Innovative research methods for the dust explosion hazard of coals

- 1 — Ph.D., Dr.Sci. Leading Researcher All-Russian Research Institute for Fire Protection of the Ministry of the Russian Federation for Civil Defense, Emergencies and Elimination of Consequences of Natural Disasters ▪ Orcid ▪ Scopus

- 2 — Ph.D. Associate Professor Empress Catherine II Saint Petersburg Mining University ▪ Orcid

Abstract

A new approach to determining the yield of volatile substances from coals in relation to explosion safety, including expert work in emergency mines during explosions, is considered. The results are based on complex experiments, including explosive tests and thermogravimetric studies of gases of various stages of metamorphism: from long-flame (grade D) to coking (grade K). Thermogravimetric studies were supplemented by explosive experiments in a 20-liter chamber, and more than 60 dust samples from emergency mine sites were also studied. Refined “stage-by-stage” indicators of the yield of volatile substances for solving dust explosion problems, which have significant advantages over the standard method of quasi-isothermal heating of dust in a muffle furnace, have been proposed and practically worked out. Methods of thermogravimetric determination of moisture and ash content of samples, as well as the yield of volatile substances at various stages of heating, with separation of the yield of combustible and non-combustible gases, have been developed. Non-overlapping intervals of the thermal reaction are identified: moisture yield (25-130 °C); heat-resistant heating (180-350 °C); primary yield of volatile substances PVS (350-600 °C); secondary yield of volatile substances SVS (600-750 °C); thermal degradation of mineral inclusions and inert dust CDS (750-840 °C). For emergency conditions, the stages of steady decrease and growth of the yield of volatile substances from post-explosive samples are determined and a criterion for the participation of coal dust in the explosion is formulated. The modified criterion makes it possible to numerically recognize the fact of dust participation in an explosion, determine the epicenter of deflagration combustion, and study the dynamics of the explosion over a mining network while determining the effectiveness of dust and explosion protection.

Introduction

Modern conditions of intensive coal mining are characterized same types of hazards: aerological [1, 2], dust [1, 3, 4], geomechanical [5, 6], and fire [7], which can lead to accidents accompanied by cases of group injuries [8, 9]. In order to reduce the aerological hazard associated with the threat of gas contamination of mine workings by methane released from coal, as well as other gases generated during the operation of equipment with diesel-hydraulic drive and other technological processes, methods for controlling the intensity of gas emissions and the concentration of dangerous gases are being improved [10, 11]. Other technical solutions to reduce aerological risks [12-14], include the development of effective ventilation schemes and methane removal systems [15], taking into account the features of the rock (solid) mass, the technology of works and the processes of gas emissions [16-18]. Attention is paid to the processes of normalization of the parameters of the mine atmosphere by reducing the volume emissions during the operation of diesel-hydraulic vehicles and similar equipment [19, 20].

Dust is formed during the mining of coal seams and mining operations, which pose a threat to human life and health [3, 21]. The fight against the dust factor is relevant not only for coal mines, but also for open-pit mining and coal transportation and processing enterprises [22]. The main efforts are aimed at developing effective means of reducing dust [23-25] and preventing coal dust explosions [26-28] taking into account its material composition, dispersion, and dust deposition characteristics [28-31].

Ensuring geomechanical safety primarily involves choosing the safest technological solutions for mining minerals, minimizing the likelihood of geogasodynamic phenomena [5, 6]. To reduce the fire risks associated with the threat of spontaneous combustion, new formulations of anti-pyrogens and inhibitors are being improved and proposed, taking into account the properties of coal and the condition of the mining [7, 32]. The most widespread negative consequences occur in the case of methane and coal dust explosions [10, 33].

Explosions in coal mines have been reported with varying frequency in all coal-producing countries. Progress and the application of modern technologies have reduced the probability of large explosions. However, they could not be completely eliminated [34-36]. The potential explosion hazard of coal dust requires improvement of its control methods both at the pre-emergency stages and during the elimination of explosions. When conducting mining rescue operations in case of explosion, it is necessary to determine the following:

- the type of accident (explosion, fire, rock burst, sudden outburst), which determines the plan of operational work to eliminate the accident;

- the epicenter of the accident (the explosion site), which will determine the affected area, the availability of fire danger or explosion hazard in the entries, to which rescue units will go to; determining the location of the accident will set the routes for rescuers and form a list of necessary forces and means for various work (exploration, evacuation of personnel, accident elimination);

- the fact that dust was involved in the explosion.

The importance of this stage was demonstrated by the accidents at the Listvyazhnaya (2021), Severnaya (2016) and Vorkutinskaya (2013) mines, which are in the Rostechnadzor technical investigation reports:

- in several accidents, the mining dispatcher put into effect an accident elimination plan based on the type of accident “Rock burst” when an actual explosion occurred with catastrophic consequences [1, 10, 36]. Since the elimination of the consequences of an explosion with the fire is significantly different from the elimination of the rock burst, this affected the effectiveness of rescue operations;

- in case of incorrect determination of the epicenter of the explosion, a complex of labor-intensive work was performed to isolate the longwall face area with explosion-resistant seals, but in fact the explosion occurred in a gate outside the isolated area [10];

- there were no ways to reliably identify the epicenter of the explosion, the number of explosions that occurred, and the participation of dust in an explosion, which made planning mine rescue and expert work more difficult [36].

During explosions, a lot of thermal and mechanical energy is released, followed by its transfer through shock waves and a flame front [37-39], which creates numerous destructions and fires.

The determination of the moisture content in coal, rock additives and the yield of volatile substances provides the first level of data on its composition and technological value. One of the main classification parameters of coal is the yield of volatile substances V (taking into account the condition for a dry sample Vd or a dry ash-free mass Vdaf), is determined on the basis of national and international standards. When analyzing the explosion hazard of small coal fractions (dust),Vdaf is also used as a criterion for classifying dust as hazardous for explosions. However, the use of the Vdaf in the field of dust explosion hazard is not directly provided for by the standards. In the framework of this paper, the yield of volatile substances V is considered only for dust explosion issues.

The existing standard methods for obtaining Vdaf for coal classification and certification are not considered or questioned in this article. According to industry rules and regulations, non-explosive dusts include coals with a Vdaf of < 15 % (in various countries – less than 10-20 %). At the same time, at the level of safety regulations for coal mines, the imperfection of using the Vdaf parameter in the field of dust explosion hazard is recognized. The fulfillment of the Vdaf criterion < 15 % requires an experimental (i.e., directly explosive) verification to definitively classify the dust of the coal under study as non-explosive. Some studies have noted detonation explosive combustion of formally non-explosive dust at Vdaf < 11.5 % [40], as well as a significant dependence of the Vdaf value on the dispersed composition of the dust (experimental explosion N 680 in the experimental mine of the Barbara).

The Vdaf parameter is used for numerical recognition of the participation of coal dust in explosion by decreasing the yield of volatile substances. During expert work at the mine after the accident, the amount of volatile substances released before the explosion of the Vdaf is compared with the same indicator of samples from the emergency site after the explosion :

The Department of technical regulation (Rostechnadzor) applies instructions according to which, when reducing the volatile yield after an accident to 3 %, dust did not participate in the explosion; when decreasing by 3-5 %, dust partially participated in the explosion; when decreasing by 5-10 % – dust participated in the explosion and the mode of combustion was near detonation; when decreasing by more than 10 % – the entire volume of coal dust deposited in the mine took part in the explosion.

In practice, criterion (1) of dust participation in the explosion and the change in Vdaf according to Rostechnadzor instructions are not fulfilled. Thus, during the elimination of the largest accident in the history of Kuzbass – the explosion at the Ulyanovskaya mine in 2007 [41] Vdaf = 35.0 % (before the explosion). According to Rostechnadzor's instructions, after the thermal impact of the explosion, the value should have decreased to about 25 %. However, multiple determinations showed the result = 35.9-37.0 %, i.e. the yield of volatile substances from samples after the explosion did not decrease, but exceeded the pre-emergency value [41]. The main reason for this discrepancy was the method of determining the yield of volatile substances with quasi-isothermal heating of dust at Т = 900 °С in a muffle furnace and incorrect representation of the processes of thermal destruction of coals. The process of destruction in the coal macromolecule after exposure to explosive factors (temperature – pressure), leading to the destruction of the core and the formation of new groups unstable from heating, has not been studied before. The standard method for determining the yield of volatile substances is not adapted to dust explosion safety issues and is outdated both in terms of the sample heating process and in relation to the equipment used.

In addition to these problematic facts [41] expert work in case of explosions is complicated by the use of rockdusting. There are no methods for analyzing the residual explosivity of coal – limestone mixtures, and there are no methods for recognizing the participation of coal dust in explosions in the presence of СаСО3 impurities.

The considered innovative approaches based on thermogravimetric methods for analyzing coal dust offer improved criteria for assessing its explosion hazard, solve the problem of recognizing dust participation in an explosion regardless of the ash content and inert additives, allow us to study the dynamics of an explosion in emergency workings and reliably determine the epicenter of deflagration combustion (explosion) of dust in accidents for planning rescue operations.

Methodology and notations

Thermogravimetric (TG) analysis is a subsequent stage in the development of thermal analysis methods and is used to study physico-chemical transformations in coal matter under technological temperature exposure (for example, during coking) or in emergency explosion conditions. Thermogravimetric functions (TG and DTG), as well as the identification characteristics of TG analysis, provide extensive opportunities for determining the limits of thermal stability of samples, combustion temperature, and the state of samples in temperature ranges, and contain information about the thermal effects of an explosion [42-44]. Thermogravimetric analysis devices eliminate the disadvantages inherent in heating in a muffle furnace: automatic drying of the sample with measurement of moisture and ash content; “limited oxygen access” is replaced by an inert atmosphere; the transitional period of temperature recovery in the furnace and other disadvantages are eliminated [43-45].

In the TG analysis, instead of isothermal heating (as in the standard definition of Vdaf), the method of sequential temperature increase is used, combined with measuring the mass of the sample with a frequency of at least 0.5 s–1. The number of measurements of mass of samples from two values (for the standard method) increases to 1000-1500, which allows the formation of thermogravimetric functions (TG and DTG), which determine the identification characteristics: moisture content of the sample W, %, intervals of thermogravimetric reactions, the maximum rate of yield of lean substances m'max, %/ min and the corresponding temperature Тmax, °С, coke residue Mkd, %, ash residue or ash content Ad, % [44].

For the TG analysis of the research, samples of coal of seven grades were selected: D, DG, G, GJ, Zh, K, A (corresponding from bituminous to coking coal; three grades are considered in the article), as well as samples of dust deposited in mines. TG studies were carried out on thermal weights TGA-951 of the DuPont-9900 complex and the thermogravimetric installation Q 600 TA Instruments according to standard methods – ASTM E 1131-20, GOST R 53293-2009. The prepared coal dust samples were heated in an inert atmosphere with a linear temperature increase from 20 to 850 °C with a heating rate of ΔТо = 20 °C/min (basic mode) or ΔТо = 100 °С/min (fast heating mode). Mass measurements were carried out every two seconds, upon reaching the heating temperatureТ = 130 °С the moisture content of the sample Wa was determined by weight loss. At Т = 850 °С to complete the coking process, the sample was kept for 15 min, after which the inert atmosphere was changed to an airy one and the ash content of the sample Ad was determined [44].

The TG and DTG curves of coal dust samples of various grades, as well as coal – limestone mixtures in the “pre-explosion” and “post-explosion” states, obtained from thermogravimetric studies, were compared, which made it possible to identify significant and qualitative differences in functions and identify temperature ranges for the yield of volatile substances [45].

The following designations have been introduced:

- the value of the primary yield of volatile substances from the dry sample (d) and the dry ash-free mass (daf) is the loss of sample mass in the range of ≈350-600 °С – PVS (primary volatiles stage), taking into account the lower and upper indices and, respectively or ;

- the value of the secondary yield of volatile substances in the range of 600-750 °С – SVS (secondary volatiles stage) is indicated respectively or ;

- the value of volatile substances from a sample subject to explosion is indicated by the subscript ex indicating the heating stage , etc. [45].

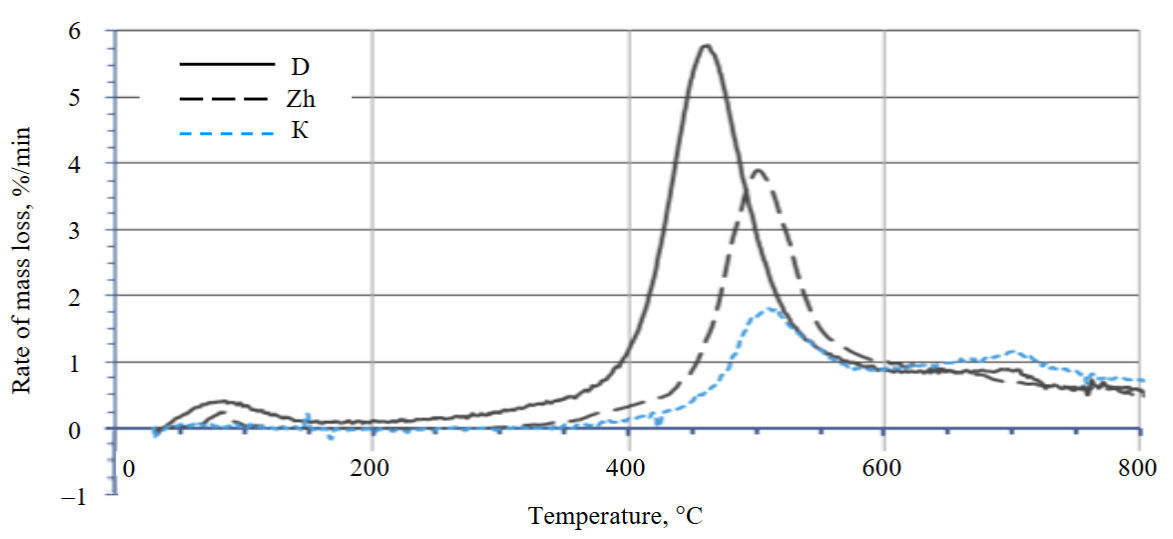

Fig.1. Mass loss rate (DTG) of grades D, Zh, K hard coals in an inert atmosphere with stages: MRS (20-130 °С); PVS (350-600 °С); SVS (600-750 °С)

Experimental works and discussion

Determination of temperature ranges for the value of volatile substances during coal destruction

The complex physical and chemical structure of coal matter, based on the principle of natura non facit saltus (nature does not make sudden leaps – lat.), determines the complexity of its thermal destruction processes, the wide range and complex composition of volatile substances that are released from coal at different temperatures of its heating. Coal is a high molecular weight compound of organic nature, a molecule that contains thousands of atoms with multiple repetitions of the main structural group. The coal macromolecule, according to the van Krevelen model, has a structure with a relatively heat-stable core and side groups of atoms. The coal’s macromolecule core is heat-stable in the range of temperature of approximately up to 600 °С. Side hydrocarbon groups of low-stage metamorphic coals (grades D, G) are heat-resistant at temperatures up to 350 °C, and coking grades of coal – up to 400 °C [44].

When the heating temperature of the coal dust sample increases in the range from 20 to 130 °С with a heating rate of ΔТо = 20 °С/min (at ΔТо = 100 °С/min in the range from 20 to 180 °C), moisture is removed. The indicated intervals are allocated in MRS (moisture removal stage) – the gross stage of the analytical moisture Wa yield.

Heating of samples to a temperature of 350-400 °C is accompanied by the transition of the coal matter mass into a plastic state. In this case, the mass loss is 2-4 % for low-stage metamorphism coals (grade D) and less than 1 % for coking coals (grades Zh, K) (Fig.1).

Increasing the heating temperature from ≈350 to 600°С leads to intensive primary decomposition of the coal substance and the yield of combustible volatile substances from it. The side hydrocarbon groups of the macromolecule pass into a gaseous state. The gas yield in this case is more than 70 ml per 1 g of coal [44]. The temperature range of 350-600 °С can be characterized as the primary volatiles stage. This stage is present in the DTG dependencies of all coal grades that are hazardous in terms of dust explosion (Fig.1). The maximum rate of volatile substances yield is achieved at a temperature of 461-511 °С. The PVS of hard coals ends with the formation of a solid product – semi-coke.

The heating range of 600-750 °C was experimentally identified as the secondary volatiles stage – SVS. The yield of combustible volatile substances from all grades of coals occurs at the SVS stage with varying intensity (Fig.1). The thermal destruction process at this stage of heating occurs at a low but stable rate of mass loss – about 0.8-0.9 %/min for the bulk of coal [44, 46].

Comparison of the mass loss rate curves or volatile substances yield rate curves for various grades of coal (Fig.1) shows that the yield of volatile substances from coals at the PVS stage decreases, the temperature of the primary yield of volatile substances maximum shifts to the right or increases from 461 to 511 °C. The SVS has a modal value of the yield velocity of volatile substances in the range of 701 ± 5 °С [44]. At the PVS and SVS stages combustible gases are yield as a product of the coal mass thermal destruction. The yield of combustible gases at the PVS and SVS stages is confirmed by experiments combined with combustible gas analysis (combined TGA/AGG experiments).

With further heating (HTH) at the stage of 750-850 °С the coking process is completed. At this stage of high-temperature heating, both combustible and non-combustible volatile substances (in the presence of mineral inclusions in the coal) are released with an intensity close to constant. The rate of mass loss is 0.7-0.8 %/min. However, the situation for the HTH stage changes significantly when analyzing mine dust. In accordance with the requirements of all national safety regulations, in order to neutralize the explosiveness of mine dust residues in workings, inertization is carried out – dilution of settled coal dust with rock dust based on limestone (CaCO3). In this case, the content of non-combustible additives in the resulting coal – limestone mixtures (that is, when studying rock dust from workings after performing inertization proceedures – rockdusting) should be 80-89 %. Intensive decomposition of rock dust into CaO and CO2 occurs in the temperature range of ≈750-850 °С. This interval is allocated to the CDS (carbon dioxide stage), when the extrapolated range of decomposition of rock dust (without coal additives) is 742-840 °С (for ΔТо = 20 °С/min) with a maximum СО2 yield at 812 °С.

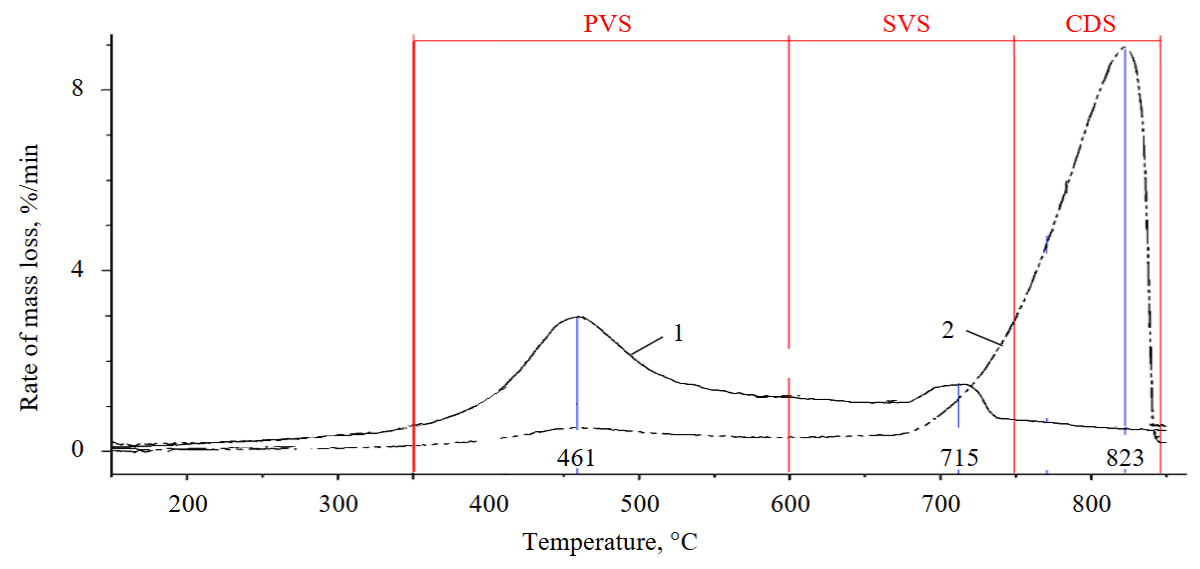

Figure 2 shows the process of volatile substances yield from grade D coal (curve 1 with PVS and SVS stages) and curve 2 for a coal – limestone mixture with a ratio of 10:90 %. The PVS and SVS stages are weakly expressed for curve 2 in comparison with curve 1 because the percentage content of coal is insignificant and the percentage yield of combustible volatile substances in the mixture is significantly reduced. The main part of the second sample thermal destruction occurs at the CDS during the thermal decomposition of СаСО3, which is accompanied by the noncombustible volatile substances CO2 yield.

Fig.2. Stages of thermal destruction and typical DTG functions of the studied samples: 1 – coal grade D; 2 – coal – limestone mixture

Thus, the proposed stage method for determining the yield of volatile substances allows separating the combustible gases emitted from non-combustible ones at different stages of heating, while isothermal heating (according to GOST R 55660-2013 or ISO 562:2010) involves feeding samples directly into the heating zone with Т ≈ 900 °С. Quasi-isothermal heating at Т ≈ 900 °С makes inevitable the thermal decomposition of both organic and a significant portion of mineral components (non-combustible gases with a predominance of CO2), which calls into question the practical application of the total yield of volatile substances for explosion hazard control. Since a dust explosion, from the point of view of the process physics, is an explosion of combustible gas components that have been released from coal samples, the use of an indicator that includes mass loss due to the yield of both combustible and non-combustible components does not reflect the explosion hazard level of the analyzed sample.

The use of the method for determining the intensity of the volatile substances value with a linear increase in temperature allows us to identify temperature ranges of the combustible volatile substances value and determine the intensity of this process. These are the PVS and SVS stages for thermally undisturbed coals. Significant information is obtained on the additional range of carbon dioxide emissions from rock dust (CDS) when analyzing mixtures of coal and rock dust. Moisture yield at the initial heating stage (MRS) is always present and differs only in the value of external moisture in the samples [44]. The thermal destruction of dry dust samples is studied after drying the samples at the MRS stage. The ash content Ad is determined after coke combustion. This allows us to recalculate the values of the stage yield of volatile substances to the state of dry ash-free mass (daf).

Research of dust in explosion experimental chambers

Initially, the basic thermogravimetric functions of the coal substance were determined (similar to curve 1 in the Fig.2) to identify changes in its state before and after the explosion. The dust was then subjected to explosion at various concentrations in a 20-liter explosion chamber. The qualitative and quantitative characteristics were then compared (Table, Fig.3). Changes in the TG characteristics after the thermal impact of the explosion are clearly shown in Fig.3.

Results of the study of coal dust samples before and after the explosion (for the daf state)

|

N |

Sample |

PVS |

SVS |

Total, % |

||

|

,% |

compared to sample 1 |

,% |

compared to sample 1 |

|||

|

1 |

Before the explosion |

25.71 |

– |

10.70 |

– |

36.41 |

|

2 |

After explosion (500 g/m3) |

10.75 |

–14.94 |

10.77 |

+0.07 |

21.52 |

|

3 |

After explosion (100 g/m3) |

13.64 |

–12.07 |

36.73 |

+26.03 |

40.37 |

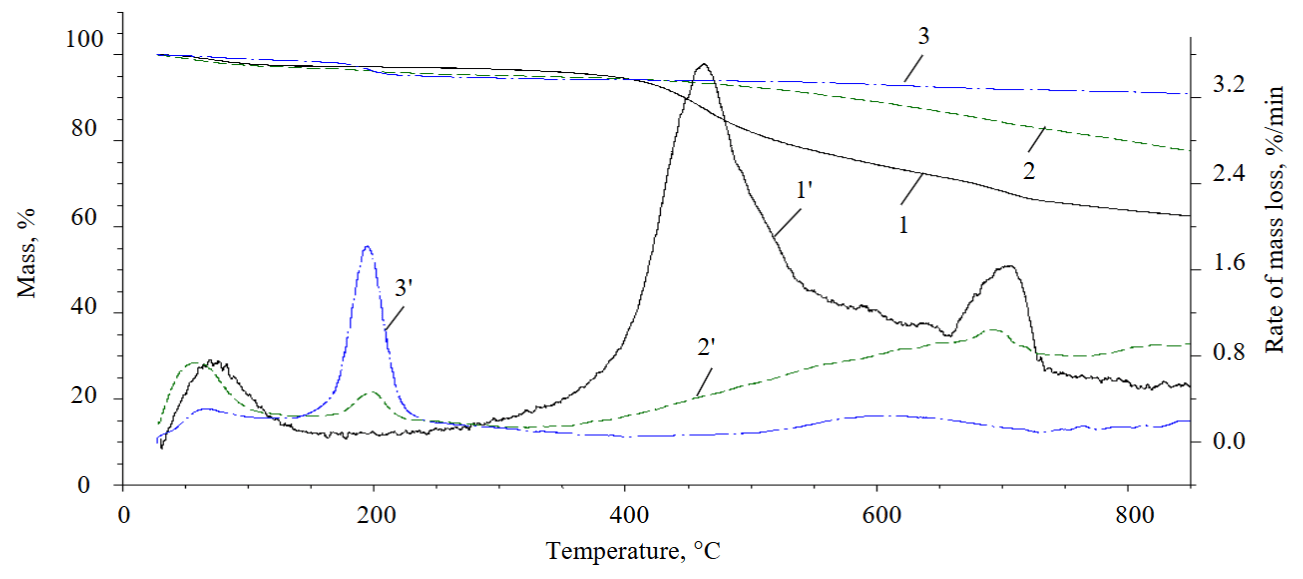

The qualitative characteristics and data in Fig.3 indicate the disappearance of the gross stage of the combustible volatile substances yield for PVS in the samples “after the explosion” (curves 2' and 3' in Fig.3, temperature range 350-600 °C). The value of mass loss and the rate of its decrease at this stage in post-explosion samples decreases sharply. Gross stages of low-temperature of volatile substances yield appear in the temperature range of 150-250 °С (curves 2′ and 3′, temperature of about 200 °С), which are absent in the characteristics of coal before the explosion (curve 1). The presence of such areas is evidence of the full-scale tests priority and the conditionality of the explosions in chambers results. At T ≤ 200-250 °С, the remains of the ignition source of the dust aerosol and/or its shell decompose thermally (according to GOST 12.1.044-2018, the ignition source is a pyrotechnic charge with an energy reserve of 2.5 kJ of the following composition: finely dispersed powders of zirconium, barium nitrate and barium peroxide in a ratio of 4:3:3 with a mass of 0.6 g or aluminium powders and barium peroxide in a ratio of 1:9.4 and a total amount of 1.0 g; an additional shell for the resulting charge weighing about 0.5 g is required). The mass of the ignition source is comparable to the mass of coal dust in the chamber. This introduces distorting additives into the composition of post-explosive dust (from the chamber), which are absent in mine dust. The characteristics of the samples, which are recalculated to the state of dry ash-free mass, are given in the Table.

Fig.3. Thermogravimetric functions for samples of grade D coal dust that were collected before and after the explosion [45]: TG-(1) and DTG-(1') curves of grade D coal before the explosion; TG-(2) and DTG-(2') curves of grade D coal after the explosion at dust concentration of 500 g/m3; TG-(3) and DTG-(3') curves of grade D coal after the explosion at dust concentration of 100 g/m3

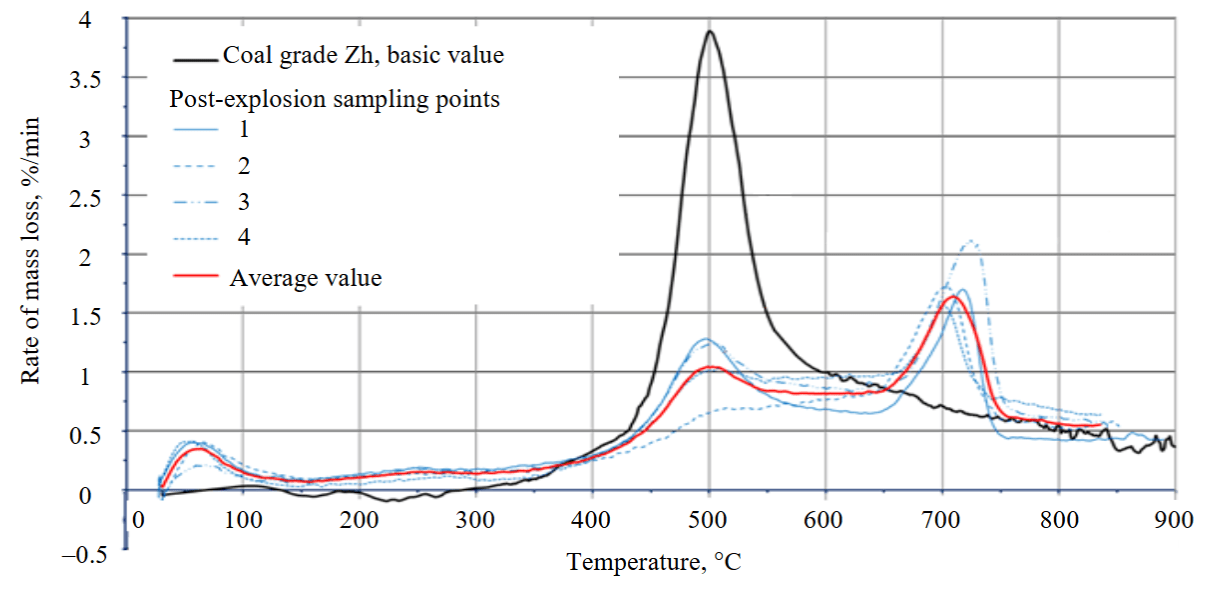

Fig.4. Comparison of TG and DTG samples of grade Zh coal with dust of this coal from the emergency section

The analysis of the obtained research results showed the following:

- the value of volatile substances at the PVS in post-explosive dust decreased by 1.9-2.4 times (from = 25.7 % to = 10.8-13.6 %);

- the value of volatile substances at the SVS in post-explosive dust increased from = 10.7 % to the maximum value of = 36.7 % (on average by 1.9 times);

- it has been experimentally established that the total yield of volatile substances for the daf state from post-explosion dust (explosion in the experimental chamber) can either decrease (line 2 of the Table) or increase (line 3 of the Table), depending on the conditions of the explosion. This explains the failure to meet criterion (1) in practice, which is described in detail in the papers [41, 44, 45].

Research of dust exploded in mines

The conditions of explosions in laboratory chambers (with a rigidly fixed volume) and in mines (the volume of the reaction is limited to two dimensions and is not limited by the length of the workings) differ significantly. Therefore, the most reliable data are obtained during large scale tests (LST) in experimental adits, drifts or galleries. There are no active experimental adits in Russia. Therefore, the sampling of the exploded dust was carried out by professional rescuers who eliminated the consequences of real explosions in two coal mines. A total of 60 dust samples and lump coal samples of grades Zh (Pechora coal basin) and D (Kuznetsk coal basin) (mining disasters in 2013-2021) were collected from the emergency section. Seam coal samples from these mines were used to determine the basic (i.e. pre-explosion) characteristics. This sampling allowed us to research the explosive properties of coals dynamics in comparison with traditional [44, 47] TGA researches of coking and energy coals.

Figure 4 shows a comparative TG analysis of base samples of grade Zh coal and coal after an emergency dust explosion in a mine, collected at four points (total of 18 samples were collected and processed from this mine in three workings of the emergency section, 2013). The considered sampling points (1-4) correspond to the places of miners fatal injuries at the explosion and are located in the following places of the extraction area (EA): 1 – 100 m behind the longwall in the supported working, in the mined-out space (return ventilation air); 2 – 50 m from the longwall; 3 – 20 m from the headgate with the conveyor drift (CD) of the lower part of the longwall; 4 – in the CD at a distance of 30 m from the headgate with the longwall on the intake air. Initially, it was assumed that the explosion occurred in the longwall. However, the TG analysis method determined that the explosion occurred outside the EA – in the transport slope, that was confirmed by the results of expert works.

The qualitative picture of the TG/DTG functions dynamics for the post-explosion state of coal dust for LST explosions has a number of results in common with explosions in 20-liter chambers. Thus, Fig.4 shows a significant decrease in the yield of primary volatile substances at the PVS stage in all dust samples after the explosion in relation to the pre-explosion values and a significant increase in the yield of secondary volatile substances at the SVS in samples after the explosion in relation to the pre-explosion values. For all analysed samples from emergency sections of mines (samples after the explosion), the total yield of volatile substances when recalculated to dry ash-free mass exceeded the similar indicator of the sample before the explosion.

For explosions in a 20-liter laboratory chamber, the total yield of volatile substances decreased in about half of the experiments (to 10 % of the initial value), and increased slightly in the other part of the experiments. This is the only significant difference between the results of laboratory research and full-scale mine explosions.

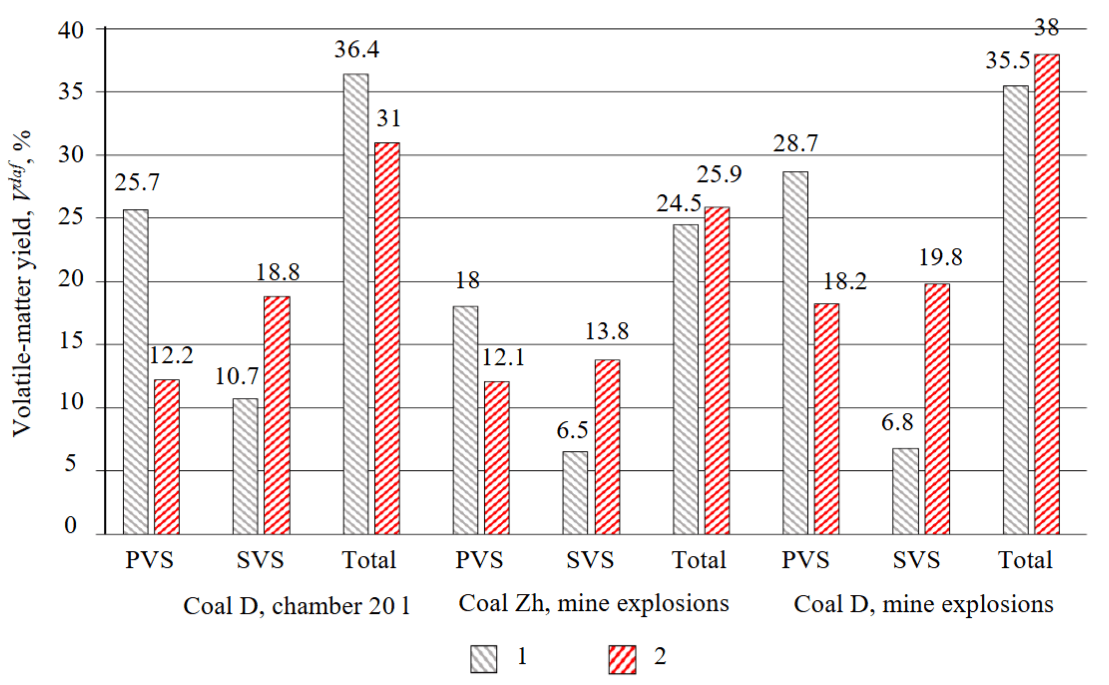

Figure 5 shows the summarized quantitative data for groups of experiments in the research of samples using the thermogravimetric method.

Based on the comparison of the stage of volatile substances yield values (; ) (logical variable), the criterion of dust participation in the explosion in the form of mathematical logic equation has the form:

According to formula (2), dust took part in the explosion (event Ex = 1) when two conditions or elementary events were simultaneously met – a significant decrease in the yield of primary volatile substances at the PVS stage in the sample after the explosion and an increase in the yield of secondary volatile substances .

Fig.5. The ratio of the volatile substances yield dynamics from coal dust samples before the explosion (1) and after the explosion (2) at different stages of heating (PVS, SVS) and the total of volatile substances yield (state of coal matter – daf)

The thermogravimetric method for recognizing the participation of coal dust in explosive combustion has been proposed and practically developed based on the method of stage-by-stage control of the volatile substances yield from post-explosion samples and their comparison with the basic pre-explosion values. Determining the involvement of dust in an explosion is a mandatory procedure both during operational work to eliminate accidents and during expert investigations of technical causes of accidents.

When selecting logically related groups of samples from the emergency section workings, their TG study is carried out and the minimum value of the parameter is sought. Initially, the minimum values are achieved at the explosion epicentre. Further, in the course of the explosion propagation in the emergency workings, in the first 100-120 m, deflagration combustion of dust is unstable and is limited by the lack of oxygen. The value in samples from these points increases in relation to the explosion epicentre (by 18±5 %) and is unstable.

A comparison of the values along the length of the emergency working characterizes the stages of formation of the flame front and the shock blast wave front (the processes have been studied in detail in full-scale explosive experiments [44]) and serves as a characteristic of the operation of explosion localization devices effectiveness and the implementation of measures to ensure dust explosion safety.

Conclusion

The yield of volatile substances from coal, determined by standard methods during isothermal heating in a muffle furnace, is one of the main classification indicators of commercial coal and is present in internationally recognized quality certificates. At the same time, along with the general Vdaf indicator, indicators for various states of coal matter (analytical Va, dry Vd, working Vr), are widely used, the list of which is determined by practical expediency. Since the use of theVdaf indicator in the field of dust explosion control has repeatedly proved in practice its unstable nature, additional indicators of the staged yield of volatile substances have been developed for the safety of mining operations.

A thermogravimetric method for obtaining stepwise indicators of the yield of volatile substances from coal dust has been experimentally developed. TG methods are more accurate due to modern devices for measuring mass (from 0.001 to ±1 % thermal weights), more technological due to the elimination of drying procedures for samples, the implementation of heating in an inert environment, which eliminates the uncertain requirement of standards for heating in an atmosphere with limited oxygen access. The TG method makes it possible to automatically determine the moisture content of a sample, to study decarboxylation, pyrolysis, oxidation, the mass fraction of coke and the ash content. By the absence of loss of mass of the dust sample at certain stages of heating, the limits of its thermal stability, the ignition temperature and a number of other indicators of fire danger and dust explosion are determined.

The use of thermogravimetric methods for studying the yield of volatile substances with a linear increase of temperature makes it possible to identify the temperature ranges of the yield of combustible volatile substances and separate them from the yield stage of non-combustible components. For thermally undisturbed coals, combustible gases that determine the explosion hazard of dust are released in the heating ranges PVS (from 350 to 600 °C) and SVS (from 600 to 750 °C). In the study of coals with high ash content or mixtures of coal and inert dust, a significant yield of nonflammable volatile substances occurs at temperatures above 750 ° C or in the conditional carbon dioxide yield range (CDS). Moisture yield at the initial heating stage (MRS) allows for automatic Wa detection and eliminates time-consuming sample drying procedures. After afterburning of coke, the ash content of Ad is determined by thermogravimetric methods, which makes it possible to recalculate the values of the stage yield of volatile substances to the daf state.

It has been experimentally established that in 100 % of the studied samples after the explosion, the yield of primary combustible volatiles at the PVS decreased significantly simultaneously with a significant increase in the yield of secondary volatiles . This made it possible to develop a modified criterion for recognizing the participation of coal dust of any ash content and mixtures of coal and inert dust in explosions.

The use of , an indicator determined by the thermogravimetric method for post-explosion samples makes it possible to determine the epicenter of the explosion with high reliability (the propagation of the explosion up to 300 m from the epicenter was studied), to study the dynamics of the propagation of the explosion along the workings of the emergency site and to determine the effectiveness of the explosion protection equipment.

The results of 10 years of research have formed the basis for instructions for professional rescue teams and can be used in a wide range of work to ensure dust explosion safety in mines or expert work by technical regulation organizations.

References

- Smirnyakov V.V., Smirnyakova V.V., Pekarchuk D.S., Orlov F.A. Analysis of methane and dust explosions in modern coal mines in Russia. International Journal of Civil Engineering and Technology. 2019. Vol. 10. Iss. 2, p. 1917-1929.

- Balovtsev S.V. Monitoring of aerological risks of accidents in coal mines. Mining Science and Technology. 2023. Vol. 8. N 4, p. 350-359. DOI: 10.17073/2500-0632-2023-10-163

- Breslin J.A. One Hundred Years of Federal Mining Safety and Health Research. Information Circular 9520. National Institute for Occupational Safety and Health, 2010, p. 98.

- Fomin A.I., Voroshilov Ya.S., Paleyev D.Yu. Research into the effect of coal dust on safetyAinAmining. Russian Mining Industry. 2019. N 1 (143), p. 33-36 (in Russian). DOI: 10.30686/1609-9192-2019-1-143-33-36

- Nguyen Ngoc Minh, Pham Duc Thang. Tendencies of mining technology development in relation to deep mines. Mining Science and Technology. 2019. Vol. 4. N 1, p. 16-22. DOI: 10.17073/2500-0632-2019-1-16-22

- Zi-Lu Liu, Zhan-Guo Ma, Kazanin O.I. et al. Deformation Control Technology of Gob-Side Entry Retaining with Large Volume CFST Roadway Side Support in Top-Coal Caving Longwall and Stability Analysis: A Case Study. Applied Sciences. 2023. Vol. 13. Iss. 15. N 8610. DOI: 10.3390/app13158610

- Xiaofeng Ren, Xiangming Hu, Di Xue et al. Novel sodium silicate/polymer composite gels for the prevention of spontaneous combustion of coal. Journal of Hazardous Materials. 2019. Vol. 371, p. 643-654. DOI: 10.1016/j.jhazmat.2019.03.041

- Gryzunov V.V., Pekarchuk D.S. Qualitative analysis of traumatism structure in coal mines. Gornyi zhurnal. 2017. N 10, p. 61-64 (in Russian). DOI: 10.17580/gzh.2017.10.13

- Litvinov A.R., Kolikov K.S., Ishkhneli O.G. Accident and traumatism at coal industry enterprises in 2010-2015. Bulletin of Research Center for Safety in Coal Industry (Industrial Safety). 2017. N 2, p. 6-17 (in Russian).

- Martirosyan A.V., Ilyushin Y.V. The Development of the Toxic and Flammable Gases Concentration Monitoring System for Coalmines. Energies. 2022. Vol. 15. Iss. 23. N 8917. DOI: 10.3390/en15238917

- Soloviov V.B., Magomet R.D. The ways of safety improvement during the outburst-prone and gas-bearing coal seams development. Journal of Industrial Pollution Control. 2017. Vol. 33. Iss. 1, p. 1042-1047.

- Kabanov E.I., Korshunov G.I., Magomet R.D. Quantitative Risk Assessment of Miners Injury During Explosions of Methane-Dust-Air Mixtures in Underground Workings. Journal of Applied Science and Engineering. 2020. Vol. 24. Iss. 1, p. 105-110. DOI: 10.6180/jase.202102_24(1).0014

- Balovtsev S.V., Skopintseva O.V. Science-based technological solutions for aerological risks reducing in operating and designing coal mines. Mining Informational and Analytical Bulletin. 2023. N 2, p. 139-151 (in Russian). DOI: 10.25018/0236_1493_2023_2_0_139

- Kabanov E.I. Analysis of accidents risk in coal mines taking into account human factor. Gornyi zhurnal. 2023. N 9, p. 48-54 (in Russian). DOI: 10.17580/gzh.2023.09.07

- Chiuzan E., Matei A. Tools available for methane recovery from mines belonging to C.E.H. Petroşani. MATEC Web of Conferences. 2024. Vol. 389. N 00007. DOI: 10.1051/matecconf/202438900007

- Vasilenko T., Кirillov А., Islamov A. et al. Permeability of a coal seam with respect to fractal features of pore space of fossil coals. Fuel. 2022. Vol. 329. N 125113. DOI: 10.1016/j.fuel.2022.125113

- Yu Liu, Chuanghui Zhang, Yu Zhang. Evolution mechanism of methane adsorption capacity in vitrinite-rich coal during coalification. Journal of Natural Gas Science and Engineering. 2021. Vol. 96. N 104307. DOI: 10.1016/j.jngse.2021.104307

- Gendler S.G., Vasilenko T.A., Stepantsova A.Yu. Investigation of mass transfer of hard coal during its transportation to the place of temporary storage. Mining Informational and Analytical Bulletin. 2023. N 9-1, p. 135-148. DOI: 10.25018/0236_1493_2023_91_0_135

- Korshunov G.I., Eremeeva A.M., Seregin A.S. Justification of reduction in air requirement in ventilation of coal roadways with running diesel engines. Mining Informational and Analytical Bulletin. 2022. N 3, p. 47-59 (in Russian). DOI: 10.25018/0236_1493_2022_3_0_47

- Eremeeva A.M., Kondrasheva N.K., Khasanov A.F., Oleynik I.L. Environmentally Friendly Diesel Fuel Obtained from Vegetable Raw Materials and Hydrocarbon Crude. Energies. 2023. Vol. 16. Iss. 5. N 2121. DOI: 10.3390/en16052121

- Harteis S.P., Alexander D.W., Harris M.L. et al. Review of rock dusting practices in underground coal mines. Information Circular 9530. National Institute for Occupational Safety and Health, 2017, p. 96.

- Gendler S.G., Rudakov M.L., Kuznetsov V.S. Evaluation Principles of the Dust Influence of Mining Enterprises on the Environment. Latvian Journal of Physics and Technical Sciences. 2019. Vol. 56. Iss. 3, p. 62-69. DOI: 10.2478/lpts-2019-0020

- Borowski G., Smirnov Y., Ivanov A., Danilov A. Effectiveness of carboxymethyl cellulose solutions for dust suppression in the mining industry. International Journal of Coal Preparation and Utilization. 2022. Vol. 42. Iss. 8, p. 2345-2356. DOI: 10.1080/19392699.2020.1841177

- Hetang Wang, Sisi Cheng, Haojie Wang et al. Synthesis and properties of coal dust suppressant based on microalgae oil extraction. Fuel. 2023. Vol. 338. N 127273. DOI: 10.1016/j.fuel.2022.127273

- Qingguo Wang, Deming Wang, Hetang Wang et al. Experimental investigations of a new surfactant adding device used for mine dust control. Powder Technology. 2018. Vol. 327, p. 303-309. DOI: 10.1016/j.powtec.2017.12.080

- Kurnia J.C., Sasmito A.P., Mujumdar A.S. Dust dispersion and management in underground mining faces. International Journal of Mining Science and Technology. 2014. Vol. 24. Iss. 1, p. 39-44. DOI: 10.1016/j.ijmst.2013.12.007

- Kornev A.V., Spitsyn A.A., Zaimentseva L.A., Zubko M.V. Research of the physico-chemical properties of hydrogel as a means of dust-explosion protection and dust reduction in coal mines. Mining Informational and Analytical Bulletin. 2023. N 9-1, p. 180-198 (in Russian). DOI: 10.25018/0236_1493_2023_91_0_180

- Zavyalova E.L., Zavyalov G.V. Development of Means for Localization of the Coal Dust Explosions. Occupational Safety in Industry. 2022. N 12, p. 13-19 (in Russian). DOI: 10.24000/0409-2961-2022-12-13-19

- Smirnyakov V.V., Rodionov V.A., Smirnyakova V.V., Orlov F.A. The influence of the shape and size of dust fractions on their distribution and accumulation in mine workings when changing the structure of air flow. Journal of Mining Institute. 2022. Vol. 253, p. 71-81. DOI: 10.31897/PMI.2022.12

- Yueze L., Saad A., Sasmito A.P., Kurnia J.C. Prediction of air flow, methane, and coal dust dispersion in a room and pillar mining face. International Journal of Mining Science and Technology. 2017. Vol. 27. Iss. 4, p. 657-662. DOI: 10.1016/j.ijmst.2017.05.019

- Xun Zhang, Chen Yu, Bing Lu et al. Study on the inhibitory mechanism of dehydrogenated antioxidants on coal spontaneous combustion. Scientific Reports. 2022. Vol. 12. N 21237. DOI: 10.1038/s41598-022-25721-1

- Zhiwei Jiang, Guolan Dou. Preparation and Characterization of Chitosan Grafting Hydrogel for Mine-Fire Fighting. ACS Omega. 2020. Vol. 5. Iss. 5, p. 2303-2309. DOI: 10.1021/acsomega.9b03551

- Thakur P. 23 – Gas and Dust Explosions. Advanced Mine Ventilation. Elsevier, 2019, p. 377-398. DOI: 10.1016/B978-0-08-100457-9.00023-7

- Hui Zhang, Weihai Han, Youlin Xu et al. Analysis on the Development Status of Coal Mine Dust Disaster Prevention Technology in China. Journal of Healthcare Engineering. 2021. Vol. 2021. N 5574579. DOI: 10.1155/2021/5574579

- Yuan-Pan Zheng, Chang-Gen Feng, Guo-Xun Jing et al. A statistical analysis of coal mine accidents caused by coal dust explosions in China. Journal of Loss Prevention in the Process Industries. 2009. Vol. 22. Iss. 4, p. 528-532. DOI: 10.1016/j.jlp.2009.02.010

- Korobeynikova E.A., Panarina A.V., Kuksova K.D., Pudovkina A.A. Explosion at Listvyazhnaya mine: reasons and conclusions. Nauka Rossii – budushchee strany: sbornik statei Vserossiiskoi nauchno-prakticheskoi konferentsii, 23 February 2022, Penza, Russia. Penza: Nauka i Prosveshchenie, 2022, p. 230-235 (in Russian).

- Harris M.L., Sapko M.J. Floor dust erosion during early stages of coal dust explosion development. International Journal of Mining Science and Technology. 2019. Vol. 29. Iss. 6, p. 825-830. DOI: 10.1016/j.ijmst.2019.09.001

- Chunlian Cheng, Rongjun Si, Lei Wang et al. Explosion and explosion suppression of gas/deposited coal dust in a realistic environment. Fuel. 2024. Vol. 357. Part A. N 129710. DOI: 10.1016/j.fuel.2023.129710

- Haiyan Wang, Yanwei Zhang, Jingde Xu et al. Experimental study on effect of dilute coal dust on gas explosion pressure/flame evolution process. Powder Technology. 2022. Vol. 404. N 117450. DOI: 10.1016/j.powtec.2022.117450

- Lebetski K.A., Romanchenko S.B. Dust explosion hazard of mining production. Мoscow: Gornoe delo, 2012, p. 464 (in Russian).

- Khludov D.S., Olennikov S.V., Musinov S.N. et al. On the method of determining the participation of coal dust in an explosion of methane-air mixture. Bulletin of Research Center for Safety in Coal Industry (Industrial Safety). 2014. N 2, p. 150-155 (in Russian).

- Samih S., Chaouki J. Coal pyrolysis and gasification in a fluidized bed thermogravimetric analyzer. The Canadian Journal of Chemical Engineering. 2018. Vol. 96. Iss. 10, p. 2144-2154. DOI: 10.1002/cjce.23198

- Qing-Wei Li, Yang Xiao, Cai-Ping Wang et al. Thermokinetic characteristics of coal spontaneous combustion based on thermogravimetric analysis. Fuel. 2019. Vol. 250, p. 235-244. DOI: 10.1016/j.fuel.2019.04.003

- Romanchenko S.B., Sobolev V.V., Naganovsky Yu.K., Gubina Е.A. Thermogravimetric experimental studies of the explosion hazard of coal dust and its mixtures with stone dust. Fire Safety. 2024. N 2 (115), p. 64-73 (in Russian). DOI: 10.37657/vniipo.pb.2024.115.2.007

- Romanchenko S.B., Trubitsyn A.A., Sobolev V.V. Physical and chemical transformations in coal dust by explosions. Bulletin of Research Center for Safety in Coal Industry (Industrial Safety). 2019. N 4, p. 7-20 (in Russian).

- Netseplyaev M.I., Lyubimova A.I., Petrukhin P.M. et al. Protection of coal dust explosions in mines. Мoscow: Nedra, 1992, p. 298 (in Russian).

- Claudionor Gomes da Silva Filho, Milioli F.E. A thermogravimetric analysis of the combustion of a Brazilian mineral coal. Química Nova. 2008. Vol. 31. Iss. 1, p. 98-103. DOI: 10.1590/S0100-40422008000100021