Modeling the acid treatment of a polymictic reservoir

Abstract

Acid treatment of wells program is directly related to oil production efficiency. Investigations aimed at improving the efficiency of acid treatment in a terrigenous reservoir have mainly reviewed the changing and adapting the reagents to minimize bridging caused by acid-rock interaction. Under real conditions, application of new and unique acid compositions is a complex process from an organizational point of view and is therefore not widely used as compared with conventional compositions based on a mixture of hydrochloric and hydrofluoric acids. The paper is based on an approach to improve acid treatment efficiency through optimal design based on near-bottomhole zone treatment simulation. The aspects for practical application of the developed acid treatment simulator for terrigenous reservoirs based on a numerical model of hydrodynamic, physical and chemical processes in a porous medium on an unstructured PEBI-grid are described. The basic uncertainties of the model are identified and analyzed. Influence of empirical parameters within the system of equations on the calculation results and modeling of the mineralogical composition of rocks are considered. Algorithm for static modelling of near-bottomhole zone for acid treatment modelling is described, as well as an approach to optimizing the design of near-bottomhole zone treatment based on adapting the results of rock tests in the model. Using experimental data, the necessity of accounting for influence of secondary and tertiary reactions on the results of modeling physical and chemical processes during acid treatment of terrigenous reservoirs was proved. The distinctive features of West Siberian objects (polymictic reservoirs) with respect to the efficiency of near-bottomhole zone treatment with clay acid have been investigated. Series of calculations to determine the optimum volume of acid injection has been carried out. Experience of previously conducted measures under the considered conditions has been analyzed and recommendations to improve the efficiency of acid treatment have been given.

Introduction

Near-bottomhole zone treatment (NBHZT) is one of the most widely used production enhancement methods because of its high cost-effectiveness. The main NBHZT technique is acid injection into the near-bottomhole zone (NBHZ) in order to improve well productivity (increase injectivity for injection wells). The efficiency of acid treatments (AT) at the fields confined to terrigenous reservoirs is in the range of 50-75 %. The efficiency of NBHZT program can be enhanced by improving the whole process chain: selecting candidate wells, determining the cause of productivity decline and type of bridging agent, selecting the optimal acid composition (AC), designing the NBHZT, controlling the quality of NBHZT operations.

The fundamentals of AC are described by V.A.Amiyan and in work [2]. Ways of increasing the AC efficiency, including those for terrigenous reservoir conditions, are described in detail in [2, 41]. The improvement of NBHZT efficiency is a combination of measures, including determination of the causes for productivity decrease, selection of optimum AC composition and design. Share of NBHZT as a method in the field development strategy is justified in [19, 20].

Most of the modern works devoted to the improvement of the AT efficiency in terrigenous reservoirs are based on the development of the optimal AC for the object in question (formation) [14-17, 26, 31]. The mineralogical composition, thermobaric conditions, probable bridging agent, secondary and tertiary reactions [36], external factors of the active part transportation into the formation are taken into account. Researchers modify AC and combine NBHZT with other flow stimulation and recovery enhancement methods in [11, 23, 34]. Example of the integrated program for certain oilfields is described in [7, 8, 18]. Investigations have been conducted on the AT design as part of an overall development program [4-6].

Little attention has been paid to reaction kinetics under AC filtration conditions in porous media, which depends on bridging agent and mineral distribution, permeability and porosity properties (PPP) and bottomhole geometry. Although the direction of modeling of AT in carbonate reservoirs with bridging agent [3, 10, 37] and horizontal completion geometry is quite relevant [27, 28], a separate attention should be paid to the works, which describe the developed simulator of AT in carbonate reservoirs [1, 9, 12].

The specifics of AT modeling in terrigenous reservoirs are the large number of reactions due to the complexity of the mineralogical composition, and the dissolution rate of different minerals varies greatly. The products of primary reactions also interact with the rock (secondary and tertiary reactions), which affects the dissolution of the rock as a whole and leads to the formation of sediments that bridge the pore space of the rock [40]. The investigations take into account these problems in order to improve AC [13, 15, 22, 24], but there are also other organizational problems, which do not allow the application of unique technologies and compositions in the fields. In particular, this is evident from the statistics given in the article [39], which shows that in most cases West Siberian fields use clay acid (a mixture of hydrochloric and hydrofluoric acids) with the addition of enriching additives. In this situation, one of the available solutions to increase the efficiency of NBHZT is the calculation and justification of the optimal mode of injecting the acid into the formation, the sequence and volume of the reagents to be injected.

The aim of the work is to improve the efficiency of the NBHZT in a polymictic reservoir.

Most of West Siberia development objects are confined to reservoirs with lower ratios of quartz to feldspars, clays and mica, hence the term “polymictic reservoir” is used instead of the more common “terrigenous reservoir”.

The main idea is to achieve the set goal by means of detailed integrated mathematical simulation of objects and processes occurring during acid injection into a polymictic reservoir. This improves the accuracy of predicted NBHZT results, allowing increased well productivity by solving the optimization problem in relation to the rate and volume of reagents injected into the formation.

Methodology

Improving AT efficiency in terrigenous reservoir conditions is a set of measures aimed at improving the efficiency of the NBHZT program in Western Siberia [39], which includes:

- development of candidate well selection algorithms based on productivity dynamics analysis;

- clarification of the causes for the decline in well productivity, the object of impact (bridging agent), calculation of the share of a particular process in the overall decline in productivity, modelling of the distribution of the decline in PPP and the share of bridging agent;

- selection and development of AC (reagents and enriching additives) based on the influenced object, provided that it is compatible with the formation fluid and reservoir rock;

- improving the efficiency of treatment design (selection of volume, sequencing and injection modes at individual stages);

- improving and controlling the quality of reagents and treatment at the well site;

- analysis of the effectiveness for the treatments carried out and being implemented.

In practice, it is common to check AC in two stages: physical and chemical (passport compliance, thermal stability, compatibility and solubility) and filtration investigations. In most cases, the restoration coefficient is checked on a prepared rock sample without modelling the permeability reduction conditions, i.e. checking the solubility of the rock in the NBHZ. Occasionally, flow experiments on rock sample show high efficiency on unbridged rock sample, indicating the potential for such compositions to improve well productivity (not just to restore it).

Selection of candidate wells and reasons of productivity reduction are described in [4, 21, 24, 25, 29]. The main conclusion is that the algorithms for identification and calculation of complications affecting the productivity of wells, based on which, among other things, candidate selection is carried out, are individual for each field and are the subject of research for a particular object of development.

The main focus is on AT modelling. Improvement in the NBHZT efficiency through detailed modelling has the greatest potential to improve the efficiency of the NBHZT program.

Criteria for the West Siberian specifics were formulated for the AT model, and based on these criteria the software package “Terrigenous Reservoir Acid Treatment Simulator” was developed. Taking into account the formulated criteria, the analysis of existing solutions was carried out [39]. The history of development for terrigenous reservoir AT simulation is described in sufficient detail in [38]. Foreign authors mainly publish articles, which use the geochemical approach to NBHZT modeling. They are devoted to the problems of reservoir heterogeneity [37], NBHZT in shale gas fields [29, 35] and AT in mature fields [32].

Based on the geochemical approach [30] and taking into account the criteria developed in relation to the specifics of West Siberia, a model [33] was developed that allows calculating the hydrodynamic, physical and chemical processes in a porous medium. Physical and chemical processes include reactions between two phases (acid and rock) and components of one phase. The model [33] is three-phase (oil with dissolved gas, water, rock) with multiple components for solid and aqueous phases. Any number of components can be involved in one reaction, and an arbitrary number of aqueous and solid components can be formed as a result. The model is implemented as a software package based on solving the system of equations numerically implicitly on an unstructured Voronoi grid (PEBI). Spatial discretization of the equations is carried out using the method of control volumes.

Let the liquid consist of Naq components, and the rock consist of Nm minerals. Molar concentrations (kg∙mol/m3) of liquid components are denoted by $C_i=\overline{1,N_{aq}}$, and shares of minerals in the rock by $V_i=\overline{1,N_{m}}$.

It is assumed that the acid effect is considered in some three-dimensional computational domain Ω. Mathematically the model is described by laws of conservation for mass of aqueous components, oil, minerals in computational domain Ω and by normalization relations connecting saturations and pressures of phases and porosity with shares of minerals in the rock.

where Ci – molar concentration of the component (aqueous or solid phase (mineral)), $C_i=\frac{N_m}V$; Nm – the number of moles of the mineral in the volume of rock under consideration; V, Vm – molar volume of the mineral, $V_m=\frac{MW}{\mathrmρ_{m}}$; MW – molar mass of mineral; ρm – mineral density; φ, φ0 – porosity and initial porosity; Ir,aq – homogeneous reaction rate in the aqueous phase; Ir,s – heterogeneous reaction rate; Nr,aq , Nr,s – number of homogeneous and heterogeneous reactions; ρα – phase densities; k(φ) – absolute permeability; krα – relative phase permeabilities; μα(pα) – viscosities of water and oil; ρα(pα) – densities of water and oil; рα – phase pressures; рc(Sw) – capillary pressure; Sα – phase saturation; $\overrightarrow{g}$ – gravity vector; MWi – molar masses of aqueous components.

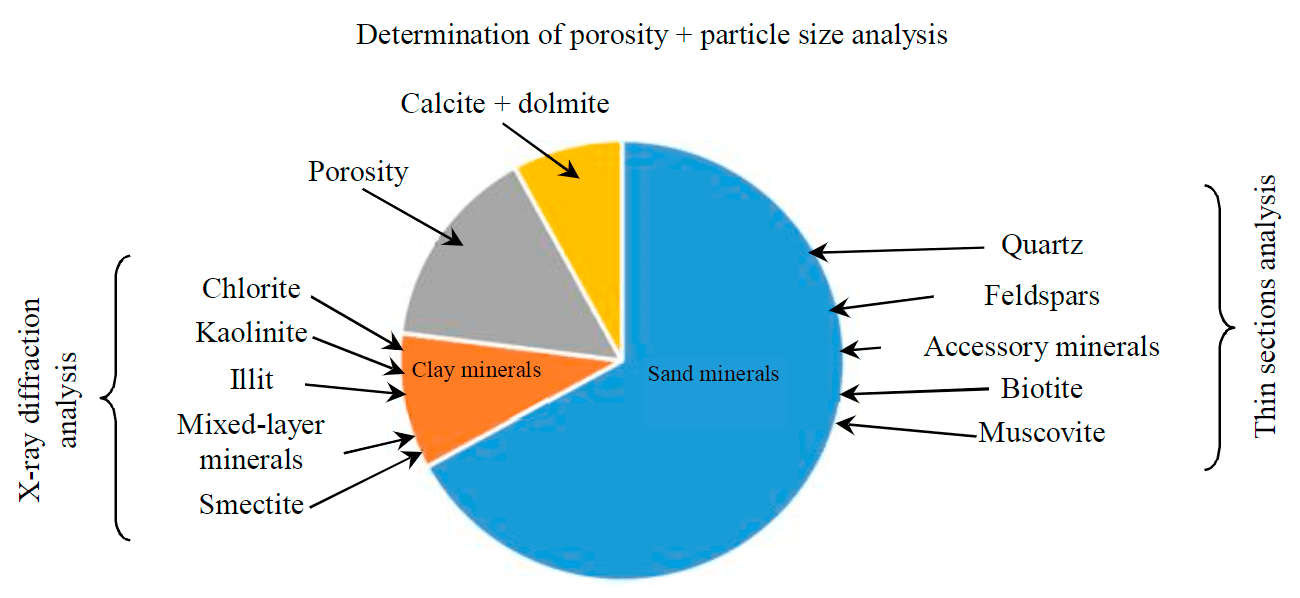

Fig.1. Scheme of using standard investigations to determine the mineralogical composition of rocks during AT modeling

The unknowns in the equation system are the molar concentrations of the aqueous components $C_i=\overline{1,N_{aq}}$, shares of minerals $V_i,i=\overline{1,N_m}$, phase saturation Sα, α=o,w, phase saturation pα=o,w, porosity φ, total of Naq+Nm+ five unknowns. The boundary conditions in the acid effect problem are the flows of aqueous components from the well, and a given pressure on the drainage circuit.

Static modelling algorithms are also required as input data. As an initial data, in addition to empirical coefficients for equations and closing relationships, a static model describing the NBHZ geometry, distribution of PPP and mineralogical composition, is needed.

Without the use of additional laboratory investigations, it is possible, on the basis of standard experiments carried out as part of the geological concept and model construction, to obtain the most of the necessary initial information.

- Information on the mineralogical composition of the rock, relative rock shares and porosity (Fig.1). The ratio of sandstones, clays and carbonates can be found based on particle size analysis. The shares of quartz, feldspars and mica belong to the fractions with a particle diameter of more than 0.1 mm, the rest are clays. The sum of fractions by particles size is equal to one, because it does not take into account the carbonate component, the results of which are shown in the report on particle size distribution (solubility in HCl). The ratio of quartz, feldspar and mica can be found in the thin sections analysis report. A detailed clay composition can be obtained from the X-ray diffraction analysis of the clay component of the rocks.

- The vertical distribution of PPP can be obtained from the results of geophysical survey interpretation (RGSI).

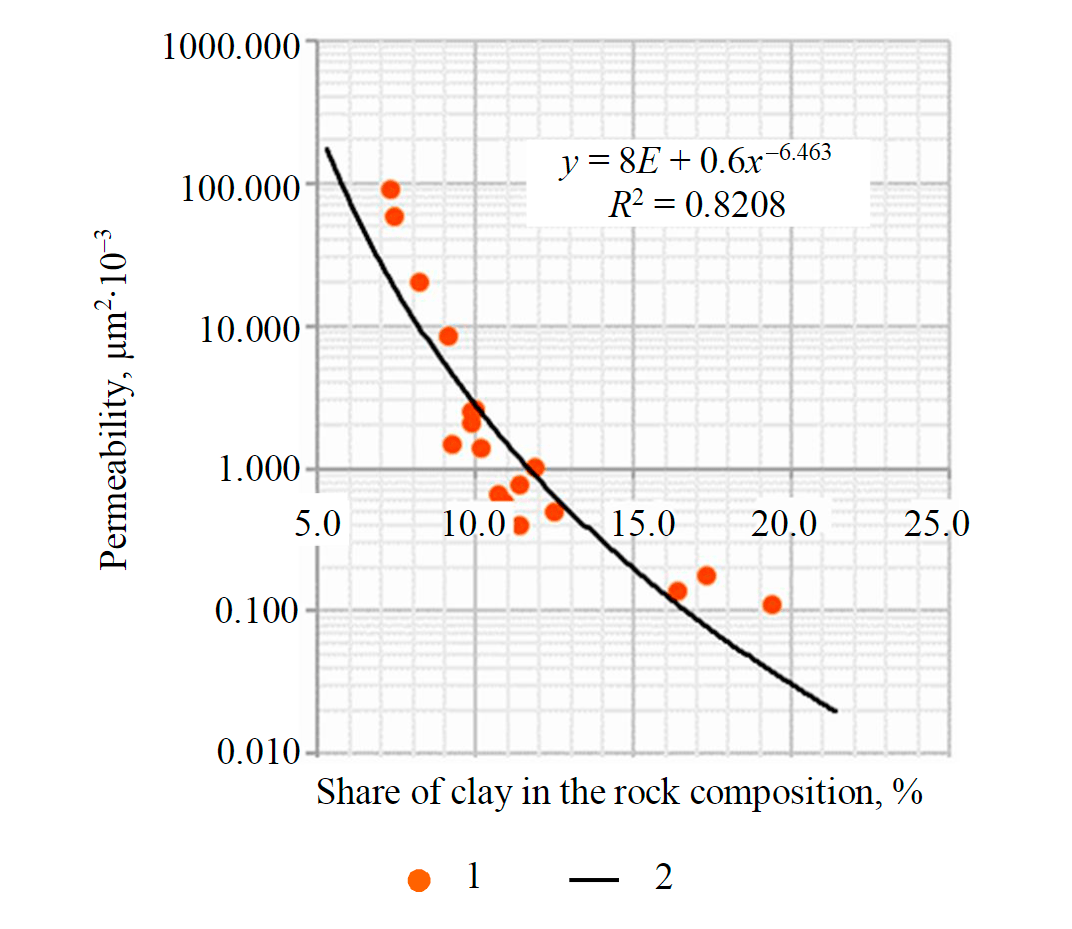

- Based on comparison of rock samples composition and RGSI sampling points, the dependence of permeability on clay content (Fig.2) and vertical distribution of clay minerals, quartz and feldspars ratios are plotted. This is important first of all because of widely observed tendency of fast reacting minerals content to affect PPP during acid injection (as per modeling results of injecting 10 rock sample volumes, the difference in resulting permeability between the sample with quartz to feldspar ratio of 2 and 1.5 is within 100-300 % depending on initial PPP).

Fig.2. Dependence of permeability on the share of clay content in the rock 1 – results of sample investigations; 2 – general trend

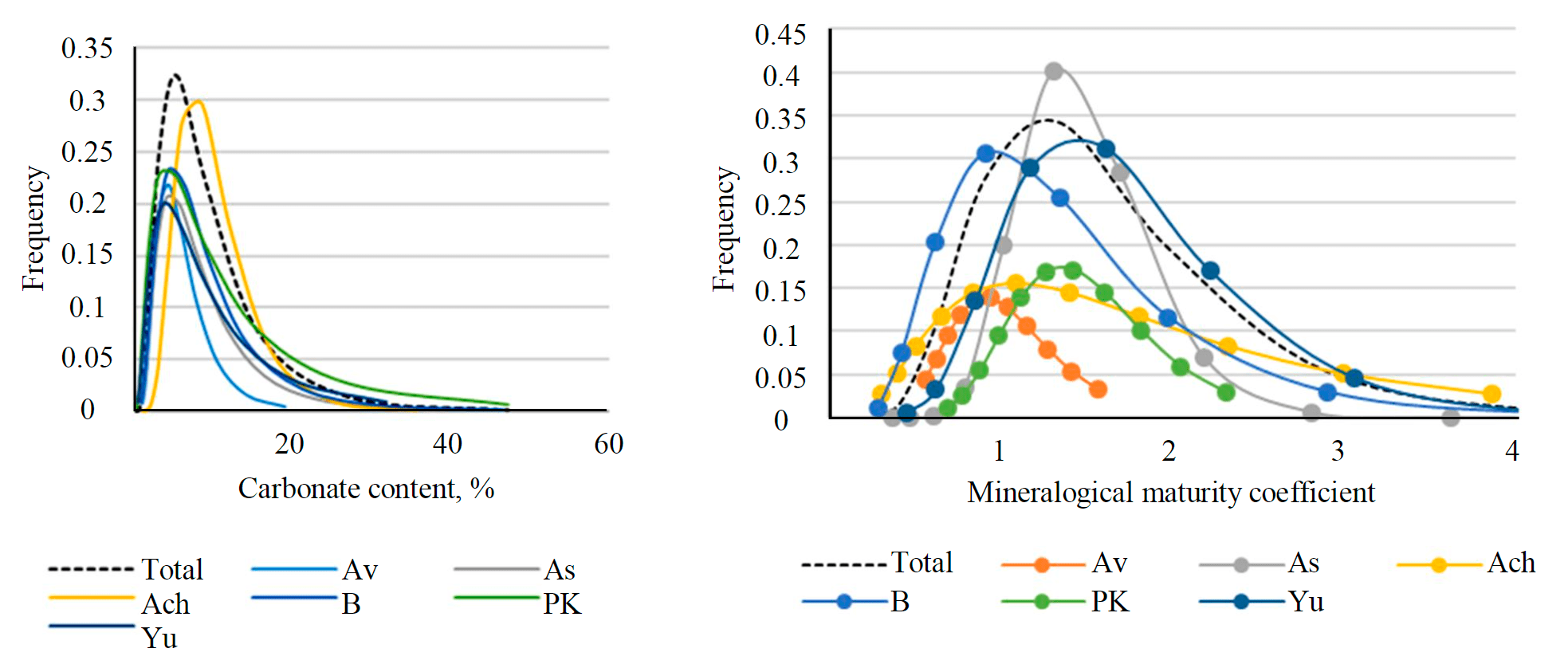

Mineralogical composition of rocks in West Siberia has been analyzed (Fig.3). The sample consists of the investigation results for 2243 rock samples distributed over oil-and-gas bearing formations and grouped into stratigraphic groups, according to which development objects are distinguished. Mineralogical maturity is the ratio of quartz to feldspar in the rock. For comparison, the Berea sandstone samples used as analogues for most of the earlier investigations are characterized by a calcite content of 0-3 %, and quartz to feldspar ratio ranging from eight times or more.

The most popular reagent for NBHZT in Western Siberia remains a mixture of HCl and HF, primarily because of organizational aspects: storage, use, turnover, etc. In [12, 30, 41] the main reactions occurring when injecting a mixture of HCl and HF into a terrigenous reservoir are described:

- reaction with quartz

- reaction with albite (feldspar)

- reaction with clays (kaolinite)

- reaction with mica (muscovite)

- reactions with calcite

Fig.3. Distribution of carbonate component and quartz and feldspar ratios by group of West Siberian deposits. Av, As, Ach, B, PK and Yu – stratigraphic groups of formations in accordance with the names of development objects for West Siberian fields

As part of the primary reactions, H2SiF6 is formed, which initiates secondary reactions with the rock (using albite as an example) to form silica gel H2SiO3

The secondary reactions and the consumption of HF produce AlF2, which together with hydrochloric acid leads to tertiary reactions with the formation of silica gel H2SiO3 (using albite as an example)

The reactions described show that the secondary and tertiary reactions of minerals with H2SiF6 and AlF2 affect the volumes of consumed hydrofluoric acid and the precipitated products of the acid reaction with the rock. In this case, the density of the precipitates has a major influence on increasing or decreasing the pore space of the rock and, consequently, its permeability.

In order to assess the impact of accounting for secondary and tertiary reactions, a series of computational experiments were carried out with gradual inclusion of additional reactions in the model (table). Secondary reactions occur during formation of reactants within primary reaction, hence, they occur later than primary reactions, which does not mean that primary reactions stop flowing (i.e. under certain conditions and reagent adequacy, primary, secondary and tertiary reactions can occur simultaneously at a certain point). The calculations used a model of vertical well, drilling-in the oil-saturated reservoir with permeability 10∙10–3 μm2 and average mineralogical composition for Western Siberia (quartz 46 %, feldspars 30 %, calcite 5 %, the rest – clays and mica). Two temperature regimes – 60 and 83 °С – were set. Other parameters were taken based on real well treatment: bottomhole geometry (directional, drilling-in single formation), oil saturation, porosity, drainage area size, formation pressure, flow rate and wellhead pressure dynamics during AC injection.

Results of computational experiments to study the effect of accounting for secondary and tertiary reactions in a terrigenous reservoir in the AT model [39]

|

Reactions |

The ratio of the well productivity after the NBHZT and the well productivity before the NBHZT (multiplicity of productivity increase) |

|

|

Without regard to temperature |

With regard to increased temperature |

|

|

Primary |

1,16 |

1,17 |

|

Secondary |

1,00 |

1,13 |

|

Tertiary |

0,57 |

1,12 |

The results of computational experiments series presented in the table indicate a high degree of consideration for temperature and completeness of reproducible physical and chemical processes, when modelling AT in polymictic and terrigenous reservoirs. This indicates an advantage of the geochemical approach over simplified analytical models and the NBHZT volumetric design approach (calculating volumes based on well geometry, optimum treatment radius and reservoir porosity). Also, the results show that without considering all the reactions or the temperature factor, there is a risk of decreasing the productivity of the well after AT, which has been confirmed by laboratory investigations [39].

Discussion

Discussion. The efficiency improvement algorithm based on modeling is presented as a step-by-step solution to an optimization problem based on laboratory and numerical experiments.

- Adapt the model to the results of AC physical and chemical investigations and rock sample experiments to find unknown empirical coefficients.

- Construct NBHZ model based on the algorithm of static model creation.

- Carry out series of calculations based on the AT model with varying volumes and injection rates.

- Determine the optimum parameters for the NBHZT.

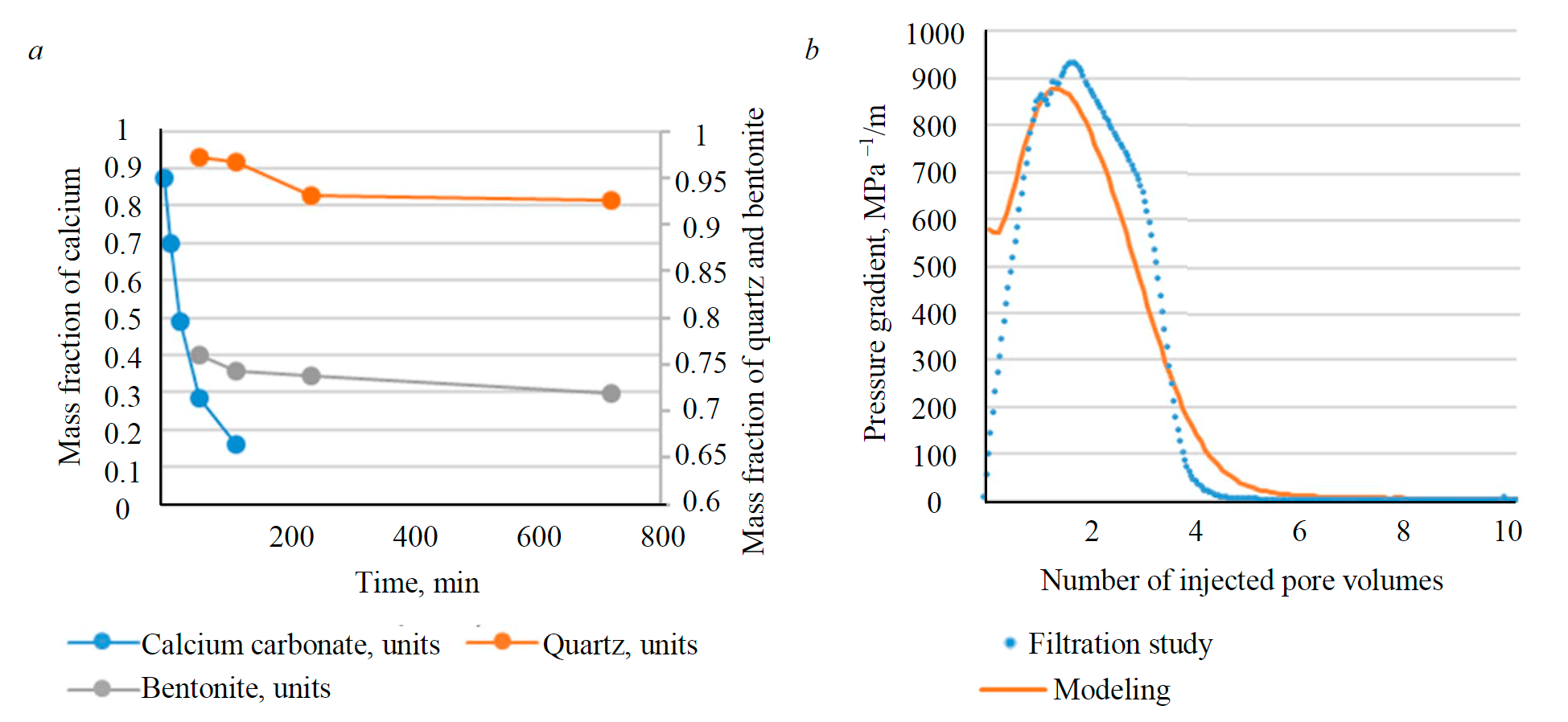

Fig.4. Results for dissolution of main minerals in AC at 90 С (a), filtration study and adaptation of model calculation (b)

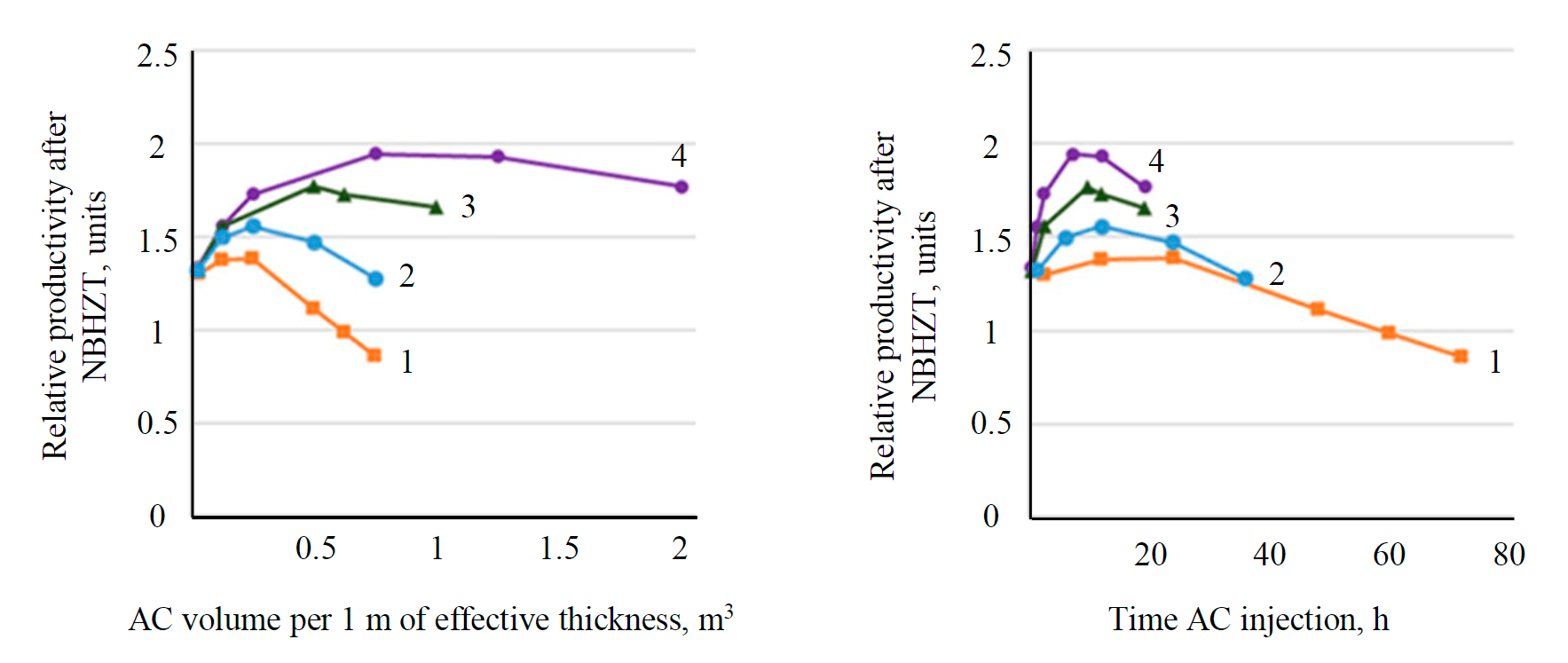

Fig.5. Simulation results of NBHZT using a selected AC with varying volume and injection rate AC flow rate at the wellhead, m3/min: 1 – 0.0007; 2 – 0.0014; 3 – 0.0035; 4 – 0.007

Physical and chemical investigations to determine solubility, thermal stability and corrosion activity of model minerals (Fig.4, a) were carried out using a standard AC based on a mixture of 12 % HCl solution and 3 % HF solution. Reaction rate coefficients for quartz and bentonite were obtained on the basis of investigations by adjusting model to actual study data. Based on model tuning to filtration study results (a similar method was implemented by Zhang [35]), an empirical coefficient for dependence of permeability change on porosity change and reaction surface area was obtained.

Series of calculations with varying parameters of volume, injected AC and injection rate were performed to solve the optimization problem for AT design. NBHZ model of the candidate well was developed in accordance with the algorithm for combining petrophysical investigations of rock samples (see Figs.1 and 2). The mineralogical composition was assumed to be similar to the sample used in the filtration study. Model bridging agent – bentonite (smectite) 20 % of pore volume at distance of a meter from borehole bottom.

The results for series of computational experiments are shown in Fig.5. Calculations show that for vertical and directional wells there are optimum points for varying the volume of injected acid composition. The optimum point of injected AC volume corresponds to the inflection point of increase in productivity as a function of AC volume. For each injection mode (controlled by flow rate value at the wellhead), the optimal injection volume can be traced. As the rate of acid injection increases, the optimal volume value also rises, thus increasing productivity gain potential of the well (Fig.6)

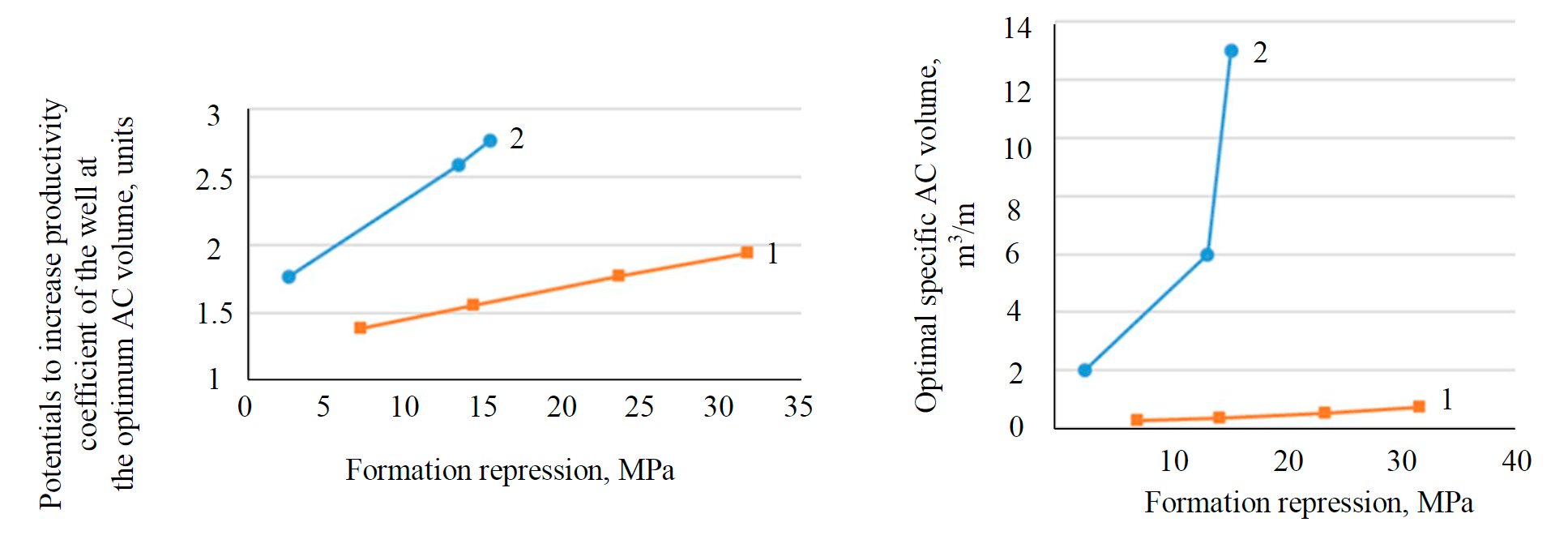

Fig.6. Dependencies of optimum AC volume during NBHZT on formation repression value during injection for different PPP of the formation NBHZ permeability, µm2∙10–3: 1 – 0.28; 2 – 10

Similar series of calculations for 10 µm2∙10–3 reservoir permeability was carried out to identify trends in changing the initial permeability parameter. According to the results of the experiments (Fig.6), it can be concluded that with the increase of permeability, the potential for rising the productivity of the well increases manifold. Primarily, it is associated with the increase of injectivity and maximum AC filtration rate in the NBHZ. Decrease of productivity with increasing AC volume after the optimum point is first of all connected with acid residence time in the rock. Thus, in the course of computational experiments, the hypothesis of maximizing the effect when injecting acid into the formation at the maximum permissible flow rate was substantiated and confirmed.

In order to assess the potential of the algorithm for designing AT in polymictic reservoirs, developed within the framework of the study, the volumes of acid injected during NBHZT at a group of Western Siberian fields have been investigated. The results of statistical analysis show that average specific volume of AC injected into formation is within 0.29-0.78 m3 per 1m of productive thickness of the reservoir for directional wells without hydraulic fracturing. For the average permeability of NBHZ is 25 µm2∙10–3 at the analyzed sampling, if the described algorithm of NBHZT design on the base of modeling is used, then the average AT efficiency improvement will be 48-54 % of the current values where efficiency means increase of well productivity after AT.

To assess the potential, a comparative analysis for determining the optimum NBHZT mode and AC volumes for the well model with averaged NBHZ properties vertically and the multilayer model with consideration of RGSI and identified petrophysical dependencies was also performed. According to results of calculations for each option, value of optimum for model with averaged properties differs by 15 % from value of injection optimum for model with consideration of PPP heterogeneity. Thus, NBHZT modeling with detailed consideration of NBHZ characteristics potentially increases efficiency in terms of well productivity ratio before and after NBHZT by 17-26 %

Conclusion

- The necessity of taking into account secondary and tertiary reactions when modeling AT of polymictic reservoirs based on theoretical study and statistical research has been proved. Full consideration of all reactions increases the accuracy of AT modeling and calculation of NBHZT efficiency depending on the design.

- An algorithm for the NBHZT design based on AT modeling has been developed.

- A way of combining rock sample investigations with data from sedimentation analysis and acid-rock sample reaction analysis to improve the predictive ability of the terrigenous reservoir AT model is proposed.

- The approach, which includes finding empirical coefficients for the model based on adaptation to the results of filtration investigations, has been tested. Adaptation implies reproducing the dynamics of the indicators measured in the course of the rock sample experiment based on numerical modeling of the experiment and by selecting empirical coefficients of the mathematical model.

- The performed series of computational experiments allowed preparing the recommendations for the AC design of polymictic reservoirs in Western Siberia. For various relationships of mineralogical composition, PPP and AT properties, there are dependencies with optimal values for specific volume of reagent injected into formation.

- On the basis of these calculations, it is shown that improved modeling accuracy can improve the accuracy of determining optimum NBHZT parameters and the efficiency of the AT in a polymictic reservoir.

- The AT model has been tested by replicating several NBHZT at real objects at West Siberian fields. Investigations are analytical in nature. The recommendations and algorithm are closely related to the results of laboratory research, which are applied within the framework of the pilot works program. With regard to their results, the actual effectiveness of the formulated recommendations will be analyzed based on the developed optimization algorithm.

References

- Bulgakova G.T., Baizigitova A.V., Sharifullin A.R. Model of matrix acid treatment for carbonates: the effect of precipitation on the dissolution process. Vestnik Ufimskogo gosudarstvennogo aviatsionnogo tekhnicheskogo universiteta. 2009. Vol. 13. N 2, p. 256-264 (in Russian).

- Glushchenko V.N., Silin M.A. Oilfield chemistry: in 5 volumes. Vol. 4: Acid treatment of wells. Мoscow: Interkontakt Nauka, 2010, p. 704 (in Russian).

- Zhuchkov S.Yu. Modeling acid effect on the bottomhole zone of a horizontal well: Avtoref. dis. … kand. tekhn. nauk. Мoscow: Rossiiskii gosudarstvennyi universitet nefti i gaza imeni I.M.Gubkina, 2013, p. 27 (in Russian).

- Zaitsev M.V. Hydrodynamic analysis of the influence of changes in near-wellbore zones on well performance during field development: Avtoref. dis. … kand. tekhn. nauk. Мoscow: Institut problem nefti i gaza Rossiiskoi akademii nauk, 2007, p. 27 (in Russian).

- Zakirov T.R. Oil formation flooding modeling with regard to acid treatment of reservoir: Avtoref. dis. … kand. fiz.-mat. nauk. Kazan: Institut mekhaniki i mashinostroeniya Kazanskogo nauchnogo tsentra Rossiiskoi akademii nauk, 2013, p. 16 (in Russian).

- Zakirov T.R., Nikiforov A.I. Modeling the acid effect on the near-wellbore zone of an oil formation during waterflooding. Matematicheskoe modelirovanie. 2013. Vol. 25. N 2, p. 53-64 (in Russian).

- Davletshina L.F., Guskova I.A., Garipova L.I., Akhmetshina A.S. An integrated approach to creating a near-bottomhole zone treatment technology for injection wells and evaluating its effectiveness. Neftyanoe khozyaistvo. 2020. N 7, p. 40-42. DOI: 10.24887/0028-2448-2020-7-40-42 (in Russian)

- Lipchinskii K.N. Physical and chemical basis for the creation of modified acid solutions and their filtration in terrigenous rocks (JS2 formation): Avtoref. dis. … kand. khim. nauk. Tyumen: Tyumenskii gosudarstvennyi universitet, 2010, p. 23 (in Russian).

- Bulgakova G.T., Kharisov R.Ya., Sharifullin A.R., Pestrikov A.V. Mathematical modeling and optimisation of hydrochloric acid treatments of wells in carbonate reservoirs. Nauchno-tekhnicheskii vestnik OAO “NK "Rosneft"”. 2014. N 2, p. 22-28 (in Russian).

- Turegeldieva K.A., Zhapbasbaev U.K., Asilbekov B.K., Zolotukhin A.B. Modeling of acid treatment in the well near-bottomhole zone with respect to its deteriorated permeability and porosity properties (part 1). Neftyanoe khozyaistvo. 2016. N 1, p. 48-54 (in Russian).

- Nasibulin I.M. Justification of an acid stimulation technology for carbonate reservoirs based on multifunctional compositions with adjustable reactive ability: Avtoref. dis. … kand. tekhn. nauk. Almetevsk: Natsionalnyi mineralno-syrevoi universitet “Gornyi”, 2013, p. 21 (in Russian).

- Bulgakova G.T., Kharisov R.Ya., Sharifullin A.R., Pestrikov A.V. Optimizing acid treatments of horizontal wells in carbonate reservoirs. Neftyanoe khozyaistvo. 2013. N 6, p. 102-105 (in Russian).

- Mardashov D.V., Podoprigora D.G., Islamov Sh.R., Bondarenko A.V. Patent N 2016108386 RF. Acid composition for near-bottomhole zone treatment of terrigenous reservoirs with increased carbonate content. Publ. 18.04.2017. Bul. N 11 (in Russian).

- Karpunin N.A., Mardashov D.V., Podoprigora D.G. i dr. Selection of an iron-stabilizing additive for acid compositions for the treatment of terrigenous reservoirs. Gazovaya promyshlennost. 2019. N 11 (792), p. 104-108 (in Russian).

- Podoprigora D.G. Substantiation for the acid development of high-temperature, low-permeability terrigenous reservoirs with increased carbonate content: Avtoref. dis. … kand. tekhn. nauk. St. Petersburg: Saint Petersburg Mining University, 2016, p. 22 (in Russian).

- Silin M.A., Magadova L.A., Tolstykh L.I. et al. Field chemistry. Мoscow: Rossiiskii gosudarstvennyi universitet nefti i gaza imeni I.M.Gubkina, 2017, p. 350 (in Russian).

- Podoprigora D.G., Shangaraeva L.A., Usenkov A.V., Ilyushin P.Yu. Development of an acid composition for well near-bottomhole zone treatment under conditions of high formation temperatures. Neftyanoe khozyaistvo. 2016. N 4, p. 122-124 (in Russian).

- Mukhametzyanov T.M., Kolyagin A.G., Segida D.A., Fedorov K.M. Implementing a comprehensive acid treatment program for production wells at a field in Western Siberia. Neftyanoe khozyaistvo. 2010. N 4, p. 24-27 (in Russian).

- Rogachev M.K., Mukhametshin V.V. Control and regulation of the hydrochloric acid treatment of the bottomhole zone based on field-geological data. Journal of Mining Institute. 2018. Vol. 231, p. 275-280. DOI: 10.25515/PMI.2018.3.275 (in Russian).

- Rogachev M.K., Mukhametshin V.V., Kuleshova L.S. Improving the efficiency of using resource base of liquid hydrocarbons in Jurassic deposits of Western Siberia. Journal of Mining Institute. 2019. Vol. 240, p. 711-715. DOI: 10.31897/PMI.2019.6.711 (in Russian).

- Sobin A.M. Regulation of oil field development based on identified fluid filtration patterns in the well near-bottomhole zone: Avtoref. dis. … kand. tekhn. nauk. Ukhta: Ukhtinskii gosudarstvennyi tekhnicheskii universitet, 2015, p. 24 (in Russian).

- Khakimov A.A., Sattarov R.I., Kachurin A.V. Improving the efficiency of acid treatments of wells with chemical methods. Neftyanoe khozyaistvo. 2011. N 10, p. 106-107 (in Russian).

- Khisamiev T.R. Comprehensive technology for improving formation productivity in clayed reservoirs: Avtoref. dis. … kand. tekhn. nauk. Ufa: Ufimskii gosudarstvennyi neftyanoi tekhnicheskii universitet, 2012, p. 24 (in Russian).

- Tsygankov V.A. Development of acid compositions for low-permeability terrigenous reservoirs with increased carbonate content: Avtoref. dis. … kand. tekhn. nauk. Мoscow: Rossiiskii gosudarstvennyi universitet nefti i gaza imeni I.M.Gubkina, 2011, p. 27 (in Russian).

- Chirkov M.V. Damage kinetics for reservoir properties of formation and its influence on performance indices of oil deposit: Avtoref. dis. … kand. tekhn. nauk. Мoscow: Institut problem nefti i gaza Rossiiskoi akademii nauk, 2009, p. 27 (in Russian).

- Shangaraeva L.A., Podoprigora D.G. Investigation of the main parameters of the polymer process fluid and its influence on the reservoir characteristics of polymictic sandstones. Naukovedenie. 2015. Vol. 7. N 3. N 39TVN315. DOI: 10.15862/39TVN315 (in Russian).

- Sharifullin A.R. Mathematical modelling of acid treatments of wells in layered inhomogeneous carbonate reservoirs: Avtoref. dis. … kand. tekhn. nauk. Ufa: Bashkirskii gosudarstvennyi universitet, 2010, p. 24 (in Russian).

- Yakubov R.N. Improvement of polymer-acid well treatment technology for intensifying oil production from watered carbonate formations: Avtoref. dis. … kand. tekhn. nauk. Ufa: Ufimskii gosudarstvennyi neftyanoi tekhnicheskii universitet, 2015, p. 24 (in Russian).

- Jinghong Hu, Hong Liu, Dan Wu, Junjing Zhan. Acidizing flowback optimization for tight sandstone gas reservoirs. Journal of Natural Gas Science and Engineering. 2015. Vol. 24, p. 311-313. DOI: 10.1016/j.jngse.2015.03.042

- Van Hong Leong, Hisham Ben Mahmud, Ming Chiat Law et al. A comparison and assessment of the modelling and simulation of the sandstone matrix acidizing process: A critical methodology study. Journal of Natural Gas Science and Engineering. 2018. Vol. 57, p. 52-67. DOI: 10.1016/j.jngse.2018.06.044

- Khan R.S., Molero N., Enkababian Ph. et al. Addressing Matrix Acidizing Stimulation Challenges in Depleted, High-Temperature, and Acid-Sensitive Sandstone Formations with a High-Performance Acid System. International Petroleum Technology Conference, 23 March – 1 April 2021, Virtual. OnePetro, 2021. N IPTC-21336-MS. DOI: 10.2523/IPTC-21336-MS

- Sau R., Goodrow A., Rockwell M. et al. An integrated software technology based on research and field application for completion, stimulation and fluid placement design in complex wells. Petroleum Technology Conference, 10-12 December 2014, Kuala Lumpur, Malaysia. OnePetro, 2014. N IPTC-17870-MS. DOI: 10.2523/IPTC-17870-MS

- Blonsky A., Mitrushkin D., Kazakov A. Development of Acidizing Simulator for Sandstone Reservoirs. SPE Russian Petroleum Technology Conference, 26-29 October 2020, Virtual. One Petro, 2020. N SPE-94566-MS. DOI: 10.2118/94566-MS

- Civan F. Reservoir Formation Damage Fundamentals, Modeling, Assessment, and Mitigation. Oxford: Elsevier, 2016, p. 1015.

- Xiang Zhou, Shicheng Zhang, Xiong Zhang et al. Core-Scale Experimental and Numerical Investigation on Fluoroboric Acidizing of a Sandstone Reservoir. Energy Technology. 2016. Vol. 4. N 7, p. 870-879. DOI: 10.1002/ente.201600005

- Economides M.J., Nolte G.K. Reservoir stimulation. 3rd edition. Wiley, 2000, p. 856.

- Khormali A., Petrakov D., Farmanzade A. Prediction and inhibition of inorganic salt formation under static and dynamic conditions-effect of pressure, temperature, and mixing ratio. International Journal of Technology. 2016. Vol. 7. N 6, p. 943-951. DOI: 10.14716/ijtech.v7i6.2871

- Li Song-yan, Li Zhao-min, Li Bin-fei. Acid/sandstone reaction modeling for sandstone-matrix acidizing. Journal of China University of Mining and Technology. 2012. Vol. 41. N 2, p. 236-241.

- Maltcev A., Shcherbakov G. The Development of the Trends in Formation Damage Removal Technologies in Sandstone Reservoirs. SPE International Conference and Exhibition on Formation Damage Control, 19-21 February 2020, Lafayette, Louisiana, USA. OnePetro, 2020. N SPE-199321-MS. DOI: 10.2118/199321-MS

- Jianye Mou, Lei Wang, Shicheng Zhang et al. Research on the Effect of Heterogeneities on Sandstone Matrix Acidizing Performance. Geofluids. 2019. Vol. 2019. N 6328909. DOI: 10.1155/2019/6328909

- Syed A.A., Kalfayan L., Montgomery C. Acid Stimulation. SPE Monograph Series VII. 2016. Vol. 26, p. 305.