Increasing the energy efficiency of an autonomous power supply system of a drilling rig in case of voltage dips

Abstract

The article discusses the emergency modes of operation of an autonomous electrical complex of a drilling rig. The concept of voltage failure and its influence on the technological process of industrial enterprises is revealed. A description of the methods used in the power supply of industrial enterprises to overcome voltage dips and load surges in autonomous power systems is presented, from which it is possible to single out the accelerated lifting of critical equipment to prevent emergency conditions, as well as the use of backup storage, usually batteries. An algorithm has been developed for the interaction of the battery and the diesel generator set as backup power sources during various modes of operation of the electric motor, taking into account load surges, which allows successfully overcoming voltage dips in the system both in transient and in steady state. It is proposed to use a combined method to eliminate the voltage dip, a feature of which is the use of a combined structure of backup power sources as part of a diesel generator set and a battery, acting on the base of the proposed interaction algorithm in autonomous electrical complexes. The method makes it possible to overcome sudden load surges and voltage dips caused by a shortage of reserve power in the electrical system. The use of a rechargeable battery as a transitional element makes it possible to switch between the main and backup power sources without stopping the technological one and to expand the overload threshold of an autonomous electrical complex up to 60 %. The use of the combined method increases the energy efficiency of the autonomous complex due to a reduction in the number of emergency shutdowns of equipment, process interruptions and additional power consumption.

Funding

The results of the study were obtained with the financial support of the Ministry of Science and Higher Education of the Russian Federation under the project FSEG-2023-0012

Introduction

Autonomous power supply systems of high power, remote from high-voltage electrical networks, are powered mainly from autonomous power plants with two diesel generator sets, one of which is the main one, and the other is a backup source [1-3]. The use of autonomous electrical complexes is widespread in the regions of the Far East and the Far North, where, for economic and technical reasons, it is difficult to carry out a centralized power supply. Remote isolated energy regions account for 60 % of the territory of the Russian Federation with extensive mineral reserves: 70 % of oil, 90 % of natural gas, 90 % of precious metals and stones. In isolated areas, the total number of generation sources is about 5,000 with a total capacity of about 2,500 MW.

Autonomous electrical complexes are divided according to the following features [4].

- Purpose and nature of consumers: for use in the power supply of the main technological consumers (industrial production, etc.); to provide power supply for the auxiliary needs of industrial facilities (industrial and domestic needs).

- According to the mode of operation: the main ones are power complexes with an operating time per year of more than 3000 hours, with a number of starts per year of less than 20, a continuous operation time of more than 350 hours, a start-up and acceptance time of 100 % load up to 30 minutes; reserve – power complexes with an operating time per year from 200 to 3000 hours, the number of starts from 20 to 50 and the time of starting and receiving 100 % of the load is not more than 5 minutes; emergency ones are power complexes with an operating time per year up to 200 hours, the number of starts per year over 50 and the time of starting and receiving 100 % of the load from 5 to 30 seconds. Emergency power complexes are used for emergency power supply to consumers of the first category and the first category of a special group, for which a break in power supply is allowed only for the duration of the ATS, when the main or backup power source is turned off.

- By type of prime movers: diesel; gas piston; gas turbine; microturbine; combined with renewable energy sources.

In systems with low load power, the backup power source is usually the battery [5]. In such isolated systems, special attention should paid to the indicators of the quality of electricity, on which the operability, reliability and efficiency of the equipment depend [6].

Voltage dip according to GOST 32144-2013 is a decrease in voltage in the electrical network below the threshold value of 0.9 to a minimum of 0.1 of the nominal voltage value. It is characterized by such parameters as the depth of the dip and its duration [7, 8]. After a voltage dip after a time interval of 10 ms, the voltage should be restored to a value of 90 % or more of the nominal value. A voltage dip below 0.1 of the nominal voltage for a certain period of time is a short-term power interruption. However, failures are the most critical emergency violations that lead to shutdowns, overload and failure of the electrical equipment of generators and consumers of electricity.

Due to short electrical connections, the lack of power maneuverability, as well as a small power reserve, autonomous power supply systems are sensitive to voltage dips. In addition, the performance of energy complexes is greatly affected by a high level of insulation pollution in industries with the stage of crushing/grinding ore, unauthorized contact with live parts with objects, errors in operational maintenance of personnel, natural factors, for example, lightning strikes. Starting high-power asynchronous electric motors with a squirrel-cage rotor leads to a decrease in frequency and, accordingly, voltage dips in isolated electrical networks, which has a direct impact on the operation of other consumers [9]. When the voltage in the electrical network decreases below the level allowed by GOST, it is possible to turn off the protection for the minimum voltage of the contactors of electric motors [10]. At the same time, which is relevant for the mining industry, voltage dips can occur due to various emergencies due to the peculiarities of the operation of electrical complexes, such as equipment jamming during drilling, etc. [11]. A voltage dip can also be caused by the onset and end of a short circuit or a sharp increase in the value of the flowing current in the electrical system or electrical installation connected to the mains, as well as disconnection of power supplies [12, 13].

For autonomous electrical complexes, there are three main causes of voltage dips: emergency shutdown of power supplies; a sharp increase in load caused by external technological circumstances; short circuits in the system.

Drill tool sticking is quite common during well drilling. One of the reasons leading to stuck drill strings is a voltage dip and inability to overcome the stick, and the subsequent power outage. To overcome these emergency modes, which account for a significant percentage of the total number of emergencies, a significant amount of time (at least 4 hours) and free reserve capacities in an isolated electrical network are required. To compensate for the negative impact of voltage dips on the continuous technological processes of industrial enterprises in the mining industry and to improve the reliability and stability of isolated power supply networks, it is necessary to develop integrated protection methods that take into account various disturbances in the power systems of electric drives of drilling rigs [14, 15].

The main difficulties in solving the problems of power supply for remote autonomous power supply systems of industrial enterprises are the remote location of mineral deposits from centralized power systems, the distributed location of production facilities within one mining and processing plant (up to 10 km), and a continuous technological process, the violation of which leads to significant economic costs for the enterprise [16].

An analysis of the literature and practical experience of various industrial plants in eliminating voltage dips allows us to identify the main and most common methods and devices: energy storage devices (uninterruptible power supplies, batteries), active filter, static compensator (STATCOM), boost converter and flywheel [17-19].

In electric drive systems of drilling rigs, in case of voltage dips, the speed of rotation of the drill string decreases, and due to the great depth of earth rocks and a relatively small moment of inertia, an instantaneous (up to 2-3 s) “sticking” of mechanisms. Accordingly, in the conditions of limited receipt of additional power from the external network, the search for ways to overcome voltage dips in isolated systems by using the reserves of existing equipment in a short period is relevant to minimize losses and increase the reliability of power supply to plants [20, 21]. The elimination of each "sticking" requires a restart of the technological process, which takes up to 4 hours and requires a significant consumption of electricity and financial resources [22].

The combined method [23, 24] is applied on the example of a drilling rig installed at a gold deposit in the Magadan region. According to statistics, in 2022 recorded an average of 19 emergency shutdowns at this field for each of the eight drilling rigs. The time of repeated restoration of the technological mode is 4 hours. Taking into account the fact that the capacity of the drilling rig is 500 kW, and the approximate cost of 1 kWh of electricity generated by a diesel generator set (DGS) is 25 rubles, the total annual additional costs for electricity are 7.6 million rubles. Thus, it is obvious that the task of improving the energy efficiency of an autonomous power supply system of a drilling rig in case of voltage dips is of great practical and scientific importance [25].

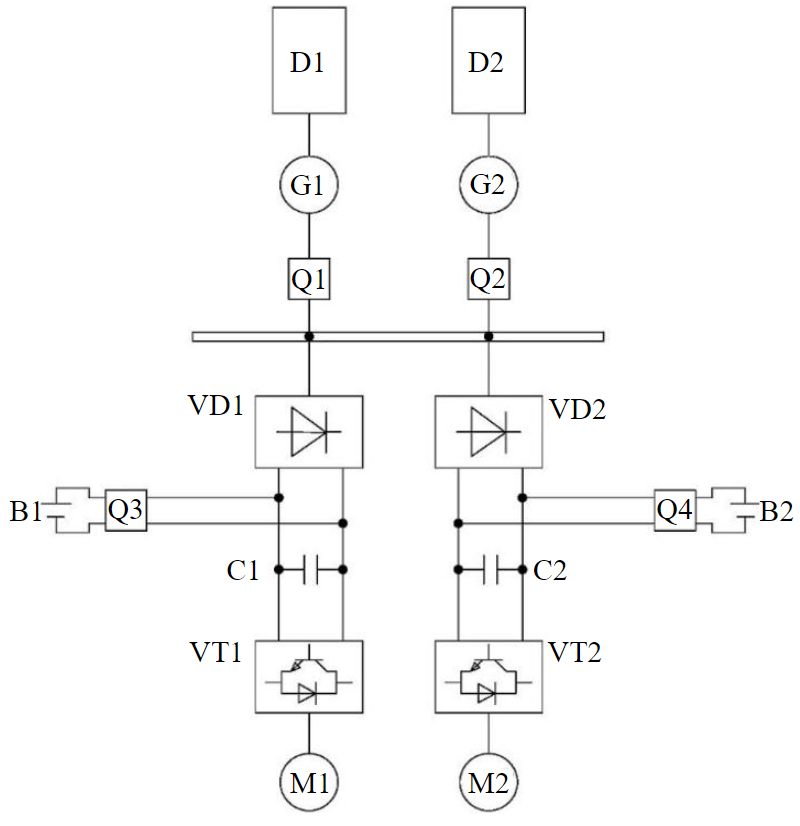

Fig.1. Schematic diagram of autonomouselectrical complex (compiled by the authors)

Methods

Figure 1 shows a schematic diagram of an autonomous electrical complex, consisting of diesel generators, switches, a frequency converter and asynchronous load motors [26-28]. The diagram (Fig.1) uses the following designations: D1-G1, D2-G2 – diesel generators; Q1, Q2, Q3, Q4 – switching devices; VD1, VD2 – rectifiers as part of the frequency converter; B1, B2 – rechargeable batteries; C1, C2 – capacitors (filters) as part of the frequency converter; VT1, VT2 – controlled igbt-transistors as part of the frequency converter; M1, M2 – load motors.

The drilling rig located at a considerable distance from the main power complex (about 3 km), so the power comes from its own diesel generator set, located in close proximity to the consumer [29]. Uncontrolled rectifiers uses as the DC link of the frequency converter [30, 31].

In this electrical complex, two-pole asynchronous electric motors with a squirrel-cage rotor 5AMN315M2 with a power of 250 kW are used, the main parameters of which are given below [32]: total electric motor power 284.5 kVA; nominal slip 0.0083 %; rated current of the stator winding 431 A; preliminary active resistance of the stator 0.017 Ohm; rotor active resistance 0.0043 Ohm; critical slip 0.044 %; stator active resistance 0.012 Ohm; stator leakage inductance 0.102 Ohm; inductive resistance of the magnetization circuit 1.968 Ohm; magnetizing circuit inductance 0.0063 H.

The calculated parameters uses for modeling electric motorsin the Simulink software package [33]. The Asynchronous Machine building block is used.

As an additional backup power source in the electrical complex, there are a stationary low-maintenance lead-acid battery (OPzS). The use of this type of battery is due to extensive operating experience, high reliability and low cost compared to other types of batteries, for example, lithium-ion [34].

The battery capacity calculate by the formula

where IB is the amount of current consumed by the battery during load, A; tB is the period of operation of the battery during the load, tB = 0.5 h, taking into account the features of work and the categorization of consumers; Kg – coefficient of available capacity, Kg = 0.9-1 p.u.; Kp – coefficient of the depth of discharge of the battery, Kp = 0.5-0.7 p.u.

The amount of current drawn from the battery during load

where Pload is the average value of the load power, W; ƞi – efficiency of converting direct current into alternating current using an inverter, ηi = 0.9-0.95; UB – nominal voltage of the storage battery, V;

The operating time of the battery and, accordingly, the calculated capacity are taken based on the required time to ensure the reliability of power supply, according to the criterion of the probable maximum duration of the voltage dip, taking into account the necessary reserve to eliminate significant load surges.

Based on the calculations (1), (2), for further research of the voltage dip, the nearest value of the battery capacity is selected according to the factory catalogs – 1500 Ah (type 12 OPzS 1500) with the following parameters: voltage of one cell – 2 V; internal resistance – 0.21 mOhm; type – lead-acid; the type of positive electrode is a tubular plate.

The calculation of the required power of diesel generators was carried out in accordance with GOST R 53987-2010, according to which the continuous power of autonomous AC diesel generators is selected with a reserve of 30 % of the installed load power. Installed capacity the installed load power of the autonomous electrical complex is 500 kW from two 5AMN315M2 electric motors with a power of 250 kW. According to GOST R 53987-2010, the calculated power of a diesel generator set must be at least 500·1.3 = 650 kW.

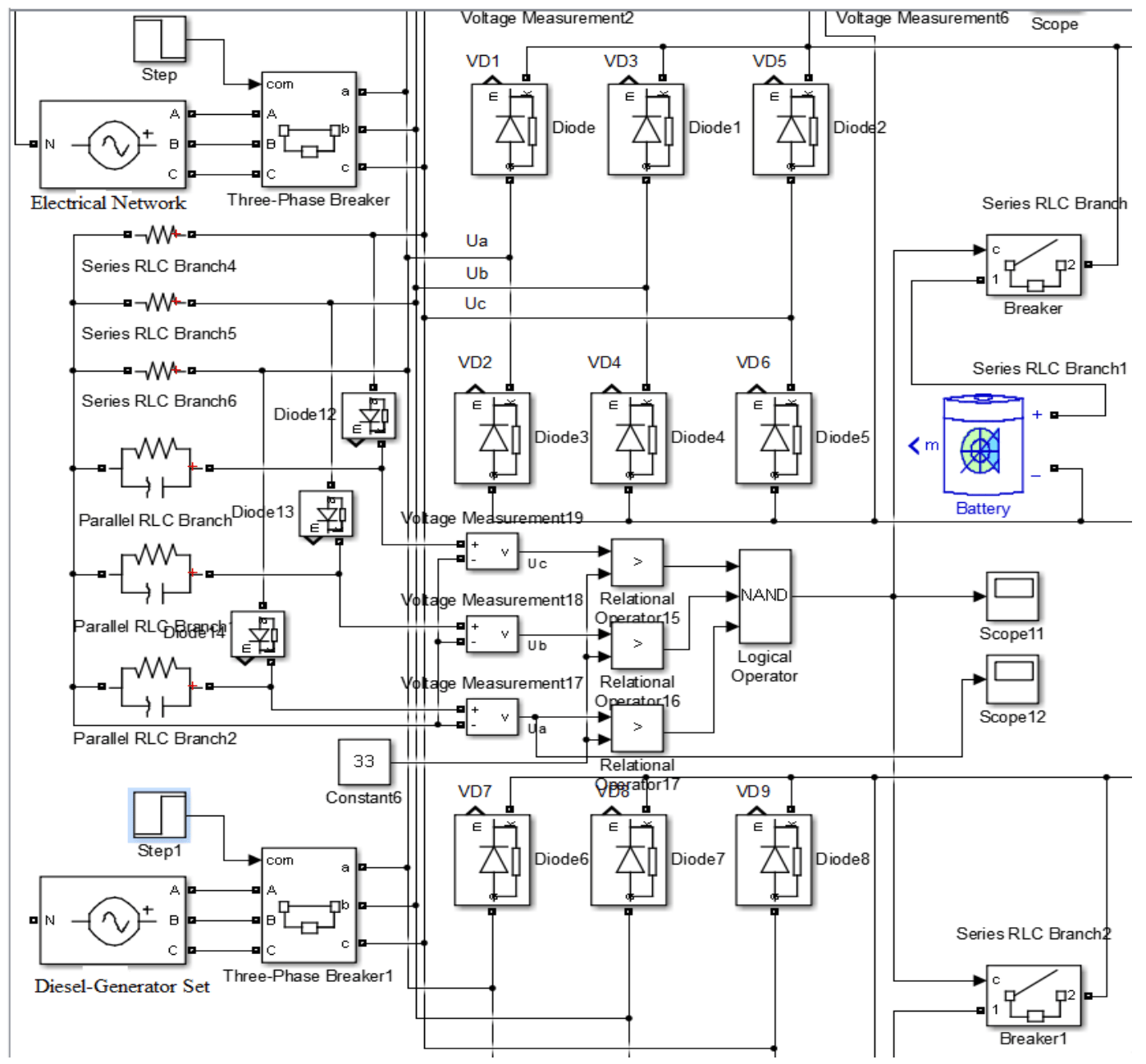

Fig.2. Computer model of the combined composition of backup power sources

Figure 2 shows a computer model of the combined composition of backup power sources (diesel generator set and battery) as part of an autonomous electrical complex of a drilling rig in the Simulink software package.

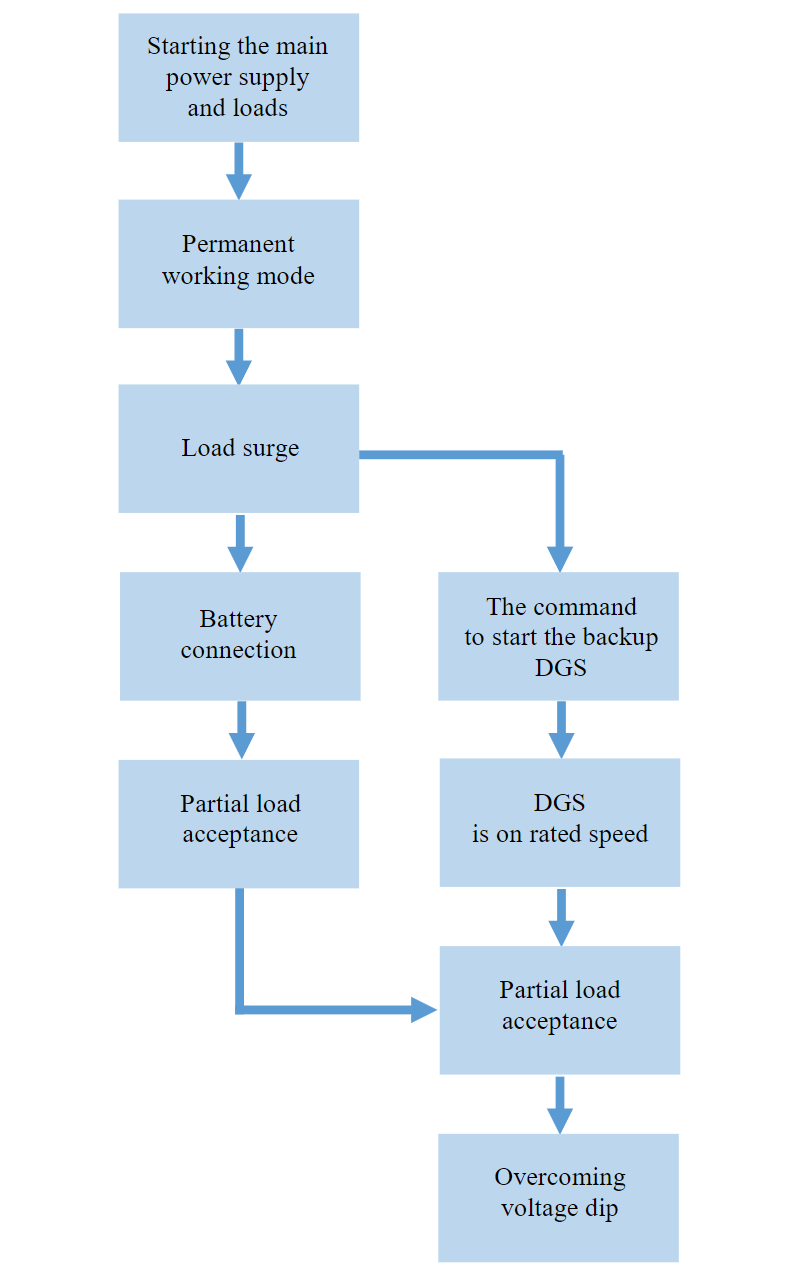

To ensure reliable power supply and continuity of technological processes, it is proposed to consider the combined operation of various backup power sources by introducing an appropriate algorithm (Fig.3) [35, 36].

The algorithm for the combined method of eliminating voltage dips is as follows: in the steady state operation of electric motors, when powered by one main diesel generator set, there is a sharp increase (surge) in the load on the shaft. For example, for drill strings – stuck in solid underground rocks. Accordingly, when the load is applied, the automatic control system sends two parallel control signals: the first to start the backup diesel generator, which will be ready to receive the load after reaching the nominal speed (approximately 3 s), the second to rapidly connect an additional backup power source – the battery. The task of this battery is to ensure short-term load acceptance together with the main diesel generator by issuing peak power – a seamless transition while maintaining the required level of voltage in the network until acceleration, reaching nominal speed and receiving the load of the backup diesel generator [37]. Then the battery is disconnected, the load distribute between two (main and standby) DGS.

Fig.3. Algorithm for connecting sources of backup power (compiled by the authors)

Computer simulation of the voltage dip process and its elimination is performed using the above-described algorithm for the interaction of a diesel generator set and a battery in the MatLab Simulink software package.

In the process of simulation, the acceleration of electric motors lasts 3 s until the moment of reaching the nominal speed of rotation of time, then there is a sharp increase in the load. According to the algorithm (Fig.), at the time t = 3 s, the battery connects to network. At the same time, a backup diesel generator set starts from the control action. Further, at the time t = 5 s, power is transferred to the started backup diesel generator set and the operation mode continues until t = 8 s.

The discussion of the results

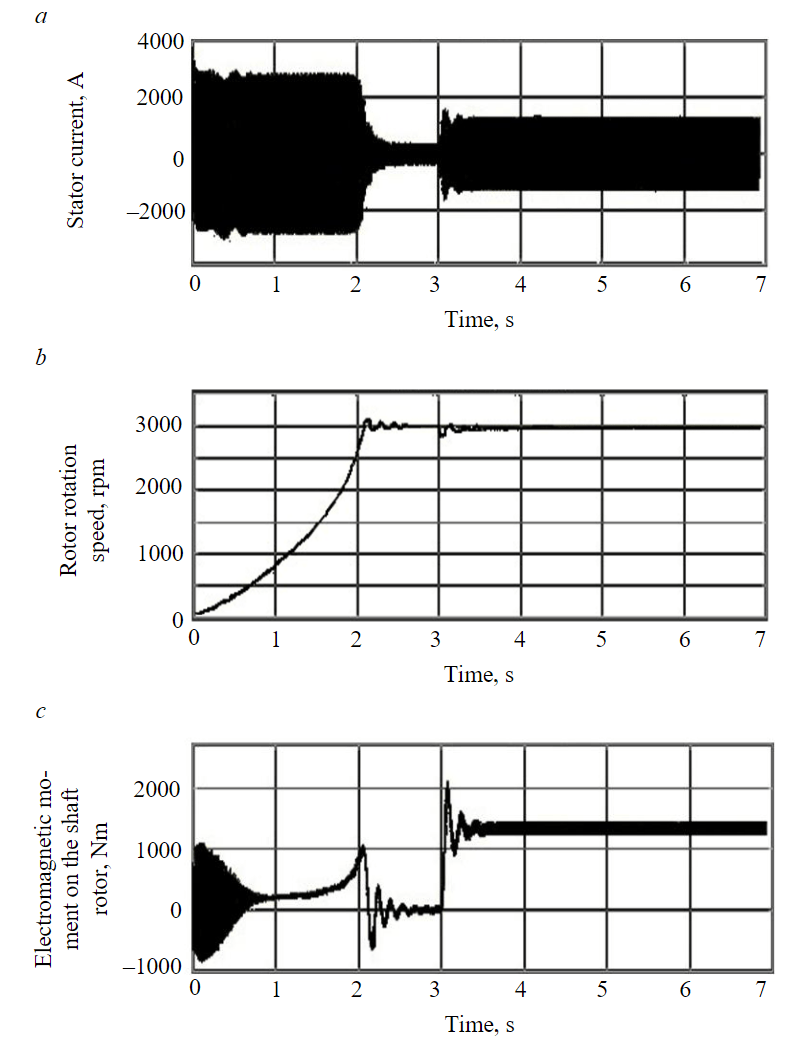

Modeling of modes with different values of load surge was carried out. Figure 4 shows graphs for a load surge of 1600 Nm.

During the acceleration of the electric motor, the largest load value is 1000 Nm, accordingly, this value is taken as the rated power of the electric motor.

According to the calculations, with a load surge of 30 %, the operating mode of the electrical system is maintained with a minimum deviation of the voltage value (within the permissible limits according to GOST), while the rotation speed of the electric motor does not decrease. With this load value, the stator current is approximately 1750 A.

The data in Fig.4 show that the combined operation of the proposed composition of backup power sources, namely, the diesel generator set and the storage battery, based on the proposed control algorithm makes it possible to overcome the load surge of 60 % of the rated power of the main diesel generator without interruption of technological processes. Figure 4, b shows that when the battery is turned on, the rotation speed of the electric motor is maintained in the allowable range and the required time interval (3 s) for starting, accelerating, and connecting a backup diesel generator set.

Further calculations are performed to study the operating mode at a load surge of 65 and 70 % of the rated power of the system. In this mode, the estimated capacity of the battery is not able to ensure a smooth transfer of the load to the backup diesel generator set, since the battery is discharged in 2 s. In this case, the stator current reaches maximum (starting) values, which indicates an overload of the autonomous electrical complex. In addition, the rotation of the electric motors slows down almost instantly. In this case, according to the standard method, it is necessary to apply an emergency lifting of drilling mechanisms to save equipment and minimize financial costs.

Similar studies have been carried out on the operating modes of an autonomous electrical complex with load surges of various sizes with an increased capacity of a lead-acid battery up to a value of 2500 Ah.

Fig.4. Graphs with a load surge of 1600 Nm: a – stator current, A; b – rotor rotation speed, rpm; c – electromagnetic torque on the rotor shaft, Nm

The power system, including the battery, copes with the load surge Tm = = 1650 Nm. The rotation speed of the motors is slightly slowed down, but without affecting the continuous process. Accordingly, with an increase in the capacity of the battery from 1500 to 2500 Ah (by 66 %), the threshold for overload and system performance expands by 3.1 % (from 1600 to 1650 Nm). Compared to the value in accordance with GOST, the overload capacity of the energy complex has increased to 65 %.

Additionally, a mode with a load surge of 70 % (Tm = 1700 Nm) of the nominal value of the diesel generator power was developed. The results show that for a battery with an increased capacity, this load is critical, the electric motors go into a sharp deceleration (rotation speed is 0 rpm in 1.2 s after the load is applied) and the process is not supported.

The results obtained show that with an increase in the capacity of the battery in excess of the calculated value, a significant improvement in the characteristics of an autonomous electrical complex for the ability of the power system to overcome voltage dips is not provided. There is a clear incommensurability of the resources spent on the achieved technical results.

Conclusion

As a result of applying the combined structure of backup power sources, acting on the base of the proposed interaction algorithm to overcome the voltage dips that occur in autonomous electrical complexes of drilling rigs, it has been established that the use of a rechargeable battery makes it possible to increase the allowable value of the system overload capacity by 23 % while ensuring the continuity of the technological process and switching between the main and backup diesel generator set in case of voltage dips.

At the same time, an increase in the battery capacity by 66 % relative to the calculated value (from 1500 to 2500 Ah) makes it possible to increase the maximum load surge that the autonomous power supply system can handle in the event of a voltage dip by 3.1 % (from 1600 to 1650 Nm).

It is shown that when using the combined composition of backup power sources together with the interaction algorithm, the number of shutdowns, restarts and, accordingly, additional power consumption decreases. The combined results lead to a reduction in operating costs and an increase in the energy efficiency of the complex.

The study proved that with an increase in the capacity of the battery in excess of the calculated value, a significant improvement in the characteristics of an autonomous electrical complex for the ability of the power system to overcome voltage dips is not provided. This decision leads to increased capital costs without the proper technical and economic effect.

References

- Georgilakis P.S., Hatziargyriou N.D. A review of power distribution planning in the modern power systems era: Models, methods and future research. Electric Power Systems Research. 2015. Vol. 121, p. 89-100. DOI: 10.1016/j.epsr.2014.12.010

- Tavares B., Soares F.J. An innovative approach for distribution network reinforcement planning: Using DER flexibility to minimize investment under uncertainty. Electric Power Systems Research. 2020. Vol. 183. N 106272. DOI: 10.1016/j.epsr.2020.106272

- Gouin V., Alvarez-Hérault M.-C., Raison B. Innovative planning method for the construction of electrical distribution network master plans. Sustainable Energy, Grids and Networks. 2017. Vol. 10, p. 84-91. DOI: 10.1016/j.segan.2017.03.004

- Yu Yang, Fan Jinfu, Wang Zhongjie et al. A dynamic ensemble method for residential short-term load forecasting. Alexandria Engineering Journal. 2023. Vol. 63, p. 75-88. DOI: 10.1016/j.aej.2022.07.050

- Bo Yang, Junting Wang, Yixuan Chen et al. Optimal sizing and placement of energy storage system in power grids: A state-of-the-art one-stop handbook. Journal of Energy Storage. 2020. Vol. 32. N 101814. DOI: 10.1016/j.est.2020.101814

- Saneev B.G., Ivanova I.Yu., Tuguzova T.F. Development of renewable energy sector in the Russian east over the first half of the 21st century amidst national trends. Energy policy. 2016. Iss. 3, p. 66-73 (in Russian).

- Shpiganovich A.N., Shpiganovitch A.A., Bogomolov I.I. Voltage sags in power systems. Izvestiya Tula State University. 2018. Iss. 12, p. 7-12 (in Russian).

- Ershov S.V., Pigalov M.S. Analysis of means and methods of limitation of influence voltage fails. Izvestiya Tula State University. 2017. Iss. 12-1, p. 95-104 (in Russian).

- Zarenia O., Salehpour M.J., Ghaedi R., Shafie-Khah M. Markov-Based Reliability Assessment for Distribution Systems Considering Failure Rates. IEEE Access. 2023. Vol. 11, p. 10018-10031. DOI: 10.1109/ACCESS.2023.3240778

- Postigo Marcos F., Domingo C.M., San Román T.G. Improving distribution network resilience through automation, distributed energy resources, and undergrounding. International Journal of Electrical Power & Energy Systems. 2022. Vol. 141. N 108116. DOI: 10.1016/j.ijepes.2022.108116

- Prathapaneni D.R., Detroja K.P. An integrated framework for optimal planning and operation schedule of microgrid under uncertainty. Sustainable Energy, Grids and Networks. 2019. Vol. 19. N 100232. DOI: 10.1016/j.segan.2019.100232

- Besselmann T.J., Cortinovis A., Van de Moortel S. et al. Increasing the Robustness of Large Electric Driven Compressor Systems During Voltage Dips. IEEE Transactions on Industry Applications. 2018. Vol. 54. Iss. 2, p. 1460-1468. DOI: 10.1109/TIA.2017.2781638

- Bagheri A., Bollen M.H.J., Gu I.Y.H. Improved characterization of multi-stage voltage dips based on the space phasor model. Electric Power Systems Research. 2018. Vol. 154, p. 319-328. DOI: 10.1016/j.epsr.2017.09.004

- Rastgou A., Moshtagh J., Bahramara S. Improved harmony search algorithm for electrical distribution network expansion planning in the presence of distributed generators. Energy. 2018. Vol. 151, p. 178-202. DOI: 10.1016/j.energy.2018.03.030

- Kandasamy M., Thangavel R., Arumugam T. et al. Strategic incorporation of DSTATCOM and distributed generations in balanced and unbalanced radial power distribution networks considering time varying loads. Energy Reports. 2023. Vol. 9, p. 4345-4359. DOI: 10.1016/j.egyr.2023.03.076

- Zhukovskiy Yu.L., Kovalchuk M.S., Batueva D.E., Senchilo N.D. Development of an Algorithm for Regulating the Load Schedule of Educational Institutions Based on the Forecast of Electric Consumption within the Framework of Application of the Demand Response. Sustainability. 2021. Vol. 13. Iss. 24. N 13801. DOI: 10.3390/su132413801

- Chervonchenko S.S., Frolov V.Ya. Voltage dip analysis of a drilling rig connected to a local power grid. VII Mezhdunarodnaya nauchno-prakticheskaya konferentsiya “Innovatsii i perspektivy razvitiya gornogo mashinostroeniya i elektromekhaniki”: IPDME-2020, 23-24 aprelya 2020, Sankt-Peterburg, Rossiya. St. Pttersburg: Sankt-Peterburgskii gornyi universitet, 2020, p. 630-634 (in Russian).

- Gukovskiy Yu.L., Sychev Yu.A., Pelenev D.N. The Automatic Correction of Selective Action of Relay Protection System against Single Phase Earth Faults In Electrical Networks of Mining Enterprises. International Journal of Applied Engineering Research. 2017. Vol. 12. N 5, p. 833-838.

- Belsky A.A., Glukhanich D.Y., Carrizosa M.J., Starshaia V.V. Analysis of specifications of solar photovoltaic panels. Renewable and Sustainable Energy Reviews. 2022. Vol. 159. N 112239. DOI: 10.1016/j.rser.2022.112239

- Barelli L., Bidini G., Pelosi D. et al. Comparative analysis of AC and DC bus configurations for flywheel-battery HESS integration in residential micro-grids. Energy. 2020. Vol. 204. N 117939. DOI: 10.1016/j.energy.2020.117939

- Shonin O.B., Novozhilov N.G., Kryltcov S.B. Enhancing the stability of a sensorless V/F controlled VFD under voltage sags. Izvestiya Tula State University. 2016. Iss. 11-2, p. 507-519 (in Russian).

- Bardanov A.I., Solovev S.V., Alvarez R. et al. Upgrading the Power Capacity of a Three-Conductor MVAC Line by Converting to DC. Energies. 2022. Vol. 15. Iss. 3. N 1080. DOI: 10.3390/en15031080

- Munoz-Guijosa J.M., Kryltcov S.B., Solovev S.V. Application of an active rectifier used to mitigate currents distortion in 6-10 kV distribution grids. Journal of Mining Institute. 2019. Vol. 236, p. 229-238. DOI: 10.31897/PMI.2019.2.229

- Iakovleva E.V., Guerra D.D. Improving the efficiency of the use of photovoltaic stations in the republic of Cuba. Journal of Physics: Conference Series. 2021. Vol. 1753. N 012056. DOI: 10.1088/1742-6596/1753/1/012056

- Vasilkov O.S., Batueva D.E., Homyakov K.A., Palyanicin P.S. Aligning the load schedule of enterprises through the use of hybrid energy storage. Izvestiya MGTU “MAMI”. 2020. N 1 (43), p. 27-34 (in Russian). DOI: 10.31992/2074-0530-2020-43-1-27-34

- Abramovich B.N. Uninterruptible Power Supply System for Mining Industry Enterprises. Journal of Mining Institute. 2018. Vol. 229, p. 31-40. DOI:10.25515/PMI.2018.1.31

- Abramovich B., Sychev Yu.A., Pelenev D.N. Invariant protection of high-voltage electric motors of technological complexes at industrial enterprises at partial single-phase ground faults. IOP Conference Series: Materials Science and Engineering. 2018. Vol. 327. Iss. 5. N 052027. DOI: 10.1088/1757-899X/327/5/052027

- Vasilyev B.Yu., Shpenst V.A., Kalashnikov O.V., Ulyanov G.N. Providing Energy Decoupling of Electric Drive and Electric Grids for Industrial Electrical Installations. Journal of Mining Institute. 2018. Vol. 229, p. 41-49. DOI: 10.25515/PMI.2018.1.41

- Forcan J., Forcan M. Optimal placement of remote-controlled switches in distribution networks considering load forecasting. Sustainable Energy, Grids and Networks. 2022. Vol. 30. N 100600. DOI: 10.1016/j.segan.2021.100600

- Ngom I., Mboup A.B., Thiaw L. et al. An Improved Control for DC-Link Fluctuation during Voltage Dip based on DFIG. 9th International Renewable Energy Congress (IREC), 20-22 March 2018, Hammamet, Tunisia. IEEE, 2018, p. 1-6. DOI: 10.1109/IREC.2018.8362458

- Pazouki E., Sozer Y., De Abreu-Garcia J.A. Fault Diagnosis and Fault-Tolerant Control Operation of Nonisolated DC-DC Converters. IEEE Transactions on Industry Applications. 2018. Vol. 54. Iss. 1. P. 310-320. DOI: 10.1109/TIA.2017.2751547

- Zhukovskiy Y.L., Korolev N.A., Koteleva N.I. About increasing informativity of diagnostic system of asynchronous electric motor by extracting additional information from values of consumed current parameter. Journal of Physics: Conference Series. 2018. Vol. 1015. Iss. 3. N 032158. DOI: 10.1088/1742-6596/1015/3/032158

- Malarev V.I., Kopteva A.V., Nogtev R.A. Electric Drive Simulation for Drilling Machine Spinner. IOP Conference Series: Earth and Environmental Science. 2018. Vol. 194. Iss. 5. N 052012. DOI: 10.1088/1755-1315/194/5/052012

- Savard C., Iakovleva E., Ivanchenko D., Rassõlkin A. Accessible Battery Model with Aging Dependency. Energies. 2021. Vol. 14. Iss. 12. N 3493. DOI: 10.3390/en14123493

- Shklyarskiy Ya.E., Batueva D.E. Operation mode selection algorithm development of a wind-diesel power plant supply complex. Journal of Mining Institute. 2022. Vol. 253, p. 115-126. DOI: 10.31897/PMI.2022.7

- Zhukovskiy Yu.L., Batueva D.E., Buldysko A.D. et al. Fossil Energy in the Framework of Sustainable Development: Analysis of Prospects and Development of Forecast Scenarios. Energies. 2021. Vol. 14. Iss. 17. N 5268. DOI: 10.3390/en14175268

- Akbari K., Rahmani E., Abbasi A., Askari M.-R. Optimal placement of distributed generation in radial networks considering reliability and cost indices. Journal of Intelligent & Fuzzy Systems. 2016. Vol. 30. Iss. 2, p. 1077-1086. DOI: 10.3233/IFS-151883