The influence of the shape and size of dust fractions on their distribution and accumulation in mine workings when changing the structure of air flow

- 1 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 3 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid

- 4 — Postgraduate Student Saint Petersburg Mining University ▪ Orcid

Abstract

The results of the analysis of statistical data on accidents at Russian mines caused by explosions in the workings space have shown that explosions of methane-dust-air mixtures at underground coal mines are the most severe accidents in terms of consequences. A detailed analysis of literature sources showed that in the total number of explosions prevails total share of hybrid mixtures, i.e. with the simultaneous participation of gas (methane) and coal dust, as well as explosions with the possible or partial involvement of coal dust. The main causes contributing to the occurrence and development of dust-air mixture explosions, including irregular monitoring of by mine engineers and technicians of the schedule of dust explosion protective measures; unreliable assessment of the dust situation, etc., are given. The main problem in this case was the difficulty of determining the location and volume of dust deposition zones in not extinguished and difficult to access for instrumental control workings. Determination of the class-shape of coal dust particles is a necessary condition for constructing a model of the dust situation reflecting the aerosol distribution in the workings space. The morphological composition of coal mine dust fractions with dispersion less than 0.1 has been studied. Particle studies conducted using an LEICA DM 4000 optical microscope and IMAGE SCOPE M software made it possible to establish the different class-shapes of dust particles found in operating mines. It was found that the coal dust particles presented in the samples correspond to the parallelepiped shape to the greatest extent. The mathematical model based on the specialized ANSYS FLUENT complex, in which this class-form is incorporated, is used for predicting the distribution of explosive and combustible coal dust in the workings space. The use of the obtained model in production conditions will allow to determine the possible places of dust deposition and to develop measures to prevent the transition of coal dust from the aerogel state to the aerosol state and thereby prevent the formation of an explosive dust-air mixture.

Introduction

The percentage of explosions of methane-dust-air mixtures at underground enterprises of coal mining organizations in Russia makes up a significant part of the total number of accidents with severe consequences, which is confirmed by the analysis of statistical data [1-3]. The results of the analysis of the acts of technical investigation showed that the total percentage of explosions with simultaneous involvement of gas and dust and explosions with possible or partial involvement of coal dust prevails. The direct cause of the explosion of the dust medium was almost always the ignition of a methane-air mixture, followed by the involvement of dust fractions in the process [4, 5].

Researchers identify the main causes contributing to the occurrence and development of the dust-air mixtures explosion [6-9]:

- irregular removal of coal dust in deposition zones in mine workings in hard-to-control places;

- irregular monitoring by mine engineering and technical workers of the schedule of dust and explosion protection measures, including within the excavation site and conveyor workings of the mine [10, 11];

- the inability to promptly obtain reliable information about the amount of coal dust deposited and the presence of methane in previously spent not extinguished workings that have an aerodynamic connection with the workings of existing excavation sites;

- the imperfection of existing methods of direct measurement in the workings of floating and settled dust, which cannot be applied due to the difficulty of access and the possibility of disruption of the concentration field distribution during measurement;

- erroneous estimation of the settled dust zones size due to the duration of the deposition process in time [12-14].

These reasons are directly related to the intensification of mining operations and are a consequence of the problem of insufficient knowledge of the coal mine dust particles properties, the relevance of which has now increased significantly [10, 14, 15]. The properties of dust particles affect the dynamics of dust distribution in the volume of mine workings [9, 16, 17]. The solution of this problem for practical implementation will make it possible to develop measures aimed at preventing the occurrence, development and propagation over long distances of hybrid mixtures explosions formed during the transition of dust deposits in the state of aerogel into an aerodisperse system – aerosol [18-20].

In practice, the most rational method of ensuring the safety of the dust factor in the process of mining operations is an early assessment of the dynamics of the explosive dust accumulations formation. Such an assessment should be carried out not only at permanent workplaces, but also in the entire space of excavation sites, where the presence of mine personnel is necessary during the mining and transportation of coal [21-23].

One of the ways to solve this problem is the method of determining the class-shape of floating and settled coal particles. Taking into account the data obtained as a result of its implementation, a distribution model for mining workings is being built. At the same time, mathematical modeling is a tool, the results of which are necessary for the development of recommendations aimed at identifying potentially dangerous zones for the occurrence and propagation. The aim of the research is to study the influence of the shape and size of dust fractions on the process of their distribution and accumulation in the space of mine workings by compiling microscopy methods and the capabilities of the software environment. Microscopy was used at the initial stage to obtain the initial data necessary to set a number of boundary conditions when modeling particle distribution processes in the mining space in the ANSYS FLUENT software environment [23, 24].

The authors analyzed the dispersed composition of coal dust during the operation of various complexes, including its dependence on the design features of cutting elements (cutters) and a number of other production and technological factors.

It has been established that the presence of certain class-shape of dust particles is not affected by the type of mining equipment, since all types of particles are present in the dust. Different coal mining technology affects only the proportion of certain class-shape of dust particles, which cannot be accurately measured due to the morphological features of the extracted raw materials, the mining equipment used, dedusting methods and a number of other parameters. Currently, in Russia, even on thin (no more than 1.2 m) layers, various mining combines are used.

To establish the class-shape of dust particles, a technique has been developed based on the study of the morphological composition of coal mine dust of the Zh grade of the Vorkutinskaya Triple mine formation and used in further work in the study of the class of particle forms of the Kuznetsk and Donbass coal basins mines. As a tool for developing an optimal model for the hybrid mixture movement, including a two-phase flow of “air-coal dust”, it is proposed to use a specialized complex ANSYS FLUENT [25, 26].

Methodology

To develop the research method, a comparative analysis of the methods for studying coal dust fractions described in [26-30] was carried out, on the basis of which a method for studying the forms of dust particles was proposed.

In the study of the size-consist of coal dust:

- Coal sampling in the conditions of the mine was carried out in accordance with GOST 10742 and GOST 9815.

- Preparation of coal samples consisted in crushing and dispersing the selected samples.

- The resulting mass was subjected to granulometric sieving and the selection of groups of the studied fractions containing particles with a characteristic size of less than 0.1 mm, while the ash content of the studied dust was determined, which was no more than 10 %.

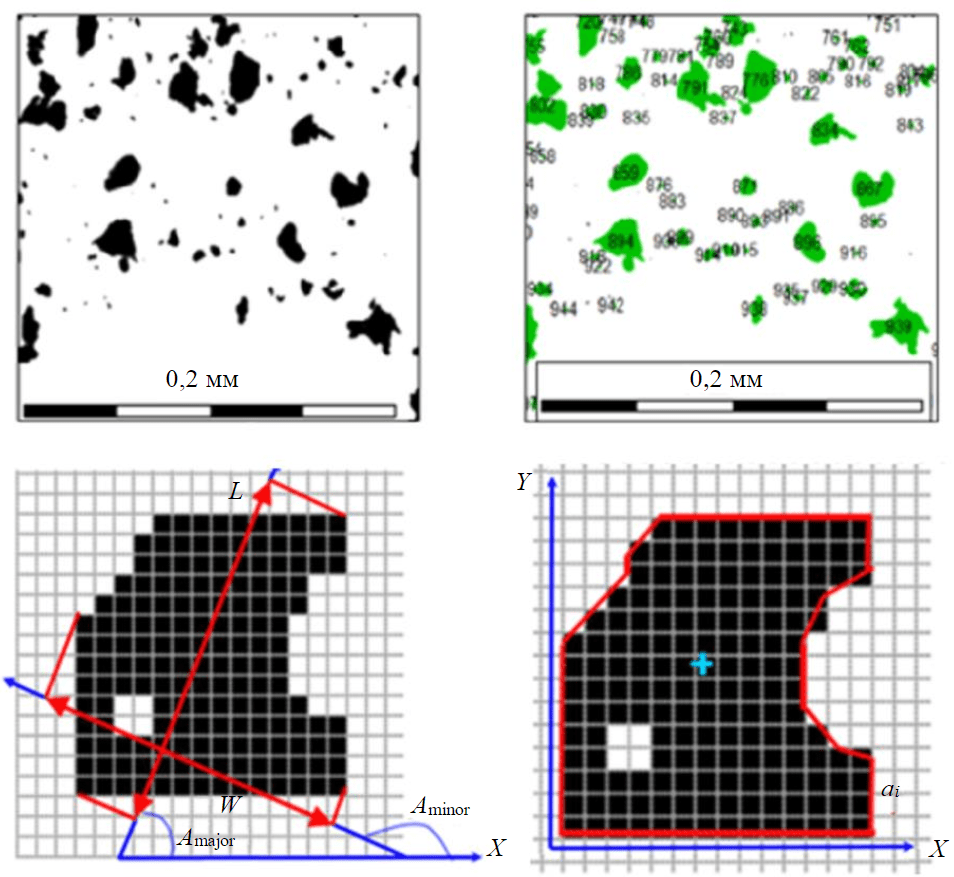

- The morphological composition of the selected coal dust fractions was studied by microscopic analysis based on obtaining high-quality photographs of a high degree of detail using an image capture camera equipped with a LEICA DM 4000 optical microscope.

- Further processing of samples was carried out using specialized IMAGE SCOPE M software with correction of background brightness, contrast and image settings. The images visible in the eyepiece of the microscope were displayed on a computer monitor and the selected parameters of the study objects were exported to various software products for further processing. One of the stages of processing the obtained image of coal dust particles is shown in Fig.1, as an example, a scheme for calculating the class-shape of particles in the IMAGE SCOPE М software package is also given.

Fig.1. The view of the visualized particles and the scheme for calculating the characteristic geometric parameters of particles in the IMAGE SCOPE software package (L is the length of the projection of the object on the major axis of the ellipse having the same moments of inertia as the object; W is the width and length of the projection of the object on the minor axis of the ellipse having the same moments of inertia as the object; ai is a segment approximating the surface of the object)

To identify the most typical class-shape of each dust fraction, after obtaining photographic images of objects, the analysis of the obtained particle images was performed. For dust particles with a size of less than 0.1 m, the presence of four three-dimensional class-shapes of coal dust fractions floating and settling in the space of workings has been established: spherical, ellipsoid, cubic, parallelepiped. In the area of larger fractions, the shape of dust particles in the form of a parallelepiped was mainly traced, determined by the direction and density of cracks in the coal rock.

The processed photographs represent projections of real shapes on the observation plane in the form of two-dimensional objects close to standard geometric shapes: circle, ellipse, square, rectangle.

According to the recommendations, in order to increase the reliability of the research results, a set of analyzed particles was sampled – at least one and a half thousand units in each fraction [6, 7, 24].

For further analysis in the IMAGE SCOPE M program, the necessary characteristic parameters of coal dust particle projection images were selected.

The areas of the research objects were determined by summing up all the pixels of the occupied area:

The perimeters of the study objects were calculated as the sum of segments approximating the line of the outer boundary of the occupied area:

The analysis of the obtained geometric parameters of the images of dust particles (length, width, area and perimeter) allowed to establish that coal dust particles mostly have an elongated shape, differing in the prevailing dimensions along one of the axes in three-dimensional space, i.e. they cannot be completely attributed to particles of isometric shape (sphere or regular polyhedron). To quantify such a class-shape, a developed technique based on the cross-method was used [31-34].

As a quantitative criterion for the geometric characteristics of particles, a symmetry coefficient was introduced, which was the ratio of the length to the width of the occupied area:

k = L/W.

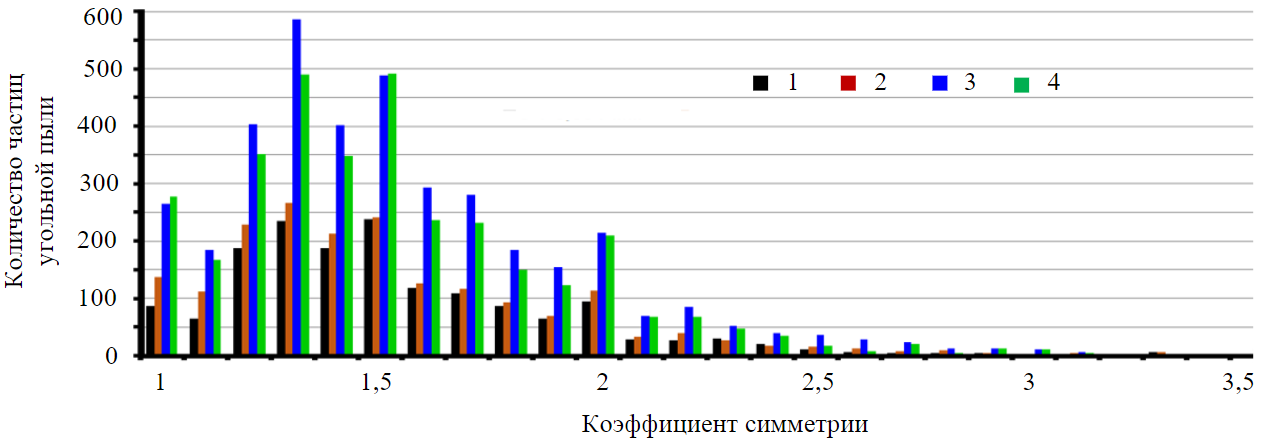

An example of the obtained dependence of the distribution of the percentage of the maximum number of particles in control batches of 1500 units with a certain symmetry coefficient is shown

in Fig.2.

It was found that most of the selected set (500-600 units, which is 33-40 % of the total number of particles in the batch under study) has a moderately elongated shape with a symmetry coefficient of 1.3-1.5. The percentage characterizing particles with a symmetry coefficient equal to one for all the studied fractions did not exceed 18 %.

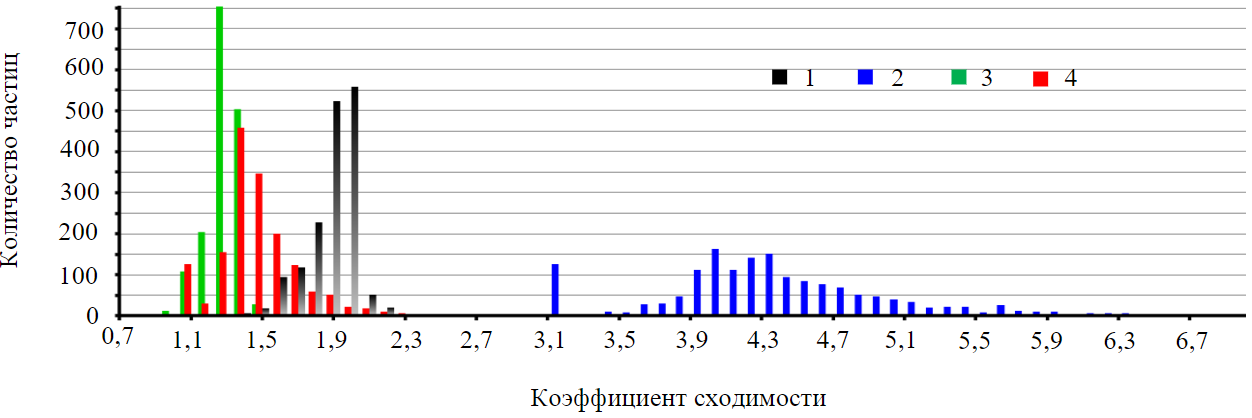

A decision was made on the rationality of using the identity of known geometric shapes with the class-shapes of coal dust to characterize the sample under study. To assess the reliability of the studies, deviations of the measured sizes of coal dust fractions from analytically determined parameters of geometric shapes closest to them in terms of the symmetry coefficient were determined.

An additional quantitative criterion for the geometric characteristics of particles is the ratio of the true value of a characteristic geometric parameter (area or perimeter) to the value calculated analytically (convergence coefficient):

K = Sa/St,

where Sa is the analytically determined area of the particle; St is the true area of the particle;

K = Рa/Рt,

Ра is an analytically defined perimeter of the particle; Рt is the true perimeter of the particle.

Fig.2. Dependence of the distribution of the number of dust particles on the symmetry coefficient 1 – 0.1-0.094 mm; 2 – 0.094-0.056; 3 – 0.056-0.05; 4 – less than 0.05

Fig.3. Dependence of the distribution of coal dust particles with a size of 0.1-0.094 mm on the convergence coefficient of the shape 1, 2 – the perimeter and area of the ellipse; 3, 4 – the perimeter and area of the rectangle

An example of the obtained dependence of the distribution of the percentage of the maximum number of particles in control batches of 1500 units with a certain coefficient of convergence of the shape is shown in Fig.3.

The analysis of the data in Fig.3 showed that coal dust fractions have different distribution patterns in all samples, while the greatest convergence, characterized by a coefficient close to one, corresponds to the class-shape of dust particles projected onto the observation plane in the form of a rectangle.

Taking into account the obtained data for the mathematical model of the two-phase flow “air-coal dust” movement, which allows to obtain the distribution of mine dust in mine workings, a characteristic class-shape of dust particles is chosen in the form of a parallelepiped.

Results

To obtain results with a high degree of reliability, a mathematical model of a two-phase flow “air-coal dust” movement in the ANSYS FLUENT software product was created taking into account the results of modeling studies of carrier gaseous mediums [35-37].

The construction of the mathematical model was carried out sequentially in several stages:

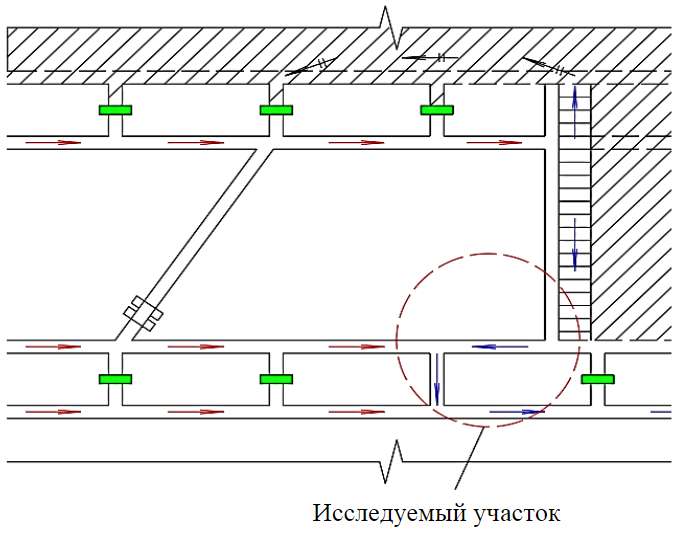

1. Creation of a three-dimensional model of the investigated section of workings. The construction was carried out geometrically similar to the natural conditions of the site of the coupling of longwall and conveyor drift. On the model of the excavation site, the direction of the carrier air medium corresponding to the combined ventilation scheme with an isolated discharge of the methane-air mixture was set. The simulated ventilation scheme of the excavation area with a dedicated study area is shown in Fig.4.

Fig.4. Ventilation scheme of the excavation site

2. Construction of the calculation grid. For workings with relatively simple geometry, as well as in the case of the possibility of using small amounts of design elements, a rectangular locally crushed grid is set. To solve more complex problems, adaptive adjustment of the grid to the geometry features in the places of interest to researchers is carried out in order to achieve a given calculation accuracy. When modeling the interface area of the lava and the conveyor drift, the cell size of 0.25 × 0.25 m was set in the form of a cubic grid, into which the model was divided.

3. Statement the solution of the problem in modeling. Taking into account the fact that the floating dust in natural conditions has a volume significantly smaller than the volume of the air mixture, the volume concentration of dust particles in the air is not exceeding 10−6. In this case, the influence of particles on the parameters of the gas phase can be neglected and the motion of particles and gas can be calculated independently of each other.

The movement of dust particles was considered taking into account the Lagrange approach. When calculating in the equation of a particle movement, its dimensions were considered as characteristics of the class-shape.

Additionally, the conditions of two-way interaction of particles with a continuous medium and action along one of the axes of gravity force were set.

The standard k-epsilon turbulence model has been adopted [38, 39], which is described as follows:

where Gk is the turbulent kinetic energy obtained from the average velocity gradients (according to the Boussinesq hypothesis),

Gk = μtΔ2,

ρ is the gas density; Сμ = const; Δ is the interval of the strain tensor,

β – coefficient of thermal expansion; Prt – the turbulent Prandtl constant for energy; qi – component of the gravity vector in the i-th direction;

T – temperature.

A constant that determines the degree of interaction of the buoyancy force on ε,

where v′ and u′ – the components of the gas velocity, respectively, for parallel and perpendicular gravity velocity.

The contribution of variable expansion to the total dissipation rate, taking into account the turbulence of compression, taken in consideration for a large Mach number, in the case when a compressible ideal gas is modeled:

where M – Mach number,

a – the sound velocity,

The constants defined for the conditions specified in the simulation have the following values: C1ε = 1.44; C2ε = 1.92; Cμ = 0.09; σk = 1.44; σε = 1.3.

4. Setting boundary conditions in modeling [26, 27, 35]. For the calculation, the following conditions were set: the flow inlet is a conditional plane indicating the entrance to the model with a given velocity; the flow outlet is a conditional plane indicating a free exit from the model; the flow boundary is a conditional wall with a given roughness characterizing the support of the mining with a boundary layer; the air flow velocity was assumed to be 4 m/s for the first inlet (outgoing jet from longwall) and 6 m/s for the second (incoming jet); the pressure for the outlet was assumed to be zero; the intensity of turbularization of the flow was 5 %; the hydraulic diameter of the workings is 3 m.

During the modeling, additional planes were set for detailed tracking of the deviation and change of the air flow velocity vectors [38-39].

5. Modeling of air flow when setting characteristic parameters. The calculation was based on the numerical method of finite volumes.

6. Visualization of the results of the obtained calculation and their evaluation. In the process of modeling of the dust-air flows movement in underground workings, it was necessary to solve the following tasks: to obtain a detailed picture of the distribution of air adequate to the real conditions of underground mining; to identify potentially possible areas of intense dust deposits formed due to changes in the flow structure; to develop a model of two-phase flows of a carrier gas-air medium with solid particles.

Discussion

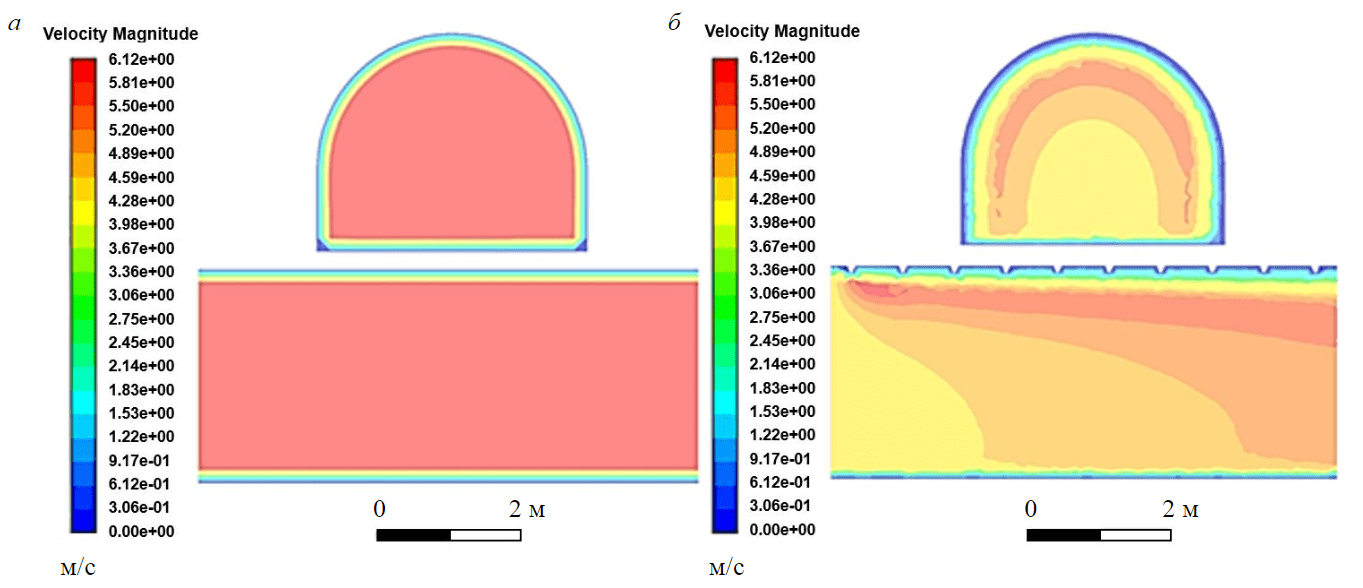

Mathematical modeling of the parameters of the air environment in solving the first problem showed the fundamental possibility of estimating the air velocity field by such a method, using as initial data the geometric characteristics of the workings and the parameters of heterogeneous flow (Fig.5-7).

The illustration of the obtained results indicates the possibility of adequate consideration of aerodynamic drag (given by the roughness of the walls of the workings when modeling in ANSYS FLUENT) and its effect on the distribution of dust particles of a given class-shape in the sections of the workings (Fig.5). A promising direction of the conducted research is to assess the distribution of dust particles of a given class shape, taking into account the types of support (aerodynamic drag) and the shape of the section of the mine workings.

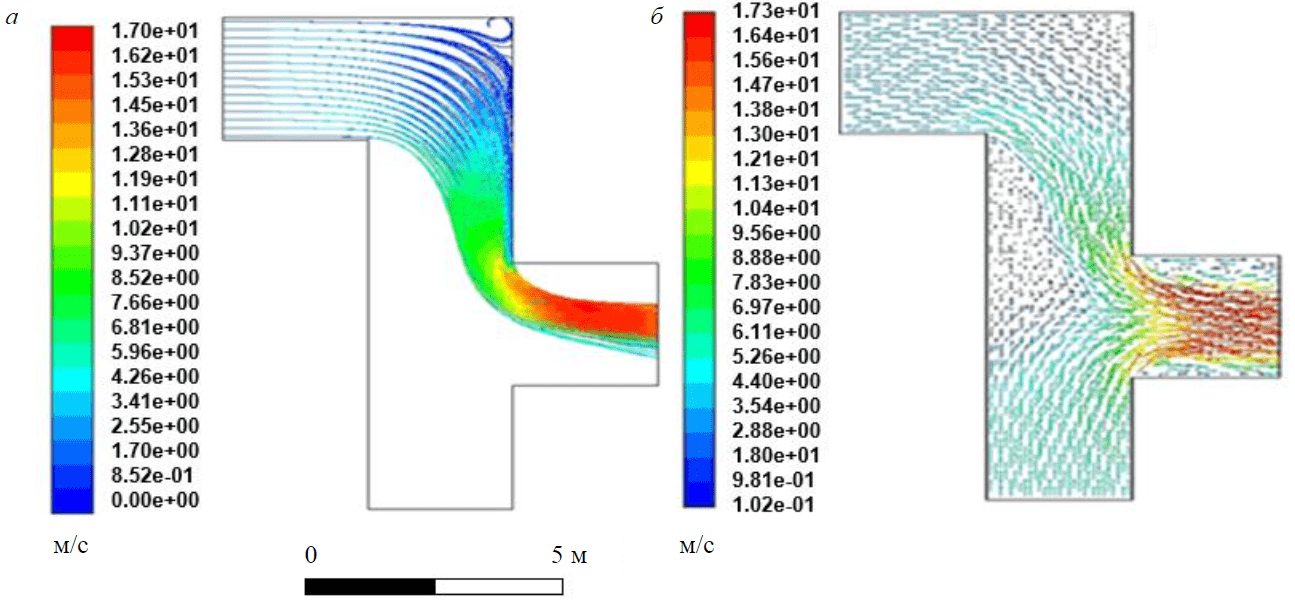

Modeling of a two-phase medium allowed to establish the visual nature of the distribution (velocity plots) of the air flow and dust particles of the studied class-shape and size in the analyzed interface area in the corresponding projection plane (Fig.6). Analyzing the obtained results, it can be concluded that it is possible to assess potential places of intense dust deposits both indirectly by the air flow velocity and directly by the simulation results.

Fig.5. Air flow velocity taking into account the type of support of the mine working (modeling in ANSYS FLUENT): a – without taking into account the aerodynamic drag, smooth–walled mine working (monolithic support); b – taking into account the aerodynamic drag from the support of the mine working

Fig.6. The velocity of a two–phase dust-air flow in ANSYS FLUENT: a – the distribution of dust particles of a given class-shape by characteristic dimensions; b – the velocity field of the air flow

The problem of setting the conditions for the entry of dust particles into the calculated model in conjunction with their characteristics was solved as follows. The specified physical and chemical characteristics of coal particles are established according to the recommendations of a number of researchers [6, 16, 40]: the particle velocity is assumed to be equal to the air flow velocity – 4 m/s; the dust concentration in the stream is 50 mg/m3; the average characteristic particle size is 0.1 mm.

Modeling was carried out based on the results of previous studies of the distribution of class-shapes by size. For a comparative evaluation, a spherical and a parallelepiped class-shape were selected and a comparison of the obtained results was carried out.

The ANSYS FLUENT software package, when introduced as a geometric criterion of the particle shape coefficient, allows modeling the behavior of particles of various shapes determined by the Vadell formula [26, 27, 35]:

where S is the particle area; s is the surface area of the sphere.

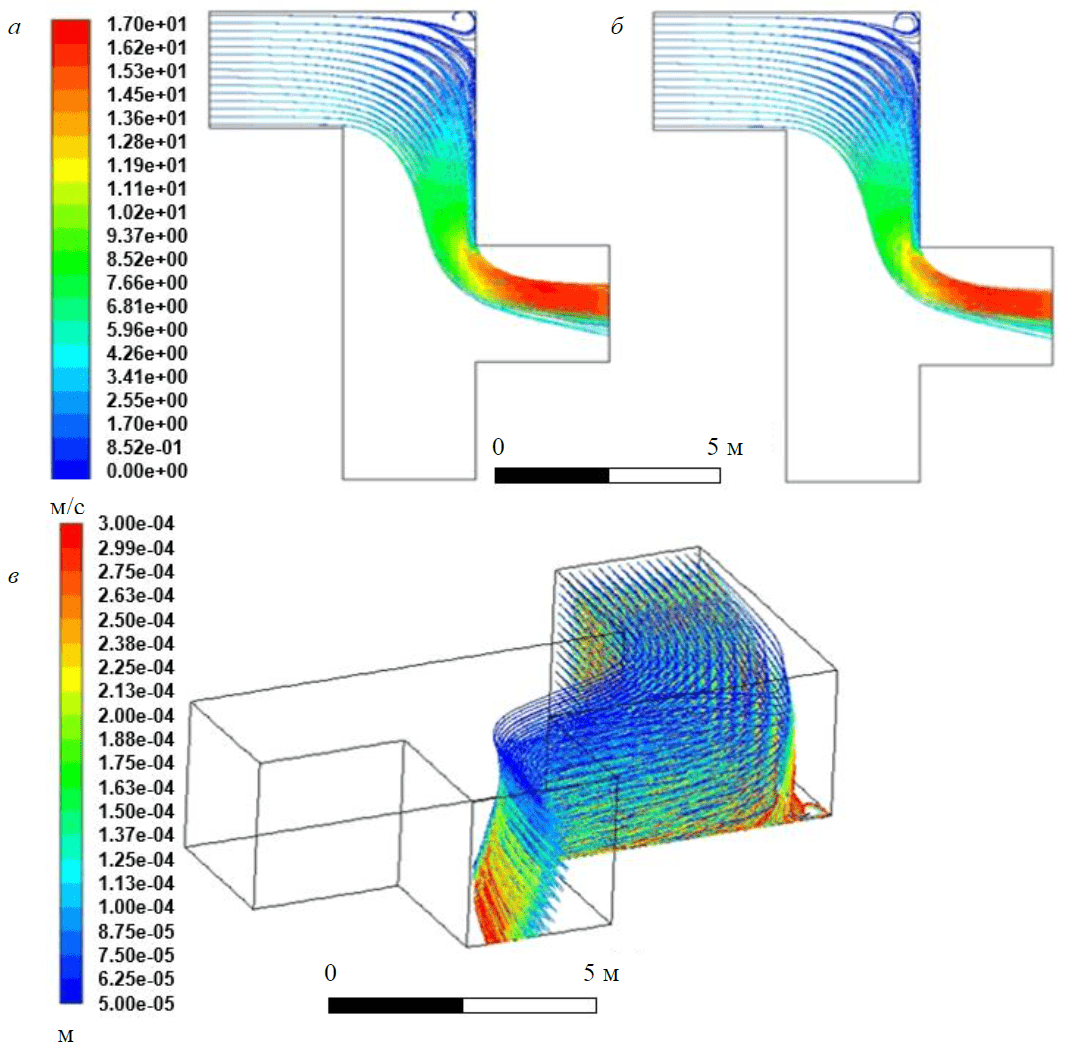

Fig.7. The result of 3D modeling in ANSYS FLUENT of the movement of dust particles of various fractions: a – for the shape of particles in the form of a parallelepiped; b – for spherical particles; c – the distribution of particles in the space of mine working

For practical calculations, the values of the coefficients of the characteristic particle shape are taken according to the data given in [24, 26, 40]: sphere – 1; parallelepiped with an aspect ratio of 1×2×2 – 0.762; parallelepiped with an aspect ratio of 1×2×1 – 0.768.

Calculation and visualization of the obtained results were the final stage of modeling (Fig.7).

Analytical studies of the distribution patterns of dust fractions obtained as a result of modeling for various class-forms of coal dust allowed to establish convergence in the range of 85-90 % (Fig.7, a). Fig.7, b visually traces the gradation of the dust distribution by characteristic size, as well as potential dust deposition sites with a predominance of large fractions. The study of sedimentation of coal dust particles over time will allow to assess the process of mass accumulation of dust deposits.

Based on the simulation results, it can be concluded that for the workings of large cross-sections with low air velocities and a simple configuration, it is possible to neglect the differences in the class-forms of dust particles and calculate as a whole for isometric particles having the shape of a sphere or a regular polyhedron, which is in good agreement with the positions of the Lagrange approach.

Conclusion

The conducted study revealed the most characteristic class-forms with a fraction size of less than 0.1 mm for all the studied coal dust samples. As the most characteristic class-forms in the form of a parallelepiped and an ellipse were established, which were chosen for further study of the dust particles behavior in hybrid mixtures “coal dust-air”.

For the practical implementation of the method of assessing the dust situation in production conditions, the use of specialized software ANSYS FLUENT as the optimal means for modeling the dust pattern in the workings in 2D and 3D formats is proposed. The analysis of modeling of two different class-forms of coal dust has shown the expediency of spherical particle shapes for the initial data when solving the tasks set. It is established that different class-forms of particles taken as initial data do not give significant differences in the final picture of the distribution of dust fractions. Based on the modeling results, it can be concluded that with large cross-sections and low air velocities in the mine workings of a simple configuration, differences in the class-forms of dust particles can be neglected.

Thus, there is a basis for simplifying the methods of applying calculated models to determine possible (most likely) places of dust deposition and developing measures to prevent the transition of coal dust from the aerogel state to the aerosol state, which makes it possible to implement them in the production environment.

The obtained results can be used to improve safety in the development of coal deposits by underground method by preventing the formation of explosive and combustible dust-air mixtures in mine workings.

References

- Kaledina N.O. Methodological Approach to the Provision of Coal Mine’s Aerological Safety. Mining informational and analytical bulletin. 2019. N S10, p. 26-31 (in Russian). DOI: 10.25018/0236-1493-2019-5-10-26-31

- Federal Agency for Environmental, Technological and Nuclear Inspection. Annual reports on the activities of the Federal Agency for Environmental, Technological and Nuclear Inspection. URL: http://www.gosnadzor.gov.ru/public/annual_reports/ (accessed 23.08.2021).

- Kobylkin A.S. Research of Coal Dust Distribution in Mines. Mining informational and analytical bulletin. 2018. N S49, p. 208-214. (in Russian). DOI: 10.25018/0236-1493-2018-11-49-208-214

- Federal Agency for Environmental, Technological and Nuclear Inspection. Completed investigations. URL: https://www.gosnadzor.ru/industrial/coal/zavershennye-rassledovaniya/ (accessed 23.08.2021).

- Kaledina N.O., Kobylkin S.S. Ventilation of blind roadways in coal mines: problems and solutions. Eurasian Mining. 2015. N 2, p. 26-30. DOI: 10.17580/em.2015.02.07

- Yangyue P., Spijker C., Raupenstrauch H. CFD modeling of particle dispersion behavior in the MIKE 3 apparatus. Alexandria Engineering Journal. 2022. Vol. 61. Iss. 12, p. 9305-9313. DOI: 10.1016/j.aej.2022.03.039

- Rodionov V.A., Pikhkonen L.V., Zhikharev S.Ya. Dispersion of the G-Type Coal Dust of the Vorgashorskoe Field and Its Influence on the Thermal Destruction Process. Perm Journal of Petroleum and Mining Engineering. 2017. Vol. 16. N 4, p. 350-356 (in Russian). DOI: 10.15593/2224-9923/2017.4.6

- Kabanov E.I., Korshunov G.I., Rodionov V.A. Expert system based on fuzzy logic for assessment of methane and dust explosion risk in coal mines. Gornyi Zhurnal. 2019. N 8, p. 85-88 (in Russian). DOI: 10.17580/gzh.2019.08.17

- Trechera P., Querol X., Lah R. et al. Chemistry and particle size distribution of respirable coal dust in underground mines in Central Eastern Europe. International Journal of Coal Science & Technology. 2022. Vol. 9. N 3. DOI: 10.1007/s40789-022-00468-2

- Ajrash M.J., Zanganeh J., Moghtaderi B. The effects of coal dust concentrations and particle sizes on the minimum auto-ignition temperature of a coal dust cloud. Fire and Materials. 2017. Vol. 41, p. 908- 915. DOI: 10.1002/fam.2437

- Kobylkin A.S. Analysis of Distribution of Harmful Gases in Mine Roadways Using Computer Modeling. Mining informational and analytical bulletin. 2014. N 10, p. 202-207 (in Russian).

- Cybulski K. Zagrozenie wybuchem pylu weglowego oraz ocena skutecznosci dzialan profilaktycznych w polskich kopalniach wegla kamiennego. Prace Naukowe Głównego Instytutu Górnictwa. 2005. N 864, p. 1-236 (in Polish).

- Fan Geng, Gang Luo, Yingchao Wang, Zhengbiao Peng, Shengyong Hu, Tiantian Zhang, Hongli Chai. Dust dispersion in a coal roadway driven by a hybrid ventilation system: A numerical study. Process Safety and Environmental Protection. 2018. Vol. 113, p. 388-400. DOI: 10.1016/j.psep.2017.11.010

- Kolesnichenko I.E.1, Artemiev V.B., Kolesnichenko E.A. et al. Mining aerodynamics: physical-chemical trends and principles. Ugol. 2018. N 5 (1106), p. 58-65. DOI: 10.18796/0041-5790-2018-5-58-64

- Kazanin O., Sidorenko, A., Drebenstedt C. Intensive underground mining technologies: Challenges and prospects for the coal mines in Russia. Acta Montanistica Slovaca. 2020. Vol. 26 (1), p. 60-69. DOI: 10.46544/AMS.v26i1.05

- Romanchenko S.B., Gendler S.G., Timchenko A.N., Kosterenko V.N. Pilot and Theoretical Studies of Dynamics of Explosive Miner Aerosols. Mining informational and analytical bulletin. 2017. N 4. S5-1, p. 181-190 (in Russian).

- Korshunov G.I., Romanchenko S.B. Development of innovative technologies of dedusting in mining and advance coal mine faces. Journal of Mining Institute. 2016. Vol. 218, p. 339-344 (in Russian).

- Gendler S.G., Rudakov M.L., Samarov L.Y. Experience and prospects of occupational and industrial safety control in mineral mining and processing. Gornyi zhurnal. 2015. N 5, p. 84-87 (in Russian).

- Haitao Li, Fuer Zhai, Shanshan Li et al. Macromorphological features and formation mechanism of particulate residues from methane/air/coal dust gas–solid two-phase hybrid explosions: An approach for material evidence analysis in accident investigation. Fuel. 2022. Vol. 315. N 123209. DOI: 10.1016/j.fuel.2022.123209

- Ritsu Dobashi. Studies on accidental gas and dust explosions. Fire Safety Journal. 2017. Vol. 91, p. 21-27. DOI: 10.1016/j.firesaf.2017.04.029

- Smirnyakov V.V., F’en N.M. Justification of a methodical approach of aerologic evaluation of methane hazard in development workings at mines of Vietnam. Journal of Mining Institute. 2018. Vol. 230, p. 197-203. DOI: 10.25515/PMI.2018.2.197

- Gendler S. G., Nguen T.K. Justification of Rational Methods for Provision of Air to Faces of Operating Coal Mines of Vietnam during Deepening of Mining. Journal of Mining Institute. 2018. Vol. 234, p. 652-657. DOI: 10.31897/PMI.2018.6.652

- Rodionov V.A., Tsygankov V.D., Zhikharev S.Ya., Kormshchikov D.S. Research procedure for coal dust aerodynamics in long roadways. Mining informational and analytical bulletin. 2021. N 10, p. 69-79. DOI: 10.25018/0236_1493_2021_10_0_69

- Haitao Li, Shanshan Li, Fuer Zhai et al. Effect of the initial oxidized status of coal dust on the deflagration severities and flame behaviors of pulverized coal explosion in various methane-air atmospheres. Fuel. 2022. Vol. 315. N 123211. DOI: 10.1016/j.fuel.2022.123211

- Peich L.M., Torrent K.G., An’ez N.F., Eskobar K.-M.M. Prevention and protection against propagation of explosionsin underground coal mines. Journal of Mining Institute. 2017. Vol. 225, p. 307-312. DOI: 10.18454/PMI.2017.3.307

- Mohammed J. Ajrash, Jafar Zanganeh, Behdad Moghtaderi. Impact of suspended coal dusts on methane deflagration properties in a large‐scale straight duct. Journal of Hazardous Materials. 2017. Vol. 338, p. 334-342. DOI: 10.1016/j.jhazmat.2017.05.030

- Official website of ANSYS, Inc. URL: https://www.ansys.com (accessed 23.01.2020).

- Chemezov E.N. Industrial safety principles in coal mining. Journal of Mining Institute. 2019. Vol 240, p. 649-653. DOI: 10.31897/PMI.2019.6.649

- Puchkov L.A., Kaledina N.O., Kobylkin S.S. et al. Local formation of ventilation parameters subject to control at ventilation automation. Ugol. 2015. N. 11. P. 58-61 (in Russian). DOI: 10.18796/0041-5790-2015-11-58-61

- Kornev A.V., Korshunov G.I., Kudelas D. Reduction of Dust in the Longwall Faces of Coal Mines: Problems and Perspective Solutions. Acta Montanistica Slovaca. 2021. Vol. 26. Iss. 1, p. 84-97. DOI: 10.46544/AMS.v26i1.07

- Fan Geng, Gang Luo, Fubao Zhou et al. Numerical investigation of dust dispersion in a coal roadway with hybrid ventilation system. Powder Technology. 2017. Vol. 313, p. 260-271. DOI: 10.1016/j.powtec.2017.03.021

- Jianping Wei, Xiangyu Xu, Wan Jiang. Influences of ventilation parameters on flow field and dust migration in an underground coal mine heading. Scientific Reports. 2020. Vol. 10. N 8563. DOI: 10.1038/s41598-020-65373-7

- Shengyong Hu, Qi Liao, Guorui Feng et al. Influences of ventilation velocity on dust dispersion in coal roadways. Powder Technology. 2020. Vol. 360, p. 683-694. DOI: 10.1016/j.powtec.2019.09.080

- Biao Sun, Weimin Cheng, Jiayuan Wang, Hao Wang. Effects of turbulent airflow from coal cutting on pollution characteristics of coal dust in fully-mechanized mining face: A case study. Journal of Cleaner Production. 2018. Vol. 201, p. 308-324. DOI: 10.1016/j.jclepro.2018.08.001

- Prostański D. Empirical Models of Zones Protecting Against Coal Dust Explosion. Archives of Mining Sciences. 2017. Vol. 62. Iss. 3, p. 611-619. DOI: 10.1515/amsc-2017-0044

- Korkodinov I.A. The Review of Set of k-ε Models for Modeling Turbulence. Bulletin of Perm National Research Polytechnic University. Mechanical Engineering, Materials Science. 2013. N 2 (15), p. 5-16 (in Russian).

- Qiang Liu, Wen Nie, Yun Hua et al. Research on tunnel ventilation systems: Dust Diffusion and Pollution Behaviour by air curtains based on CFD technology and field measurement. Building and Environment. 2019. Vol. 147, p. 444-460. DOI: 10.1016/j.buildenv.2018.08.061

- Ugur U., Igathinathane C. Particle size distribution modeling of milled coals by dynamic image analysis and mechanical sieving. Fuel Processing Technology. 2016. Vol. 143, p. 100-109. DOI: 10.1016/j.fuproc.2015.11.007

- Kobylkin A.S. Dust distribution at a coal shearer in the face area. Mining informational and analytical bulletin. 2020. N 6-1, p. 65-73 (in Russian). DOI: 10.25018/0236-1493-2020-61-0-65-73

- Zhiharev S.Y., Pikhkonen P.V., Rodionov V.A. Research of Fire and Explosion Hazardous Properties for Hard Coal at the Prokopyevsk Coal Field of the Kuznetsk Coal Basin. Izvestiya Tula State University. Sciences of Earth. 2017. N 3, p. 65-74 (in Russian).