Complex processing of high-carbon ash and slag waste

- 1 — Ph.D. Senior Researcher Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 3 — Ph.D. Researcher Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus

Abstract

The paper considers a current issue of ash and slag processing for the Polyus Aldan JSC, that has accumulated over 1 million tons of this waste. Following the results of the review of Russian and foreign literature, four promising areas of their use were selected: road construction, building materials, reclamation of disturbed lands, and inert aggregates. To assess the possibility of implementing the selected disposal directions, the samples of ash and slag waste of the enterprise were sampled and analyzed. Fuel characteristics, chemical and mineral composition, as well as physico-chemical and mechanical properties of waste were determined. Taking into account the results of complex laboratory studies and the requirements of regulatory documents, each of the selected areas of using ash and slag waste was evaluated. It was found that their disposal by traditional methods has limitations, mainly related to the high content of unburned fuel residues. The high content of combustible substances and the high specific heat of combustion with a relatively low ash content suggested the possibility of thermal disposal of the studied waste. Based on the literature data, the characteristics of the preparation of organic coal-water suspensions based on the studied ash and slag waste were selected. As a result of a series of experiments on their flaring, the expediency of using the obtained fuel at the enterprise under consideration has been proved. The authors note the possibility of using ash obtained after thermal waste disposal in the road construction industry. The prospects for further research of technologies for the preparation and combustion modes of suspension fuel based on ash and slag waste are determined.

Introduction

The share of coal in the world electricity production is about 40 %. In the Russian Federation, its consumption is growing, primarily in regions limited by other fuels. At power plants of the Far Eastern economic region, coal consumption reaches 85 %, while in the European part of Russia, in the Urals and Siberia, 64 % of gas and only 28 % of coal are consumed [1].

When coal is burned, such by-products as ash and slag waste (ASW) are formed. The volume of already accumulated ASW reaches 1.6 billion tons with an annual increase of up to 80 million tons. The occupied area is more than 25 thousand hectares. In the Republic of Sakha (Yakutia), over 100 million tons of ASW with an annual increase of 1.1-1.5 million tons have been accumulated on landfills with an area of more than 700 hectares.

ASW are dispersed powders consisting of fly ash, slag, and unburned carbon of the original fuel. Depending on the quality characteristics of the fuel, its combustion mode, and the type of boiler, the content of its components varies within the following values: 10-60 % for unburned carbon, 30-80 % for fly ash, and 10-70 % for slags.

ASW dumps negatively affect all the media, pollute the soil [2, 3], air [4], ground and surface waters [5], adversely affecting the regional environmental situation and human health [1]. Enterprises incur significant costs associated with the storage and placement of ASW. The task of their effective processing in order to solve these problems is extremely relevant.

The object of the study was the company Polyus Aldan JSC, located in the Republic of Sakha (Yakutia) and developing 11 gold deposits on the territory of the Kuranakh ore field. The mining facilities include a boiler room of the heat supply shop, serving the housing stock, industrial, and social facilities of Lower Kuranakh village settlement. From 1964 to 2019, the company accumulated over 1 million tons of ASW with an annual increase of more than 9 thousand tons. The purpose of the work is to study and substantiate the potential directions of using ASW of the Polyus Aldan JSC based on the results of complex laboratory studies.

Methodology

According to the results of the review of Russian and international literature, promising areas of waste disposal were selected [6-8]. The road construction sector [9-11] and agriculture [12-14] are the most relevant ways of application. In this case, the waste is not just disposed of but processed at a profit for an enterprise [15-17]. In extractive industries, the backfilling of ASW into the mined space has become widespread [18-20]. This method is less preferable due to the low economic effect and prolonged environmental hazard [21-23].

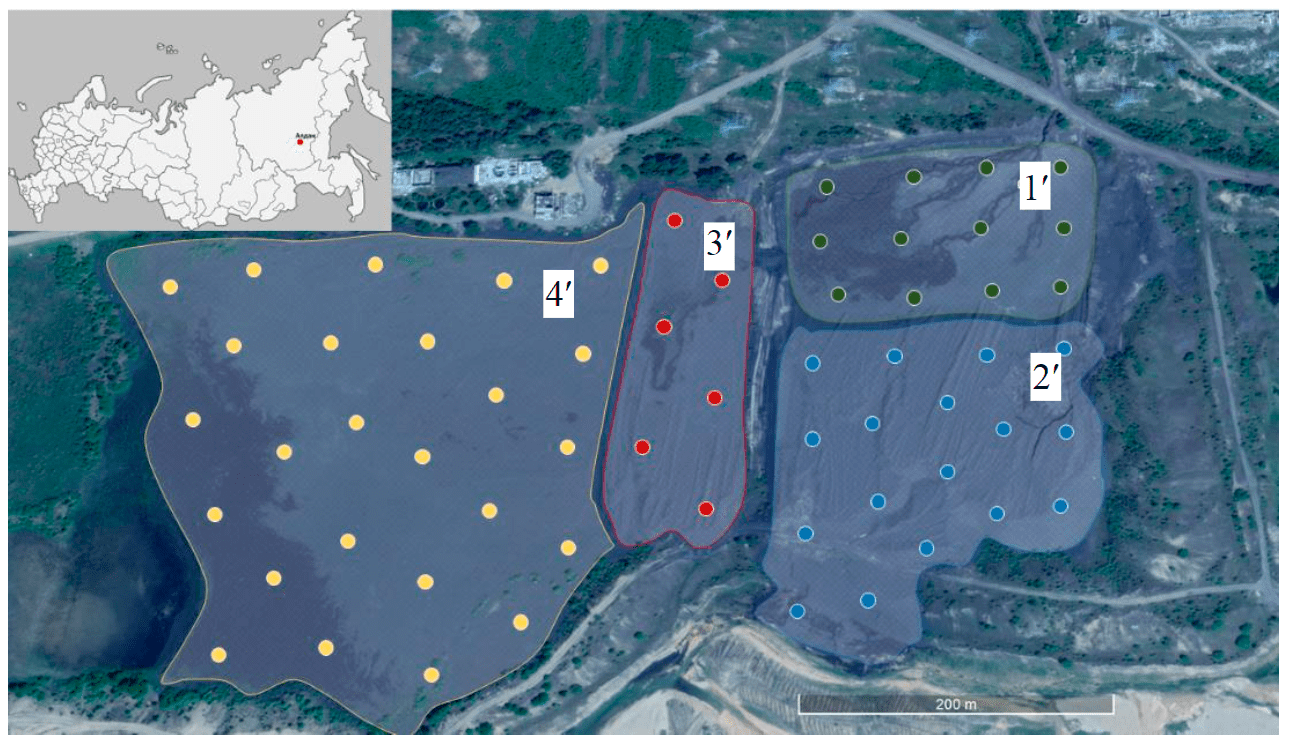

The choice of the direction of waste disposal is determined, first of all, by their composition and fuel characteristics, as well as physico-chemical and mechanical properties. To determine these characteristics and assess the homogeneity of waste by area and depth of occurrence, sampling was carried out in accordance with the requirements of PND F 12.4.2.1-99 “Waste of mineral origin. Recommendations for sampling and preparation of samples. General provisions” and GOST R 57789-2017 “Ashes, slags and ash-slags mixtures of HPP for manufacturing of artificial porous aggregates. Specifications”. The ash and slag waste pond measuring 700×350 m was divided into four sections, visually homogeneous in composition, size, and moisture content of the material (Fig.1).

Point samples weighing 400-600 g were taken from the surface of the digs with a metal scoop from depths of 0.5, 1, 1.5 m, and 2 m with a geological drill (Fig.1). The composition and properties of the samples were studied in the Environmental Modeling Laboratory of the Common Use Center, Saint Petersburg Mining University.

Dry ash content is the most unevenly distributed characteristic of coal and its waste [24, 25]. To clarify the number of homogeneous sections of the ASW pond, this indicator was determined for each point sample. Laboratory samples were prepared from the combined samples of refined homogeneous sites for further comprehensive research.

Fig.1. Layout of homogeneous sections of the ASW pond with sampling points

The primary fuel characteristics of ASW were determined in accordance with the regulatory documents for solid mineral fuel. The highest and lowest heat of combustion of ASW was determined using the bomb calorimeter IKA 2000. Humidity, ash content, and volatile yield were determined by the LECO TGA701 thermogravimetric analyzer. The content of the main elements of the organic mass, carbon, hydrogen, sulfur, and nitrogen, were studied by an instrumental method on a LECO CHN628 elemental analyzer with a sulfur add-on module. The mass fraction of oxygen in the fuel mass of ASW was calculated by the formula:

О = 100 – (С + H + N + H2O + A),

where C, H, and N are the mass fractions of carbon, hydrogen, and nitrogen in the absolutely dry ASW, respectively, %; H2O is the moisture content, %; A is the ash content in the absolutely dry ASW, %.

X-ray phase analysis of ASW was carried out on a powder diffractometer XRD-6000. The phases were searched using the international JSPDC database. The chemical composition of the mineral part of the ash was determined by atomic emission spectrometry with inductively coupled plasma on ICPE 9000 with the preliminary decomposition of samples in the Multiwave 3000 SOLV microwave system. Additionally, the content of water-soluble and mobile forms of elements was determined, as well as the content of humic acids, according to RD 34.02.202-95 “Recommendations for the reclamation of waste ash and slag dumps of thermal power plants”.

In accordance with the requirements of the Order of the Ministry of Natural Resources and Environment of the Russian Federation dated 4.12.2014 N 536 “On approval of Criteria for classifying waste to hazard classes I-V according to the degree of negative impact on the environment” and the Federal Law “On Production and Consumption Waste” dated 24.06.1998 N 89-FZ, the hazard class of ASW was determined by the calculation method and biotesting using two test objects of various systematic groups (Chlorella algae and Daphnia crustaceans).

Physico-chemical and mechanical properties were determined in accordance with regulatory documents on the use of ash in road construction (ODM 218.2.031-2013 “Guidelines for the use of fly ash and ash-slag mixtures from coal combustion at thermal power plants in road construction”) as a component of concrete (GOST 25592-2019 “Mixes of fly-ash and slag of thermal plants for concretes. Specifications”) and cement (TU 3470-10347-92 “Ash and slag waste of HPP for manufacturing of cement”), for the production of artificial fillers (GOST R 57789-2017 “Ashes, slags and ash-slags mixtures of HPP for manufacturing of artificial porous aggregates. Specifications”).

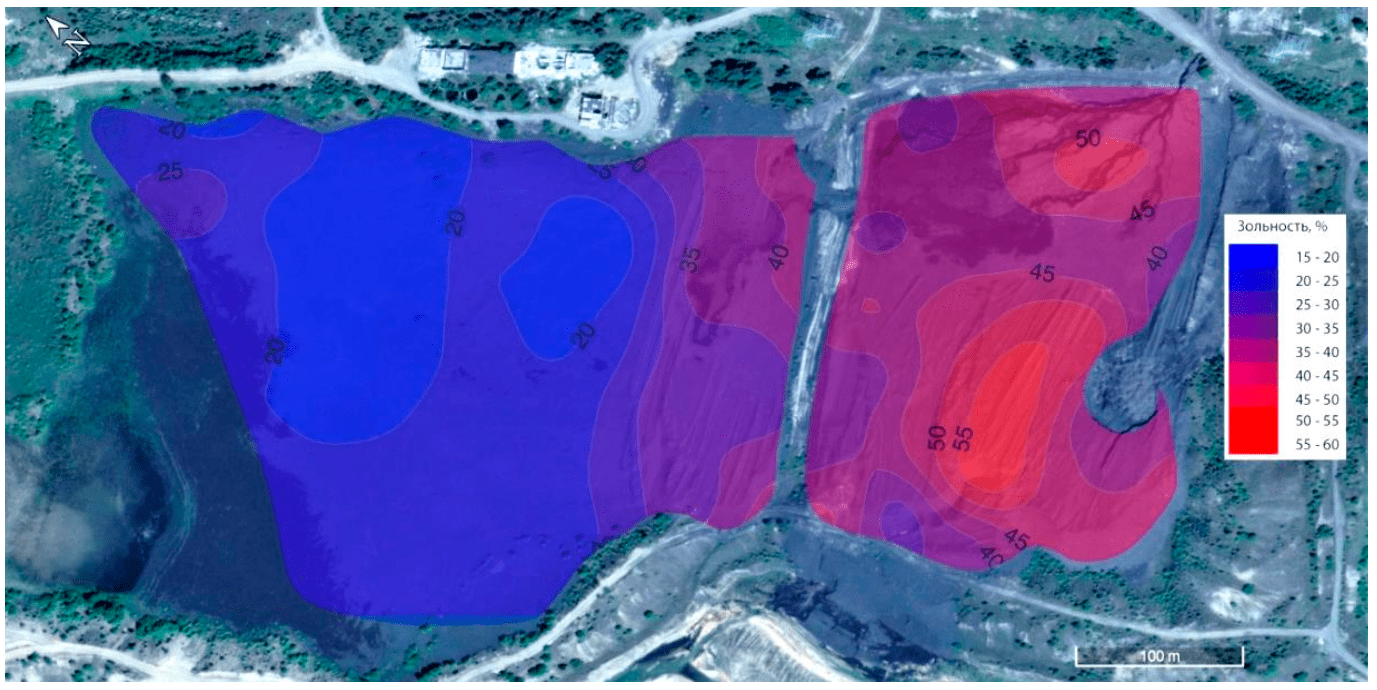

The results of the determination of the ash content of ASW in an absolutely dry state for each point sample were processed using the Surfer software (Fig.2).

Fig.2. Spatial distribution of ash content under the absolute dry condition

According to this indicator, the pond is divided into two homogeneous sections. The homogeneous section 1 includes the initial sections 1′ and 2′ with average values of ash content of 39.9 ± 12.8 % and 40.7 ± 11.7 %, respectively. The homogeneous section 2 includes the initial sections 3′ and 4′ with an average ash content of 28.9 ± 3.2 % and 21.6 ± 3.8 %, respectively. Further studies of ASW were carried out for combined samples of homogeneous sites 1 (sample 1) and 2 (sample 2).

According to the results of X-ray phase analysis, samples 1 and 2 are identical. Quartz is the main crystalline phase, calcite, mullite, augite, and hematite are found in small amounts.

The fuel characteristics are presented in Table 1. The total content of the elements in the mineral part of ASW, as well as the number of their mobile and water-soluble forms in terms of an absolutely dry state are presented in Table 2.

Table 1

The main fuel characteristics of ASW under the absolute dry condition

|

Characteristic |

Sample 1 |

Sample 2 |

|

Mass fraction, % moisture |

5.72 |

7.54 |

|

sulfur |

0.15 |

0.24 |

|

carbon |

52.0 |

63.3 |

|

hydrogen |

1.67 |

1.41 |

|

nitrogen |

0.49 |

0.59 |

|

oxygen |

4.9 |

11.0 |

|

Ash content |

40.8 |

23.6 |

|

Highest specific heat of combustion, MJ/kg |

17.9 |

24.9 |

|

Lowest specific heat of combustion, MJ/kg |

17.4 |

24.4 |

|

Volatile output, % |

16.2 |

18.5 |

Table 2

Total content and content of mobile and water-soluble forms of elements in the mineral phase of ASW, mg/kg

|

Element |

Sample 1 |

Sample 2 |

MPC (TPC) for the total content* |

||||

|

Mode of occurrence |

Mode of occurrence |

||||||

|

Total |

Mobile |

Water soluble |

Total |

Mobile |

Water soluble |

||

|

Al |

40390 |

293 |

0.93 |

23694 |

312 |

1.5 |

n/s |

|

Ca |

17462 |

9917 |

80 |

11092 |

7673 |

75 |

n/s |

|

Mg |

4239 |

657 |

44 |

2476 |

551 |

34 |

n/s |

|

Ti |

2105 |

2.1 |

0.10 |

1640 |

2.3 |

0.14 |

n/s |

|

Fe |

21338 |

283 |

0.65 |

12815 |

256 |

0.88 |

n/s |

|

Na |

1200 |

50 |

5.2 |

873 |

48 |

4.8 |

n/s |

|

K |

665 |

15 |

1.5 |

335 |

12 |

1.1 |

n/s |

|

As |

8.7 |

1.8 |

0.21 |

4.6 |

5.3 |

1.4 |

5.0 |

|

Cd |

2.0 |

0.42 |

0.046 |

1.4 |

0.31 |

0.032 |

0.5 |

|

Co |

32 |

1.1 |

0.10 |

87 |

0.68 |

0.075 |

n/s |

|

Cr |

15 |

0.21 |

≤ 0.005 |

12 |

0.12 |

0.009 |

0.05 |

|

Cu |

15 |

0.35 |

≤ 0.005 |

12 |

0.26 |

≤ 0.005 |

33 |

|

Ni |

13 |

0.29 |

≤ 0.03 |

8.9 |

0.14 |

≤ 0.03 |

20 |

|

Pb |

≤ 0.8 |

≤ 0.8 |

≤ 0.8 |

≤ 0.8 |

≤ 0.8 |

≤ 0.8 |

32 |

|

Zn |

6.6 |

1.1 |

≤ 0.03 |

4.4 |

0.70 |

≤ 0.03 |

55 |

|

Sr |

206 |

31 |

0.81 |

125 |

28 |

0.70 |

n/s |

|

Ba |

358 |

34 |

0.19 |

225 |

36 |

0.16 |

n/s |

|

P |

369 |

25 |

0.44 |

240 |

30 |

0.60 |

n/s |

|

Mn |

286 |

30 |

0.053 |

145 |

21 |

0.047 |

1500 |

|

Si |

114800 |

– |

– |

56900 |

– |

– |

n/s |

|

Hg |

0.086 |

≤ 0.011 |

≤ 0.011 |

0.044 |

≤ 0.011 |

≤ 0.011 |

2.1 |

* The values of Maximum Permissible Concentrations (MPC) and Tentative Permissible Concentrations (TPC) are given in accordance with SanPiN 1.2.3685-21 Hygienic standards and requirements for ensuring the safety and (or) harmlessness to humans of environmental factors for sandy and sandy loam soils; n/s – the indicator is not standardized.

Table 3

Basic physico-chemical and mechanical characteristics of ASW

|

Characteristic |

Site 1 |

Site 2 |

|

Sediment on a 0.08×0.08 mm |

88.6 |

80.8 |

|

Loss on ignition, % |

60.0 |

76.5 |

|

Full water absorption, % |

61.5 |

149.2 |

|

Bulk density, kg/m3 |

679 |

405 |

|

Filtration coefficient, m/day |

4.52 |

7.53 |

|

pH of salt extract (KCl) |

8.18 |

7.99 |

|

Neutralizing ability, % |

0.24 |

0.21 |

As a result of calculations carried out on the basis of the obtained data on the ASW composition (Tables 1, 2), the environmental hazard degree of samples 1 and 2 is 3.3 and 1.8, respectively (K ≤ 10), therefore, the waste is “practically non-hazardous” (hazard class V). According to the biotesting results, samples 1 and 2 are “low-hazar-dous” (hazard class IV) for both test objects used.

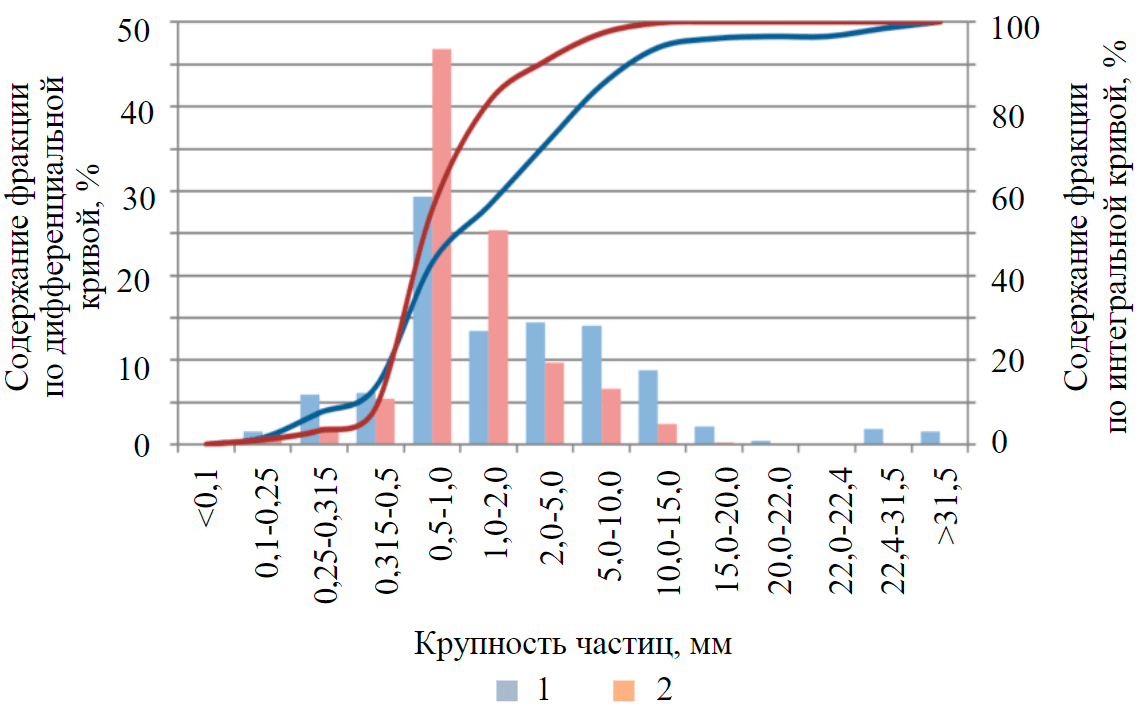

The humic acid content was 1.45 and 0.1 % by weight, for samples 1 and 2, respectively. The phy-sico-chemical and mechanical properties of ASW are presented in Table 3, as well as in graphical form in Fig.3.

Discussion

To select and substantiate the method of ASW disposal, each of the listed options was considered, taking into account the results of laboratory studies.

Road construction

According to the main document regulating the possibility of ASW application in road construction, according to the loss on ignition values (Table 3), the studied samples belong to waste with a high content of combustible substances, which makes it impossible to use them in road surfaces. In addition, the IV hazard class determines the need for special measures when using ASW in the road industry.

Building materials

To assess the possibility of using the waste under study as a component of concrete, a state standard was used, according to which the bulk density of ASW for light concrete should be over 1,200 kg/m3; in the studied samples, it is significantly lower (Table 3). Loss on ignition for both samples (Table 3) is well beyond the permissible level of 25 %. The high content of combustible substances also limits the use of the studied waste in the composition of cement. According to the state standard regulating the production of artificial porous aggregates, the studied samples do not meet the requirements for the contents of aluminum, iron, titanium oxides, total sodium and potassium, as well as for the remainder of unburned fuel.

Reclamation of disturbed lands

The content of nutrients in waste (nitrogen, phosphorus, potassium, sulfur, calcium, and magnesium) is low, therefore, from a biological point of view, ash slags are “sterile” materials (Tables 1, 2). The low content of humic acids in ASW indicates the almost complete absence of organic substances available to plants. Thus, it is difficult to consider the studied waste as a source of nutritional components for plants.

Low neutralizing ability of the studied samples (Table 3) does not allow the use of ASW for periodic and supportive liming of acidic soils as a substitute for traditionally used lime materials.

Fig.3. Differential and integral curves of waste size of samples from sites 1 and 2

By the value of the filtration coefficient and water absorption (Table 3), sample 1 corresponds to permeable soils, and sample 2 corresponds to highly permeable soils (GOST 25100-2020 “Soils. Classification”). Both studied samples contain a large number of mesoaggregates (0.25-10 mm), 83.4 and 96.12 % in samples 1 and 2, respectively (Fig.3), which means that the application of ASW can improve the structure and water-physical properties of the soil [12]. However, their use as an ameliorant is limited due to the excess of the Tentative Permissible Concentrations for arsenic and cadmium (Table 2) related to elements of hazard class I.

Inert fillers

By the chemical composition (Table 2), ASW are inert materials characterized by a high content of silicon and aluminum oxides and a low content of calcium and magnesium oxides. According to GOST 25100-2020, such waste can serve as aggregates of mine workings, levelers of planar elements, and formers of barriers between structural elements of the quarry, as well as neutralizers of other aggregates.

When carrying out reclamation works with the use of ASW, it is necessary to assess the risks of their negative environmental impact. The potential danger of the studied ASW is associated with the presence of mobile forms of major and trace elements in their composition, including heavy metals (see Table 2). When they get into surface waters, they can be a source of increased concentrations of pollutants in reservoirs, accumulate in soils, flora, and fauna [26, 27].

Thus, the utilization of the studied ASW by traditional methods has a number of limitations, primarily related to the high content of combustible substances and the presence of a significant amount of ecotoxicants. On the other hand, the high content of combustible substances and the high specific heat of combustion with relatively low ash content allow us to talk about the possibility of using ash as fuel, which is limited by the low content of volatile components and high content of low-reactive non-volatile carbon (see Table 1). Therefore, it seems very promising to burn them as part of fuel suspensions after the injection of a mixture of additives with a high content of volatile components (organic waste, spent motor oils, etc.).

Organic coal-water suspensions

Studies of coal-water [28, 29] and organic coal-water [30, 31] suspensions, including those obtained from low-grade carbon-containing raw materials, allow us to conclude that there are high prospects for the utilization of ash and slag waste as a component of organic coal-water fuel compositions [32-34]. With a carbon content of more than 50 % (Table 1), waste can become the basis of a suspension fuel with calorific characteristics similar to the coal currently used in the boiler house.

According to [30, 34, 35], the combustion of fuel suspensions is most effective when the size of the dispersion phase is less than 150 μm and the content of solid particles in the suspension makes up 50-70 % by mass. To raise the content of volatile components in fuel suspensions and, consequently, to reduce their ignition temperature, raise the specific heat of combustion and reduce the share of unburned carbon, additives of oil refining waste are injected with the 5-50 % share of the total solid component mass in the fuel suspension [32-34].

Based on this, the following characteristics of the preparation of organic coal-water suspensions based on the studied ASW were selected for preliminary tests: grinding fineness < 150 µm, 40 % water content in suspension, and the 15 % content of used mineral oil. Spent engine oil is formed in significant volumes during the activities of the enterprise (133 tons/year); it significantly improves the energy characteristics of the suspension fuel due to the high specific heat of combustion (45.8 MJ/kg), low ignition temperature (226 °С) and a high content of volatile components.

In order to confirm the possibility of utilization of the studied ASW as part of organic coal-water suspensions, tests were carried out on a flare burning stand. As a result of a number of experiments, it was possible to achieve stable combustion of the torch of the sprayed suspension with a temperature in the active combustion zone of 1200-1300 °C at an excess air coefficient of 2.5. The working heat of combustion of the resulting fuel was more than 13 MJ/kg. This value allows the use of the resulting fuel by boiler units installed at the enterprise. Mechanical underburning was less than 5 %, and the content of ecotoxicants decreased to standard values, so ash is suitable for disposal in construction as a component of concrete and porous aggregates.

Conclusion

The need to dispose of the waste is dictated by economic considerations and environmental protection requirements. Ash and slag dumps pollute the air and water basins, change the chemical and mineral composition of soils. Dusting of dumps negatively affects the health of people and the productivity of agricultural land. The replacement of natural raw materials with ASW contributes to the protection of the subsoil, and the elimination of ash and slag dumps has a positive effect on the environmental situation.

In the course of the conducted research in laboratory conditions, the composition and basic properties of the boiler rooms of the heat supply workshop of the Polyus Aldan JSC were determined. Their utilization by traditional methods, such as using as a material for reclamation/amelioration of disturbed lands, inert material during the construction/operation of engineering structures, and a component of building materials has limitations associated mainly with a high content of combustible substances (unburned fuel residues) and the presence of ecotoxicants. Utilization of the studied ASW in the composition of organic coal-water suspensions is the most promising way. An assessment of the efficiency of transferring one boiler unit of Polyus Aldan JSC to the combustion of organic coal-water suspensions showed that the use of ASW in the annual balance of energy production in the amount of 8-20 % will give an economic effect of more than 9 million rubles by reducing the cost of purchasing coal and maintaining the ash pond. At the same time, the technogenic load on the environment will gradually decrease.

Thus, further studies of technologies for the preparation and combustion modes of suspension fuel based on ASW are very promising. Separate surveys are required for the layout of the facilities preparing organic coal-water suspensions, taking into account the territorial conditions and the possibility of placing installations near the boiler room or ash storage.

References

- Shulginov N., Kucherov Y., Fedorov Y. National regulation and standards development for Russian power system operation and control. International ETG Congress; Die Energiewende – Blueprints for the new energy age, 17-18 November 2015, Bonn, Germany. N 7388537.

- Sarapulova G.I. Environmental Geochemical Assessment of Technogenic Soils. Journal of Mining Institute. 2018. Vol. 234, p. 658-662. DOI: 10.25515/PMI.2018.6.658

- Bykova M.V., Alekseenko A.V., Pashkevich M.A., Drebenstedt C. Thermal desorption treatment of petroleum hydrocarbon-contaminated soils of Tundra, Taiga, and forest steppe landscapes. Environmental Geochemistry and Health. 2021. Vol. 43, p. 2331-2346. DOI: 10.1007/s10653-020-00802-0

- Ivanov A.V., Smirnov Yu.D., Chupin S.A. Development of the concept of an innovative laboratory installation for the study of dust-forming surfaces. Journal of Mining Institute. 2021. Vol. 251, p. 757-766. DOI: 10.31897/PMI.2021.5.15

- Kharko P., Matveeva V. Bottom Sediments in a River under Acid and Alkaline Wastewater Discharge. Ecological Engineering & Environmental Technology. 2021. Vol. 22, p. 35-41. DOI: 10.12912/27197050/134870

- Sorokin A.P., Avdeiko G.P., Alekseev A.V. et al. The strategy of the development of fuel and energy potential i the Russian Far East economic region up to 2020. Vladivostok: Dalnauka, 2001, p. 15-23. (in Russian).

- Smolii V.A., Kosarev A.S., Yatsenko E.A., Goltsman B.M. Physical and chemical features of the production of cellular glass materials based on cullet and ash and slag wastes of thermal power engineering. Izvestiya vysshikh uchebnykh zavedenii. Severo-Kavkazskii region. Tekhnicheskie nauki. 2018. N 3, p. 112-118. DOI: 10.17213/0321-2653-2018-3-112-118

- Ibrahim N.M., Ismail K.N., Chea Mat R., Peng P.J. Effect of pre-treated incineration bottom ash as sand replacement material to compressive strength of foamed concrete. AIP Conference Proceedings. 2018. Vol. 2030. N 020203. DOI: 10.1063/1.5066844

- Kairakbaev A.K., Abdrakhimov V.Z., Abdrakhimova E.S. The use of ash material of East Kazakhstan in the production of porous aggregate on the basis of liquid-glass composition. Ugol. 2019. N 1, p. 70-73. DOI: 10.18796/0041-5790-2019-1-70-73

- Khalyushev A.K., Prudnikov V.V., Stelmakh S.A. et al. Estimation of efficiency of mineral additives combination in the fine-grained concrete. Vestnik yevraziyskoy nauki. 2017. Vol. 9. N 5, p. 25-34 (in Russian).

- Kazmina O.V., Kuznetsova N.A., Vereshchagin V.I., Kazmin V.P. Obtaining foam glass materials based on ash and slag waste from thermal power plants. Izvestiya Tomskogo politekhnicheskogo universiteta. Inzhiniring georesursov. 2011. Vol. 319 (3), p. 52-56 (in Russian).

- Grebenshchikova Е.А., Yust N.A., Pykhteeva M.A. Тhe influence of chemical melioration on physical and chemical properties of the soil by introduction of ash waste. The Bulletin of KrasGAU. 2016. N 6, p. 3-8 (in Russian).

- Shabarov A.N., Nikolaeva N.V. Complex utilization of treatment wastes from thermal power plants. Journal of Mining Institute. 2016. Vol. 220, p. 607-610. DOI: 10.18454/PMI.2016.4.607

- Vit C., Matej L., Jindrich M., Drochytka R. Influence of type of secondary raw material on consistency of fresh mixture for AAC production. Materials Science Forum. 2020. Vol. 998, p. 305-310. DOI: 10.4028/www.scientific.net/MSF.998.305

- Hsu S.,Chi M., Huang R. Influence of fly ash fineness and high replacement ratios on concrete properties. Journal of Marine Science and Technology. 2019. Vol. 27 (2), p. 161-169. DOI: 10.6119/JMST.201904_27(2).0009

- Kurama H., Topcu I.B., Karakurt C. Properties of the autoclaved aerated concrete produced from coal bottom ash. Journal of materials processing technology. 2009. Vol. 209, p. 767-773. DOI: 10.1016/j.jmatprotec.2008.02.044

- Qiao X.C., Ng B.R., Tyrer M. et al. Production of lightweight concrete using incinerator bottom ash. Construction and Building Materials. 2008. Vol. 22, p. 473-480. DOI: 10.1016/j.conbuildmat.2006.11.013

- Bazhin V.Yu. Changes in thermal plasticity of low grade coals during selective extraction of metals. Journal of Mining Institute. 2016. Vol. 220, p. 578-581. DOI: 10.18454/PMI.2016.4.578

- Ovchinnikov R.V. The Modified Slags of Thermal Power Plants an Effective Component of the Mixed Knitting. Izvestiya vysshikh uchebnykh zavedeniy. Severo-Kavkazskiy region. Tekhnicheskiye nauki. 2013. N 2, p. 70-74 (in Russian).

- Borowski G., Smirnov Y., Ivanov A., Danilov A. Effectiveness of carboxymethyl cellulose solutions for dust suppression in the mining industry. International Journal of Coal Preparation and Utilization. 2020. DOI: 10.1080/19392699.2020.1841177

- Bocharov V.L., Kramarev P.N., Strogonova L.N. Geoecological aspects of the forecast of environmental changes in the areas of dumpsites for the disposal of ash and slag waste from power plants. Vestnik Voronezhskogo gosudarstvennogo universiteta. Seriya: geologiya. 2005. N 1, p. 233-239 (in Russian).

- Gendler S.G., Fazylov I.R. Methods of regulation air temperature in the Russian oil mains. Topical Issues of Rational Use of Natural Resources. St. Petersburg, 2020, p. 16-21.

- Marinin M.A., Dolzhikov V.V., Isheyskiy V.A. Improving the efficiency of drilling and blasting operations for high water cut conditions // Key Engineering Materials. 2020. 836. P. 124–130. DOI: 10.4028/www.scientific.net/KEM.836.124

- Ogunro V.O., Inyang H.I., Hooper F. et al. Control of Bottom Ash Aggregate in Superpave Bituminous Mixes. Journal of Materials in Civil Engineering. 2004. Vol. 16, p. 604-613. DOI: 10.1061/(ASCE)0899-1561(2004)16:6(604)

- Kim B., Prezzi M., Salgado R. Geotechnical Properties of Fly and Bottom Ash Mixtures for Use in Highway Embankments. Journal of Geotechnical and Geoenvironmental Engineering. 2005. Vol. 131, p. 914-924. DOI: 10.1061/(ASCE)1090-0241(2005)131:7(914)

- Matveeva V.A., Isakov A.E., Sverchkov I.P. The reduction of negative impact on environment in the area of coal processing enterprises. Innovation-Based Development of the Mineral Resources Sector: Challenges and Prospects. 11th Conference of the Russian-German Raw Materials 2018. 2019. Vol. 1, p. 431-436.

- Chukaeva M., Zaytseva T., Matveeva V., Sverchkov I. Purification of Oil-Contaminated Wastewater with a Modified Natural Adsorbent. Ecological Engineering & Environmental Technology. 2021. Vol. 22(2), p. 46-51. DOI: 10.12912/27197050/133331

- Glushkov D.O., Lyrshchikov S.Y., Shevyrev S.A., Strizhak P.A. Burning Properties of Slurry Based on Coal and Oil Processing Waste. Energy Fuels. 2016. Vol. 30. N 4, p. 3441-3450. DOI: 10.1021/acs.energyfuels.5b02881

- Li J., Zhang X., Yang W., Blasiak W. Effects of Flue Gas Internal Recirculation on NOx and SOx Emissions in a Co-Firing Boiler. International Journal of Clean Coal and Energy. 2013. Vol. 2. N 2, p. 13-21. DOI: 10.4236/ijcce.2013.22002

- Murko V.I., Senchurova Yu.A., Fedyaev V.I., Karpenok V.I. Research on the technology of combustion of suspension coal fuel in a vortex chamber. Vestnik Kuzbasskogo gosudarstvennogo tekhnicheskogo universiteta. 2013. N 2, p. 103-105 (in Russian).

- Nyashina G.S. Study of ways to reduce the impact of thermal power plants on the environment when burning suspension fuels from coal waste and biomass: Avtoref. dis. … kand. tekhn. nauk. Tomsk: Natsionalnyi issledovatelskii Tomskii politekhnicheskii universitet, 2018, p. 22 (in Russian).

- Dmitrienko M.A., Nyashina G.S., Strizhak P.A. Environmental indicators of the combustion of prospective coal water slurry containing petrochemicals. Journal of Hazardous Materials. 2017. Vol. 338, p. 148-159. DOI: 10.1016/j.jhazmat.2017.05.031

- Park J.-H., Lee Y.-J., Jin M.-H. et. al. Enhancement of slurryability and heating value of coal water slurry (CWS) by torrefaction treatment of low rank coal (LRC). Fuel. 2017. Vol. 203, p. 607-617. DOI: 10.1016/j.fuel.2017.03.016

- Xue Z., Gong Y., Guo Q. et al. Visualization study on breakup modes of coal water slurry in an impinging entrained-flow gasifier. Fuel. 2019. Vol. 244, p. 40-47. DOI: 10.1016/j.fuel.2019.01.186

- Еrmakova L.А., Mochalov S.P., Kalashnikov S.N., Permyakov А.А. Mechanism of coal-water fuel drops combustion in the swirl burner of an automated energy generating complex. Vestnik Kemerovskogo gosudarstvennogo universiteta. 2012. Vol. 2. N 4(52), p.164-169 (in Russian).

References

- Shulginov N., Kucherov Y., Fedorov Y. National regulation and standards development for Russian power system operation and control. International ETG Congress; Die Energiewende – Blueprints for the new energy age, 17-18 November 2015, Bonn, Germany. N 7388537.

- Sarapulova G.I. Environmental Geochemical Assessment of Technogenic Soils. Journal of Mining Institute. 2018. Vol. 234, p. 658-662. DOI:10.25515/PMI.2018.6.658

- Bykova M.V., Alekseenko A.V., Pashkevich M.A., Drebenstedt C. Thermal desorption treatment of petroleum hydrocarbon-contaminated soils of Tundra, Taiga, and forest steppe landscapes. Environmental Geochemistry and Health. 2021. Vol. 43, p. 2331-2346. DOI: 10.1007/s10653-020-00802-0

- Ivanov A.V., Smirnov Yu.D., Chupin S.A. Development of the concept of an innovative laboratory installation for the study of dust-forming surfaces. Journal of Mining Institute. 2021. Vol. 251, p. 757-766. DOI: 10.31897/PMI.2021.5.15

- Kharko P., Matveeva V. Bottom Sediments in a River under Acid and Alkaline Wastewater Discharge. Ecological Engineering & Environmental Technology. 2021. Vol. 22, p. 35-41. DOI: 10.12912/27197050/134870

- Sorokin A.P., Avdeiko G.P., Alekseev A.V. et al. The strategy of the development of fuel and energy potential i the Russian Far East economic region up to 2020. Vladivostok: Dalnauka, 2001, p. 15-23. (in Russian).

- Smolii V.A., Kosarev A.S., Yatsenko E.A., Goltsman B.M. Physical and chemical features of the production of cellular glass materials based on cullet and ash and slag wastes of thermal power engineering. Izvestiya vysshikh uchebnykh zavedenii. Severo-Kavkazskii region. Tekhnicheskie nauki. 2018. N 3, p. 112-118. DOI: 10.17213/0321-2653-2018-3-112-118

- Ibrahim N.M., Ismail K.N., Chea Mat R., Peng P.J. Effect of pre-treated incineration bottom ash as sand replacement material to compressive strength of foamed concrete. AIP Conference Proceedings. 2018. Vol. 2030. N 020203. DOI: 10.1063/1.5066844

- Kairakbaev A.K., Abdrakhimov V.Z., Abdrakhimova E.S. The use of ash material of East Kazakhstan in the production of porous aggregate on the basis of liquid-glass composition. Ugol. 2019. N 1, p. 70-73. DOI: 10.18796/0041-5790-2019-1-70-73

- Khalyushev A.K., Prudnikov V.V., Stelmakh S.A. et al. Estimation of efficiency of mineral additives combination in the fine-grained concrete. Vestnik yevraziyskoy nauki. 2017. Vol. 9. N 5, p. 25-34 (in Russian).

- Kazmina O.V., Kuznetsova N.A., Vereshchagin V.I., Kazmin V.P. Obtaining foam glass materials based on ash and slag waste from thermal power plants. Izvestiya Tomskogo politekhnicheskogo universiteta. Inzhiniring georesursov. 2011. Vol. 319 (3), p. 52-56 (in Russian).

- Grebenshchikova Е.А., Yust N.A., Pykhteeva M.A. Тhe influence of chemical melioration on physical and chemical properties of the soil by introduction of ash waste. The Bulletin of KrasGAU. 2016. N 6, p. 3-8 (in Russian).

- Shabarov A.N., Nikolaeva N.V. Complex utilization of treatment wastes from thermal power plants. Journal of Mining Institute. 2016. Vol. 220, p. 607-610. DOI 10.18454/PMI.2016.4.607

- Vit C., Matej L., Jindrich M., Drochytka R. Influence of type of secondary raw material on consistency of fresh mixture for AAC production. Materials Science Forum. 2020. Vol. 998, p. 305-310. DOI:10.4028/www.scientific.net/MSF.998.305

- Hsu S., Chi M., Huang R. Influence of fly ash fineness and high replacement ratios on concrete properties. Journal of Marine Science and Technology. 2019. Vol. 27 (2), p. 161-169. DOI: 10.6119/JMST.201904_27(2).0009

- Kurama H., Topcu I.B., Karakurt C. Properties of the autoclaved aerated concrete produced from coal bottom ash. Journal of materials processing technology. 2009. Vol. 209, p. 767-773. DOI: 10.1016/j.jmatprotec.2008.02.044

- Qiao X.C., Ng B.R., Tyrer M. et al. Production of lightweight concrete using incinerator bottom ash. Construction and Building Materials. 2008. Vol. 22, p. 473-480. DOI: 10.1016/j.conbuildmat.2006.11.013

- Bazhin V.Yu. Changes in thermal plasticity of low grade coals during selective extraction of metals. Journal of Mining Institute. 2016. Vol. 220, p. 578-581. DOI 10.18454/PMI.2016.4.578

- Ovchinnikov R.V. The Modified Slags of Thermal Power Plants an Effective Component of the Mixed Knitting. Izvestiya vysshikh uchebnykh zavedeniy. Severo-Kavkazskiy region. Tekhnicheskiye nauki. 2013. N 2, p. 70-74 (in Russian).

- Borowski G., Smirnov Y., Ivanov A., Danilov A. Effectiveness of carboxymethyl cellulose solutions for dust suppression in the mining industry. International Journal of Coal Preparation and Utilization. 2020. DOI:10.1080/19392699.2020.1841177

- Bocharov V.L., Kramarev P.N., Strogonova L.N. Geoecological aspects of the forecast of environmental changes in the areas of dumpsites for the disposal of ash and slag waste from power plants. Vestnik Voronezhskogo gosudarstvennogo universiteta. Seriya: geologiya. 2005. N 1, p. 233-239 (in Russian).

- Gendler S.G., Fazylov I.R. Methods of regulation air temperature in the Russian oil mains. Topical Issues of Rational Use of Natural Resources. St. Petersburg, 2020, p. 16-21.

- Marinin M.A., Dolzhikov V.V., Isheyskiy V.A. Improving the efficiency of drilling and blasting operations for high water cut conditions. Journal of Mining Science. 2019. 55(5), p. 783-788. DOI: 10.4028/www.scientific.net/KEM.836.124

- Ogunro V.O., Inyang H.I., Hooper F. et al. Control of Bottom Ash Aggregate in Superpave Bituminous Mixes. Journal of Materials in Civil Engineering. 2004. Vol. 16, p. 604-613. DOI: 10.1061/(ASCE)0899-1561(2004)16:6(604)

- Kim B., Prezzi M., Salgado R. Geotechnical Properties of Fly and Bottom Ash Mixtures for Use in Highway Embankments. Journal of Geotechnical and Geoenvironmental Engineering. 2005. Vol. 131, p. 914-924. DOI: 10.1061/(ASCE)1090-0241(2005)131:7(914)

- Matveeva V.A., Isakov A.E., Sverchkov I.P. The reduction of negative impact on environment in the area of coal processing enterprises. Innovation-Based Development of the Mineral Resources Sector: Challenges and Prospects. 11th Conference of the Russian-German Raw Materials 2018. 2019. Vol. 1, p. 431-436.

- Chukaeva M., Zaytseva T., Matveeva V., Sverchkov I. Purification of Oil-Contaminated Wastewater with a Modified Natural Adsorbent. Ecological Engineering & Environmental Technology. 2021. Vol. 22(2), p. 46-51. DOI: 10.12912/27197050/133331

- Glushkov D.O., Lyrshchikov S.Y., Shevyrev S.A., Strizhak P.A. Burning Properties of Slurry Based on Coal and Oil Processing Waste. Energy Fuels. 2016. Vol. 30. N 4, p. 3441-3450. DOI: 10.1021/acs.energyfuels.5b02881

- Li J., Zhang X., Yang W., Blasiak W. Effects of Flue Gas Internal Recirculation on NOx and SOx Emissions in a Co-Firing Boiler. International Journal of Clean Coal and Energy. 2013. Vol. 2. N 2, p. 13-21. DOI: 10.4236/ijcce.2013.22002

- Murko V.I., Senchurova Yu.A., Fedyaev V.I., Karpenok V.I. Research on the technology of combustion of suspension coal fuel in a vortex chamber. Vestnik Kuzbasskogo gosudarstvennogo tekhnicheskogo universiteta. 2013. N 2, p. 103-105 (in Russian).

- Nyashina G.S. Study of ways to reduce the impact of thermal power plants on the environment when burning suspension fuels from coal waste and biomass: Avtoref. dis. … kand. tekhn. nauk. Tomsk: Natsionalnyi issledovatelskii Tomskii politekhnicheskii universitet, 2018, p. 22 (in Russian).

- Dmitrienko M.A., Nyashina G.S., Strizhak P.A. Environmental indicators of the combustion of prospective coal water slurry containing petrochemicals. Journal of Hazardous Materials. 2017. Vol. 338, p. 148-159. DOI: 10.1016/j.jhazmat.2017.05.031

- Park J.-H., Lee Y.-J., Jin M.-H. et. al. Enhancement of slurryability and heating value of coal water slurry (CWS) by torrefaction treatment of low rank coal (LRC). Fuel. 2017. Vol. 203, p. 607-617. DOI: 10.1016/j.fuel.2017.03.016

- Xue Z., Gong Y., Guo Q. et al. Visualization study on breakup modes of coal water slurry in an impinging entrained-flow gasifier. Fuel. 2019. Vol. 244, p. 40-47. DOI: 10.1016/j.fuel.2019.01.186

- Еrmakova L.А., Mochalov S.P., Kalashnikov S.N., Permyakov А.А. Mechanism of coal-water fuel drops combustion in the swirl burner of an automated energy generating complex. Vestnik Kemerovskogo gosudarstvennogo universiteta. 2012. Vol. 2. N 4(52), p.164-169 (in Russian).