Specific action of collector from phosphoric acid alkyl esters class in flotation of apatite-nepheline ores

- 1 — Ph.D. Leading Researcher Mining Institute, KSC RAS ▪ Orcid

- 2 — Senior Researcher Mining Institute, KSC RAS ▪ Orcid

- 3 — Ph.D. Researcher Geological Institute, KSC RAS ▪ Orcid

- 4 — Ph.D. Director of Department Kirovsk Branch of Apatit ▪ Orcid

Abstract

Increasing amount of apatite-nepheline ores with complex mineral composition involved in processing, growing content of the associated minerals in ore which are similar in their floatability to apatite lead to the necessity of using highly selective collectors. Non-frothing flotation method gave a comparative assessment of floatability of pure minerals and demonstrated a high selectivity of the action of phosphoric acid esters in relation to apatite. The effect of four reagent modes differing in the number of selective synthetic collectors was studied using the example of flotation of an apatite-nepheline ore sample containing 17.27 % apatite and 40.18 % nepheline. Mineralogical analysis of crushed ore showed that it contained two apatite varieties – coarse-grained free and finer poikilitic as inclusions in rock-forming minerals. Free apatite opens and occurs as open grains even in coarse-grained (+0.16 mm) grades. Poikilitic apatite occurs as intergrowths with different minerals, mainly with nepheline and its alteration products (natrolite, spreustein, sodalite, etc.), and pyroxene. Optical microscopy demonstrated that a growing share of reagent from the phosphoric acid oxyethylated esters class in the composition of the collector mixture allows improving the quality of the produced apatite concentrates by reducing the number of apatite intergrowths with nepheline and pyroxenes in the concentrates. In the concentrate obtained in the most selective reagent mode, the intergrowths are characterized by a 50/50 and higher ratio in favour of apatite. Concentrates of lower quality comprised intergrowths with lower apatite content, to 20/80 or less.

Introduction

The Khibiny deposits of complex apatite-nepheline ores have the world largest reserves of phosphate raw materials [1, 2]. Phosphorus-bearing ores as raw materials for the production of mineral fertilizers are among the strategic types of mineral raw materials that ensure the economic (food) security of the country [3]. However, over the years of mining such deposits Р2О5 content in ore decreased from 29 to 12 %, and in recent years, poor ores and ores characterized by a complex mineral composition were increasingly involved in processing [4, 5]. Total content of the main minerals of ore – apatite and nepheline – decreases; therefore, the proportion of the associated minerals including those similar in their flotation activity to apatite increases. In flotation of such ores, the negative influence of ions in the liquid phase of flotation pulp is more pronounced [6, 7]. Upgrading of the process flow diagram [8] and the use of selectively acting reagents in flotation are of utmost importance [9, 10]. Increase of the separation efficiency of mineral complexes can be achieved, on the one hand, by using depressants [11, 12]. On the other hand, the introduction of selective collectors, for example, polyacrylates [13] or amino acid derivatives [14, 15] into the composition of the reagent mixture makes it possible to flexibly regulate its properties.

Fatty acids are traditional reagents for apatite flotation [16, 17]; their sources are wood processing products [18] and different vegetable oils [19, 20]. However, a low selectivity of action [21] and sensitivity to flotation conditions [22, 23] do not allow attaining the required flotation process performance for ores with complex mineral composition [24]. Therefore, fatty acids, as a rule, are used in combination with reagents that differ in composition and structure [25, 26]. Thus, the observed synergistic effect of the joint action of fatty acids and reagents Span 80 (sorbitanoleate) and alkyl sulphonates is due to their joint adsorption on the surface of apatite as well as preferential adsorption on the surface of rock minerals [27, 28]. Oxyethylated alkylphenols and aliphatic alcohols promote stronger fixation of fatty acids on the surface of apatite [29]. The combination of sodium oleate with Atrac 50S reagent and depressants ensures a major difference between the floatability of apatite, calcite and quartz [30]. Studies on flotation of different samples of apatite-nepheline ore demonstrated a high selectivity of Phospholan PE-65 reagent, which is a mixture of mono- and diesters of phosphoric acid and oxyethylated fatty alcohols, in relation to apatite [9, 23, 31]. A growing share of this component to ~1/3 in the collector mixture (CM) in combination with tall oil fatty acids (TOFA) improves the quality of the apatite concentrate obtained by flotation from apatite-nepheline ores [32]. A positive effect of joint action is also manifested by a growing recovery of apatite and is explained by the authors by the formation of combined supramolecular structures with a weaker dispersion interaction in the solution, which contribute to increase in adsorption of reagents on the mineral surface [33].

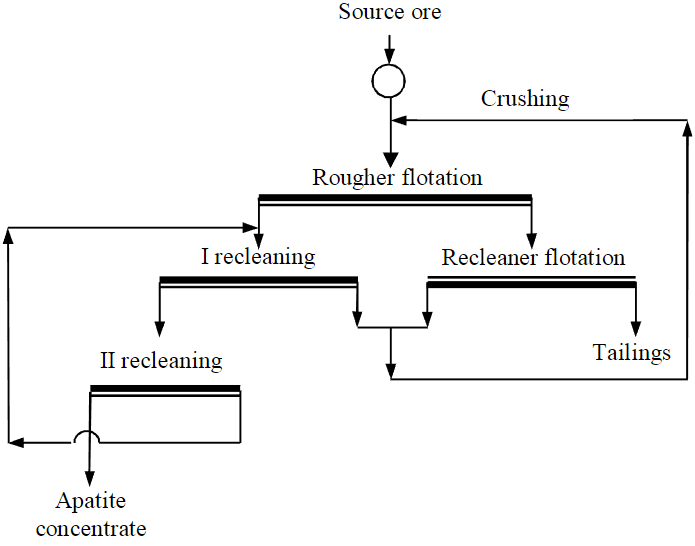

Fig.1. Scheme of a closed cycle laboratory flotation of apatite-nepheline ore

The purpose of this work is to assess the efficiency and selectivity of flotation separation of apatite-nepheline ore minerals depending on the CM composition.

Materials and methods

A core sample of apatite-nepheline ore from the Rasvumchorr Plateau deposit was taken for the study. Mineral composition of the source ore was determined by X-ray phase method using D2 PHASER powder X-ray diffractometer manufactured by Bruker AXS GmbH (Germany). The content of the main components of ore and its beneficiation products was determined by X-ray diffraction and spectrophotometry using UNICO spectrophotometer (Р2О5).

Ore was crushed to a particle size –1.6 mm sequentially on laboratory jaw and roll crushers. Crushing of an ore subsample weighing 500 g to flotation size was performed in a laboratory ball mill with S:L:B ratio 1:0.8:6. After crushing, the content in ore of –0.071 mm grade was 35.9 %, and of +0.16 mm grade – 30.8 %. Ore flotation was performed in the laboratory flotation machine in a closed cycle using recycled water from the beneficiation plant. The flotation scheme included rougher flotation, recleaning flotation and two recleaning operations (Fig.1). Liquid glass depressant (LGl) was fed into crushing; pH of apatite flotation was maintained at 9.6-9.8 by adding the required amount of sodium hydroxide to the pulp.

Flotation results were assessed from the main process performance, %: content of the useful component in the concentrate βР2О5 and in tailings θР2О5; product yield γ and recovery of the determined component ε. The recovery was calculated from the formula ε = (βγ)/α, where α is the content of the determined component in flotation feed, %.

In ore flotation, the CM containing wood processing products (a mixture of tall oils) and synthetic reagents Phospholan PE-65, which are a mixture of mono- and diesters of phosphoric acid and oxyethylated fatty alcohols, and Atrac-2600 – amino acid derivatives was used. The interaction efficiency of reagents under consideration with minerals was assessed by the non-frothing flotation method. Flotation in the Hallimond tube was performed on monomineral fractions of apatite and aegirine with particle size of –0.16+0.1 mm; flotation pH was 9.7-9.8. Agitation time of mineral with regulator (0.1 % NaOH solution) is 1 min, with collector – 2 min. Flotation time 3 min, air flow rate 5.3 ml/min. In non-frothing flotation, Phospholan PE-65 and ATRAC-2600 reagents and sodium oleate as a representative of fatty acid collectors were tested as a monocollector. All collectors in laboratory ore flotation and non-frothing flotation of pure minerals were used as solutions of their sodium salts obtained by saponification of the corresponding reagent with sodium hydroxide.

The resulting ore processing products (source ore, concentrates and tailings) were investigated by optical microscopy in artificial polished sections based on epoxy resin under Leica DM 2500P ore-petrographic polarizing microscope. Express diagnostics of minerals in polished sections was accomplished by Raman spectroscopy with EnSpectr R532 spectrometer (manufactured by OOO “Spectr-M”, Institute of Solid State Physics of RAS, Chernogolovka) combined with Olympus BX-43 optical microscope at the Mining Institute of the Federal Research Centre “Kola Science Centre of the Russian Academy of Sciences”, Apatity. Laser power (with a wavelength of 532 nm) was 18 mW, spectral resolution 5-8 cm–1, microscope lens 20 × (NA 0.4), exposure time 500 ms, number of repetitions 20, accuracy of wave number determination did not exceed ±1 cm–1, laser beam diameter about 2 µm. Minerals were determined by matching the spectra with standards from the RRUFF DB [34].

Discussion of results

The studied sample of apatite-nepheline ore was characterized by a low content of fluorapatite (hereinafter referred to as apatite) – 17.27 wt.% and a high content of nepheline – 40.18 wt.% (Table 1). The main components in the apatite-nepheline ore sample, wt.%: P2O5 – 7.01; Al2O3tot – 17.46; TiO2 – 2.70; Fetot – 5.09; K2O – 3.85; Na2O – 8.39; Na2O/K2O – 2.18. Ore was a mixture of both normal and “oxidized” ore. This is indicated by the presence of fragments of spreustein, altered nepheline, natrolite with fine sulphide dissemination as well as apatite with partially dissolved boundaries. Such apatite is usually confined to pyroxene.

Table 1

Mineral composition of ore sample

|

Mineral |

Content in sample, wt.% |

Mineral |

Content in sample, wt.% |

|

|

Fluorapatite |

17.27 |

Zeolite |

6.90 |

|

|

Nepheline |

40.18 |

including natrolite |

5.39 |

|

|

Pyroxene |

5.24 |

Titanite |

2.89 |

|

|

Amphibole |

3.91 |

Ilmenite |

0.26 |

|

|

Feldspar |

11.92 |

Titaniferous magnetite |

0.44 |

|

|

Cancrinite |

0.86 |

Lamprophyllite |

1.28 |

|

|

Sodalite |

0.36 |

Mica |

6.60 |

|

|

|

|

Clayey mineral |

1.89 |

|

|

Total |

100 |

|

|

|

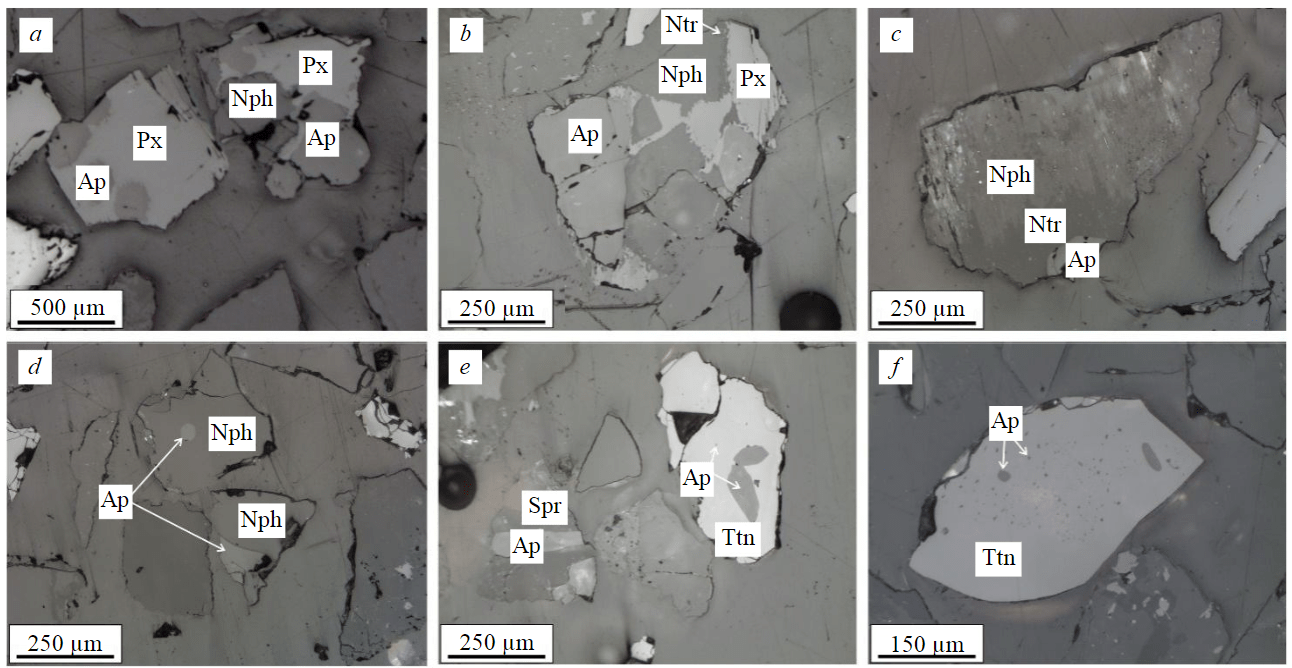

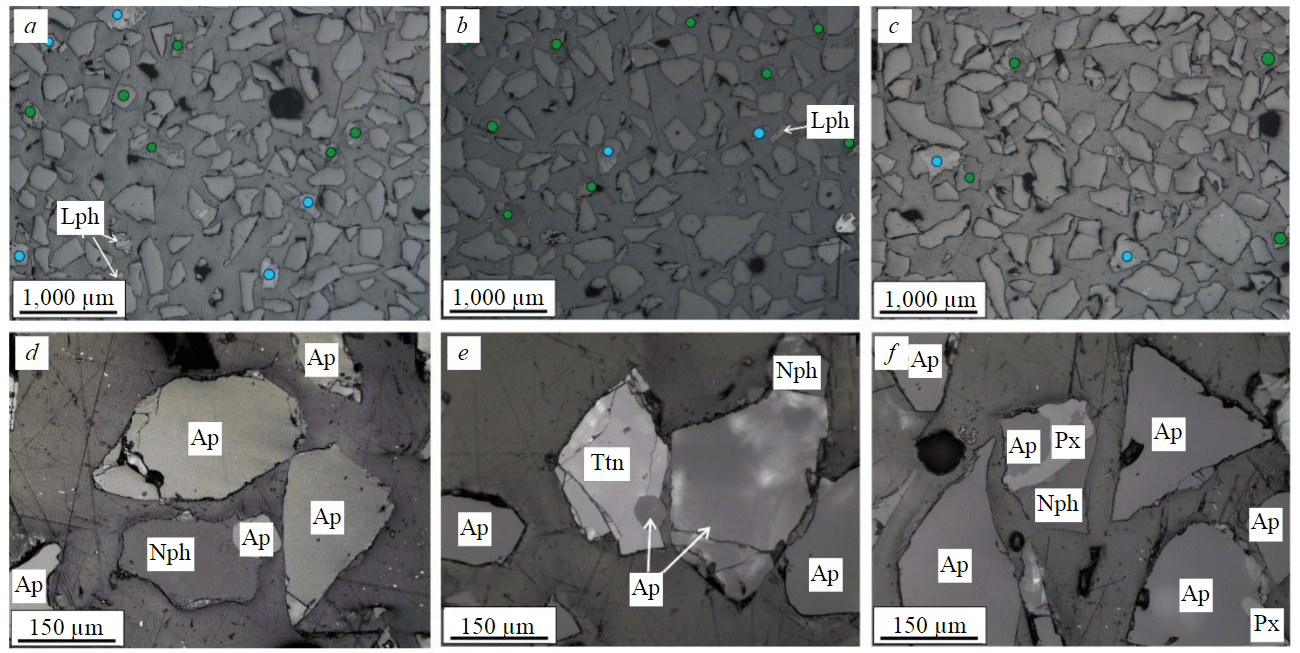

The study of crushed source ore showed that ore contained two morphological varieties of apatite – coarse-grained free and finer poikilitic as inclusions in rock-forming minerals, which is typical for the Khibiny apatite-nepheline ores [5]. Free apatite opens and occurs as open grains even in coarse-grained (+0.16 mm) grades [35]. Poikilitic apatite occurs as intergrowths with different minerals, mainly with nepheline and its alteration products (natrolite, spreustein, sodalite, etc.), and pyroxene (Fig.2). Such apatite in coarse-grained grades occurs as intergrowths. It has also several varieties. Coarse-grained poikilitic apatite will open with further crushing, but ore contains fragments, for example, nepheline with single small grains of apatite or titanite with fine emulsion dissemination of apatite. Recovery of such apatite is difficult or even impossible.

Fig.2. Apatite intergrowths in source ore: a, b – multicomponent intergrowths of poikilitic apatite with pyroxene and nepheline; c – partly opened remnant of an apatite grain at the margin of nepheline-natrolite aggregate; d, e – two-component intergrowths-inclusions of finer poikilitic apatite in nepheline and titanite; f – fine emulsion impregnation of apatite in titanite. Photo in reflected polarized light. Ap – apatite; Nph – nepheline; Ntr – natrolite; Px – pyroxene; Spr – spreustein; Ttn – titanite

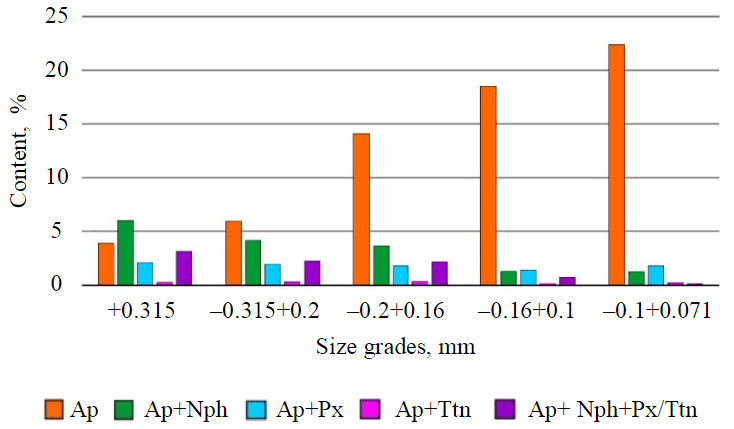

Fig.3. Size grade distribution of open apatite and apatite intergrowths with other minerals by class size in crushed ore

Diagram (Fig.3) shows the results of analysing intergrowths of crushed ore screened into five size grades. The content of open apatite grains naturally increases with decreasing size grade. There is a natural decrease in apatite intergrowths with nepheline and titanite as well as complex multicomponent intergrowths. The number of apatite intergrowths with pyroxene remains almost the same.

At the first stage, flotation tests were performed using the then accepted CM which was a mixture of 60 % tall oils and synthetic reagents – 26 % Phospholan PE-65 and 24 % Atrac 2600. The results showed that the use of this reagent mixture did not allow obtaining apatite concentrate of required quality, Р2О5 content in concentrate did not exceed 38 % (Table 2). Neither varying collector consumption, nor growing depressant consumption improved the flotation performance.

Preliminary optical analysis showed that at a given crushing size, 32 % of apatite in +0.16 mm grade was in intergrowths with nepheline and pyroxene, and, thus, low quality of the produced concentrate is obviously due to the occurrence of floated apatite intergrowths with associated minerals in the froth product. Previous studies showed that that the growing share of selective reagent Phospholan PE-65 in the mixture allows increasing Р2О5 content in the concentrate [32]. The CM with 40 % of this reagent in combination with 60 % tall oils was tested. As a result, at the same consumption of collector and depressant, the quality of concentrate improved by ~0.5 % with a natural decrease in Р2О5 recovery (Table 2).

Table 2

Results of apatite-nepheline ore sample flotation on recycled water

|

Reagent mode |

Reagent consumption, g/t |

Process performance, % |

|||||

|

LGi |

Collector |

αP2О5 |

γ |

βР2О5 |

εР2О5 |

θР2О5 |

|

|

1. Collector mixture |

90 |

75 |

7.28 |

18.1 |

37.80 |

94.0 |

0.54 |

|

90 |

60 |

7.25 |

17.8 |

37.96 |

93.0 |

0.62 |

|

|

130 |

60 |

7.19 |

17.6 |

37.93 |

93.2 |

0.59 |

|

|

2. Tall oils 60 %, Phospholan PE-65 40 % |

130 |

60 |

7.08 |

17.1 |

38.48 |

92.7 |

0.62 |

|

130 |

50 |

7.09 |

17.0 |

38.36 |

92.1 |

0.67 |

|

|

3. TOFA 60 %, Phospholan PE-65 40 % |

90 |

60 |

7.06 |

16.6 |

38.69 |

89.4 |

0,90 |

|

130 |

60 |

7.04 |

16.4 |

38.73 |

89.3 |

0.92 |

|

|

130 |

60 |

7.12 |

16.6 |

38.61 |

90.0 |

0.85 |

|

|

130 |

60 |

6.87 |

16.3 |

38.56 |

91.5 |

0.70 |

|

|

130 |

80 |

7.40 |

17.5 |

38.69 |

91.4 |

0.80 |

|

|

4. Atrac-2600 50 %, Phospholan PE-65 50 % |

130 |

60 |

7.18 |

13.8 |

39.06 |

74.8 |

2.10 |

|

130 |

90 |

6.92 |

15.0 |

39.34 |

84.8 |

1.24 |

|

|

90 |

90 |

6.98 |

15.2 |

39.02 |

85.0 |

1.24 |

|

|

90 |

105 |

7.13 |

15.9 |

38.96 |

84.3 |

1.11 |

|

Results of flotation experiments and granulometric analysis of concentrates obtained

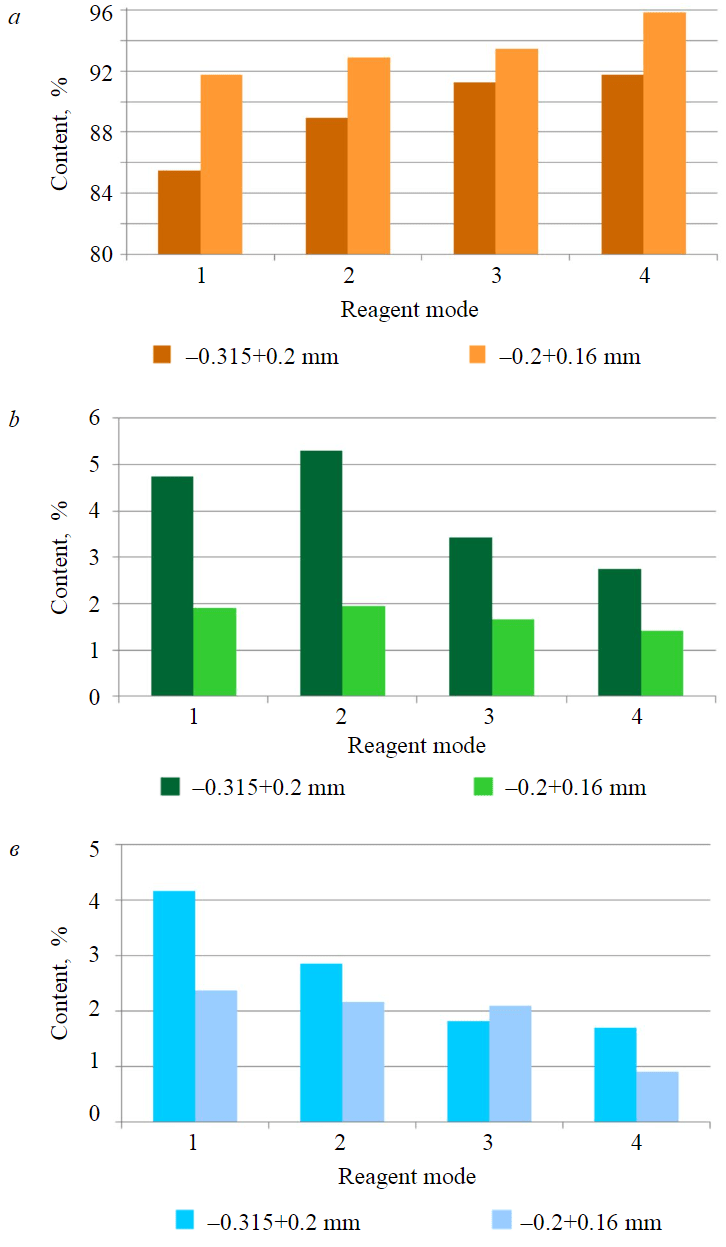

at equal collector consumption (Table 3) suggest that selective synthetic reagents Phospholan PE-65 and Atrac 2600, unlike fatty acids, do not float apatite intergrowths with associated minerals. From Table 3 and diagram in Fig.4, a pattern can be traced: the more “selective” the reagents mixture used, the lower their content in +0.16 mm grade concentrate. This correlates with results of flotation experiments.

Table 3

Content of apatite intergrowths in concentrates of size class +0.16 mm, %

|

Reagent mode |

Concentrate yield |

Share of apatite intergrowths |

Flotation performance |

|||||

|

Concentrate |

Tailings |

|||||||

|

+0.2 |

–0.07 |

+0.2 |

–0.2+0.16 |

Yield |

Content |

Recovery |

Content |

|

|

1 |

24.0 |

32.9 |

9.09 |

5.05 |

17.6 |

37.93 |

93.2 |

0.59 |

|

2 |

23.5 |

32.1 |

8.92 |

4.4 |

17.1 |

38.48 |

92.7 |

0.62 |

|

3 |

22.9 |

32.8 |

5.62 |

4.07 |

16.4 |

38.73 |

89.3 |

0.92 |

|

4 |

22.5 |

32.0 |

5.25 |

2.59 |

15.9 |

38.96 |

84.3 |

1.11 |

Notes: 1 – collector mixture (60 g/t); 2 – tall oils 60 % + Phospholan PE-65 40 % (60 g/t); 3 – TOFA 60 % + + Phospholan PE-65 40 % (60 g/t); 4 – Atrac-2600 50 % + Phospholan PE-65 50 % (105 g/t).

TOFA reagent is the most selective collector of tall products; it is an isolated fraction of fatty acids [36]. As a result of using a more selective mixture of TOFA and Phospholan PE-65 in a ratio of 60/40, a slight improvement in the quality of concentrate was recorded. However, it should be noted that there was a decrease in concentrate yield and, as a consequence, a decrease in Р2О5 recovery (see Table 2).

Studies conducted on samples representing ore from destruction zones showed that the reagents Phospholan PE-65 and Atrac-2600 in the composition of the CM allow obtaining an apatite concentrate containing at least 39 % Р2О5 with recovery not less than 93 % [37]. As monocollectors, these synthetic reagents are characterized by a rather low activity, so the consumption of the mixture of Phospholan PE-65 and

Atrac-2600 in a 50/50 ratio increased to 90-105 g/t. In these cases, an even higher quality of the resulting concentrate was recorded with significant losses in recovery (see Table 2).

Fig.4. Changes in the content of open apatite and its intergrowths in two main grades in concentrates obtained in experiments with different reagent modes: a – Ap; b – Ap+Nph; c – Ap+Px. Numbers of experiments correspond to numbers of modes in Table 3

The analysis of concentrate intergrowths obtained in ore flotation in different reagent modes at the same consumption (with the exception of Phospholan PE-65: Atrac-2600 = 50/50 mixture) showed that in case of using a more selective mixture, the share of intergrowths of apatite with pyroxenes and nepheline in the concentrate decreases. There is no decrease in the number of intergrowths with titanite, the floatability of which is comparable to apatite.

When moving from reagent mode 1 to mode 4 in grade –0.2+0.16 mm, the share of open apatite increases, the content of open nepheline, pyroxene and other minerals as well as all types of intergrowths with apatite decreases. Intergrowths of apatite with titanite are present in all experiments in small amounts, and open titanite is not recorded, which indicates that titanite was introduced due to intergrowth with apatite. The content of apatite intergrowths with nepheline and pyroxene is approximately at the same level, with a slight prevalence of intergrowths with pyroxene. Judging by flotation performance, reagent mode 4 shows the highest P2O5 content with the lowest recovery and the greatest loss of P2O5 in tailings. In concentrate obtained with this mode, there are not just fewer intergrowths, but the intergrowths proper are characterized by the ratio in favour of apatite from 50/50 and higher. In other experiments, intergrowths with lower apatite content, to 20/80 or less, fell into concentrate (Fig.5).

As for the shape of intergrowths, apatite in most of them will open during further crushing. These are classic intergrowths in which apatite grains are in the marginal part. Intergrowths in which apatite occurs as dissemination are relatively rare. Fine dissemination of apatite in other minerals is also relatively rare. Intergrowths that cannot be opened include cases when the finest dissemination of apatite occurs in titanite, as well as when apatite proper contains fine inclusions of rock-forming minerals.

Fig.5. General view of concentrates: a-c – apatite and nepheline intergrowths (green dots), apatite and pyroxene intergrowths (blue dots), unmarked grains – open apatite; d-f – detailed photos of some intergrowths. Photos in reflected polarized light

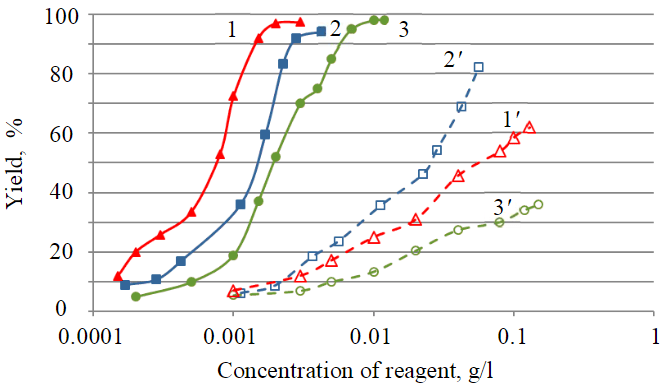

Specificity of the action of reagents Phospholan PE-65 and Atrac-2600 in relation to the associated minerals of apatite is confirmed by the results of non-frothing flotation of monomineral fractions (Fig.6). For comparison, sodium oleate was considered as a fatty acid collector.

Fig.6. Results of non-frothing flotation of apatite (1-3) and aegirine (1'-3') with reagents: Phospholan PE-65 (1, 1'), sodium oleate (2, 2') and Atrac-2600 (3, 3')

It is known that minerals of apatite-nepheline ore are arranged according to their flotation activity: apatite – titanite – aegirine – nepheline, feldspars. Comparison of concentration dependences of minerals floatability with considered reagents shows that Phospholan PE-65 reagent has an advantage over the fatty acid collector when interacting with apatite, while aegirine is better floated by sodium oleate in comparison with Phospholan PE-65 reagent. Consequently, Phospholan PE-65 is sorbed to a much lesser extent on the surface of aegirine and does not contribute to the transfer of this mineral to the froth bed. Curve of apatite floatability with Atrac-2600 reagent lies below the curve for sodium oleate, but at the same time, floatability of aegirine with this reagent is the lowest compared to other collectors considered. Atrac-2600 reagent, like Phospholan PE-65, exhibits selectivity in separation of apatite and the associated minerals, but is inferior in its activity in flotation of apatite. The use of a mixture of these selective reagents as a collector ensured production of the highest quality concentrate in flotation of apatite-nepheline ore (Table 3).

Due to the high cost of synthetic reagents, it is advisable to use them in mixture with tall oils. One of the factors determining the efficiency of collector mixtures with participation of reagent Phospholan PE-65 (phosphoric acid esters and oxyethylated alcohols) or Atrac-2600 (derivatives of amino acids) is their high selectivity of action in relation to minerals of apatite-nepheline ores.

Conclusions

The effect of four reagent modes was studied using the example of apatite-nepheline ore sample flotation. It was shown that an increase of Phospholan PE-65 reagent together with tall oils in composition of the CM allows improving the quality of the apatite concentrates produced. Mineralogical studies proved that quality improvement is accompanied by a decreasing number of apatite intergrowths with nepheline and pyroxenes in concentrates. This is due to a high selectivity of Phospholan PE-65 reagent in relation to apatite. A collector mixture of two synthetic reagents – Phospholan PE-65 and Atrac-2600 can improve the quality of the resulting concentrate but is characterized by a much lower activity.

References

- Chanturiya V.А., Vaisberg L.A., Kozlov А.P. Promising trends in investigations aimed at all-round utilization of mineral raw materials. Obogashchenie rud. 2014. N 2, p. 3-9 (in Russian). DOI: 10.17580/or.2014.02.01

- Guryev А.А. Sustainable Development of Crude Ore Resources and Benefication Facilities of JSC “Apatit” Based on Best Engineering Solutions. Journal of Mining Institute. 2017. Vol. 228, p. 662-673. DOI: 10.25515/pmi.2017.6.662

- Aleksandrova T.N. Сomplex and deep processing of mineral raw materials of natural and technogenic origin: state and prospects. Journal of Mining Institute. 2022. Vol. 256, p. 503-504.

- Tereshchenko S.V., Pavlishina D.N. X-ray luminescence separation of low-grade apatite ores. Mining informational and analytical bulletin. 2017. N 11, p. 130-137 (in Russian). DOI: 10.25018/0236-1493-2017-11-0-130-137

- Neradovsky Yu.N., Kompanchenko A.A., Chernyavsky A.V. Mineralogical and processing features of Khibiny apatitenepheline ores. Obogashchenie rud. 2022. N 3, p. 22-27 (in Russian). DOI: 10.17580/or.2022.03.04

- El-Mofty S.E., El-Midany A.A. Role of calcium ions and their interaction with depressants in phosphate flotation. Chemical Papers. 2018. Vol. 72. Iss. 10, p. 2641-2646. DOI: 10.1007/s11696-018-0499-2

- Yaoyang Ruan, Zeqiang Zhang, Huihua Luo et al. Effects of Metal Ions on the Flotation of Apatite, Dolomite and Quartz. Minerals. 2018. Vol. 8. Iss. 4. N 141. DOI: 10.3390/min8040141

- Wenbiao Liu, Wenxuan Huang, Feng Rao et al. Utilization of DTAB as a collector for the reverse flotation separation of quartz from fluorapatite. International Journal of Minerals, Metallurgy and Materials. 2022. Vol. 29. Iss. 3, p. 446-454. DOI: 10.1007/s12613-021-2321-3

- Marchevskaya V.V., Korneeva U.V. Correlation between the material constitution components in apatite-nepheline ores of the Khybiny Rock Massif (the Kola Peninsula). Vestnik of MSTU. 2020. Vol. 23. N 2, p. 173-181 (in Russian). DOI: 10.21443/1560-9278-2020-23-2-173-181

- Aleksandrova T.N., Elbendari A.M. Increasing the efficiency of phosphate ore processing using flotation method. Journal of Mining Institute. 2021. Vol. 248, p. 260-271. DOI: 10.31897/PMI.2021.2.10

- Chunhui Zhong, Bo Feng, Wenpu Zhang et al. The role of sodium alginate in the flotation separation of apatite and dolomite. Powder Technology. 2020. Vol. 373, p. 620-626. DOI: 10.1016/j.powtec.2020.07.007

- Yanfei Chen, Qiming Feng, Guofan Zhang et al. Effect of Sodium Pyrophosphate on the Reverse Flotation of Dolomite from Apatite. Minerals. 2018. Vol 8. Iss. 7. N 278. DOI: 10.3390/min8070278

- Liuyang Dong, Qian Wei, Wenqing Qin, Fen Jiao. Selective adsorption of sodium polyacrylate on calcite surface: Implications for flotation separation of apatite from calcite. Separation and Purification Technology. 2020. Vol. 241. N 116415. DOI: 10.1016/j.seppur.2019.116415

- de Lima F.V., Budemberg G., Cruz S.H., Braga A.S. A Collector Promoter for Apatite Flotation in the Serra do Salitre Complex. Minerals. 2023. Vol. 13. Iss. 5. N 599. DOI: 10.3390/min13050599

- Qinbo Cao, Heng Zou, Xiumin Chen, Shuming Wen. Flotation selectivity of N-hexadecanoylglycine in the fluorapatite–dolomite system. Minerals Engineering. 2019. Vol. 131, p. 353-362. DOI: 10.1016/j.mineng.2018.11.033

- Filippova I.V., Filippov L.O., Lafhaj Z. et al. Effect of calcium minerals reactivity on fatty acids adsorption and flotation. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2018. Vol. 545, p. 157-166. DOI: 10.1016/j.colsurfa.2018.02.059

- Aleksandrova T., Elbendari A., Nikolaeva N. Beneficiation of a Low-grade Phosphate Ore Using a Reverse Flotation Technique. Mineral Processing and Extractive Metallurgy Review. 2022. Vol. 43. Iss. 1, p. 22-27. DOI: 10.1080/08827508.2020.1806834

- Yaoyang Ruan, Dongsheng He, Ruan Chi. Review on Beneficiation Techniques and Reagents Used for Phosphate Ores. Minerals. 2019. Vol. 9. Iss. 4. N 253. DOI: 10.3390/min9040253

- de Oliveira P., Mansur H., Mansur A. et al. Apatite flotation using pataua palm tree oil as collector. Journal of Materials Research and Technology. 2019. Vol. 8. Iss. 5, p. 4612-4619. DOI: 10.1016/j.jmrt.2019.08.005

- de Carvalho J.A.E., Brandão P.R.G., Henriques A.B. et al. Selective flotation of apatite from micaceous minerals using patauá palm tree oil collector. Minerals Engineering. 2020. Vol. 156. N 106474. DOI: 10.1016/j.mineng.2020.106474

- Jun Xie, Xianhai Li, Song Mao et al. Effects of structure of fatty acid collectors on the adsorption of fluorapatite (001) surface: A first-principles calculations. Applied Surface Science. 2018. Vol. 444, p. 699-709. DOI: 10.1016/j.apsusc.2018.03.105

- Yaoyang Ruan, Zeqiang Zhang, Huihua Luo et al. Ambient Temperature Flotation of Sedimentary Phosphate Ore Using Cottonseed Oil as a Collector. Minerals. 2017. Vol. 7. Iss. 5. N 65. DOI: 10.3390/min7050065

- Elbendari A., Aleksandrov A., Nikolaeva N., Afanasova A. Selective flotation of phosphorus-bearing ores. VIII International Scientific Conference, “Problems of Complex Development of Georesources”, 8-10 September 2020, Khabarovsk, Russian Federation. E3S Web of Conferences, 2020. Vol. 192. N 02021. DOI: 10.1051/e3sconf/202019202021

- Xin Liu, Yimin Zhang, Tao Liu et al. Characterization and Separation Studies of a Fine Sedimentary Phosphate Ore Slime. Minerals. 2017. Vol. 7. Iss. 6. N 94. DOI: 10.3390/min7060094

- Filippov L.O., Filippova I.V., Lafhaj Z., Fornasiero D. The role of a fatty alcohol in improving calcium minerals flotation with oleate. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2019. Vol. 560, p. 410-417. DOI: 10.1016/j.colsurfa.2018.10.022

- Morozov V.V., Barmin I.S., Tugolukov A.V., Polivanskaya V.V. Improvement of flotation efficiency of apatite-bearing ore and old tailings based on adjustment of aggregative stability of slimes. Gornyi Zhurnal. 2019. N 1, p. 56-61 (in Russian). DOI: 10.17580/gzh.2019.01.12

- Zhan Ding, Jie Li, Yunxiao Bi et al. The adsorption mechanism of synergic reagents and its effect on apatite flotation in oleamide-sodium dodecyl benzene sulfonate (SDBS) system. Minerals Engineering. 2021. Vol. 170. N 107070. DOI: 10.1016/j.mineng.2021.107070

- ShuYong Liu, Baisui Han, Tonglin Zhao. The effect of various surfactants on fatty acid for apatite flotation and their adsorption mechanism. Physicochemical Problems of Mineral Processing. 2021. Vol. 57 (5), p. 46-56. DOI: 10.37190/ppmp/140227

- Renju Cheng, Chengxiu Li, Xing Liu, Shanzhi Deng. Synergism of octane phenol polyoxyethylene-10 and oleic acid in apatite flotation. Physicochemical Problems of Mineral Processing. 2017. Vol. 53. Iss. 2, p. 1214-1227. DOI: 10.5277/ppmp170241

- Aarab I., Derqaoui M., Abidi A. et al. Direct flotation of low-grade Moroccan phosphate ores: a preliminary micro-flotation study to develop new beneficiation routes. Arabian Journal of Geosciences. 2020. Vol. 13. Iss. 23. N 1252. DOI: 10.1007/s12517-020-06279-6

- Litvinova T., Kashurin R., Zhadovskiy I., Gerasev S. The Kinetic Aspects of the Dissolution of Slightly Soluble Lanthanoid Carbonates. Metalls. 2021. Vol. 11. Iss. 11. N 1793. DOI: 10.3390/met11111793

- Nikitina I.V., Taran A.E., Perunkova T.N., Mitrofanova G.V. Stimulation of flotation of rebellious apatite–nepheline ore with selective collecting agents. Mining informational and analytical bulletin. 2021. N 11, p. 95-108 (in Russian). DOI: 10.25018/0236_1493_2021_11_0_95

- Sergeev V.V., Cheremisina O.V., Fedorov A.T. et al. Interaction Features of Sodium Oleate and Oxyethylated Phosphoric Acid Esters with the Apatite Surface. ACS Omega. 2022. Vol. 7. Iss. 3, p. 3016-3023. DOI: 10.1021/acsomega.1c06047

- Lafuente B., Downs R.T., Yang H., Stone N. The power of databases: the RRUFF project. Highlights in Mineralogical Crystallography. 2016, p. 1-30. DOI: 10.1515/9783110417104-003

- Zakharova AA., Voytekhovsky Yu.L. Methodology for predicting the washability of apatite ores (Kirovsky mine, Kola Peninsula). Obogashchenie rud. 2022. N 1, p. 27-30 (in Russian). DOI: 10.17580/or.2022.01.05

- Lavrinenko A.A., Shrader EH.A., Kharchikov A.N., Kunilova I.V. Assessment of apatite flotation selectivity from complex ore. Mezhdunarodnoe soveshchanie “Innovatsionnye protsessy kompleksnoi i glubokoi pererabotki mine-ralnogo syrya” (Plaksinskie chteniya 2013): Materialy Mezhdunarodnogo soveshchaniya, 16-19 sentyabrya 2013, Tomsk, Rossiya. Tomsk: Tomskii politekhnicheskii universitet, 2013. p. 366-368.

- Mukhina T.N., Marchevskaya V.V., Kalugin A.I. Improvement of apatite recovery from the Khibiny apatite–nepheline ore in flotation. Gornyi Zhurnal. 2020. N 5, p. 34-39 (in Russian). DOI: 10.17580/gzh.2020.05.06