservoirs. Computers & Industrial Engineering. 2019. Vol. 128, p. 937-947. DOI: 10.1016/j.cie.2018.08.018

- Golovina E., Pasternak S., Tsiglianu P., Tselischev N. Sustainable Management of Transboundary Groundwater Resources: Past and Future. Sustainability. 2021. Vol. 13. Iss. 21. N 12102. DOI: 10.3390/su132112102

- Ulanov V.L., Ulanova E.Yu. Impact of External Factors on National Energy Security. Journal of Mining Institute. 2019. Vol. 238, p. 474-480. DOI: 10.31897/PMI.2019.4.474

- Yurak V.V., Dushin A.V., Mochalova L.A. Vs sustainable development: scenarios for the future. Journal of Mining Institute. 2020. Vol. 242, p. 242-247. DOI: 10.31897/PMI.2020.2.242

- Kuklina E.A. Digital Transformation Strategy as a Tool for Implementing the Business Strategy of a Company in the Oil and Gas Sector of Modern Russia. Administrative Consulting. 2021. N 6, p. 40-53 (in Russian). DOI: 10.22394/1726-1139-2021-6-40-53

- Samoun M.H.B., Holmås H., Santamarta S. et al. Going Digital Is Hard for Oil and Gas Companies–but the Payoff Is Worth It. URL: https://web-assets.bcg.com/img-src/BCG-Going-Digital-Is-Hard-for-Oil-and-Gas-Companies-but-the-Payoff-Is-Worth-It-Mar-2019_tcm9-215951.pdf (accessed 15.03.2022).

- Petrenko Ye., Denisov I., Metsik O. Foresight Management of National Oil and Gas Industry Development. Energies. 2022. Vol. 15. Iss. 2. N 491. DOI: 10.3390/en15020491

- Kane G.C., Palmer D., Phillips A.N. et al. Strategy, Not Technology, Drives Digital Transformation. MIT Sloan Management Review. 2015. Vol. 14, p. 1-25.

- Berg C.F., Lopez O., Berland H. Industrial applications of digital rock technology. Journal of Petroleum Science and Engineering. 2017. Vol. 157, p. 131-147. DOI: 10.1016/j.petrol.2017.06.074

- Grabowska S., Saniuk S. Assessment of the Competitiveness and Effectiveness of an Open Business Model in the Industry 4.0 Environment. Journal of Open Innovation: Technology, Market, and Complexity. 2022. Vol. 8. Iss. 1. N 57. DOI: 10.3390/joitmc8010057

- Ivanova I.A., Pulyaeva V.N., Vlasenko L.V. et al. Digitalization of organizations: Current issues, managerial challenges and socio-economic risks. Journal of Physics: Conference Series. 2019. Vol. 1399. Iss. 3. N 033038. DOI: 10.1088/1742-6596/1399/3/033038

- Rafiq M., Maqbool S., Martins J.M. et al. A Study on Balanced Scorecard and Its Impact on Sustainable Development of Renewable Energy Organizations; A Mediating Role of Political and Regulatory Institutions. Risks. 2021. Vol. 9. Iss. 6. N 110. DOI: 10.3390/risks9060110

- Kaplan R.S., Norton D.P. The Balanced Scorecard – Measures That Drive Performance. Harvard Business Review. 1992. N 70 (1), p. 71-79.

- Stalmachova K., Chinoracky R., Strenitzerova M. Changes in Business Models Caused by Digital Transformation and the COVID-19 Pandemic and Possibilities of Their Measurement–Case Study. Sustainability. 2022. Vol. 14. Iss. 1. N 127. DOI: 10.3390/su14010127

- Chih-Chao Chung, Li-Chung Chao, Chih-Hong Chen, Shi-Jer Lou. A Balanced Scorecard of Sustainable Management in the Taiwanese Bicycle Industry: Development of Performance Indicators and Importance Analysis. Sustainability. 2016. Vol. 8. Iss. 6. N 518. DOI: 10.3390/su8060518

- Hussain A., Farooq M.U., Habib M.S. et al. COVID-19 Challenges: Can Industry 4.0 Technologies Help with Business Continuity? Sustainability. 2021. Vol. 13. Iss. 21. N 11971. DOI: 10.3390/su132111971

- Hongfang Lu, Lijun Guo, Azimi M., Kun Huang. Oil and Gas 4.0 era: A systematic review and outlook. Computers in Industry. 2019. Vol. 111, p. 68-90. DOI: 10.1016/j.compind.2019.06.007

- Vuksanović Herceg I., Kuč V., Mijušković V.M., Herceg T. Challenges and Driving Forces for Industry 4.0 Implementation. Sustainability. 2020. Vol. 12. Iss. 10. N 4208. DOI: 10.3390/su12104208

- Nedosekin A.O., Rejshahrit E.I., Kozlovskiy A.N. Strategic approach to assessing economic sustainability objects of mineral resources sector of Russia. Journal of Mining Institute. 2019. Vol. 237, p. 354-360. DOI: 10.31897/PMI.2019.3.354

- Arcese G., Campagna G., Flammini S., Martucci O. Near Field Communication: Technology and Market Trends. Technologies. 2014. Vol. 2. Iss. 3, p. 143-163. DOI: 10.3390/technologies2030143

- Muñoz-Saavedra L., Miró-Amarante L., Domínguez-Morales M. Augmented and Virtual Reality Evolution and Future Tendency. Applied Sciences. 2020. Vol. 10. Iss. 1. N 322. DOI: 10.3390/app10010322

- Pashkevich M.A., Petrova T.A. Development of an operational environmental monitoring system for hazardous industrial facilities of Gazprom Dobycha Urengoy. Journal of Physics: Conference Series. 2019. Vol. 1384. Iss. 1. N 012040. DOI: 10.1088/1742-6596/1384/1/012040Berdik D., Otoum S., Schmidt N. et al. A Survey on Blockchain for Information Systems Management and Security. Information Processing & Management. 2021. Vol. 58. Iss. 1. N 102397. DOI: 10.1016/j.ipm.2020.102397