Metrological support of equipment for geophysical research

- 1 — Ph.D. Head of the Directorate of Technologies in the Fuel and Energy Complex Russian energy Agency of the Ministry of energy of Russian Federation ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Project director in the technology in the fuel and energy sector directorate Ministry of Energy of the Russian Federation ▪ Orcid

- 3 — Dr.Habil. Professor Ufa State Petroleum Technical University ▪ Orcid ▪ Elibrary ▪ Scopus

Abstract

The article discusses the problems associated with metrological support of equipment for geophysical research, issues of ensuring the uniformity of well measurements, the creation of Russian standards for calibrating well equipment when determining the porosity coefficients and oil, gas, water saturation, determining the parameters of defects during well cementing and technical condition of casing strings and the water-oil-gas flow. The problems of creating full-fledged methods for measuring the parameters of oil and gas fields with conventional and hard-to-recover reserves have been investigated. The key directions of development of the Russian metrological support of geophysical well measurements were determined. The tasks that need to be solved to create metrological support for geophysical well logging as an industry that meet international standards are indicated. The expediency of creating a Russian Geophysical Center for Metrology and Certification, the need to develop a new and update the existing regulatory framework, which will allow Russian geophysics to reach the level of world leaders in the field of geophysical research, are substantiated.

Introduction. Russia possesses large mineral reserves, which are the basis for guaranteed ensuring the country economic and energy security, meeting current and future needs of the Russian economy in hydrocarbons, coal and other minerals. As of January 1, 2015, the volume of recorded reserves in Russian fields reached 18.3 billion tons of oil and 50.2 trillion m3 of gas [9]. By 2035, due to geological exploration, a cumulative increase in oil reserves in the amount of more than 13-15 billion tons, gas reserves – 25-27 trillion m3 can be provided [9]. At the same time, the volume of deep drilling for oil and gas can reach 25 million cubic meters. For the entire period up to 2035, the West Siberian, Leno-Tunguska, Caspian, Timan-Pechora and Volga-Urals oil and gas provinces (onshore) will remain the main areas of growth in oil and gas reserves.

Western Siberia, under certain conditions, has a chance to remain the main oil-producing province of Russia for a long time:

• The degree of exploration of the resource base, even in areas of intensive oil production, does not exceed 80 %, which allows us to expect the discovery of significant reserves of “new” oil.

• Introduction of new technologies aimed at increasing the oil recovery factor at the fields under development will increase production by more than 4 billion tons.

• Involvement in the development of 21.5 thousand idle stock of marginal (less than 5 tons / day) and highly watered (over 95 %) wells will make it possible to produce more than 12 million tons of oil annually.

The development of fields with hard-to-recover reserves (HTR reserves) and the Arctic shelf is one of the most important areas for stabilizing the level of oil production in the Khanty-Mansiysk Autonomous Area – Yugra, Western Siberia and the Russian Federation as a whole. By 2030, the level of production from HTR reserves may exceed 20 million tons/year [9].

Geological study of subsoil for the purpose of assessing and accounting for mineral reserves, control over their rational extraction and reproduction are based on geophysical measurements carried out during prospecting, exploration and development of mineral deposits using geophysical equipment.

The world market for geophysical services is developing. New methods of geophysical well logging (GWL) are aimed at improving the accuracy of determining the parameters of deposited formations, the use of new technologies for construction and injection of wells, at the rational extraction of deposits. These measures make it possible to achieve an increase in the well flow rates and estimate the state reserves of hydrocarbons with an admissible relative measurement error of up to ±16 % for explored mineral deposits (category A) and ±56 % for the reserves of a deposit (part of it), the presence of which is justified by geological and geophysical research (category C2 [4]).

At the moment Russian GWL are able to provide indicators of uncertainty (or inaccuracy) of measurements when assessing oil and gas reserves, at best, at a level of ±10 %, which is lower than that of the world leaders, whose declared indicators reach ±2 % [6]. Improving the measurement accuracy is associated with both updating of the technical part of geophysical well logging (GWL) equipment (modern sensors, electronic components, the use of new materials in the production of GWL equipment), and with the development of their metrological support [3,5,6,11,13].

To improve the accuracy of measurements by GWL equipment and to develop methodologies for data interpretation, it is necessary to solve the following issues of GWL metrological support:

• Development and manufacture of modern standards, which will reduce the permissible relative error of GWL equipment to ±2 %.

• Development and production of test-bench equipment with absolute errors of reproduction of influencing physical quantities with a relative error of up to ±1 %.

• Development of scientifically grounded standardized and certified methods for conducting geophysical measurements in wells.

• Formation of human resources in the field of GWL metrological support, corresponding to world standards.

Advantages of developing its own system of metrological support for GWL in Russia:

• Increase in the accuracy of estimating the mineral resource base up to ±2 % for category A (as of July 2020 for oil, it ranges from ±16 to ±56 %, depending on the category of reserves), the degree of validity of decisions on recovering reserves.

• Search and study of productive strata and confirmation of reserves in new fields, including fields with HTR reserves and the Arctic shelf, with reasonable accuracy indicators.

• Identification of overlooked reserves at fields put into operation.

• Increase in the quality of services for geophysical well logging, quality control of certified downhole equipment.

• Access of geophysical measurement service to regions of the world with confirmation of the uniformity of geophysical standards of the Russian Federation with similar standards of other countries.

The development of metrological support is determined by two key areas:

• Creation of missing rock standards in full. The need to create new rock standards is due to the fact that search and development of new deposits with different geographic locations are being actively pursued, new little-studied structures appear, for which there are no standards, it creates significant difficulties in assessing reservoir properties and interpreting well log data. A detailed study of new fields is necessary to reduce development and operation costs, minimize risks associated with omission of hydrocarbon reserves, as well as to develop new technologies for extraction of hydrocarbons, increase the recovery factor, and estimate state mineral reserves with a permissible relative error of up to ±2 %. This requires the calibration of GWL equipment on the standards of parameters of rocks crossed by the well.

• Mathematical modeling [11,12]. Geophysical measurements are carried out in heterogeneous media, which causes significant difficulties both in creation of the necessary methods and measuring instruments, and in the development of metrological support methods, therefore, the number of rock standards in large metrological centers of the world is estimated in thousands. For example, the Environmental Effects Calibration Facility (EECF) in Houston has the largest set of artificial rock simulators (over 1000 different options) for geophysical measurements carried out around the world [13]. If there is no suitable one among the breed simulators, specialists of the center can select the necessary parameters using fillers and special inserts.

It is impossible to take into account the influence of entire gamut of factors influencing the measurement result using only standards, therefore the accuracy indicators of GWL will be at the level of ±10 %. In world practice, to improve the accuracy of measurements of GWL equipment and to minimize the influence of external factors on the measurement results, mathematical modeling is used, it can significantly increase the accuracy of well measurements.

The use of mathematical algorithms allows: to take into account some systematic effects that affect the measurement error with geophysical instruments for different operating conditions; apply compensation mathematical algorithms in geophysical tools for atypical logging conditions (weighted drilling mud, misalignment of tools with the well axis, etc.); correct measurements of GWL equipment in different diameters and structures with repeatability of measurement results for the same rocks within ±2 %.

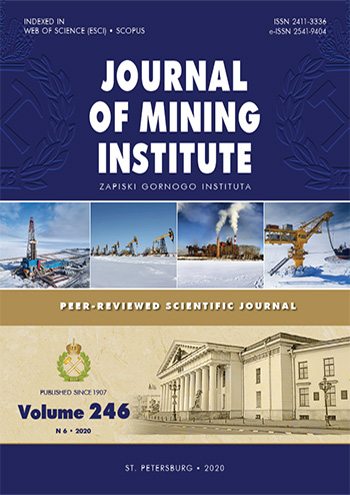

Improving the accuracy of well measurements is especially critical for the economy when determining porosity ratio of the rock and oil, gas, and water saturation of the reservoir. These coefficients are used to assess (calculate) state reserves of the mineral resource base. Based on their values, a decision is made to develop a deposit (aquifer) with construction of all expensive infrastructure. Estimation of geological oil reserves is carried out according to the formula shown in Fig.1.

To estimate the permissible relative error of geological oil reserves of less than ±10 %, it is required to measure all the initial parameters with an error of no more than ±2 %.

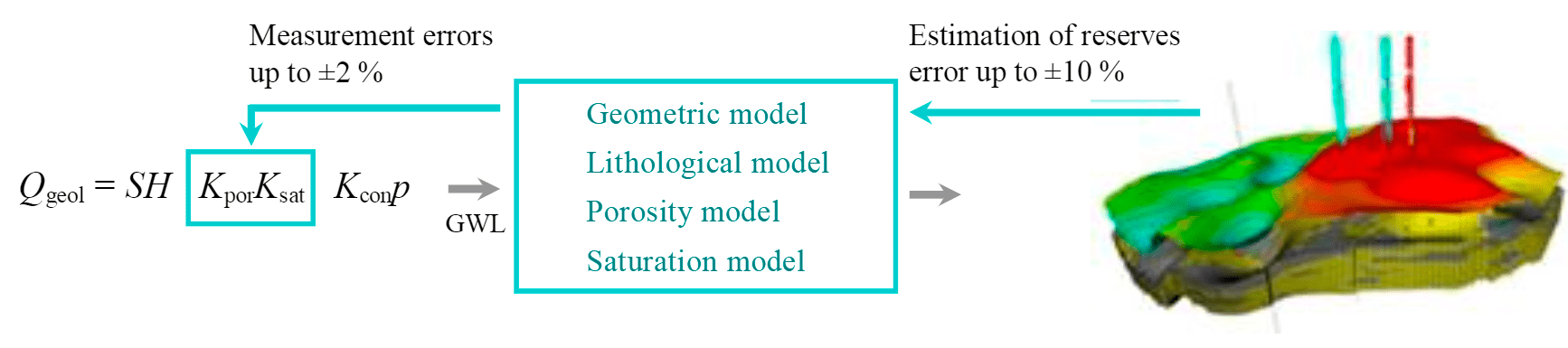

Mathematical modeling in the metrological support of GWL equipment is inextricably linked with physical standards of rocks, which are necessary for working out mathematical algorithms and for confirming the correctness of calculations carried out using a mathematical model. Methodologies for interpreting GWL data are being worked out on the standards. Figure 2 shows a block diagram of metrological support using a mathematical model of the measuring process, used in world practice in the absence of real standards of rocks crossed by a well.

It should be noted that the use of measurement modeling for conditions when there are no real standards does not always allow assessing the adequacy of the mathematical model to a real object and assessing the real errors of the well measurements performed.

The estimation of geological oil reserves in the field is determined by method of indirect measurements of oil mass according to the values shown in Fig.1. Let us estimate the proportion of the influence of the product porosity and oil saturation coefficients, determined from GWL data, on the error of oil reserves. The ratio of the error to the measured value of porosity of the oil reservoir characterizes the share of losses from the planned volume of oil production, but not produced due to its unreliable estimate [6]. For example, for a field with an estimated recoverable oil reserves of 10 million tons and an average value of the porosity ratio of the formation of 0.2 fractions of a unit (effective porosity 20 %) according to the method [6], it is possible to calculate losses from the planned, but not produced oil. Thus, the absolute measurement error of the porosity ratio of ±1 % will cause losses equal to 1/20 of the estimated oil mass reserves, and will amount to ±0.5 million tons. At the cost of marketable oil 18 thousand rubles per ton losses may amount to about 9 billion rubles. When measuring oil saturation coefficient of the pore space, 0.8 fractions of units (effective porosity 80 %), the absolute measurement error of the porosity ratio is ±4 %, additional losses of another 9 billion rubles can be expected. If we take into account that the measurement errors of porosity and oil saturation coefficients can be greater, and add more errors in the measurement of the effective reservoir thickness, the reservoir area and the oil recovery factor (ORF), then the losses from undeveloped oil in such a field can amount to more than 50 billion rubles.

By 2035, due to geological exploration, a cumulative increase in oil reserves of up to 15 billion tons can be ensured. According to the method for calculating the minimum losses caused by errors in GWL equipment (with an effective porosity of 20 %), losses by 2035 can reach 13.5 trillion rub. If oil saturation coefficient is within the same limits (0.8 fractions of a unit), the absolute error in measuring the porosity coefficient is ± 4 % (effective oil saturation 80 %), then possible losses can double, and taking into account other errors, even more. It is necessary to take into account the fact that these losses are calculated only for geological exploration, without taking into account losses during production drilling and completing wells (for example, in a hydraulic fracturing operation when identifying zones of a productive formation with maximum fracturing).

Metrological support of GWL in Russia. The main criterion for the competence of a metrological center in the field of GWL metrology is the ability to reproduce physical quantities with a minimum permissible error. Means for reproducing physical quantities in the metrological support of well logging are standards of rock parameters and standards of well parameters [5]. Industry does not serially produce only rock standards out of all the necessary equipment for metrological centers in Russia. This is due to the fact that the properties and content of geophysical standards are different, metrological centers are engaged in the production of standards mainly to meet their own needs and the needs of geophysical companies. Therefore, creation of primary standards and their comparison with working ones ones to ensure the uniformity of wells measurements is an important and priority task of the metrological center.

When creating a reference base, it should be borne in mind that real porous layers of different mineralogical composition may contain water, oil, gas and clay material in the pores. The well can also contain various substances and materials – mineralized water, clay and polymer solution, oil-based solution with a range of additives, aerated solutions, cement, steel column. The column may contain water, oil or gas, which affect the concentration measurement error, which can be estimated and reduced only if there are standards with different fluids in the required ratio.

Since real porous formations are studied simultaneously with different types of neutron logging (NL), gamma-gamma logging (GGL), nuclear magnetic logging (NML) and induction logging (IL) probes, the standards should also allow reproducing Kpor simultaneously for each type of probe [5, 7]. In addition, a part of the set of Kpor standards should simultaneously reproduce the oil saturation and gas saturation coefficient. If the clay content is considered as an influencing value, then it is necessary to build part of the Kpor standards with reproduction of Kcl.

The standards of porosity, water, oil, gas saturation and clay content should be based on the possibility of constructing typical calibration functions (CF), verification functions (VF) and calibration and verification functions (CVF) for the total number of typical gas-turbine installations (normal calibration conditions).

The NL equipment readings vary depending on Kpor, mineral composition of the matrix, fluid in the pores and in the well, and on the diameter of the well. The total number of created standards Kpor is determined by the influencing values. Their number can be estimated from the following calculations.

The number of reproducible Kpor values is generally assumed to be Nk.por = 3, since this is the minimum number of values for a parabolic CF for one set of influencing quantities (gas-turbine installations). The amount of pure minerals Nmn = 3 – is sandstone, calcite and dolomite. The amount of pure homogeneous aggregates 100 % of the pore space Np = 7 (water with 0; 50; 100; 200 g/l NaCl, oil, gas, clay). The number of well diameters Nd.w = 3.

The total minimum number of required porosity standards is calculated by the formula

To change the normal values of substance parameters in each well, it is necessary to be able to change the density and composition of the clay solution (Ncl with different contents of bentonite, barite, oil) and the content of potassium chloride (sodium) N(K)Cl in it, change the reference inserts in wells with different values of the well diameter Nd.w, the diameter of the drill string Nd.str, the wall thickness of the string Nth.str the cement density Ndem. cem. and the eccentricity of the drill string relative to the well Nref. str..

The total minimum amount of required solutions in wells of porosity standards is calculated by the formula

The total minimum number of required reference inserts into the wells of the porosity standards

If we assume that changes in the string wall thickness insignificantly affect the NL instrumentation readings and select one (average) value, then the number of reference inserts can be reduced to 81.

It is possible to optimize the number of required porosity standards by combining three wells of different diameters in bulk standards and reduce the amount of pure substances in the pores to four (water, oil, clay, replaceable aqueous solution of NaCl). The optimal number of standards of porosity and density is calculated by the formula

Standards of water, oil, gas saturation and clay content of porous formations should be created on the basis of possibility of constructing standard CF, VF and CVF for equipment with integrated gamma ray logging probes – spectroscopy (INGL-S), IL, NML. To determine the parameters of water, oil, gas saturation and clay content, it is necessary to first measure Kpor, which is an influencing quantity.

The readings of the INGL-S equipment vary depending on Kpor, the mineral composition of the matrix, the substance in the pores and in the well, and the diameter of the well. The total number of Kpor standards created is determined by the influencing values on the readings of the INGL-S equipment. There are fewer factors influencing the IL and NML readings, since they do not depend on the chemical composition of the rock matrix.

The total minimum number of required standards for water, oil, gas saturation and clay content, taking into account the available standards with 0 and 100 % content in the pores of these components, can be calculated by the formula

where Nk.w, Nk.oil, Nk.gas, Nk.clay – is the number of reproducible values of the coefficients of water saturation, oil saturation, gas saturation, clay content, respectively.

If three wells are combined in one casing and gas in the pores is excluded, then the minimum number of required standards of water, oil saturation and clay content can be calculated by the formula

The total minimum number of standards for porosity, water, oil, gas saturation and clay content of porous formations is 63.

The results of the inventory of the main metrological centers in the Russian Federation for the presence of the required number of standards:

• Metrological services of geophysical companies are equipped with an incomplete set of necessary standards for making measurements in oil and gas wells (the level of equipment of leading geophysical companies in Russia with standards is from 10 to 35 %);

• The reference base of geophysical companies is dominated by standards for measuring simple physical quantities: acoustic parameters (speed and attenuation coefficient of ultrasound), temperature, pressure, water flow rate, density and electrical conductivity, well diameter, depth of probe immersion in the borehole, angular values. The standards of rocks porosity are insufficient for constructing accurate measurement techniques in typical geological and technical conditions (there is a small proportion of standards based on marble, less often on the basis of quartz). There are no standards for the porosity of dolomite rocks, oil-saturated and gas-saturated rocks. It is impossible to assess the influence (build influence functions) of clay content and chlorine concentration in the reservoir and in the well on the readings of nuclear geophysical downhole tools. There are no standards for the coefficient of oil and gas saturation and permeability of rocks for different geological and technical conditions, as well as electrolytic standards for electrical logging probes and many others.

• The uniformity of measurements of the porosity ratio of rocks in Russia remains an unresolved issue. The reliability of the assessment of initial, current and residual reserves of oil, gas and other minerals with a permissible relative error of the logging equipment ±10 % is not guaranteed. Accordingly, the oil recovery factor is estimated with a confidence level of no more than ±10 %.

• There is no single metrological service in Russia responsible for measurements in the field of subsoil use. Therefore, creation of the Russian Geophysical Center for Metrology and Certification (RGCMC) with a full set of primary state standards is a priority task in the metrological support of Russian GWL. Without it, state accounting of hydrocarbon raw materials is possible, but with a large error (at least ±10 %), and competition of Russian geophysics in the world market is impossible.

Due to the lack of reference standards and scientifically grounded standards, geophysical instrumentation in the Russian Federation is currently significantly inferior to foreign competitors in the accuracy of well logging results. There is no possibility of creating full-fledged calibration methods, assessing the geological parameters of traditional oil and gas fields and HTR-reservoirs. The development of scientifically based methods for calibrating well logging instruments and interpreting data (especially for new, little-studied sections, as well as standards for these sections) with high accuracy and reliability is difficult. The training of qualified personnel in the field of metrological support is insufficiently developed, because existing standards were developed in the 80s of the last century. The properties of these standards have already been studied in detail, they are relevant for the last century [7, 17]. Therefore, GWL metrology, the creation of standards capable of reproducing the physical properties of the HTR sections and the Arctic shelf, is developing slowly.

The absence of a number of standards, in particular such as the standards of porosity of dolomite oil-saturated and gas-saturated rocks, does not allow Russian geophysics to develop in the field of creating fundamentally new geophysical methods for research in wells, new equipment, for example, for the application of methods of magnetic resonance imaging of reservoirs, acoustic fracture scanners, spectroscopy, etc. [17]. For example, on September 3, 2019, a new foreign system was announced, in which methods of microelectric and high-frequency ultrasonic logging were implemented in one tool, which made it possible to increase the resolution of determining fractures in the formation with an accuracy of 1 mm [10]. This well logging method has been successfully applied in Russian HTR fields and has shown its effectiveness when using hydraulic fracturing technology. To create equipment of this class, standards with known characteristics of microelectric logging and rock fracture parameters are required.

Priority directions in the field of metrological support of GWL. Today the following priority areas of Russian metrology in the field of GWL can be identified [5].

1. Manufacturing of reference samples with the required technical and physical parameters:

• standards of oil and water saturation coefficient of porous rocks with porosity from 1 to 40 % with basic permissible absolute error (0.9 + 0.02 Kpor). According to the material composition of the mineral matrix, they can be sandy (quartzite), calcite and dolomite: standards of the porosity ratio and the oil, gas, water saturation coefficient of porous sandy, calcite and dolomite formations intersected by wells of different diameters, completed with cemented casing strings for neutron logging equipment; porosity standards with plastic housings for nuclear magnetic logging equipment;

• standards of clay content and concentration of uranium (U), thorium (Th) and potassium (K) of porous sandy rocks with exposure dose rate of gamma radiation from 2 to 250 μR/h, basic relative error is ±15 %; standards of calcite and dolomite strata intersected by wells of different diameters, with different cemented casing strings for gamma-ray logging and spectrometry equipment when constructing calibration functions for different normal measurement conditions;

• standards of cased well parameters for gamma-acoustic control of technical condition, interval time of ultrasound propagation from 140 to 600 μs/m with an admissible basic relative error of ±3 %, an ultrasound attenuation coefficient from 2 to 30 dB/m with an admitted basic relative error ±15 %: standards of cement density at a fixed casing wall thickness and formation density for different geological and technological conditions; standards for the parameters of the “micro-gap” between the casing and cement, between the cement and the rock, the parameters of a typical defect “channel”;

• standards of flow parameters in the casing and behind the casing flows of fluids are required for GWL control of the development of oil and gas fields on a set of standards that reproduce the parameters of the water – oil – gas flow in production strings of directional and horizontal wells: a working standard of flow parameters in the string for wells flow meters, moisture meters, density meters and resistivity meters; standard installation of a multiphase flow meter for water – oil – gas.

• standards of electrical parameters of seams with the range of measurements of electric conductivity from the specific electrical conductivity of an infinite homogeneous medium and the measurement range of 0.025-50 S/m with an admissible basic relative error of ±0.5 %; development of a technique for direct measurements of the specific electrical conductivity for a formation crossed by a well; calibration with experimental construction of the CVF of two variables at a standard well diameter; verification of methods for measuring the specific electrical conductivity of a formation in the presence of an invaded zone.

2. Ensuring the comparison of Russian standards with those of the EEC, SCO and BRICS member states, as well as the United States to maintain the uniformity of geophysical measurements at the international level, the competitiveness of Russian geophysics and recognition by international metrological centers.

3. Initiation of work on the technologies and software for mathematical modeling development.

4. Development of new methods for calibration of logging equipment and, accordingly, new methods of data interpretation, in order to reduce the relative measurement error to ±2 %, regardless of external factors.

Creation of a metrological center in Russia. In the world practice of GWL, countries – leaders in the field of geophysical science, engineering and technology have created their own national metrological centers. The purpose of creating such centers is to ensure the uniformity of the required measurement accuracy with the help of calibration laboratories certified in accordance with the requirements of the international standard GOST R SO-IEC 17025-2006.

Creation of a single RGCMC with the participation of the state (allocation of a land plot for new construction, competencies and equipment), state and private oil and gas companies (creation of modern high-precision geophysical standards, construction of storage for them and buildings for testing and certification of geophysical equipment) and oil service organizations, will improve the accuracy of geophysical data on Russian fields, including HTR reserves and on the Arctic shelf, as well as enter the international level of providing geophysical services.

The functioning of the RGCMC will allow solving the following tasks:

• creation, storage and maintenance of high-precision primary national geophysical standards of the world level;

• ensuring the transfer of units of geophysical quantities to working standards and instruments of geophysical companies in Russia and foreign ones operating in Russia [5];

• ensuring in the oil and gas sector the unity and required accuracy of downhole geophysical measurements performed with the participation of domestic and foreign companies [5];

• creation of a unified regulatory framework and carrying out metrological examination of reports on the assessment of oil and gas reserves, field development projects;

• guaranteeing the reliability of the assessment of mineral reserves and resources of the Russian Federation, including deposits with HTR reserves and deposits on the shelf of the Arctic and the Far East;

• certification of measuring equipment and audit of participants in the market of geophysical services; certification of equipment to confirm compliance with the requirements of domestic and foreign geophysical standards;

• certification of geophysical services for maintaining the register of geophysical companies, the competence of which is confirmed by an independent accredited body – RGCMC;

• creation and maintenance of the register of available geophysical technologies, both Russian and foreign, for subsoil use;

• comparison of Russian geophysical standards with the standards of the member states of the EEC, SCO and BRICS, as well as the PRC, USA, France and Great Britain; maintaining the uniformity of geophysical measurements at the international level;

• participation in the training of highly qualified specialists with a deep knowledge of the theory and practice of downhole measurements of parameters of oil and gas reservoirs intersected by wells [2];

• protection of subsoil users from unreliable geophysical information;

• increasing the competitiveness of Russian geophysics in the world market;

• creation of a reference base taking into account the geological features of the sections of fields in the regions of the Russian Federation.

Solving these problems will provide scientifically based management of rational oil recovery in Russia with a reliable estimate of oil and gas reserves. The development and implementation of requirements for the system of ensuring the uniformity of geophysical measurements, certification of geophysical equipment, technologies and geophysical services in the Russian Federation will allow training qualified personnel in the field of metrological support of GWL in accordance with the leading industry trends. It is important to note that such a center does not necessarily have to be located in one place, but may have a developed regional network and use the existing infrastructure, including that associated with the defense industry enterprises.

Related industries and personnel. To create world-class metrological support in Russia, personnel in the field of geology, geophysics, petrophysics, mathematics, chemistry, physics will be required. With the development of equipping metrological centers with the necessary equipment, the following opportunities will appear: conducting scientific research and substantiating research results using the equipment of the metrological center; development of new (including combined) logging equipment and the ability to confirm the characteristics of this equipment; development of new methods and technologies for studying reservoir properties; development and scientific justification based on experimental research, measurement methodology and interpretation of well logging data; conducting research work in the field of geology and geophysics.

All these possibilities will make a significant contribution to the development of science both in the field of metrology and in related fields (geology, geophysics, petrophysics, etc.) and, as a result, will allow obtaining world-class personnel in all related areas.

To create standards of stands, the competence of the following Russian industrial enterprises will be required:

• the military-industrial complex of the Russian Federation for the creation of high-precision reference sensors and measuring instruments: precision temperature sensors with a resolution of at least 0.1, an error of less than 1 % (operating temperature up to 150 0С, operating sinusoidal vibrations up to 30 g, operating shock load up to 1000 g); precision pressure sensors with a resolution of at least 0.1, an error of less than 1 % (operating temperature up to 150 0С, operating sinusoidal vibrations up to 30 g, operating shock load up to 1000 g); precision electronic component base; high-temperature shock vibration-resistant accelerometers (operating temperature up to 150 0С, operating sinusoidal vibrations up to 30 g, operating shock load up to 1000 g); high-temperature shock, vibration-resistant magnetometers (operating temperature up to 150 0С, operating sinusoidal vibrations up to 30 g, operating shock load up to 1000 g); electromechanical devices (downhole electric turbine generators, centralizers, surface-controlled downhole pressure devices, precision pumps with control of the amount of pumped fluid with an accuracy of at least 0.1 %, etc.).

• the mining industry to obtain the necessary fractions of rocks with the required physicochemical properties and create new standards for new little-studied or unexplored deposits, as well as deposits with HTR reserves and on the Arctic shelf.

Conclusion. The existing domestic geophysical measuring technique and equipment are widely used in the fields being developed – up to 80 % of the total volume of geophysical work (up to 20 % of the work is performed by foreign companies). Exploration and development of new and little-studied oil and gas fields in Russia, including in the Arctic zone [8, 16] and fields with HTR reserves [16] require prompt solutions of the issues related to the creation in the Russian Federation of its own reference base, stands and measurement techniques for new fields , updating, modernization of metrological equipment and methodologies for interpretation of well logging data for existing oil and gas fields.

The accuracy indicators of Russian logging complexes are at the level of ±10 % due to the limited set of standards for metrological work. Modern international requirements of the oil and gas industry to the accuracy indicators of well logging results are ±2 %. To achieve the world level of GWL metrology in the Russian Federation, standards, metrological benches and up-to-date methodologies for interpreting GWL data for new and little-studied oil and gas fields [14, 15] are required both in Russia and in the world.

Among foundations for creation of a unified and efficient industry of GWL metrology in the Russian Federation, including to ensure the entry of domestic service companies providing logging services to the international oilfield service market and to maintain the current level of oil production under the optimistic scenario at 550 million tons per year by 2035. [1], such things should be named:

• production of Russian laboratory metrological equipment – up to 4000 items;

• creation of test stands – up to 25 sets;

• creation of sets of series of rock samples with reference to regional geology – up to 3000 units of metrological standards;

• organization of a unified national metrological center, including regional metrological centers (up to eight), distributed in federal districts of Russia or in oil and gas provinces;

• development of unmanned technologies for conducting routine laboratory work (in the Russian Federation it is possible to automate up to 500,000 equipment calibration operations per year);

• predictive analytics for analyzing the results of geophysical surveys.

Full implementation of all proposals for the development of domestic well logging metrology in the oil and gas industry will allow to obtain the following results by 2035:

• growth of up to 40 % of the level of labor productivity due to the introduction of unmanned technologies and optimization of research algorithms;

• reduction of operating costs for exploration and development of deposits by increasing the accuracy of measuring well logging in the fuel and energy complex – in 2020 prices up to 117-135 billion rubles;

• creation of new jobs in metrology of GWL in the Russian Federation for highly qualified personnel – up to 30 % of the current total number of engineers and workers in the industry;

• reduction of dependence on the imported metrological equipment and applied research methods up to 90 %;

• an opportunity to occupy up to 20 % of the world market of geophysical studies of wells, amounting to $ 8.8 billion as of 2019 [18].

According to the analysis results, there is a possibility of increasing a number of risks in the development of GWL metrology in Russia in accordance with the proposed plan. First of all, these are technological risks due to possible sanctions restrictions on the supply of foreign equipment and technologies and the dominance of foreign companies when carrying out a set of well logging works at new oil and gas fields. The development and implementation of our own technologies and technical competencies while securing long-term contracts between customers and manufacturers should reduce these risks. There are also financial risks: high capital costs for retrofitting and creation of metrological centers, costs for creating a system for processing metrological data on a national scale. Financing of the work is supposed to be carried out on the basis of the public-private partnership scheme. It is also worth noting production risks: the risk of failure to meet and break the deadlines for the development of equipment and stands, the risk of non-compliance of the manufactured products with the original technical industry requirements. Only active interaction of developers and manufacturers with government authorities, introduction of the best world project management practices with a clear link to domestic realities and the specifics of the oil and gas complex can completely eliminate negative production factors.