Methodology for thermal desorption treatment of local soil pollution by oil products at the facilities of the mineral resource industry

- 1 — Ph.D., Dr.Sci. Head of the Department Saint Petersburg Mining University ▪ Orcid ▪ Scopus ▪ ResearcherID

- 2 — Postgraduate Student Saint Petersburg Mining University ▪ Orcid ▪ Scopus ▪ ResearcherID

Abstract

The analysis of the main environmental consequences of leaks and local spills of petroleum products at the enterprises of the mineral resource complex is presented. It is established that the problem of soil contamination with petroleum products at the facilities of the mineral resource complex and enterprises of other industries is caused by significant volumes of consumption of the main types of oil products. Based on the results of the author's previous field research, a series of experiments was carried out, consisting in modeling artificial soil pollution with petroleum products such as gasoline, diesel fuel, highly refined oil, motor oil, and transmission oil, followed by their purification by heat treatment at temperatures of 150, 200, and 250 °C. The 250 °C limit of the heating temperature was set due to the need to partially preserve the structure and quality of the soil after heat treatment to preserve its fertility. When the processing temperature rises to 450 °C, all humates are completely burned out and, as a result, productivity is lost. Confirmation is provided by the results of experiments to determine the humus content in uncontaminated soil and soil treated at different temperatures. It was found that at a maximum processing temperature of 250 °C, about 50 % of the initial organic carbon content is preserved. According to the results of the conducted experimental studies, the dependences of the required processing temperature on the concentration of petroleum products to reduce the concentration of petroleum products to an acceptable level have been established. The methodology of thermal desorption cleaning of soils with varying degrees of contamination at enterprises of the mineral resource complex is presented.

Introduction

According to official information provided by the Ministry of Energy of the Russian Federation, over the past ten years, the volume of domestic trade in petroleum products (PP) on the largest exchanges in Russia has increased one and a half times and amounted to more than 20 million tons in 2020 [1]. The increase in the production of petroleum products is due to the fact that liquid fuel obtained from hydrocarbon raw materials is convenient and easy to operate, characterized by a large amount of energy per unit volume [2]. The major types of petroleum products consumed include gasoline, diesel fuel, and various other fuels and lubricants [3-5].

Technological processes at the production facilities of the mineral resource complex using petroleum products can lead to the occurrence of local emergency spills and leaks, which represent spot uneven contamination with an area of up to 5 m2. The risk of oil products entering the soil surface occurs in places where equipment is serviced and refueled, parking for cars and heavy machinery, etc. Territories for the storage of petroleum products (tank farms) ensure the autonomy of mining and processing enterprises; however, they are potential sources of oil products entering the soil as a result of draining and filling operations [6-8].

When conducting monitoring activities at the production facilities of the mineral resource complex, the main directions for controlling soil pollution are specific substances formed in the process of extraction, processing, and production of finished products according to different technologies [9-11]. The point flow of petroleum products into the environment is often ignored due to the difficulty of visual identification and the lack of control of their content in the framework of production monitoring as an inappropriate potential contaminant of soils of the mining and processing industry.

It should be noted that other industries that operate petroleum products in the urban environment (construction, housing and communal services, gas stations, transport, etc.), also create a risk of local spills and leaks [12-14].

Thus, the failure to account for incidents of local spills and leaks, as well as the lack of control of soil contamination with petroleum products, can lead to persistent contamination and the formation of lithochemical pollution plumes and flows in the case of multi-year spot contamination. The accumulation of hydrocarbon components over time can lead to irreversible consequences for the ecosystem, which is associated with the high migratory ability of some petroleum products and the limited resistance of soils to pollutants, and their ability to self-purification.

The severity of the consequences for soils with the local intake of petroleum products is caused by many factors but has common mechanisms. With an increase in the content of organic carbon of anthropogenic origin, the sources of which are petroleum products, there is a quantitative and qualitative transformation in the humus horizon, the mobility of humus components increases due to changes in the redox properties of soils, the hydrophobicity of soils increases, which entails a violation of the flow of water to the roots of plants. Subsequently, these factors lead to the loss of soil nutrients, leading to oppression of vegetation up to its complete death due to suppression of photosynthetic activity and productivity [15-17].

According to the results of microbiological studies by various Russian and foreign authors, the presence of petroleum products in soils violates the soil microbiocenosis by reducing the number of colonies of microorganisms that are unable to oxidize hydrocarbon components [18-20]. With the help of biological tests, it has been proved that there is also a decrease in the survival rate of various invertebrate organisms [21-23].

Climatic conditions and soil type can affect the nature of pollution and accumulation of hydrocarbon components. When spills occur in areas where precipitation exceeds their evaporation, there is a high probability of the appearance of lithochemical pollution plumes and flows due to the ability of petroleum products to form a stable oil-water emulsion. In areas where the evaporation of moisture from the soil exceeds the amount of precipitation, partial removal of light fractions with moisture occurs. Heavier hydrocarbon fractions can also accumulate and migrate [24, 25].

Based on the information provided, we can talk about the need for timely detection of local spills and leaks in the territories of various production facilities to prevent the consequences arising from long-term anthropogenic impact. To assess the level of soil contamination with petroleum products in the Russian Federation, the following threshold levels of concentration of petroleum products are recommended: permissible level of contamination – less than 1000 mg/kg; low – from 1000 to 2000 mg/kg; average – from 2001 to 3000 mg/kg; high – from 3001 to 5000 mg/kg; very high – more than 5000 mg/kg [26-28].

Thus, carrying out operational measures aimed at reducing the concentration of petroleum products in soils at local areas of spills and leaks to an acceptable level, i.e., less than 1000 mg/kg, will prevent the accumulation and uncontrolled migration of pollutants.

Following our review of modern methods for soil purification from petroleum products, we chose the process of thermal desorption as a promising technology, which has many advantages, such as suitability to various types of pollutants, a short treatment period, high efficiency, technical simplicity of the method, and the possibility of selecting the optimal temperature regime depending on the final goal of purification [25, 29]. The aim of the research is to develop a methodology for thermo-desorption remediation of local soil pollution from petroleum products at the facilities of the mineral resource complex. The objectives of the research are to monitor soils in the impact zone of production facilities as sources of oil products and to study the thermal effects on oil-contaminated soils in vitro.

Methodology

The author's research allowed to establish the level of soil contamination with petroleum products on the territory of two production facilities that have a risk of local emergency spills and technological leaks, as well as to investigate the possibility of using low-temperature thermal desorption to reduce the concentration of pollutants to an acceptable level with subsequent return of soils to the ecosystem [25].

During the engineering and environmental survey of the territories of production facilities, the following signs of potential contamination with petroleum products of test sites for subsequent sampling were identified:

- the study area is partially or completely devoid of vegetation (visual assessment);

- soils have a characteristic smell of petroleum products of varying intensity (organoleptic assessment);

- proximity of production facilities with an increased probability of leaks and spills (subjective probabilistic assessment).

The content of petroleum products was determined using standard methods by fluorimetric and spectrophotometric methods (PND F 16.1:2.21-98, RD 52.18.575-96). The use of several methods to determine the level of soil pollution made it possible to exclude the uncertainty of the obtained

results [30].

The choice of the methods used is due to the simplicity of the equipment operation, the sensitivity to low concentrations (in the case of the application of the fluorimetric method), and the similarity of the spectra of most petroleum products in the near-infrared area when using the spectrophotometric method, which allows to obtain the value of the gross content of petroleum products regardless of the type of petroleum product that polluted the soil [31-33].

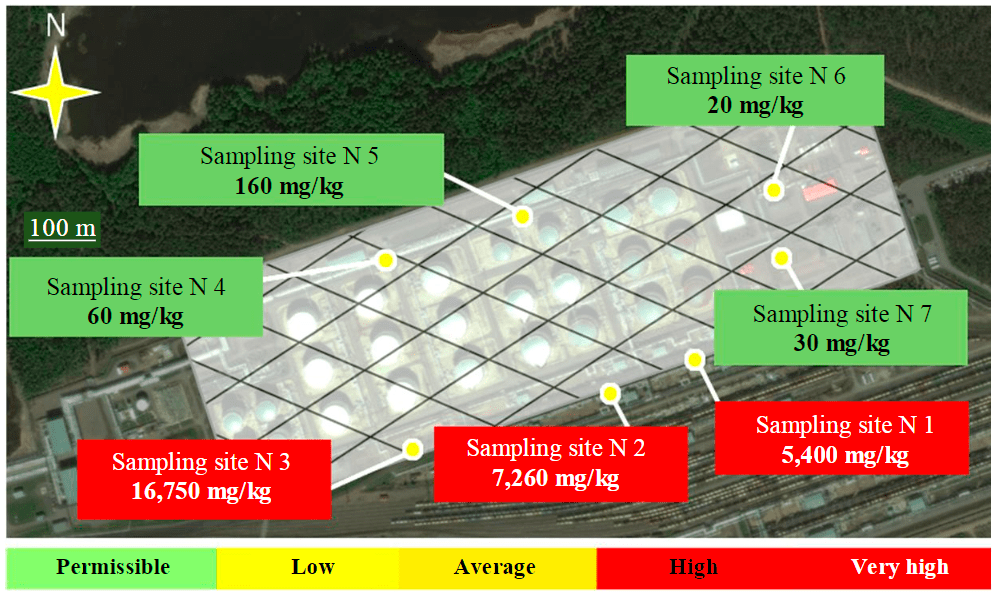

A tank farm for storing oil products was the first study object. The risk of local spills and leaks is caused here by the presence of a drain-filling overpass. Considering that the territory of the park itself is concreted and paved, test sites were laid along the perimeter. In total, nine test sites were laid with a total of 21 soil samples (along three horizons A0, A1, and A2 with a sampling depth of 0-5, 5-15, and 15-20 cm, respectively). The scheme of sampling sites and the content of petroleum products are shown in Fig.1. Furthermore, one background soil sample was taken outside the impact zone of the production facility (not contaminated with petroleum products). The soils of the territory of the investigated production facility are podzolic [25].

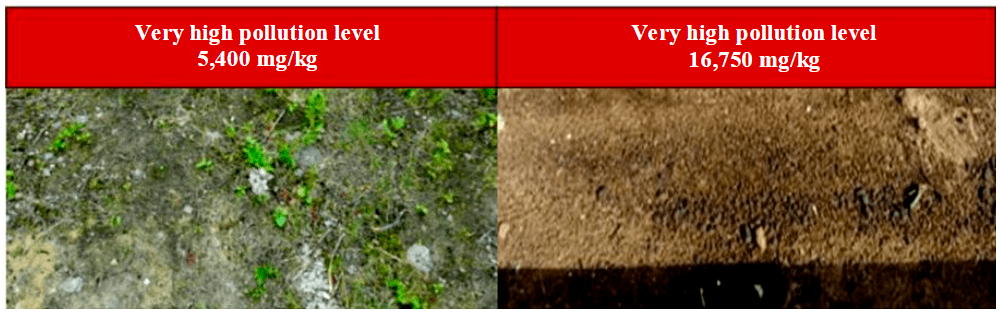

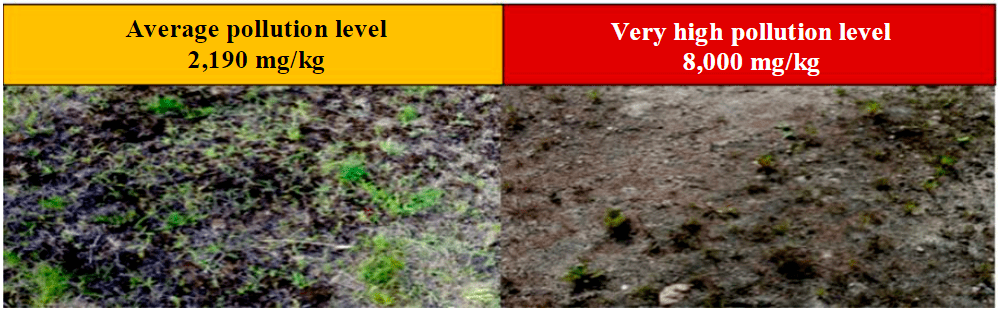

The results of visual assessment and laboratory studies to determine the level of soil pollution allowed us to establish that vegetation suppression of varying degrees is observed at the sampling sites, depending on the bulk content of the pollutant (Fig.2).

Fig.1. Scheme of soil sampling sites on the territory of the first studied object, indicating the average values of the bulk content for three sampled horizons and the levels of soil pollution with oil products

Fig.2. Comparison of a visual assessment on the territory of the first studied object and the results of laboratory analysis of the level of soil pollution with oil products (according to the average value of the bulk content for three sampled horizons)

Fig.3. Scheme of soil sampling sites on the territory of the second studied object (indicating the values of the bulk content and levels of soil pollution with oil products)

Fig.4. Comparison of a visual assessment on the territory of the second studied object and the results of laboratory analysis of the level of soil pollution with oil products

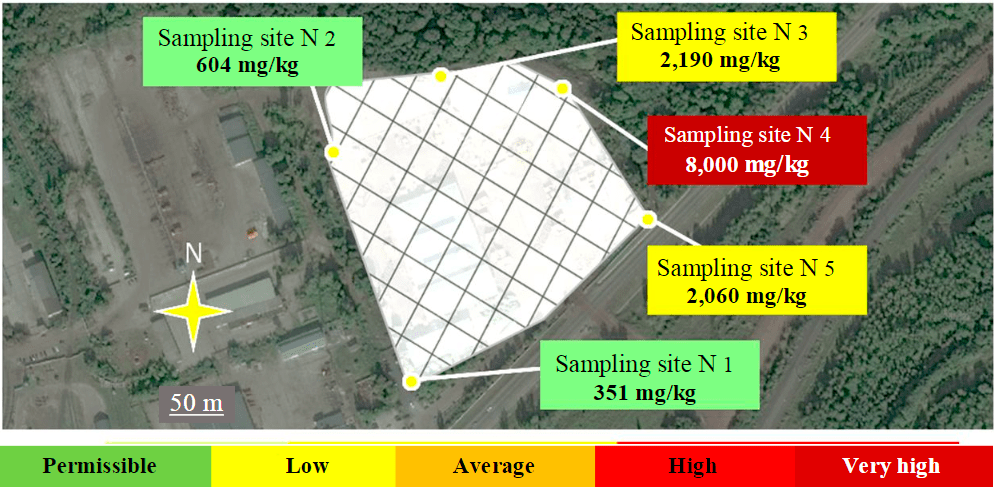

A parking site of quarry vehicles located on the territory of a large mining enterprise of the Russian Federation was the second object under study. The risk of local spills and leaks may be caused by the maintenance of machinery and the use of other equipment. In total, five test sites were laid, sampling was carried out to the depth of the entire surface layer (0-20 cm) with the receipt of five combined samples. The scheme of sampling sites and the content of petroleum products are shown in Fig.3. One background soil sample was also taken outside the impact zone of the production facility (not contaminated with petroleum products). The soils of the territory of the investigated production facility are gray forest [25].

On the territory of the second production facility, the dependence of vegetation oppression on the level of soil contamination with petroleum products was revealed (Fig.4).

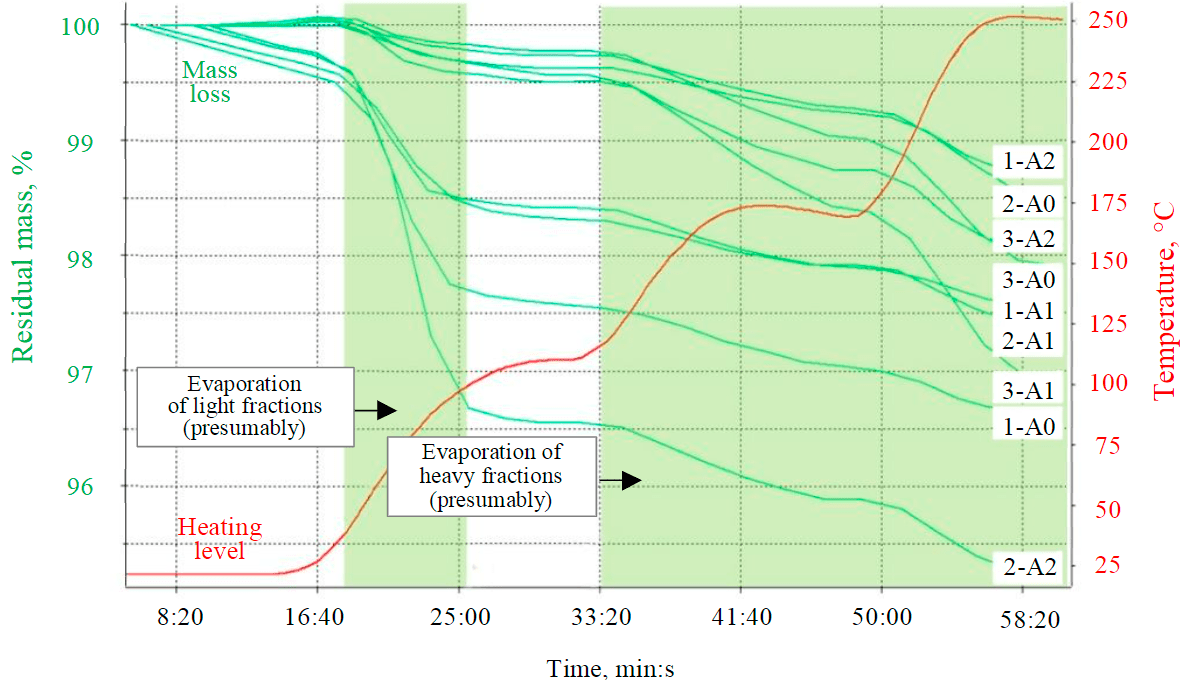

The temperature conditions were simulated using the LECO TGA701 thermogravimetric analyzer. The experiment was carried out on contaminated soils taken from the territory of the first study object, having higher values of the gross content of petroleum products and contaminated (presumably) with gasoline and diesel fuel, and applied further on soils sampled from the territory of the second study object, contaminated (presumably) with gasoline, diesel fuel and oils (in small quantities).

The purpose of this stage of research was to establish an optimal temperature regime for soils taken from the territories of real production facilities, at which the concentration of petroleum products decreases to an acceptable level. Additionally, studies were carried out to determine the total content of organic carbon by low-temperature thermocatalytic oxidation of soil samples using a

TOC-V CSH analyzer for the subsequent calculation of the total content of humus by the indirect method (due to the lack of direct determination methods) for background samples of soils treated at the established optimal temperature regime (to determine the residual humus content) and not treated (to determine the initial humus content).

To develop a methodology for the thermal desorption treatment of local soil contamination from petroleum products at the facilities of the mineral resource complex, the maximum concentration of petroleum products has been established, which can be reduced to an acceptable level when using the previously established temperature regime (treatment at 250 °C).

The research was carried out in five stages:

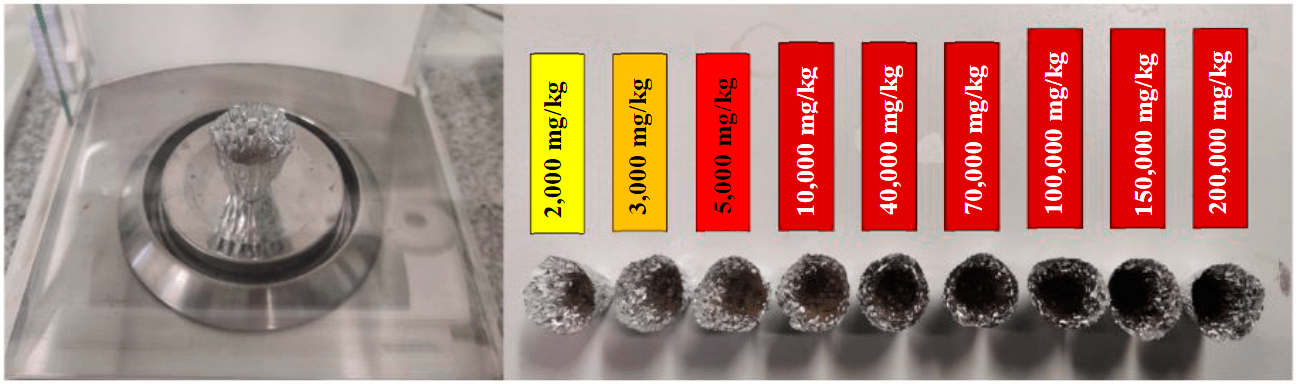

- Simulation of soil pollution in the concentration range from 2,000 to 200,000 mg/kg using various petroleum products.

- Thermal desorption treatment of contaminated soils with a final treatment temperature of 150, 200, and 250 °C.

- Analysis of thermogravimetric curves to obtain the percentage of loss by weight of contaminated soils during heat treatment.

- Determination of the residual content of petroleum products in treated soils by spectrometric analysis.

- Analysis of the experimental results with obtaining the values of the maximum concentrations of various petroleum products, which can be reduced to an acceptable level at the final processing temperature of 150, 200, and 250 °C.

To simulate pollution, virgin soil of the Leningrad Oblast (podzolic) with a background content of petroleum products less than 25 mg/kg (according to the results of laboratory studies, taking into account the sensitivity of the method used) and the following types of petroleum products were used: gasoline AI-95 (B), diesel fuel Euro-5 (DT), highly refined mineral oil (deep purification) R-2 (MV), synthetic engine oil 5W-40 (MM), and semi-synthetic transmission oil GL-4 75W-90 (TM).

The sampling of virgin soil samples (2 g with an accuracy of 0.001) was carried out in special aluminum crucibles (Fig.5, left), which were subsequently placed in ceramic crucibles of the

LECO TGA701 thermogravimetric analyzer. Quantitative application of the studied petroleum products was carried out by gravimetric method using a microliter syringe to create contaminated soils in the range from 2,000 to 200,000 mg/kg (Fig.5, right).

For each of the studied types of petroleum products, a series of experiments was carried out, consisting of heat treatment of contaminated soils with maximum heating up to 150, 200, and 250 °C.

The residual content of petroleum products in treated soils was determined only by the spectrometric method using the IR-Fourier Shimadzu spectrometer IRAffinity-1. The exclusion of the fluorimetric method from the methods for determining the content of petroleum products is due to the fact that only aromatic hydrocarbons have the fluorescence effect; these compounds are partially or completely desorbed during heat treatment, which can significantly distort the results when determining the residual content [34-36].

Fig.5. Simulation of contaminants in the concentration range from 2,000 to 200,000 mg/kg (using diesel fuel as an example)

In order to measure the humus loss in soils at various processing temperatures, studies were conducted to determine the total content of organic carbon for clean soil (not thermally treated) – to assess the initial humus content; the clean soils were treated thermally at temperatures of 150, 200, and 250 °C; the similar procedure was applied to soil samples artificially contaminated with petroleum products with a residual content of less than 25 mg/kg – to obtain the residual humus content.

To assess the mass loss for uncontaminated soil during heat treatment, clean soil samples were loaded during each series of the experiment. According to the obtained thermogravimetric curves (TGC) of uncontaminated soil, the following indicators were calculated: the percentage of soil moisture by mass loss when heated from 25 to 105 °C; the estimated residual humus content by the difference in the total mass loss of clean soils when heated to 150, 200, and 250 °C, and the humidity.

During the thermal treatment of soils contaminated with the studied petroleum products in the concentration range from 2,000 to 200,000 mg/kg with a maximum heating temperature of 150, 200, and 250 °C, the following results were obtained:

- total percentage of mass loss during the heat treatment;

- percentage of mass loss of petroleum products, taking into account the total mass loss of a clean soil sample;

- residual content of petroleum products drawn after the TGC, taking into account the percentage of mass loss of a clean soil sample;

- residual content of petroleum products;

- the treatment intensity;

- characteristics of the total percentage of mass loss of a pure soil sample by TGC with an indication of the residual humus content;

- the maximum content of petroleum product in the soil, which can be reduced to an acceptable level.

All the results of previous and current studies were obtained using the equipment of the Common Use Center of the Saint Petersburg Mining University.

Results

After a series of experiments on thermal effects on oil-contaminated soils from the first production facility, it was found that at the final processing temperature of 250 °C, the concentration of petroleum products decreases to an acceptable level in all the samples of contaminated soils. The results are presented in Fig.6 and in Table 1, (the residual concentration of petroleum products is presented taking into account the sensitivity of the applied methods).

Fig.6. Thermogravimetric curve of the optimal temperature regime for cleaning the studied soils from oil products

The established tem-perature regime was also applied to clean the soils selected from the territory of the second production facility. The residual contents of the pollutant are presented in Table 2.

The initial content of soil humus in the area of the first production fa-cility was 1.59 %, the resi-dual (after heat treatment at 250 °C) was 0.78 %. The initial contеnt of soilhumus in the area of the second production facility was 3.92 %, the residual was 2.02 %. The loss of humus from the initial content is 50.94 and 48.97 %, respectively.

Table 1

PP concentration in soil samples taken from the territory of the tank farm, before and after the thermal treatment

|

Sampling site |

Sampled horizon |

Concentration before treatment, mg/kg |

The average value of the concentration in the soil layer (0-20 cm), mg/kg |

Concentration after treatment, mg/kg |

|

1 |

А0 |

7,000 |

5,400 |

Below 25 |

|

А1 |

5,650 |

Below 25 |

||

|

А2 |

3,540 |

Below 25 |

||

|

2 |

А0 |

6,650 |

7,260 |

360 |

|

А1 |

7,200 |

410 |

||

|

А2 |

7,950 |

130 |

||

|

3 |

А0 |

16,300 |

16,750 |

20 |

|

А1 |

24,850 |

Below 25 |

||

|

А2 |

9,100 |

Below 25 |

Table 2

PP concentration in soil samples taken from the territory of the quarry vehicle parking, before and after the thermal treatment

|

Sampling site |

Concentration before treatment, mg/kg |

Concentration after treatment, mg/kg |

|

1 |

2,190 |

415 |

|

2 |

8,000 |

670 |

|

3 |

2,060 |

345 |

Experimental studies on soils taken from the territories of the real production facilities showed that the final processing temperature did not exceed 250 °C, which is significantly lower than the burning temperature of all humates (450 °C), and the residual humus content is about 50 % of the original, which allows the return of soils to the ecosystem as either a technical substrate or a fertile layer. At the same time, there may be an economic effect due to the absence of the need to bury contaminated soils and the use of imported soil.

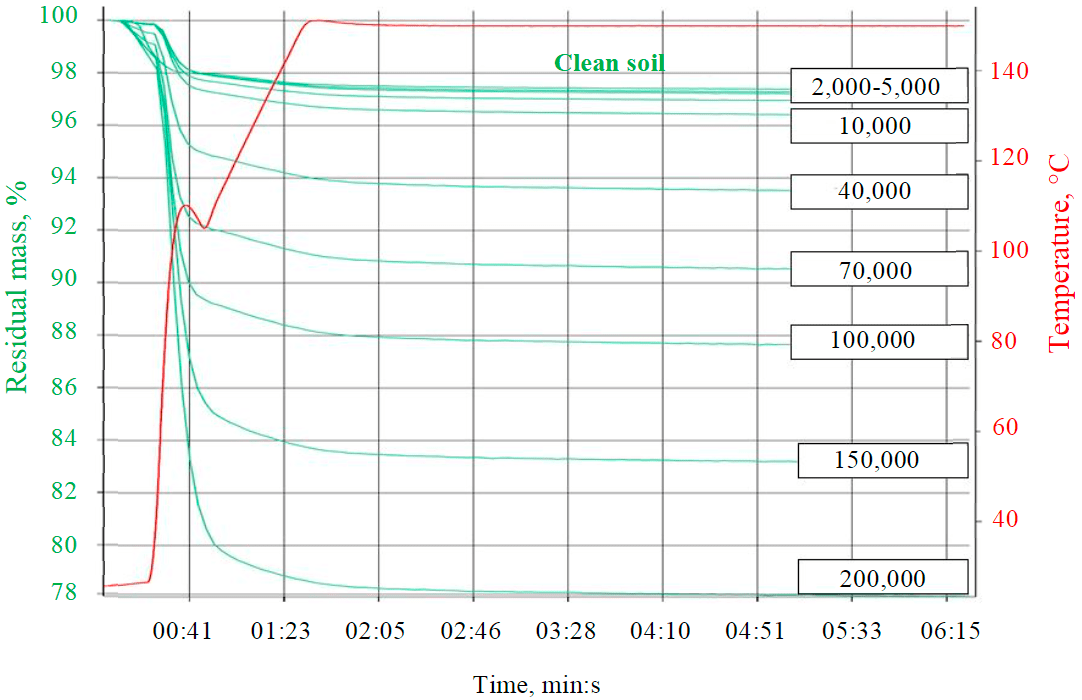

Table 3 shows an example of a data array obtained by heat treatment of soils artificially polluted with gasoline, where the concentrations ranged between 2,000 and 200,000 mg/kg under the maximum heating temperature of 150 °C. Figure 7 shows an example of interpreted TGC for soils contaminated with gasoline in the concentration range from 2,000 to 200,000 mg/kg and treated at the temperature of 150 °C.

It should be noted that the specification of the equipment used (the LECO TGA701 thermogra-vimetric analyzer) makes it possible to treat soil samples at a given final temperature to a relatively constant mass, which provides an almost complete yield of fractions of petroleum products that can be desorbed. Based on the results obtained, it was found that during the desorption of petroleum products, the processing time depends on the type of petroleum product contained in the soil. Thus, when contaminated with gasoline and diesel fuel, the average processing time to obtain purified soil was about 6 hours over the entire studied temperature range, considering the time for the heating to a given temperature. Under similar thermal conditions, the processing time of soils contaminated with highly refined, motor, and transmission oils was 8-10 hours.

Table 3

Results of experimental and laboratory studies for soils contaminated with gasoline and treated at the temperature of 150 °C

|

Initial PP concentration, mg/kg |

2,000 (0.2 %) |

3,000 (0.3 %) |

5,000 (0.5 %) |

10,000 (1 %) |

40,000 (4 %) |

70,000 (7 %) |

100,000 (10 %) |

150,000 (15 %) |

200,000 (20 %) |

|

|

Mass loss (loss of PP), % |

2.81 (~0.2) |

2.91 (~0.3) |

3.10 (0.49) |

3.59 (0.98) |

6.51 (3.9) |

9.44 (6.83) |

12.36 (9.75) |

17.20 (14.59) |

22.05 (19.44) |

|

|

Residual PP concentration, mg/kg (by mass loss, TGC) |

~0 |

~0 |

100 |

200 |

1,000 |

1,700 |

2,500 |

4,100 |

5,600 |

|

|

Residual PP concentration, mg/kg (by the analysis results) |

41.4 |

77.8 |

118.3 |

242.6 |

1,024.3 |

1,760.0 |

2,481.3 |

4,245.4 |

5,454.6 |

|

|

Degree of treatment, % |

98.0 |

97.3 |

98.0 |

98.0 |

97.5 |

97.5 |

97.5 |

97.3 |

97.2 |

|

|

Loss of clean soil, % |

Total loss (according to TGC) 2.61 % (including moisture 2.05 %) Humus burning (according to TGC) 0.56 % Humus burning (according to the analysis results) 0.64 % |

|||||||||

|

Maximum concentration for treatment, mg/kg |

39,100 |

|||||||||

The results of laboratory analyses to determine the total organic carbon content showed that the average percentage of humus content in soils used to simulate the process of contamination with various petroleum products is:

- 89% for the uncontaminated soil with the background PP content ≤ 25 mg/kg,

- 25% for the soil treated at 150 °C and the PP content ≤ 25 mg/kg,

- 12% for the soil treated at 200 °С and the PP content ≤ 25 mg/kg,

- 48% for the soil treated at 250 °C and the PP content ≤ 25 mg/kg.

Fig.7. TGC for soils contaminated with gasoline in the concentration range from 2,000 to 200,000 mg/kg and treated at the temperature of 150 °С

The results of experimental studies on the thermal desorp-tion treatment of soils artifi-cially contaminated with gaso-line showed that when treated with a maximum heating tem-perature of 150 °C, an efficien-cy of 97.6 % (average value) is observed, allowing soil purifica-tion to an acceptable level of 1,000 mg/kg, with a pollutant content of up to 39,100 mg/kg, which corresponds to a very high level of pollution. An in-crease in the treatment tem-perature to 200 °C ensures a cleaning efficiency of more than 99 % and allows reducing the concentration to an acceptable level in the entire studied range (from 2,000 to 200,000 mg/kg). At the same time, the maximum concentration in soils, which can be reduced to an acceptable level under this temperature regime, cannot be limited, which is due to the almost complete desorption of gasoline at 200 °C.

In case of soil contamination with diesel fuel, treatment at 150 °C allows treatment with a pollutant content of up to 3,100 mg/kg, which corresponds to a high level of pollution. An increase in the treatment temperature to 200 °C ensures the purification of soils with a diesel fuel content of 6,200 mg/kg, i.e. very high pollution level. At 250 °C, the maximum concentration that can be reduced to an acceptable level is 11,500 mg/kg. An increase in the final processing temperature from 150 to 200, and 250 °C leads to an increase in the degree of purification from 67.8 to 79.6 and 89.9 %, respectively.

The studied oils (highly refined, motor, and transmission) are the most difficult pollutants for soil remediation, which is caused by the presence of heavier hydrocarbon fractions. The results of experimental studies have shown that treatment at 150 °C is low-effective (the degree of purification is ~7 %). An increase in the treatment temperature to 200 °C makes it possible to clean soils contaminated with oils up to 2,000 mg/kg (degree of purification ~50.5 %), which corresponds to the threshold value of low and medium pollution levels. The maximum concentration of oils that can be reduced to an acceptable level in the studied range of low-temperature desorption is 3,800 mg/kg (68.0 % degree of purification), which is characterized as a high level of soil contamination with petroleum products.

Discussion

According to international studies, the thermal conductivity of different types of soils differs little from each other, therefore heating minimally depends on the heterogeneity of the soil structure or the distribution of pollutants, while the soils treated with thermal desorption are dried, which makes even dense clays sufficiently permeable for desorption and this method is effective [37, 38]. The studied soils belong to the type of podzolic and gray forest, prevalent in approximately 50 % of the territory of the Russian Federation [25]. Despite the provided information, with the practical application of the technology on the territory of a specific production facility, it is possible to conduct preliminary studies of thermal desorption using several reference soil samples.

Experimental studies on the establishment of an optimal temperature regime by thermal action on soils selected from the territories of the real production facilities confirm the assumption that low-temperature thermal desorption can be used to clean soils from petroleum products in the event of local spills and leaks. The specification of the studied production facilities and the petroleum products used on their territory show that the soils are presumably contaminated with gasoline and diesel fuel at the first facility and with gasoline, diesel fuel, and oils at the second one. This explains the higher values of the residual content of petroleum products in the soils of the quarry vehicle parking due to the low degree of desorption of oils compared to gasoline and diesel fuel at 250 °C. It was found that heat treatment at 250 °C of background soil samples of both objects having different initial humus content and belonging to different types of soils allows preserving about 50 % of humus from its initial content.

The assumption about the possibility of using low-temperature thermal desorption to purify soils from petroleum products while preserving part of the humus was confirmed by experimental studies, that had not been conducted before, to simulate soil contamination with petroleum products, represented by gasoline, diesel fuel, and various oils, and their heat treatment within the established temperature regime. It should be noted that the desorption time is mainly affected only by the type of petroleum product, which is associated with the boiling point temperatures and different contents of light and heavy fractions. In the soils with a processing temperature of 250 °C, preservation of ~50 % of humus from the initial content is also observed. When processing soils at 150 and 200 °C, the preservation of humus from the initial content is more effective, ca. 90 and 80 %, respectively.

Based on the results of the analysis of production processes with the risk of local spills and leaks, measures have been developed to sanitize territories using low-temperature desorption from petroleum products in two main scenarios with a guaranteed result of reducing the pollutant content to an acceptable value:

- in the case when the type of petroleum product is determined, which is the only hydrocarbon pollutant in the territory with the detected excess of the permissible level (1,000 mg/kg);

- in the case when several potential types of petroleum products have been identified (a mixture of petroleum products) or identification of the type of petroleum product is impossible with the detected excess of the permissible level (1,000 mg/kg).

When remediating territories according to the first scenario, it is recommended:

- Thermal desorption treatment at 150 °C in case of soil contamination with gasoline up to 39,100 mg/kg (treatment time ~6 h) and with diesel fuel up to 3,100 mg/kg (treatment time ~6 h).

- Thermal desorption treatment at 200 °C in case of soil contamination with gasoline over 39,100 mg/kg (treatment time ~6 h), diesel fuel in the concentration ranging from 3,100 to 6,200 mg/kg (treatment time ~6 h), oils (highly refined, motor and transmission) up to 2,000 mg/kg (treatment time 8-10 h).

- Thermal desorption treatment at 250 °C in case of soil contamination with diesel fuel in the concentration range from 6,200 to 11,500 mg/kg (treatment time ~6 h), oils (highly refined, motor, and transmission) in the concentration range from 2,000 to 3,800 mg/kg (treatment time 8-10 h).

When remediating territories according to the second scenario, it is recommended:

- Focusing on the established dependencies of the required treatment temperature on the concentration of petroleum products having lower purification rates (due to the inability to accurately determine the mass fractions of each of the petroleum products that have contaminated the soil) if several potential types of petroleum products (a mixture of PP) are identified.

- Cleaning the soil at a temperature of 250 °C with a gross content of petroleum products ≤ 3,800 mg/kg to ensure a guaranteed result if it is impossible to identify the type and (or) types of petroleum products for one reason or another.

Conclusion

Based on the results of experimental studies on the heat treatment of contaminated soils sampled at the territories of real production facilities, a series of experiments on cleaning artificially polluted soils with various petroleum products in the concentration range from 2,000 to 200,000 mg/kg at maximum treatment temperatures of 150, 200, and 250 °C, as well as determining the percentage of humus losses during heat treatment, the authors developed the methodology for low-temperature thermal desorption at enterprises of the mineral resource complex and options for which this treatment is economically and environmentally appropriate.

The developed methodology can be used at enterprises of the mineral resource complex and other industries (construction, housing and communal services, gas stations, transport, etc.) in order to maintain an acceptable level of petroleum products in the soil and (or) during land rehabilitation. In the case of rehabilitation, the amount of humus that needs to be introduced to restore fertility is reduced by preserving part of the initial humus content in the thermally treated soils. Technical support for the practical application of low-temperature thermal desorption may consist in the use of existing installations, such as an indirect heating drum furnace with the possibility of modernization or the design of mobile installations, depending on the situation.

References

- Ministry of Energy of the Russian Federation. Board of the Ministry of Energy of Russia 2021: Report on the functioning and development of the Russian fuel and energy complex in 2020. 2021. URL: https://minenergo.gov.ru/node/20322 (accessеd 20.08.2021) (in Russian).

- Zhukovskiy Y.L., Batueva D.E., Buldysko A.D. et al. Fossil energy in the framework of sustainable development: Analysis of prospects and development of forecast scenarios. Energies. 2021. Vol. 14. Iss. 17. N 5268. DOI: 10.3390/en14175268

- Kondrasheva N.K., Eremeeva A.M., Nelkenbaum K.S. Development of domestic technologies of producing high quality clean diesel fuel. Izvestiya Vysshikh Uchebnykh Zavedenii, Seriya Khimiya i Khimicheskaya Tekhnologiya. 2018. Vol. 61. Iss. 9-10,

- p. 76-82. DOI: 10.6060/ivkkt.20186109-10.5651

- Motin A. Forecasting the production and consumption of petroleum products until 2020. Gosudarstvennaya sluzhba. 2008. N 5 (55), p. 192-196 (in Russian).

- Sinyak Yu.V. Forecast estimates of demand for motor fuels for the needs of vehicles and petroleum products for final consumption (on the example of the Tula Oblast). Nauchnye trudy: Institut narodnokhozyaystvennogo prognozirovaniya RAN. 2017. Vol. 15, p. 218-233 (in Russian).

- Alekseenko V.A., Maximovich N.G., Alekseenko A.V. Geochemical Barriers for Soil Protection in Mining Areas. Assessment, Restoration and Reclamation of Mining Influenced Soils. Academic Press, 2017, p. 255-274. DOI: 10.1016/B978-0-12-809588-1.00009-8

- Sultanbekov R.R., Nazarova M.N. The influence of total sediment of petroleum products on the corrosiveness of the metal of the tanks during storage. I International Conference “Corrosion in the Oil and Gas Industry”, 22-24 May 2019, Saint Petersburg, Russia. E3S Web Conference, 2019. N 01015. DOI: 10.1051/e3sconf/201912101015

- Sultanbekov R.R., Terekhin R.D., Nazarova M.N. Effect of temperature fields and bottom sediments of oil products on the stress-strain state of the design of a vertical steel tank. VIII International Conference “Deformation and fracture of materials and nanomaterials” 19-22 November 2019, Moscow, Russian Federation. Journal of Physics: Conference Series, 2020. Vol. 1431. N 012055. DOI: 10.1088/1742-6596/1431/1/012055

- Kulikova M.A. Mechanism of soil and vegetation cover pollution in the impact zone of aluminum industry enterprises. Journal of Mining Institute. 2008. Vol. 174, p. 233-235 (in Russian).

- Markin N.S., Korolkov A.T. Geochemical Characteristics of the Soils of the Most Polluted Part of Baley (Zabaykalsky Krai). The Bulletin of Irkutsk State University. Series “Earth Sciences”. 2021. Vol. 35, p. 71-83 (in Russian). DOI: 10.26516/2073-3402.2021.35.71

- Jia Q., Zhessakov A. Study on ecological evaluation of urban land based on GIS and RS technology. Arabian Journal of Geosciences. 2021. Vol. 14. Iss. 4. N 261. DOI: 10.1007/s12517-021-06586-6

- Inshakov S.A., Inshakov N.A. Evaluation of Ecological Security of Petrol Stations. Tambov University Reports. Series Na-tural and Technical Sciences. Vol. 19. N 5, p. 1420-1421 (in Russian).

- Makovozov A.O. Geoecology of an industrially developed region and improvement of methods for monitoring the state of the environment (on the example of the city of Vladikavkaz). Journal of Mining Institute. 2003. Vol. 155. N 2, p. 41-42 (in Russian).

- Vvedenskij R.V., Gendler S.G., Titova T.S. Environmental impact of the tunnel construction. Magazine of Civil Engineering. 2018. Vol. 79. Iss. 3, p. 140-149. DOI: 10.18720/MCE.79.15

- Kazakova M.P., Kolupaeva E.S. Land reclamation, oil and oil product pollution. Voprosy rossiyskoy yustitsii. 2020. N 9, p. 776-781 (in Russian).

- Gennadiev A.N., Pikovskii Yu.I. The Maps of Soil Tolerance toward Pollution with Oil Products and Polycyclic Aromatic Hydrocarbons: Methodological Aspects. Eurasian Soil Science. 2007. Vol. 40. Iss. 1, p. 70-81. DOI: 10.1134/S1064229307010115

- Kuzhaeva A., Berlinskii I. Effects of oil pollution on the environment. International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management (SGEM 2018), 2-8 July 2018, St. Petersburg, Russian. SGEM, 2018. Vol. 18, p. 313-320. DOI: 10.5593/sgem2018/5.1/S20.041

- Merzlyakova A.S., Okolelova A.A., Zaikina V.N., Pasikova A.V. Changing the Properties of Oil-Contaminated Soils. Proceedings of Universities. Applied Chemistry and Biotechnology. 2017. Vol. 7. N 2, p. 164-171 (in Russian). DOI: 10.21285/2227-2925-2017-7-2-173-180

- Usacheva Y.N. Functional Potency and Number of Microorganisms in Oil-Contaminated Soils. Bulletin of Nizhnevartovsk State University. 2013. Vol. 15, p. 218-233 (in Russian).

- Leadin S. Khudur, Esmaeil Shahsavar, Grant T. Webster, Dayanthi Nugegoda, Andrew S. Ball. The impact of lead co-contamination on ecotoxicity and the bacterial community during the bioremediation of total petroleum hydrocarbon-contaminated soils. Environmental Pollution. 2019. Vol. 253, p. 939-948. DOI: 10.1016/j.envpol.2019.07.107

- Sinkova E.A. Experimental studies of the effectiveness of biological treatment of oil-contaminated soils. Journal of Mining Institute. 2003. Vol. 155. N 1, p. 85-89 (in Russian).

- Berkadu A.A., Quanyuan Chen. Surfactant-Enhanced Soil Washing for Removal of Petroleum Hydrocarbons from Conta-minated Soils: A Review. Pedosphere. 2018. Vol. 28. Iss. 2, p. 383-410. DOI: 10.1016/S1002-0160(18)60027-X

- Kovaleva E.I. Ecological Evaluation of Oil-Contaminated Soils (Sakhalin) Using Enchytraeidae. Eurasian Soil Science. 2017. Vol. 50. Iss. 3, p. 350-358. DOI: 10.1134/S1064229317030073

- Shtripling L.O., Kholkin E.G., Merkulov V.V. Improving the efficiency of the installation for the neutralization of oil-contaminated soil at low temperatures. Omskiy nauchnyy vestnik. 2020. N 4 (172), p. 5-8 (in Russian). DOI: 10.25206/1813-8225-2020-172-5-8

- Bykova M.V., Alekseenko A.V., Pashkevich M.A., Drebenstedt C. Thermal desorption treatment of petroleum hydrocarbon-contaminated soils of tundra, taiga, and forest steppe landscapes. Environmental Geochemistry and Health. 2021. Vol. 43. Iss. 6,

- p. 2331-2346. DOI: 10.1007/s10653-020-00802-0

- Vasil'chenko A.V., Voevodina T.S. The Problem of environmental assessment of soil pollution by oil products. Vestnik Orenburgskogo gosudarstvennogo universiteta. 2015. N 10 (185), p. 147-151 (in Russian).

- On the procedure for determining the damage from land pollution by chemicals: Letter of the Ministry of Natural Resources of Russia (Ministry of Environmental Protection and Natural Resources of the Russian Federation) dated December 27, 1993 N 04-25. URL: https://legal acts.ru/doc/pismo-minprirody-rossii-ot-27121993-n-04-2561-5678/ (accessеd 20.05.2021) (in Russian).

- Okolelova A.A., Zheltobryukhov V.F. Peculiarities of determination and regulation of oil products in soils. Estestvenno-gumanitarnye issledovaniya. 2013. N 1 (4), p. 12-18 (in Russian).

- Bykova M.V., Pashkevich M.A., Matveeva V.A., Sverchkov I.P. Assessment and abatement of the soil oil-contamination level in industrial areas. Topical Issues of Rational Use of Natural Resources: Proceedings of the International forum-contest of young researchers. CRC Press, 2018, p. 347-361.

- Kunitsyna I.A., Okolelova A.A., Karaseva A.S. Features of various methods for determining organic carbon in soils. Izvestiya Nizhnevolzhskogo agrouniversitetskogo kompleksa: nauka i vysshee professionalnoe obrazovanie. 2012. N 3 (27), p. 1-4 (in Russian).

- Antonec K.V. Comprehensive Monitoring of Oil and Gas Pollution. International agricultural journal. 2021. Vol. 64. N 1,

- p. 49-54 (in Russian).

- Finochenko V.A., Finochenko T.A. Analysis of methods for determining the concentration of petroleum products in natural and waste waters. Vestnik RGUPS. 2003. N 1, p. 100-102 (in Russian).

- Shekov A.A., Koryakin A.A., Zyryanov V.S. Investigation of gasolines by fluorescent analysis. Vestnik Vostochno-Sibirskogo instituta MVD Rossii. 2010. N 1 (52), p. 71-75 (in Russian).

- Pankratova K.G., Shchelokov V.I., Stupakova G.A. et al. Determination of oil products in the soil by NIR spectroscopy:

- Determination of individual oil products simultaneously present in the soil. Plodorodie. 2013. N 2, p. 47-49 (in Russian).

- Shekov A.A., Zyryanov V.S., Kuznetsov K.L. Study of evaporated organic solvents by fluorescence spectroscopy. Vestnik Vostochno-Sibirskogo instituta MVD Rossii. 2014. N 3 (70), p. 39-46 (in Russian).

- Fedotov Yu.V., Belov M.L., Kravtsov D.A., Gorodnichev V.A. Experimental Investigation of the Dynamics in Laser-Induced Fluorescence Spectra of Oil Pollution. Herald of the Bauman Moscow State Technical University, Series Natural Sciences. 2019. N 1 (82), p. 66-76 (in Russian). DOI: 10.18698/1812-3368-2019-1-66-76

- Baker R.S., Kuhlman M. A description of the mechanisms of in-situ thermal destruction (ISTD) reactions. Proceedings of the 2nd International Conference on Oxidation and Reduction Technologies for Soil and Groundwater, 17-21 November 2002, Toronto, Canada. Civil and Environmental Engineering, 2002, p. 10.

- Yeung A.T. Remediation technologies for contaminated sites. Advances in environmental geotechnics. Hangzhou: Zhejiang University Press, 2010, p. 328-369. DOI: 10.1007/978-3-642-04460-1_25