Selection and assessment of the stripping system in open pit mining of steeply dipping deposits

- 1 — Ph.D., Dr.Sci. Professor Nosov Magnitogorsk State Technical University ▪ Orcid

- 2 — Ph.D., Dr.Sci. Head of Department Nosov Magnitogorsk State Technical University ▪ Orcid

- 3 — Ph.D. Associate Professor Nosov Magnitogorsk State Technical University ▪ Orcid

Abstract

Selection of the type and parameters of the stripping scheme is one of the most complicated tasks in design of the mining of steeply dipping deposits. The stripping scheme adopted in the project largely determines the capital and operating costs of mining and affects the development strategy of the company in general. The greatest number of alternative stripping methods are associated with mining conditions of reserves in large steeply dipping deposits, which were exploited for several decades. Current approaches to selecting the method and scheme of stripping involve the use of a specific type of transport; however, the type and model of the vehicle are not taken into account in the current classifications of stripping methods and schemes. It is necessary to develop a systems approach to selection of the stripping methods for mining steeply dipping deposits. The purpose of the study is to substantiate the parameters and develop a multifactorial criterion for assessing the stripping system for selecting an alternative for the development of a mining plant. The article proposes an approach in which the choice of the opencast transport, substantiation of the stripping method and scheme will be considered as part of the stripping system, which will allow a comprehensive solution of the problems of increasing the efficiency of mining at different stages of quarry operations. A refined definition and structure of the stripping system are proposed. As a criterion for assessing the efficiency of the stripping system, a rank coefficient is selected that takes into account the target values, the weight of parameters and groups included in the calculation, the computation of which is based on the use of a combination of multicriteria analysis methods. The approach allows considering not only the economic performance, but also other factors, which largely determines further development of the plant. The study primarily focuses on deep open pit conditions of ore deposit mining. The established rank allows choosing the most efficient strategy for the development of mining plants.

Funding

The study was supported by a grant from the Russian Science Foundation N 23-21-10040.

Introduction

Increasing depth and size of an open pit in plan entails growth of mining costs and necessitates the improvement of mining equipment and mining technology. As noted by many authors, the main growth of expenses on quarrying with increasing depth and other parameters is associated with the costs of rock mass transportation [1-3] and stripping scheme compilation [4, 5]. Substantiation of the operating parameters of opencast transport is a complex multifactorial task [6, 7], and economic performance of deposit mining depends on the efficiency of planning and management of transport complexes [8-10]. At the same time, opencast transport and the stripping scheme are considered in different systems – transport [11], mining and conveyor [12], and logistics [13]. Adaptation to changing external and internal conditions of deposit development often proceeds by technical re-equipping of the opencast transport system, which provides for a change in the type or models of the vehicles used [14-16]. Changes made in one of the considered systems without considering the elements of other systems can result in a low efficiency of transformations in the open pit.

When stripping the deposits, the terms “stripping method” and “stripping scheme” are used [17]. In the theory of stripping open pit fields, the concept of the “stripping system” or “general stripping scheme” is also known – this is the order and sequence of a stagewise compilation, change (development) of the stripping scheme during the period of the open pit existence, ensuring the stripping of mining floors to the working depth. In this definition, there are no signs of a system, the elements and associations are not identified, and this concept is almost never used in practice. The stripping system differs from the stripping scheme only in considering all stages of deposit development. None of the known definitions and characteristics of stripping reflects the type of transport moving the cargo that determines the costs and the efficiency of resource consumption. Development of the stripping scheme and rock mass transportation is considered without taking into account the interrelations between them; therefore, the current methodological approach does not allow assessing the performance and stability of the stripping system.

Due to emergence of the new and development of existing transport complexes for open pit mining (OPM) some complexes are not covered by the generally accepted classifications of the stripping methods. For example, location of quarry lifts on metal supports [18, 19], tower structures [20, 21] placed on open pit walls provide access to the mining floors, but do not involve the construction of steep trenches and are not related to trenchless stripping. Definitions of the stripping method and scheme most precisely characterize the use of one type of transport in a pit. In modern conditions, efficient development of deep-lying deposits is possible only with a combination of several types of transport, setting-up of loading points of various designs and purposes in the quarry. Moreover, the stripping method and scheme before and after the loading point will differ. This leads to the need of revising the substantiation of the structure and operation of the stripping system and of clarifying the concept. The lack of systems approach leads to losses caused by the inconsistency of individual elements of stripping design, which will only increase with growing depth of mining operations.

Methodology for assessing the stripping system

The “stripping system” is a subsystem of mining and technical system (MTS) designed to provide access to a deposit or a local area, formation and implementation of cargo flows of minerals, overburden, equipment, and materials, which consists of mine openings, hauling equipment and devices, and intra-quarry rock mass loading points [22].

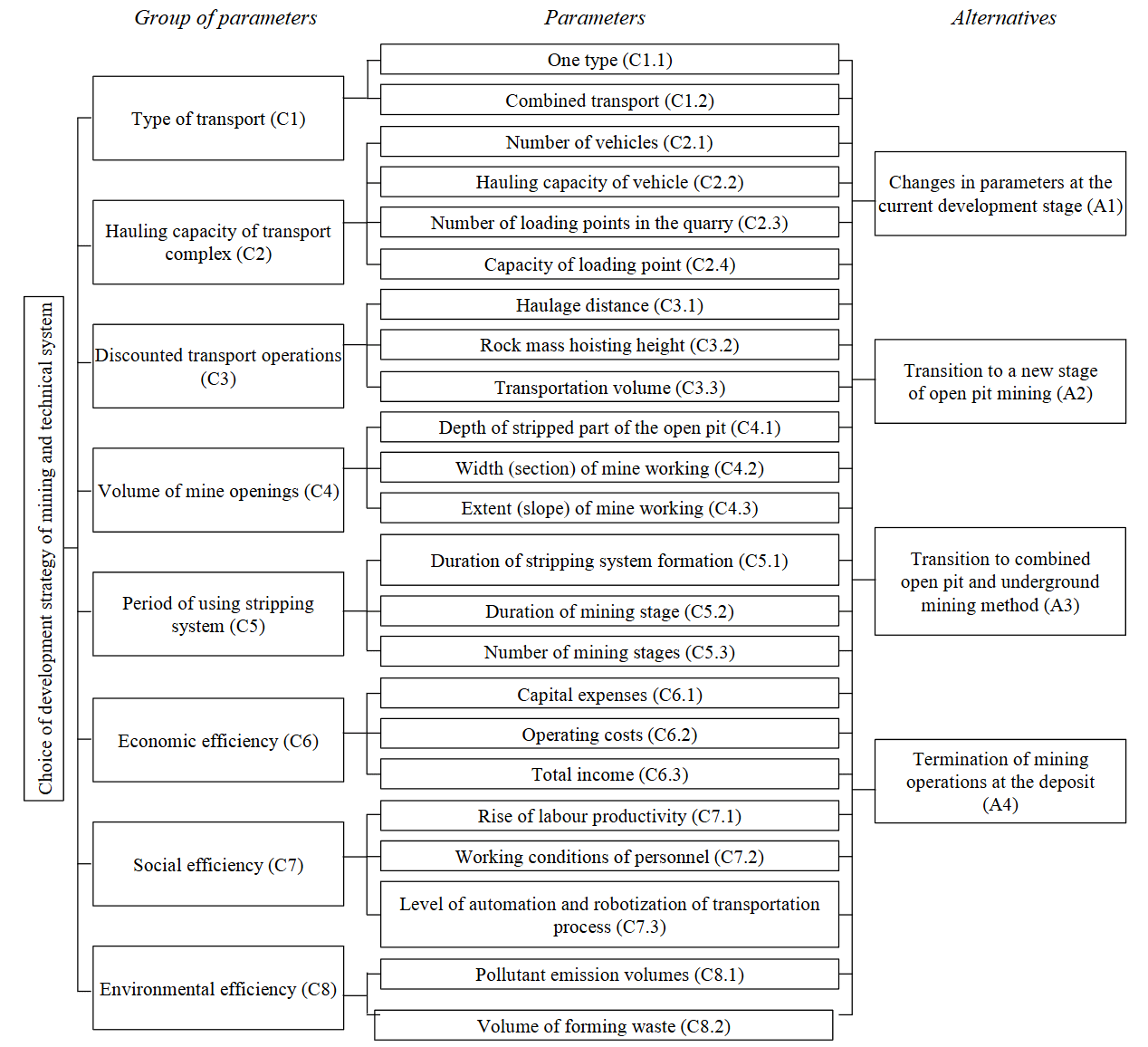

The paper systematizes the parameters of the stripping system that affect the development of the mining and technical system, taking into account the practice of operating, reconstruction of the stripping system at the operating facilities and analysis of research on opencast transport efficiency, development of the optimal versions of the stripping schemes ensuring stability and efficiency of the system development. Systematization is based on the functional approach with distinguishing of the engineering, technological, economic, social, and environmental factors. A two-level assessment is proposed using 8 groups and 23 parameters, which are substantiated in [23] (Fig.1). The first level of hierarchy takes into account the parameters of the stripping system assessment when interacting with the MTS and the environment. The second level includes specific parameters of the stripping system operation. The classification of parameters allows making a comprehensive assessment of the stripping system and choosing the strategy for further MTS development.

The parameters under consideration are assessed by qualitative and quantitative values, affect the final result and have different goals. Therefore, it is necessary to elaborate a comprehensive assessment criterion and method that allow considering these specific features.

It is proposed to assess the stripping system as well as to choose the development strategy for steeply dipping deposits, using a comprehensive efficiency criterion, for which a rank coefficient is selected that allows considering a large number of parameters, the qualitative and quantitative value as well as the target function of each parameter. The developed criterion has the following form:

where хij – value of the i-th alternative assessment according to the j-th criterion for all parameters of the stripping system; i – influencing parameter; wj – weight coefficient of the parameter; ki – utility of alternatives.

It is reasonable to rank the parameters by determining the weight coefficients using the Fuzzy Analytic Hierarchy Process (Fuzzy AHP) [24, 25]. The method is widely used in solving multicriteria problems, including those in mining [26-28].

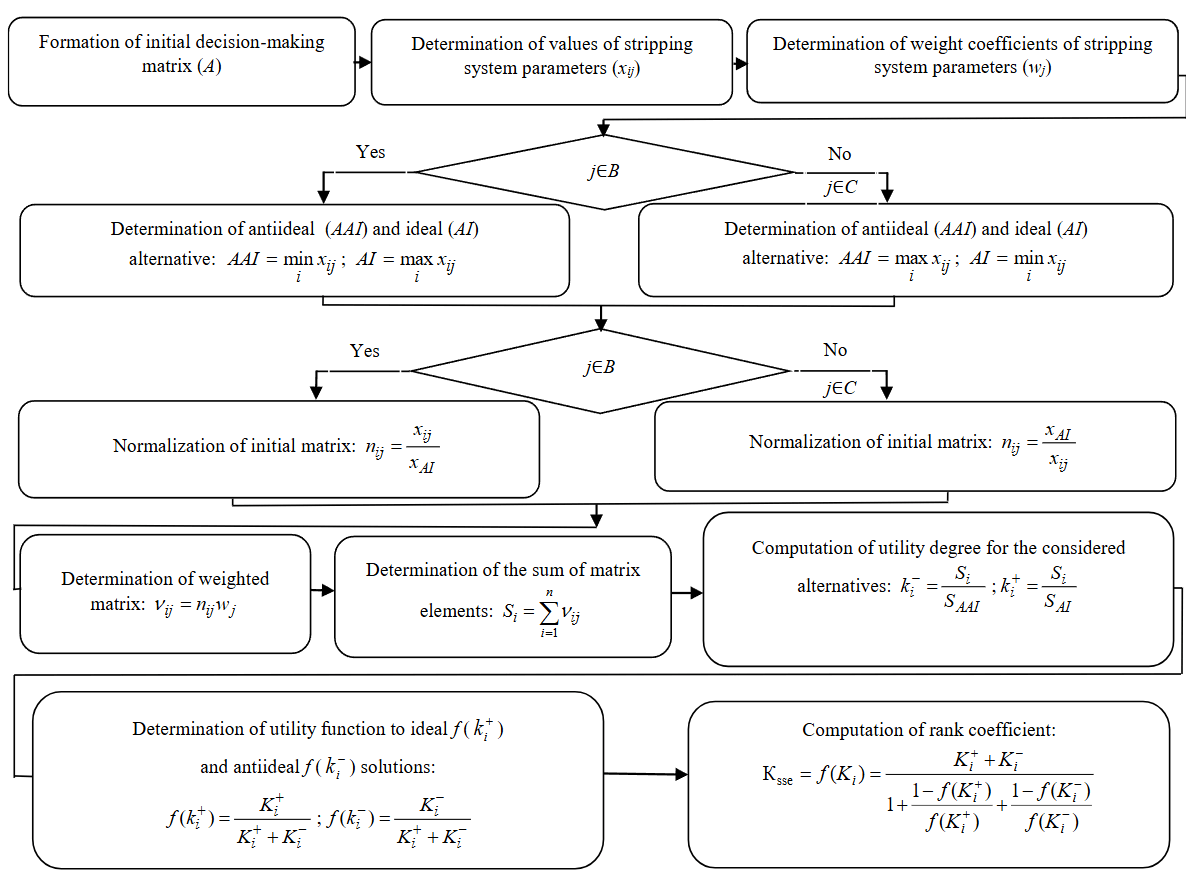

A large number of influencing variables with different target values tending to the maximum or minimum possible as well as the complexity of assessing a number of parameters with quantitative values predetermined the need to use combined multicriteria fuzzy methods to select an appropriate stripping method for the corresponding strategy of the MTS development. In the course of research, different methods were tested, and the MARCOS method [29-31] was selected which meets the set conditions for solving the problem. The sequence of performing calculations of the rank coefficient taking into account the multicriteria methods is presented in Fig.2 [17].

As a result of the calculation, the final rank based on the value of the proposed criterion is established for each MTS development strategy under consideration. For the strategies with the highest ranks, the feasibility study is accomplished, and the final choice is made.

Fig.1. Parameters of assessing the stripping system and MTS development strategy alternatives

Fig.2. Flowchart for calculating the rank coefficient

В – maximization criteria; С – minimization criteria

Discussion of results

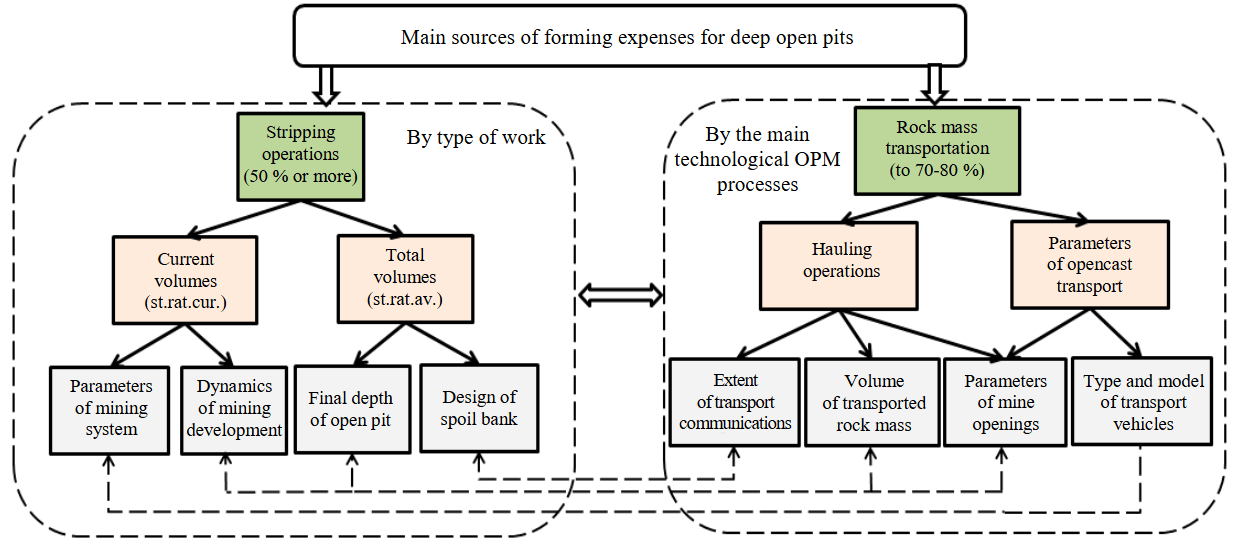

Main elements of the stripping system in the current approach are only mine openings placed in a certain way in the open pit space. Parameters of mine openings are determined by parameters of opencast transport, but such element as opencast transport is absent from the current definitions and classifications of stripping. The efficiency of the mining and technical system in deep open pits is determined by the costs of stripping operations and rock mass transportation, which are largely interrelated (Fig. 3).

Fig.3. Main types of expenses determining the efficiency of open pit mining in deep pits

The main sources of expenses on the technological processes are the costs of opencast transport, which account for up to 70 %; and for the types of work – the costs of stripping operations, which amount to 50 % or more, depending on the average operational coefficient of stripping and the adopted mode of mining operations. At the same time, from 30 to 50 % of stripping operations, according to [22], are accounted for by development of the stripping scheme. The highest values are typical for deep open pits, which form during mining of steeply dipping deposits. The stripping system, combining mine openings and opencast transport, is the most expensive subsystem of the MTS. Therefore, the decisions made in designing the stripping system will significantly affect the stability of operation of the mining and technical system as a whole.

The entire development period of large deposits, i.e. the deposits mined over several decades, can be divided into stages of updating the reserves involved in development, revising the pit outline, changing the equipment and technology used in operations, etc. Accordingly, the stripping scheme is developed stage by stage. The function of individual workings in the formed stripping scheme can change with transition to new stages of open pit mining and a change in the deposit development method. For example, mine openings of the initial stage can be used as auxiliary ones at a new stage, when switching to an underground mining method – for movement of dump trucks in the underground mine, or, as proposed in [17], for lifting the rock mass, equipment and materials to the surface and lowering them to the loading point. The functionalities of the stripping system differ at each individual stage. Therefore, it is necessary to design the stripping system using a more precise definition of this term considering mine openings, transport communications, loading points, transport vehicles, transport structures, and also to specify the functions of individual elements at each operation stage of the mining and technical system; for this purpose, the concept of the stripping system was expanded.

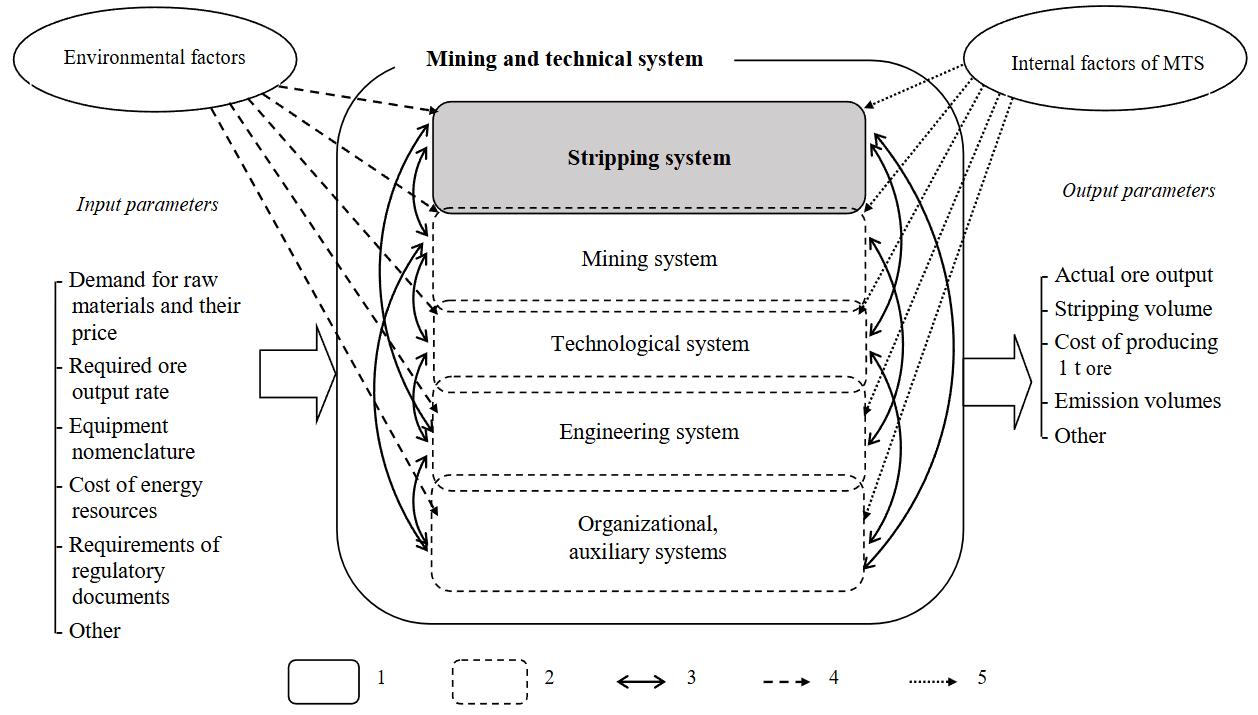

The stripping system is connected with other subsystems of the mining and technical system by both direct and reverse links, and some elements can be part of several MTS subsystems (Fig.4) [17].

Fig.4. Stripping subsystem in MTS structure

1 – MTS outline; 2 – MTS systems; 3 – connections between systems; 4 – environmental impact on MTS systems; 5 – influence of internal factors on MTS systems

The stripping system is characterized by the number and purpose of elements, parameters of connections between them and the duration of elements operation in an unchanged form. The main function of the stripping system is to create and maintain the transport connection between the facilities on the surface and the pit floors to form a stable cargo flow at different stages of deposit mining. A stable cargo flow is a flow of cargo moved by vehicles along the mine openings, transport communications and structures, ensuring design target values of the mining and technical system in terms of volumes and quality of cargo flow.

In [17] the structure, stripping method and schemes as well as the available definitions, were analysed. The results of analysis as well as the proposed structure of the stripping system are presented in Table 1. The orange area includes elements and parameters that follow from the definition, the yellow area includes those based on indirect features.

Table 1

Structure of stripping method, scheme and system

|

Type of transport |

Type of mine opening or structure |

Parameters of workings or structures (width, inclination angle) of mine opening or structure |

Shape of route |

Depthwise range of transport use |

Type of loading point |

Depth of loading point |

Planned period of use |

Purpose of workings (structures) |

|

|

Stripping method |

|

|

|

|

|

||

|

|

Stripping scheme |

|

|

|

|

|||

|

Stripping system |

||||||||

The proposed definition of the stripping system displays the parameters that can be used as classification features when describing the system:

- transport vehicles – type and model of the vehicle used, range of use by open pit depth;

- mine openings – type, purpose, width, inclination angle, route shape, location of workings, transport devices on open pit walls;

- loading points – type, quantity, location depth.

The stripping system is designed in detail for the current stage of development and is enlarged for the entire planned period of deposit mining. During open pit operations, the stripping system can undergo changes. Individual parameters of the system elements can change during the current stage of development; more global changes occur when moving to another stage or method of mining [32]. The stripping system changes in accordance with the selected strategy for the MTS development (Table 2). Another alternative strategy for the MTS development is termination of ore mining at the deposit and further use of the forming spaces as man-made georesources [33-35].

Table 2

Types of changes in the stripping system and their specific features

|

Types of MTS development strategies |

Specific features of changes made |

Variable parameters of stripping system |

|

Changes in parameters at the current mining stage |

Changes do not imply adjustments to the final outline of the open pit |

Transport model, parameters of mine openings and loading points |

|

Transition to a new stage of open pit mining |

Parameters of stripping system are designed taking into account the new outline of the open pit |

Type, model of transport, stripping scheme, parameters of mine openings, loading points |

|

Transition to the new mining method |

Integration of parameters of the quarry and underground mine stripping system is accomplished |

Type, model of transport, stripping scheme, type and parameters of mine openings, parameters of loading points |

Changes in the stripping system can proceed as follows:

- During the development stage, changes are most often caused by technical re-equipment in connection with acquisition of dump trucks of other models. For the new models of vehicles, the width and inclination angle of workings can be revised. For combined types of transport, the range of using each type by depth can change, up to complete rejection of one of the types of transport. In the course of changes, the pit outline is not revised.

- When passing to a new stage of open pit mining, the final outline of the pit changes and the stripping system is significantly transformed. In this case, the stripping scheme can change completely, or individual elements of the old scheme can be used as auxiliary ones at the new stage. Such parameters of the stripping system as the type of transport and the model of transport vehicles, the parameters of mine openings and loading points can change.

- When switching to an underground mining method, a new underground mine opening scheme is created, which involves driving new workings and organizing underground mine transport operations along them. In this case, the open pit stripping scheme can be used unchanged, can be partially changed for the purposes of the underground mine, or can be dismantled or not used at all. In such event, the type of transport, the model of vehicles, the shape of the route, the parameters of workings and transport devices, the number of points for rock mass hoisting from the pit change. When switching to the open pit and underground mining method, labour intensity of changing the stripping system is largely determined by the function which the existing open pit stripping system will perform for further operation of the underground mine.

Choice of the development strategy of the mining and technical system for the planned stage of mining is accompanied by a change in the stripping system. The described approach to the comprehensive assessment of the stripping system allows determining the efficiency of the considered strategies for the development of the mining and technical system taking into account the character-ristics of each stage of development.

The approach was tested under conditions an iron ore plant in the Ural region [17]. Four strategies for the MTS development were assessed: A1 – change in parameters of the current stage; A2 – transition to a new stage of OPM; A3 – transition to the open-underground method, and A4 – termination of the mining plant operations. Based on the calculation results, it was ascertained that strategy A3 has the highest rank (rank coefficient value 0.5908); strategy A2 has the second rank (0.5757), the third rank is taken by A4 (0.5647), and A1 has the lowest rank (0.4226). Strategy A3 was determined as an alternative for the MTS development. For the selected option, the value of total discounted income was calculated amounting to over 1.6 billion rub. The economic effect of the chosen development strategy is attained by transition to development of peripheral reserves of the deposit, the involvement of additional volumes of ore in mining compared to other strategies, reduction of capital expenditures on the construction of an underground mine and operating costs for the delivery of ore during stagewise formation of the stripping system.

Conclusion

The influence of external and internal factors on the operation of a mining plant necessitates to change the types of opencast transport used and to revise the stripping scheme. In this case, opencast transport and the stripping scheme are considered in the structure of different systems: transport, mining transport, and logistics. Current definition of the stripping system actually duplicates the concept of the stripping scheme and is not used in designing and research. It is proposed to clarify the existing terminology and apply a systems approach to substantiate the structure, parameters, and functions of the stripping system. Such approach allows a comprehensive consideration of the choice of the type of opencast transport taking into account the parameters of the mine openings and structures required for the open pit operation, and designing the optimal structure of the stripping system that allows minimizing the costs of deposit development. The highest costs in the stripping system are typical for the development of deep, steeply dipping deposits. Due to the long periods of deposit development, mining is accomplished by stages with subsequent transition to the underground mining method. During transition from one stage to another or a change of the mining method, it is most difficult to change the open pit stripping system. Possible options for transforming the stripping system produced during the period of changing the MTS development strategy are considered. To assess the efficiency of the stripping system, a rank coefficient is proposed, the calculation of which is based on the use of a combination of multicriteria analysis methods Fuzzy AHP and MARCOS. A calculation is performed for an iron ore plant in the Ural region, which made it possible to determine the preferred method for the development of the MTS strategy – transition to the combined mining method which involves compilation of a joint scheme for the open pit and underground mine stripping.

References

- Paricheh M., Osanloo M. Determination of the optimum in-pit crusher location in open-pit mining under production and operating cost uncertainties. 6th International Conference on Computer Applications in the Minerals Industries, 5-7 October 2016, Istanbul, Turkey. Istanbul: AGRO ARGE Danışmanlık San. ve Tic. A.Ş., 2016. № CAMI2016-34.

- Teplicka K., Hurna S. Optimizing internal transport in terms of technical parameters in a mining company. Acta logistica. 2023. Vol. 10. Iss. 1, p. 95-103. DOI: 10.22306/al.v10i1.360

- Yakovlev V.L., Bersenev V.A., Glebov A.V. et al. Selecting Cyclical-and-Continuous Process Flow Diagrams for Deep Open Pit Mines. Journal of Mining Science. Vol. 55. N 5, p. 783-788. DOI: 10.1134/S106273911905615X

- Glebov I.A. Overview of opening schemes for deep horizons of diamond ore quarries in the focus of technology for refining reserves by tunnel exits. Problems of Subsoil Use. N 2, p. 61-72 (in Russian). DOI: 10.25635/2313-1586.2020.02.061

- Akishev A.N., Lel Yu.I., Glebov I.A. The innovative technology of stripping and mining deep kimberlite open pits. News of the Tula state university. Sciences of Earth. Iss. 3, p. 111-123 (in Russian). DOI: 10.25635/IM.2019.87.37803

- Samimi Namin F., Ghasemzadeh H., Aghajari A.M. A comprehensive approach to selecting mine transportation system using AHP and FUZZY-TOPSIS. Decision Making and Analysis. 2023. Vol. 1. Iss. 1, p. 23-39. DOI: 10.55976/dma.12023117323-39

- Shi Qiang Liu, Zhaoyun Lin, Debiao Li et al. Recent Research Agendas in Mining Equipment Management: A Review. Mining. 2022. Vol. 2. Iss. 4, p. 769-790. DOI: 10.3390/mining2040043

- Dongzhi Gao, Ronggang Han, Tengteng Li et al. Experimental Study on Energy Consumption and Emissions of Heavy-Duty Hybrid Dump Truck. SAE International Journal of Advances and Current Practices in Mobility. 2024. Vol. 6. Iss. 4, p. 2359-2365. DOI: 10.4271/2023-01-7014

- Kanyepe J. Transport management practices and performance of diamond mining companies in Zimbabwe. Cogent Business & Management. 2023. Vol. 10. Iss. 2. N 2216429. DOI: 10.1080/23311975.2023.2216429

- Al Habib N., Ben-Awuah E., Askari-Nasab H. Short-term planning of open pit mines with Semi-Mobile IPCC: a shovel allocation model. International Journal of Mining, Reclamation and Environment. 2023. Vol. 38. Iss. 3, p. 236-266. DOI: 10.1080/17480930.2023.2262823

- Iakovlev V.L., Iakovlev V.A. Open pit transport systems formation with the account of adaptation to deep-lying complex-structured deposits development changing conditions. News of the Higher Institutions. Mining Journal. N 6, p. 118-126 (in Russian). DOI: 10.21440/0536-1028-2018-6-118-126

- Drizhenko A.Yu. Development of open pit mining-and-transportation system theory. Mining Informational and Analytical Bulletin. N 10, p. 134-142 (in Russian).

- Osintsev N.A. Multi-Criteria Decision-Making Methods in Green Logistics. World of Transport and Transportation. Vol. 19. Iss. 5 (96), p. 231-240. DOI: 10.30932/1992-3252-2021-19-5-13

- Malli T., Mizrak Ozfirat P., Yetkin M.E., Ozfirat M.K. Truck Selection with the Fuzzy-WSM Method in Transportation Systems of Open Pit Mines. Tehnički vjesnik. 2021. Vol. 28. N 1, p. 58-64. DOI: 10.17559/TV-20190910100025

- Nehring M., Knights P.F., Kizil M.S., Hay E. A comparison of strategic mine planning approaches for in-pit crushing and conveying, and truck/shovel systems. International Journal of Mining Science and Technology. 2018. Vol. 28. Iss. 2, p. 205-214. DOI: 10.1016/j.ijmst.2017.12.026

- Shi Qiang Liu, Zhaoyun Lin, Debiao Li et al. Recent Research Agendas in Mining Equipment Management: A Review. Mining. 2022. Vol. 2. Iss. 4, p. 769-790. DOI: 10.3390/mining2040043

- Burmistrov K.V. Geotechnological solutions on formation of a stripping system for deep open pit floors. Magnitogorsk: Izd-vo Magnitogorskogo gosudarstvennogo tekhnicheskogo universiteta im. G.I.Nosova, 2023, p. 297.

- Sheshko E.E., Pestrikov O.V. Justification of the required hold-down dependence on the length and angle of high-angle pressure belt conveyor. Gornyi zhurnal. N 5, p. 83-87 (in Russian). DOI: 10.17580/gzh.2021.05.10

- Babii K., Chetveryk M., Perehudov V. et al. Features of using equipment for in-pit crushing and conveying technology on the open pit walls with complex structure. Mining of Mineral Deposits. 2022. Vol. 16. Iss. 4, p. 96-102. DOI: 10.33271/mining16.04.096

- Minkin A., Börsting P., Becker N. Pipe Conveying the next Stage: A new Technology for Steep Incline High Capacity Open Pit Conveying. bulk solids handling. 2016. Vol. 36. N 2, p. 16-23.

- Chendyrev M.A. Evaluation of technology and conditions of slope in-career hoisting installation. Problems of Subsoil Use. N 2, p. 37-49 (in Russian). DOI: 10.25635/2313-1586.2020.02.037

- Burmistrov K.V. Development of geotechnological solutions on maintaining the stability of mining plants operation by stagewise stripping of reserves in deep floors during open and combined mining of steeply dipping deposits: Avtoref. dis. ... d-ra tekhn. nauk. Magnitogorsk: Magnitogorskii gosudarstvennyi tekhnicheskii universitet im. G.I.Nosova, 2022, p. 35.

- Rakhmangulov A., Burmistrov K., Osintsev N. Sustainable Open Pit Mining and Technical Systems: Concept, Principles, and Indicators. Sustainability. 2021. Vol. 13. Iss. 3. N 1101. DOI: 10.3390/su13031101

- Saaty T.L. Decision making with the analytic hierarchy process. Services Sciences. 2008. Vol. 1. N 1, p. 83-98. DOI: 10.1504/IJSSCI.2008.017590

- Leal J.E. AHP-express: A simplified version of the analytical hierarchy process method. MethodsX. 2020. Vol. 7. N 100748. DOI: 10.1016/j.mex.2019.11.021

- Yazdani-Chamzini A. An integrated fuzzy multi criteria group decision making model for handling equipment selection. Journal of Civil Engineering and Management. 2014. Vol. 20. N 5, p. 660-673. DOI: 10.3846/13923730.2013.802714

- Blagojević A., Vesković S., Kasalica S. et al. The application of the fuzzy AHP and DEA for measuring the efficiency of freight transport railway undertakings. Operational Research in Engineering Sciences: Theory and Applications. 2020. Vol. 3. Iss. 2, p. 1-23. DOI: 10.31181/oresta2003001b

- Gupta P., Mehlawat M.K., Aggarwal U., Charles V. An integrated AHP-DEA multi-objective optimization model for sustainable transportation in mining industry. Resources Policy. 2021. Vol. 71. N 101180. DOI: 10.1016/j.resourpol.2018.04.007

- Pamucar D., Ecer F., Deveci M. Assessment of alternative fuel vehicles for sustainable road transportation of United States using integrated fuzzy FUCOM and neutrosophic fuzzy MARCOS methodology. Science of The Total Environment. 2021. Vol. 788. N 147763. DOI: 10.1016/j.scitotenv.2021.147763

- Stević Ž., Brković N. A Novel Integrated FUCOM-MARCOS Model for Evaluation of Human Resources in a Transport Company. Logistics. 2020. Vol. 4. Iss. 1. N 4. DOI: 10.3390/logistics4010004

- Pan Wu, Guoyan Zhao, Yang Li. Green Mining Strategy Selection via an Integrated SWOT-PEST Analysis and Fuzzy AHP-MARCOS Approach. Sustainability. 2022. Vol. 14. Iss. 13. N 577. DOI: 10.3390/su14137577

- Yakovlev V.L., Sokolov I.V., Sakantsev G.G., Kravchuk I.L. Transition processes in hybrid mineral mining. Gornyi zhurnal. N 7, p. 46-50 (in Russian). DOI: 10.17580/gzh.2017.07.08

- Khayrutdinov M.M., Kaung P.A., Chzho M.M., Tyulyaeva Yu.S. Ensuring Environmental Safety in the Implementation of the Resource-renewable Technologies. Occupational Safety in Industry. N 5, p. 57-62 (in Russian). DOI: 10.24000/0409-2961-2022-5-57-62

- Argimbaev K.R. Technogenic Deposit Reclamation as an Environmental Protection Factor. Journal of Engineering and Applied Sciences. 2019. Vol. 14. Iss. 17, p. 6342-6345. DOI: 10.36478/jeasci.2019.6342.6345

- Golik V.I., Klyuev R.V., Martyushev N.V. et al. Technology for Nonwaste Recovery of Tailings of the Mizur Mining and Processing Plant. Metallurgist. 2023. Vol. 66. Iss. 11-12, p. 1476-1480. DOI: 10.1007/s11015-023-01462-y

References

- Paricheh M., Osanloo M. Determination of the optimum in-pit crusher location in open-pit mining under production and operating cost uncertainties. 6th International Conference on Computer Applications in the Minerals Industries, 5-7 October 2016, Istanbul, Turkey. Istanbul: AGRO ARGE Danışmanlık San. ve Tic. A.Ş., 2016. № CAMI2016-34.

- Teplicka K., Hurna S. Optimizing internal transport in terms of technical parameters in a mining company. Acta logistica. 2023. Vol. 10. Iss. 1, p. 95-103. DOI: 10.22306/al.v10i1.360

- Yakovlev V.L., Bersenev V.A., Glebov A.V. et al. Selecting Cyclical-and-Continuous Process Flow Diagrams for Deep Open Pit Mines. Journal of Mining Science. 2019. Vol. 55. N 5, p. 783-788. DOI: 10.1134/S106273911905615X

- Glebov I.A. Overview of opening schemes for deep horizons of diamond ore quarries in the focus of technology for refining reserves by tunnel exits. Problems of Subsoil Use. 2020. N 2, p. 61-72 (in Russian). DOI: 10.25635/2313-1586.2020.02.061

- Akishev A.N., Lel Yu.I., Glebov I.A. The innovative technology of stripping and mining deep kimberlite open pits. News of the Tula state university. Sciences of Earth. 2019. Iss. 3, p. 111-123 (in Russian). DOI: 10.25635/IM.2019.87.37803

- Samimi Namin F., Ghasemzadeh H., Aghajari A.M. A comprehensive approach to selecting mine transportation system using AHP and FUZZY-TOPSIS. Decision Making and Analysis. 2023. Vol. 1. Iss. 1, p. 23-39. DOI: 10.55976/dma.12023117323-39

- Shi Qiang Liu, Zhaoyun Lin, Debiao Li et al. Recent Research Agendas in Mining Equipment Management: A Review. Mining. 2022. Vol. 2. Iss. 4, p. 769-790. DOI: 10.3390/mining2040043

- Dongzhi Gao, Ronggang Han, Tengteng Li et al. Experimental Study on Energy Consumption and Emissions of Heavy-Duty Hybrid Dump Truck. SAE International Journal of Advances and Current Practices in Mobility. 2024. Vol. 6. Iss. 4, p. 2359-2365. DOI: 10.4271/2023-01-7014

- Kanyepe J. Transport management practices and performance of diamond mining companies in Zimbabwe. Cogent Business & Management. 2023. Vol. 10. Iss. 2. N 2216429. DOI: 10.1080/23311975.2023.2216429

- Al Habib N., Ben-Awuah E., Askari-Nasab H. Short-term planning of open pit mines with Semi-Mobile IPCC: a shovel allocation model. International Journal of Mining, Reclamation and Environment. 2023. Vol. 38. Iss. 3, p. 236-266. DOI: 10.1080/17480930.2023.2262823

- Iakovlev V.L., Iakovlev V.A. Open pit transport systems formation with the account of adaptation to deep-lying complex-structured deposits development changing conditions. News of the Higher Institutions. Mining Journal. 2018. N 6, p. 118-126 (in Russian). DOI: 10.21440/0536-1028-2018-6-118-126

- Drizhenko A.Yu. Development of open pit mining-and-transportation system theory. Mining Informational and Analytical Bulletin. 2014. N 10, p. 134-142 (in Russian).

- Osintsev N.A. Multi-Criteria Decision-Making Methods in Green Logistics. World of Transport and Transportation. 2021. Vol. 19. Iss. 5 (96), p. 231-240. DOI: 10.30932/1992-3252-2021-19-5-13

- Malli T., Mizrak Ozfirat P., Yetkin M.E., Ozfirat M.K. Truck Selection with the Fuzzy-WSM Method in Transportation Systems of Open Pit Mines. Tehnički vjesnik. 2021. Vol. 28. N 1, p. 58-64. DOI: 10.17559/TV-20190910100025

- Nehring M., Knights P.F., Kizil M.S., Hay E. A comparison of strategic mine planning approaches for in-pit crushing and conveying, and truck/shovel systems. International Journal of Mining Science and Technology. 2018. Vol. 28. Iss. 2, p. 205-214. DOI: 10.1016/j.ijmst.2017.12.026

- Shi Qiang Liu, Zhaoyun Lin, Debiao Li et al. Recent Research Agendas in Mining Equipment Management: A Review. Mining. 2022. Vol. 2. Iss. 4, p. 769-790. DOI: 10.3390/mining2040043

- Burmistrov K.V. Geotechnological solutions on formation of a stripping system for deep open pit floors. Magnitogorsk: Izd-vo Magnitogorskogo gosudarstvennogo tekhnicheskogo universiteta im. G.I.Nosova, 2023, p. 297.

- Sheshko E.E., Pestrikov O.V. Justification of the required hold-down dependence on the length and angle of high-angle pressure belt conveyor. Gornyi zhurnal. 2021. N 5, p. 83-87 (in Russian). DOI: 10.17580/gzh.2021.05.10

- Babii K., Chetveryk M., Perehudov V. et al. Features of using equipment for in-pit crushing and conveying technology on the open pit walls with complex structure. Mining of Mineral Deposits. 2022. Vol. 16. Iss. 4, p. 96-102. DOI: 10.33271/mining16.04.096

- Minkin A., Börsting P., Becker N. Pipe Conveying the next Stage: A new Technology for Steep Incline High Capacity Open Pit Conveying. bulk solids handling. 2016. Vol. 36. N 2, p. 16-23.

- Chendyrev M.A. Evaluation of technology and conditions of slope in-career hoisting installation. Problems of Subsoil Use. 2020. N 2, p. 37-49 (in Russian). DOI: 10.25635/2313-1586.2020.02.037

- Burmistrov K.V. Development of geotechnological solutions on maintaining the stability of mining plants operation by stagewise stripping of reserves in deep floors during open and combined mining of steeply dipping deposits: Avtoref. dis. ... d-ra tekhn. nauk. Magnitogorsk: Magnitogorskii gosudarstvennyi tekhnicheskii universitet im. G.I.Nosova, 2022, p. 35.

- Rakhmangulov A., Burmistrov K., Osintsev N. Sustainable Open Pit Mining and Technical Systems: Concept, Principles, and Indicators. Sustainability. 2021. Vol. 13. Iss. 3. N 1101. DOI: 10.3390/su13031101

- Saaty T.L. Decision making with the analytic hierarchy process. Services Sciences. 2008. Vol. 1. N 1, p. 83-98. DOI: 10.1504/IJSSCI.2008.017590

- Leal J.E. AHP-express: A simplified version of the analytical hierarchy process method. MethodsX. 2020. Vol. 7. N 100748. DOI: 10.1016/j.mex.2019.11.021

- Yazdani-Chamzini A. An integrated fuzzy multi criteria group decision making model for handling equipment selection. Journal of Civil Engineering and Management. 2014. Vol. 20. N 5, p. 660-673. DOI: 10.3846/13923730.2013.802714

- Blagojević A., Vesković S., Kasalica S. et al. The application of the fuzzy AHP and DEA for measuring the efficiency of freight transport railway undertakings. Operational Research in Engineering Sciences: Theory and Applications. 2020. Vol. 3. Iss. 2, p. 1-23. DOI: 10.31181/oresta2003001b

- Gupta P., Mehlawat M.K., Aggarwal U., Charles V. An integrated AHP-DEA multi-objective optimization model for sustainable transportation in mining industry. Resources Policy. 2021. Vol. 71. N 101180. DOI: 10.1016/j.resourpol.2018.04.007

- Pamucar D., Ecer F., Deveci M. Assessment of alternative fuel vehicles for sustainable road transportation of United States using integrated fuzzy FUCOM and neutrosophic fuzzy MARCOS methodology. Science of The Total Environment. 2021. Vol. 788. N 147763. DOI: 10.1016/j.scitotenv.2021.147763

- Stević Ž., Brković N. A Novel Integrated FUCOM-MARCOS Model for Evaluation of Human Resources in a Transport Company. Logistics. 2020. Vol. 4. Iss. 1. N 4. DOI: 10.3390/logistics4010004

- Pan Wu, Guoyan Zhao, Yang Li. Green Mining Strategy Selection via an Integrated SWOT-PEST Analysis and Fuzzy AHP-MARCOS Approach. Sustainability. 2022. Vol. 14. Iss. 13. N 577. DOI: 10.3390/su14137577

- Yakovlev V.L., Sokolov I.V., Sakantsev G.G., Kravchuk I.L. Transition processes in hybrid mineral mining. Gornyi zhurnal. 2017. N 7, p. 46-50 (in Russian). DOI: 10.17580/gzh.2017.07.08

- Khayrutdinov M.M., Kaung P.A., Chzho M.M., Tyulyaeva Yu.S. Ensuring Environmental Safety in the Implementation of the Resource-renewable Technologies. Occupational Safety in Industry. 2022. N 5, p. 57-62 (in Russian). DOI: 10.24000/0409-2961-2022-5-57-62

- Argimbaev K.R. Technogenic Deposit Reclamation as an Environmental Protection Factor. Journal of Engineering and Applied Sciences. 2019. Vol. 14. Iss. 17, p. 6342-6345. DOI: 10.36478/jeasci.2019.6342.6345

- Golik V.I., Klyuev R.V., Martyushev N.V. et al. Technology for Nonwaste Recovery of Tailings of the Mizur Mining and Processing Plant. Metallurgist. 2023. Vol. 66. Iss. 11-12, p. 1476-1480. DOI: 10.1007/s11015-023-01462-y