Improving the efficiency of the technology and organization of the longwall face move during the intensive flat-lying coal seams mining at the Kuzbass mines

- 1 — Ph.D. General Director JSC SUEK-Kuzbass

- 2 — Ph.D., Dr.Sci. Dean Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 3 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus

Abstract

The reasons for the lag of the indicators of the leading Russian coal mines engaged in the longwall mining of the flat-lying coal seams from similar foreign mines are considered. The analysis of the efficiency of the longwall face move operations at the JSC SUEK-Kuzbass mines was carried out. A significant excess of the planned deadlines for the longwall face move during the thick flat-lying seams mining, the reasons for the low efficiency of disassembling operations and the main directions for improving the technology of disassembling operations are revealed. The directions of ensuring the operational condition of the recovery room formed by the longwall face are considered. The recommended scheme of converged coal seams mining and a three-dimensional model of a rock mass to justify its parameters are presented. Numerical studies using the finite element method are performed. The results of modeling the stress-strain state of a rock mass in the vicinity of a recovery room formed under conditions of increased stresses from the boundary part of a previously mined overlying seam are shown. The main factors determining the possibility of ensuring the operational condition of the recovery rooms are established. It is shown that it is necessary to take into account the influence of the increased stresses zone when choosing timbering standards and organizing disassembling operations at a interbed thickness of 60 m or less. A sufficient distance from the gob of above- or undermined seams was determined to ensure the operational condition of the recovery room of 50 m, for the set-up room – 30 m. Recommendations are given for improving technology and organization of the longwall face move operations at the mines applied longwall mining of flat-lying coal seams with the formation of a recovery room by the longwall face.

Introduction

The Kuznetsk coal basin is the main coal-producing region of Russia. It accounts for 251 million tons out of 445 million produced in Russia in 2019 (more than 56 % of all coal production). The main technology of underground coal mining in Russia – the longwall mining [1, 4, 29] – is characterized by a high level of mechanization and safety of mining operations [28, 30, 31]. The use of modern state-of-the art equipment in the longwall faces ensures the mining operations with record daily and monthly productivity, exceeding the productivity of the best longwalls in the leading coal-producing countries [5, 6, 28]. Thus, in 2017-2018, production from one longwall at the mine “Named after V.D.Yalevskiy” reached 1.4-1.6 million tons per month. However, the average annual longwall productivity of even the best Russian mines still significantly lag behind the longwall productivity of foreign coal mines [10, 11, 22], which, in our opinion, is explained by the long downtime of state-of-the art longwall equipment. The economic losses caused by equipment downtime can range from 5 to 40 million rubles per day, and the duration of downtime can reach 150-200 days a year. One of the main reasons for long downtime of state-of-the art longwall equipment is the lack of efficiency of longwall face move operations at the coal mines of Russia [2, 27].

The purpose of this work is to develop and justify technological and organizational solutions that create conditions for improving the efficiency of longwall face move during intensive flat-lying coal seams mining at Russian mines by identifying the causes of violations of the technological stability and the subsequent targeted impact on these causes through a comprehensive justification of the parameters of technological schemes and the organization of work.

Formulation of the problem

JSC SUEK-Kuzbass carries out underground coal mining in seven mines with simultaneous operation of up to nine longwalls. Most of the company's mines operate one longwall, only the mines “Named after S.M.Kirov” and “Named after V.D.Yalevskiy” operates by two longwalls. The frequency of longwall face move at coal mines is determined by the productivity of longwall and the volume of reserves within the longwall panel. The average frequency of the longwall face moves at the mines of JSC SUEK-Kuzbass is approximately one move per year. This frequency persists for many years, since the increase in the productivity of longwalls is accompanied by an increase in the size of the longwall panels. The planned period of longwall face move differs for medium-thickness and high-thickness seams due to a significant difference in the weight of the longwall face equipment. The weight of one shield for various types of shield supports used in mines for medium-thickness seams mining is less than 20 tons (for example, the Joy RS-2400/2*650 support shield weighs 16.9 tons), and for thick seams – 27-40 tons. At the mines of JSC SUEK-Kuzbass, the most advanced method of longwall face move is used, which provides the recovery room formation by the longwall face – the use of roof bolts and polymer mesh for reliable support of the recovery room. When medium-thickness seams mining, the planned duration of the longwall face move is 45-68 days, of which 15-18 days are spent on the recovery room formation. When mining thick seams, the planned duration is 61 days, of which 15-20 days is the recovery room formation.

To assess the effectiveness of the longwall face move operations at the mines of JSC SUEK-Kuzbass, the analysis was performed of 46 cases of longwall face moves (2014-2019) – 24 cases during the mining of medium-thickness seams (Table 1) and 22 cases during the mining of thick seams (Table 2).

Table 1

Results of the analysis of the efficiency of longwall face move operations during the medium-thickness seams mining

|

Mine |

Year |

Longwall number-disassembling / assembling |

Longwall length, m |

Distance of equipment transportation, m |

Depth of mining, m |

Extractable seam thickness, m |

Exceeding the planned deadlines for the recovery room formation, day |

Total excess of planned deadlines of longwall face move, day |

|

Named after S.M.Kirov |

2014 |

24-56/24-57 |

230/300 |

1300 |

290 |

2.3 |

20 |

10 |

|

Komsomolets |

2014 |

17-32/17-33 |

300/300 |

1500 |

390 |

2.1 |

14 |

11 |

|

Named after S.M.Kirov |

2015 |

24-56/ 24-57 |

300/300 |

2300 |

380 |

2.3 |

–2 |

15 |

|

Named after S.M.Kirov |

2015 |

25-94/25-95 |

270/300 |

500 |

350 |

2.3 |

18 |

74 |

|

Komsomolets |

2015 |

17-33/17-34 |

300/300 |

1500 |

380 |

2.1 |

8 |

21 |

|

Named after A.D.Ruban |

2016 |

12-12/12-10 |

220/220 |

2250 |

240 |

2.3 |

11 |

19 |

|

Named after S.M.Kirov |

2016 |

24-57/24-58 |

300/303 |

2400 |

410 |

2.3 |

–1 |

18 |

|

Komsomolets |

2016 |

17-34/17-31 |

300/200 |

1500 |

265 |

2.1 |

1 |

16 |

|

Polysaevskaya |

2016 |

17-47/17-49 |

300/300 |

300 |

330 |

1.6 |

9 |

42 |

|

Named after A.D.Ruban |

2017 |

12-10/12-08 |

220/220 |

2500 |

200 |

2 |

6 |

–10 |

|

Named after S.M.Kirov |

2017 |

24-58/24-59 |

300/304 |

2600 |

430 |

2.3 |

–3 |

–14 |

|

Komsomolets |

2017 |

17-31/17-31 bis |

300/300 |

1400 |

400 |

2.1 |

–1 |

–10 |

|

Komsomolets |

2017 |

17-31 bis/17-35 |

300/220 |

1450 |

400 |

2.1 |

–1 |

6 |

|

Polysaevskaya |

2017 |

17-49/17-51 |

300/300 |

3000 |

310 |

1.6 |

2 |

20 |

|

Named after A.D.Ruban |

2018 |

12-08/12-06 |

220/220 |

2650 |

140 |

2.1 |

5 |

14 |

|

Named after S.M.Kirov |

2018 |

24-59/24-60 |

300/305 |

2900 |

430 |

2.3 |

–3 |

4 |

|

Named after S.M.Kirov |

2018 |

25-96/25-101 |

300/300 |

1400 |

310 |

2.3 |

–3 |

26 |

|

Komsomolets |

2018 |

17-35/18-46 |

300/300 |

5500 |

370 |

2.1 |

0 |

63 |

|

Named after A.D.Ruban |

2019 |

12-06/12-04 |

220/220 |

2150 |

110 |

2.1 |

–1 |

44 |

|

Named after S.M.Kirov |

2019 |

25-101/25-97-1 |

300/300 |

900 |

360 |

2.3 |

0 |

48 |

|

Named after S.M.Kirov |

2019 |

25-97-1/25-97 |

300/300 |

3300 |

360 |

2.3 |

–1 |

90 |

|

Named after S.M.Kirov |

2019 |

24-60/24-62 |

300/300 |

2900 |

470 |

2.3 |

2 |

107 |

|

Komsomolets |

2019 |

18-46/18-47 |

300/300 |

2600 |

430 |

2.1 |

–2 |

16 |

|

Polysaevskaya |

2019 |

17-51/17-53 |

300/300 |

3000 |

370 |

1.6 |

2 |

31 |

When mining medium-thickness seams, the average excess of the planned deadlines of longwall face move is 27 days, including the excess of the terms of the recovery room formation – 3 days. When mining thick seams, the average excess of the planned deadlines for longwall face move is 50 days, including 8 days during the recovery room formation (Table 2). The longest duration of disassembling operations is observed at the mine “Named after V.D.Yalevskiy” (former mines N 7 and “Kotinskaya”), which is characterized by the highest longwalls productivity. It is the significant lag in the rate of the entries development for the new longwall panel from the rate of the longwall face advancing [2, 27] in the current situation that is the reason for the untimely preparation of new longwall panel and the main reason for the increase in the longwall face move duration.

Table 2

Results of the analysis of the efficiency of the longwall face move operation during the thick seams mining

|

Mine |

Year |

Longwall number-disassembling / assembling |

Longwall length, m |

Distance of equipment transportation, m |

Depth of mining, m |

Extractable seam thickness, m |

Exceeding the planned deadlines for the recovery room formation, day |

Total excess of planned deadlines of longwall face move, day |

|

N 7 |

2014 |

52-07/52-09 |

250/250 |

250 |

220 |

4.3 |

7 |

2 |

|

Named after November 7 |

2014 |

13-58/13-80 |

290/290 |

2200 |

230 |

4.2 |

4 |

9 |

|

Named after A.D.Ruban |

2014 |

804/802 |

200/220 |

3100 |

125 |

4.4 |

9 |

14 |

|

Taldinskaya-Zapadnaya-2 |

2014 |

70-08/70-09 |

300/300 |

2850 |

200 |

4.5 |

22 |

–7 |

|

N 7 |

2015 |

52-09/52-11 |

250-290 |

1800 |

380 |

4.3 |

10 |

96 |

|

Named after November 7 |

2015 |

13-78/13-58-2 |

280/180 |

1750 |

210 |

4.4 |

7 |

3 |

|

Named after November 7 |

2015 |

13-80/13-78 |

290/280 |

2340 |

200 |

4.5 |

6 |

–9 |

|

Named after A.D.Ruban |

2015 |

802/801 |

200/220 |

3100 |

90 |

4.4 |

9 |

46 |

|

Kotinskaya |

2015 |

52-09/52-10 |

280/200 |

4200 |

330 |

4.3 |

24 |

100 |

|

Named after November 7 |

2016 |

13-58-2/13-85 |

180/240 |

4100 |

120 |

4.5 |

–5 |

–10 |

|

Named after November 7 |

2016 |

13-85/13-86 |

240/290 |

600 |

100 |

4.6 |

–3 |

–12 |

|

Kotinskaya |

2016 |

52-10/50-02 |

300/400 |

7000 |

330 |

4.3/3.7 |

6 |

15 |

|

Taldinskaya-Zapadnaya-1 |

2016 |

66-06/66-05 |

300/300 |

1600 |

120 |

4.5 |

18 |

131 |

|

Named after V.D.Yalevskiy |

2017 |

50-02/50-03 |

400/400 |

2600 |

105 |

3.7 |

–8 |

72 |

|

Named after V.D.Yalevskiy |

2017 |

52-10/52-13 |

300/180 |

3300 |

280 |

4.3 |

0 |

30 |

|

Taldinskaya-Zapadnaya-1 |

2017 |

66-05/66-08 |

300/300 |

2800 |

130 |

4.5 |

–1 |

57 |

|

Taldinskaya-Zapadnaya-2 |

2017 |

70-09/70-10 |

300/300 |

2900 |

180 |

4.5 |

5 |

26 |

|

Named after V.D.Yalevskiy |

2018 |

50-03/50-04 |

400/400 |

2800 |

200 |

3.7 |

–4 |

127 |

|

Taldinskaya-Zapadnaya-1 |

2018 |

66-08/66-09 |

300/280 |

1800 |

130 |

4.5 |

6 |

115 |

|

Named after A.D.Ruban |

2019 |

812/814 |

300/300 |

3800 |

110 |

4.4 |

47 |

18 |

|

Named after V.D.Yalevskiy |

2019 |

50-04/50-05 |

400/400 |

3000 |

270 |

3.7 |

5 |

61 |

|

Named after V.D.Yalevskiy |

2019 |

52-13/52-14-1 |

300/400 |

5500 |

270 |

4.3 |

6 |

218 |

A detailed analysis of cases of significant terms excess of longwall face move showed that their main cause is associated with the instability of the roof and the edge of the recovery room. Increased fallout in such cases makes it difficult to form, maintain and use the recovery room. From 2014 to 2019, the recovery room supporting was constantly improved – the transition from the use of timber-plates to roof bolting with a polymer mesh, which significantly reduced the labor intensity and increased the work safety on the recovery room formation. In complicated mining and geological conditions, there are problems with maintaining the set-up room. For example, the cross-section of the set-up room 70-09 at the Taldinskaya-Zapadnaya-2 mine decreased due to floor heaving, which required labor-intensive work on dinting and increased the longwall face move time by 22 days.

The tendency to increase the longwall length to 400 m and the longwall panel length to 4 km or more at mines with the thick coal seams (currently there are two longwalls at the mine “Named after V.D.Yalevskiy”, in the future – the Taldinskaya-Zapadnaya-2 mine, etc.), predetermined a sharp increase in the total weight and transportation distance of equipment during longwall face move. The low capacity of hanging monorails leads to an increase in the duration of longwall face move and makes it necessary to search for other technological solutions. The main direction of improving the transport system is currently considered the use of pneumatic wheeled vehicles and the transition to the three entry for panel preparation, one of which (additional) will be used for the transport of cargo, materials and equipment.

A large number of scientific papers are devoted to ensuring the operational condition of set-up and recovery rooms. The greatest attention is paid to the maintenance of recovery rooms that are affected by the bearing pressure of longwall [3, 7, 13], since the set-up room does not have such an influence and, as a result, is operated in more favorable conditions. There are two main directions for ensuring the operational condition of the recovery rooms, based on the choice of a rational place for their formation by the longwall face equipment: 1) the location of the recovery room directly behind the fracture crack of the main roof to minimize the bearing pressure in its vicinity [15, 17]; 2) the location of the recovery room outside the zones of increased rock pressure from the edge parts and the pillars formed on the converged coal seams. The development of converged coal seams is characterized by a significant impact not only on the recovery rooms condition, but also on any entries on the longwall panels [19, 23, 33], especially those that are also in the influence zone of longwall operations carried out on the developed seam [12, 14, 20].

The technology of recovery room forming behind a fracture crack, which is described in detail in [16], deserves attention. The proposed method makes it possible to predict the step of the main roof caving and ensures the recovery room formation directly behind the collapse crack of the main roof, minimizing the load on the edges and roof of the recovery room and allowing, as experience shows, to significantly reduce labor costs and the disassembling time when working out medium-thickness coal seams [15-17].

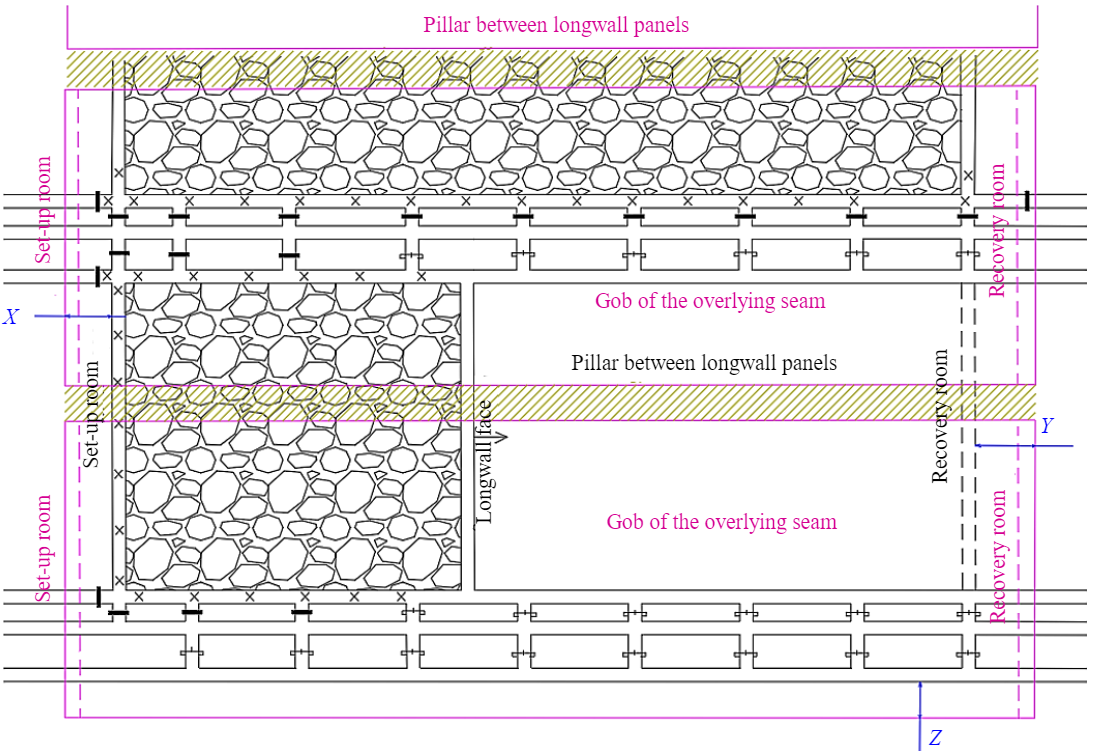

When mining of converged coal seams with the leaving of non-destructible coal pillars between the longwall panels, stress shadow zones (SSZ) are formed, in which the level of the roof displacement of the workings can increase by 2-3 times. Also, the level of displacement in the roof of workings in the SSZ zones from the edge parts of the rock mass can increase approximately twice. When mining the converged coal seams, the set-up and recovery rooms are most often located in the immediate vicinity of the edge parts of the rock mass formed along the converged coal seam. The analysis of foreign experience shows the need to shift the set-up and recovery rooms under the gob by 30 m or more. The current tendency to increase the longwall panels sizes [8, 9, 26] complicates such a link between the work on the converged seams [25, 32]. To ensure the operational condition of the workings of the converged seams, it is recommended that they be located with an offset under the gob [18, 21, 24]. However, the location of all workings under the gob is possible only with the scheme of interconnection of work on seams (Fig.1). Taking into account that the descending order of development is the most rational for converged seams with the leaving of non-destructible pillars (especially when mining thick seams), such a scheme can be recommended for widespread use in the mines of Kuzbass. The features of the proposed scheme are the preparation of the longwall panels using three entries, which ensures an increase in the efficiency of methane release and transport management at the working area. The main parameters of the scheme are: the longwall panel length and width, the width of the pillars, the value of the displacement Z of the entries of the lower seam relative to the edge part of the upper seam rock mass, the value of the displacement X of the set-up room relative to the set-up room of the upper seam, the value of the displacement Y of the recovery room relative to the recovery room of the upper seam. As a disadvantage of the presented scheme, it should be noted that the use of the scheme limits the longwall panel length along the underlying seam. To eliminate this drawback, it is possible to locate the set-up and (or) recovery rooms of the previously abovemined (undermined) seam under the edge parts of the mass of the working seam at a distance exceeding the width of the bearing pressure zone. This approach ensures that the recovery room is located outside the zone of influence of increased stresses from the edge part of the rock mass.

Method of conducting numerical studies

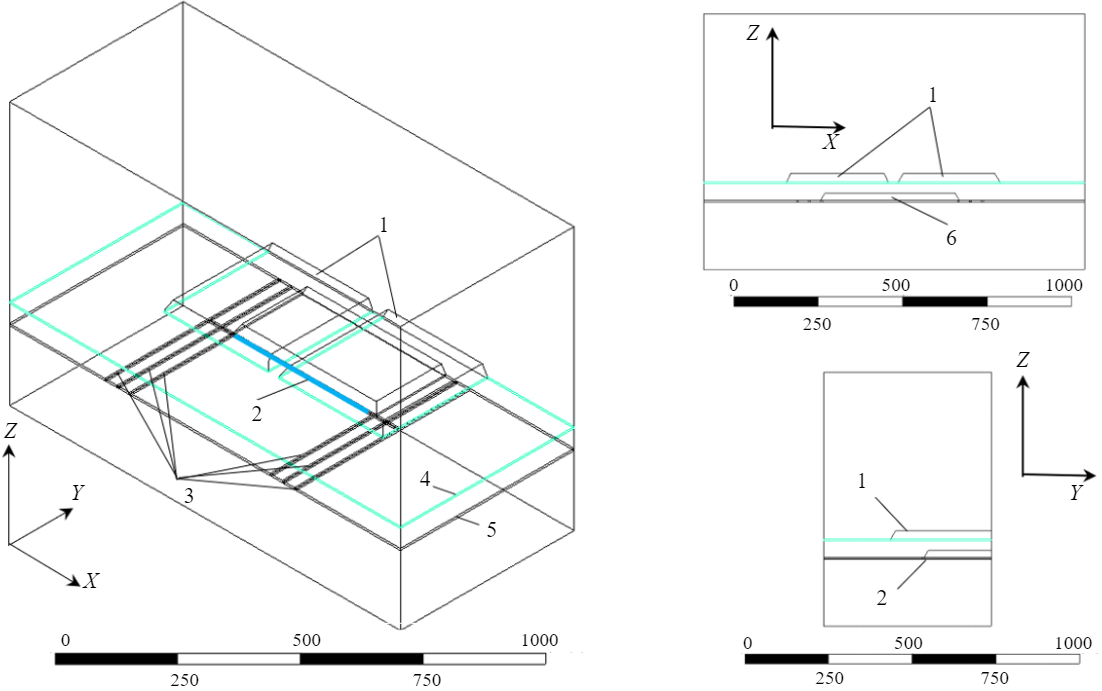

To justify the parameters of the presented scheme, numerical studies were performed using the finite element method. The developed three-dimensional model of the rock mass (Fig.2) included two coal seams, rocks, the gobs of two longwall panels along the upper seam, the gob and the recovery room, as well as precinct entries along the lower seam.

The modeling was carried out for the part of the mined longwall panel directly adjacent to the recovery room. During the modeling, the depth of mining operations, the thickness and deformation characteristics of the interbed, the parameters X, Y, Z (see Fig.1), which determine the location of the workings of the abovemined seam relative to the edge parts and the pillars formed on the abovemined seam, were changed.

Fig.1. The recommended scheme of the workings location of the mining seam, taking into account the gobs and pillars along the overlying seam

Fig.2. Three-dimensional model of a rock mass 1 – the gob of the upper seam; 2 – the recovery room; 3 – the workings of the longwall panel; 4 – the upper seam; 5 – the lower seam; 6 – the gob of the lower seam

Discussion of the results

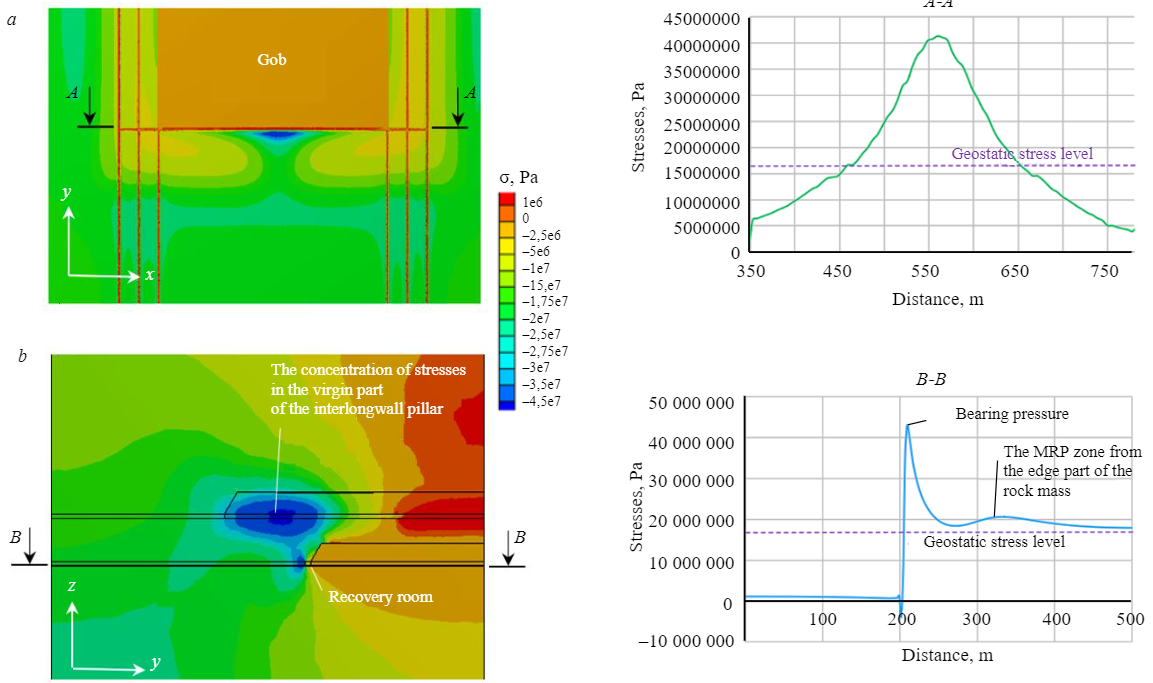

As an example of the obtained results, Fig.3 shows the distribution of vertical stresses: in the plane of the lower seam (Fig.3, a) and the vertical plane passing along the central part of the pillar formed between the mined out longwall panels along the upper seam (Fig.3, b). The results are presented for the following data set: depth 600 m, interbed thickness – 50 m, longwall length along the abovemined seam 300 m, width of the pillars 30 m, longwall length along the abovemined seam 400 m, width of the pillars 40 m, displacement of the recovery room under the gob 100 m.

As can be seen from Fig.3, the location of the recovery room with a significant (100 m) displacement under the gob when using the recommended scheme for the layout of workings does not exclude the formation of zones with increased stresses associated with the influence of a non-destructible inter-longwall pillar. Considering the absolute values of stresses in this zone, it can be concluded that they do not exceed the stresses that could occur in the zone of the bearing pressure of the longwall in the absence of the influence of overworking. Thus, for the situation under consideration, the stress level is not elevated, but the uneven nature of its distribution and the crucial influence of the pillar forming the SSZ should be taken into account when determining the parameters of the supporting patterns and choosing the sequence of disassembling of the the equipment. In addition, in the event of dead-end breakthroughs, their location in high-stresses zones under the pillars should be completely excluded or minimized.

Fig. 3. Fields and plots of vertical stresses in typical cross-sections of the model

Studies have shown that the interbed thickness plays a major role and, all other things being equal, determines the conditions for maintaining the set-up and recovery rooms. For the simulated mining situation, a decrease in the interbed thickness while maintaining other constant parameters leads to a significant increase in the stress level under the pillar and a deterioration in the conditions for the formation and further operation of the recovery room. To determine the rational location of the recovery room, the current regulatory document* can be used, taking into account the influence of the edge parts and pillars on the level of roof displacements in the workings fixed with roof bolting support. The calculation of the expected displacements showed that in order to ensure the operational condition of the set-up room, its displacement under the gob of the abovemined seam by 30 m is sufficient.

Conclusion

The continuous improvement of the reliability and energy-efficiency of the longwall equipment created conditions for increasing the sizes of the longwall panels (the length and width), which made it possible to reduce the number of longwall panels within the mine fields and, as a result, the number of the longwall face moves, ensuring a reduction in the cost of coal mining. However, an increase in the longwall length led to an increase in the total mass of the longwall equipment, and the panel length led to an increase in the distance of its transportation, which ultimately increased the complexity of the longwall face move operations and necessitated the improvement of the applied technological schemes and labor organization.

The conducted studies have shown that at present, the greatest complexity lies in the longwall face move operations during the mining of thick seams. Exceeding planned deadlines for the longwall face move operations at the mines of JSC SUEK-Kuzbass is on average 50 days, reaching in some cases 100-200 days. The main reasons for the lower efficiency of longwall face move operations during the mining of thick seams include: a higher mass of equipment, complex geotechnical conditions for the formation and maintenance of recovery rooms, which complicate their subsequent operation, low throughput of hanging monorails, insufficient efficiency of the technological schemes used for the longwall face move operations.

Numerical studies have shown the need to take into account the uneven distribution of stresses within the recovery room when using the recommended scheme for mining previously abovemined seams. Studies have established that the main factors determining the possibility of ensuring the operational condition of the recovery rooms are: the interbed thickness, the properties of the interbed rocks, the recovery room displacement. The recovery room shift of 50 m is sufficient to minimize the impact of abovemining and ensure its operational condition, however, when choosing the supporting parameters and the sequence of the shields extraction, taking into account the uneven distribution of stresses (due to the influence of the pillars) is a necessary condition for the effective formation and maintenance of recovery rooms in abovemined areas. The set-up room shift when using the recommended scheme (see Fig.1) should be at least 30 m.

The following measures are recommended to improve the technology and organization of the longwall face move operation during the intensive mining of flat-lying coal seams in the Kuzbass mines:

- ensuring timely preparation of the new longwall panel due to the advanced development of panel entries and main workings;

- ensuring the rational location of the set-up and recovery rooms chambers relative to the edge parts and pillars formed on the adjacent seams;

- formation of the recovery room taking into account the main roof-caving increment;

- the use of longwall bolting unit of the Hygromatik type to increase the speed of the recovery room bolting;

- application of the three entries panel layout to improve the efficiency of transport and control of gas release at the longwall panels;

- ensuring the advanced implementation of dead-end breakthroughs to the place of recovery room formation, creating the possibility of independent work on the equipment removal simultaneously on several sites of the recovery room;

- implementation and wide application of pneumatic wheeled vehicles with ensuring conditions for their operation;

- the set-up room location in the one line with the recovery room (in suitable geological and mining conditions) to reduce the distance of equipment transportation;

- carrying out the advanced mounting of the longwall conveyor and the shearer.

The proposed recommendations will ensure a significant reduction in the timing of longwall face move operations by creating favorable conditions for the formation and maintenance of recovery rooms, timely preparation of a new longwall panel, the use of modern transport equipment and the organization of longwall face move operations.

*Federal norms and rules in the field of industrial safety: Instructions for the calculation and use of anchor supports in coal mines. Series 05. 2015. Iss. 42, p. 186.