Determination of technical condition index of the production facility of energy complexes in the decision support system for strategic development of energy infrastructure of gas industry

- 1 — Ph.D. Head of the Department PJSC Gazprom

- 2 — Ph.D., Dr.Sci. Adviser to the General Director JSC Gazprom Promgaz

- 3 — Ph.D., Dr.Sci. Chief Researcher JSC Gazprom Promgaz

Abstract

Changes in the business conditions of gas industry enterprises and the regulatory framework for the creation and operation of energy facilities require the development of the energy infrastructure of production facilities. The diversity and a large number of existing energy facilities, as well as the use of a risk-oriented approach to the gas industry management lead to the need to create decision support systems for the strategic development of the energy infrastructure of production facilities on an industry-wide scale. The purpose of the study is to develop a set of mathematical models for calculating the index of the technical condition of energy complexes of production facilities used to prepare structured information as a part of a decision support system creation for the strategic development of the system, which will allow us making a decision on the minimum required volume and timing of reconstruction of the energy infrastructure of a production facility under modern conditions with restrictions on the reconstruction budget. The solution of such a multi-criteria problem required: justification of a set of admissible solution alternatives, risk assessment when making specific decisions, development of a system and mathematical dependencies for assessing the criterion indicators that make up the technical condition index taking into account preferences and decision rules, as well as the rules for calculating the weight of the assessment components in the value of the integral indicator. Based on the developed mathematical models, an algorithm for the technical condition index determination of a single energy complex of a production facility was formulated, which is an integral part of the generalized algorithm for applying the mathematical support of the decision-making system for the strategic development of the energy infrastructure of gas industry enterprises.

Introduction

Provision of the high level of competitiveness in the context of dynamic changes in the economic conditions of enterprises in the gas industry [1, 2] is impossible without complex business processes improvement, including the development of optimal solutions for the development of the energy infrastructure of production facilities, in the context of applying a risk-oriented approach (RBA) to manage the industry which implies framework restrictions in the various types of programs financing.

When using familiar deterministic approaches, it is difficult to make a well-founded decision on drawing up balanced lists of measures for complex target programs for the reconstruction and technical re-equipment of energy facilities for a set of various production facilities (PF) in the gas industry with a large number of energy systems of various profiles. An effective means of assistance in the decision-making process for the development of hierarchically complex production complexes is the use of decision support systems (DSS) [3-5].

Structuring information on the technical level and condition of the analyzed energy facilities, including using developed analysis methods [6, 7], carried out within the framework of a scientifically based decision support system, allows us to improve the business process of making a comprehensive decision on the strategic development of the energy infrastructure of gas industry enterprises.

DSS for the strategic development of energy infrastructure is based on mathematical support that allows for the quantitative determination of the entire spectrum of significant indicators and criteria that assess energy facilities at the present moment and in the future, including the use of various options for technical solutions for their reconstruction, taking into account the provisions of the adopted Concept for the Development of Energy Supply for Production Facilities in the Gas Industry [6].

The assessment of gas industry enterprises currently consists of assessments of individual production facilities with the systems of power supply, heat supply, water supply and water disposal that provide their operation, as well as industrial ventilation and air conditioning systems, which are proposed to be considered [6] as single energy complexes (EC). The authors of [7, 8] propose to assess the condition and technical level of energy complexes, as well as their compliance with specified requirements, by determining the technical condition index (TCI). It seems relevant to develop mathematical models and algorithms for the technical condition index determination of the PFEC, which allow us to provide information support within the framework of the DSS for managing the strategic development of the energy infrastructure, taking into account the prevention of a decrease in the level of competitiveness of industry enterprises associated with the emergence of unjustified risks due to the discrepancy between the technical level and condition of production facilities and the changed requirements in the context of applying the RBA to manage the gas industry.

Methods

The functioning of the energy infrastructure of production facilities in the context of the RBA use for the management of their development leads to the necessity to take into account a number of risks [9, 10], among which the most significant for the energy infrastructure of the gas industry are the following:

- market risks of the gas industry, causing a change in the quantity of production, storage, processing, and commodity-transport work, as well as the need to diversify commercial products, which changes the requirements for the energy infrastructure of the gas industry in terms of the nomenclature and volumes of energy resources produced (transmitted) by energy facilities;

- environmental risks, leading to the need to compensate for damage caused to the environment and the costs of bringing the technical solutions of the energy infrastructure of the gas industry to the newly specified environmental requirements;

- production and technical risks associated with the growth of potential damage due to probable failures of power equipment caused by various reasons, including increased physical wear, poor quality performance of maintenance, current and capital repairs (M&R) of equipment, as well as errors made by operations personnel.

The objective of the mathematical support for the TCI of the PFEC determination is to prepare structured information for making a decision on the minimum required volume and timeframe for the energy infrastructure reconstruction in order to provide the effective production facility work in modern conditions with restrictions on reconstruction financing in the conditions of the RBA application.

An analysis of sources [11-13, etc.] showed that mathematical models and algorithms were currently actively and successfully used to solve a number of problems of decision support systems for various purposes. At the same time, the literature usually provides only separate fragments of the development of DSS [12-14], or considers general issues of their use [15-17].

A description of the mathematical support for determining the TCI of the PFEC in the conditions of restrictions imposed by the application of the RBA to the management of the development of the gas industry is currently absent from the literature, so its development is required.

Mathematical support for DSS for the strategic development of the energy infrastructure management as applied to the assessment of the TCI of EC of a single PF

A number of technological problems solved by enterprises in the gas industry determines the composition of production facilities and the corresponding composition of energy facilities that make it possible to solve these problems. It is necessary to assess the compliance of the following energy complexes hierarchies with the technological problems to be solved:

- a separate production facility (integrated gas treatment unit, compressor station, gas distribution station, etc.);

- a group of production facilities, facilities for transporting hydrocarbon raw materials or processed products along the main gas pipelines (gas condensate field, the main gas pipeline, gas processing plant);

- a group of facilities of a separate enterprise in the gas industry and the gas industry as a whole.

The basic cell of the developed complex of mathematical models and algorithms for the decision-making system for managing the development of the energy infrastructure of enterprises in the industry is the mathematical support intended for the assessment of the TCI of EC of a single PF. The structure of the EC of a separate PF is given in the article [7], their indicators are further used to determine the characteristics of the energy complexes of PF groups.

Requirements for the developed complex of mathematical models

Taking into account the list of problems proposed for the solution [7], the following is accepted:

- mathematical models are created to determine the TCI of the EC of a typical PF for the extraction, storage, and transportation of natural gas. The energy infrastructure of unique production facilities assessment is provided by the additional adaptation of the basic mathematical support to the conditions of specific facilities;

- the assessed energy complexes at the time of creation fully complied with the requirements of current regulatory documents and provided the production facility work without restrictions, i.e. the TCI had a maximum value equal to one;

- the technical solutions of the systems included in the PFEC are assessed simultaneously according to the complex criterion of technological efficiency and safety and the complex criterion of economic efficiency [6, 18];

- the components included in the TCI of the PFEC are determined using the minimum required amount of available initial data;

- the assessment of the values of the indicators of existing EC is carried out taking into account their service life;

- mathematical models and the algorithm for their application help to identify critical changes in the requirements for the energy infrastructure on the part of PF and to choose the minimum sufficient organizational and technical solution to achieve them;

- mathematical models for determining individual components of the TCI and the TCI itself provide comparability of the same indicators when assessing the PFEC of various types and allow for the formation of trends in indicators when changing scenario conditions, which facilitates the adoption of informed decisions when making lists of measures to develop the EC in the context of the RBA to manage in the industry;

- trends in the values of indicators, criteria and the TCI of the PFEC are determined for the entire period of commercial use of the energy infrastructure under consideration;

- mathematical support for assessing the TCI of the PFEC allows us to evaluate the risks from non-compliance of existing energy infrastructure facilities with the changed requirements for providing the production facility functioning in the new conditions, as well as to facilitate the adoption of options for the reconstruction and new construction of energy infrastructure facilities that correspond to these risks.

Determining the value of the TCI of the PFEC for the purpose of making a decision on the need to improve the energy complex in modern conditions (after changing the requirements for energy supply or business conditions) is a multi-criteria task that can be represented by the following tuple [19]:

where t – the type of task (1 – the EC development and construction, compliance with the technical specification indicators is assessed, 2 – the EC operation, compliance with the changed requirements for the EC during operation is assessed); X – the set of admissible alternatives for solving the EC development problem (from complete reconstruction to improvement of a separate installation in order to improve a separate criterion indicator); R – the set of criteria that make up the assessments of the TCI EC; A – the set of scales for assessing the criteria applicable to different stages of the EC life cycle; F – the mapping of the set of admissible alternatives on the set of risk assessments when making specific decisions on EC development; G – the decision maker’s preference system using preferences for different periods of the EC life cycle; D – the decision rule reflecting the DM preference system for different PFEC.

Next, we will consider the option of supporting decision-making at the stage of the PFEC operation.

The list of risks directly related to changes in energy supply requirements [9, 20, 21] made it possible to determine the minimum sufficient list of assessed complex indicators of the PFEC:

- the possibility of providing a certain quantity and quality of energy resources, the quantity and quality of water and wastewater treatment in all specified modes of the facility operation;

- an assessment of the reliability of the equipment included in the EC is associated with the required volumes and delivery times of products of gas industry enterprises provision to consumers;

- an assessment of the environmental, structural, electrical, fire and explosion safety of energy complexes, as well as the energy efficiency of the technological processes they implement, the cost-effectiveness of creation and operation, is connected with the requirements provision for the PF from the point of view of safety and efficiency of its operation.

In accordance with the adopted Concept for the Development of Energy Supply for Production Facilities in the Gas Industry [6, 22] and current regulatory documents, it is proposed to assess the energy complexes of each specific production facility as follows.

1. The indicators of five systems included in the PFEC are determined according to seven complex technical and economic criteria.

- Systems included in the PFEC: power supply (PSS, i = 1); heat supply (HSS, i = 2); water supply (WSS, i = 3); water disposal (WDS, i = 4); industrial ventilation and air conditioning of industrial and administrative and household buildings and structures (IVAC, i = 5).

- Complex criteria: availability of energy resources (j = 1); quality of energy resources (j = 2); reliability of equipment (j = 3); safety of the EC operation (j = 4); energy efficiency of functioning (j = 5); perfection of operation of the EC (j = 6); costs of creation and operation (j = 7).

2. The technical and economic indicators, criteria and TCI for the PFEC as a whole are determined.

The description of the mathematical support for determining the TCI of the PFEC is carried out according to the principle of “system included in the EC indicator” with the assignment of corresponding indices to all values – Rij for individual power supply systems and Rec for the PFEC as a whole.

Mathematical models for determining the TCI of the EC of production facilities

Initial data for calculating the indicators that make up the TCI of the PFEC. The issues of modeling individual properties of power equipment and power supply systems are considered in [22-24, etc.], and the specifics of using models in various types of DSS are discussed in [25]. To perform calculations using the models provided in the analyzed sources, it is necessary to use a large amount of initial data, its search requires significant labor costs, especially given the diversity of technical solutions for existing and designed energy facilities.

In the approach under consideration, in order to reduce the time spent on collecting initial data and developing mathematical support for a comparative assessment of the state of the PFEC, the authors [6] propose identifying the most typical combinations of technical solutions included in their composition PSS, HSS, WSS, WDS, and IVAC with characteristic sets of power equipment.

The results of the development of mathematical models have shown the possibility of performing comparative assessments of individual indicators and assessing the TCI of the PFEC in terms of solving problems of managing the strategic development of the EC of gas industry enterprises using a block of initial data available to the heads of the PF operation services without involving third-party highly qualified specialists.

Determination of the values of complex technical and economic indicators of the systems included in the PFEC. The main purpose of the developed mathematical models is to assess the values of the EC indicators of specific PF to determine compliance with the changed requirements. In conditions of significant uncertainty of the initial information for the entire set of equipment of energy facilities included in the EC, the assessments are performed in comparison with the “base” (design) state according to indirect signs that are the same for all energy facilities in the gas industry, characterizing the state and technical level of technical solutions for PSS, HSS, WSS, WDS, and IVAC.

Mathematical models for the values of individual indicators assessment are divided into two groups: those requiring calculations based on mathematical dependencies and those requiring a compliance score based on rules.

The first group includes models for determining the following criteria: energy resource supply Ri1, reliability of energy equipment EC Ri3, and costs of creating and operating energy EC Ri7.

The criterion for supply with energy resources is determined by the ratio of the maximum possible amount of energy resource (electric or thermal energy), supply of source water, air, discharge and treatment of wastewater in relation to the corresponding required amount (using the example of PSS):

where P1pos – the total maximum possible power of electric power sources for the analyzed voltage level taking into account the maximum factor of their load and providing the specified reliability, kW; P1 req = Pyear max – the maximum design or maximum actual electric power for the analyzed voltage level over the previous 5 years, kW.

The criterion is determined for energy resources and working environments of the required nomenclature: electric energy with different voltage levels of alternating and direct current; thermal energy in the form of steam and coolant for heating and hot water supply of production, for household needs, etc.

The criterion is calculated for the most energy-intensive operating mode of the production facility, the most unfavorable microclimate compensation mode (for heat supply systems, IVAC), maximum consumption of source water and purification of the maximum amount of wastewater of all types when powered from the main and backup sources of energy resources and water, compatible in time.

The reliability criterion of energy complex equipment Ri3 is determined by analyzing the circuit design of the power supply system. In the absence of statistical information on failures, the reliability of the equipment is indirectly determined by the value of the relative service life (the ratio of the actual service life Тf of the power equipment to the designated service life Тn): Ri3= Тf / Тn < = > 1.

If the value of the equipment reliability criterion is below one, the equipment is operated within the service life and corresponds to the design value. With an increase in the period of operation of the power facility beyond the designated service life, the value of the relative time of its operation becomes bigger than one, which leads to a decrease in the meantime to failure of the least reliable element in accordance with the Weibull distribution and a decrease in the reliability of the system in relation to the design.

The value of the Ri3 criterion is determined for all systems included in the EC by groups of energy and water consumers, water disposal, and wastewater treatment.

The criterion of costs for creation and operation Ri7 is determined in accordance with generally accepted rules, including calculation of capital investments in construction (reconstruction) based on cost estimates or estimate documentation for individual subsystems, systems, and the EC as a whole; costs of operation of subsystems, systems, and the PFEC (purchase of fuel, energy resources and water, payment for discharge of treated wastewater of different quality; costs of current maintenance, current and capital repairs of maintenance, repair and overhaul; damage from failure of power equipment),

where CIcreation i – capital investments in creation of the system, million rub.; CIreconstr.ik – capital investments in the k-th reconstruction of the system during the life cycle (LC), million rub.; Coper.in – costs of the regime maintenance (including costs of purchasing energy resources, fines and penalties due to non-compliance of the EC with the requirements of regulatory documents, damage from possible failures of the EC equipment), maintenance, repair and overhaul for the n-th year of operation of the EC during the life cycle, million rub. per year.

The difference in the calculation of the values that make up the Ri7 criterion, according to the developed models from the generally accepted ones, is the determination of operating costs and damage from the failure of power equipment depending on the service life of the PFEC. When the EC is outside the designated service life, operating costs increase. The increase is determined jointly by statistical calculation and expert methods.

The second group (with regard to the stage of testing the developed mathematical support for the DSS) includes all other complex criteria, determined according to the following rules.

The energy resource quality criterion Ri2 determines the quality compliance of all types of energy resources Ri2l, generated (transmitted) by all subsystems, systems to all consumer groups. It is determined based on measurements of energy resource parameters at the consumer input: Ri2= f (Ri21, Ri22, …, Ri2l).

The operational safety criterion Ri4 determines the compliance of all energy facilities included in the PFEC with the requirements of regulatory documents for the following components: structural, fire and explosion safety, electrical safety, safety according to boiler supervision requirements, and environmental safety. The values of the components of the safety criterion Ri4l are determined by safety requirement inspection reports with division into systems and types of safety: Ri4 = f (Ri41, Ri42, …, Ri4l).

The energy efficiency criterion of operation Ri5 determines the compliance of energy facilities included in the PFEC with the requirements of regulatory documents for the following components: specific consumption of all types of energy resources, losses of all types of energy resources during the operation of energy facilities in all modes. The values of the components of the energy efficiency criterion Ri5l are determined based on the results of an energy survey of the EC by the composition of the implemented automation systems for the purpose of energy saving: Ri5 = f (Ri51, Ri52, …, Ri5l).

The criterion of operational perfection Ri6 determines the efficiency of maintaining the power supply system mode, performing work on maintenance, repair of equipment of all energy facilities included in the PFEC which depend on the level of integration of the EC into the automation systems of the facility and enterprise: Ri6 = f (Ri61, Ri62).

The score of conformity according to the listed criteria is established by experts on the preapproved rules.

Compliance score rules (for example the operating safety criterion): 5 – no acts on types of security violations; 4 – not a standard on minor parameters; 3 – not a standard on essential parameters; 2 – not a standard on a number of significant couple of parameters; 1 – there is a requirement to suspend the system.

The models given allow us to determine the values of criteria numerically of individual EC topics in units and scores.

In the future, once sufficient statistical information has been collected on the evaluation objects, it is intended to improve the filling of TCI components and mathematical models for their evaluation, as well as more fully integrate the estimation models into the automated system of TCI determination of the PFEC in order to minimize the human factor.

Providing the comparability of assessments of EC criteria of different types. It is proposed that the values of TCI be reduced as follows:

- An interpretation is performed for each TCI indicator, determining which of the values of a given indicator (highest or lowest) is the best in terms of the maximum TCI of EC value provision.

- The normalization base Rj bas (best values of indicators bases) is defined for evaluation of the eponymous indicators of all systems and components of complex indicators used in comparison:

for the case where the best value of the indicator is maximal,

for the case where the best value of the indicator is minimal,

As a result of normalizing the value of all indicators and criteria, the interval is 0...1, the highest value of the normalized indicator or criterion being the best EC state in terms of providing the maximum TCI value of the subsystem being assessed, system or EC for this indicator (criterion).

- The values of normalized indicators (criteria) for all evaluated PF systems are reduced into matrices of equal dimension. In the absence of a specific type of system or subsystem within a particular EC (e.g., no water supply system in the energy complex along highway consumers or no average voltage level in PSS, or no steam output at boiler in HSS) the corresponding elements of the matrix are filled with the units. This excludes the impact of these indicators on the value of the integrated estimate when the indicators are reduced.

- The components are grouped together to determine the complex criteria for each of the EC’s systems and to determine the value of TCI of the PFEC. The convolution is produced using a separable convolution with geometric averaging. This method of convolution of individual properties allows the maximum value of the integral index (criterion) to be obtained in the case of the best combination of estimates of individual properties given their weight (significance), while the value of the criterion given its significance is greater, the higher the weight of the criterion in the integral evaluation [26, 27]. Properties missing for particular systems with the value of “1” do not change the value of the criterion, and the value of the criterion itself or TCI after convolution is within the range 0...1.

Various methods can be used to determine the values of the weighting factors for the complex criteria that are part of TCI of the PFEC integral indicator. The most frequently used are expert, statistical, marginal and marginal values, as well as various cost methods [28-30].

The above-mentioned methods for determining the weight of individual indicators (criteria) have their advantages and disadvantages. The obtained weights should allow to obtain adequate results for the task addressed is to form an optimal list of activities to achieve a minimum sufficient level of individual indicators and TCI of the PFEC in conditions of minimization of evaluation costs of Technical condition index.

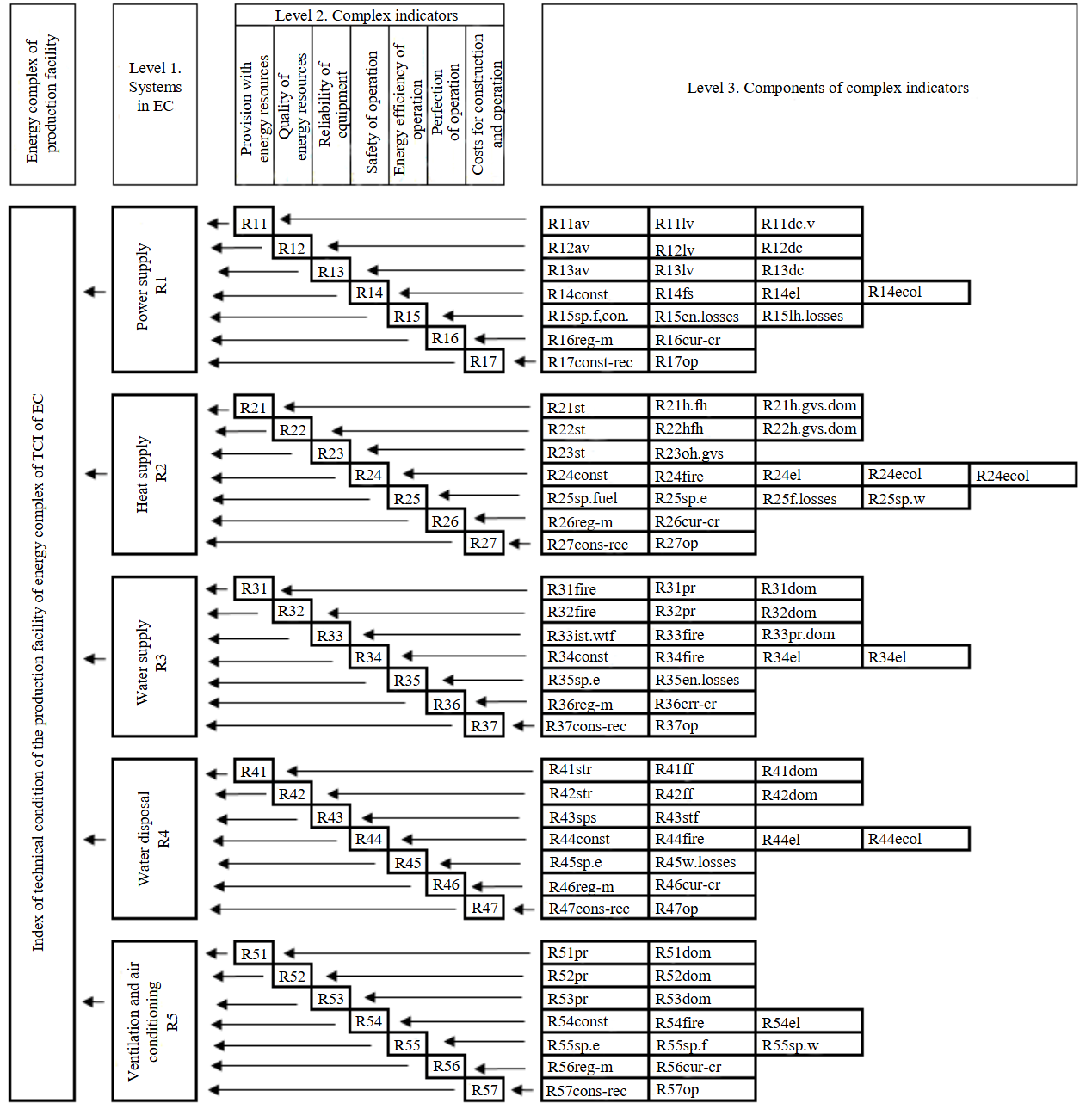

Within the framework of the developed mathematical support and in accordance with the obtained three-level “tree of properties” of the PFEC (Fig.1) it is necessary to determine the weights of the criteria for the three levels.

Level 3. Weighting of the individual l components within the value of the specific complex criterion Kw1jl (for example, constituting the criteria of the quantity of electrical energy of PSS by the voltage levels and types of current, or the reliability of the operation of the sources and WDS providing water supply systems for fire-fighting or production and household needs). The weight of the individual components of Kw1jl can be determined by experts. The expert group consists of six or more highly qualified experts with the highest level of knowledge about the subject of assessment and a high degree of adaptation to sources of information [29, 31, 32].

Fig.1. “The tree of properties” for the assessment of energy complexes of production facility

av / lv / dc.v – average / low voltage / direct current voltage; st / h.pr / h.gvs.dom – steam (st) / heat for production heating and ventilation / hot water supply for domestic use; fire / pr / dom – firefighting / production / domestic water supply; str / pr / dom – water disposal of stormwater / production / domestic runoffs; pr / dom – production / domestic ventilation and air conditioning; stf / wtf / sps – sewage treatment facilities / water treatment facilities / sewage pump stations; const / fire / el / ecol / boil – construction safety / fire-explosion / ecological safety / electrical safety / boiler safety inspection; sp.fuel / sp.e / sp.h / sp.w – specific fuel consumption, specific energy, heat, water; losses. el / h / w – electrical energy losses / heat losses / water losses; mt / cr-cp – maintenance / current and capital repairs; cons-rec / op – construction and reconstruction / operation

The assessment carried out in the framework of the testing of the developed mathematical support showed that the significance of the components within the complex criterion is usually determined by experts as equal. Therefore, at this stage the components of the complex criteria are taken into consideration with equal weight:

where lj – the number of components in j-th complex; the sum of the weights of the components of the complex in this case is 1.

Level 2. Weight of the integrated criteria in the TCI integral indicator of the upstream system within the EC and the TCI of the energy complex as a whole. Determining the weightiness of criteria within TCI requires a panel, as it involves taking into account changes in the business environment of gas enterprises or other difficult to formalize information. This assessment is carried out at the rate of change in the conditions of operation (for example, once a year before the formation of targeted integrated energy development programs), its results Kw1j are applied in the assessment of EC indicators of all types. The experts with the highest qualification for each j-th complex criterion give the score from 1 to 10.

The convergence of estimates within the expert group is determined by mathematical statistics by calculating the correlation coefficient [26]:

where C – the sum of the squares of the deviations of the scores for each assessment parameter from the average score; m – the number of experts; n – the number of assessment parameters.

For concordance factors of more than 0.5, the convergence of views of experts is considered sufficient and reassessment rounds are used to increase it after further increase of the expert’s level awareness [29].

Once sufficient convergence of expert opinion has been obtained, the value of the points awarded shall be normalized using rule 4. The maximum score awarded for all seven criteria is taken as the base value.

Level 1. Weighting of individual systems (PSS, HSS, WSS, WDS, IVAC) Kв2i as a part of the in-category indicator of TCI of EC. The weights of this type can be determined by expert assessments [33]. For this purpose, the use of a ranking method based on an analysis of the number and importance of links between individual systems in the EC structure according to the type of production facility by the Fishburn method [34-36] is preferred.

The composition of systems, subsystems and linkage structure in the PFEC are defined by the regulatory regulations of the gas industry and correspond to the type of production facility, their significance being proposed to determine a comparative estimate of the damage that may occur in time failure of the equipment of each system using the following method of calibration: 1 – no damage (information link); 2 – system failure leads to a failure of one EC system and does not lead to the termination of the process at PFEC; 3 – system failure leads to a total EC failure and disruption of the production facility process.

The total weight of an individual system is determined by multiplying the number of its links with other EC systems by the damage assessment score in the event of its failure. The weight assessment is normalized using rule 4. The sum of the weights obtained from all five systems is taken as the base value.

Determination of complex criteria and integral indicator of TCI EC of production facility. Combining the components of the individual complex criteria and the complex criteria within the individual PFEC systems is carried out with expressions

where rijl – the normalized value of the l-th component of the j-th complex criterion for the i-th system of the PFEC; rij – the normalized value of the j-th complex criterion for the i-th system of the PFEC; Kw1jl, Kw1j the weighting coefficients of individual l-th components of the j-th complex criterion of a specific type and the j-thcomplex indicator itself in the TCI of the system included in the PFEC.

Convolution of complex criteria of individual systems of the PFEC into the TCI integral indicator of the PFEC is carried out according to the expression

where ri – the normalized value of the complex criterion for the i-th system of the PFEC; Kw2i– the weight coefficient (significance) of the i-th system in the PFEC.

As a result of applying a comprehensive assessment taking into account the “tree of properties” and the weight of individual components in the comprehensive criteria and integral indicator, a ranking-expert function was obtained that allows determining the deviation of the value of the TCI of a specific object from the maximum achievable value with the possibility of identifying the direction, which has the greatest impact on improving the value of the energy complex of TCI.

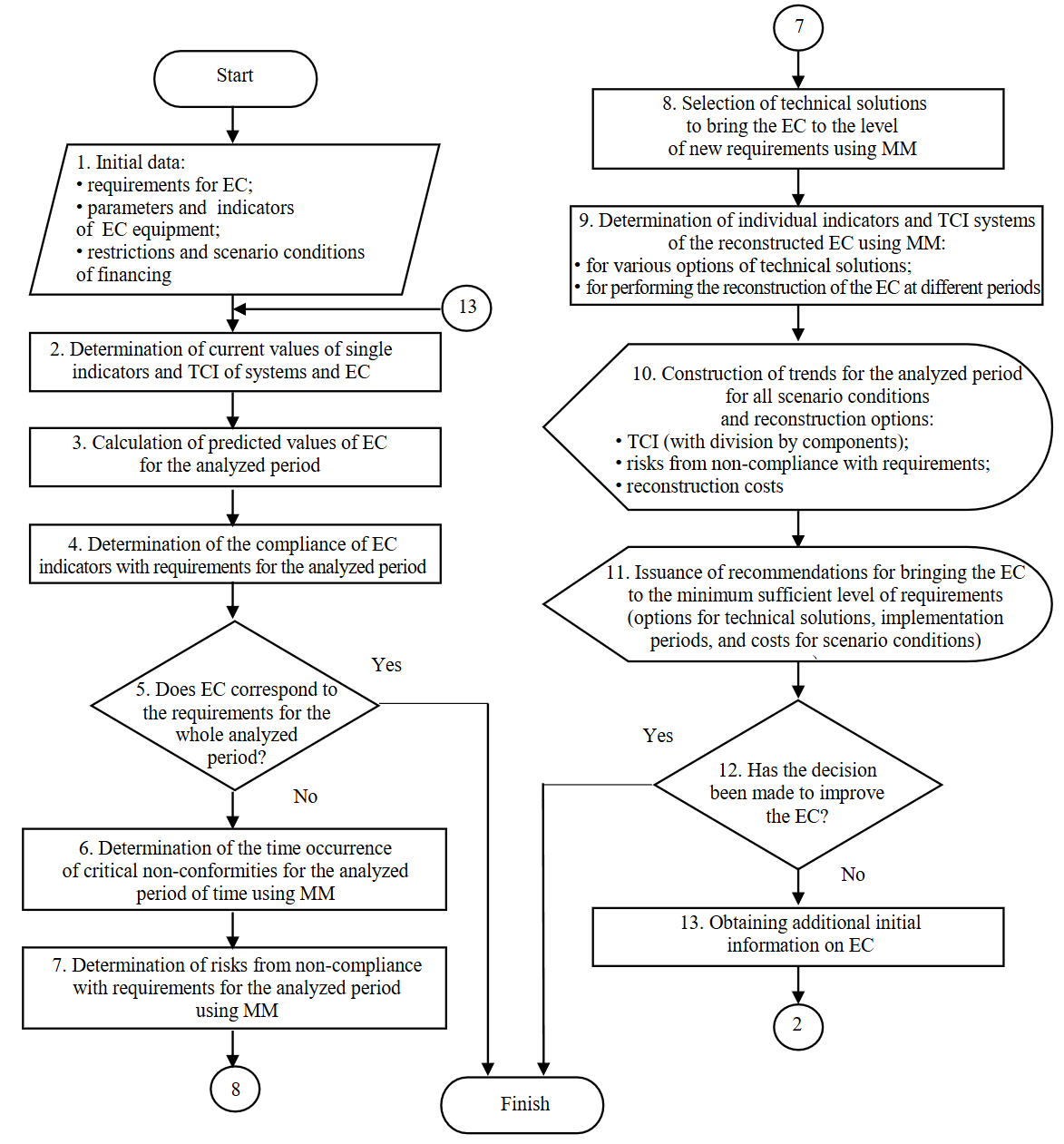

Algorithm for applying mathematical models for determining the TCI of a single EC in the DSS. Based on the proposed set of mathematical models, an algorithm for preparing information for constructing trends in criterion indicators and the TCI of individual systems and EC for the analyzed period has been developed (Fig.2). The duration of the period is selected differently (for example, it can correspond to the designated service life of a specific type power equipment).

Comparison of calculated and required values of criteria at the present stage allows us to identify discrepancies in all parameters significant for power equipment with indication of the discrepancy value and the period of occurrence of critical discrepancy. The values of critical discrepancies of EC parameters are connected with the existence of industrial, technical and environmental risks. Risks are expressed in monetary terms (for example, the impossibility of completing a production task in full and the associated damage, costs for equipment failures, fines and penalties, and the purchase of additional energy resources).

Elimination of the discrepancy between the parameters of the EC is connected with its reconstruction. For a specific type of production facility, from the general list containing 69 promising technical solutions for improving energy facilities, set out in the Concept of Development of Energy Supply [6], technical solutions are selected that allow us to improve that part of the energy supply requirements that does not correspond to the new conditions.

For each of the selected options for technical solutions, the criterion indicators of the reconstructed energy complex, the reconstruction costs with possible time scenarios for its implementation are determined, the corresponding trends are built for the entire analyzed period and recommendations are formed for bringing the EC indicators to the minimum sufficient level of requirements.

Analysis of the calculated trends of the TCI and its components allows us to determine appropriate directions and a set of measures to achieve the required level of the TCI and individual components in each specific period of the life cycle of a production facility.

Fig.2. An enlarged algorithm for the application of the complex of mathematical models (ММ) for the TCI determination of a single EC

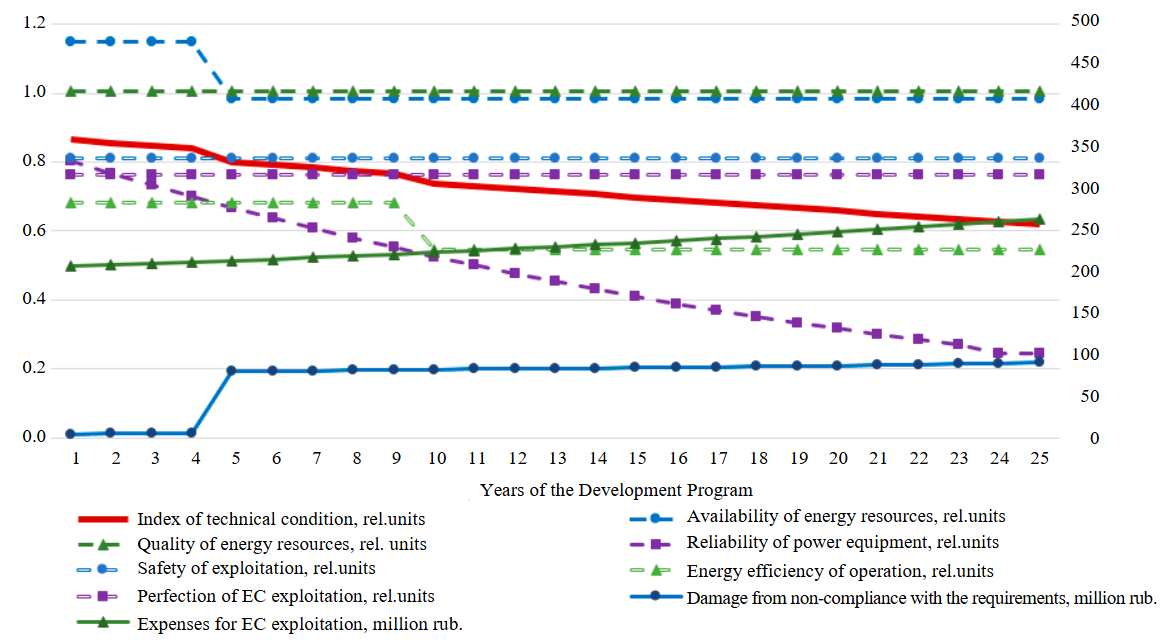

As an example, in Fig.3 the results of calculation of TCI components are given, carried out using the models developed under conditions: increase of the load on PSS by 20 % during the fifth year of implementation of the Development Program, caused by the increase of natural gas supply to the consumer, and to increase the energy efficiency requirements of EC equipment by 20 % in the tenth year connected with the introduction of new regulatory instruments.

Fig.3. Characteristic of TCI and EC indicators of the compressor station

Trends in TCI components showed the following:

- the reliability of EC equipment is lower than required (0.95 rel. units) from the first year;

- the energy supply becomes lower than required (1.2 rel. units), starting from the fifth year;

- the energy efficiency of the power plant becomes lower than required (4 rel. units) from the tenth year.

The total costs of the EC operation as a cumulative total (taking into account potential damage from equipment failures and risks of non-delivery of marketable products) begin to exceed the amount of capital investment in the creation of the EC (project) in the ninth year of the Development Program implementation.

Results

The developed set of mathematical models and algorithm is the basis for a decision support system on the strategic development of energy infrastructure as a part of methodology of energy facilities development management in the gas industry.

The mathematical support allows us to numerically determine the integral TCI indicator of existing energy complexes and its components over the entire life cycle of the PF, as well as to assess the change in the components of TCI for cases of implementation of various options of power plants production facilities reconstruction.

The set of mathematical models and algorithm of their application take into account the features imposed by the operating conditions of existing PF under the limitations introduced by the use of PF in the management of development of gas industry enterprises.

Conclusion

Significant changes in operating conditions and the application of RBA in the gas industry management require the creation of a decision support system for the strategic development of the energy infrastructure of PF, which is based on a set of mathematical models for the determination of the technical state (condition) index of a single energy complex.

Determination of the TCI PFEC value for the purpose of making a decision on the necessity to improve the energy complex under modern conditions is a multi-criteria task, its solution is proposed to be done using a tuple that takes into account: the type of task, acceptable alternatives for its solution considering a variety of risk assessments when making specific decisions, criteria that make up the TCI assessment taking into account the system of preferences and the decision makers rules.

The study defines goals, objectives, and mathematical relationships of the EC of TCI for the preparation of structured information when deciding on the minimum amount and time required for the energy infrastructure reconstruction in modern conditions with restrictions on financing of reconstruction in the context of the application of the RBA were determined.

The mathematical models for identifying the individual components of TCI in the approach proposed involve the use of an input block available to managers of the operation services.

In the proposed approach to the assessment of TCI, the EC has developed a combined expert-analytical way to determine the weight of individual components of complex criteria indicators, the significance of the criteria themselves, determining the TCI for individual power supply systems, and the weights of individual power supply systems in the energy complex.

The developed augmented algorithm of mathematical models for determining the TCI of a single EC assumes that the existing EC or PFECs, after reconstruction, meet the new requirements over the whole analyzed period, assessment of the risks from the mismatch of EC indicators with new requirements, as well as a set of tools for constructing trends in indicators and corresponding reconstruction costs and risk profiles to make an informed decision on the strategic development of PFEC.

In the future, it is advisable to continue research towards the definition of TCI of EC group of production facilities, formation of requirements for energy complexes on the basis of information about changes in the management conditions of enterprises of the gas industry.

References

- Semikashev V.V., Gayvoronskaya M.S. Analysis of the State and Development Prospects of the Russian Gas Industry before and after 2022. Scientific works: Institute of Economic Forecasting of the Russian Academy of Sciences, 2022. Vol. 20, p. 108-127 (in Russian). DOI: 10.47711/2076-318-2022-108-127

- Larionova E.I., Chinaeva T.I., Shpakovskaya E.P. Analysis of the development of Oil and Gas Industry in present conditions. Statistics and Economics. 2019. Vol. 16. N 6, p. 29-36 (in Russian). DOI: 10.21686/2500-3925-2019-6-29-36

- Darmilova Zh.D., Darmilov E.I., Krivenko N.I. Peculiarities of making management decisions in the oil and gas industry. Scientific Bulletin of the Southern Institute of Management. 2019. N 4, p. 36-42 (in Russian). DOI: 10.31775/2305-3100-2019-4-36-42

- Zhang Yu-mei. Mathematical Modeling of Attribute Encryption of Big Data Based on Data Redundancy Technology. Computer Simulation. 2021. Iss. 5, p. 418-422.

- Dastres R., Soori M. Advances in Web-Based Decision Support Systems. International Journal of Engineering and Future Technology. 2022. Vol. 19. Iss. 1, p. 1-15.

- Markelov V.A., Bronnikov A.N., Shapovalo A.A. Concept of developing the power system of production facilities under dynamically changing conditions applied to business activities of gas industry companies. Gazovaya promyshlennost. 2023. Special Issue 3 (853), p. 8-11 (in Russian).

- Shapovalo A.A. Methodology for managing energy development of production facilities in the gas industry. Journal of Mining Institute. 2025. Vol. 272. N 16378, p. 181-190.

- Poiss G., Vitolina S., Marks J. Development of Indicators for Technical Condition Indexing of Power Transformers. Advances in Science, Technology and Engineering Systems Journal. 2018. Vol. 3. N 1, p. 148-154. DOI: 10.25046/aj030118

- Nyenno I., Selivanova N., Korolenko N. et al. The energy policy risk management system model: theories and practices. Polityka Energetyczna – Energy Policy Journal. 2020. Vol. 23. Iss. 4, p. 33-48. DOI: 10.33223/epj/127699

- Londoño A.A., Velásquez J.D. Risk Management in Electricity Markets: Dominant Topics and Research Trends. Risks. 2023. Vol. 11. Iss. 7. N 116. DOI: 10.3390/risks11070116

- Imanbayev K., Sinchev B., Sibanbayeva S. et al. Analysis and mathematical modeling of big data processing. Peer-to-Peer Networking and Applications. 2021. Vol. 14. Iss. 5, p. 2626-2634. DOI: 10.1007/s12083-020-00978-3

- Sagitova L.A. Structure of the decision support system for increasing the energy efficiency of the regional energy complex. Info-communication Technologies. 2021. Vol. 19. N 2, p. 256-262 (in Russian).

- Drożdż W., Vovk Y., Widera K. et al. Sustainability assessment of the energy generation systems. Journal of Sustainable Development of Transport and Logistics. 2023. Vol. 8. N 2, p. 249-258. DOI: 10.14254/jsdtl.2023.8-2.19

- Tikhanychev O. Formulation of the task of ensuring automation of the full cycle of decision support. Journal of Applied Informatics. 2021. Vol. 16. N 6 (96), p. 103-112 (in Russian). DOI: 10.37791/2687-0649-2021-16-6-103-112

- Balashova I., Tereshchenko T. Decision support systems. The scientific heritage. 2021. N 79, p. 3-7 (in Russian). DOI: 10.24412/9215-0365-2021-79-4-3-7

- Samoilenko V.S., Fedotova A.Y. Architecture of intelligent decision-making support system. International Research Journal. 2024. N 8 (146), p. 7 (in Russian). DOI: 10.60797/IRJ.2024.146.10

- Sayapin O.V., Tikhanychev O.V., Bezvesilnaya A.A., Chiskidov S.V. On one trend in the development of algorithms implemented in decision support systems. Software & Systems. 2023. Vol. 36. N 3, p. 388-397 (in Russian). DOI: 10.15827/0236-235X.142.388-397

- Sturov A.Yu., Kuvshinov M.S. How to assess the cost-effectiveness of information management systems. Bulletin of the South Ural State University. Series Economics and Management. 2020. Vol. 14. N 3. p. 108-116 (in Russian). DOI: 10.14529/em200312

- Rozhko O.N., Shikhalev A.M. Assessment of Options for Logistics Objects in the Region Using Multi-Criteria Optimization (Case Study of the Republic of Tatarstan). Economic and Social Changes: Facts, Trends, Forecast. 2017. Vol. 10. N 6, p. 153-169. DOI: 10.15838/esc/2017.6.54.10

- Kamchatova E. Risk management of generating energy companies. Vestnik Universiteta. 2018. N 2, p. 50-56 (in Russian). DOI: 10.26425/1816-4277-2018-2-50-56

- Rahmani J. The main approaches to evaluating the effectiveness of applying the risk analysis and management methodology at energy company. T-Comm. 2022. Vol. 16. N 9, p. 46-55. DOI: 10.36724/2072-8735-2022-16-9-46-55

- Stennikov V.A., Barakhtenko E.A., Sokolov D.V., Mayorov G.S. Development of ontologies for automating computational processes in the energy pipeline system design. Ontology of Designing. 2023. Vol. 13. N 4 (50), p. 548-561 (in Russian). DOI: 10.18287/2223-9537-2023-13-4-548-561

- Shklyarsky J.E., Zamyatina E.N., Zamyatin E.O. Evaluation of the energy efficiency of the electrotechnical complex. News of the Tula state university. Technical sciences. 2020. Iss. 3, p. 339-347 (in Russian).

- Tokarev I.S. Development of parameters for an industry-specific methodology for calculating the electric energy storage system for gas industry facilities. Journal of Mining Institute. 2025. Vol. 272. N 16516, p. 171-180.

- Fernando J.G., Baldelovar M. Decision Support System: Overview, Different Types and Elements. Technoarete Transactions on Intelligent Data Mining and Knowledge Discovery. 2022. Vol. 2. Iss. 2, p. 13-18. DOI: 10.36647/TTIDMKD/02.02.A003

- Kendall M.G. Rank correlation methods. Moscow: Statistika, 1975, p. 214 (in Russian).

- Ganggang Xu, Chong Zhao, Abdollah Jalilian et al. Nonparametric estimation of the pair correlation function of replicated inhomogeneous point processes. Electronic Journal of Statistics. 2020. Vol. 14. Iss. 2, p. 3730-3765. DOI: 10.1214/20-EJS1755

- Klyuev R.V., Morgoeva A.D., Gavrina O.A. et al. Forecasting planned electricity consumption for the united power system using machine learning. Journal of Mining Institute. 2023. Vol. 261, p. 392-402.

- Korobov V.B. Theory and practice of expert methods. Moscow: INFRA-M, 2021, p. 281 (in Russian). DOI: 10.12737/monography_5caee0067f1835.43206494

- Ilyushin Yu.V., Afanaseva O.V. Development of Scada-model for trunk gas pipeline’s compressor station. Journal of Mining Institute. 2019. Vol. 240, p. 686-693. DOI: 10.31897/PMI.2019.6.686

- Boiko Y. Methods of forming an expert assessment of the criteria of an information system for managing projects and programs. Technology transfer: Fundamental Principles and Innovative Technical Solutions. 2018, p. 9-11. DOI: 10.21303/2585-6847.2018.00766

- Serebryakova E.A. Methods of expert evaluation of construction projects according to qualitative criteria. Modeling, optimization and information technology. 2023. Vol. 11. N 4, p. 12 (in Russian). DOI: 10.26102/2310-6018/2023.43.4.007

- Korobov V.B., Tutygin A.G., Lokhov A.S. A rank-expert deviation function to classify complex objects. Control Sciences. 2023. N 6, p. 48-55. DOI: 10.25728/cs.2023.6.5

- Sigal A.V. Using Fishburne’s sequences in suitable modeling used for sample data. Business Informatics. 2021. Vol. 15. N 4, p. 50-60. DOI: 10.17323/2587-814X.2021.4.50.60

- Fishburn P.C. Independence in Utility Theory with Whole Product Sets. Operations Research. 1965. Vol. 13. N 1, p. 28-45. DOI: 10.1287/opre.13.1.28

- Saaty T.L. Creative Thinking, Problem Solving and Decision Making. Pittsburgh: RWS Publications, 2001, p. 267.