Spatial non-linearity of methane release dynamics in underground boreholes for sustainable mining

- 1 — Ph.D. Assistant Professor North Caucasian Mining and Metallurgical Institute ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Ph.D. researcher Federal Research Centre the Subtropical Scientific Centre of the Russian Academy of Sciences ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

Abstract

The paper is devoted to the problem of increasing energy efficiency of coalmine methane utilization to provide sustainable development of geotechnologies in the context of transition to a clean resource-saving energy production. Its relevance results from the fact that the anthropogenic effect of coalmine methane emissions on the global climate change processes is 21 times higher than the impact of carbon dioxide. Suites of gassy coal seams and surrounding rocks should be classified as technogenic coal-gas deposits, while gas extracted from them should be treated as an alternative energy source. Existing practices and methods of controlling coalmine methane need to be improved, as the current “mine – longwall” concept does not fully take into account spatial and temporal specifics of production face advancement. Therefore, related issues are relevant for many areas of expertise, and especially so for green coal mining. The goal of this paper is to identify patterns that describe non-linear nature of methane release dynamics in the underground boreholes to provide sustainable development of geotechnologies due to quality improvement of the withdrawn methane-air mixture. For the first time in spatial-temporal studies (in the plane of CH4-S) of methane concentration dynamics, according to the designed approach, the parameter of distance from the longwall (L) is introduced, which allows to create function space for the analyzed process (CH4 of S-L). Results of coalmine measurements are interpreted using the method of local polynomial regression (LOESS). The study is based on using non-linear variations of methane concentration in the underground boreholes and specific features of their implementation to perform vacuum pumping in the most productive areas of the undermined rock mass in order to maintain safe aerogas conditions of the extraction block during intensive mining of deep-lying gassy seams. Identification of patterns in the influence of situational geomechanical conditions of coal mining on the initiation of metastable gas-coal solution transformation and genesis of wave processes in the coal-rock mass allows to improve reliability of predicting methane release dynamics, as well as workflow manageability of mining operations. Presented results demonstrate that development of high-methane Donbass seams is associated with insufficient reliability of gas drainage system operation at distances over 40 m behind the longwall face. Obtained results confirm a working hypothesis about the presence of spatial migration of methane concentration waves in the underground gas drainage boreholes. It is necessary to continue research in the area of estimating deviation angles of “advance fracturing” zone boundaries from the face line direction. Practical significance of research results lies in the possibility to use them in the development of scientific foundation for 3D gas drainage of a man-made coal-methane reservoir, taking into account spatial and temporal advancement of the production face.

Introduction. In our country, issues associated with the problems of coalmine methane are especially relevant due to the necessary “transition to a clean and resource-saving energy production and improvement of mining efficiency…”, which is one of the priority goals in the strategy of scientific and technological development of the Russian Federation. At the same time it agrees with a progressive global trend – utilization of the elements of the “green economy” concept in the development of underground geotechnologies in order to transit to “sustainable mining” [2, 21, 36]. Required elements of sustainable development (in the area of green mining) include complex subsoil development as part of the “Industry 4.0” program, maintenance of a resourceful environment, as well as measures, aimed at energy conservation in the mining sector [4, 28, 38].

Environmental focus of the mining sector is restrained by the absent conceptual vision of methane not only as a greenhouse gas, but also as an internal source of increasing coal mining profitability. Utilization of methane in gas reciprocating units for power and heat generation allows to increase energy efficiency of mining operations, while considerably lowering the costs of coal extraction. Operation of a local gas drainage network with concentration of gas in the mixture below 25 % is prohibited by current safety regulations, and integrity failure of even a single borehole (especially in the wellhead area) leads to formation of aerodynamic connection to the atmosphere of the mine working. It is a considerable threat to the safety of mining operations and provision of environmentally balanced management of natural resources.

Suites of gassy coal seams and surrounding rocks should be classified as technogenic coalgas deposits, while gas extracted from them should be treated as an alternative energy source (non-conventional type of hydrocarbon resources). Their intensive development is responsible for the difficulties in the description of interconnections between non-linear geomechanical and gas dynamic processes in the rock mass. This aggravates the problems of maintaining required quality of the withdrawn gas-air mixture for cogeneration purposes. The main deterrents against its effective involvement into the process of energy generation are the problems in the following areas: borehole stabilization [15], improvement of their drilling efficiency [11], imperfections of cutter-loader operating modes [25], significant surface methane emission from manmade faults and closed mines [16]. To overcome them, both time-tested methods (hydraulic fracturing) [7], and entirely new trends (biotechnologies) of coal-rock mass gas drainage are being developed [14]. At the same time, theoretical foundations and mechanisms of interconnections between aerogas and geomechanical processes during intensified mining operations remain understudied.

In its own turn, non-linear nature of mining pressure is manifested in the form of various borehole contour deformations and can lead to borehole failure [26, 43]. The nature of deformation wave processes during intensive development of gassy seams (assuming the equivalence of pressure in the powered support props and parameters of roof rock displacement) is usually explained using the moving arch concept by V.D.Slesarev (G.Ya.Polevshchikov [19]) or pendulum-type waves (V.N.Oparin [10]). These assumptions serve as a basis for particular case explanations of non-linear dynamics with respect to aerogas conditions modeling in gas drainage boreholes.

For the most effective gas drainage (especially spatial one) of methane release sources, it is necessary to represent time-domain advancement models of extreme fracturing areas in the plane of the longwall and development workings [8]. Studies [40, 41] introduce the mechanism of methane drainage in the area influenced by the development working. It is described by a model of generating stress relief in the annular-shaped zones (fracture, plastic, elastic and original stress zones in the rock mass) around the working and the borehole [27]. These zones witness redistribution of stress-strain state in the rock mass, which increases fracturing and permeability of gassy rocks. In a simplified manner presented concept describes development of zonal disintegration processes (E.I.Shemyakin, M.V.Kurlenya, V.N.Oparin), namely: “annular-shaped alternating zones of slightly disturbed and broken rocks form in the rock mass … around mine workings” [6].

Along the airway at different distances from the face line, according to the different level of anthropogenic disturbance, the rock mass is divided into the zones of maximum and transient permeability, barrier and stabilization [39]. Allowance for interaction of geomechanical factors in 3D models of rock strata displacement permits to predict the distribution of methane release in the volume of surrounding coal-rock mass. At the same time, its non-linear component is reflected only to a degree.

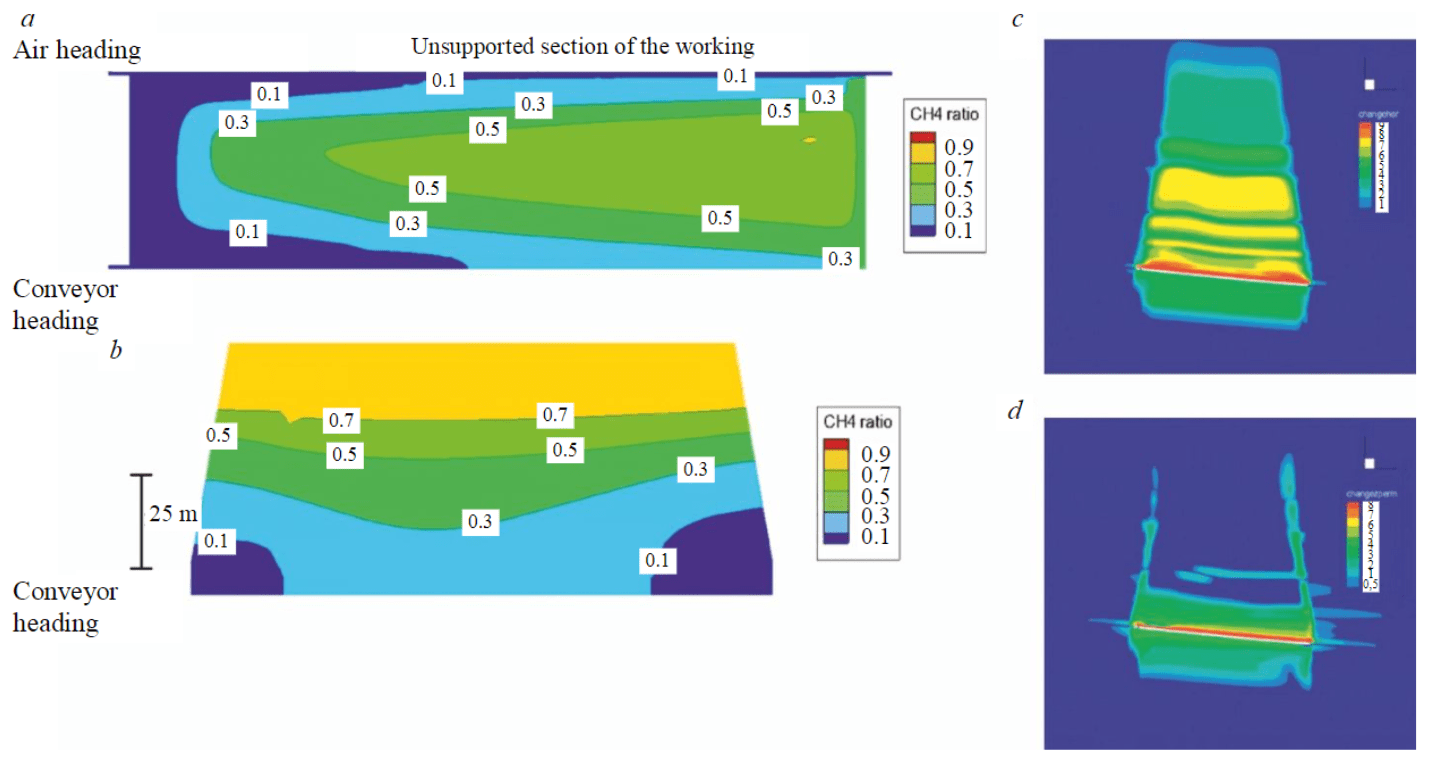

The most influential foreign studies on this topic are the works by H.Guo, L.Yuan, B.Shen et al., who applied experimental and analytical method to modeling of geomechanical and aerogas processes (Fig.1).

As a result, it is revealed that abutment pressure can spread up to the distance of 300 m ahead of the production face. Activation of overlying strata displacement intensifies stratification and fracture formation in the range of 170 m behind the longwall, while the height of man-made gas reservoir can reach up to 145 m from bottom to the top of the seam. In this zone stress level is much lower than in the abutment zone (presence of stress relief), which leads to intensification of methane release. In study [32] a flow model of methane-air mixture is developed, which takes into account deformation processes, occurring in the rock mass that surrounds the gas drainage borehole. It allows to consider the influence of various factors (gas sorption, coal porosity, sealing depth and air inflow) on methane concentration in the withdrawn mixture.

The majority of foreign and Russian researchers present results of their field observations on the dynamics of methane release depending on the time of measurements [18], distance to the longwall face [44] along the length of the extraction column [5, 35] or a combination of those [29]. The main drawback of most models is insufficient allowance for the time factor, as well as variations of situational geomechanical conditions of coal mining. This does not permit to identify nonlinear component of deformation processes and, consequently, reduces the quality of models for methane release dynamics.

The most influential studies of Russian researchers in this area are works [3, 9, 17, 42]. Study [17] was aimed at developing a theory of coalmine methane energy potential and identifying specific features of its implementation in the rock mass. As a result, a connection was established between the dynamics of methane release and non-linear manifestations of elastic pendulum-type waves in the coal-rock mass. This line of research requires development and verification of theoretical and experimental models, with sufficient certainty describing non-linearity of dynamics, as well as its differences from fluctuating and induced component (caused by production face advance).

Accordingly, this study is based on a hypothesis that “non-linear manifestations of stress-strain state in the surrounding rock mass (caused by spatial and temporal advancement of the production face) induce transformation of metastable gas-coal solution and generate methane concentration waves, which can shift depending on the distance to the longwall face and increasing span of the main roof”.

As seen from the above, identifying specific features of spatial arrangement of methane concentration waves in the underground boreholes is a fundamental scientific problem for providing sustainable advances in the underground technologies of gassy coal seam development at great depths. For this reason, the research subject is a specific nature of non-linear aerogas conditions of gas drainage boreholes, caused by stress relief waves and displacement of the roof rock.

Insufficient operational reliability of local gas drainage network can render impossible the use of coalmine methane as a fuel for gas reciprocating units in cogeneration plants. This maintains the relevance of developing a complex program in the area of ecological transformation and improvement of energy efficiency in the mining sector. Hence, the goal of this work is to identify patterns that describe non-linear nature of methane release dynamics in the underground boreholes to provide sustainable development of geotechnologies.

Materials and methods. The majority of researchers [5, 22, 34] have identified patterns and established semi-empirical dependencies of methane release dynamics or parameters of borehole spatial arrangement (distances to benchmarks S or to the face line L). On the other hand, the complex of obtained results does not allow to describe the general mechanism of the studied process in a fairly complete manner. Inaccuracies in the general statement of the problem and a limited approach to solving it are manifested in the impossibility to plot a four-dimensional space (including time) on a plane, which considerably narrows down the scope of solutions for such tasks.

The problems of spatial distribution of the studied parameter (coefficient of equivalent stress concentration in the rock mass, wind speed or frequency-directed wave spectrum) under the influence of internal and external factors are solved to a certain extent in the related areas of expertise. For example, stability of mine workings is successfully maintained using 3D modeling of various shape contours based on the finite element method (implemented in different software packages) [30, 31]. The drawbacks of this approach are similar to the ones specified in paper [32] (static description of the process, first-order consideration of horizontal permeability of the overlying rock mass, no reckoning of the non-linear nature of geomechanical processes or their influence on permeability, 2D interpretation of field-observed displacements in roof rock layers, irregularity of methane release over time).

In hydrometeorology [12 - 13] using reanalysis data from NCEP/NCAR Reanalysis1, spectral hydrodynamic modeling (based on Simulating Waves Nearshore Model) of wind wave parameters is performed. At the same time, comparison to the field observations (from reference weather stations) are carried out by means of regression analysis (in 2D formulation), which significantly limits the applicability of obtained results. A more rational approach is to approximate the studied spatial and temporal variables using Fourier series, as exemplified in solution to the problems of ore dressing optimization [23].

Results of observations were interpreted by means of local polynomial regression LOESS using the method from paper [20] to identify the approximating function in the presence of widely scattered data. The refinement of incomplete sampling was performed by means of 3D interpolation (Akima, Preusser, Renka, Watson). Optimization procedures were chosen for their determination coefficient, so that the projection of an optimized surface fitted the initial data as accurately as possible. The most satisfactory results were obtained with Watson algorithm, which interpolates using the procedure of circular aerial base, and Renka algorithm with its standard triangulation procedure by R.Renka.

Study [1] reported on wave variations of methane concentration in gas drained rocks mass during the development of m3 seam with methane content up to 23 m3/t daf. In the longwall technology of coal mining, before the start of panel development, сross-measure boreholes were drilled towards the production face every 25 m (there were 6-8 boreholes in simultaneous operation). The study identified non-linear nature of variations in methane concentration during gas drainage of the rock mass using boreholes with the same spatial orientation. This fact was registered behind the longwall as well as more than 45 m ahead of the face line. The drawback of this work is the absence of a method to visualize spatial distribution of gas flows in 3D. Therefore, experimental datasets [1] were used to process and obtain “isogas” surfaces (in 3D formulation), which reflected the dynamics of methane concentration depending on the distance to the face line and wellhead location in relation to the beginning of the extraction block. Measurements were performed at the wellhead of each borehole by a standard measurement procedure using Dräger X-AM 2500 gas analyzers with a catalytic sensor CatEx 125 PR Mining. In order to enhance reliability of experimental study, the data from Dräger X-AM 2500 were occasionally verified by SHI-12 interferometer (on the average, deviations did not exceed 10 %).

For the first time in spatial-temporal studies (in the plane of CH4-S) of methane concentration dynamics, according to the designed approach, the parameter of distance from the longwall (L) was introduced, which allowed to create function space for the analyzed process (CH4 a function of S-L).

Results and discussions. As a result of experimental data interpretation, a dependency is established between the variation of methane concentration in the underground boreholes and the parameters of production face advancement, which takes the form of a range of 2D (X = S, Y = L) Chebyshev polynomials of the first kind (of 7th order).

Chebyshev polynomials (in trigonometric notation):

The range of point determination (orthogonality interval for approximating Chebyshov polynomials) is \(\ S^{'}=S\) for all \(\ S \in [-1,1]\) and \(\ L^{'}=L\) for all \(\ L \in [-1,1]\).

Resulting (approximating with R2 = 0,967) function of methane concentration dependency on distance from the longwall face with increasing span of the main roof takes the form:

where СН4 – is the methane concentration, %; L is the distance from the wellhead to the production face, m; S is the distance from the beginning of the extraction block to the production face, m.

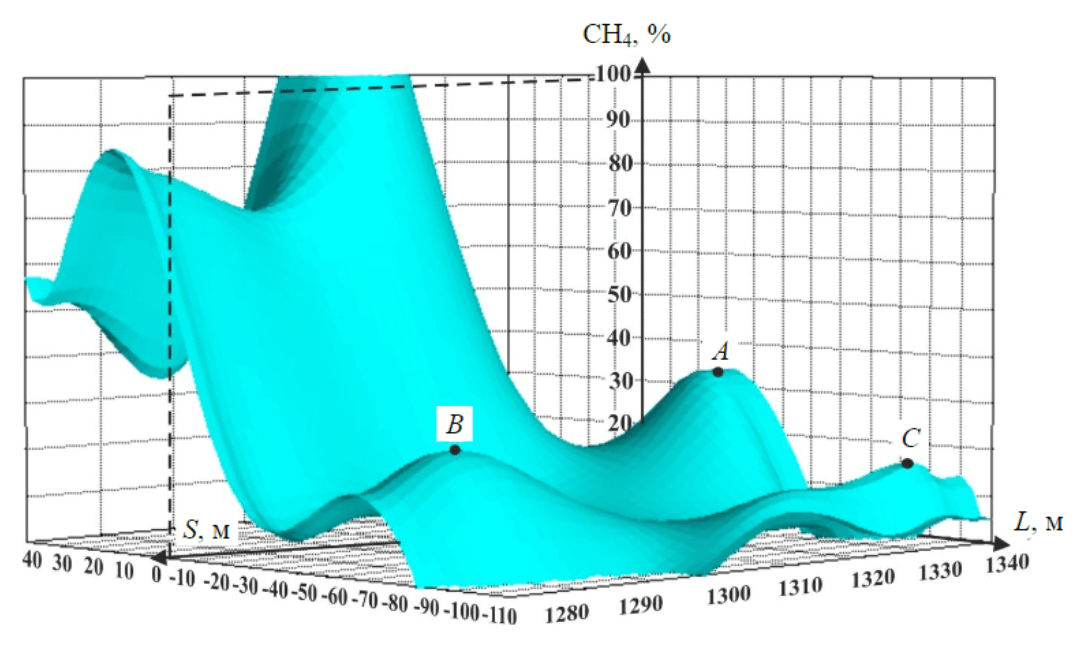

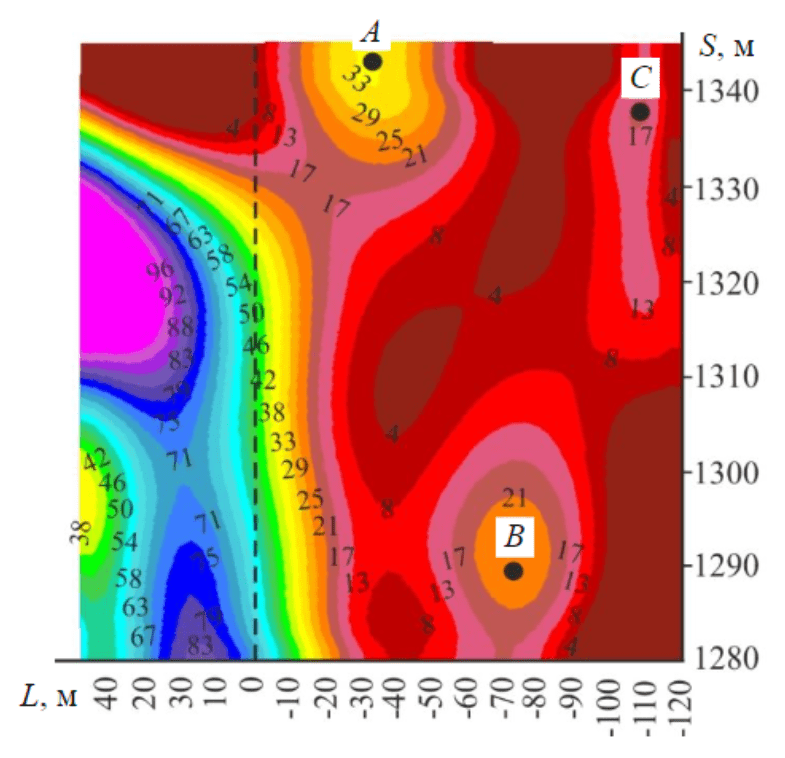

Analysis of surface 1 in the plane of CH4-L allows to identify zonal arrangement of local methane release maximums (Fig.2).

Displacements of regions with cyclical variation of methane concentration dynamics are graphically shown in Fig.2. The dash line marks zero distance to the face, negative values of L correspond to distances in front of the longwall, positive ones – in the gob area. It can be seen from the analysis of surface shape that the operation of boreholes, most of the time located in front of the longwall (over 10 m), is characterized by poor reliability (less than 25 %). Moreover, values and arrangement of local maximums and minimums also shift in a nonlinear manner across the entire (S-L) plane.

As stated in paper [1], presumably “the greatest influence on this process is exerted by the values of roof span and distance to the longwall” (Fig.3). Moreover, up to the distance of around 1.335 m from the beginning of the block (roof span of 25 m), local maximum region of methane release A, located at a 30 m distance from the longwall, started shifting closer to the longwall, gradually being replaced by local minimums.

From Fig.3 it follows that the specific features of spatial and temporal distribution of methane concentration are caused by increasing threshold span of the main roof. Three local maximum regions – points A, B and C. are observed on the examined surface (with wellheads in front of the face line). Extrema of the surface function in these regions appear at the following distances from the longwall: A (32 %) – в –41; B (23 %) – в –79 и C (17 %) – in –116 m.

The first region with operable conditions of the boreholes and an extremum in the point A is observed at the distance of 32-41 m from the longwall, located at the benchmark of 1.349 m, which corresponds to 11 m span of the main roof. At a comparable span, but 118 m ahead of the longwall (point C) methane concentration remains dangerously low. The region of local methane release maximum with an extremum in point B at the benchmark of approximately 1.294 m also corresponds to borehole failure parameters. It should be noted that the distribution area of this region expands, which can be explained by increasing roof span and increasing rock overhang with stratification along interlayer rock contacts, 67-72 m behind the longwall.

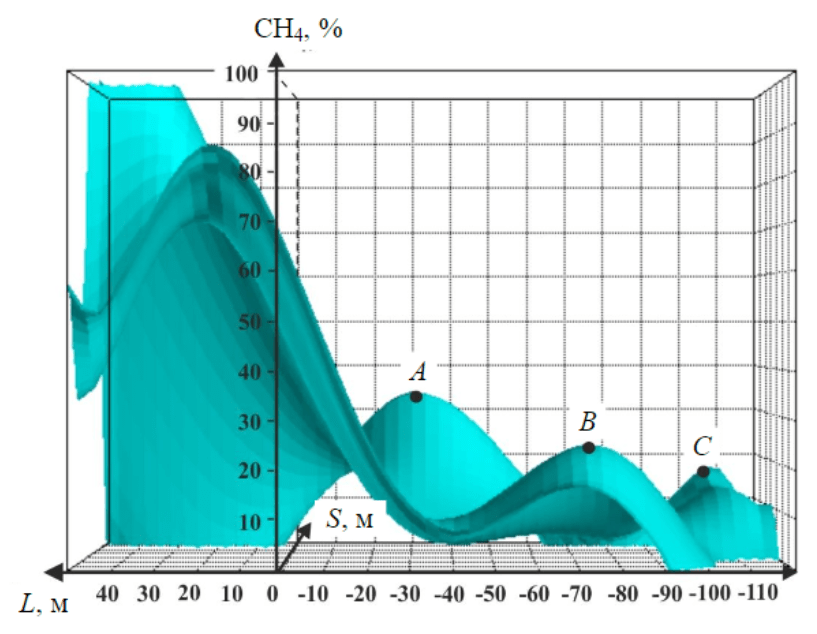

Projection of the obtained surface on the axis S-L (the length of air heading to the benchmarks of 18th eastern longwall – the distance to the longwall face) is presented in Fig.4. Contour lines (isogases) indicate geometric location of points with equal values of methane concentration.

The overall picture of methane release dynamics, presented in Fig.4, visually confirms theoretical notions and a hypothesis about non-linear aspects of abutment pressure, caused by manifestations of zonal disintegration. Curiously, the front of advance fracturing zone (F.A.Abramov, A.Labass, M.M.Andreev) is not parallel to the face line, but set at a certain (shallow) angle to it. This phenomenon needs to be elaborated and verified, which maintains the relevance of subsequent research in this area.

Identified specific features of methane release dynamics can explain the results of studying the walls of undermining boreholes in the Zhuji mine (China) [43], as well as methane release dynamics in the Kotinskaya mine (Kuzbass) [42]. Chinese researchers discovered that modern casing of wellheads and borehole shafts did not compensate for mining pressure manifestations, which led to their failure. One of the promising lines of research in this area is the application of stress-relief drilling combined with methods of physical-chemical anchoring [24].

Conclusions. Judging from the results of the study, a hypothesis about the wave migration nature of methane release is confirmed. From here the following conclusions can be drawn:

• it is identified that increase of the main roof span from 17 to 80 m, as well as decrease of the distance to the face line (in front of the longwall) from 110 to 30 m cause a non-linear polynomial increase of methane concentration in the underground boreholes from 13 to 33 %;

• increase of the roof rock span from 10 to 70 m leads to an increase in the local maximum of methane release 70-90 m ahead of the face line, in which case aerogas conditions of the gas drainage system require better management;

• development of deep-lying gassy coal seams using existing geotechnologies, as well as measures on operational management of the local gas drainage network do not allow to provide a safe level (≤ 25 %) of methane concentration in the withdrawn mixture at the distance to the longwall face ≤ 20 m.

Suggested approach to 3D data visualization can be used for more precise description of spatial gas content distribution in the suite of coal seams (as addition to GIS [33]) or specific characteristics of hydrocarbon potential distribution in tectonic screen traps [37].

Therefore, in order to improve technologies that maintain reliability of gas drainage systems and enhance the quality of withdrawn methane-air mixture, it is especially relevant to apply identified patterns and quantitative characteristics.