A study of the use sedimentation compositions in order to conformance control of steam injection wells

- 1 — Head of Laboratory Ukhta State Technical University ▪ Orcid

- 2 — Ph.D., Dr.Sci. Professor Ukhta State Technical University ▪ Orcid ▪ Elibrary

Abstract

The most industrially developed methods of enhanced oil recovery of the production of high-viscosity oils and natural bitumen are thermal methods of influencing the reservoir: steam cyclic stimulation of production wells, steam assisted gravity drainage, and areal steam injection. The thermal methods also include the thermomine method, which involves the construction of underground mine working with galleries of producing wells and a thermally enhanced oil recovery. An example of using the thermomine method – the Yarega area of the Yarega field. The technology of the thermomine method are continuously being improved during the development of Yarega area. The most common the underground-surface method: the steam is injected from the surface through vertical steam injection wells, and oil is extracted in the underground mine through gently sloping production wells. The practice of areal steam injection and the results of geophysical studies of steam injection wells have shown that when using the underground-surface method of production the Yarega area, the steam mainly enters the upper part of the reservoir, which implies uneven production of reserves in thickness. There is a need to increase the pressure of steam injection in order to involve reserves of extra-viscous oil in the process of the heat carrier treatment. However, an increase in the injection pressure of the steam is problematic in some cases due to the presence of heterogeneities in the formation (disjunctive seismic faults every 20-25 m, as well as numerous microfractures with fissure opening). The paper presents the results of an experimental study of the use of sedimentation compounds during steam injection under different thermobaric conditions. The scientific novelty is to evaluate the effectiveness of the use of sedimentation compounds when injecting steam into zonally heterogeneous sand packed tubes. Solutions of iron sulfate, sodium carbonate, and calcium chloride were selected as sedimentation compounds. The average permeability of the heterogeneous sand packed tube was reduced by 55 % when steam was injected with a temperature of more than 170 °C as a result of performing three treatments with sedimentation compounds. The effective pore volume during steam injection has been increased by 70.6 %, which, during well tests affects an increase in the surface efficiency of steam treatment, and as a result, an increase in oil recovery.

Introduction

Thermal methods of enhanced oil recovery (EOR) are mainly used in the production of deposits of high-viscosity oils and natural bitumen [1, 2]. Global experience in the production of hard-to-recover heavy oil reserves has shown that the share of thermal EOR used reaches 67 % of all technologies used at these production targets [3]. In addition to thermal EOR, chemical methods, injection of hydrocarbon or carbon dioxide gas, and other less common methods of exposure are used [4-6].

Thermal EOR include such technologies as areal steam injection (areal steam treatment) [7], cyclic steam simulated [8], steam assisted gravity drainage [9], in situ combustion [10], thermomine method [11] et al. A key factor in any steam treatment is a decrease in oil viscosity and an increase in its mobility [12]. Despite the high efficiency of thermal EOR, there is a constant improvement in impact technologies in order to reduce the costs of hydrocarbon production.

An example of the use of thermal EOR in the Komi Republic is the Yarega oil and titanium field. The oil reservoir is confined to the deposits of the Upper and Middle Devonian, it lies at a shallow depth – the roof is marked in the depth range of 140-210 m. The initial geological reserves amount to more than 200 million tons of oil with abnormal viscosity (12-14 Pa×s in reservoir conditions). The thermomine methods are used within the Yarega area of the Yarega field [13], and steam assisted gravity drainage of the reservoir is used on the Lyaelskaya area [14].

At the initial stage, since 1932, the Yarega area of the Yarega field was produced using the “classical” method – penetration the deposit from the surface with vertical wells and extracting oil from the gas dissolved in it. 38.5 thousand tons of extra-viscous oil were produced during the blowout of production wells at pilot industrial sites in 1935-1945, which corresponded to an oil recovery ratio of less than 2 %. To increase the efficiency of oil extraction, a project for the construction of three oil mines was developed in 1939. The mining of mine fields was carried out in a depletion in 1939-1972, as a result of which it was possible to increase the oil recovery ratio (ORR) to 6 %. The reservoir pressure was reduced from 1.4 MPa to atmospheric pressure as a result of the depletion of the productive deposit, which in turn contributed to the introduction of thermal EOR [15].

The oil recovery ratio has been increased to 53 % with a steam oil ratio (SOR) of 2.7 t/t since the beginning of the introduction of the thermomine method in 1972-2002. The main problems of production using the heat carrier treatment on the deposit of extra-viscous oil were the heterogeneity in sandstones of the reservoir (the presence of seismic faults every 20-25 m); the presence of numerous wells drilled during depletion; high temperature in oil mine; steam break-throughs into producing wells and minе workings. It was decided to inject the steam from the surface due to the high cost of building and equipping oil mines with a steam injection system. The underground-surface method of thermomine of production involves only the drainage of oil in the oil mine through a system of gently sloping wells. Steam injection is carried out by vertical wells from the surface along the contour of the oil gallery, which implies a decrease in temperature in the mine workings and an increase in the injection pressure of the steam to 1.6 MPa and, as a result, an increase in the steam treatment zone. Its temperature also increases as the steam injection pressure increases, which has a beneficial effect on oil recovery [16].

75 dip-working blocks with geological reserves of 105 million tons of oil have been put into development since the beginning of the thermomine method. A dip-working block is understood as a separate oil gallery with a certain type of steam injection, depending on the thermomine development system. The main thermomine method is currently the underground-surface method, which has mastered seven dip-working blocks with initial geological reserves of 4.2 million tons of oil. The average ORR for decommissioned blocks was 62.2 %, and the average SOR was 2.6 t/t (2.6 t of steam per 1 t of oil produced).

Problem statement

There are a number of factors that have been identified during the development of dip-working blocks despite the high efficiency of the underground-surface thermomine development system. The steam is mainly concentrated near the roof of the oil reservoir during the heat carrier treatment from the surface, which leads to a number of complications during development: uneven reserve recovery along the thickness of the reservoir [17]; breakthrough of the heat carrier to gently sloping production wells and mine workings [18]; the inability to increase the injection pressure of the heat carrier to 1.6 MPa in steam injection wells.

Geophysical studies of steam injection wells are performed as a method of monitoring the heat carrier intake by the reservoir thickness [19]. According to the results of spinner survey of these studies, preroofed part heating of the reservoir is confirmed in most steam injection wells. The low vertical sweep efficiency of the heat carrier of the bottomhole zone of steam injection wells is due to both low injection pressure and the predominance of gravitational forces.

Another problem of the heat carrier treatment in the underground-surface thermomine development system is the hydrodynamic connectivity between steam injection wells. Channels with low flow coefficient are formed at high steam injection rates due to the weak consolidation of the terrigenous reservoir [20], which mainly spread near the roof of the reservoir. There is also a decrease in the rock strength parameters of the reservoir, accompanied by sand problem under such conditions [21], which can occur both in gently sloping production wells and in neighboring steam injection wells. The presence of the heat carrier inflow intervals in the bottomhole zone of stopped steam injection wells in some cases exceeds 50 % of the penetrated thickness of the reservoir, which significantly reduces the effectiveness of the heat carrier treatment deep into the reservoir in the direction of the oil gallery of the dip-working block.

Reservoir zones with disjunctive seismic faults and wells drilled in the Ukhta system prevent the spread of the steam treatment zone. The expansion of the heat front occurs mainly due to thermal conductivity at the initial stage of the steam treatment. In this case oil recovery is mainly due to thermal expansion, and without creating a proper pressure gradient from the roof to the bottom of the reservoir, development is carried out in a gravity drive.

It is proposed to consider a number of technological solutions aimed at conformance control of steam and involving uninvaded zones of the reservoir in the recovery process to isolate highly permeable zones of the reservoir. There are several technologies aimed at isolating highly permeable reservoir intervals. These methods can be both selective and non-selective [22]. When developing deposits of extra-viscous oil by thermal EOR, non-selective technologies for isolating reservoir intervals are impractical. Isolation of the exposed reservoir interval can significantly affect the intake capacity of the heat carrier, which directly influences on the ORR. Therefore, it is worth considering exclusively selective isolation methods, their use will reduce permeability only in water-saturated zones of the reservoir.

The limitation of water inflow to producers from injection wells is achieved using various methods [23], such as injection of gelling compounds [24-26], polymer-dispersed systems [27-29], emulsion compositions [30, 31], silicate solutions [32], sedimentation compounds [33] et al. Table 1 provides a brief comparative description of the chemical compounds used to conformance control (CC) of injection wells.

Table 1

Comparison of chemical compounds for conformance control

|

Types compounds |

Advantage |

Disadvantage |

|

Polymer-dispersed systems and gel-forming compounds |

The different viscosity of the composition depends on the concentration of the polymer (gel-forming compound) and dispersed particles, as well as the possibility of regulating the formation time of the gel-forming system due to temperature or cross linker. High efficiency of CC due to the creation of a hydrodynamic barrier by a polymer or gel-forming system in the bottomhole zone of the formation |

High cost of reagents. Mechanical and chemical degradation of polymer molecules depending on the nature of the polymer and the type of reservoir. Relatively low thermal stability (stability of solutions rarely reaches 120-130 °C). Gradual loss of viscosity of the formed gel-structure due to the diffusion process |

|

Silicate compounds |

Low cost. Gel or sediment formation, depending on the reagent used. Mobility in the pore volume |

Inability to use in conditions over temperature 95 °С. Low efficiency of CC in highly permeable reservoirs |

|

Sedimentation compounds |

Low cost. High thermal stability. Mobility in the pore volume |

Low efficiency of CC compared to polymer or gel-forming compounds. The duration effect of СС depends on the properties of the reservoir and reservoir water |

|

Metal oxides (nanoparticles) |

They are mainly used in the composition of other types of chemical compounds for CC. High thermal stability |

High cost. Low efficiency of CC and pore volume clogging |

CC technologies are constantly being improved in order to increase efficiency and reduce the cost of well interventions. Various surface acting agents (SAA) are used as a method to increase the efficiency of polymer systems, contributing to an increase in the mobility of the system for deeper treatment of the reservoir [34]. The combined compositions of polymer-dispersed and silicate systems also make it possible to influence the bottomhole and uninvaded zones of the reservoir, thereby changing the filtration flow of the injected water [35]. Nanoparticles, on the other hand, are most often used as EOR reagent due to their oil-displacing ability and reduced wettability of polymer-dispersed systems [36, 37].

When using gas EOR, gas breakthroughs to producing wells are possible, which significantly reduces the efficiency of the oil production process, therefore, viscous foaming compounds based on various surfactants are being developed to facilitate the redistribution of gas into less permeable areas of the fractured-porous reservoir [38].

The listed methods have their advantages and disadvantages, but there is one similarity – the use of aqueous solutions in certain temperature conditions. For high-temperature conditions, heat-resistant gel-forming systems are being developed and constantly improved [39-41], aimed at blocking the filtration flow of the heat carrier. Unfortunately, the use of foaming systems in conditions of steam injection is unlikely due to low thermal stability, as well as filtration of two phases – steam and hot water.

In practice technologies already exist to water shut-off to producing wells and conformance control the heat carrier in the conditions of the permo-carbon deposit of the Usinsk field. The use of gel-forming (thermotropic) [42] and oil-displacing compositions [43] made it possible to increase the efficiency of oil production during steam cyclic treatments of producing wells. To increase efficiency, the addition of surface acting agents and solvents is provided [44, 45]. The use of these technologies in thermomine conditions is problematic due to the possibility of gaseous products of chemical reactions entering the mine atmosphere.

As a method of limiting the flow of the heat carrier in the form of steam or hot water, it is proposed to consider sedimentation compounds, which, when mixed in water, form fine sediments with a high depth of penetration into the pore structure of the formation, causing a flow-deflecting effect [46].

Ion exchange reactions using sedimentation compounds form water-soluble salts and non-soluble precipitates that cause the pore volume clogging. A striking example of the use of sedimentation solutions are solutions of sodium carbonate and calcium chloride, which, when mixed, form non-soluble calcium carbonate and water-soluble sodium chloride. An additional effect of using sedimentation compounds is an increase in reservoir cementation due to an increase in carbonate content [47], which in the future may reduce sand problem occurrence in wells using thermal EOR.

Purpose and objectives of the work

To prevent possible complications during the development of the Yarega area by the underground-surface method and to increase the efficiency of steam treatment, there is a need to carry out well interventions aimed at conformance control of the heat carrier. Not all current technologies for conformance control are suitable for use in thermomine conditions, for example, due to the presence of gaseous products of chemical reactions or lack of thermal stability. Therefore, the selection of effective sedimentation compounds (SC) to increase the surface efficiency of heat treatment is relevant.

The purpose of the study – to evaluate the effectiveness of the use of sedimentation compounds during the heat carrier injection. To achieve this purpose, a number of objectives are being solved:

- Formation of a zonally heterogeneous sand packed tube model of the Yarega area of the Yarega field.

- Determination of the pore volume of the model and the factor of open porosity when saturated with distilled water.

- Injecting of sedimentation compounds during filtration of the heat carrier with different injection rates and thermobaric conditions.

- Assessment of changes in controlled parameters after injection of sedimentation compounds with a steam-water mixture.

- Determination of the change in the effective pore volume at a certain filtration rate after injection of SC.

The scientific novelty of the work – the use of SC in rock when injection a steam-water mixture with a temperature of up to 200 °С. In the framework of determining the efficiency of using sedimentation compounds in the pore volume, a method was used to evaluate the measurement of effective pore volume due to the redistribution of the filtration flow.

Methodology of study

The study was performed using the main components of the PIK-OFP/EP-K-T filtration unit, a flow-through superheater steam generator, a two-plunger pump LN-800-100 and a PetroOm immitance meter with a cuvette to determine the electrical resistance of a liquid. To create heterogeneous sand packed, natural reservoir core grinding is used in the ratio of the most common fractions of the formation of the Yarega field with a particle diameter of 0.1-0.25 mm – 45 % and a particle diameter of 0.25-0.5 mm – 55 %, as well as extracted core reservoir models with a diameter of 30 mm sawn along their axis.

The overall dimensions of the steel pipe with internal thread are as follows: length – 500 mm; diameter – 30 mm; volume – 353.25 ml. The formation of a heterogeneous sand packed consists of the following steps:

- immersion of the filter paper strip into the steel pipe of the sand packed tube and closing of the outlet end of the model;

- immersion of semi-cylindrical core reservoir models at an angle of inclination of a steel pipe of about 10°;

- filling of sand into the second half of the sand packed tube in an upright position and its further shrinkage due to its own weight by hitting the power elements of the steel pipe with a rubber mallet.

For the first half (lower part) of the sand packed tube, reservoir core models with absolute gas (helium) permeability before longitudinal sawing were selected: N 13 – 9913.3 mD; N 45 – 5262.4 mD; N 33 – 2320.0 mD; N 101 – 1078.0 mD. The average permeability of reservoir core models along the length of the model reservoir is about 5500 mD. Semi-cylindrical reservoir core models are positioned with an increase in permeability to the outlet of the sand packed tube, i.e., with the creation of a maximum difference in permeability at the inlet between the submerged “core” part and the filled sand.

The total mass of the rock of the sand packed tube was 655.88 g (407.75 g of naturally ground core and 248.13 g – the total mass of core samples). The prepared reservoir model in an upright position was connected to the pump LN-800-100 from below using a connecting tube of the inlet end for saturation with distilled water with the volume flow rate of 0.2 ml/min. The outlet tube from the reservoir model is immersed in a measuring cylinder to assess the volume of water that has passed through the sand packed tube. The saturation process can be considered completed when the volume of injected water, according to telemetry data, is equal to the collected volume at the outlet in the measuring cylinder. At the end of saturation, the output end of the sand packed tube is closed and the reservoir model is crimped to 2 MPa in order to determine the tightness of all connections, pressure is maintained for 4 h, the sand packed tube is gradually vented from above into the measuring cylinder, water is injected until the cumulative flow at the inlet and outlet of the reservoir model is stabilized. As a result of saturation with distilled water, the pore volume (Vpor) was 93.4 ml (the factor of open porosity of the sand packed tube was 26.4 %).

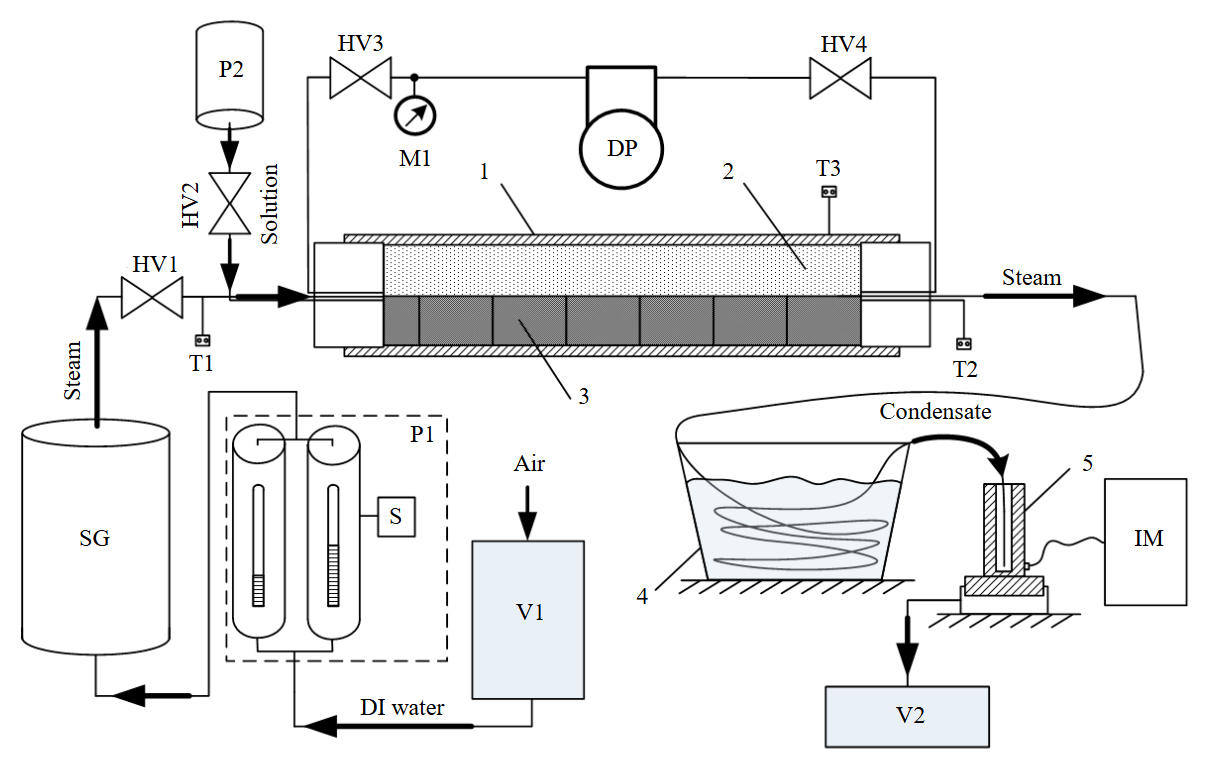

After determining the pore volume of the reservoir model, it is transferred to a horizontal position and connected to a filtration unit according to the hydraulic scheme (Fig.1). A differential pressure gauge is used to assess the change in permeability, and thermocouples at the input and output of the reservoir model are used to change the temperature. Constant monitoring of the electrical resistance of the liquid in the measuring cell of the PetroOm device is provided to control the output of the products of chemical reactions of SC. The presence of non-soluble particles in the outgoing condensate was determined by passing the entire volume of steam condensate from the tank through a paper filter, followed by drying and mass determination. For the steam-condensate phase transition, a flexible polyurethane tube with a length of about 4 m and a volume of 12 ml was connected to the sand packed tube in a refrigerant tank.

Fig.1. Hydraulic scheme of an experiment on injecting sedimentary compounds

into a heterogeneous sand packed tube

1 – pipe with an internal thread for flow coefficient; 2 – natural reservoir core grinding; 3 – semi-cylindrical reservoir core models; 4 – refrigerant tank for the phase transition of the heat carrier; 5 – cuvette of an immitance meter (IM); V1 – tank with distilled water; P1 – two-plunger pump for supplying distilled water with a sensor S pressure and volume flow rate; SG – flow steam generator-superheater; P2 – pump for injection sedimentary compounds and sodium chloride solution; M1 – pressure of the steam injection; DP – differential pressure; Т1, Т2 – temperature at the inlet and outlet the sand packed tube; Т3 – temperature of steel pipe of the sand packed tube near the outlet; HV1, HV2, HV3, HV4 – hydraulic valve; V2 – tank collection steam condensate

Solutions of iron sulfate, sodium carbonate, and calcium chloride with concentrations of 0.45 g/ml (the maximum concentration of reagents) are used as SC. The volumes of solutions of inorganic salts are 3, 6 and 3 ml. The algorithm for processing the model of SC:

- stop steam injection, injection of an iron sulfate solution followed by steam injection for 2 min with 50 % of the steady rate of injection before the start of treatment;

- stopping steam injection, injecting an identical volume of process water to flush the discharge line while continuing to supply 50 % of the volume flow rate of the heat carrier;

- similarly, a sodium carbonate solution is injected, with 75 % of the volume flow rate set before treatment with sedimentation compounds;

- injection of the last solution, a calcium chloride solution, followed by steam injection with the volume flow rate before performing SC treatment.

After processing the rock with SC, pressure changes are monitored under different modes of the heat carrier injection (volume flow rates of distilled water into the steam generator). A total of six heat carrier filtration modes are provided with volume flow rates of 3; 5; 8; 10; 13, and 15 ml/min.

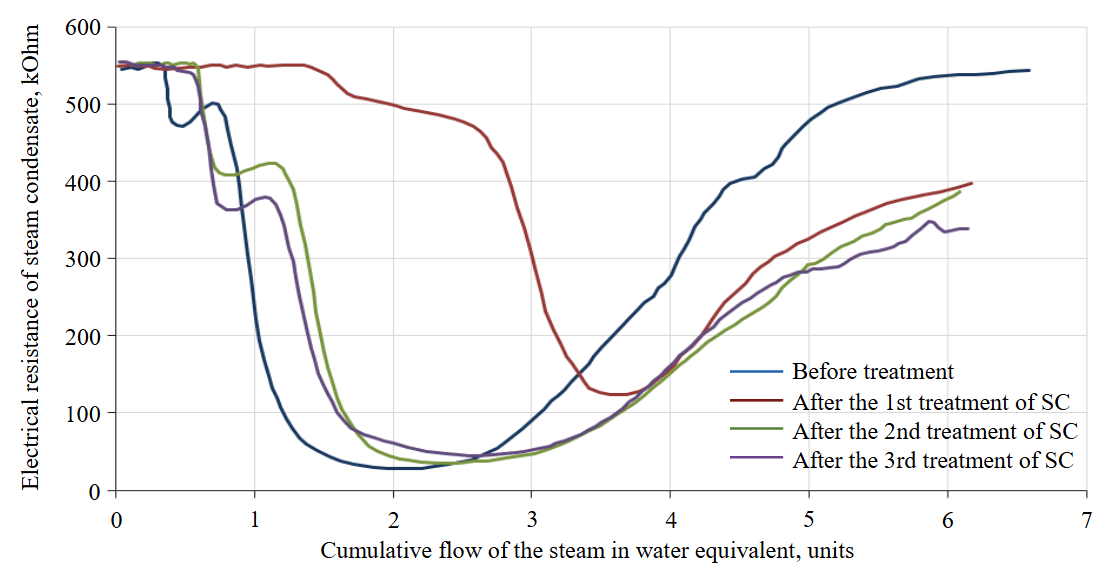

The measurement of the effective pore volume of the rock at a certain flow velocity of the heat carrier is performed as follows:

- injection with a constant volume flow of a steam-water mixture until the electrical resistance of the steam condensate at the outlet is stabilized;

- steam injection stop, injection of a solution of sodium chloride with a concentration of 0.01 g/ml with a volume of 2 ml according to the hydraulic scheme (Fig.1);

- continuation of steam injection with monitoring of changes in the electrical resistance of the steam condensate as cumulative flows of the steam are injected in water equivalent;

- injecting of SC, steam injection until the products of chemical reactions are completely released and the electrical resistance of the steam condensate at the outlet is stabilized;

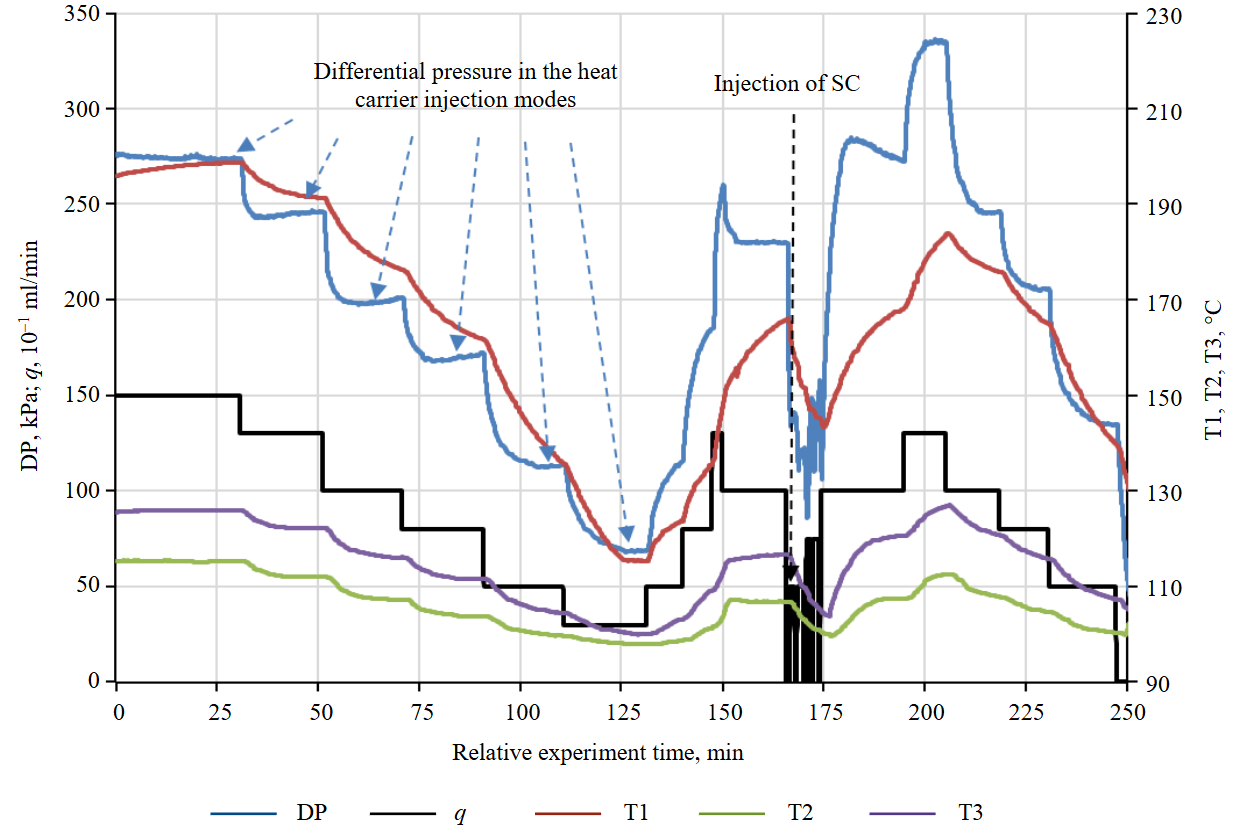

Fig.2. The results of the created differential pressure at different volume flow rates of the heat carrier and injection of SC

- injection of a solution of sodium chloride with a concentration of 0.01 g/ml volume 2 ml and tracking the dynamics of electrical resistance at the same volume flow rate of the heat carrier;

- comparison of the dynamics of the fixed yield of sodium chloride ions at a constant volume flow rate of the heat carrier before and after injection of SC with an assessment of the change in the effective pore volume in the water equivalent.

The effective pore volume is understood as the pore volume through which the injected sodium chloride solution moves with the heat carrier. When using SC, the pore volume should be reduced due to the non-soluble particles formed in the communicating pores involved in filtration.

Discussion of results

At the concentration of solutions of SC with volumes of 3; 6; 3 ml, as a result of chemical reactions, it is possible to obtain 2.7 g of precipitation – iron carbonate, calcium carbonate with possible inclusions of iron hydroxide and low-soluble calcium sulfate.

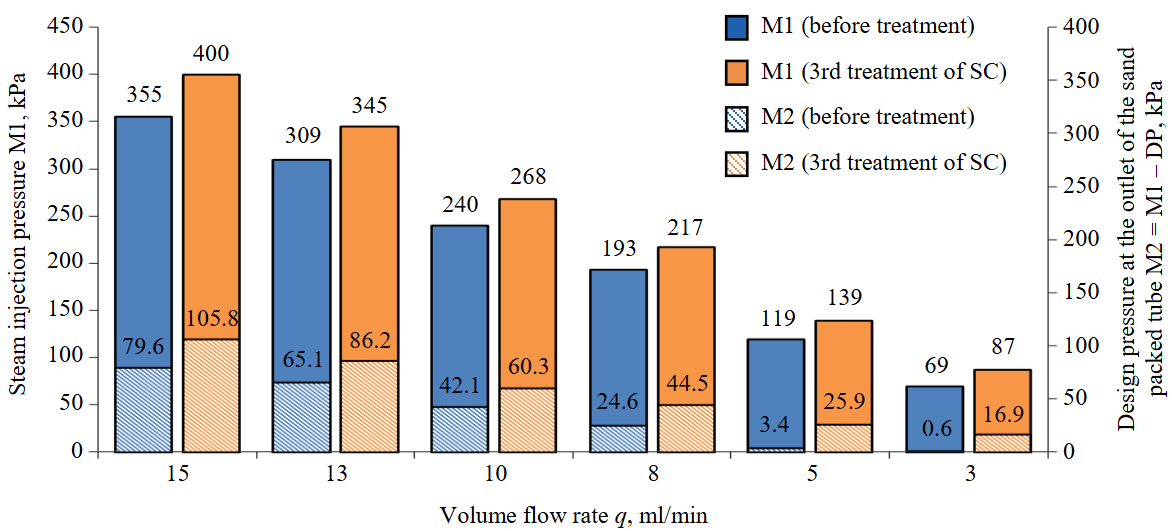

Figure 2 shows the dynamics of the main indicators before and after the injection of SC. A volume flow rate of 10 ml/min was before processing SC, since with flow rates below, the temperature at the outlet of the sand packed tube was close to 100 °C due to high heat loss. The temperature of the heat carrier was 173.4 °C at the inlet to the sand packed tube at the volume flow rate of 10 ml/min, and temperature was 106.7 °C at the outlet.

A short-term release of insoluble iron carbonate precipitates was observed after injection of SC. The mass of precipitation released from the model was 0.21 g after filtering the condensed steam through a paper filter (white tape). The heat carrier supply was stopped until the model was completely cooled after injecting SC, then the model was warmed up with the heat carrier, followed by the determination of the differential pressure from the volume flow of water into the steam generator from the moment SC were treated (Fig.3). An assessment of the resistance to “outwashing” of the formed precipitation under non-stationary thermobaric conditions was performed, depending on the number of cumulative flows of the heat carrier.

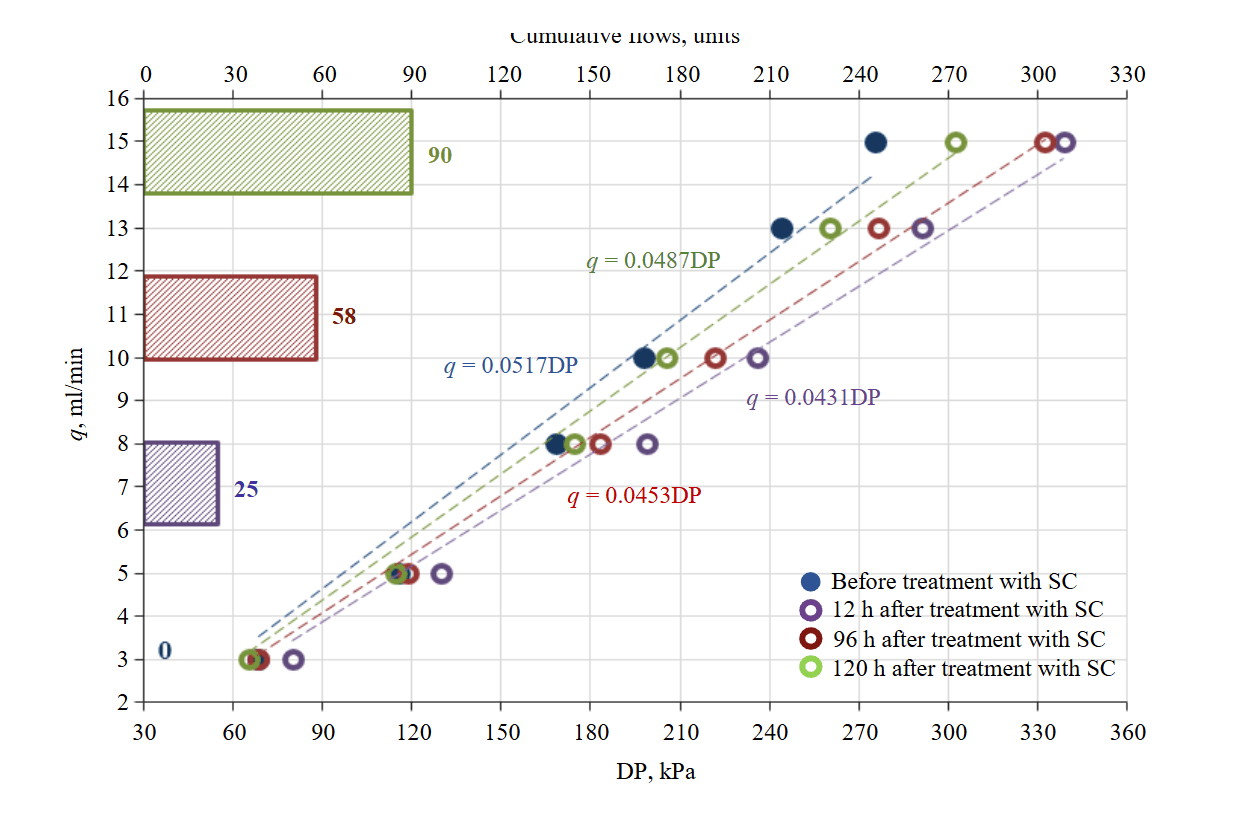

Fig.3. The dependence of the volume flow of distilled water on the differential pressure before and after the first treatment of SC over time and the amount of cumulative flows of the steam in the water equivalent

A change in the dependence of the differential pressure with an increase in the cumulative flow of the heat carrier injecting was recorded as a result of the injection of the heat carrier at various volume rates of distilled water into a flow steam generator-superheater (Fig.3). There is a change in the dynamics of the differential pressure with the same volume flow rates of the heat carrier, caused mainly by the number of cumulative flows of the steam after the model cools completely. Thus, when injecting 25Vpor of steam in the water equivalent, the differential pressure in all modes is 19.1 % higher on average compared to the dynamics before treatment with SC. The differential pressure on average exceeds only 4.9 % with the cumulative flow of the steam of 90Vpor. The maximum increase in differential pressure is observed at high filtration rates.

After the first treatment of SC according to the results obtained, repeated injections of reagents were performed in order to assess the increase in differential pressure at each injection mode of the steam.

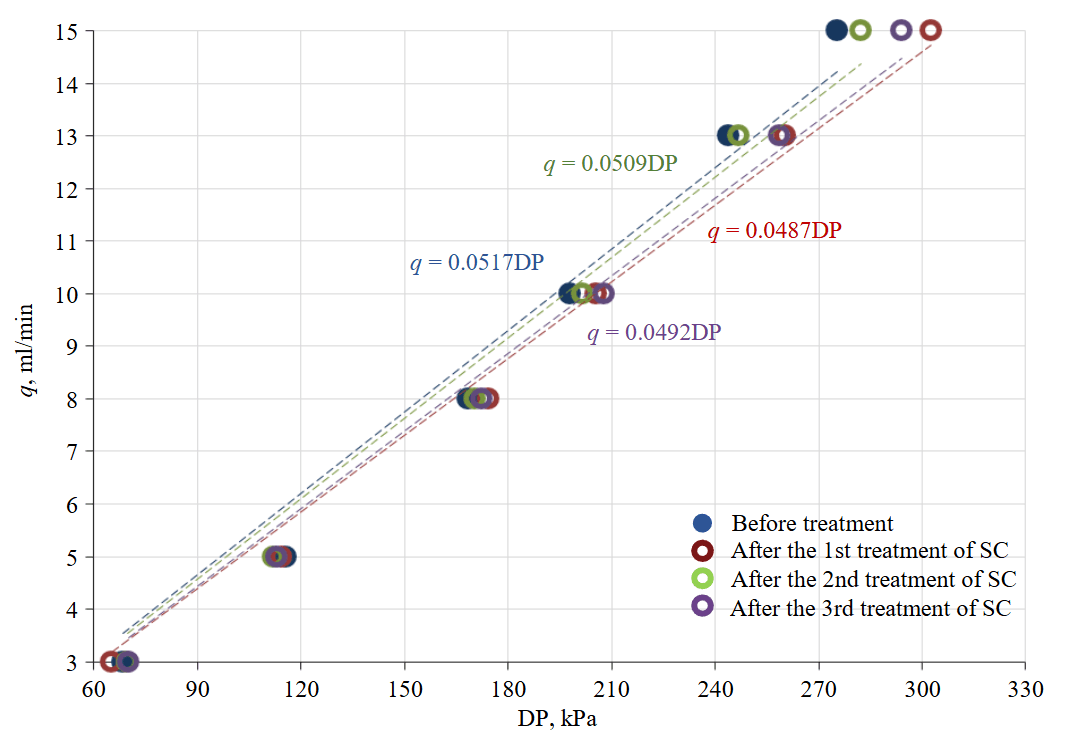

After the second treatment with SC, beige precipitation (calcium carbonate) with a total mass of 0.17 g is observed in the released steam condensate. Similarly to the first treatment with SC, precipitation is observed within 4-8 min after injection of the last solution, calcium chloride. The presence of insoluble calcium carbonate in the steam condensate is observed through 5-7 min after the start of steam injection with the volume flow rate of 10 ml/min as a result of the third treatment with SC. 90Vpor of the steam was injected in water equivalent if after the first treatment with SC, 163Vpor was injected then after the second, and 185Vpor – after the third (Fig.4).

The increase in the amount of steam after injection with SC is explained by the probability of precipitation release after previous treatment with SC. Since no non-soluble particles are detected in the outgoing steam condensate as a result of injecting the steam at various filtration rates, the stability of precipitation in the pores of the sand packed tube is confirmed. The short-term precipitation output after the application of SC can be explained by the breakthrough of sedimentation solutions to the exit of the sand packed tube and their formation when mixed in the outgoing steam condensate.

A similar situation is observed as when injecting a steam after the first injection of SC – a change in the average differential pressure in terms of the differential pressure from treatment to treatment with SC (Fig.4). The effectiveness of each treatment is poorly discernible in a comparative analysis of the results obtained, since the differential pressure is the pressure difference at the inlet and outlet of the sand packed tube, which can increase simultaneously in the case of sedimentation along the entire length of the reservoir model.

Fig.4. Dependence of the volume flow rate of distilled water on the differential pressure before and after treatment of SC with cumulative flows of the steam

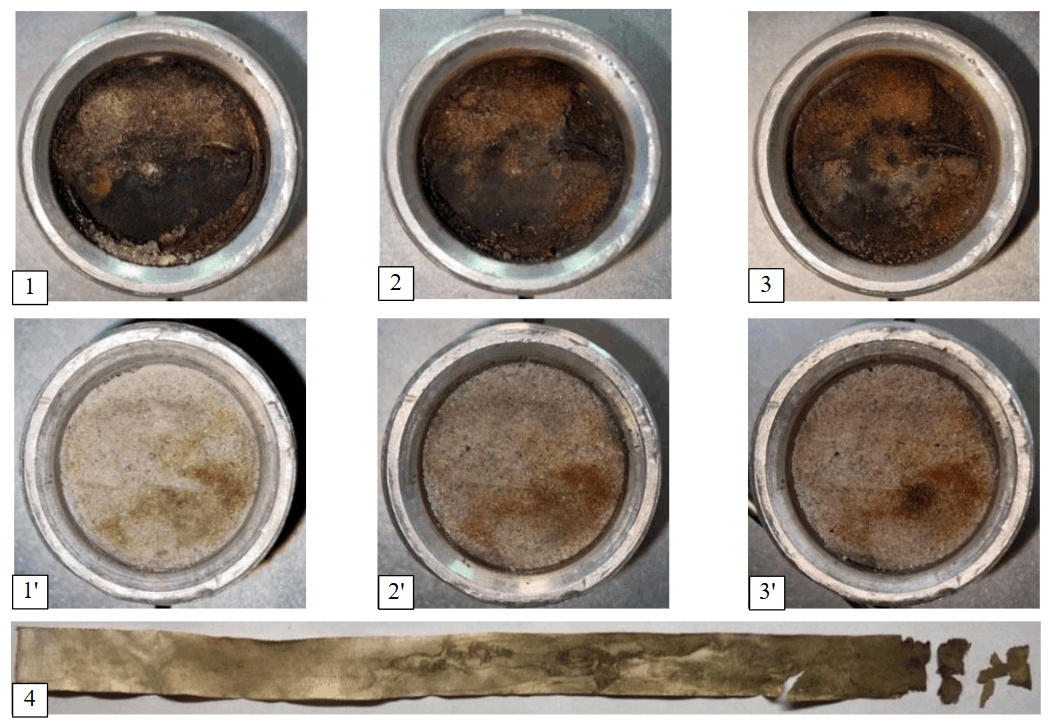

After stopping the injection of the steam during visual inspection of the ends of the sand packed tube, the process of sedimentation at the outlet is detected (Fig.5). In parallel, an assessment of the pressure of the injected steam was performed (Fig.6), as well as a study of the effective pore volume of the heat carrier after injecting SC with injecting of the steam.

Fig.5. Ends of the sand packed tube after injection of SC: 1 and 1' – inlet and outlet of the sand packed tube after the 1st injection of SC; 2 and 2' – inlet and outlet of the sand packed tube after the 2nd injection of SC; 3 and 3' – inlet and outlet of the model after the 3rd injection of SC; 4 – a strip of filter paper in contact with sand

Fig.6. Steam injection pressures at the inlet and calculated outlet pressures of the sand packed tube at volumetric steam injection rates

The calculated outlet pressures of the sand packed tube indicate a significant increase to the initial values with steam flow rates of less than 8 ml/min. A phase transition of the injected steam into hot water is observed closer to the outlet of the sand packed tube at these volume rates due to heat loss, in all modes of steam injection – an increase in outlet pressure with each injection of SC. Filter paper (see Fig.5) after analyzing the sand packed tube, confirms sedimentation along almost the entire length of the sand packed tube (more than 90 % of the entire length of the filter paper from the side of contact with sand).

Fig.7. Change in the electrical resistance of the outgoing steam condensate after injection of a sodium chloride solution from the cumulative flow of the steam at a constant volume flow rate of 10 ml/min

There is a gradual decrease in steam injection pressure and differential pressure when injecting cumulative flows of the steam of after each treatment with SC. This process is caused by the compaction of fine sediments at the entrance to the sand packed tube, which leads to a gradual breakthrough of steam through zones with artificially created flow coefficient.

When studying the effective pore volume after treatment of SC and injecting of the steam, a change in the dynamics of the electrical resistance of the outgoing steam condensate is noted (Fig.7). The structure of the pore volume changes significantly after the first treatment of SC, the effective pore volume is increased by 70.6 % compared to the initial one.

All the results of the experimental study on the injection of SC are summarized in Table 2. The effectiveness of using SC during injection of the steam is traced when performing a study of the filtration flow (determining the effective pore volume of the reservoir model). It can be seen that after all injections of SC, despite the ongoing geomechanical processes, the stability of the effective pore volume is observed after the third injection of SC and the cumulative flow of the steam with a volume of 185Vpor.

Table 2

The results of the study of the effectiveness of the use of SCwith the volume flow rate of 10 ml/min of the heat carrier

|

Parameter |

Value |

|||

|

Before SC |

Injection of SC |

|||

|

1 |

2 |

3 |

||

|

The mass of formed sediments in the reservoir model, g |

– |

2.49 |

2.53 |

2.55 |

|

The number of cumulative flows of the steam after injection of SC, units |

– |

90 |

163 |

185 |

|

Steam injection pressure, kPa |

240 |

254 |

265 |

268 |

|

Differential pressure, kPa |

197.9 |

205.5 |

201.6 |

207.7 |

|

Design pressure at the outlet of the sand packed tube, kPa |

42.1 |

48.5 |

58.4 |

60.3 |

|

Steam injection temperature, °С |

173.4 |

173.5 |

174.8 |

174.3 |

|

Temperature of the steel pipe of the sand packed tube near the outlet, °С |

116.9 |

118.4 |

117.8 |

118.8 |

|

Temperature of the heat carrier at the outlet of the sand packed tube, °С |

106.8 |

107.7 |

107.8 |

108.6 |

|

The minimum electrical resistance of steam condensate, kOhm |

28.7 |

113.6 |

35.3 |

44.4 |

|

The beginning of a decrease in steam condensate resistance in the cumulative flow (effective pore volume), f.u. |

0.35 |

1.41 |

0.59 |

0.59 |

|

The minimum electrical resistance of steam condensate, recorded in the cumulative flow, f.u. |

1.96 |

3.57 |

2.49 |

2.59 |

|

The maximum concentration of NaCl in steam condensate, g/l |

0.14 |

0.04 |

0.12 |

0.11 |

Concentrations of SC were maximal due to the solubility of sodium carbonate in process or fresh water. Obviously, the concentrations of reagents of SC can be adjusted downwards, but their volume ratio should remain unchanged at 1:2:1 in order to fully react with each other and form non-soluble precipitation. The injection of buffer liquid (process water) leads to ion diffusion and a decrease in concentration at the inlet of the reservoir model. By changing the filtration rate (the rate of injection of the steam), the first solution of SC reacts with the second in the pore volume, and after injecting the third solution, the final ion exchange with the remaining carbonate ions occurs, formation of precipitation and their sedimentation inside the pores. Thus, due to changes in the filtration rate and ion diffusion, precipitation colmatates along the entire length of the sand packed tube.

Conclusion

Results of the study of the use of sedimentation compounds when injecting steam at various filtration rates and thermobaric conditions showed the following:

- Reduction of average permeability of the sand packed tube by 21.1 % after the first treatment of SC. The effective pore volume has changed by 303 % (by 1.06Vpor), due to the creation of flow coefficient in the pore space in the path of the heat carrier.

- After treatments of SC a change in the effective pore volume and average permeability along the length of the sand packed tube was recorded due to injection of the heat carrier during the redistribution of sediment in the pores. After the second treatment of SC the permeability decreased by 47.1 %, after the third – by 55.0 %. The final effective pore volume was increased by 70.6 % as a result of treatments of SC.

It can be concluded that the use of SC in the conditions of steam injection wells of the Yarega area can contribute to the redistribution of the steam by creating additional filtration resistances in the bottomhole and uninvaded zones of the formation. Thermal stability and low cost of sedimentation reagents suggest high profitability when used in steam injection wells. However, it is necessary to conduct pilot work on the joint injection of steam and SC in the conditions of the development of the fractured-pore formation of the Yarega field in order to calculate the commercial effectiveness of the use of SC.

The effectiveness of SC will depend on the mineral composition of the rock, which may be a limiting factor in the implementation of the technology. Conducting additional experimental studies aimed at determining the strength properties after the application of SC, as well as changing the wettability of rock, will expand the advantages of the proposed technology of CC in terrigenous reservoirs using steam-thermal EOR.

References

- Gomaa S., Salem K.G., El-hoshoudy A.N. Enhanced heavy and extra heavy oil recovery: Current status and new trends. Petroleum. 2024. Vol. 10. Iss. 3, p. 399-410. DOI: 10.1016/j.petlm.2023.10.001

- Raupov I.R., Sytnik Yu.A. Enhanced oil recovery in high-viscosity and extra-viscous oil fields. Neftegaz.RU. 2022. N 7 (127), p. 14-22 (in Russian).

- Mokheimer E.M.A., Hamdy M., Abubakar Z. et al. A Comprehensive Review of Thermal Enhanced Oil Recovery: Tech-niques Evaluation. Journal of Energy Resources Technology. 2019. Vol. 141. Iss. 3. N 030801. DOI: 10.1115/1.4041096

- Yibo Li, Zhiqiang Wang, Zhiming Hu et al. A review of in situ upgrading technology for heavy crude oil. Petroleum. 2021. Vol. 7. Iss. 2, p. 117-122. DOI: 10.1016/j.petlm.2020.09.004

- Guodong Cui, Ting Liu, Jingyu Xie et al. A review of SAGD technology development and its possible application potential on thin-layer super-heavy oil reservoirs. Geoscience Frontiers. 2022. Vol. 13. Iss. 4. N 101382. DOI: 10.1016/j.gsf.2022.101382

- Vijitha Mohan, Yi Su, Jingyi Wang, Gates I.D. Rich solvent – Steam assisted gravity drainage (RS-SAGD): An option for clean oil sands recovery processes. Cleaner Engineering and Technology. 2022. Vol. 8. N 100463. DOI: 10.1016/j.clet.2022.100463

- Kirmani F.U.D., Raza A., Gholami R. et al. Analyzing the effect of steam quality and injection temperature on the perfor-mance of steam flooding. Energy Geoscience. 2021. Vol. 2. Iss. 1, p. 83-86. DOI: 10.1016/j.engeos.2020.11.002

- Huanquan Sun, Haitao Wang, Xulong Cao et al. Innovations and applications of the thermal recovery techniques for heavy oil. Energy Geoscience. 2024. Vol. 5. Iss. 4. N 100332. DOI: 10.1016/j.engeos.2024.100332

- Zhi Yang, Xingge Sun, Chihui Luo et al. Vertical-well-assisted SAGD dilation process in heterogeneous super-heavy oil reservoirs: Numerical simulations. Underground Space. 2021. Vol. 6. Iss. 6, p. 603-618. DOI: 10.1016/j.undsp.2020.12.003

- Anbari H., Robinson J.P., Greaves M., Rigby S.P. Field performance and numerical simulation study on the toe to heel air injection (THAI) process in a heavy oil reservoir with bottom water. Journal of Petroleum Science and Engineering. 2023. Vol. 220. Part B. N 111202. DOI: 10.1016/j.petrol.2022.111202

- Ruzin L.M., Chuprov I.F., Morozyuk O.A., Durkin S.M. Technological principles of development of deposits of abnormally viscous oil and bitumen. Izhevsk: Institut komp'yuternykh issledovanii, 2015, p. 476 (in Russian).

- Xiaohu Dong, Huiqing Liu, Zhangxin Chen et al. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Applied Energy. 2019. Vol. 239. Iss. 1, p. 1190-1211. DOI: 10.1016/j.apenergy.2019.01.244

- Durkin S.M. Improvement of oil mining development methods. Ukhta: Ukhtinskii gosudarstvennyi tekhnicheskii universitet, 2022, p. 128 (in Russian).

- Durkin S.M., Menshikova I.N., Ruzin L.M., Terentiev A.A. Expierence of development of the Liael area of Yaregskoye heavy oil field using different technologies. Oil Industry Journal. 2019. N 10, p. 62-67 (in Russian). DOI: 10.24887/0028-2448-2018-10-62-67

- Konoplev Yu.P., Gerasimov I.V. 80 years of oil production on the Yaregskoye field of high-viscosity oil. Oil Industry Journal. 2017. N 7, p. 30-32 (in Russian). DOI: 10.24887/0028-2448-2017-7-30-32

- Nor M.A., Konoplev Yu.P., Mitroshin A.V., Andreev D.V. Fundamentals of thermomine development. Syktyvkar: Komi respublikanskaya tipografiya, 2022, p. 240 (in Russian).

- Konoplev Yu.P., Buslaev V.F., Yagubov Z.Kh., Tskhadaya N.D. Thermomine development of oil fields. Мoscow: Nedra, 2006, p. 288 (in Russian).

- Nor M.A., Nor E.V., Tskhadaya N.D. Sources of heating microclimate in the process of thermal mining development of high-viscosity oil fields. Journal of Mining Institute. 2017. Vol. 225, p. 360-363. DOI: 10.18454/PMI.2017.3.360

- Irbakhtin A.N., Savrey D.Yu. Analysis of the geophysical research results of wells designed for steam cyclic treatment using the thermometry method. Geology, geophysics and development of oil and gas fields. 2020. N 12 (348), p. 27-32 (in Russian). DOI: 10.30713/2413-5011-2020-12(348)-27-32

- Dong Zhao, Jian Hou, Qingjun Du et al. Pore-Throat Structure Changes During Steam Flooding: An Experimental Study Based on Micro-CT Scanning. SPE Reservoir Characterisation and Simulation Conference and Exhibition, 24-26 January 2023, Abu Dhabi, UAE. OnePetro, 2023. N SPE-212705-MS. DOI: 10.2118/212705-MS

- Soroush M., Roostaei M., Hosseini S.A. et al. Challenges and Potentials for Sand and Flow Control and Management in the Sandstone Oil Fields of Kazakhstan: A Literature Review. SPE Drilling & Completion. 2023. Vol. 36. Iss. 1, p. 208-231. DOI: 10.2118/199247-PA

- Zemtsov Yu.V., Mazaev V.V. Current state of physical and chemical methods for enhanced oil recovery: literary and patent review. Ekaterinburg: Izdatelskie resheniya, 2021, p. 240 (in Russian).

- Zemtsov Yu.V., Mazaev V.V. On process criteria selection for low-volume chemical EOR treatments in various geological and field reservoir conditions. Neft. Gas. Novacii. 2021. N 7 (247), p. 54-59 (in Russian).

- Karadkar P., Almohsin A., Bataweel M., Jin Huang. In-Situ Pore Plugging Using Nanosilica-Based Fluid System for Gas Shutoff to Maximize Oil Production. SPE Production & Operations. 2023. Vol. 38. Iss. 1, p. 104-112. DOI: 10.2118/197578-PA

- Wei-Peng Wu, Ji-Rui Hou, Ming Qu et al. A novel polymer gel with high-temperature and high-salinity resistance for con-formance control in carbonate reservoirs. Petroleum Science. 2022. Vol. 19. Iss. 6, p. 3159-3170. DOI: 10.1016/j.petsci.2022.05.003

- Qian-Hui Wu, Ji-Jiang Ge, Lei Ding, Gui-Cai Zhang. Unlocking the potentials of gel conformance for water shutoff in frac-tured reservoirs: Favorable attributes of the double network gel for enhancing oil recovery. Petroleum Science. 2023. Vol. 20. Iss. 2, p. 1005-1017. DOI: 10.1016/j.petsci.2022.10.018

- Mambetov S.F., Zemtsov Yu.V. Stability studies of dispersed systems for physicochemical methods to enhance oil recovery in the presence of a hydrophobic filler. Oil and Gas Studies. 2023. N 4 (160), p. 42-51 (in Russian). DOI: 10.31660/0445-0108-2023-4-42-51

- Zahirovic I., Danilovic D., Šuput Vranjin M., Tripkovic M. Laboratory Testing of Nanosilica-Reinforced Silicate and Polyacrylamide Gels. SPE Journal. 2023. Vol. 28. Iss. 3, p. 1241-1249. DOI: 10.2118/214294-PA

- Shehbaz S.M., Bera A. Effects of nanoparticles, polymer and accelerator concentrations, and salinity on gelation behavior of polymer gel systems for water shut-off jobs in oil reservoirs. Petroleum Research. 2023. Vol. 8. Iss. 2, p. 234-243. DOI: 10.1016/j.ptlrs.2022.06.005

- Belov V.I., Zaripov A.T., Beregovoy A.N. et al. Enhancing oil recovery from waterflooded reservoirs at Tatneft’s fields using emulsion compositions. Oil Industry Journal. 2021. N 7, p. 32-35 (in Russian). DOI: 10.24887/0028-2448-2021-7-32-35

- Jie Wang, Ting Wang, Hualei Xu, Houshun Jiang. Graded regulation technology for enhanced oil recovery and water shutoff in pore-cavity-fracture carbonate reservoirs. Arabian Journal of Chemistry. 2022. Vol. 15. Iss. 7. N 103907. DOI: 10.1016/j.arabjc.2022.103907

- Songxia Liu, Ott W.K. Sodium silicate applications in oil, gas & geothermal well operations. Journal of Petroleum Science and Engineering. 2020. Vol. 195. N 107693. DOI: 10.1016/j.petrol.2020.107693

- Fedorov K.M., Shevelev A.P., Vydysh I.V. et al. Methodology for assessing and predicting the reaction of producers to the conformance control of injectors. Oil Industry Journal. 2022. N 9, p. 106-110 (in Russian). DOI: 10.24887/0028-2448-2022-9-106-110

- Rodriguez F., Belhaj H., Morales R. et al. Chemical Enhanced Oil Recovery (CEOR) Applications for Extra-Heavy Oil Reservoirs in the Eastern Venezuela Basin: The First Surfactant-Polymer Pilot Test. SPE Advances in Integrated Reservoir Modelling and Field Development Conference and Exhibition, 2-4 June 2025, Abu Dhabi, UAE. OnePetro, 2025. N SPE-225344-MS. DOI: 10.2118/225344-MS

- Lifeng Chen, Feiyang Huang, Gang Li et al. Experimental Study on Fiber Balls for Bridging in Fractured-Vuggy Reservoir. SPE Journal. 2023. Vol. 28. Iss. 4, p. 1880-1894. DOI: 10.2118/214315-PA

- Aboahmed A., Mohanty K. Chemical Huff and Puff for Shale Oil Recovery Using Surfactants, Nanoparticles and Ketones. SPE/AAPG/SEG Unconventional Resources Technology Conference, 9-11 June 2025, Houston, TX, USA. OnePetro, 2025. N URTEC-4235291-MS. DOI: 10.15530/urtec-2025-4235291

- Pakeer A.A., Baouchi Y., Hashmet M.R., Alblooshi Y. Laboratory and Simulation Studies of Novel Hybrid Nano-Polymer EOR in Carbonate Reservoirs. SPE Advances in Integrated Reservoir Modelling and Field Development Conference and Exhibition, 2-4 June 2025, Abu Dhabi, UAE. OnePetro, 2025. N SPE-225353-MS. DOI: 10.2118/225353-MS

- Singh R., Yifan Wang, Katiyar A. et al. Novel Foaming Formulations Development to Enable Gas Huff-N-Puff Field Pilots. SPE/AAPG/SEG Unconventional Resources Technology Conference, 9-11 June 2025, Houston, TX, USA. OnePetro, 2025. N URTEC-4246479-MS. DOI: 10.15530/urtec-2025-4246479

- Zhan-Xi Pang, Qian-Hui Wang, Qiang Meng et al. The mechanisms of thermal solidification agent promoting steam diversion in heavy oil reservoirs. Petroleum Science. 2024. Vol. 21. Iss. 3, p. 1902-1914. DOI: 10.1016/j.petsci.2024.01.001

- Yongqing Bai, Zonglun Cao, Yongfeng Hu et al. Highly thermoconductive biogel for enhancing thermal efficiency and soil self-remediation in heavy oil recovery. Journal of Cleaner Production. 2023. Vol. 398. N 136643. DOI: 10.1016/j.jclepro.2023.136643

- Sijia Liu, Xiaodong Wu, Yanhan Li et al. Hydrophobic in-situ SiO2-TiO2 composite aerogel for heavy oil thermal recovery: Synthesis and high temperature performance. Applied Thermal Engineering. 2021. Vol. 190. N 116745. DOI: 10.1016/j.applthermaleng.2021.116745

- Altunina L.K., Kuvshinov V.A., Kuvshinov I.V. Application of Thermotropic Compositions for EOR with Cyclic steam Stimulation at Permian-Carboniferous Deposit of Usinsk Oilfield. Journal of Siberian Federal University. Chemistry. 2019. N 12 (1), p. 136-143 (in Russian). DOI: 10.17516/1998-2836-0113

- Altunina L.K., Kuvshinov V.A., Kuvshinov I.V. et al. Physical-chemical and complex EOR/IOR technologies for the Permian-Carboniferous deposit of heavy oil of the Usinskoye oil field. Oil Industry Journal. 2017. N 7, p. 26-29 (in Russian). DOI: 10.24887/0028-2448-2017-7-26-29

- Altunina L.K., Kuvshinov V.A., Staseva L.A. et al. Oil-Displacing Surfactant Composition with Controlled Viscosity for En-hanced Oil Recovery from Heavy Oil Deposits. Georesursy. 2016. Vol. 18. N 4. Part 1, p. 281-288 (in Russian). DOI: 10.18599/grs.18.4.5

- Altunina L.K., Kuvshinov V.A., Stayeva L.A., Kuvshinov I.V. Enhanced oil recovery from high-viscosity oil deposits by acid systems based on surfactants, coordining solvents and complex compounds. Georesursy. 2019. Vol. 21. N 4, p. 103-113 (in Russian). DOI: 10.18599/grs.2019.4.103-113

- Kladova A.V., Shamsutdinova E.V., Uzyarkina E.G. Technological requirements to sediment-forming compounds to increase oil recovery of formations. Oilfield engineering. 2023. N 10 (658), p. 46-49 (in Russian). DOI: 10.33285/0207-2351-2023-10(658)-46-49

- Qiang Wang, Yuhuan Bu, Chang Lu. Reinforcement Methods and Key Materials for Sand Control in Weakly Cemented Sandstone. The 35th International Ocean and Polar Engineering Conference, 1-6 June 2025, Seoul, Korea. OnePetro, 2025. N ISOPE-I-25-013.