Development of blocking compositions with a bridging agent for oil well killing in conditions of abnormally low formation pressure and carbonate reservoir rocks

- Ph.D. Head of the Department Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

Abstract

Production well killing before workover operations in late-stage oil and gas-condensate fields can be complicated by abnormally low formation pressure, carbonate type of reservoir rocks, and high gas-oil ratio. These complications lead to the intensive absorption of technological fluids by the formation and gas ingresses, which, in its turn, increases the time of killing wells and putting them on production, reduction of productivity, and additional costs. Therefore, it is crucial to develop a high-performance well-killing composition that would allow improving the efficiency of killing wells in complicated geological, physical, and technological conditions at the expense of reliable overlapping of the perforation interval (or open wellbore) to prevent gas intakes and gas outflow from the formation. To develop blocking compounds, a set of laboratory tests has been carried out, including physical and chemical (determination of density, viscosity, thermal stability, sedimentation stability, etc.) and research of blocking and filtration properties of compositions during simulation of a fractured reservoir. In the course of laboratory tests, the choice of fractional composition and polymer filler concentration was substantiated in the blocking emulsion and polymer compositions to increase the efficiency of their application under the complicated conditions of killing oil wells. As a result of laboratory research and field tests, the emulsion and polymer blocking compositions containing bridging agent (microcalcite) were developed, which increase the oil well killing efficiency by preventing the absorption of technological fluids in the formations and, as a result, preserving its productivity.

Introduction

Oil wells killing before workover operations at fields on a later stage of development, with a carbonate type of reservoir, abnormally low formation pressure (ALFP) and a high gas-oil ratio, is usually accompanied by a number of complications: intensive absorption of process fluids, gas breakthroughs from the formation into well, lowering the liquid level in the well, etc. [21, 25, 36]. These complications lead to an increase in the duration of the well killing and the timing of putting it into operation, a decrease in productivity and additional costs [1, 24, 32].

This can be aggravated by additional technical and technological conditions: two or more productive intervals with different formation pressures, an open and extended horizontal wellbore, wells equipped with bottomhole packers, hydraulic fracturing (HF) and/or massive hydrochloric acid treatments (HCAT), presence of aggressive components (hydrogen sulphide and/or carbon dioxide) in the formation fluid [1, 28, 38].

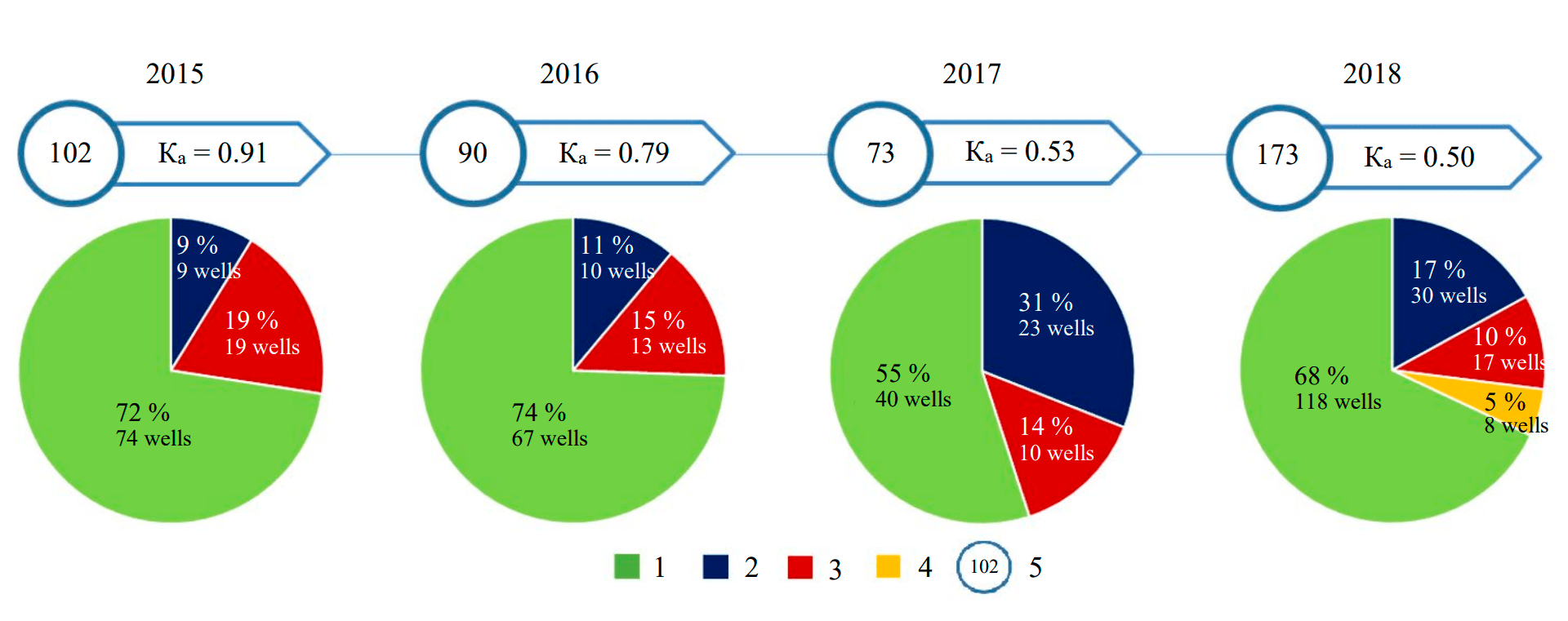

Analysis of killing wells efficiency at the one of the oil, gas and condensate field (OGCF) with carbonate type of reservoir and abnormally low formation pressure (formation pressure is less than hydrostatic pressure by more than 20 %, i.e. anomalous formation pressure coefficient (Ka < 0.8) showed that the killing efficiency (the percentage of wells killed successfully the first time (for 1 cycle) from the total number of killed wells during 2015-2018) makes 70 %.The main reasons for repeated well killing were technical (no possibility to flush the sub-packer zone, significant length of tubing liner under the packer, presence of emergency equipment in the well, changes in well repair conditions, prolonged repair terms, pressing of the blocking pack into the formation, etc.), geological (presence of fault and decompaction zones, intensive absorptions due to earlier production stimulation operations, lack of information on the volume of caverns and fractures of the rock in the near-bottomhole zone, displacement of killing fluids from the well in the presence of overpressure, open and extended horizontal wellbore, incorrect formation pressure at the moment of killing, non-recovered formation pressure after HF, etc.) and organizational factors (Fig.1) [3, 9, 13, 33].

Fig.1. Effectiveness of production wells killing (438 wells) at oil and gas condensate field 1 – killed in one cycle; killed in several cycles due to technical (2), geological (3), organizational (4) factors; 5 – number of wells

Thus, it is important to develop a blocking composition to increase the efficiency of wells killing under complex geological, physical and technological conditions by reliably blocking the perforation interval (or open wellbore) in order to prevent absorption and gas breakthrough from the formation.

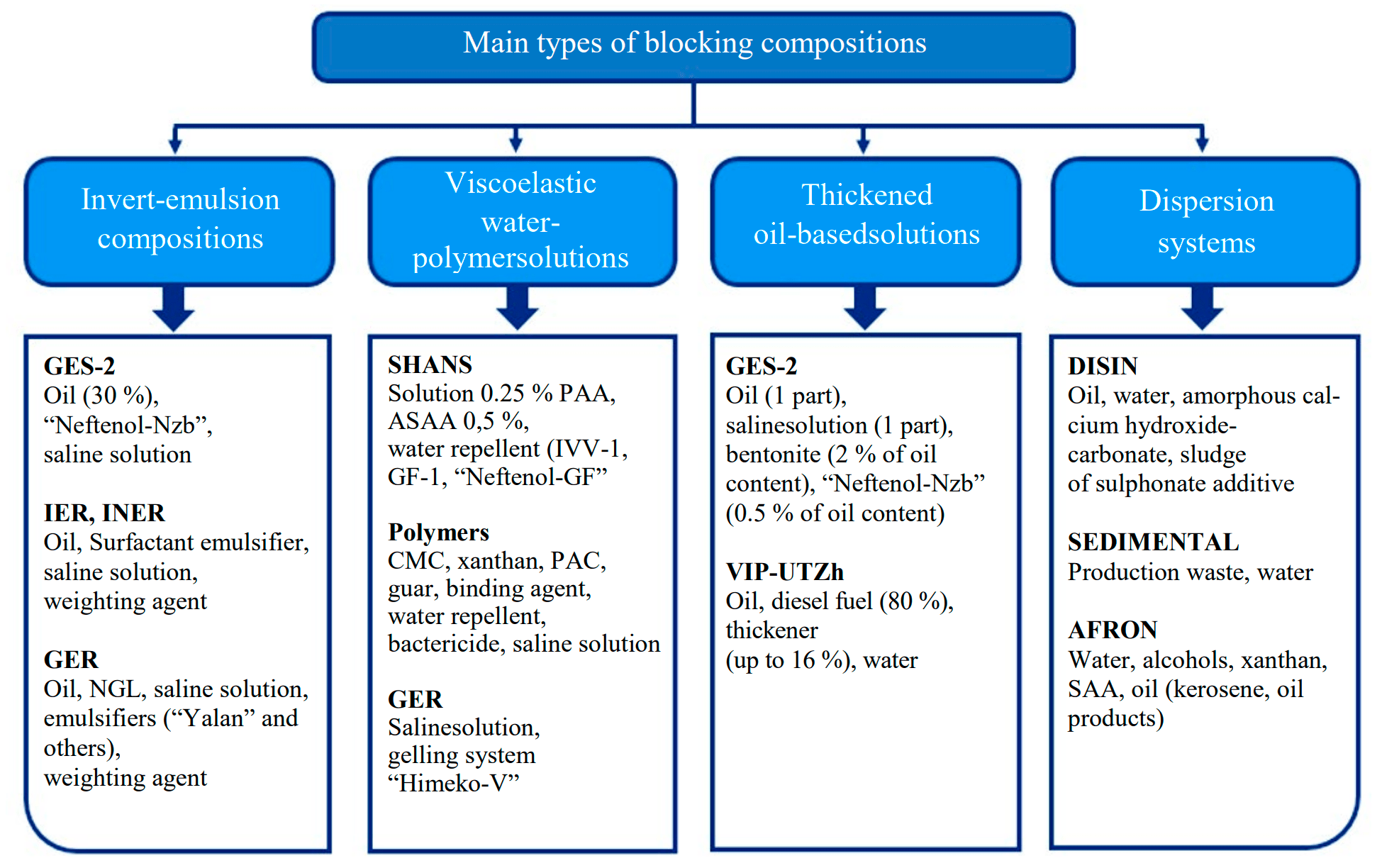

Two main physical principles of decreasing absorption of killing fluid are widely used: increasing the viscosity of the blocking killing fluid (BKF) and bridging the pores and filtration channels with solid particles. These principles are realized in BKF, which are gelled aqueous solutions, emulsions and disperse systems with solid (suspensions) or gas (aphrons) phases (Fig.2) [14, 15, 30, 34]. Ways to increase blocking properties of well killing fluid: increasing the viscosity of BKF, bridging pores (fractures) and filtration channels with solid particles.

The most common types of bridging agents used in the oil and gas industry in various process fluids during well workovers are [6, 11, 29]:

- acid-soluble – dolomite, chalk, siderite, aluminosilicates, iron or calcium hydroxides, magnesium oxide;

- oil-soluble – resins, rubbers, products and wastes of oil refinery;

- water-soluble – salts (calcium, magnesium, potassium, sodium chlorides) and polymers (carboxymethyl cellulose, hydroxyethyl cellulose, polyacrylamide, guar, xanthan, lignin, starch);

- insoluble – paper, soot, clay, bentonite, sawdust, barite, rice and walnut husks, artificial fibres, silica.

Hydrocarbon emulsion systems and viscoelastic water-polymer solutions are among the most frequently used well killing agents [18, 22, 23], their blocking properties can be increased by adding different bridging agents [4, 8, 35]. The most technologically advanced type of bridging agent is calcium carbonate (CaCO3) [5, 10, 27]. It relates to the category of acid-soluble bridging agents and may be removed from the well by hydrochloric acid treatment [7, 8, 26]. However, it should be taken into account that it leads to complication and, consequently, increase in cost for the technological operation of well preparation for the workover [12, 19].

Methodology

Program of laboratory research to develop blocking compositions with improved properties compared to traditionally used invert-emulsion solution (IES) and biopolymer composition (BC) of LLC “Veteran” (Buzuluk) consisted of the following stages:

Fig.2. Main types of blocking compositions for well killing

- determination of the main physical and chemical parameters of the emulsion (or biopolymer) composition with the filler (microcalcite) in comparison with the used IES (or BC): density (GOST 3900-85 “Oil and oil products. Methods for determination of density”); thermal stability; sedimentation stability; dynamic viscosity (GOST 1929-87 “Oil products. Methods for determination of dynamic viscosity in rotational viscometer”); corrosion rate (GOST 9.502-82 “Unified system of corrosion and aging protection. Metal corrosion inhibitors for water systems. Corrosion test methods”); pour point (GOST 20287-91 “Petroleum products. Methods for determination of flow and pour point temperatures”), etc.;

- study of the blocking and filtration properties of blocking compositions in fractured reservoir modelling;

- formulation of recommendations based on a comprehensive analysis of the results for physical, chemical and filtration investigations of blocking compositions to improve the efficiency of production wells killing under the conditions of OGCF with fractured reservoirs, abnormally low formation pressure, intensive absorptions and high gas content (gas-oil ratio more than 200 m3/m3).

The thermal stability of the tested blocking compositions was determined by the following procedure. Prepared composition was placed in a thermostat at 90 °C and incubated for three days. Every 24 hours the condition of the blocking composition and the change in its appearance were visually assessed. Blocking composition was considered unstable if aqueous phase separation, stratification and sedimentation occurred.

The essence of the method for evaluating the sedimentation stability of blocking compositions was to determine the density change by volume (the upper half of the composition compared to the lower half) after thermostatic conditioning

where Сss – sedimentation stability coefficient, %; ρ1 – density of the composition in the upper half of the tube, kg/m3; ρ2 – density of the composition in the lower half of the tube, kg/m3.

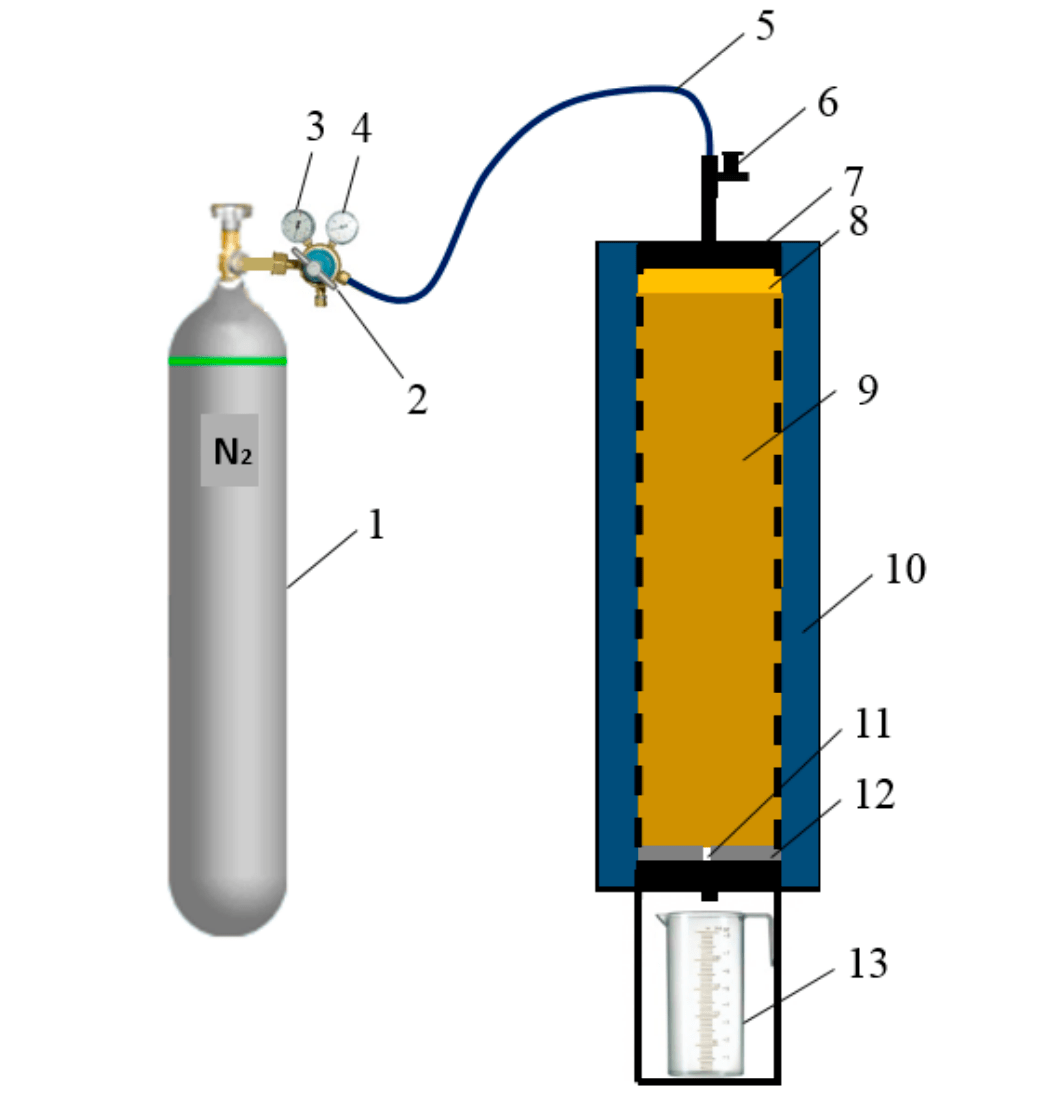

Fig.3. Schematic diagram of a filter press with fracture simulation 1 – nitrogen cylinder; 2 – pressure regulator (reducer); 3 – pressure gauge (cylinder pressure); 4 – pressure gauge (inlet pressure to the filter press); 5 – gas supply line to the filter press; 6 – isolation valve; 7 – cap; 8 – gas space; 9 – investigated blocking pack; 10 – thermocup; 11 – fracture; 12 – metal disc with a crack; 13 – measuring vessel

After incubation of the test composition at 90 °C for three days, the densities of the top and bottom volumes in the test tube were measured. The composition was considered sediment stable if the sediment stability coefficient was more than 98 %.

To prepare IES, which are homogenous opaque liquids of light brown colour, emulsifier “YALAN-E2” (volume fraction (concentration) 2 %), commercial oil from OGCF (20 %), calcium chloride aqueous solution with density 1.318 g/cm3 (78 %) were used.

The following reagents were used in the preparation of the BС, which are homogenous opaque yellowish liquids: BС1 (water-soluble organic polymer in dry form), BС2 (inorganic binding agent in dry form), BС3 (binding regulator in liquid form).

Microcalcite mixtures of four types (ground or milled marble) with different particle sizes, manufactured in accordance with TU 5716-001-56390243-2015 (“Shishimsky Mramori K°” LLC, Chelyabinsk Region) were used as a filler in the IES and BC: MK-500 (up to 0.5 mm); MK-200/500 (0.2-0.5 mm); MK-500/1000 (0.5-1 mm); MK-1000/1500 (1-1.5 mm).

According to the experience of using calcium carbonate as a bridging agent during drilling and well workover the most popular range of its mass fraction (concentration) in the composition of blocking fluid is 5-30 % [2, 16, 20]. This concentration was used to compare the efficiency of various grades of bridging agents. After choosing the most effective filler brand, its concentration in the blocking fluid was reduced to the minimum effective value (with allowance for reserve).

In order to assess the blocking properties of process fluids in relation to fractures with different degrees of opening, an experimental bench was made (Fig.3) [14] using a high-temperature high-pressure filter press (FANN). This test bench allows the simulation of fractures with different width (0.1; 0.5; 1; 1.5 mm).

It has been established that in carbonate reservoirs of the Volga-Ural oil and gas province (where OGCF is located) the fracture width does not exceed 1.5 mm on average. At the same time, the minimum possible (from the technical point of view) fracture opening, equal to 0.1 mm, is taken as the lower value.

The efficiency of well killing fluids was estimated based on the results of laboratory filtration experiments on their effect on changes in permeability of reservoir models (rock samples) with fractures of different degrees of opening (0.1-1.0 mm). Filtration tests were conducted with the FDES-645 formation damage evaluation unit (Coretest Systems Corporation) under conditions close to the formation conditions of the studied OGCF (at temperature 37 °C and pressure 9 MPa). Samples of the natural rock sample material of the OGCF with the simulation of the fractures with the opening of 0.1, 0.5 and 1 mm were used [11, 37].

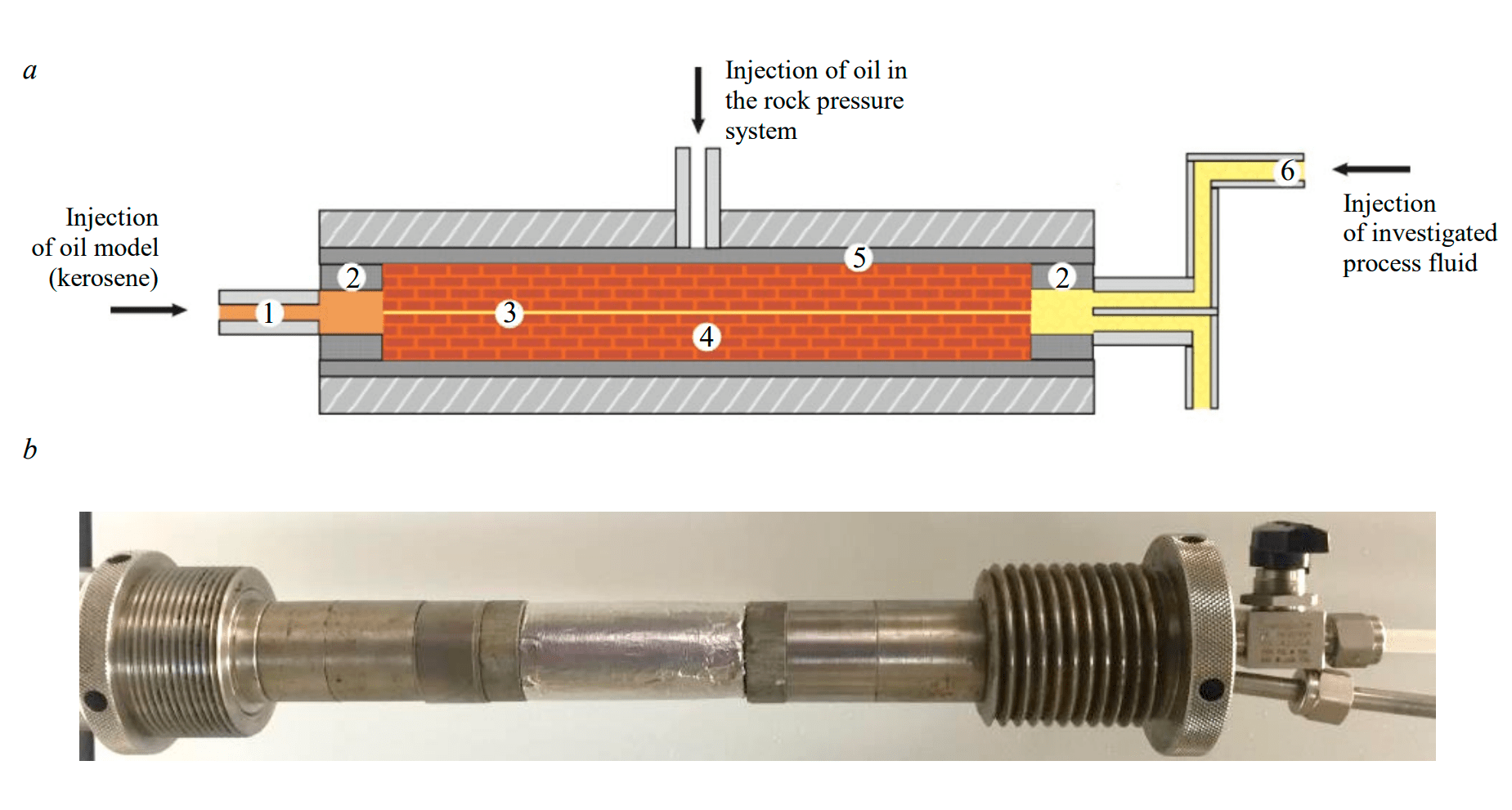

Figure 4 shows the design of a rock sample holder used in filtration investigations with emulsion and polymer blocking killing fluids, which contain bridging agent [11].

Fig.4. Operation diagram (a) and external view (b) of the rock sample holder for filtration investigations with fractured reservoir rock 1 – oil model (kerosene); 2 – flushing rings; 3 – artificially created fracture; 4 – carbonate rock; 5 – rock pressure system; 6 – investigated composition

The main objective of the research was to assess the effect of blocking compositions IES and BC used at the OGCF on the filtration characteristics of rock samples (with fractures) in comparison with the developed ones (IES + bridging agent) when simulating the oil well killing-development process.

When simulating well killing (injection of blocking solution into the rock sample), the pressure drop (repression) was 1 MPa, which corresponded to the standard process. While simulating well killing under conditions of excess bottomhole pressure (in case of ALFP) the value of repression was increased up to 4 MPa. The direction of injecting process fluids into the rock sample corresponded to the directions of oil and killing fluids movement in the producing wells. Filtration direction corresponding to the flow of oil from the formation into the well (simulation of well development) was opposite to the direction of blocking pack injection into the rock sample (simulation of well killing).

Stages of laboratory filtration investigations:

- determination of initial rock sample permeability by kerosene (oil model of the OGCF, with viscosity matching the viscosity of the gas-saturated formation oil);

- modeling the placement of the blocking fluid composition opposite the well perforation interval;

- simulation of a production well operation after killing and development (determining the coefficient of relative change in initial permeability of a rock sample by kerosene).

The main criteria for evaluating the effectiveness of blocking compositions: ability to withstand a pressure drop of at least 0.9 MPa (at least 10 % of formation pressure) while filtering through the fracture; ability to maintain rock sample permeability at least 70 %; minimum volume of blocking composition filtered through the fracture; minimum gradient of kerosene filtration start pressure when simulating well development.

Discussion

As a result of a series of physical, chemical and filtration investigations it was found that multi-fractional microcalcite should be added to the invert-emulsion solution and biopolymer composition traditionally used at OGCF in order to increase their blocking properties with regard to fractures of carbonate reservoirs.

Results of physical, chemical and rheological investigations of IES when microcalcite is added to it showed the following changes in its properties: density increases by 2.4-13 % depending on microcalcite concentration (5-30 %); thermal stability does not change (composition is thermostable at temperature up to 90 °C); sedimentation stability is maintained (difference in densities of the upper emulsion layer relative to the lower one does not exceed 16 kg/m3); effective viscosity decreases by 40-45 % and amounts to 500 mPa∙s, and the static shear stress – by 17-28 % and amounts to 38 Pa; composition does not mix with oil, formation water and aqueous solutions of sodium chloride and calcium; corrosion rate slightly increases (up to 0.06 mm/year), but remains within the requirements of regulatory documents; pour point is stable (–15 °С).

Physical, chemical and rheological investigations of BC with addition of microcalcite showed the following [31, 38]: composition is sedimentary stable at any concentration of microcalcite because of high viscosity; addition of microcalcite does not influence thermal stability of BC at temperature up to 80 °С; addition of microcalcite in 5 % by mass leads to approximately 2 times decrease of gel-formation start time, insignificant increase of composition effective viscosity by about 3.5 % and decrease of critical shear stress approximately 2 times; BC composition with microcalcite breaks down only partially in 6 % hydrochloric acid solution within 24 hours, at the same time first of all microcalcite dissolves with gas (CO2) release; composition does not mix with oil and water solution of calcium chloride; corrosion rate of BC with microcalcite exceeds the set standard (0.10-0.12 mm/year); composition received after mixing BC-1, BC-2 and fresh water freezes at the temperature of –8 °С, i.e., when using BC in winter, it must be heated in the process of preparation.

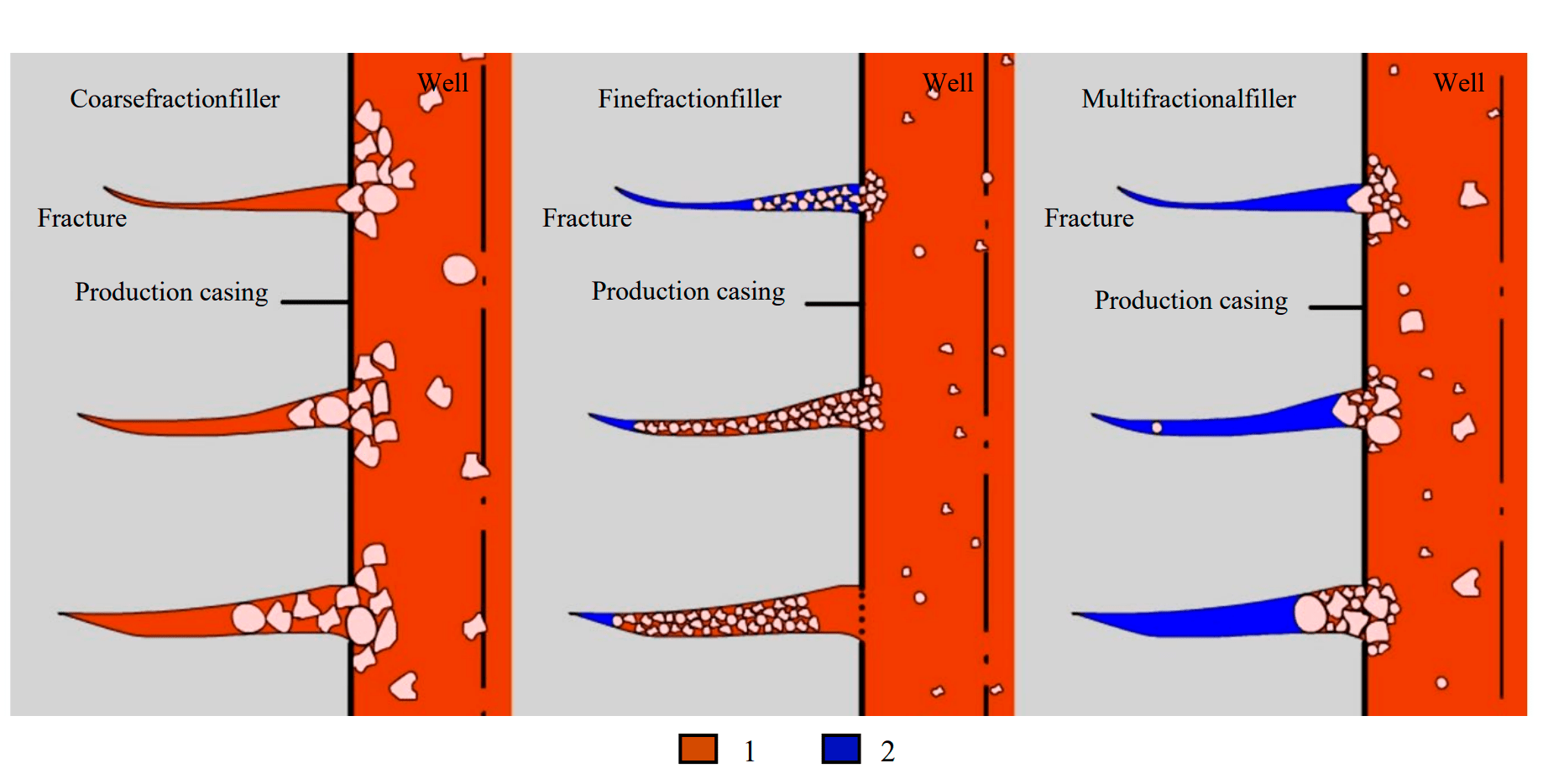

Results of filtration investigations carried out with the use of filter-press have shown that application of blocking compositions IES and BC in pure form under conditions of fractured reservoir does not contribute to creation of a reliable blocking screen withstanding high pressure drops. In order to increase blocking properties of IES and BC compositions used at OGCF it is recommended to use multifractional filler (microcalcite) (Tab.1).

Use of MK-200/500, MK-500/1000 fillers and halite in IES composition does not guarantee reliable blocking properties (even at high mass concentration of the filler) due to the absence of finely dispersed bridging agent particles, which are necessary for blocking passages between coarse particles. Moreover, use of only fine-dispersed bridging agent (chalk) particles in the composition does not produce the desired effect due to their comparable size with the size of microfractures in carbonate reservoirs, which may eventually lead to the absorption of the blocking agent into the formation and, consequently, to the worsening of filtration characteristics in the NBHZ.

Blocking compositions IES/BC + 5 % MK-500 are recommended for use in carbonate reservoirs with fracture opening of less than 0.5 mm based on filtration investigations. This grade of microcalcite ensures the formation of impermeable screen at the fracture inlet. The chosen mass fraction (concentration) of 5 % of microcalcite in the blocking composition is determined by the minimum value (with account of reserve), which prevents filtration of technological liquid through the fracture.

For carbonate reservoirs with fracture opening less than 1.5 mm blocking compositions IES/BC + 3 % MK-500 + 3 % MK-1000/1500 are recommended. This combination of microcalcite grades ensures uniform distribution of the filler fractions in the blocking composition in the range of up to 1.5 mm. The chosen overall mass fraction (concentration) of 6 % mix of different grades of microcalcite in the blocking composition is explained by the fact that at a lower concentration of the filler a bigger volume of the composition needs to be filtered through a fracture to form an impermeable screen; the increase of the microcalcite concentration is unreasonable due to inefficiency of the system.

Table 1

Blocking properties of emulsion and polymer blocking compositions investigated using a FANN filter press

|

Width (opening) of the fracture, mm |

Component composition of blocking packs |

Initial pressure of blocking pack filtration through the fracture, MPa |

Blocking pack volume, filtered through the fracture, cm3 |

|

Bridging agent selection (fracture opening 0.1 and 0.5 mm) |

|||

|

0.1 |

IES |

< 1 |

400 |

|

IES + 30 % МК-160 (chalkanalog) |

< 1 |

450 |

|

|

IES + 30 % МК-500 |

> 8 |

28 |

|

|

IES + 30 % МК-200/500 |

<1 |

320 |

|

|

IES + 30 % МК-500/1000 (shell rock analogue) |

<1 |

320 |

|

|

IES + 30 % Halite |

<1 |

350 |

|

|

0.5 |

IES |

<1 |

450 |

|

IES + 30 % МК-200/500 |

<1 |

450 |

|

|

IES + 30 % МК-400 |

> 8 |

360 |

|

|

IES + 30 % МК-500 |

> 8 |

6 |

|

|

Selecting the optimum concentration of MK-500 (fracture opening 0.5 mm) |

|||

|

0.5 |

IES + 10 % МК-500 |

> 8 |

7 |

|

IES + 5 % МК-500 |

> 8 |

8 |

|

|

IES + 3 % МК-500 |

> 8 |

10 |

|

|

IES + 1 % МК-500 |

>5 |

90 |

|

|

Selection of bridging agent and its optimum concentration (fracture opening 1, 1.5 and 2 mm) |

|||

|

1 |

IES + 30 % МК-500 |

< 1 |

450 |

|

IES + 20 % МК (10 % МК-500 + 10 % МК-500/1000) |

> 8 |

40 |

|

|

IES + 10 % МК (5 % МК-500 + 5 % МК-500/1000) |

> 6 |

450 |

|

|

IES + 10 % МК (5 % МК-500 + 5 % МК-1000/1500) |

> 8 |

4 |

|

|

IES + 6 % МК (3 % МК-500 + 3 % МК-1000/1500) |

> 8 |

4 |

|

|

IES + 3 % МК (1.5 % МК-500 + 1.5 % МК-1000/1500) |

> 8 |

153 |

|

|

1.5 |

IES + 6 % МК (3 % МК-500 + 3 % МК-1000/1500) |

>7 |

100 |

|

2 |

IES + 6 % МК (3 % МК-500 + 3 % МК-1000/1500) |

<1 |

450 |

|

Study of the BC blocking properties (fracture opening 0.1 -1.5 mm) |

|||

|

0.1 |

BC |

<1 |

450 |

|

0.5 |

BC + 5 % МК-500 |

> 8 |

50 |

|

1.0 |

BC + 6 % МК (3 % МК-500 + 3 % МК-1000/1500) |

> 8 |

80 |

|

1.5 |

BC + 6 % МК (3 % МК-500 + 3 % МК-1000/1500) |

>7 |

105 |

After evaluation of blocking properties for the investigated compositions at increased pressure drop (up to 8 MPa) on filter-press with metal disks simulating fractures of different opening degree, a series of filtration investigations was carried out on FDES-645 using natural rock samples during modeling of killing and development of production wells. Experiments were conducted to assess the effect of blocking compositions on filtration characteristics of fractured carbonate rock reservoirs. While filtering of blocking compositions into the rock sample, pressuredrop corresponding to the standard well killing process was simulated when bottomhole pressure exceeds formation pressure by not more than 5-10 % (Tab.2).

Results of filtration investigations have shown that blocking compositions with microcalcite (IES/BC + 5 % MK-500 and IES/BC + 3 % MK-500 + 3 % MK-1000/1500) provide more effective filtration characteristics of carbonate reservoirs with fractures in comparison with blocking compositions IER and BC without fillers.

Table 2

Filtration properties of emulsion and polymer blocking compositions, investigated using the FDES-645 filtration unit

|

Width (opening) of the fracture, mm |

Component composition of blocking packs |

Relative permeability change coefficient of fractured rock sample, % |

Maximum pressure gradient of kerosene breakthrough during simulated well development, atm/m |

Blocking pack volume, filtered into the fracture, cm3 |

|

0.1 |

IES |

–32 |

54.9 |

0.3 |

|

IES + 5 % МК-500 |

–15 |

50.7 |

< 0.2 |

|

|

BC |

–79 |

493 |

0.8 |

|

|

BC + 5 % МК-500 |

–19 |

75.1 |

< 0.1 |

|

|

0.5 |

IES |

–93 |

209 |

14 |

|

IES + 5 % МК-500 |

–43 |

22.2 |

< 0.2 |

|

|

BC |

–57 |

265 |

1.9 |

|

|

BC + 3 % МК-500 + 3 % МК-1000/1500 |

–27 |

96.2 |

0.4 |

|

|

1 |

IES |

0 |

1.3 |

300 |

|

IES + 5 % МК-500 |

0 |

1.5 |

300 |

|

|

IES + 3 % МК-500 + 3 % МК-1000/1500 |

0 |

1.3 |

< 0.2 |

|

|

BC |

–55 |

340 |

200.2 |

|

|

BC + 3 % МК-500 + 3 % МК-1000/1500 |

–19 |

88.5 |

2.5 |

|

|

1.5 |

IES |

0 |

0.5 |

300 |

|

BC |

–42 |

165 |

300 |

|

|

IES + 3 % МК-500 + 3 % МК-1000/1500 |

–5 |

24.5 |

40 |

|

|

BC + 3 % МК-500 + 3 % МК-1000/1500 |

–14 |

57.8 |

26 |

Mechanism for increasing blocking properties of studied technological fluids lies in creation of vault-type frame at the entrance of reservoir fractures, resulting in sealing of fracture mouth and formation of impermeable barrier that prevents further absorption of blocking agent by formation (Fig.5) [11]. At the same time, the barrier, based on the principle of a check valve, can be easily destroyed when the flow direction changes (from formation to well) in the process of well development and putting it into operation, which helps to restore the potential of the well.

Fig.5. Screen formation in the near-bottomhole zone when using filler of different fractions in the blocking composition 1 – IES/BC; 2 – for mationfluid

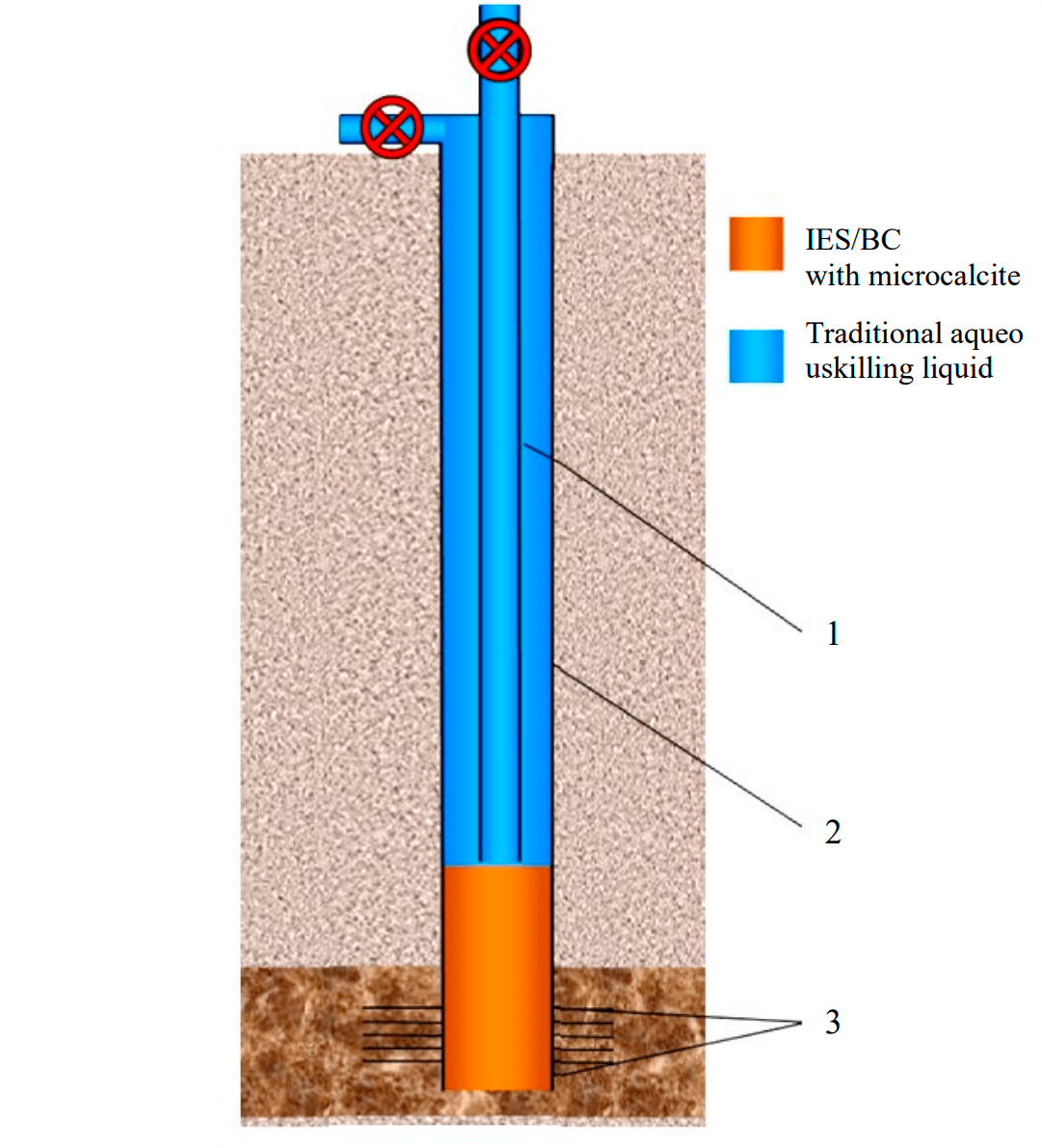

Technology for application of blocking compositions IES and BC with microcalcite consists of their placement in front of perforation interval with partial penetration into near-bottomhole zone. Above the blocking compositions there is an aqueous salt solution of a required density in order to create necessary pressure at borehole bottom (Fig.6). As a result of mathematical modeling algorithms

were developed, which formed the basis of specialized software systems for design of well killing under complicated operating conditions [17].

Fig.6. Scheme for killing an oil production well with IES/BC blocking composition with microcalcite 1 – tubing; 2 – production casing; 3 – perforation interval

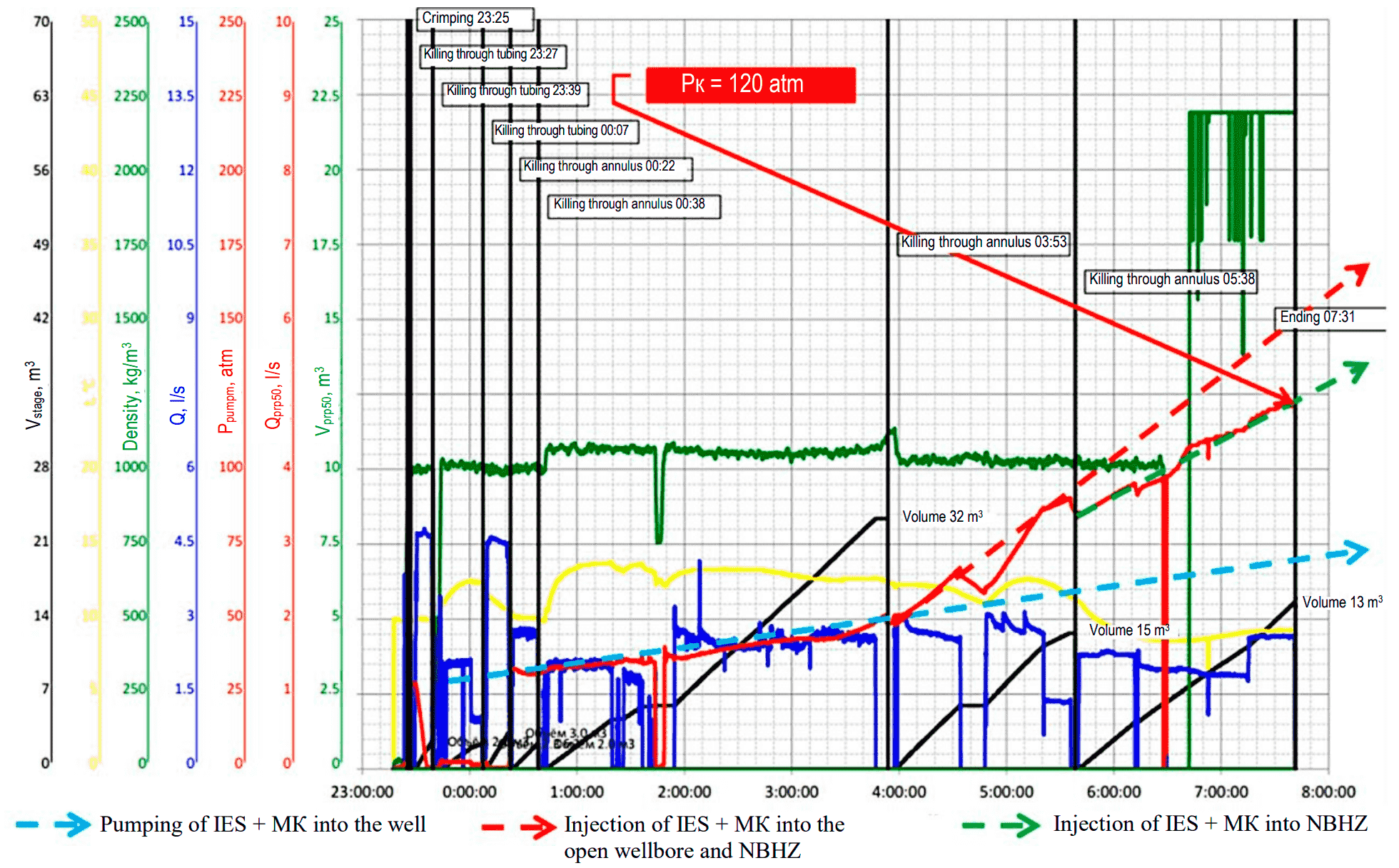

Pilot testing of the IES technology with microcalcite was carried out at a production well of the OGCF. Blocking composition consisted of the components in the following concentration: calcium chloride aqueous solution – 78 % by volume; oil – 20 % by volume; emulsifying reagent Neftenol NZb – 2 % by volume; microcalcite: MK-500 – 3 % by mass; MK-1000/1500 – 3 % by mass. Total volume of IES preparation with microcalcite was 32 m3.

Analysis of the results for field tests of the IES technology with microcalcite at one of the OGCF with carbonate reservoirs showed that during well killing a higher pressure is observed when injecting the blocking composition of IES with microcalcite into the near-bottomhole zone of the formation in comparison with the same well treatment with traditional IES composition without bridging agent, which means the formation of blocking screen in fractures that prevents an absorption of process fluid (Fig.7). At the end of killing stage, the pressure on pumping unit (CА-320) was 120 atm, which is 20 atm more than during the previous killing operation at the same well with the use of IES without filler.

Fig.7. Dynamics of technological indicators for oil production well killing with IES blocking composition with microcalcite

Conclusion

As a result of laboratory research and field tests for the use at OGCF with the carbonate type of reservoir under complicated conditions (carbonate reservoir rocks and ALFP) it is recommended to use blocking compositions IES and BC with bridging agent (microcalcite) of different fractions during production wells killing before the workover. Implementation of the indicated technology can help prevent absorptions and gas influxes during wells killing, decrease the volume of well killing fluids used, shorten killing operations, preserve well productivity, decrease water cut of produced fluid and reduce the well development period and putting it into operation.

References

- Akimov O.V. Improving well killing techniques to enhance development of low-permeability terrigenous reservoirs: Avtoref. dis. ... kand. tekhn. nauk. Ufa: Ufimskii gosudarstvennyi neftyanoi tekhnicheskii universitet, 2011, p. 24 (in Russian).

- Alekseev A.A. Heading for carbonates: Developing carbonate reservoirs at “Gazprom Neft”. Sibirskaya neft. 2017. N 138, p. 28-35 (in Russian).

- Atvinovskaya T.V. Role of killing fluids in the well workover process. Vestnik GGTU im. P.O.Sukhogo. 2018. N 2, p. 34-41 (in Russian).

- BridzhersK.L. Completion and workover fluids. Moscow: Institut kompyuternykh issledovanii, 2016, p. 236 (in Russian).

- Vagina T.Sh., Gavrilova A.A. Development of blocking compositions for well killing at the western Siberian fields with account of modern requirements. Stroitelstvo neftyanykh I gazovykh skvazhin na sushe i na more. 2014. N 6, p. 38-41 (in Russian).

- Zdolnik S.E., Khandriko A.N., Akhankin O.B. et al. Technologies of killing of wells with lost return control in conditions of an intensification of terrigenous reservoirs development. Neftyanoe khozyaistvo. 2007. N 11, p. 62-65 (in Russian).

- Glushchenko V.N., Ptashko O.A. Thickened calcium free well kill fluid. Neft. Gaz. Novatsii. 2013. N 10 (177), p. 58-61 (in Russian). Glushchenko V.N., Silin M.A. Near-bottomhole zone and technogenic factors of its state. Neftepromyslovaya khimiya: v 5 t. Vol. 3. Moscow: Interkontakt Nauka, 2010, p. 650 (in Russian).

- Dvoinikov M.V. Research on technical and technological parameters of inclined drilling. Journal of Mining Institute. 2017. Vol. 223, p. 86-92. DOI: 10.18454/PMI.2017.1.86

- Demakhin S.A., MerkulovA.P., Kasyanov D.N. Well killing with blocking packs is an effective mean of preserving the filtration properties of the reservoir. Neft. Gaz. Novatsii. 2015. N 1, p. 66-69 (in Russian).

- Islamov Sh.R. Justification of oil well killing technology prior to workover in fractured-pore carbonate reservoirs: Avtoref. dis. … kand. tekhn. nauk. St. Petersburg: Sankt-Peterburgskii gornyi universitet, 2021, p. 20 (in Russian).

- Kozlov E.N., Kustyshev A.V., Abdullina R.S. Some special features of wells killing at Talakansky oil-gas-condensate field. Stroitelstvo neftyanykh i gazovykh skvazhin na sushe i na more. 2014. N 6, p. 31-33 (in Russian).

- Krylov V.I., Kretsul V.V., Gimazetdinov V.M. Main factors which pay impact on productive formations contamination and development of recommendations for well productivity enhancement. Stroitelstvo neftyanykh i gazovykh skvazhin na sushe i na more. 2015. N 12, p. 31-36 (in Russian).

- Litvinenko V.S., Nikolaev N.I. Technological fluids for increasing effectivity of construction and exploitation oil and gas wells. Journal of Mining Institute. 2011. Vol. 194, p. 84-90 (in Russian).

- Zhelonin P.V., Mukhametshin D.M., Archikov A.B. et al. Justification of well killing technology selection algorithm. Nauchno-tekhnicheskii vestnik OAO NK “Rosneft”. 2015. N 2, p. 76-81 (in Russian).

- Orlov G.A, KendisM.Sh., Glushchenko V.N. Application of inverted emulsions in oil production. Moscow: Nedra, 1991, p. 222 (in Russian).

- Ovcharenko Yu.V., Gumerov R.R., Bazyrov I.Sh. et al. Well killing specifics in conditions of fractured and porous carbonate reservoirs of the Eastern part of the Orenburgskoye oil-gas-condensate field. Neftyanoe khozyaistvo. 2017. N 12, p. 52-55. DOI: 10.24887/0028-2448-2017-12-52-55 (in Russian).

- Perepelkin A.S., BikmetovA.Yu. Elaboration of biopolymer mud for wells killing with abnormally low reservoir pressure. Territoriya NEFTEGAZ. 2014. N 6, p. 16-19 (in Russian).

- Silin M.A., Magadova L.A., Gaevoi E.G. et al. Application of killing fluids on the polysaccharide base in wells with low pressure and after fracturing. Neftyanoe khozyaistvo. 2010. N 4, p. 104-106 (in Russian).

- Dmitruk V.V., Rakhimov S.N., Boyarkin A.A., Shtakhov E.N. Improving the effectiveness of killing wells of Urengoyskoye field. Neftyanoe khozyaistvo. 2010. N 5, p. 130-132 (in Russian).

- Zdolnik S.E., Zgoba I.M., Telin A.G., Gusakov V.N. Problems of well killing at the Priobskoye field and ways of solving them. Nauchno-tekhnicheskii vestnik OAO NK “Rosneft”. 2006. N 1, p. 35-38 (in Russian).

- Boikov E.V., Evdokimov I.N., Kilmamatov A. et al. A newly developed criteria matrix determining applicability of kill fluids. Burenie i neft. 2019. N 2, p. 20-27 (in Russian).

- Ponomareva I.N., Ilyushin P.Yu., Martyushev D.A., Rakhimzyanov R.M. Results of research into improving the efficiency of well killing technologies. Neftyanoe khozyaistvo. 2017. N 1, p. 2-5 (in Russian).

- Rogachev M.K., Mukhametshin V.V., Kuleshova L.S. Improving the efficiency of using resource base of liquid hydrocarbons in Jurassic deposits of Western Siberia. Journal of Mining Institute. 2019. Vol. 240, p. 711-715. DOI: 10.31897/PMI.2019.6.711

- Rogov E.A. Study of the well near-bottomhole zone permeability during treatment by process fluids. Journal of Mining Institute. 2020. Vol. 242, p. 169-173. DOI: 10.31897/PMI.2020.2.169

- Ryabokon S.A. Completion and workover process fluids. Krasnodar, 2009, p. 338 (in Russian).

- Gusakov V.N., Kraevskii N.N., Khakimov A.F. et al. Absorption prevention technology for well workovers under low formation pressure conditions. Neftyanoe khozyaistvo. 2013. N 10, p. 50-51 (in Russian).

- Tokunov V.I., Saushin A.Z. Process fluids and compositions to enhance oil and gas well productivity. Moscow: Nedra, 2004, p. 711 (in Russian).

- Shishkin A.V. Calcium nitrate – component of well kill fluid and an additive to squeeze compositions. Neft. Gaz. Novatsii. 2013. N 12, p. 51-53 (in Russian).

- Shikhaliev I.Yu., Shikhalieva I.S., Sedlyarova V.D., Shikhalieva I.I. Efficiency of lightened emulsions application for well killing during repair-and-renewal operations in productive formations with abnormally low formation pressure. Stroitelstvo neftyanykh i gazovykh skvazhin na sushe i na more. 2014. N 6, p. 34-38 (in Russian).

- Khaibullina K.S., Korobov G.Yu., Lekomtsev A.V. Development of an asphalt-resin-paraffin deposits inhibitor and substantiation of the technological parameters of its injection into the bottom-hole formation zone. Periodico Tche Quimica. 2020. Vol. 17. N 34, p. 769-781.

- Leusheva E.L., Morenov V., Tabatabaee Moradi M. Effect of carbonate additives on dynamic filtration index of drilling mud. International Journal of Engineering. 2020. Vol. 33. Iss. 5, p. 934-939. DOI: 10.5829/IJE.2020.33.05B.26

- Litvinenko V.S., Dvoynikov M.V., Trushko V.L. Elaboration of a conceptual solution for the development of the Arctic shelf from seasonally flooded coastal areas. International Journal of Mining Science and Technology. DOI: 10.1016/j.ijmst.2021.09.010(In press).

- Litvinenko V. Foreword: Sixty-year Russian history of Antarctic sub-glacial lake exploration and Arctic natural resource development. Geochemistry. 2020. Vol. 80. Iss. 3. N 125652. DOI: 10.1016/j.chemer.2020.125652

- Morenov V., Leusheva E. Influence of the solid phase fractional composition on the filtration characteristics of the drilling mud. International Journal of Engineering. 2019. Vol. 32. Iss. 5, p. 794-798. DOI: 10.5829/ije.2019.32.05b.22

- Prischepa O.M., Nefedov Y.V., Kochneva O.E. Raw material base of hard-to-extract oil reserves of Russia. Periodico Tche Quimica. 2020. Vol. 17. N 34, p. 915-924.

- Palyanitsina A., Sukhikh A. Peculiarities of assessing the reservoir properties of clayish reservoirs depending on the water of reservoir pressure maintenance system properties. Journal of Applied Engineering Science. 2020. Vol. 18. N 1, p. 10-14. DOI: 10.5937/jaes18-24544

- Sabukevich V.S., Podoprigora D.G., Shagiakhmetov A.M. Rationale for selection of an oil field optimal development system in the eastern part of the Pechora sea and its calculation. Periodico Tche Quimica. 2020. Vol. 17. N 34, p. 634-655.

- Shagiakhmetov A.M.,Podoprigora D.G., Terleyev A.V. The study of the dependence of the rheological properties ofgelforming compositions on the crack opening when modeling their flow on a rotational viscometer. Periodico Tche Quimica. 2020. Vol. 17. N 34, p. 933-939.