Predicting dynamic formation pressure using artificial intelligence methods

- 1 — Engineer Branch of LLC “LUKOIL-Inzhiniring” in Perm “PermNIPIneft” ▪ Orcid ▪ Elibrary ▪ Scopus

- 2 — Ph.D. Associate Professor Perm National Research Polytechnic University ▪ Orcid

- 3 — Ph.D., Dr.Sci. Professor Perm National Research Polytechnic University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

Abstract

Determining formation pressure in the well extraction zones is a key task in monitoring the development of hydrocarbon fields. Direct measurements of formation pressure require prolonged well shutdowns, resulting in underproduction and the possibility of technical problems with the subsequent start-up of wells. The impossibility of simultaneous shutdown of all wells of the pool makes it difficult to assess the real energy state of the deposit. This article presents research aimed at developing an indirect method for determining the formation pressure without shutting down the wells for investigation, which enables to determine its value at any time. As a mathematical basis, two artificial intelligence methods are used – multidimensional regression analysis and a neural network. The technique based on the construction of multiple regression equations shows sufficient performance, but high sensitivity to the input data. This technique enables to study the process of formation pressure establishment during different periods of deposit development. Its application is expedient in case of regular actual determinations of indicators used as input data. The technique based on the artificial neural network enables to reliably determine formation pressure even with a minimal set of input data and is implemented as a specially designed software product. The relevant task of continuing the research is to evaluate promising prognostic features of artificial intelligence methods for assessing the energy state of deposits in hydrocarbon extraction zones.

Introduction

Control of formation pressure in well drainage zones is a priority task for monitoring of hydrocarbon fields development. According to the works [1-3] relevant and reliable information about formation pressure values is necessary at all stages of field development. Formation pressure is the most important input parameter used in planning and design of well operation. From a well construction perspective, formation pressure data are used to determine the rig size, casing depth for cementing design, drilling mud and completion fluid calculations, and the selection of wellhead and downhole pumping equipment. Formation pressure data are used for production prediction and well performance analysis, development modeling and geomechanical analysis [4-6].

In practice, this problem is mainly solved by carrying out hydrodynamic investigations (HDI) under unsteady conditions. The formation pressure is taken to be the pressure that has settled at the bottomhole after its long shutdown. The process of pressure recovery lasts from several hours to several weeks and in any case leads to the loss of hydrocarbon production, which is the main factor limiting the widespread and regular investigations [7]. Furthermore, it is often technically problematic to restart wells after a prolonged shutdown because of deposits of asphaltenes, resins and paraffins in the wellbore.

The necessity for regular control of energy state of a deposit together with impossibility of mass hydrodynamic investigations make it expedient to develop indirect methods of formation pressure determination, which exclude technological stage of prolonged well shutdown. A number of scientific works are devoted to the development of indirect methods for determining dynamic formation pressure.

For example, work [8] proposes a method of formation pressure estimation during exploration drilling, which allows identifying zones of abnormally high formation pressure in the presence of seismic data on trap depths. The indicated way of estimation is based on methods using d- and σ-exponents, which take into account mechanical drilling speed, rotor rotation rate, bit load and its diameter, lithological constant and degree of rocks compaction, drilling mud and rock density. Obviously, the main disadvantage of the method is the possibility of its practical application only at the stage of well construction. Formation pressure is also determined at the stage of well construction as part of reservoir testing [9].

Authors of [10] propose predicting formation pore pressure using a modified Atashbari model from wireline logging data. This method is based on using the dependence of rock porosity and compressibility on formation pressure. The method was tested on a gas-saturated carbonate reservoir of the Apollonia Formation in the Middle Eocene of the Abu El Gharadig Basin, Egypt.

The method of formation pressure determination during well workover is suggested in [11]. During the calculation, it is suggested to use the starting point of fluid inflow from the formation to the well by the previously known, homogeneous in density, killing fluid when the well is put into operation after killing according to the mathematical formula.

The method of formation pressure determination according to the data of putting well into operation after workover is proposed in the article [12]. The essence of the method is the use of maps for putting wells into operation. The method is applicable only for wells, which were subjected to killing during current or complete workover, and only for wells, equipped with electric submersible pumps.

A new method for calculating pressure at any point of a single source and a single drain using wellhead pressure, tested and actively used at oil fields in China, is described in work [13].

An algorithm for indirect formation pressure determination under conditions of three-phase inflow of water, oil and released dissolved gas using Data Mining methods, system and statistical descriptive analysis is proposed in the article [14].

Method for formation pressure determination, based on combination of generalized formulation of material balance and pseudo-stationary state theory, is proposed in [15]. Possibilities of this method are demonstrated by the authors on the example of five vertical and horizontal wells, satisfactory convergence of calculated and actual values of formation pressure is obtained in all cases. However, a disadvantage of the method is its applicability only for steady-state flow rates or bottomhole pressures. A similar method based on material balance is proposed in [16]. A disadvantage of this method is the possibility of its application to wells with radial flow mode.

The method of formation pressure determination in deep mechanized wells without stopping them is presented in the work [17]. The essence of the method is that liquid is introduced or pumped into annular space and its level rises above static position, according to level drop the corresponding curve and pump characteristic is built. A tangential line to the pump characteristic is then drawn. The tangential point is the depth of the static level, which is then converted to formation pressure. This method was improved in [18], its peculiarity is the reduction of investigation time.

In [19] it is proposed to determine the formation pressure according to the measurement data in the well stopped for workover, for example for the purpose of hydraulic fracturing. In essence, this method (ASA) is an analogue of hydrodynamic investigations, because it involves the need to stop the well, and consequently is characterized by all its disadvantages.

A method that can be used to determine average formation pressure as a function of depletion time is proposed in [7]. This method is based on the combined use of the pseudosteady state equation and its integral function. As a result, it is possible to construct a graph, the processing of which determines the difference between the average formation pressure and bottomhole pressure. In turn, if bottomhole pressure is known, formation pressure can be determined without difficulty.

A new method, which allows determining the current formation pressure in the well operation area, is proposed in [20]. The method is reduced to construction of a graph, which is a straight line, separating the pressure value corresponding to the formation pressure value on the ordinate axis. The authors point out that the method has been developed for horizontal wells, but it can be adapted for vertical wells without any difficulties. The mathematical procedure used in the method is based on the selection of an appropriate source and Green's functions for a horizontal well during unrestricted flow and assuming that the well is a purely linear source.

A new mathematical method of productivity and formation pressure determination based on fluid energy balance theory in pseudostationary state is proposed in article [21]. The method is reduced to non-linear regression analysis performed using VB computer language. Similar methods based on material balance theory are also presented in [22].

Work [23] is devoted to the problem of formation pressure estimation in a deposit represented by several productive formations. To calculate the average pressure in individual formations the authors propose to use the selective inflow method (SIP) for optimal distribution of production and monitoring the depletion effects for formation energy over time. The selective inflow method has been implemented on some production wells in northern Pakistan. This method should be regarded as some analogue of the known formation hydrodynamic characterization method based on production curve analysis (by Fetkovich et al.). A similar method based on analysis of well productivity dynamics is presented in [24].

All described methods can be divided into three groups. The first group includes methods of formation pressure determination based on the use of drilling or well workover data, which limits their applicability [25]. The second group includes methods of various modifications of the material balance method. Correspondingly, all disadvantages and restrictions of this method developed for reserves estimation should be referred to indirect methods of formation pressure estimation developed on its basis. The third group unites the methods of mathematical processing of the historical well operation data [26, 27]. The correctness of formation pressure determination by these methods directly depends on the reliability of mathematical apparatus for description of filtration processes in individual geological and physical conditions [28, 29].

The application of artificial intelligence methods should be considered as a new direction in assessing the energy state of hydrocarbon deposits [30-32]. At present, these methods are being increasingly used to solve various problems [33-35]. Thus, in [36] the authors propose to use a fuzzy self-organizing neural network, which can automatically perform unsupervised clustering and classification of seismic attributes. The reservoir parameters are then estimated using another neural network. Based on a synthetic model based on real data, the change in pore (formation) pressure in the gas formation is calculated [37, 38].

Multiple regression analysis, which is essentially one of artificial intelligence methods, is proposed to be used by the authors of [39, 40] for formation pressure estimation in any period of well operation without stopping them for investigation. Advantages of the method include the use as input data only those parameters that are determined in the practice of geological and production support for oil field development, simplicity of calculations and high statistical estimates of model validity when determining formation pressure. Multiple regression is a well-known and widespread, but not the only method of artificial intelligence [41-43]. Therefore, this article presents the results of research aimed at developing an indirect method of formation pressure determination, based on the application of neural networks (another common method of artificial intelligence), as well as its comparison with the method based on the application of multiple regression and actual measurements of the required parameter.

Methodology

The study was carried out for an oil field in Perm region, where three development sites have been identified. Two sites are confined to carbonate Turnaisian-Famennian and Bashkir sediments, as well as to Visean terrigenous reservoirs. The productive sediments are characterized by different gas saturation of formation oil (68.1, 21.3 and 66.5 m3/t, correspondingly) and, as a result, different conditions and patterns of reserve recovery processes.

The same production material was used for constructing formation pressure prediction models using multiple regression and neural networks – the results of 200 investigations of 25 production wells during their operation period.

The following parameters were used as input for multiple regression equations: actual current formation pressure determined during the HDI Pcf MPa; initial formation pressure, determined from the first HDI Pinf MPa; the duration of the well operation after commissioning from drilling (Т, days); current liquid flow rates Q1 m3/day and oil Qoil t/day; current bottomhole pressure Pb MPa; initial permeability coefficient, determined from the first HDI kinr mD; current permeability coefficient kcr mD; skin factor S; cumulative oil production Qcoil t; cumulative liquid production Qc1 m3; cumulative water production Qcw t; gas-oil ratio Gr m3/day. The values of all parameters characterize well operation during the period corresponding to the actual formation pressure measurement (HDI).

A multilevel approach was used to construct the multiple regression equations. At the first level, models were built using the entire sample (for all formations). On the second level, models are built differentially for each productive object, and on the third level – for characteristic intervals of formation pressure, allocation of which is substantiated and confirmed by application of discriminant analysis. The model combining results of modeling at all three levels is proposed for practical application. Statistical assessments are calculated and given for each model: multiple correlation coefficient R, significance level p, standard error S0.

Models developed for the Turnaisian-Famennian formation are presented as an example.

The first level of modeling:

at R = 0.892, р< 0.0000, S0 = 1.38 MPa.

The second level of modeling:

at R =0.919, р<0.0000, S0 = 1.47 MPa.

The third level of modeling, the first range of formation pressure:

at R = 0.958, р < 0.0000, S0 = 0.55 MPa.

The third level of modeling, the second range of formation pressure:

at R = 0.924, р< 0.0000, S0 = 0.95 MPa.

The resulting model is as follows:

at R = 0.979, р< 0.0000, S0 = 0.74 MPa.

The ranges of applicability for all models correspond to the original sample and are given in [39].

A large set of input data used in construction of multiple regression equations, on the one hand, provides maximum possible accuracy of predictive estimates of formation pressure, but, on the other hand, the resulting equations are cumbersome and sensitive to the quality of input data. Therefore, when developing formation pressure models using a neural network, the challenge is to minimize the amount of input data while maintaining high accuracy of predictive estimates for the required parameter.

During the development of the formation pressure determination technique, the optimal values of hyperparameters were selected using the grid search method [44, 45]. The solution of this problem with the help of artificial neural network model consists in selecting its optimal architecture and determining the activation function for its weights. In the reproduction and prediction of formation pressure parameter the architecture of a fully coupled neural network, which is the best way of identifying and using the mutual influence of factors with regard to all possible relations between the factors, has been chosen. ADAM gradient optimization was used in the specification of the weights for the neural network. The constructed model consists of three layers where the first layer contains 64 neurons, the second layer contains 32 and the third layer contains 16 neurons. A hyperbolic tangent is chosen as the activation function on each layer, which increases the sensitivity of the model to changes in values. The layer representing the formation pressure value has a linear activation function to communicate with the previous layer. During training of the neural network, the absolute deviation metric was used as the loss function.

A comparative assessment of formation pressure prediction reliability using multiple regression and artificial neural network is made by comparing calculated values with actual measurement data using appropriate statistical criteria (correlation coefficient and graph, significance level, etc.).

Results

The technique of formation pressure determination based on the application of artificial neural network has been implemented as a software product. The input data include such parameters as liquid flow rates and exploitation coefficients for each well.

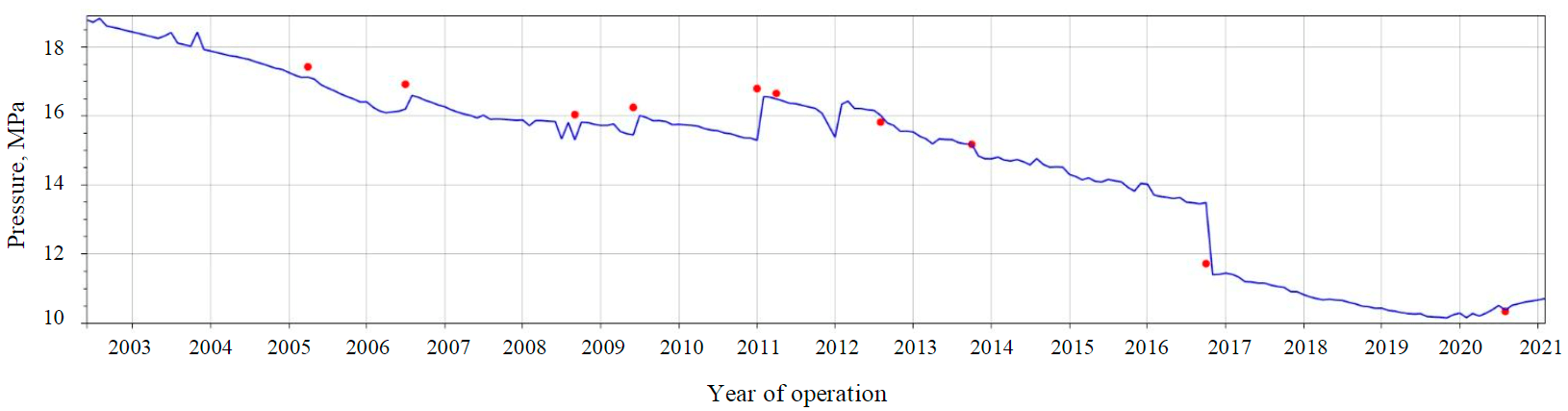

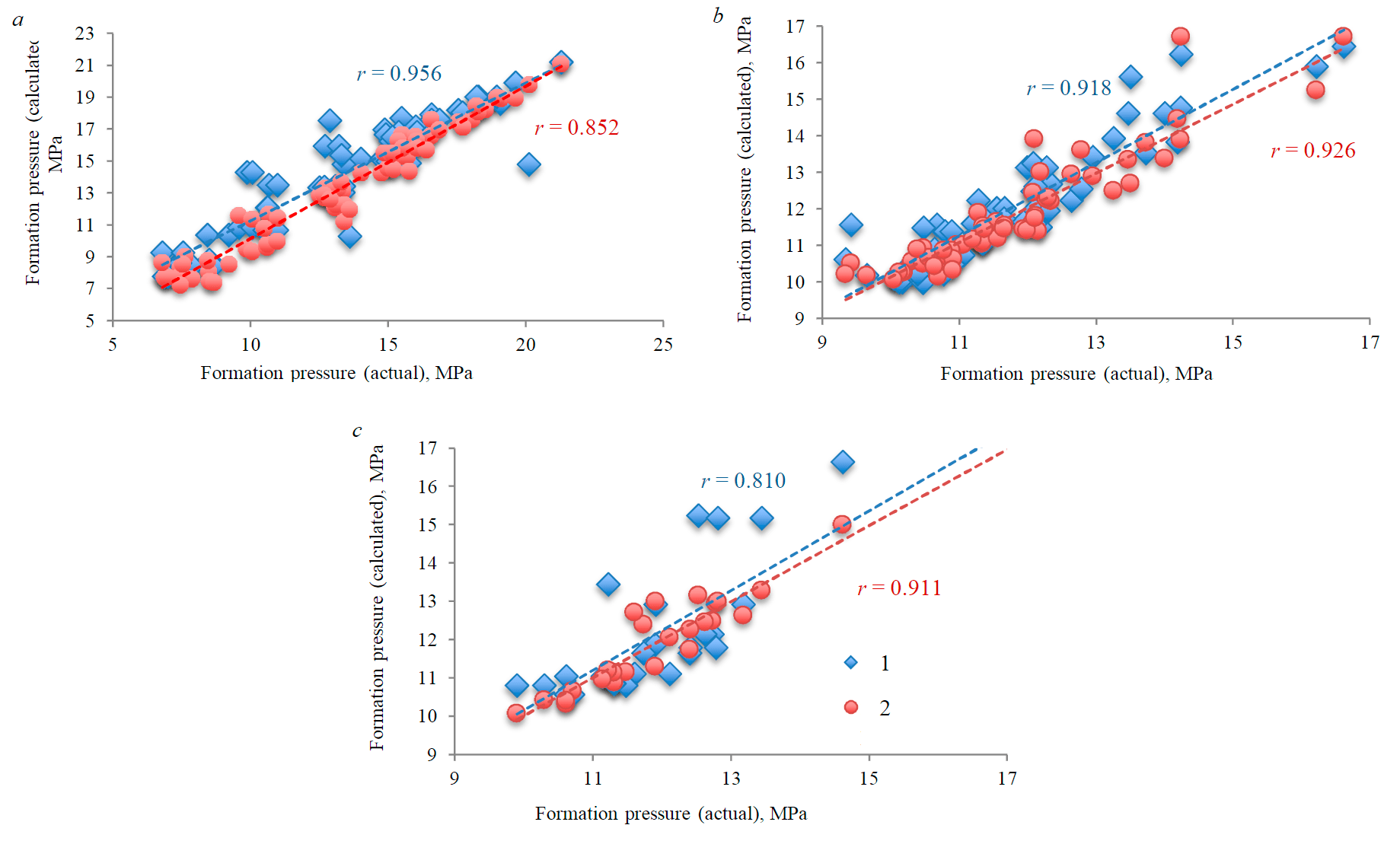

For the convenience of perception the results of calculations are visualized in the form of tables and the graph (Fig.1) reflecting the formation pressure dynamics during the operation of well, on which the actual measurement data (red dots) is also plotted. Comparison of calculated and actually measured formation pressures for wells of all development objects is shown in Fig.2.

Fig.1. Comparison of actual and model formation pressures over the course of the well operating history

Fig.2. Comparison of calculated and actual formation pressure for wells in Turneisian-Famennian (a), Bobrikov (b) and Bashkir (c) development objects 1 – neural network; 2 – multiple regression

As it follows from the analysis presented in Fig.2, in all cases both methods show high reliability of formation pressure determination for wells exploiting both terrigenous and carbonate deposits of the considered field. Lesser efficiency of the model based on artificial neural network application for formation pressure determination in the wells of Bashkir sediments can be explained by insignificant volume of the used sample and low degree of the network learning. Absolute average deviations from the actual measurement for the Turneisian-Famennian, Bobrikov and Bashkir development objects, obtained by applying neural network methods were 0.72; 0.86; 0.83 MPa, while applying multiple regression methods – 0.75; 0.87; 0.81 MPa.

Neural network and multiple regression methods have equal minimum deviation of predicted formation pressure values from actual values, indicating the efficiency and prospects of using these methods.

Discussion

During the performed analytical review of Russian and foreign works aimed at determining formation pressure by indirect methods (without shutting down the wells for hydrodynamic investigations), it was found that the chosen direction is still urgent. Currently developed methods for assessing indicators of energy state are characterized by a number of disadvantages.

In this work, artificial intelligence methods – multiple regression and a neural network – were selected as mathematical tools. To solve this problem both methods were tested in relation to the oil field in Perm region, productive objects of which are represented by terrigenous and carbonate reservoirs with different gas saturation of formation oil.

During implementation of the selected methods, techniques to determine formation pressure without shutting down wells for investigations were developed. The techniques are based on mathematical processing of accumulated experience on actual measurements of formation pressure and other field characteristics. Both techniques have demonstrated high reliability of formation pressure determination for all three considered productive sediments.

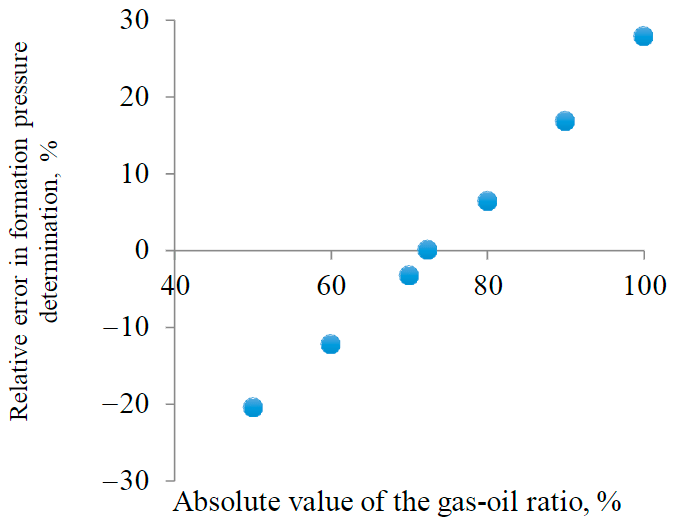

The technique based on the construction of multidimensional statistical models – multiple regression equations – shows a slightly higher performance than the neural network. This is probably due to the original multilevel approach to constructing statistical models. At the same time, a peculiarity of constructed statistical models is the use of rather large amount of input data and, as a result, dependence on accuracy of their definition. For instance, equation (4) includes gas-oil ratio value. When assessing sensitivity of the model to its value the graph in Fig.3 was obtained.

Fig.3. Sensitivity of the multidimensional statistical model to the value of the gas-oil ratio

As the diagram in Fig.3 shows, the use of unreliable values for the gas-oil ratio leads to significant inaccuracy in formation pressure determination when using the technique based on application of multidimensional statistical models. Given the sharp dynamics for the gas-oil ratio, which is typical for the considered field, this problem can limit application of multidimensional statistical models in the absence of actual measurements of the extracted gas quantity. A similarly high sensitivity was established for other parameters used as input data in multidimensional statistical models.

This disadvantage is absent in the technique, which is based on the use of an artificial neural network. The only inputs used in this case are flow rates and exploitation rates, which are recorded with sufficient accuracy and regularity.

At the same time, the technique based on the application of artificial neural networks lacks the ability to study and analyze the establishment of formation pressure during field development. This problem is successfully solved by building multidimensional statistical models. In particular, as applied to the object under study, it has been established that the main parameters controlling current formation pressure value are its initial value and the period of well operation. During statistical modeling two characteristic periods of formation pressure behavior were also substantiated. In the initial period, the establishment of formation pressure is mainly influenced by geological factors (initial formation pressure, well operation time and cumulative water production), which follows from the analysis of equation (3). The second range of formation pressure behaviour is described by equation (4), which includes a number of technological parameters (bottomhole pressure, initial formation pressure, skin factor and gas-oil ratio, initial permeability coefficient determined from the first HDI) [39].

Conclusion

The article is devoted to the development and comparative analysis of techniques for determining dynamic formation pressure without shutting down the wells for investigation using methods of artificial intelligence – multiple regression and neural network. Both techniques are based on the analysis of accumulated experience of previous investigations and allow determining the formation pressure with a high degree of reliability based on a set of field data.

The technique, based on the application of multiple regression, also allows investigating the establishment of formation pressure during different periods of deposit development. It is appropriate for regular actual determinations of the indicators used as input data. The presented technique should not be considered as an alternative to the HDI. Its use and application is expedient for express-evaluation of formation pressure or, when it is impossible to stop the well, for investigation due to technological reasons.

The technique, which uses machine learning methods, is based on a non-parametric multidimensional model linking well operation indicators over time. The proposed method takes into account the dynamics of well operation indicators, and the predicted formation pressure correlates well with the values measured by HDI. Furthermore, the proposed method avoids tedious coefficient calibration procedure compared to methods based on parametric transformations.

Based on the calculated formation pressure using machine learning, it is possible to determine the deposit development mode at a given moment, to design a formation pressure maintenance system in advance or evaluate its efficiency, and to justify further rational decisions on oil field development.

References

- Escobar F.H., Hernandez Y.A., Hernandez C.M. Pressure transient analysis for long homogeneous reservoirs using TDS technique. Journal of Petroleum Science and Engineering. 2007. Vol. 8(1-2), p. 68-82. DOI: 10.1016/j.petrol.2006.11.010

- Hazim Al-Attar. A Simple Method For Estimating Average Reservoir Pressure and Well Flow Efficiency in Volumetric Oil Reservoirs. Conference: Second ADRAC, February 2014, Abu Dhabi, United Arab Emirates.

- Oloruntobi O., Butt S. Energy-based formation pressure prediction. Journal of Petroleum Science and Engineering. 2019. Vol. 173, p. 955-964. DOI: 10.1016/j.petrol.2018.10.060

- Guoyi Yu, Feng Xu, Yingzhi Cui et al. A new method of predicting the saturation pressure of oil reservoir and its application. International Journal of Hydrogen Energy. 2020. Vol. 45. Iss. 55, p. 30244-30253. DOI: 10.1016/j.ijhydene.2020.08.042

- Lichun Kuang, He Liu, Yili Ren et al. Application and development trend of artificial intelligence in petroleum exploration and development. Petroleum Exploration and Development. 2021. Vol. 48. Iss. 1, p. 1-14. DOI: 10.1016/S1876-3804(21)60001-0

- Clement Afagwu, Isah Abubakar, Shams Kalam et al. Pressure-transient analysis in shale gas reservoirs: A review. Journal of Natural Gas Science and Engineering. 2020. Vol. 78. N 103319. DOI: 10.1016/j.jngse.2020.103319

- Mohammed S., Enty G.S., Amarfio E.M. Determination of Average Reservoir Pressure from Constant-Rate Drawdown Tests. SPE Nigeria Annual International Conference and Exhibition, August 2014, Lagos, Nigeria. SPE-172424-MS. DOI: 10.2118/172424-MS

- Shakirov A.A. Formation pressure determination by AGIP-K apparatus using multicycle probing technology. Karotazhnik. 2017. N 3 (273), p. 62-66. (in Russian).

- Grishchenko V.A., Kharisov M.N., Yakupov R.F. et al. Analysis of the results of formation pressure indirect determination according to the wells operational mode change using the genetic algorithm. Geology, geophysics and development of oil and gas fields. 2021. N 8 (356), p. 36-41 (in Russian).

- Weiqiang Li, Longxin Mu, Lun Zhao et al. Pore-throat structure characteristics and its impact on the porosity and permeability relationship of Carboniferous carbonate reservoirs in eastern edge of Pre-Caspian Basin. Petroleum Exploration and Development. 2020. Vol. 47. Iss. 5, p. 1027-1041.DOI:10.1016/S1876-3804(20)60114-8

- Balandin L.N., Gribennikov O.A. Patent N 2539445 of the Russian Federation. Method for determination of formation pressure in an oil well equipped with an electric submersible pump. Publ. 20.01.2015. Bul. N 2 (in Russian).

- Fatikhov S.Z., Fedorov V.N. Analysis of methods for determining formation pressure in case of low-permeability reservoirs. Neftyanoye khozyaystvo. 2018. N 4, p. 62-65 (in Russian). DOI: 10.24887/0028-2448-2018-4-62-65

- Xiaoyong Wen, Jing Yang, Shaoyang Geng, Ke Li. Study on new method for evaluating reservoir formation pressure by wellhead pressure. IOP Conference Series: Earth and Environmental Science. 2019. Vol. 384. N 012037. DOI: 10.1088/1755-1315/384/1/012037

- Kharisov M.N., Yunusova E.A., Maiski R.A. Inderect determination of the reservoir pressure using DATA MINING. Problems of Gathering, Treatment and Transportation of Oil and Oil Products. 2018. N 3 (113), p. 40-48 (in Russian). DOI: 10.17122/ntj-oil-2018-3-40-48

- Ziyuan Cong, Yuwei Li, Yishan Pan et al. Study on CO2 Foam Fracturing Model and Fracture Propagation Simulation. Energy. 2022. Vol. 238. N 121778. DOI:10.1016/j.energy.2021.121778

- Zhiliang Hea Jianfang Sunb Panhong Guo. Construction of carbonate reservoir knowledge base and its application in fracture-cavity reservoir geological modeling. Petroleum Exploration and Development. 2021. Vol. 48. Iss. 4, p. 824-834. DOI: 10.1016/S1876-3804(21)60069-1

- Elmahdy M., Farag A.E., Tarabees E., Bakr A. Pore Pressure Prediction in Unconventional Carbonate Reservoir. Paper presented at the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, April 2018, Dammam, Saudi Arabia. SPE-194224-MS. DOI: 10.2118/194224-MS

- Tsarenko A.V., Gimranov R.G. Numerical simulation for determination of reservoir pressure on the Piltunsky section of the Piltun-Astokhskoe field. Gazovaya promyshlennost. 2018. N 12 (778), p. 32-36 (in Russian).

- Bobreneva Yu. O., Davletbaev A.Y., Makhota N.A., Kamalova Z.K. Estimation of Reservoir Pressure from the Sensor Data Before and After Injection Tests in Low-Permeability Formations. Paper presented at the SPE Russian Petroleum Technology Conference, October 2017, Moscow, Russia. SPE-187763-MS. DOI: 10.2118/187763-MS

- Idudje H., Adewole S. A Method of Estimating Reservoir Pressure using Drawdown Test Data. SPE Nigeria Annual International Conference and Exhibition, Virtual, August 2020. SPE-203700-MS. DOI: 10.2118/203700-MS

- Adel M. Salem. Determination of Average Reservoir Pressure using Pressure buildup Test: Analytical and Simulation Approach for Egyptian Oil Fields. Journal of Petroleum and Mining Engineering. 2019. Vol. 21. Iss. 1, p. 9-16. DOI:10.21608/JPME.2020.73176

- Zhang A., Fan Z., Song H., Zhang H. Reservoir pressure prediction of gas condensate reservoir with oil rim. Journal of China University of Petroleum (Edition of Natural Science). 2014. Vol. 38(5), p.124-129. DOI: 10.3969/j.issn.1673-5005.2014.05.017

- Аsad Ilyas, Safwan Arshad, Jawad Ahmed et al. Determining Average Reservoir Pressures in Multilayered Completed Wells Using Selective Inflow Performance (SIP) Technique. SPE/PAPG Annual Technical Conference, December 2012, Islamabad, Pakistan. SPE-163131-MS. DOI: 10.2118/163131-MS

- Bobby Poe, Gottumukkala Varma. Novel methodology to estimate reservoir pressure and productivity index in unconventional and conventional reservoirs using production data. Offshore Technology Conference Asia, March 2016, Kuala Lumpur, Malaysia. N OTC-26429-MS. DOI: 10.4043/26429-MS

- Akhmetova A.A., Pimenov E.D., Gorin A.N. et al. Evaluation of the applicability mini-fracturing data to determine reservoir pressure and transmissibility. Neftyanoye khozyaystvo. 2018. N 7, p. 90-94 (in Russian). DOI: 10.24887/0028-2448-2018-7-90-94

- Ladeishchikova T.S., Volkov V.A., Sobyanin N.N., Mitroshin A.V. Indirect methods for estimating current formation pressure in a well to be applied when building integrated models of fields. Oilfield engineering. 2021. N 7(631), p. 39-45 (in Russian). DOI: 10.33285/0207-2351-2021-7(631)-39-45

- Kuznetsova E.A., Shilov A.V., Nikulin S.E., Chernykh I.A. Determination and forecast of reservoir pressure, productivity and filtration parameters without stopping wells based on analysis of well production history in the software KAPPA TOPAZE for wells of oil fields LLC “LUKOIL-PERM” with depth gauges and telemetry sensors. Oilfield engineering. 2019. N 12 (612), p. 82-84 (in Russian). DOI: 10.30713/0207-2351-2019-12(612)-82-84

- Belhouchet H.E., Benzagouta M.S., Dobbi A. et al. A new empirical model for enhancing well log permeability prediction, using nonlinear regression method: Case study from Hassi-Berkine oil field reservoir – Algeria. Journal of King Saud University – Engineering Sciences. 2021. Vol. 33. Iss. 2, p. 136-145. DOI: 10.1016/j.jksues.2020.04.008

- Ahmed ElGibaly, Mohamed Abdalla Osman. Perforation friction modeling in limited entry fracturing using artificial neural network. Egyptian Journal of Petroleum. 2019. Vol. 28. Iss. 3, p. 297-305. DOI: 10.1016/j.ejpe.2019.08.001

- Bobb I.F. International experience of E&P software solutions development. Georesursy. 2018. Vol. 20. Iss. 3. Part 1, p. 193-196 (in Russian). DOI: 10.18599/grs.2018.3.193-196

- Evsyutkin I.V., Markov N.G. Deep artificial neural networks for fore casting debit values for production wells. Bulletin of the Tomsk Polytechnic University. Geo Аssets Engineering. 2020. Vol. 331. N 11, p. 88-95 (in Russian). DOI: 10.18799/24131830/2020/11/2888

- Ran Jia, Yikai Lv, Gongwen Wang et al. A stacking methodology of machine learning for 3D geological modeling with geological-geophysical datasets, Laochang Sn camp, Gejiu (China). Computers & Geosciences. 2021. Vol. 151. N 104754. DOI: 10.1016/j.cageo.2021.104754

- Gerke K.M., Korost D.V., Karsanina M.V.et al. Modern approaches to pore space scale digital modeling of core structure and multiphase flow. Georesursy. 2021. Vol. 23. N 2, p. 197-213 (in Russian). DOI: 10.18599/grs.2021.2.20

- Chernikov A.D., Eremin N.A., Stolyarov V.E. et al. Application of artificial intelligence methods for identifying and predicting complications in the construction of oil and gas wells: problems and solutions. Georesursy. 2020. Vol. 22. N 3, p. 87-96(in Russian). DOI: 10.18599/grs.2020.3.87-96

- Popov N.A., Putilov I.S., Gulyaeva A.A., Vinokurova E.V. Application of deep learning technologies for studying thin sections on the example of Usinsk oil field. Bulletin of the Tomsk Polytechnic University. Geo Аssets Engineering. 2020. Vol. 331. N 6, p. 100-112 (in Russian). DOI: 10.18799/24131830/2020/6/2681

- Zhu Zhenyu, Liu Zhipeng, Mi Fang, Sang Shuyun. Reservoir pressure prediction using time-lapse seismic multi-attribute analysis. SEG Technical Program Expanded Abstracts. 2013, p. 5036-5040. DOI:10.1190/segam2013-1436.1

- Anirbid Sircar, Kriti Yadav, Kamakshi Rayavarapu et al. Application of machine learning and artificial intelligence in oil and gas industry. Petroleum Research. 2021. Vol. 6. Iss. 4, p. 379-391. DOI: 10.1016/j.ptlrs.2021.05.009

- Ghareb Hamada, Veronique Joseph. Developed correlations between sound wave velocity and porosity, permeability and mechanical properties of sandstone core samples. Petroleum Research. 2020. Vol. 5. Iss. 4, p. 326-338. DOI: 10.1016/j.ptlrs.2020.07.001

- Galkin V.I., Ponomareva I.N., Martyushev D.A. Prediction of reservoir pressure and study of its behavior in the development of oil fields based on the construction of multilevel multidimensional probabilisticstatistical models. Georesursy. 2021. Vol. 23. N 3, p. 73-82 (in Russian). DOI:10.18599/grs.2021.3.10

- Galkin V.I., Ponomareva I.N., Chernykh I.A. Patent N 2715490 of the Russian Federation. Method for determining the current formation pressure in an operating well of the Turneisian-Famennian deposit without shutting down the well. Publ. 28.02.2020. Bull. N 7. (in Russian).

- Hanqin Shi, Liang Tao. Visual comparison based on linear regression model and linear discriminant analysis. Journal of Visual Communication and Image Representation. 2018. Vol. 57, p. 118-124. DOI: 10.1016/j.jvcir.2018.10.026

- Gomaa Sayed, Emara Ramadan, Mahmoud Omar, El-hoshoudy A.N. New correlations to calculate vertical sweep efficiency in oil reservoirs using nonlinear multiple regression and artificial neural network. Journal of King Saud University – Engineering Sciences. 2021. DOI: 10.1016/j.jksues.2021.07.010

- Mohaghegh Shahab D. Subsurface analytics: Contribution of artificial intelligence and machine learning to reservoir engineering, reservoir modeling, and reservoir management. Petroleum Exploration and Development. 2020. Vol. 47. Iss. 2, p. 225-228. DOI: 10.1016/S1876-3804(20)60041-6

- Daniel Asante Otchere, Tarek Omar Arbi Ganata, Raoof Gholami, Syahrir Ridha. Application of supervised machine learning paradigms in the prediction of petroleum reservoir properties: Comparative analysis of ANN and SVM models. Journal of Petroleum Science and Engineering. 2021. Vol. 200. N 108182. DOI:10.1016/j.petrol.2020.108182

- Farno E., Coventry K., Slatter P., Eshtiaghi N. Role of regression analysis and variation of rheological data in calculation of pressure drop for sludge pipelines. Water Research. 2018. Vol. 137, p. 1-8. DOI: 10.1016/j.watres.2018.02.059