Filtration studies on cores and sand packed tubes from the Urengoy field for determining the efficiency of simultaneous water and gas injection on formation when extracting condensate from low-pressure reservoirs and oil from oil rims

- Ph.D. Researcher Peoples' Friendship University of Russia ▪ Orcid

Abstract

Oil rims as well as gas condensate reservoirs of Russia's largest Urengoy field are developed by depletion drive without formation pressure maintenance, which has led to serious complications in production of oil, gas and condensate. In addition, field development by depletion drive results in low values of oil and condensate recovery. These problems are also relevant for other oil and gas condensate fields. One of the possible solutions is simultaneous water and gas injection. Rational values of gas content in the mixture for affecting gas condensate fields and oil rims of oil and gas condensate fields should be selected using the data of filtration studies on core models. The article presents the results of filtration experiments on displacement of condensate and oil by water, gas and water-gas mixtures when simulating the conditions of the Urengoy field. Simultaneous water and gas injection showed good results in the experiments on displacement of condensate, residual gas and oil. It has been ascertained that water-gas mixtures with low gas content (10-20 %) have a better oil-displacement ability (9.5-13.5 % higher) than water. An experiment using a composite linear reservoir model from cemented core material, as regards the main characteristics of oil displacement, gave the same results as filtration experiments with sand packed tubes and demonstrated a high efficiency of simultaneous water and gas injection as a method of increasing oil recovery at oil and gas condensate fields.

Introduction

Condensate formation in the reservoir is a consequence of developing gas condensate and oil and gas condensate fields in depletion drive. It is possible to prevent condensate formation in the reservoir and the loss of this valuable raw material by applying the cycling process. As a result of successive production of condensate and gas, it is possible to achieve a high degree of condensate recovery from the field. However, this technology requires significant expenses. Therefore, in Russia (and earlier in the USSR), the industrial method of developing gas condensate fields is the depletion drive which leads to a formation of retrograde condensate in the reservoir.

A promising way to recover the condensate forming in the reservoir is the use of displacement agents. In addition, it is advisable to use them for development of oil rims at oil and gas condensate fields (OGCF). In conditions of depleted oil and gas condensate fields, water, gas, and a water-gas mixture (WGM) can be used as displacement agents.

Problem statement

Oil rims as well as gas condensate reservoirs of Russia’s largest Urengoy OGCF are developed in depletion drive without maintaining reservoir pressure [1]. As a result, the formation pressure values decreased significantlywhich led to serious complications in production of oil, gas, and condensate. In addition, the consequence of field development in depletion drive are low values of oil and condensate recovery.

This is relevant for oil and gas condensate fields in Western Siberia – Yamburgskoye, Pestsovoye, Severo-Urengoy and Tazovskoye [2]; Eastern Siberia – Chayandinskoye OGCF [3]. To solve these problems at the OGCF, the technology of injecting water-gas mixtures with rational values of gas content into the reservoir by pump-ejector systems can be applied.

Simultaneous water and gas (SWAG) injection in the reservoir by pump-ejector systems is an efficient method for increasing fluid recovery at the fields with low-viscosity [4, 5] and high-viscosity oils [6, 7], in particular, the Arctic fields [8]. The publications describe in detail the technological aspects of a possible use of the pump-ejector system at the Urengoy field [9], the successful experience of field implementation at the Samodurovskoye field [10, 11], the prospects for improving the applied technology [12-14], the characteristics for single-stage and two-stage pump-ejector compression [15], and a possibility of using the existing field infrastructure [12].

According to article [16], SWAG injection allows achieving water cut reduction from 98 to 80 % in carbonate reservoirs of Eastern Siberia and increasing well flow rate to 100 t oil per day. Summarizing the twenty years-experience of carbonate fields development in Brazil it was shown that SWAG injection with CO2 injection can become an efficient method for displacing residual oil, reducing water cut and increasing the economic efficiency of a long-term development [17]. When CO2 is injected, the profitability of oil production increases significantly [18]. The assessment of the efficiency of using various models, analytical tools [19-21] and engineering support methods [22] is also important.

To account for interwell interference during SWAG injection with CO2 injection, neural networks were used [23]. Intelligent well completion is applied at immiscible SWAG injection to obtain the best inflow result in offshore fields [24]. SWAG injection can be used both as an efficient tertiary method of enhanced oil recovery (EOR), and from the beginning of development [25]. For considering the vertical stratification of water-gas mixture in the reservoir and optimizing the injection strategy, the current 3D hydrodynamic model of the field can be used with an additional foam injection module [26]. Foam systems [27-29] together with SWAG injection are used in world practice to improve the stability of water-gas mixture, intensify sweep efficiency, and increase profitability [30, 31].

Polymer flooding [32] is an efficient and environmentally friendly tertiary method for enhanced oil recovery at high-viscosity oil fields. To eliminate uncertainties in joint water and gas injection into the reservoir, nitrogen can be used [33]. In addition, machine learning algorithms can be applied to identify candidate wells for SWAG injection by injecting rims, control their size and gas-water ratio under conditions of geological uncertainty [34], and also predict dynamic formation pressure using artificial intelligence methods [35]. The concept of a digital field in the current economic realities of the Russian oil and gas sector is considered in article [36]; a review of the experience of using digital technologies at offshore fields of Russia and the practice of increasing production is presented in [37, 38]. The process of managing field development under conditions of uncertainty is significantly influenced by automation and informatization of the corresponding management decisions [39, 40]. The results of filtration experiments using two- and three-phase filtration models when simulating SWAG injection are inbuilt into the constantly operating hydrodynamic reservoir model [41].

When introducing SWAG injection by sequential injection of rims at large fields, it is necessary to optimize the injection process, choose the right volume of rims for increasing the economic and technological effects, and also use tracers to determine the movement direction of the displacement front [42-44]. SWAG injection can be used to utilize the associated petroleum gas [10, 45, 46] and CO2 [23, 47, 48]. Monitoring of pilot projects of SWAG injection with CO2 is presented in article [49], and the optimization methods in [17, 18, 44]. According to the results of filtration experiments, when water and gas are jointly injected into the reservoir, it is important to determine the range of the optimal gas content in the mixture, at which the maximum increase in the displacement efficiency is achieved [4, 46, 50].

Proppant hydraulic fracturing can be used as an efficient method for increasing oil recovery at the Kashiro-Vereiskiye carbonate formations, as shown by the example of studying cores from the Moskudyinskoye field [51]. In article [52], on the example of a carbonate formation, the application of a probabilistic technique for predicting the efficiency of proppant hydraulic fracturing technology was considered and a forecast was made of increase in oil production rate of wells with the use of the probabilistic analysis of geological and technological data in different periods of performing hydraulic fracturing with a fairly good degree of correlation with actual flow rate increments.

Simulation of the technology of oriented slotted hydro sand jet perforation to improve the development efficiency of terrigenous oil-saturated reservoirs by a system of oriented selective slotted channels is presented in article [53]. For carbonate reservoirs with a high degree of heterogeneity, it is possible to use radial drilling to increase oil recovery [54]. For the fields with complex mining and geological conditions and low-efficiency reservoirs, it is necessary to consider the geomechanical properties of the reservoir in the course of development [55, 56]. Cracking resistance coefficient is associated with geophysical characteristics of rocks at hydrocarbon fields [57].

When studying the specific features of formation of bottomhole zones of oil pays during operation of producing wells at the fields in the northern Perm Region with high gas saturation of formation oil, an analysis of the skin factor was considered, and multidimensional mathematical models were built to determine the main factor affecting the state of bottomhole zones [58]. To increase the economic efficiency of hydrochloric acid treatment at the Chaikinskoye deposit in Perm Region, an algorithm was developed that can be implemented without difficulty using any programming language [59].

When constructing a geological and hydrodynamic model of a carbonate oil formation, it is necessary to consider the vertical anisotropy of permeability, as shown in the example of one field in the Perm Region [60]. The results of studies on the influence of low bottomhole temperatures in the intervals of oil pays on the technological properties of solutions used for drilling and completion of wells in order to determine the possibility of increasing gas recovery coefficient at the field of the “Power of Siberia” gas pipeline are presented in article [61]. To reduce the degree of uncertainty in assessing the formations in terms of the degree and nature of geological heterogeneity, a method was developed for grouping low-productive oil fields in carbonate reservoirs for the rational use of resources within the Urals-Volga Region [62].

Article [63] analyses the development of fields on the Arctic shelf of Russia using expert forecasting methods. Estimation of the fields in Eastern Siberia in terms of economic effect and development prospects is presented in article [64]. Unconventional oil and gas resources and problems of their development are described in article [65]; the need to refine the acoustic methods of geological exploration, when developing the fields in permafrost conditions, is shown in article [66].

The main problems in the development of depleted oil and gas condensate fields at present are the lack of research into the processes that occur when condensate and oil are displaced by water-gas mixtures and the selection of the optimal gas content to achieve the highest values of condensate and oil recovery coefficients. Therefore, the main task of the studies presented in the article was to conduct appropriate filtration experiments on the displacement of condensate and oil by water, gas and WGM on core models and cores of the Urengoy oil and gas condensate field and to process the results obtained.

Methodology

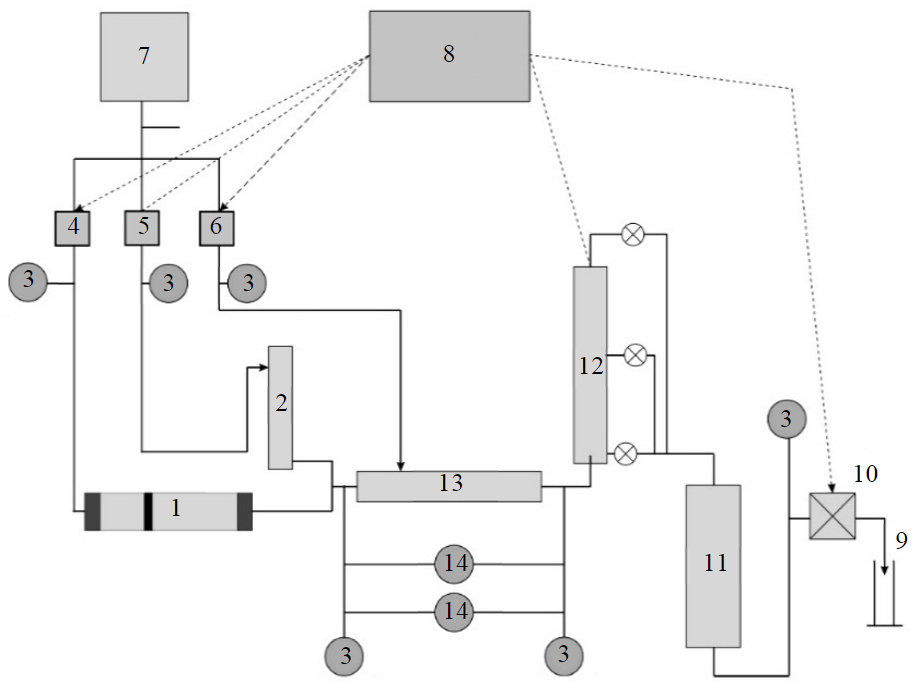

During filtration studies, various options for extracting retrograde condensate and oil were tested at the UIK-5 three-phase filtration unit (Fig.1). The unit is designed to simulate the reservoir conditions at oil and gas fields, work with gases, gasified liquids at high pressures and temperatures, testing chemical reagents for enhanced oil recovery, etc. It consists of four high-pressure plunger pumps with stepper motors (three working pumps with plunger chamber volume of 30 ml and one auxiliary pump with plunger chamber volume of 6 ml to create compression in reservoir models), an ultrasonic separator-meter (can be used as a two-phase meter (for measuring volumes of oil and water), and a three-phase meter for gas, oil and water), several pressure sensors, two differential pressure sensors, tanks and high pressure columns, a control valve to maintain reservoir pressure, valves for manual and program control, etc.

Fig.1. Scheme of filtration plant 1 – piston column with gas; 2 – clarifier with water; 3 – pressure sensors; 4, 5, 6 – pump pairs; 7 – container with petrolatum liquidum; 8 – control computer; 9 – receiver; 10 – pressure regulator; 11 – piston clarifier; 12 – ultrasonic three-phase separator-meter; 13 – reservoir model or core holder; 14 – differential pressure sensors

Plunger pumps are controlled by a computer, which ensures their continuous operation without pressure surges at the time of switching plunger chambers. Level of liquids in the separator-meter is measured by an ultrasonic sensor by reflection from the interface. During experiment, the program records the readings of pressure and differential pressure sensors, levels in the settling separator, pump performance and temperature in core holder.

During the experiments, reservoir conditions at the Urengoy Field were simulated, both sand packed tubes and core reservoir models were used.

A brief geological and physical characteristic of the investigated developed pay at the Urengoy oil and gas condensate field is as follows: pay horizon BU112 with an average occurrence depth of 2,769 m, oil and gas condensate pool, terrigenous reservoir, porosity coefficient 0.14; permeability 13.68 µm2; reservoir oil saturation 0.549; gas saturation 0.588; initial formation temperature 79 °С; initial formation pressure 27.6 MPa. Saturation pressure of oil with gas and pressure of the onset of condensation also have a value of 27.6 MPa, i.e., condensate and free gas formation occurs from the beginning of development; therefore, oilfield workers faced the task of APG utilization at a high GOR of 228.1 m3/t and the need to use EOR to increase fluid recovery from the formation. Oil is low-viscosity – in reservoir conditions it was 0.49 mPa·s, density 0.667 t/m3. Oil recovery factor for the base development option is 0.434, potential condensate content is 199 g/m3. Characteristics of reservoir models for condensate displacement are given in Tablе 1, for oil displacement – in Tablе 2.

Table 1

Characteristic of sand packed tubes for the study of condensate displacement

|

Experiment number* |

Permeability, μm2

|

Initial saturation, %

|

Tube

length, cm

|

|||

|

By gas (Кgas) |

By water (Кwater) |

Water |

Condensate |

Gas |

||

|

1 |

15,2 |

11,8 |

20,3 |

19,9 |

59,8 |

34,5 |

|

3 |

12,3 |

– |

22,2 |

28,5 |

49,3 |

39,5 |

|

6 |

12,7 |

– |

22,7 |

29,0 |

48,3 |

34,5 |

|

7 |

0,764 |

– |

29,0 |

29,9 |

41,1 |

34,5 |

|

8 |

13,3 |

9,54 |

20,6 |

26,9 |

52,5 |

34,5 |

|

9 |

11,2 |

8,95 |

19,5 |

29,2 |

51,3 |

34,5 |

|

10 |

0,920 |

0,608 |

29,0 |

28,4 |

42,6 |

34,5 |

|

15 |

0,626 |

0,393 |

29,3 |

29,6 |

41,1 |

34,5 |

|

17 |

0,355 |

0,215 |

29,2 |

29,3 |

41,5 |

34,5 |

|

18 |

0,362 |

0,227 |

29,3 |

29,1 |

41,4 |

34,5 |

*Gas displacement was carried out in experiment 9; water – 1, 3, 10, 15, 17; water-gas mixtures – 6, 7, 18; WGM with surfactant – 8.

Table 2

Characteristic of sand packed tubes for the study of oil displacement

|

Experiment number |

Pore volume, ml |

Permeability, µm |

Initial saturation, % |

||||

|

By gas |

By water |

By oil |

Oil |

Water |

Gas |

||

|

20 |

74.8 |

0.48 |

0.233 |

0.204 |

59.2 |

25.1 |

15.7 |

|

21 |

74.6 |

0.445 |

0.231 |

0.159 |

58.4 |

24.9 |

16.7 |

|

22 |

76.0 |

0.415 |

0.258 |

0.194 |

58.3 |

25.4 |

16.3 |

|

24 |

71.2 |

0.381 |

0.211 |

0.174 |

58.0 |

26.1 |

15.9 |

|

25 |

73.4 |

0.402 |

0.209 |

0.173 |

74.9 |

25.1 |

0 |

In the experiments, condensate and oil were displaced by water, gas, or WGM in simulation of depleted reservoirs with reduced pressure. Water displacement was performed in accordance with the requirements of OST 39-195-86 “Oil. Method for determination of oil displacement efficiency by water in laboratory conditions.” Experiments on gas and WGM displacement performed out following the procedure described in [14].

Study of condensate displacement by gas

The experiments were carried out at low pore pressure (3 MPa) typical for depleted reservoirs. The reservoir model was horizontal.

Nitrogen was chosen as gas agent. The use of commercial gas (methane) for condensate production is not economically reasonable. The only available gas agent for condensate displacement is nitrogen, which can be obtained from atmospheric air.

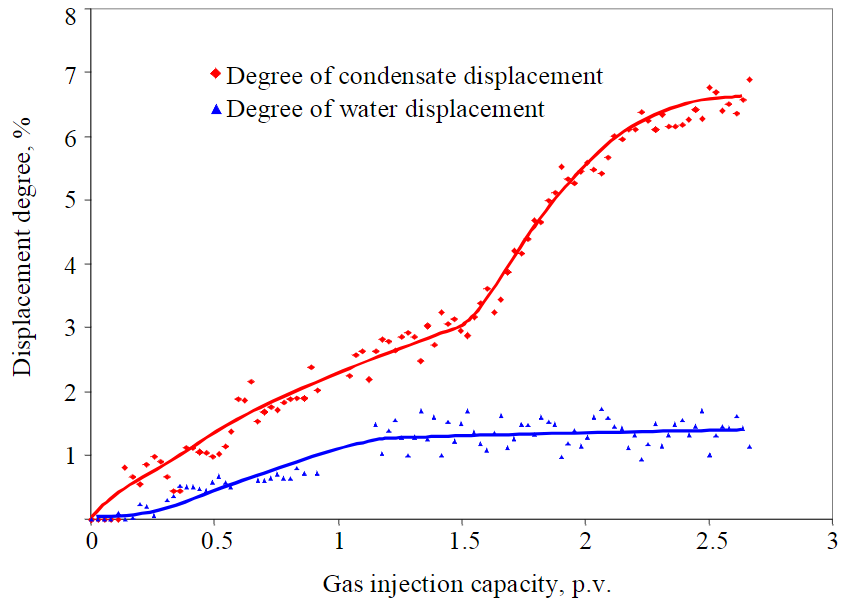

The experiment showed that gas displacement efficiency is very low (Fig.2). The reasons for this are an immiscible character of condensate displacement, shielding effect of water, and low viscosity of gas. As a result of pumping 2.66 pore volumes (p.v.) with gas, only 6.6 % of condensate and 1.4 % of water were displaced. Judging by condensate displacement kinetics, the main mechanism of water and condensate displacement is evaporation into the dry gas flow. In the separator-meter at 20 °C, hydrocarbon vapours condensed, which made it possible to measure their amount. After pumping 1.2-1.4 p.v. of gas, water release from the reservoir model practically stopped. Termination of water release led to acceleration of condensate release from the reservoir model, which indicates a certain shielding by water in the porous part of condensate.

Fig.2. Dynamics of condensate displacement by gas

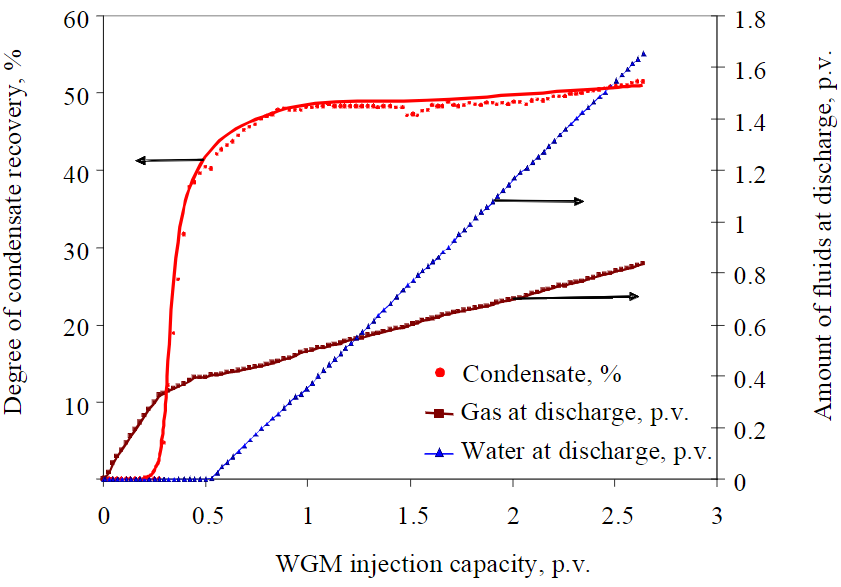

Fig.3. Filtration dynamics in experiment N 6 (condensate displacement by WGM)

Condensate displacement by water-gas mixture

The study of condensate displacement by water showed that it is associated with formation of water-gas mixture (WGM) in a porous medium at gas-water boundary. Therefore, in the following experiments, condensate displacement by a mixture (20 % nitrogenand 80 % water in reservoir conditions) was studied.

Condensate displacement experiment (experiment N 6, Tablе 3) was carried out using a high-permeability reservoir model. Mixing of gas and water was carried out at the entrance to the model. Gas was supplied by a separate pump using a piston column. Final saturations of the porous medium were determined by the material balance method (condensate) and from the results of weighing (water and gas). Characteristics of the reservoir model are given in Table 1; the results of experiment are shown in Fig.3. The experiment demonstrated that gas is initially displaced from the model, then condensate appears at discharge of the reservoir model (together with gas). At the time when condensate appeared, the rate of gas release from the reservoir model decreased noticeably (a break in the dependence curve of gas amount at discharge on the injection volume).

Dynamics of condensate displacement shows that because of water filtration in a porous medium, a bank of condensate formed. After pumping 0.50 p.v. by WGM water appeared at discharge from the reservoir model. At the same time, the release of condensate decreased markedly and gradually stopped.

Comparison of the results of experiment N 6 (displacement of condensate by WGM) and N 3 (displacement of condensate by water) shows that when WGM and water are used in a porous medium, a bank of condensate forms. Condensate displacement in experiment N 6 is practically the same as in experiment N 3. The degree of condensate displacement in experiment N 3 was 51.5 %, and saturation of the porous medium with it decreased from 29 to 14.1 %.

In the studies, a series of experiments was carried out on condensate displacement by a mixture, the results of which are given in Tablе 3.

Table 3

Results of filtration experiments on condensate displacement by water and water-gas mixture

|

Experiment number |

Кgas, |

Initial saturation, % |

Breakthrough after pumping, p.v. |

Displacement degree, % |

Residual saturation, % |

|||||

|

Water |

Condensate |

Gas |

Condensate |

Water |

Condensate |

Gas |

Condensate |

Gas |

||

|

3 |

12.3 |

22.2 |

28.5 |

49.3 |

0.30 |

0.43 |

47.6 |

75.3 |

14.9 |

12.1 |

|

6 |

12.7 |

22.7 |

29.0 |

48.3 |

0.27 |

0.50 |

51.5 |

~60 |

14.1 |

16.4 |

|

7 |

0.764 |

29.0 |

29.9 |

41.1 |

0.22-0.23 |

0.42 |

54.9 |

~70 |

13.5 |

16.5 |

|

8 |

13.3 |

26.9 |

20.6 |

52.5 |

0.26-0.27 |

0.68 |

52 |

~63 |

12.9 |

19.6 |

|

18 |

0.362 |

29.3 |

29.1 |

41.4 |

0.10-0.12 |

0.26 |

49.5 |

~80 |

14.7 |

26.5 |

Comparison of results of condensate displacement by water and mixture demonstrated the following:

- abilities of water and WGM to displace condensate from gas-saturated porous medium are quite close, which is associated with formation of a WGM when water is pumped into gas-saturated porous medium, while the average values of the degree of condensate displacement during water and WGM filtration are 49.7 and 52.0%, respectively.

- residual condensate saturation after displacement by water and WGM differ slightly, the average values of residual condensate saturation in case of displacement by water and WGM are 14.55 and 14.1%, respectively.

- WGM condensate displacement starts faster than in case of using water (induction period on condensate displacement curves is shorter), thus, when condensate is displaced by WGM, formation of a condensate bank occurs faster than in case of displacement by water.

Filtration experiments on oil displacement using sand packed tubes and core material from the Urengoy OGCF

To study oil displacement, a series of filtration experiments was carried out on sand packed tubes and cores of the Urengoy OGCF.

Currently, oil in oil rims at the Urengoy OGCF is degassed because of a drop in reservoir pressure to values below saturation pressure. This led to appearance in the porous medium of another phase, gas phase. Thus, it became necessary to conduct the research aimed at selecting an efficient displacement agent for the development of degassed oil reserves in oil rims of the field.

At the Urengoy OGCF, water and WGM with low gas content are available. The use of gas only (for example, in the mode of miscible or limited miscible displacement of oil by gas agent) and WGM with a high gas content is economically unattractive, since it requires the injection of large volumes of gas (commercial methane or nitrogen) into the reservoir.

In experiments, the displacement of model degassed oil by water and WGM with gas volume content of 20 and 10 % was studied. The first part of the experiments was conducted using sand packed tubes. In addition, an experiment was made with a composite linear model of the reservoir from the core of the pay horizon at the Urengoy OGCF (Tablе 4).

Table 4

Characteristic of composite linear model 2K

|

Sample code |

Sample |

Diameter, cm |

Length, cm |

Pore |

Porosity, % |

Permeability by gas, µm2 |

Initial water saturation, % |

|

4-13a |

23.18 |

2.991 |

3.299 |

4.269 |

18.416 |

0.189 |

32.35 |

|

4-10b |

23.195 |

2.992 |

3.299 |

4.649 |

20.044 |

0.159 |

30.06 |

|

1-9b |

22.492 |

2.985 |

3.214 |

4.441 |

19.746 |

0.146 |

26.04 |

|

4-10a |

22.556 |

2.98 |

3.23 |

4.560 |

20.216 |

0.146 |

29.43 |

|

4-7a |

22.851 |

2.987 |

3.26 |

4.217 |

18.456 |

0.140 |

40.60 |

|

Average values |

2.987 |

3.26 |

4.427 |

19.38 |

0.156 |

31.696 |

|

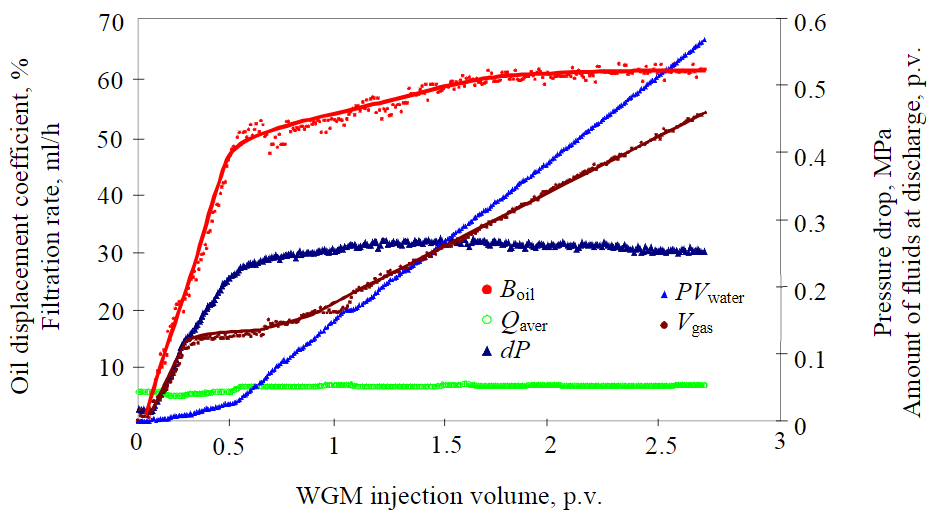

Fig.4. Oil displacement dynamics in experiment 2K

The results of experiment N 2K on oil displacement from the linear composite reservoir model (Tablе 5) from cores of the Urengoy OGCF (Tablе 5, Fig.4) show that oil displacement by WGM and dynamics of oil displacement in experiment N 2K (cores) and N 22 and 24 (sand packed tubes) are of the same type. A small amount of gas is initially displaced from the model, after which a mixture of oil, gas and a small amount of water is observed at discharge from the model, displacement of oil is piston-like. After injection of WGM into 0.47-0.48 p.v. there is an increase in the accumulation rate of water at discharge of the model. At the same time, oil displacement rate noticeably decreases, and pressure begins to stabilize. Overall, for the period of piston-like oil displacement, the displacement degree was 50 %.

Table 5

Results of filtration experiment 2K

|

Stage |

Fluid |

Injection volume, |

Pressure drop, MPA |

Filtration/rate, ml/hour |

Saturation, % |

Oil displacement coefficient, % |

Т, |

Backpressure, MPa |

|||

|

Maximum |

Final |

Oil |

Water |

Gas |

|||||||

|

1 |

Oil |

4.67 |

– |

0.0447 |

6.0 |

68.4 |

31.6 |

0 |

– |

20 |

3.0 |

|

2 |

Nitrogen |

0.121 |

0.0299 |

0.0277 |

6.0 |

54.5 |

31.6 |

13.9 |

– |

20 |

3.0 |

|

3 |

WGM* |

2.64 |

0.268 |

0.258 |

6.0 |

21.3 |

~58 |

~21 |

61 |

70 |

10.0 |

*Breakthrough of water – 0.48 p.v., gas – 0.58 p.v.

Characteristic of reservoir model

Porous medium is cemented core material from the Urengoy OGCF. Permeability: by gas 0.159, by oil at residual water saturation 0.0443 µm2; p.v. 22.14 ml; length 16.31 cm, diameter 2.99 cm. Fluids: oil from the Urengoy OGCF with density 839 kg/m3, viscosity (20 °C) 5.06 mPa·s, mineralized water – sodium chloride solution with density 1,011 kg/m3, WGM – a mixture of mineralized water and nitrogen in 80/20 volume ratio (under reservoir conditions).

Gas is displaced from the reservoir model immediately after the start of filtration. In the range from 0.27 to 0.58 p.v. the amount of gas at discharge practically does not increase (there is a plateau), after which gas discharge continued at a constant rate (gas breakthrough from the WGM). Thus, the displacement of gas contained in the sample and gas breakthrough from the WGM are well separated in time. Based on the plateau level, it was estimated that WGM displaced ~ 90 % of gas contained in the reservoir model.

WGM was injected into 2.64 p.v. of the model. By the end of the experiment, oil displacement from the porous medium ceased; final displacement efficiency was 61 % and residual oil saturation 21.3 %.

Comparison of the results of experiments using natural core (N 2K) and sand packed tubes (N 22, 24) showed good agreement between the degree of oil displacement and residual oil saturation for the types of porous media used (Tablе 6). Thus, sand packed tubes of the reservoir from hydrophilic river sand are adequately simulating the conditions of hydrophilic reservoir at the Urengoy OGCF.

Table 6

Results of filtration experiments on oil displacement

|

Experiment number |

Permeability by gas, µm 2 |

Displacement fluid |

Injection volume, p.v. |

Initial saturation, % |

Degree of oil displacement, % |

Residual oil saturation, % |

Breakthrough of oil, p.v. |

ΔPres, |

|||

|

Oil |

Gas |

At piston mode |

Final |

||||||||

|

20 |

0.480 |

Water |

2.76 |

59.2 |

15.7 |

38.0 |

47.5 |

31.1 |

0.13 |

0.0254 |

|

|

21 |

0.445 |

WGM (80/20) |

0.90 |

58.4 |

16.7 |

42.6 |

50.2 |

29.1 |

0.10 |

0.0485 |

|

|

22 |

0.415 |

WGM (80/20) |

2.56 |

58.3 |

16.3 |

40.0 |

57.0 |

25.1 |

0.12 |

0.0319 |

|

|

24 |

0.381 |

WGM (90/10) |

2.69 |

58.0 |

15.9 |

43.5 |

58.1 |

24.3 |

0.10-0.11 |

0.0419 |

|

|

25 |

0.402 |

WGM (80/20) |

2.78 |

74.9 |

0 |

61.0 |

72.1 |

20.9 |

0 |

0.0397 |

|

|

2К |

0.159** |

WGM (80/20) |

2.64 |

54.5 |

13.9 |

50 |

61 |

21.3 |

0.045 |

0.258 |

|

*ΔPres – the set (final) pressure drop. **Complex linear model of reservoir from core material.

The experiments showed the following:

- WGM is a much more efficient oil-displacement agent than water. When using WGM, higher oil displacement ratios are recorded both in piston sections and in final ones after pumping 2.56-2.78v. fluids (Tablе 6). Thus, even under conditions of immiscible displacement, WGM is a much more efficient fluid than water.

- Filtration experiments were conducted under conditions (inert dry gas, small length of sand packed tubes, shielding effect of water on mass transfer between oil and gas, pressure much lower than miscibility pressure and reservoir pressure), which provided an immiscible mode of oil displacement by gas. In a real reservoir, the efficiency of oil displacement can increase due to a decrease in interfacial tension at gas-oil interfaces as a result of multi-contact mass transfer between oil and gas phases.

- An experiment using a composite linear reservoir model from cemented core material (N2K), as regards the main characteristics of oil displacement, gave the results that coincide with filtration experiments with sand packed tubes (N 22/12, 24/12). Sand packed tubes of hydrophilic river sand adequately simulate the conditions of a hydrophilic reservoir at the Urengoy OGCF.

- Comparison of the results of experiments with reservoir models containing degassed and non-gassed oil shows that the presence of a gas phase in a porous medium reduces the efficiency of oil displacement and increases residual oil saturation of porous media. In experiments N22 and 24, when degassed oil is displaced by the mixture, residual oil saturation is 24.3-25.1 %; in experiment N 25 (non-degassed oil), residual oil saturation is 20.9 %. Thus, the process of oil degassing leads to a loss of reserves. Apparently, the reason for this is the entrapment of part of oil by gas in a porous medium.

- Comparison of the results of experiments N22 and 24 shows that WGM with low gas content (10 %) is a more efficient agent for displacing degassed oil than when a mixture with gas content 20 % is injected into the model for the conditions of the Urengoy OGCF. Thus, it is possible to reduce gas consumption in water-gas technology, which will cut down the costs and facilitate the implementation.

- In all the experiments simulating reservoir stimulation, an induction period was recorded on oil displacement curves. Its presence is explained by the fact that the initially injected fluid enters gas-saturated channels of the porous medium displacing low-viscosity gas from them. And only after the reservoir channels are filled with water and/or WGM, oil displacement begins, and the higher the degree of oil degassing and gas saturation of the porous medium, the longer fluid injection will not lead to oil displacement from the reservoir. Increasing degree of oil degassing reduces the efficiency of subsequent oil production.

- The study of degassed oil displacement by water and WGM was performed with reservoir models having almost the same initial gas and oil saturation. Apparently, this, as well as a small length of reservoir models, are the reasons why the duration of the induction period did not depend on composition of the displacement fluid. It can be assumed that in real reservoir conditions, a higher filtration resistance of WGM (compared to water) will allow to quickly reach pressure gradients at which oil begins to move.

- Data in Table 6 show that pressure drops during WGM filtration (experiments N22, 24 and 25) turned out to be greater than during water filtration (experiment N 20), which indicates that WGM injection into the reservoir will occur at higher injection pressures and/or lower well injectivity. However, the difference in filtration characteristics of fluids will make it possible to affect the reservoir more fully. It is possible to push down the WGM rim in the reservoir by pumping water, which will reduce the costs and gas consumption. When WGM is injected, filtration resistance increases 1.4-1.5-fold. It can be presumed that the injectivity of wells in case of WGM injection will also be 1.4-1.5 times lower than during flooding.

Conclusion

It was ascertained that for conditions of the Urengoy OGCF, water-gas mixtures with low gas content (10-20 %) have a higher oil displacement ability with respect to degassed oil as compared to water. The displacement degree of degassed oil by WGM is 9.5-13.5 % higher, and residual oil saturation is 6.0-9.8 % lower than in case of water displacement.

The experiment with a composite linear reservoir model from cemented core material, in terms of the main characteristics of oil displacement, gave the results that coincide with those of filtration experiments with sand packed tubes and showed a high efficiency of SWAG injection as a method of increasing oil recovery when used on oil rims of gas condensate fields.

Based on the performed studies, it can be concluded that SWAG injection showed good results in experiments on displacement of condensate, residual gas, and oil.

References

- Koryakin A.Yu. Integrated solutions for the development and operation of wells of the Urengoysky production complex. Мoscow: RGU nefti i gaza imeni I.M.Gubkina, 2016, p. 272 (in Russian).

- Dubiv I.V. Assessment of prospective development technologies complicated-structure fields of high-viscous oil (Taz OGCF example). Bureniye i neft'. 2014. N 5, p. 28-30.

- Perepelichenko V.F. Prospects of development of the unique oil and gas condensate field of Yakutia. Georesources, geoenergetics, geopolitics. 2012. N 1 (5), p. 67 (in Russian).

- Drozdov N.A. Investigation of water-alternating-gas injection. Neftyanoye khozyaystvo. 2011. N 11, p. 80-83 (in Russian).

- Drozdov А.N., Gorelkina Е.I. Development of a pump-ejector system for SWAG injection into reservoir using associated petroleum gas from the annulus space of production wells. Journal of Mining Institute. 2022. Vol. 254, p. 191-201. DOI: 10.31897/PMI.2022.34

- Drozdov A.N., Drozdov N.A. Laboratory Researches of the Heavy Oil Displacement from the Russkoye Field’s Core Models at the SWAG Injection and Development of Technological Schemes of Pump-Ejecting Systems for the Water-Gas Mixtures Delivering. SPE Heavy Oil Conference Canada, 12-14 June 2012. SPE 157819. DOI: 10.2118/157819-MS

- Drozdov A.N., Drozdov N.A., Malyavko E.A. et al. Investigation of SWAG Injection and Prospects of Its Implementation with the Usage of Pump-Ejecting Systems at Existing Oil-Field Infrastructure. SPE Russian Oil and Gas Exploration and Production Technical Conference and Exhibition, 16-18 October 2012, Moscow, Russia. SPE-160687-MS, p. 852-866. DOI: 10.2118/160687-ms

- Drozdov A., Gorbyleva Ya., Drozdov N., Gorelkina E. Perspectives of application of simultaneous water and gas injection for utilizing associated petroleum gas and enhancing oil recovery in the Arctic fields. IOP Conference Series: Earth and Environmental Science. 2021. Vol. 678. N 012039. DOI: 10.1088/1755-1315/678/1/012039

- Drozdov A.N., Drozdov N.A. Principal Proposals on Technical Implementation of SWAG injection on the Urengoy Field. Territorija “NEFTEGAS” (Oil and Gas Territory). 2017. N 10, p. 56-60. (in Russian).

- Drozdov A.N., Drozdov N.A., Bunkin N.F., Kozlov V.A. Study of Suppression of Gas Bubbles Coalescence in the Liquid for Use in Technologies of Oil Production and Associated Gas Utilization. SPE Russian Petroleum Technology Conference, 16-18 October 2017, Moscow, Russia. SPE-187741-MS. DOI: 10.2118/187741-MS

- Drozdov A.N., Gorelkina E.I., Gorbyleva Ya.A., Narozhnyy I.M. Application of pump-ejecting system for SWAG injection and utilization of associated gas. International Conference on Engineering Systems 14-16 October 2020, Moscow, Russia. Journal of Physics: Conference Series. 2020. Vol. 1687. N 012040. DOI: 10.1088/1742-6596/1687/1/012040

- Drozdov A.N., Gorbyleva Y.А. Improving the Operation of Pump-ejector Systems at Varying Flow Rates of Associated Petroleum Gas. Journal of Mining Institute. 2019. Vol. 238, p. 415-422. DOI: 10.31897/PMI.2019.4.415

- Drozdov A.N., Karabaev S.D., Olmaskhanov N.Р. et al. Investigation of pump-ejector systems characteristics for water alternating gas injection. Advances in Raw Material Industries for Sustainable Development Goals. London: Taylor & Francis Group, 2021, p. 358-367. DOI: 10.1201/9781003164395-45

- Gorelkina E.I. Improvement of Pump-Ejector Systems in order to Increase the Gas Discharge Pressure and System Efficiency. International science and technology conference “Earth science”, 8-10 December 2020, Vladivostok, Russian Federation. IOP Conference Series: Earth and Environmental Science. 2021. Vol. 666. N 062007. DOI:10.1088/1755-1315/666/6/062007

- Drozdov A.N. Stand Investigations of ESP's and Gas Separator's Characteristics on GasLiquid Mixtures with Different Values of Free-Gas Volume, Intake Pressure, Foaminess and Viscosity of Liquid. SPE Annual Technical Conference and Exhibition, 19-22 September 2010, Florence, Italy. SPE-134198-MS. DOI: 10.2118/134198-MS

- Zharko V., Burdakov D. Pilot Project Evaluating WAG Efficiency for Carbonate Reservoir in Eastern Siberia. SPE Russian Petroleum Technology Conference, 12-15 October 2021. SPE-206417-MS. DOI: 10.2118/206417-MS

- Azari V., Rodrigues H., Suieshova A. et al. Long-term Strategy Optimization of Scale Squeeze Treatment in a Carbonate Reservoir Under CO2-WAG Water-Alternating-Gas Injection. SPE International Conference on Oilfield Chemistry, 6-7 December 2021. SPE-204352-MS. DOI: 10.2118/204352-MS

- Xiaoying Li, Shuhua Wang, Bin Yuan, Shengnan Chen. Optimal Design and Uncertainty Assessment of CO2 WAG Operations: A Field Case Study. SPE Improved Oil Recovery Conference, 14-18 April 2018. SPE-190157-MS. DOI: 10.2118/190157-MS

- Holtz M.H. Immiscible Water Alternating Gas (IWAG) EOR: Current State of the Art. SPE Improved Oil Recovery Conference, 11-13 April 2016, Tulsa, Oklahoma, USA. SPE-179604-MS. DOI: 10.2118/179604-MS

- Kohata A., Willingham T., Chen P., Al Sowaidi A. Evaluation of Miscible Water Alternating Gas WAG Injection by Comparing with Lesson Learnt from an Immiscible Gas Injection Pilot. Abu Dhabi International Petroleum Exhibition & Conference, 13-16 November 2017, Abu Dhabi, UAE. SPE-188243-MS. DOI: 10.2118/188243-MS

- Shahrokhi O., Sohrabi M., Masalmeh Sh. The Impact of Gas/Oil IFT and Gas Type on the Performance of Gas, WAG and SWAG Injection Schemes in Carbonates Rocks. SPE EOR Conference at Oil and Gas West Asia, 26-28 March 2018, Muscat, Oman. SPE-190338-MS. DOI: 10.2118/190338-MS

- Ghazo S. Successful Implementation of EPC for New WAG Wells Project at SE-Field at ADCO. Abu Dhabi International Petroleum Exhibition & Conference, 7-10 November 2016, Abu Dhabi, UAE. SPE-183096-MS. DOI: 10.2118/183096-MS

- Chen H., Sen D., Datta-Gupta A., Nagao M. Model-Free Assessment of Inter-Well Connectivity in CO2 WAG Projects Using Statistical Recurrent Unit Models. SPE Annual Technical Conference and Exhibition, 21-23 September 2021, Dubai, UAE. SPE-205944-MS. DOI: 10.2118/205944-MS

- Mavis S., Berok J., Sinanan H.B. et al. Intelligent Completion Implementation in Immiscible WAG Wells in a Mature Offshore Field EOR Project. SPE Asia Pacific Oil & Gas Conference and Exhibition, 17-19 November 2020. SPE-202313-MS.DOI: 10.2118/202313-MS

- Larsen A., Førland T., Øian E., Jarlsby D.O. Simulation Study for Field Implementation of WAG as Initial Drainage Strategy. SPE Norway Subsurface Conference, 2-3 November 2020. SPE-200727-MS. DOI: 10.2118/200727-MS

- Katiyar A., Quoc N. A Numerically Optimized WAG Injection Strategy for Successful Implementation of Foam Assisted Gas EOR. SPE Annual Technical Conference and Exhibition, 26-29 October 2020. SPE-201758-MS. DOI: 10.2118/201758-MS

- Bascialla G., Montes J., Romero P. et al. Feasibility of Foam Application in a Giant Mature Field Under Miscible WAG Injection. Abu Dhabi International Petroleum Exhibition & Conference, 13-16 November 2017, Abu Dhabi, UAE. SPE-188424-MS. DOI: 10.2118/188424-MS

- Batot G., Delaplace Ph., Bourbiaux B. et al. WAG Management with Foams: Influence of Injected Gas Properties and Surfactant Adsorption. Abu Dhabi International Petroleum Exhibition & Conference, 7-10 November 2016, Abu Dhabi, UAE. SPE-183326-MS. DOI: 10.2118/183326-MS

- Groenenboom J., Kechut N.I., Mar-Or A. Foam-Assisted WAG: Injection Strategies to Optimize Performance. SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, 17-19 October 2017, Jakarta, Indonesia. SPE-186991-MS. DOI: 10.2118/186991-MS

- Mohd Shafian S.R., Kamarul Bahrim R., Foo Y. et al. Foam Mobility Control During WAG Injection in a Difficult Reservoir With High Temperature and High Acid Gas. SPE Asia Pacific Enhanced Oil Recovery Conference, 11-13 August 2015, Kuala Lumpur, Malaysia. SPE-174571-MS. DOI: 10.2118/174571-MS

- Spirov P., Rudyk S.N., Khan A.A. Foam Assisted WAG, Snorre Revisit with New Foam Screening Model. North Africa Technical Conference and Exhibition, 20-22 February 2012, Cairo, Egypt. SPE-150829-MS. DOI: 10.2118/150829-MS

- Palyanitsina A., Safiullina E., Byazrov R. et al. Environmentally Safe Technology to Increase Efficiency of High-Viscosity Oil Production for the Objects with Advanced Water Cut. Energies. 2022. Vol. 15(3), p. 1-20. DOI: 10.3390/en15030753

- Mukhametzyanov I., Glavnov N., Akchurin R. et al. Field Test of Nitrogen Injectivity as a Method to Reduce the Uncertainties for the Miscible WAG Project. SPE Improved Oil Recovery Conference, 31 August – 4 September 2020. SPE-200386-MS. DOI: 10.2118/200386-MS

- Nwachukwu A., Hoonyoung J., Sun A. et al. Machine Learning-Based Optimization of Well Locations and WAG Parameters under Geologic Uncertainty. SPE Improved Oil Recovery Conference, 14-18 April 2018, Tulsa, Oklahoma, USA. SPE-190239-MS. DOI: 10.2118/190239-MS

- Zakharov L.А., Martyushev D.А., Ponomareva I.N. Predicting dynamic formation pressure using artificial intelligence methods. Journal of Mining Institute. 2022. Vol. 253, p. 23-32. DOI: 10.31897/PMI.2022.11

- Katysheva E., Tsvetkova A. Economic and institutional problems of the russian oil and gas complex digital transformation. International Multidisciplinary Scientific Geo Conference Surveying Geology and Mining Ecology Management, 30 June – 6 July 2019. Proceedings 19th International Multidisciplinary Scientific GeoConference SGEM. 2019. Vol. 19. N 5.3, p. 203-208.DOI: 10.5593/sgem2019/5.3/S21.026

- Samylovskaya E., Makhovikov A., Lutonin A. et al. Digital Technologies in Arctic Oil and Gas Resources Extraction: Global Trends and Russian Experience. Resources. 2022. Vol. 11(3), p. 1-29. DOI: 10.3390/resources11030029

- Semenova T. Value Improving Practices in Production of Hydrocarbon Resources in the Arctic Regions. Journal of Marine Science and Engineering. 2022. Vol. 10, p. 187-199. DOI: 10.3390/jmse10020187

- Koptev V.Y., Kopteva A.V., Poddubniy D.A. Increase in Energy Efficiency of Oil and Gas Companies by Perfecting of Management Systems. Proceedings of the 2019 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus). 2019, p. 548-552. DOI: 10.1109/EIConRus.2019.8657041

- Litvinenko V., Bowbriсk I., Naumov I., Zaitseva Z. Global guidelines and requirements for professional competencies of natural resource extraction engineers: Implications for ESG principles and sustainable development goals. Journal of Cleaner Production. 2022. Vol. 338. N 130530. DOI: 10.1016/j.jclepro.2022.130530

- Moghadasi L., Ranaee E., Renna D. et al. Combining Two- and Three-Phase Coreflooding Experiments for Reservoir Simulation Under WAG Practices. International Petroleum Technology Conference, 13-15 January 2020, Dhahran, Kingdom of Saudi Arabia. N IPTC-19914-Abstract. DOI: 10.2523/IPTC-19914-Abstract

- Al-Qattan A., Gharbi R., Aladwani F. The Performance of Miscible Displacement in Marrat Reservoir. SPE Kuwait Oil and Gas Show and Conference, 8-10 October 2013, Kuwait City, Kuwait. SPE-167278-MS. DOI: 10.2118/167278-MS

- Carpenter C. Largest WAG Pilot in Giant Al-Shaheen Field Reveals Optimization Methods. Journal of Petroleum Technology. 2019. Vol. 71(06), p. 79-80. DOI: 10.2118/0619-0079-JPT

- Klenner R., Gao P., Taghizadeh O. et al. Optimization of Production and CO2 Utilization Via Parametric Representation and Evaluation of WAG Schedules. SPE Improved Oil Recovery Conference, 11-13 April 2016, Tulsa, Oklahoma, USA. SPE-179582-MS. DOI: 10.2118/179582-MS

- Popov D.I. Study of the possibilities of water-gas stimulation of formation using pump-ejector systems. Journal of Mining Institute. 2008. Vol. 174, p. 53-55 (in Russian).

- Gimazov A.A., Russkikh K.G., Murinov K.Yu. et al. Core Flow Models For Analysis Of Laboratory Tests On Parameters For WAG Simulations: A Case Study From R. Trebs Oil Field. SPE Russian Petroleum Technology Conference, 26-28 October 2015, Moscow, Russia. SPE-176593-MS. DOI: 10.2118/176593-MS

- Bo R., Male F., Wang Y. et al. Oil Saturation in Residual Oil Zones and Its Effect on CO2 WAG Injection Strategies. SPE Annual Technical Conference and Exhibition, 30 September – 2 October 2019, Calgary, Alberta, Canada. SPE-196230-MS.DOI: 10.2118/196230-MS

- Hao Chen, Shenglai Yang, Jianchun Liu et al. Experimental Study on Injection Strategy of CO2 Near-Miscible Flooding in Low Permeability Reservoirs with High Water Cut. International Petroleum Technology Conference, 14-16 November 2016, Bangkok, Thailand. N IPTC-18770-MS. DOI: 10.2523/IPTC-18770-MS

- Hasan S., Kumar M., Abdelrahman M. et al. Reservoir Monitoring Activities for CO2 WAG Pilots. Abu Dhabi International Petroleum Exhibition & Conference, 15-18 November 2021, Abu Dhabi, UAE. SPE-208076-MS. DOI: 10.2118/208076-MS

- Itriago C.Y., Araujo M., Molinaris J. Best Practices for Laboratory Evaluation of Immiscible WAG. SPE Improved Oil Recovery Conference, 14-18 April 2018, Tulsa, Oklahoma, USA. SPE-190303-MS. DOI: 10.2118/190303-MS

- Votinov А.S., Seredin V.V., Kolychev I.Yu., Galkin S.V. Possibilities of accounting the fracturing of Kashiro-Vereyskian carbonate objects in planning of proppant hydraulic fracturing. Journal of Mining Institute. 2021. Vol. 252, p. 861-871. DOI: 10.31897/PMI.2021.6.8

- Galkin V.I., Koltyrin А.N. Investigation of probabilistic models for forecasting the efficiency of proppant hydraulic fracturing technology. Journal of Mining Institute. 2020. Vol. 246, p. 650-659. DOI: 10.31897/PMI.2020.6.7

- Chernyshov S.E., Repina V.A., Krysin N.I., MacDonald David Iain MacPherson. Improving the efficiency of terrigenous oil-saturated reservoir development by the system of oriented selective slotted channels. Journal of Mining Institute. 2020. Vol. 246, p. 660-666. DOI: 10.31897/PMI.2020.6.8

- Galkin S.V., Kochnev A.A., Zotikov V.I. Estimate of Radial Drilling Technology Efficiency for the Bashkir Operational Oilfields Objects of Perm Krai. Journal of Mining Institute. 2019. Vol. 238, p. 410-414. DOI: 10.31897/PMI.2019.4.410

- Galkin S.V., Krivoshchekov S.N., Kozyrev N.D., Kochnev A.A., Mengaliev A.G. Accounting of geomechanical layer properties in multi-layer oil field development. Journal of Mining Institute. 2020. Vol. 244, p. 408-417. DOI:10.31897/PMI.2020.4.3

- Petrakov D., Kupavykh K., Kupavykh A. The effect of fluid saturation on the elastic-plastic properties of oil reservoir rocks. Curved and Layered Structures. 2020. Vol. 7. Iss. 1, p. 29-34. DOI: 10.1515/cls-2020-0003

- Kashnikov Yu.A., Ashikhmin S.G., Kukhtinskii A.E., Shustov D.V. The relationship of fracture toughness coefficients and geophysical characteristics of rocks of hydrocarbon deposits. Journal of Mining Institute. 2020. Vol. 241, p. 83-90. DOI: 10.31897/PMI.2020.1.83

- Galkin V.I., Martyushev D.A., Ponomareva I.N., Chernykh I.A. Developing features of the near-bottomhole zones in productive formations at fields with high gas saturation of formation oil. Journal of Mining Institute. 2021. Vol. 249, p. 386-392. DOI: 10.31897/PMI.2021.3.7

- Krivoshchekov S.N., Kochnev А.А., Ravelev K.A. Development of an algorithm for determining the technological parameters of acid composition injection during treatment of the near-bottomhole zone, taking into account economic efficiency. Journal of Mining Institute. 2021. Vol. 250, p. 587-595. DOI: 10.31897/PMI.2021.4.12

- Martyushev D.A. Improving the geological and hydrodynamic model of a carbonate oil object by taking into account the permeability anisotropy parameter. Journal of Mining Institute. 2020. Vol. 243, p. 313-318. DOI: 10.31897/PMI.2020.3.313

- Dvoynikov M.V., Budovskaya M.E. Development of a hydrocarbon completion system for wells with low bottomhole temperatures for conditions of oil and gas fields in Eastern Siberia. Journal of Mining Institute. 2022. Vol. 253, p. 12-22. DOI: 10.31897/PMI.2022.4

- Mukhametshin V.Sh., Khakimzyanov I.N. Features of grouping low-producing oil deposits in carbonate reservoirs for the rational use of resources within the Ural-Volga region. Journal of Mining Institute. 2021. Vol. 252, p. 896-907. DOI: 10.31897/PMI.2021.6.11

- Chanysheva A., Ilinova A. The Future of Russian Arctic Oil and Gas Projects: Problems of Assessing the Prospects. Journal of Marine Science and Engineering. 2021. Vol. 9(5), p. 1-15. DOI: 10.3390/jmse9050528

- Ibatullin A.Kh., Zharkov A.M., Kochneva O.E. Geological and economic assessment of resources of oil field of the West-Siberian oil and gas province. Advances in Raw Material Industries for Sustainable Development Goals. London: Taylor & Francis Group, 2021, p. 52-61.

- Prischepa O.M., Nefedov Y.V., Guznenko V.A. Unconventional oil and gas resources of high-carbon low-permeable strata of the domanic type of Russia. Conference Proceedings Geomodel 2021 – 23th Conference on Oil and Gas Geological Exploration and Development. 2021, p. 1-6. DOI: 10.3997/2214-4609.202157102

- Syasko V., Shikhov A. Assessing the State of Structural Foundations in Permafrost Regions by Means of Acoustic Testing. Applied Sciences (Switzerland). 2022. Vol. 12(5). N 2364. DOI: 10.3390/app12052364