Comparative analysis of the influence of various nano-additives on the characteristics of diesel fuel-based drilling fluids

- 1 — Ph.D. Associate professor Siberian Federal University ▪ Orcid ▪ Scopus

- 2 — Ph.D., Dr.Sci. Professor Siberian Federal University ▪ Orcid ▪ Elibrary ▪ Scopus

- 3 — Lecturer Siberian Federal University ▪ Orcid ▪ Elibrary ▪ Scopus

- 4 — Researcher Siberian Federal University ▪ Orcid ▪ Elibrary ▪ Scopus

Abstract

The results of experiments aimed at studying the influence of various nanomaterials on the key properties of drilling emulsions based on diesel fuel are presented. The nanomaterials used included spherical SiO2 nanoparticles with sizes of 5 and 80 nm, single-walled and multi-walled carbon nanotubes, as well as Al2O3 nanofibers. The nanomaterials were incorporated into standard formulations of drilling fluids containing a hydrocarbon phase of 65 %, with a mass concentration of nanomaterials in the emulsions reaching up to 2 %. The study examined the rheological, filtration, and antifriction properties, as well as the colloidal stability and inhibiting capacity of the modified drilling emulsions. It was demonstrated that even at low concentrations, the nanomaterials significantly affect the properties of drilling emulsions, indicating their potential for practical applications. Furthermore, the use of nanotubes exhibits effectiveness at lower concentrations (0.1 wt.%) compared to spherical nanoparticles.

Funding

The research was funded by the Russian Science Foundation grant N 23-79-30022, https://rscf.ru/project/23-79-30022.

Introduction

The success of the drilling process for oil and gas wells largely depends on the proper selection of the drilling fluid, which should fulfill a number of key functions, such as the removal of cuttings, maintaining hydrostatic pressure in the well, cooling the drilling tool, and others [1-3]. Currently, the industry faces technical, environmental, and economic challenges associated with the materials previously used for drilling fluids [4-6]. The optimal technologies and reagents of the past are becoming less suitable for the existing drilling conditions [7, 8]. This is partly due to the active development of fields in permafrost conditions, the drilling of increasingly deep wells, a significant increase in the horizontal section length within the oil-bearing strata, abnormal pressure and temperature at the bottom of the well, stricter environmental requirements, etc. [9-12].

Drilling practices in complex conditions demonstrate that the use of standard additives often fails to meet all the required specifications [13]. Currently, active research is underway to find new materials that can enhance the properties of drilling fluids [14-18]. Special attention is given to the study and application of various nanomaterials in the field of drilling operations. Due to their unique characteristics – high specific surface area and specific physicochemical properties – nanomaterials showcase significant potential in improving and regulating the properties of drilling fluids.

Numerous studies aimed at investigating the effects of nano-additives on various parameters of drilling fluids [19-21] have shown that the addition of spherical nanoparticles, both in water-based and hydrocarbon-based systems, can substantially enhance the well-cleaning process. Nanomaterials contribute to changes in the contact angle [22], improve anticorrosive properties [23, 24], increase the efficiency of cuttings removal through rheological enhancements [25-27], reduce filtration losses [28-30] and improve antifriction properties [31, 32]. All of these factors lead to improved cleaning of the borehole and wellbore walls.

The study [33] demonstrated that at high volumetric concentrations of Al2O3 nanoparticles in a hydrocarbon-based solution, the viscosity remains virtually unchanged. Only larger particles exhibited an increase in viscosity as nanoparticle concentration increased. The work [26] examined the impact of medium-sized iron oxide and silicon oxide nanoparticles (average size 50 nm) on the prope-rties of water-based drilling fluids. A twofold increase in effective viscosity of the solution was demonstrated at a nanoparticle concentration of 2.5 wt.%. The shear stress increased by nearly three times as a result. The volume of filtration losses decreased with the introduction of iron oxide nanoparticles (by 50 % at a concentration of 0.5 wt.%). Conversely, the introduction of silicon oxide nanoparticles resulted in a 30 % increase in the volume of filtration at a concentration of 1.5 wt.%.

Contrasting results regarding the effects of these nanoparticles have also been reported in the literature. In study [22], it was found that increasing the concentration of hydrophobic silicon oxide nanoparticles (Aerosil R200, average particle size 12 nm) to 1.2 wt.% reduces the filtration losses of the solution by 5 to 7 times compared to the base solution. A similar effect was observed in work [34]. The addition of nanosized clays with particle sizes of 30-50 nm at concentrations of up to 6 wt.% led to a reduction in filtration losses by more than half compared to the use of traditional plugging agents. In study [30], the effects of silicon oxide and copper oxide nanoparticles with an average particle diameter of approximately 50 nm on the characteristics of water-based drilling fluids were investigated. The results were ambiguous: the addition of copper oxide nanoparticles reduced the plastic viscosity by 24 % at a concentration of 0.8 wt.%, while the introduction of silicon oxide nanoparticles led to an increase in viscosity. However, in both cases, the volume of filtration decreased – with a maximum reduction of 31 % for silicon oxide and 24 % for copper oxide.

In study [35], a comprehensive investigation was conducted on the effect of adding 80 nm silicon oxide nanoparticles on the properties of hydrocarbon-based drilling fluids. It was shown that with an increase in nanoparticle concentration the exponent in the power-law model of the drilling fluid's rheological properties decreases, while the plastic viscosity, consistency index, and yield stress, on the contrary, increase severalfold. Furthermore, filtration losses are reduced by 50-70 %, and the coalescence rate of the drilling emulsion decreases by more than six times upon the addition of nanoparticles.

There are significantly fewer studies focused on improving drilling fluids using carbon nanotubes compared to those examining the effects of nanoparticles. In article [36], the behavior of drilling fluid upon the addition of nanotubes and spherical nanoparticles was investigated. The results indicated that the addition of multi-walled carbon nanotubes (MWCNTs) is more effective in reducing the friction coefficient compared to silicon dioxide nanoparticles. Additionally, the solution containing nanotubes demonstrated improved filtration properties (reduced losses and lower filter cake thickness). In study [37], oxidized multi-walled carbon nanotubes were employed to decrease the permeability of the clay filter cake in water-based drilling fluids, resulting in a reduction in permeability of more than 80 %. Furthermore, a significant increase in effective viscosity and yield stress was observed at low concentrations of MWCNTs. At the same time, the reduction of filtration losses with a similar modification of the MWCNT solution at a concentration of only 6 % was established in study [38].

In article [39], an attempt was made to optimize the properties of a water-based bentonite drilling fluid by adding different types of carbon nanotubes. Experiments showed that the introduction of a polymer (0.25 wt.%) and an equivalent amount of nanotubes positively influenced the rheological characteristics of the drilling fluid. An increase in temperature resulted in a decrease in plastic viscosity and an increase in yield stress, indicating a process of thermal degradation of the fluid. In study [40], the influence of the concentration of multi-walled carbon nanotubes (MWCNTs) on the properties of water-based drilling fluid at various temperatures (ranging from 25 to 180 °C) was analyzed. It was found that the solutions exhibited the properties of a viscoplastic fluid. As the concentration of MWCNTs increased, the viscosity of the drilling fluid rose. Additionally, the process of increasing nanotube concentrations resulted in a more monotonous viscosity-temperature relationship.

The literature review indicates that MWCNTs are increasingly used to enhance the properties of drilling fluids. There is a notable lack of studies that utilize single-walled carbon nanotubes (SWCNTs) for these purposes. However, the use of SWCNTs appears to be more promising, as demonstrated in the work of the authors [41], which presents the results of a comprehensive comparative analysis of hydrocarbon-based drilling fluids modified with MWCNTs and SWCNTs. It was shown that very small additions of carbon nanotubes could significantly regulate the main functional characteristics of drilling fluids. For instance, adding just 0.025 wt.% of single-walled nanotubes increases the effective viscosity by approximately 45 %, the yield point by 1.7 times, reduces filtration losses by 55 %, and decreases the friction coefficient by 20 %. It was also noted that the use of SWCNTs is several times more effective compared with MWCNTs.

In the majority of existing studies on this topic, the effects of nanomaterials are examined in relation to a rather limited number of individual parameters of drilling fluids, typically focusing on rheology and filtration losses. However, modern drilling fluids are subject to a diverse array of requirements that necessitate systematic investigations. Most studies concerning the influence of various nanomaterials have been conducted for water-based drilling fluids. Nevertheless, in practice, the most promising solutions for drilling in complex conditions are hydrocarbon-based fluids, which consist of inverse emulsions. Current scientific literature lacks sufficient information on how the addition of nanoparticles and carbon nanotubes specifically affects the functional properties of hydrocarbon-based drilling fluids, particularly regarding single-walled carbon nanotubes. Furthermore, due to the use of various nanomaterials and compositions of base fluids, the research conducted by different scientists remains fragmented and disjointed. As a result, drawing conclusions about the effectiveness of specific nanomaterial additives is currently challenging. This work is dedicated to the results of systematic experiments investigating the influence of different nanomaterial additives on the viscosity, rheology, filtration and antifriction properties, as well as on the colloidal stability and swelling kinetics of clays in hydrocarbon-based drilling fluids.

Methods

The base drilling fluid of hydrocarbon composition is an inverse emulsion (water in oil). For its preparation, a standard ratio of 65 % hydrocarbon phase (diesel fuel) and 35 % aqueous phase was selected. A detailed synthesis of drilling fluids using nanomaterials is presented in works [41, 42]. First, a highly concentrated aqueous solution of KCl with a density of 1100 kg/cm3 was prepared. Subsequently, the nanomaterial was added to this solution, and the resulting suspension was treated with ultrasound using the “Volna-M” disperser (22 kHz, 400 W). The suspension was then mixed with the diesel fuel under continuous stirring in a high-speed mixer (OFITE 152-18 – Princle Castle). Components were gradually introduced into the prepared dispersion medium according to the formulation (Table 1). After the addition of each component, the solution was mixed thoroughly. Initially, organophilic clay was introduced into the dispersion medium to enhance the structural-mechanical properties and promote the formation of a filter cake. Non-ionic emulsifier and hydrophobizing agent were then added to stabilize the emulsion, ensuring uniform wettability of the solid phase. During the laboratory investigations and preparation of drilling fluids, the authors adhered to accepted international standards for determining the parameters of drilling fluids as outlined by API.

To modify the drilling fluid, hydrophobic nanosized particles of pyrogenic silica, treated with polydimethylsiloxane, were used. These particles had average sizes of 5 and 80 nm, referred to as S149 and S24, respectively. Multi-walled carbon nanotubes (MWCNTs) with an inner diameter of 5-15 nm and an outer diameter of 8-30 nm were considered, with lengths exceeding 5 µm; the number of layers ranged from 30 to 40, and the specific surface area was above 270 m2/g. Additionally, single-walled carbon nanotubes (SWCNTs) with an average diameter of 1.6±0.4 nm and lengths greater than 4 µm were employed. The specific surface area, according to BET (Brunauer – Emmett – Teller) analysis, was 510 m2/g. Aluminum oxide nanofibers (γ-Al2O3) produced through a process based on the oxidation of molten aluminum in a controlled gas environment (ANF) were also used.

Table 1

Formulation of drilling fluids with nano-additives

|

Component |

Amount |

Mass concentration |

|

Hydrocarbon Dispersion Medium, ml |

195 |

55.6 |

|

CaCl2 Brine, ml |

88.3-94.1 |

38.5-40.4 |

|

Emulsifier, ml |

6.6 |

2.16 |

|

Thickener, g |

2.7 |

1.4 |

|

Hydrophobizing Agent , ml |

1.3 |

0.375 |

|

SiO2, g |

6.12 |

2 |

|

SWCNTs, g |

0.3 |

0.1 |

|

MWCNTs, g |

0.75 |

0.25 |

|

ANF, g |

0.75; 3.03 |

0.25; 1 |

The following functional characteristics of the hydrocarbon-based drilling fluid modified with nanomaterials were investigated: rheology and micro-rheology, fluid loss and filtration cake friction coefficient, colloidal stability, and the ability of the drilling fluid to inhibit the hydration of clays.

Rheology was studied under standard conditions (T = 25 °C, P = 1 atm) using a rotational viscometer (Ofite 900). The confidence interval for measurement errors did not exceed 2 %. Filtration losses were assessed after passing the drilling fluid through a paper filter using the Ofite 12BL-6 filter press at T = 25 °C and P = 7 atm for 30 min. The lubricating properties of the drilling fluid were determined by the linear friction coefficient of the resulting filtration cake. The colloidal stability of the samples was monitored using a Turbiscan analyzer, which enables the analysis of the stability of moving samples based on the optical method of multiple light scattering. The inhibiting capacity of the drilling fluid was measured using the Ofite 150-80 linear swelling tester, which can conduct studies on the interaction between moving fluids and samples of inorganic rocks containing chemically reactive clays.

Discussion of results

Viscosity of drilling fluids modified with nanoparticles

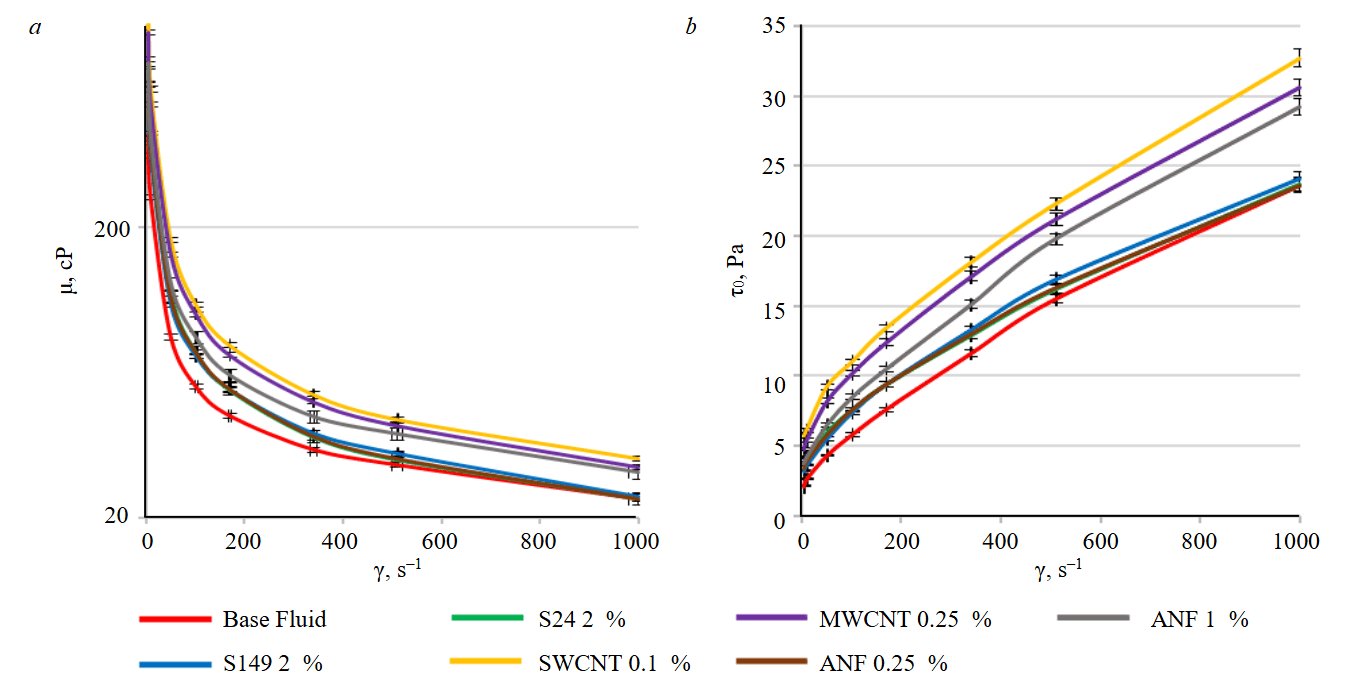

A systematic investigation of the viscosity and rheology of drilling emulsions modified with nanomaterials was initially conducted. Viscosity control is a critical step in the development of new drilling fluid formulations, as it determines the flow regimes of the drilling fluid, the efficiency of cuttings transportation to the surface, hydraulic resistances in the circulation system, and various other factors. The measurement results are presented in Fig.1.

Drilling fluids are classified as non-Newtonian liquids, and their viscosity depends on the shear rate. All investigated drilling emulsions exhibit the characteristics of viscoplastic non-Newtonian fluids and possess a yield point, as evident from the flow curves (Fig.1).

The analysis results demonstrate that the nanomaterials employed contribute to an increase in the effective viscosity of drilling fluids even at low concentrations. For instance, the addition of 2 wt.% of SiO2 nanoparticles enhances the viscosity by 20 %. To achieve a similar change in the viscosity of the drilling fluid with nanofibers, a concentration that is an order of magnitude lower (0.25 wt.%) is needed compared to spherical nanoparticles, whereas for nanotubes, the required concentration is nearly two orders of magnitude lower (0.1 wt.%). When modifying with spherical particles, it is important to consider their size – smaller particles have a more pronounced effect on the properties of the fluid. Specifically, at low shear rates, the viscosity of the drilling emulsion modified with 18 nm nanoparticles is 47 % higher than the effective viscosity of the drilling fluid that includes 80 nm nanoparticles. This can be regarded as a very significant result, as it indicates substantial modification of the drilling fluid properties across a wide range of concentrations and nanomaterial additives. Moreover, the solution fully retained its colloidal stability.

Fig.1. Dependence of viscosity (a) and shear stress (b) on shear rate for modified drilling fluid S149 2 % and S24 2 % refer to the addition of 2 wt.% of nanoparticles with average sizes of 5 and 80 nm, respectively, to the base fluid; MWCNT 0.25 % denotes the addition of 0.25 wt.% of multi-walled carbon nanotubes; SWCNT 0.1 % represents the addition of 0.1 wt.% of single-walled carbon nanotubes; ANF 0.25 % and ANF 1 % indicate the addition of 0.25 and 1 wt.% of alumina nanofibers

To analyze the viscosity dependence on shear rate, three common rheological models were employed:

- Power-law model

where K is the consistency coefficient in Pa·sⁿ; n is the nonlinearity index;

- Bingham plastic model

where τ0 is the yield stress in Pa; kv is the plastic viscosity in mPa·s;

- Herschel – Bulkley model

A comparison of the rheological parameters obtained using these models is presented in Table 2.

Table 2

Parameters of models describing the rheology of inverse emulsions with nano-additives

|

Mass concentration of nano-additives w, wt.% |

Power-law model |

Bingham plastic model |

Herschel – Bulkley model |

|||||||

|

К, Pa∙sn |

n |

R2 |

τ0, Pa |

kv, cP |

R2 |

τ0, Pa |

К, Pa∙sn |

n |

R2 |

|

|

Base Fluid |

1.6969 |

0.3516 |

0.9605 |

4.913 |

19.49 |

0.9735 |

2.93 |

0.452 |

0.519 |

0.9998 |

|

S149 2 % |

1.4072 |

0.3851 |

0.967 |

4.617 |

20.514 |

0.966 |

2.69 |

0.393 |

0.549 |

0.9999 |

|

S24 2 % |

0.8572 |

0.4487 |

0.9669 |

3.238 |

21.062 |

0.9817 |

1.849 |

0.255 |

0.614 |

0.9997 |

|

SWCNT 0.1 % |

2.6642 |

0.3337 |

0.9615 |

7.349 |

26.324 |

0.9712 |

4.421 |

0.696 |

0.501 |

0.9998 |

|

MWCNT 0.25 % |

2.2776 |

0.348 |

0.9655 |

6.61 |

25.017 |

0.9692 |

3.936 |

0.608 |

0.514 |

0.9998 |

|

ANF 0.25 % |

1.5667 |

0.3649 |

0.9662 |

4.787 |

19.674 |

0.9701 |

2.284 |

0.426 |

0.53 |

0.9996 |

|

ANF 1 % |

1.6362 |

0.3856 |

0.9583 |

5.165 |

24.94 |

0.9779 |

3.036 |

0.45 |

0.555 |

0.9997 |

Values of the correlation coefficient R2 for the approximation of flow curves using the corresponding rheological model were determined by the least squares method. The analysis indicated that the Herschel – Bulkley model best describes the rheology of drilling fluids. For fluids containing hydrocarbon nanotubes, the plastic viscosity, consistency measure, and yield stress are significantly higher. The nonlinearity index is comparable for all examined fluids.

Colloidal stability of drilling fluids modified with nano-additives

Drilling fluids constitute complex multicomponent liquids with a high content of hydrocarbon and solid phases, exhibiting a wide particle size distribution. Additionally, during the drilling process, the fluid must remain a stable colloidal system. However, drilling emulsions with a high concentration of hydrocarbon phase are often susceptible to coalescence processes. The rate of destabilization increases particularly upon heating the drilling fluid. During the operation of drilling fluids, it is often necessary to work at elevated temperatures; therefore, stability is a significant concern. A literature review reveals that comparisons of various nanomaterials for stabilizing inverse drilling emulsions are currently lacking.

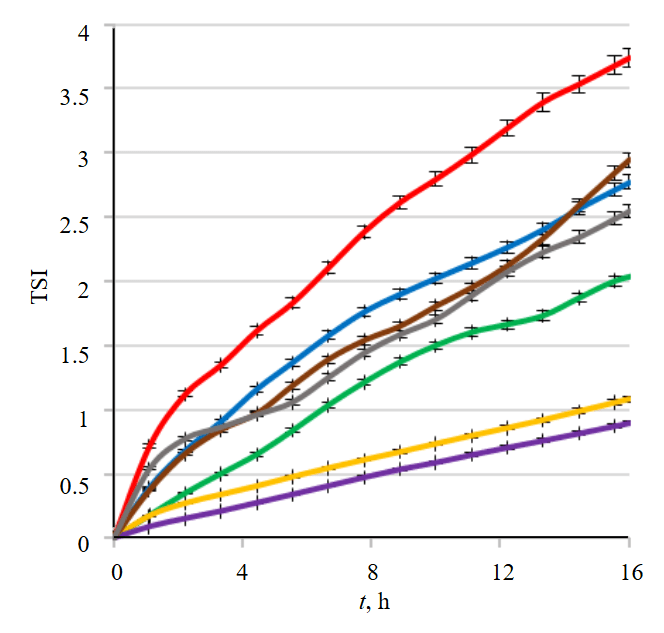

This study investigates the effect of nano-additives on the colloidal stability of drilling emulsions under standard conditions. The research was conducted using a Turbiscan LAB analyzer. The behavior of the transmission coefficient and backscattering of light for samples of drilling emulsions with nano-additives was examined. The destabilization rate of these processes is quantitatively analyzed using the destabilization index (TSI – Turbiscan stability index). This parameter is calculated as the integrated height difference of the backscattering light profiles at different time intervals. A lower TSI value indicates a more stable drilling fluid sample. Figure 2 illustrates the behavior of the destabilization index of the drilling emulsion with nano-additives over time, after which the sample was allowed to remain at rest. The dependence of emulsion stability on the aspect ratio of the nanomaterials is clearly observable – for SWCNTs (Single-walled carbon nanotubes), it is an order of magnitude larger compared to MWCNTs (Multi-walled carbon nanotubes). This significant difference in aspect ratio causes substantial variations in the degree of influence that nanotubes have on the properties of drilling fluids. For instance, as shown in Fig.2, with an increase in aspect ratio and concentration of nano-additives, the TSI index decreases monotonically. This indicates that the nano-additive significantly stabilizes the drilling emulsion. It was also established that, at a concentration of 2 wt.% of spherical 5 nm SiO2 nanoparticles, the rate of emulsion destabilization decreases by approximately twofold. The kinetics of destabilization for drilling fluids containing 0.1 wt.% of single-walled nanotubes reduces this rate by 3.5 times. Data analysis indicated that the base model of the hydrocarbon-based solution was well fitted. Compared to water-based solutions, its colloidal stability is at a relatively high level (TSI index ≈ 4 against 15 for water-based solutions), and the addition of nanomaterials further enhances its stabilization.

Fig.2. Kinetics of destabilization of drilling fluids with additives of various nanomaterials

Refer to the symbols see in Fig.1

Thus, it was demonstrated that the addition of nanomaterials decreases the kinetics of destabilization of the drilling fluid, with this effect being more pronounced at higher concentrations of nano-aditives and increased aspect ratios.

Filtration and antifriction properties of drilling fluids modified with nano-additives

Filtration losses are a well-known problem in drilling oil and gas wells. Minimizing fluid losses and forming a thin filtration cake with low permeability by using a suitable additive for filtration control is crucial for preventing instability in the wellbore. Specifically, fluid penetration into hydrocarbon-bearing strata can lead to reservoir damage and a decrease in productivity by blocking hydrocarbon flow pathways or causing casing collapse. The absorption of drilling fluid in overlying strata can result in differential sticking of drilling tools due to sharp pressure drops or complete loss of wellbore stability. This causes significant complications during the drilling process and incurs substantial costs in well construction.

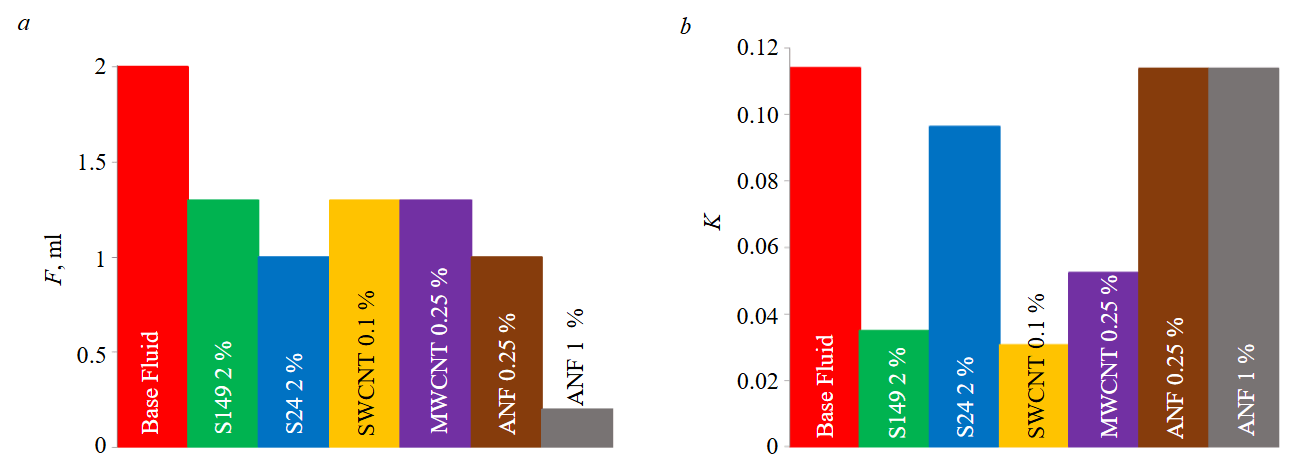

To determine filtration properties according to API methodology, the volume of liquid that passes through the filter is measured 30 min after the filtration starts. Drilling fluid tests were conducted under low pressure and low temperature (LTLP). Filtration losses were assessed using a paper filter at a pressure of 7 atm. The relationship between fluid loss of the hydrocarbon-based drilling fluid on a diesel fuel basis and the concentration of nanomaterials is illustrated in Fig.3, a. All exami-ned nanomaterials lead to a reduction in the filtration losses of the base drilling fluid. In particular, the maximum reduction (by a factor of 10) is achieved with the addition of aluminum oxide nanofibers at a concentration of 1 wt.%. The other nanomaterials result in reductions averaging 1.5-2 times, which also significantly affects the fluid loss of the drilling fluid and contributes to maintaining wellbore stability.

The lubricating properties of the flushing fluid also influence the efficiency of the drilling process. A drilling fluid with high lubricating properties can increase the rate of penetration, significantly reducing costs during well construction. Conversely, inadequate lubrication can lead to wear of the drill bit and casing, increased tensile forces and resistance during tool deployment, issues with torque, and potential sticking. Additionally, it has been established that the primary causes of drilling tool sticking, which is among the complex failures in drilling, are the poor lubricating ability of the drilling fluid and a thick filtration cake. For an effective and trouble-free drilling process, it is crucial that the filtration cake of the drilling fluid has the lowest possible friction coefficient when in contact with the wellbore wall.

To simulate the friction effect of the drill pipe against the wellbore wall, standard testing of drilling fluid involves measuring the friction coefficient of the filtration cake. The dependence of the friction coefficient of the hydrocarbon-based drilling fluid filtration cake on the concentration of nanotube additives is presented in Fig.3, b. The addition of aluminum oxide nanofibers does not alter the friction coefficient of the drilling fluid, whereas small-diameter spherical nanoparticles and carbon nanotubes significantly impact this parameter. Single-walled carbon nanotubes, at a minimum nano-additive concentration of 0.1 wt.%, reduce the friction coefficient of the drilling fluid by a factor of 3.7. In the case of spherical nanoparticle additives in the drilling fluid, the primary mechanism for reducing friction is considered the so-called ball-bearing mechanism, in which nanoparticles fill the spaces within the filtration cake between the coarse dispersed particles of the fluid. This leads to improved rolling of metal surfaces against each other. In contrast, the mechanism for reducing friction with nanotubes is different. It has been shown that carbon nanotubes significantly reduce the friction coefficient of the filtration cake, facilitating substantial optimization of the drilling process by decreasing the likelihood of drill tool sticking, increasing the rate of penetration, and preserving the lifespan of the rock-breaking tool.

Fig.3. Dependence of water yield (a) and friction coefficient (b) of drilling fluids with additives of various nanomaterials

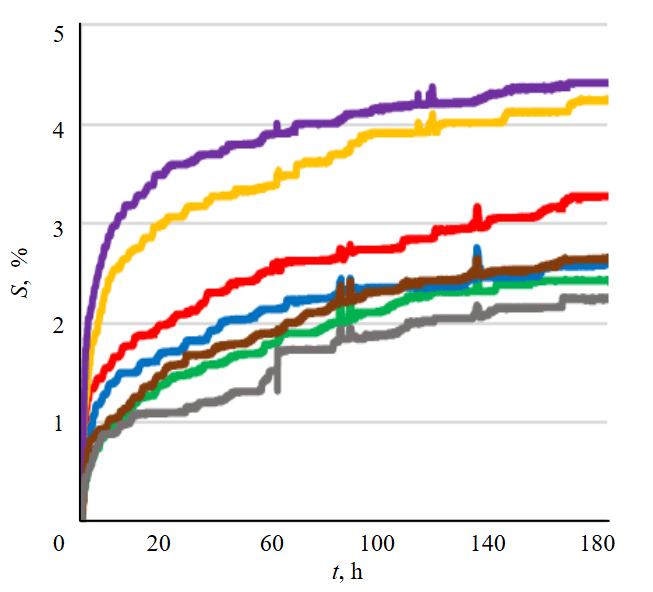

Fig.4. Dependence of linear swelling of clay rock samples in drilling fluids modified with various nanomaterials

Refer to the symbols in Fig.1

Inhibition of clay by drilling fluids modified with nano-additives

Another important property of drilling fluids is their ability to inhibit the swelling of clay minerals. During the drilling process, the drilling fluid interacts with the wellbore walls, which are composed of clay and other minerals. Consequently, the aqueous phase present in the fluid promotes the swelling of clay, leading to the loosening and collapse of the wellbore walls. Therefore, it is essential that the drilling fluid aids in inhibiting clay swelling. This study presents a comparative analysis of the effects of various nano-additives on the swelling rate of clay cylinders in diesel oil-based drilling fluids for the first time. The kinetics of clay swelling were examined using the Ofite 150-80 apparatus. For the experiments, montmorillonite clay cylinders measuring 28×12 mm and having a high degree of hydration were compressed, and changes in their linear dimensions during the hydration process were measured.

Analysis of the results indicated that the addition of carbon nanotubes increased the clay hydration rate by approximately 25 % compared to the base fluid (Fig.4). This can be considered a negative aspect from the perspective of maintaining the stability of wellbore walls. However, the selected base drilling fluid already exhibits a very high rate of clay swelling (around 70 %). The presence of carbon nanotubes does not significantly degrade the inhibitory capacity of this fluid. In contrast, spherical silica nanoparticles and alumina nanofibers further enhance the inhibition of clay in hydrocarbon-based drilling fluids. Specifically, the maximum concentration of nanofibers at 1 wt.% results in a 1.5-fold reduction in clay hydration, thereby making this material a viable inhibitor for drilling clay-containing formations.

Quantitative comparison of the results obtained in this study with those of other authors is not feasible, as different researchers employ varying formulations and chemical reagents for preparing even the base drilling fluids, let alone the nano-modified ones. The diversity of materials used, along with their concentrations, sizes, and morphologies of nanoparticles, is extensive; therefore, so the concept of quantitative comparison is hardly applicable here the concept of quantittive comparison is hardly is hardly applicable in this context. However, a qualitative analysis of the results indicates that they generally align with the findings of other researchers who have operated under similar conditions. This observation pertains to the main trends in the modification of drilling fluid properties through the incorporation of nanomaterials.

Conclusion

This study represents the first comprehensive investigation of the influence of various nanomaterials on the key functional properties of hydrocarbon-based drilling fluids, containing 65 % hydrocarbon phase. Different shapes, materials, and sizes of particles were considered as modifiers.

Key findings:

- Nanomaterials have a significant impact on the properties of hydrocarbon-based drilling emulsions, with nanotubes showing greater efficacy at lower concentrations compared to spherical nanoparticles. The difference becomes evident at a concentration of nanotubes as low as 0.1 wt.%.

- With an increase in the aspect ratio and concentration of nano-additives, the destabilization of drilling fluids monotonously decreases. A more significant effect on emulsion stabilization is observed for nanotubes compared to spherical nanoparticles. At a concentration of 2 wt.% of 5 nm silica nanoparticles, the rate of emulsion destabilization decreases by approximately twofold. The kinetics of destabilization for drilling fluids containing 0.1 wt.% of single-walled nanotubes results in a reduction of this parameter by 3.5 times. It has been demonstrated that the addition of nanomaterials significantly reduces the kinetics of destabilization of the drilling fluid, with a greater effect observed at higher concentrations of nano-additives and their aspect ratios.

- All the examined nanomaterials lead to a reduction in the filtration losses of the base drilling fluid. Notably, the maximum reduction (by a factor of 10) is achieved with the addition of alumina nanofibers at a concentration of 1 wt.%. The use of other nanomaterials results in a decrease in filtration losses by an average of 1.5 to 2 times, which also significantly impacts the yield of the drilling fluid.

- The addition of alumina nanofibers does not alter the friction coefficient of the drilling fluid; however, small-diameter spherical nanoparticles and carbon nanotubes significantly affect this parameter. Specifically, single-walled nanotubes at a minimal concentration of 0.1 wt.% reduce the friction coefficient of the drilling fluid by a factor of 3.7.

- The incorporation of spherical silica nanoparticles and alumina nanofibers results in enhanced inhibition of clay by hydrocarbon-based drilling fluids modified with these nanomaterials. Notably, the maximum concentration of 1 wt.% of nanofibers leads to a 1.5-fold reduction in clay hydration, enabling the use of this material as an inhibitor in the drilling of clay-bearing formations. The introduction of nanotubes into the drilling fluid increases the rate of clay swelling; however, this increase is insignificant even when compared to the degree of hydration of clay formations when interacting with water-based drilling fluids.

References

- Apaleke A.S., Al-Majed A., Hossain M.E. Drilling Fluid: State of The Art and Future Trend. North Africa Technical Conference and Exhibition, 20-22 February 2012, Cairo, Egypt. OnePetro, 2012. N SPE-149555-MS. DOI: 10.2118/149555-MS

- Guancheng Jiang, Tengfei Dong, Kaixiao Cui et al. Research status and development directions of intelligent drilling fluid technologies. Petroleum Exploration and Development. 2022. Vol. 49. Iss. 3, p. 660-670. DOI: 10.1016/S1876-3804(22)60055-7

- Tabatabaee Moradi S.Sh. A probabilistic study on hole cleaning optimization. Journal of Mining Institute. 2022. Vol. 258, p. 956-963. DOI: 10.31897/PMI.2022.67

- Ulyasheva N.M., Leusheva E.L., Galishin R.N. Development of the drilling mud composition for directional wellbore drilling considering rheological parameters of the fluid. Journal of Mining Institute. 2020. Vol. 244, p. 454-461. DOI: 10.31897/PMI.2020.4.8

- Leusheva E.L., Morozov A.O., Morozov D.O. Ecological Biodegradable Additives for Improving Rheological and Filtration Characteristics of Water-Based Drilling Mud. Perm Journal of Petroleum and Mining Engineering. 2024. Vol. 24. N 3, р. 120-130 (in Russian). DOI: 10.15593/2712-8008/2024.3.3

- Lavrentiadi Yu.S., Leusheva E.L. Increasing the Environmental Friendly of Process Fluids Used for Well Drilling. Perm Journal of Petroleum and Mining Engineering. 2023. Vol. 23. N 1, р. 32-43 (in Russian). DOI: 10.15593/2712-8008/2023.1.5

- Leusheva E.L., Alikhanov N.Т., Brovkina N.N. Study on the rheological properties of barite-free drilling mud with high density. Journal of Mining Institute. 2022. Vol. 258, p. 976-985. DOI: 10.31897/PMI.2022.38

- Blinov P.A., Dvoynikov M.V. Rheological and Filtration Parameters of the Polymer Salt Drilling Fluids Based on Xanthan Gum. Journal of Engineering and Applied Sciences. 2018. Vol. 13. N 14, p. 5661-5664. DOI: 10.36478/jeasci.2020.694.697

- Siddig O., Mahmoud A.A., Elkatatny S. A review of the various treatments of oil-based drilling fluids filter cakes. Journal of Petroleum Exploration and Production Technology. 2022. Vol. 12. Iss. 2, p. 365-381. DOI: 10.1007/s13202-021-01427-4

- Jiancheng Li, Peng Yang, Jian Guan et al. A new type of whole oil-based drilling fluid. Petroleum Exploration and Development. 2014. Vol. 41. Iss. 4, p. 538-544. DOI: 10.1016/S1876-3804(14)60064-1

- Guanzheng Zhuang, Zepeng Zhang, Jaber M. Organoclays used as colloidal and rheological additives in oil-based drilling fluids: An overview. Applied Clay Science. 2019. Vol. 177, p. 63-81. DOI: 10.1016/j.clay.2019.05.006

- Leusheva E., Morenov V., Liu T. Dependence of the Equivalent Circulation Density of Formate Drilling Fluids on the Molecular Mass of the Polymer Reagent. Energies. 2021. Vol. 14. Iss. 22. N 7639. DOI: 10.3390/en14227639

- Nikitin V.I. Problem solution analysis on finding the velocity distribution for laminar flow of a non-linear viscous flushing fluid in the annular space of a well. Journal of Mining Institute. 2022. Vol. 258, p. 964-975. DOI: 10.31897/PMI.2022.93

- Al-Hameedi A.T.T., Alkinani H.H., Dunn-Norman S. et al. Insights into the application of new eco-friendly drilling fluid additive to improve the fluid properties in water-based drilling fluid systems. Journal of Petroleum Science and Engineering. 2019. Vol. 183. N 106424. DOI: 10.1016/j.petrol.2019.106424

- Ali M., Jarni H.H., Aftab A. et al. Nanomaterial-Based Drilling Fluids for Exploitation of Unconventional Reservoirs: A Review. Energies. 2020. Vol. 13. Iss. 13. N 3417. DOI: 10.3390/en13133417

- Zheng-Qiang Xiong, Xiao-Dong Li, Fan Fu, Yan-Ning Li. Performance evaluation of laponite as a mud-making material for drilling fluids. Petroleum Science. 2019. Vol. 16. Iss. 4, p. 890-900. DOI: 10.1007/s12182-018-0298-17

- Leusheva E.L. Evaluation of Possible Application of Powder Made from Fallen Tree Leaves as a Drilling Mud Additive. International Journal of Engineering, Transactions B: Applications. 2024. Vol. 37. Iss. 8, p. 1592-1599. DOI: 10.5829/IJE.2024.37.08B.12

- Zubkova O.S., Kuchin V.N., Toropchina M.A., Ivkin A.S. Potential Application of Saponite Clay for Production of Drilling Fluids. International Journal of Engineering, Transactions B: Applications. 2024. Vol. 37. Iss. 11, p. 2142-2149. DOI: 10.5829/IJE.2024.37.11B.01

- Adil A., Baig T., Jamil F. et al. Nanoparticle-based cutting fluids in drilling: a recent review. The International Journal of Advanced Manufacturing Technology. 2024. Vol. 131. Iss. 5-6, p. 2247-2264. DOI: 10.1007/s00170-023-11048-2

- Seetharaman G.R., Sangwai J.S. Effect of Nanoparticles on the Performance of Drilling Fluids. Nanotechnology for Energy and Environmental Engineering. Springer, 2020, p. 279-297. DOI: 10.1007/978-3-030-33774-2_12

- Irfran Y., Sui D, Agista M.N., Zhixin Yu. The Potential of Nanotechnology in Petroleum Industry with Focus on Drilling Fluids. Petroleum & Petrochemical Engineering Journal. 2017. Vol. 1. Iss. 1. N 000106.

- Hui Mao, Zhengsong Qiu, Zhonghou Shen, Weian Huang. Hydrophobic associated polymer based silica nanoparticles composite with core–shell structure as a filtrate reducer for drilling fluid at utra-high temperature. Journal of Petroleum Science and Engineering. 2015. Vol. 129, p. 1-14. DOI: 10.1016/j.petrol.2015.03.003

- Cheraghian G. Nanoparticles in drilling fluid: A review of the state-of-the-art. Journal of Materials Research and Technology. 2021. Vol. 13, p. 737-753. DOI: 10.1016/j.jmrt.2021.04.089

- Al-Shargabi M., Davoodi S., Wood D.A. et al. Nanoparticle applications as beneficial oil and gas drilling fluid additives: A review. Journal of Molecular Liquids. 2022. Vol. 352. N 118725. DOI: 10.1016/j.molliq.2022.118725

- Elkatatny S. Enhancing the Stability of Invert Emulsion Drilling Fluid for Drilling in High-Pressure High-Temperature Conditions. Energies. 2018. Vol. 11. Iss. 9. N 2393. DOI: 10.3390/en11092393

- Mahmoud O., Nasr-El-Din H.A., Vryzas Z., Kelessidis V.C. Using Ferric Oxide and Silica Nanoparticles To Develop Modified Calcium Bentonite Drilling Fluids. SPE Drilling &Completion. 2018. Vol. 33. Iss. 1, p. 12-26. DOI: 10.2118/178949-PA

- Mohamadian N., Ghorbani H., Wood D.A., Hormozi H.K. Rheological and filtration characteristics of drilling fluids enhanced by nanoparticles with selected additives: an experimental study. Advances in Geo-Energy Research. 2018. Vol. 2. N 3, p. 228-236. DOI: 10.26804/ager.2018.03.01

- Minakov A.V., Mikhienkova E.I., Voronenkova Y.O. et al. Systematic experimental investigation of filtration losses of drilling fluids containing silicon oxide nanoparticles. Journal of Natural Gas Science and Engineering. 2019. Vol. 71. N 102984. DOI: 10.1016/j.jngse.2019.102984

- Parizad А.P., Shahbazi K. Experimental investigation of the effects of SnO2 nanoparticles and KCl salt on a water base drilling fluid properties. The Canadian Journal of Chemical Engineering. 2016. Vol. 94. Iss. 10, p. 1924-1938. DOI: 10.1002/cjce.22575

- Medh S., Chowdhury S., Gupta D.K., Mazumdar A. An investigation on the effects of silica and copper oxide nanoparticles on rheological and fluid loss property of drilling fluids. Journal of Petroleum Exploration and Production Technology. 2019. Vol. 10. Iss. 1, p. 91-101. DOI: 10.1007/s13202-019-0721-y

- Majid S. Al Ruqeishi, Younis Al Salmi, Mohiuddin T. Nanoparticles as Drilling Fluids Rheological Properties Modifiers. Progress in Petrochemical Science. 2018. Vol. 1. Iss. 5. N PPS.000521.2018. DOI: 10.31031/PPS.2018.01.000521

- Żyła G. Viscosity and thermal conductivity of MgO–EG nanofluids. Journal of Thermal Analysis and Calorimetry. 2017. Vol. 129. Iss. 1, p. 171-180. DOI: 10.1007/s10973-017-6130-x

- Nguyen C.T., Desgranges F., Roy G. et al. Temperature and particle-size dependent viscosity data for water-based nanofluids – Hysteresis phenomenon. International Journal of Heat and Fluid Flow. 2007. Vol. 28. Iss. 6, p. 1492-1506. DOI: 10.1016/j.ijheatfluidflow.2007.02.004

- Shakib J.T., Kanani V., Pourafshary P. Nano-clays as additives for controlling filtration properties of water–bentonite suspensions. Journal of Petroleum Science and Engineering. 2016. Vol. 138, p. 257-264. DOI: 10.1016/j.petrol.2015.11.018

- Mikhienkova E.I., Lysakov S.V., Neverov A.L. et al. Experimental study on the influence of nanoparticles on oil-based drilling fluid properties. Journal of Petroleum Science and Engineering. 2022. Vol. 208. Part B. N 109452. DOI: 10.1016/j.petrol.2021.109452

- Ismail A.R., Aftab A., Ibupoto Z.H., Zolkifile N. The novel approach for the enhancement of rheological properties of water-based drilling fluids by using multi-walled carbon nanotube, nanosilica and glass beads. Journal of Petroleum Science and Engineering. 2016. Vol. 139, p. 264-275. DOI: 10.1016/j.petrol.2016.01.036

- Kazemi-Beydokhti A., Hajiabadi S.H. Rheological investigation of smart polymer/carbon nanotube complex on properties of water-based drilling fluids. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2018. Vol. 556, p. 23-29. DOI: 10.1016/j.colsurfa.2018.07.058

- Ozkan A. Effect of gold nanoparticle functionalized multi-walled carbon nanotubes on the properties of Na-bentonite water based drilling fluid. Fresenius Environmental Bulletin. 2020. Vol. 29. N 1, p. 143-151.

- Ahmad H.M., Kamal M.S., Murtaza M., Al-Harthi M.A. Improving the Drilling Fluid Properties Using Nanoparticles and Water-Soluble Polymers. SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, 24-27 April 2017, Dammam, Saudi Arabia. OnePetro, 2017. N SPE-188140-MS. DOI: 10.2118/188140-MS

- Anoop K., Sadr R., Yrac R., Amani M. Rheology of a colloidal suspension of carbon nanotube particles in a water-based drilling fluid. Powder Technology. 2019. Vol. 342, p. 585-593. DOI: 10.1016/j.powtec.2018.10.016

- Lysakova E., Skorobogatova A., Neverov A. et al. Comparative analysis of the effect of single-walled and multi-walled carbon nanotube additives on the properties of hydrocarbon-based drilling fluids. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2023. Vol. 678. N 132434. DOI: 10.1016/j.colsurfa.2023.132434

- Minakov A.V., Lysakova E.I., Skorobogatova A.D. et al. Experimental study of the effect of crystalline aluminum oxide nanofibers on the properties of oil-based drilling fluids. Journal of Molecular Liquids. 2023. Vol. 388. N 122676. DOI: 10.1016/j.molliq.2023.122676