Technique for calculating technological parameters of non-Newtonian liquids injection into oil well during workover

- 1 — Ph.D. Head of the Department Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Postgraduate Student Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus

- 3 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

Abstract

Technique for automated calculation of technological parameters for non-Newtonian liquids injection into a well during workover is presented. At the first stage the algorithm processes initial flow or viscosity curve in order to determine rheological parameters and coefficients included in equations of rheological models of non-Newtonian fluids. At the second stage, based on data from the previous stage, the program calculates well design and pump operation modes, permissible values of liquid flow rate and viscosity, to prevent possible hydraulic fracturing. Based on the results of calculations and dependencies, a decision is made on the necessity of changing the technological parameters of non-Newtonian liquid injection and/or its composition (components content, chemical base) in order to prevent the violation of the technological operation, such as unintentional formation of fractures due to hydraulic fracturing. Fracturing can lead to catastrophic absorptions and, consequently, to increased consumption of technological liquids pumped into the well during workover. Furthermore, there is an increased risk of uncontrolled gas breakthrough through highly conductive channels.

Introduction

In the course of oil field development, the energy potential of a formation is gradually decreasing. At the same time, well operation is accompanied by occasional complications, which include deterioration of permeability and porosity properties of the near-bottomhole zone, gas or water breakthrough via highly permeable channels from worked-out formation intervals, mechanical wear of downhole equipment, etc. In order to eliminate them and maintain the target level of oil production, current and overhaul repair works are required [1, 2]. The preparation stages of such works include well killing, consisting in the injection of technological liquid (TL) into wellbore in order to prevent the gas, oil and water influx.

One of the main conditions for successful well killing is proper selection of technological liquids for specific conditions, which are limited by geophysical parameters (for example, permeability and porosity) and technical characteristics of pumping units (flow rate or pressure). For this purpose a set of laboratory experiments is carried out, which includes physical, chemical, rheological and filtration investigations [3-5]. The analysis of the results allows a comprehensive study of the properties and selection of the most effective liquid for the considered conditions.

Based on many years of well killing practice in Russia and worldwide, there is the following variety of liquids, which can be classified according to application conditions (Table 1) [6-8].

Table 1

Field of application for the main types of well killing liquids

|

Technological liquid |

Application conditions |

|||||||

|

Water-cut ≥ 60 % |

Water-cut < 60 % |

Low formation pressure (abnormally low formation pressure, undercompensation) |

Abnormally high formation pressure |

High-temperature formations (>80 ᵒС) |

Water-sensitive (clay) |

Highly permeable formations, natural or artificial fractures |

Gas and gas condensate |

|

|

Water systems |

||||||||

|

Technical water |

+ |

– |

– |

– |

+ |

– |

– |

– |

|

Formation mineralized water |

+ |

– |

– |

– |

+ |

+ |

– |

– |

|

Water solutions of inorganic salts |

+ |

– |

– |

+ |

+ |

+ |

– |

– |

|

Clay suspensions |

+ |

– |

– |

+ |

+ |

– |

– |

– |

|

Foam compositions |

+ |

+ |

+ |

– |

+ |

+ |

– |

+ |

|

Hydrocarbon systems |

||||||||

|

Commercial oil |

– |

+ |

+ |

– |

+ |

+ |

– |

– |

|

Thickened oil |

– |

+ |

+ |

– |

– |

+ |

– |

– |

|

Blocking systems |

||||||||

|

Invert-emulsion |

+ |

+ |

+ |

+ |

+ |

+ |

+ |

+ |

|

Lime-bitumen |

+ |

+ |

+ |

+ |

+ |

+ |

+ |

+ |

|

Polymer |

+ |

+ |

+ |

+ |

+ |

+ |

+ |

+ |

According to Table 1, blocking compositions (polymer, invert-emulsion and lime-bitumen systems) proved to be efficient TL for well killing in the broad range of work conditions. Their application is most economically expedient in the conditions of high gas-oil ratio, presence of hydrogen sulphide, natural or artificial (hydraulic fracturing conducted earlier) fracturing of reservoirs, abnormally low formation pressure. In this case the risk of possible gas breakthrough into the well and absorption of killing liquid into the near-bottomhole zone is decreased [12, 13].

Statement of the problem

Development of chemical reagents for oil production objects, in particular for specific objects with given geological and physical conditions, should be carried out by conducting thorough laboratory investigations, including physical, chemical, rheological and filtration experiments [14]. Incorrect selection of technological liquid can lead to uncontrolled blow out of formation fluid, loss of a part of fluid as a result of filtration into formation, deterioration of permeability of productive formation, etc.

When killing wells under the conditions of workover operations it is also important to meet the technological requirements of liquid injection into the well [15]. The violation of work regulations can lead to more expensive technology because of long equipment downtime, increase in time of well development and putting it into operation. In addition, it is important to prevent the formation of new technogenic fractures caused by non-compliance of injection parameters with the set values [16].

An advanced solution in the development of blocking liquids is the use of linear and non-linear (cross-linked) polymer compositions with time-controlled gelation. The rate of change in viscosity of such compositions can be controlled over a wide range for more efficient technological operations [17, 18].

Compared to other types of TL (Table 1), polymer-based technologies have demonstrated to be the most reliable means of isolating highly permeable formation intervals, which are used to prevent water and gas breakthrough into production wells [19].

This article considers the theoretical and practical aspects of rheological investigations of polymer compositions, including those used for killing oil wells during their underground workover [20, 21]. The developed algorithm of calculation and subsequent control of basic technological parameters of polymer compositions injection into the well according to the results of rheological investigations is presented.

Methodology

The sequence of rheological investigations with further evaluation of the technological parameters of polymer compositions [4, 22] is as follows:

- preparation of the polymer solution;

- rheological investigation of the polymer composition (viscosity and flow curve plotting; evaluation of the initial shear stress (static yield point);

- selection of the rheological model that most accurately describes the flow or viscosity curve according to a coefficient of determination R2, which is as close to 1 as possible;

- determination of the rheological characteristics included in the equations of the rheological models (plastic viscosity; yield point; finite viscosity; Newtonian (initial) viscosity; maximum measured shear stress; consistency factor; yield index);

- calculation of technological parameters for injection of polymer composition into the well (friction loss considering coefficients of hydraulic resistance during visco-elastic fluids flow; bottomhole pressure for direct and reverse injection; effective viscosity of the polymer solution during its movement along different elements of the well; total volume of killing liquid; time of filling the well);

- calculation of hydraulic fracturing parameters (fracturing pressure; minimum horizontal stress; critical solution viscosity for given pump flow rates, at which fracturing will occur).

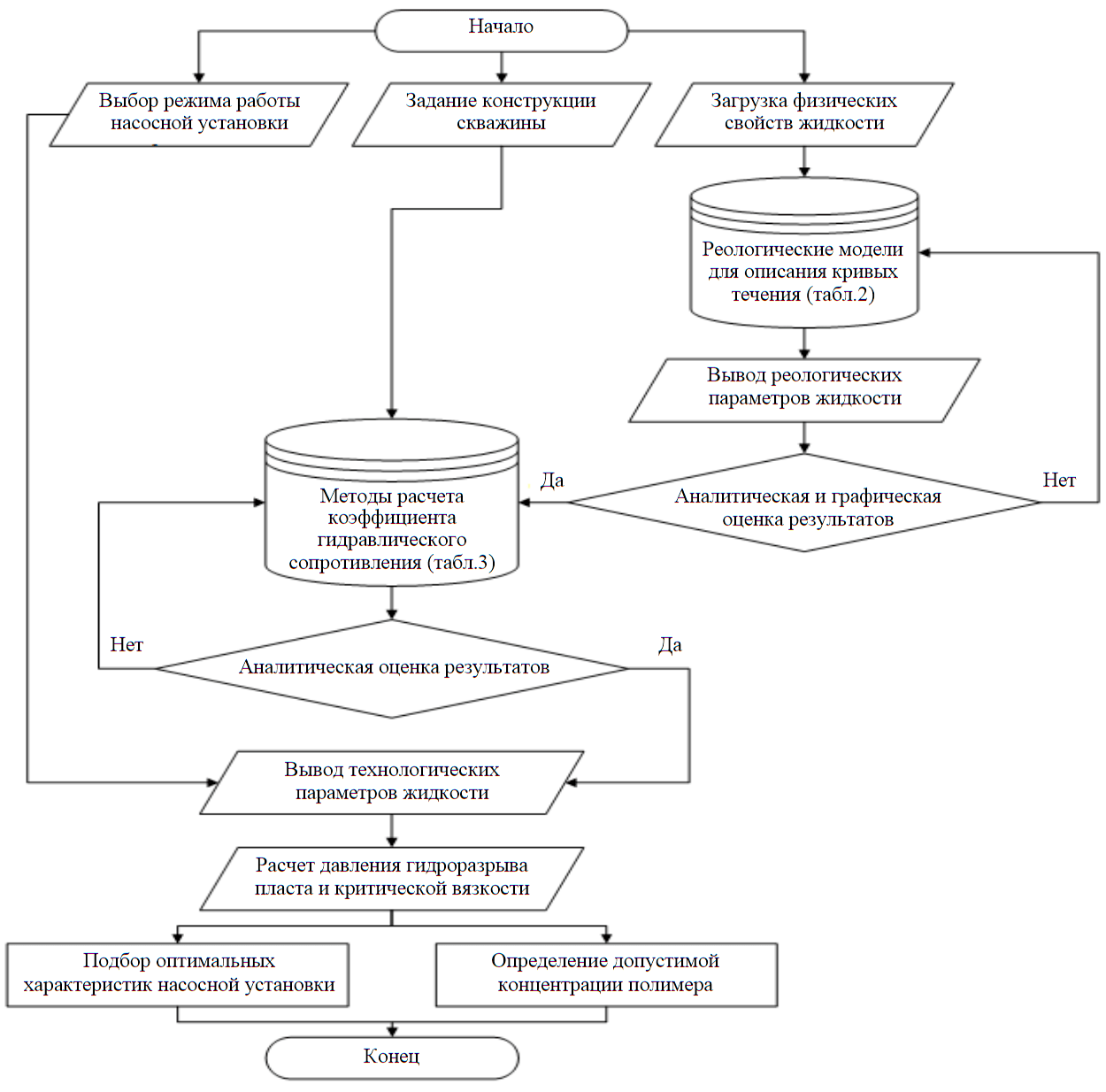

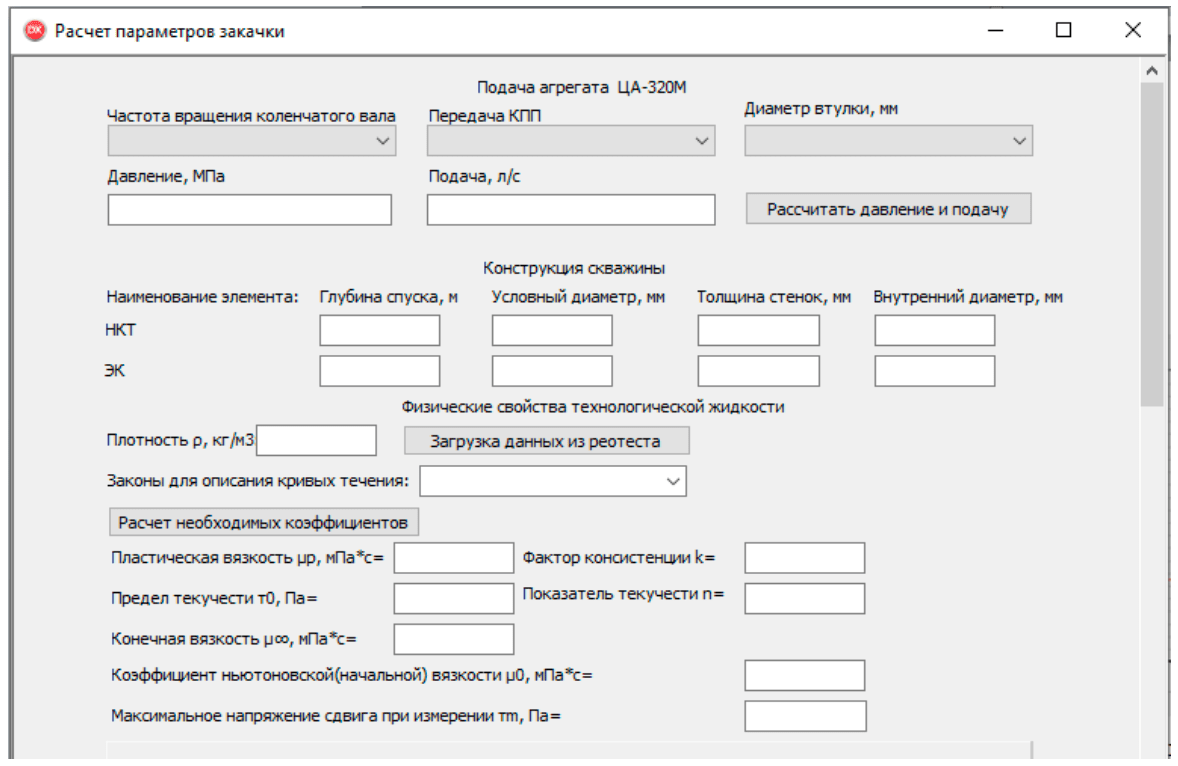

This algorithm (Fig.1) is presented in the form of program code written in Object Pascal programming language [23]. In order to reduce time spent on calculations and expert evaluation of obtained results, a visual interface, composed in Delphi 10 Seattle, was also developed (Fig.2). The algorithm for calculating the main parameters of fluid injection into the well developed by the authors is based on standard conventional equations.

The program is designed to process input data, calculate technological parameters of the process and plot the dependence of the current bottomhole pressure on various characteristics of the pumping unit. The input parameters for this calculation are well design, injection pump operating modes (pressure and flow rate), density of the fluid under study and data from rotary viscometers (rate and shear stress, liquid viscosity) (Fig.1).

Preparation of the polymer solution

To prepare the polymer solution, an accurate analytical scale, top-driven mixer is used. To prevent mechanical destruction of the polymer macromolecules, the rotation frequency of the mixer shaft should be set to the lowest possible value. Chemical dishes with the same geometry are used each time the solution is mixed, which prevents the Reynolds number and flow mode from changing. Complete hydration of the polymer in the solvent is considered to be the end of the preparation, as indicated by the absence of polymer crystals.

Conducting rheological investigations of the polymer composition

Rheological investigations are carried out using a rotary viscometer according to the following stages [24, 25]:

- The initial rheological curve of compositions (at a given formation temperature) is constructed in Controlled Rate mode (CR test). The essence of research method is to obtain dependence of shear stress on shear rate with gradual increase of the latter parameter from 0 to 300 s–1 (liquid flow curve).

Fig.1. Calculation algorithm for technological parameters of non-Newtonian liquids

- The static yield point (initial shear stress) (at a given formation temperature) is determined in Controlled Stress mode (CS test) with increasing step of shear stress over a given time interval, and the longer the time of investigation, the more accurate the static yield point value is obtained. The initial shear stress is the maximum stress value, after which the measuring system moves and the shear rate increases.

Selection of a rheological model

At this stage, the rheological model that best describes the flow curve of the investigated liquid is selected graphically (Table 2). In addition, the coefficient of determination R2 is calculated, which characterizes the proportion of variation for the dependent variable and allows evaluating the quality of the rheological model selection [20, 26, 27].

Determination of rheological characteristics

The result of the investigations and calculations with the proposed algorithm is the determination of rheological characteristics that describe the nature and behaviour of the studied liquid (values of plastic viscosity, yield point, finite viscosity, Newtonian (initial) viscosity, maximum measured shear stress, consistency index and fluidity index) [4, 28].

Fig.2. Interface of the developed algorithm

Table 2

Formulas for determining the viscosity and shear stress depending on shear rate for different types of liquids

|

Name of the rheological model |

Dependence formula of τ on γ |

Formula for determining μ |

|

|

Ostwald – de Waale |

|

|

|

|

Golub |

|

|

|

|

De Haven |

|

|

|

|

Krieger – Dougherty |

|

|

|

|

Cross |

|

|

|

|

Reiner – Filipov |

|

|

|

|

Meter |

|

|

|

|

Ellis |

|

|

|

|

Herschel – Bulkley |

|

|

|

|

Casson |

|

|

|

|

Shvedov – Bingham |

|

|

|

Note. μ – effective viscosity; τ – shear stress; γ – shear rate; k – consistency index; n – yield index; μо – Newtonian (initial) viscosity; μ∞ – finite viscosity; τm – maximum measured shear stress; τо – yield point; μp – plastic viscosity; α, е ‒ constants.

The search for rheological values takes place in several stages. The first step is a linear regression analysis of the viscosity and shear stresses resulting from the rheological investigations carried out. The result of this analysis is a relationship of the form: y = a + bx. The parameters of this regression equation are estimated by the least-squares method [29]. In this case according to Shvedov-Bingham equation (Table 2), the value of coefficient a corresponds to the value of yield point τ0, coefficient

b – to plastic viscosity μр.

The initial viscosity μ0 is defined as the highest value of the viscosity of the solution resulting from the investigations and corresponds to the yield point τ0. At the same time, the minimum value of the viscosity (at γ→∞) corresponds to the finite viscosity μ∞. Based on the initial and final viscosity values the following calculation is carried out:

The maximum measured shear stress τm corresponds to the viscosity value obtained from formula (1) and can be found from the summary table of the research results [30].

The next step is to find the values of the consistency index k and the yield index n. Namely, based on the obtained values of viscosity and shear stress, a power dependence of the following form is constructed: y = axb. Estimation of parameters of the power-law regression is also carried out by the least-squares method [29]. The coefficient a corresponds to the consistency index k, and the

coefficient b to the yield index, according to the Ostwald – de Waale equation (Table 2).

Calculation of the technological parameters for injecting the polymer composition into the well

Then the technological parameters of polymer composition injection into the well are calculated in the considered algorithm: friction pressure loss, bottomhole pressure for direct and reverse injection methods, effective viscosity for different elements of the well design, as well as total volume of killing liquid and filling time of the well [31, 32].

The bottomhole pressure is calculated from the wellhead pressure, hydrostatic pressure and pressure friction loss:

where Рwh – wellhead pressure, MPa; ρ – density of the technological liquid, kg/m3; L – depth of the well, m; λ ‒ hydraulic resistance coefficient; d ‒ diameter of the tubing string, m; w ‒ flow velocity of the technological liquid through the tubing string, m/s.

Application of standard methods for calculating pressure loss can lead to errors due to their inapplicability for viscoplastic liquids flowing through pipes. The most correct way of calculating the pressure loss is to use methods, which take into account the properties of the liquids and the nature of their flow. That is why on the basis of Reynolds number the method for calculation of hydraulic resistance coefficient in case of liquid movement in tubing, annular space and wellbore interval from the depth of tubing end to the bottomhole is selected.

This paper uses the methods for calculating the hydraulic resistance coefficient shown in Table 3 [33].

Table 3

Methods for calculating the hydraulic resistance coefficient for viscoplastic liquids flowing through pipes

|

Name of method |

Calculation of the coefficient |

|

|

Shishchenko R.I. and Mirzadzhanzade A.Kh. |

|

|

|

Shishchenko R.I. and Ibatulov K.A. |

|

|

|

Filatov B.S. |

|

|

|

Mitelman B.I. |

|

|

|

Metzner A. and Reed J. |

|

|

|

Soloviev E.M. |

|

|

Note. λ ‒ hydraulic resistance coefficient; Re′ ‒ generalized Reynolds number; с, m ‒ coefficients depending on the effective viscosity of the liquid; ν – average flow velocity; d – internal diameter of the pipe; d′ – external diameter of the pipe; D – internal diameter of the production casing; ρ – density of the liquid.

Calculation of hydraulic fracturing parameters

To control the injection process, the hydraulic fracturing pressure has been calculated, which, according to [34], is determined by the following relationship:

where T – uniaxial tensile durability limit of the rock , MPa; Рр – pore pressure, MPa; σh – minimum horizontal stress, MPa; σH – maximum horizontal stress, MPa.

The horizontal stress values are calculated using the following formulas [35]:

where ν and Е – Poisson's ratio (units) and Young's modulus (GPa) respectively; σV – vertical stress, MPa; a – Bio coefficient, units; ԑН and ԑh – maximum and minimum strain values respectively, units.

The solution viscosity, at which hydraulic fracturing will occur, is determined by the formula [36]:

where Рh − horizontal component of rock pressure, MPa; Q – flow rate of liquid, m3/s; μ – effective viscosity of liquid, mPa·s.

With the viscosity value obtained, the permissible concentrations for the components of the polymer composition can be determined based on rheological investigations of the solution.

Discussion. As a result of the investigation, an algorithm and software on its basis were developed to calculate the technological parameters of liquid injection into the well, using data obtained from rotary viscometers.

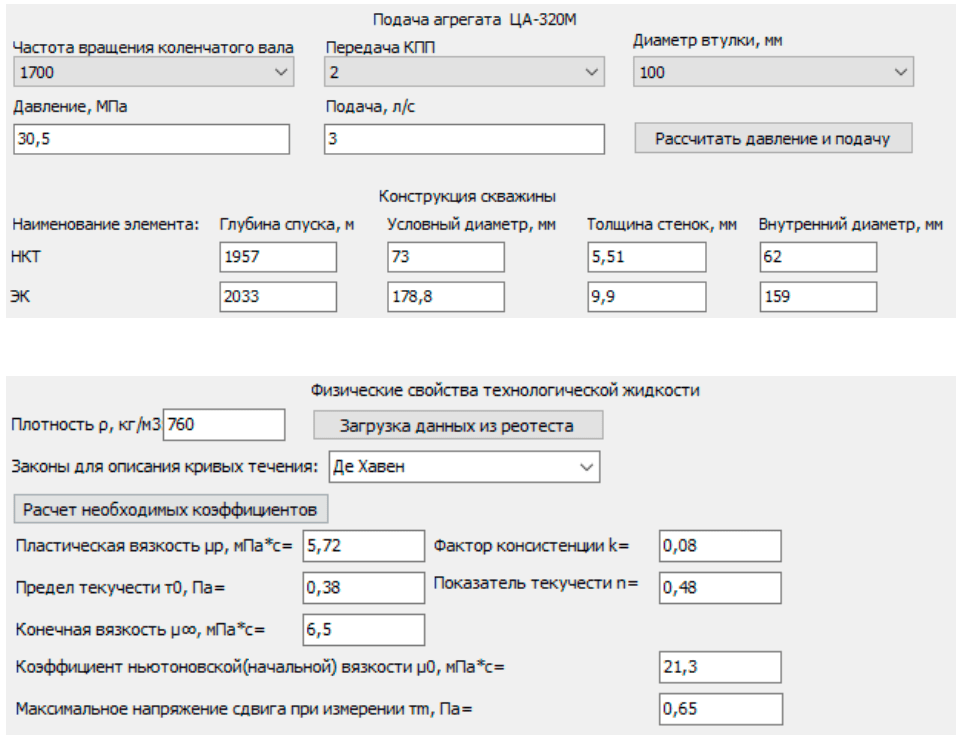

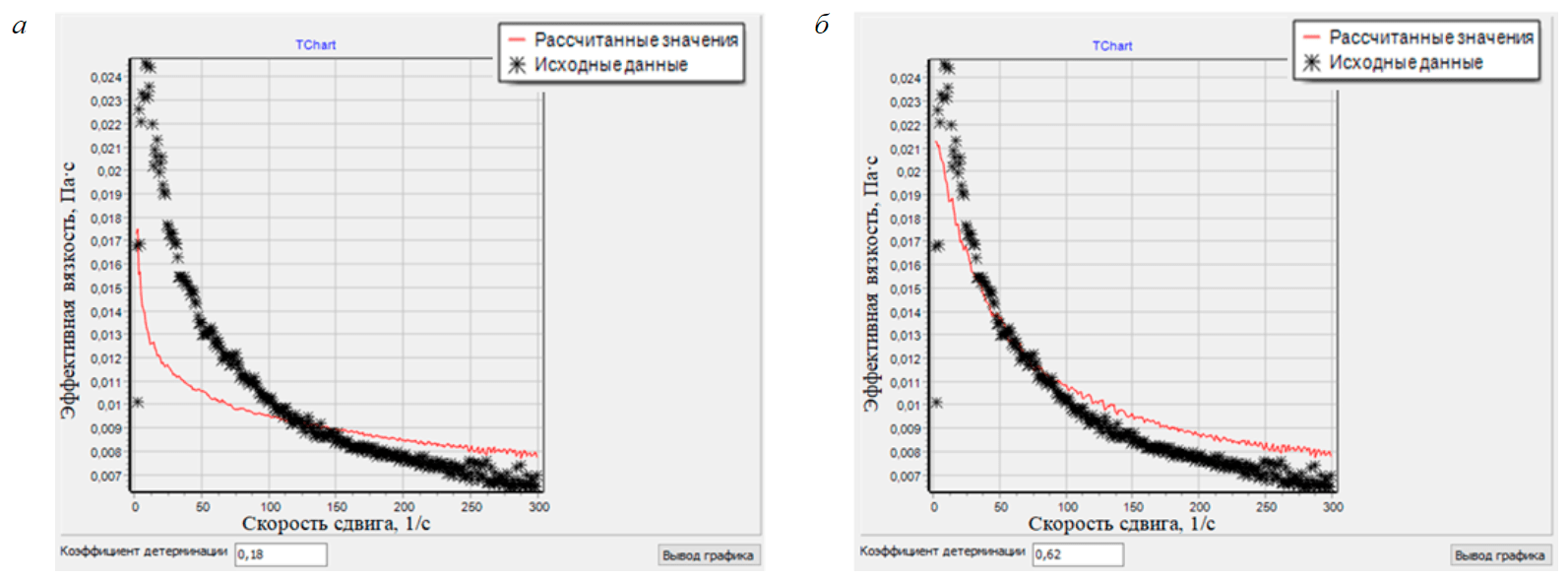

Let us consider a typical calculation in Delphi 10 Seattle. The first step is to set the technological parameters of the pumping unit, diameter and running depth of the casing. Next, the values of polymer composition density and the data obtained earlier from rheological investigations are entered. The rheological model for description of flow curves, for example, De Haven law (Table 2) is selected and rheological characteristics of studied liquid are calculated (Fig.3). To analyze the results a graph of viscosity dependence on shear rate is drawn (Fig.4).

The rheological model of De Haven incorrectly describes rheological behaviour of the considered polymer composition (Fig.4, a), as the curves constructed differ from each other considerably, while a rather low coefficient of determination (R2 = 0.18) is observed. However when the model for rheological curves description is changed, for instance to Reiner – Filipov law (Table 2), similar curves with higher value of determination coefficient R2 = 0.62 are observed (Fig.4, b).

Fig.3. Initial data and results of rheological calculations

Fig.4. Viscosity curve plots based on initial data and values calculated by De Haven (a) and Reiner – Filipov (b) laws

Fig.5. Calculated parameters of the polymer composition

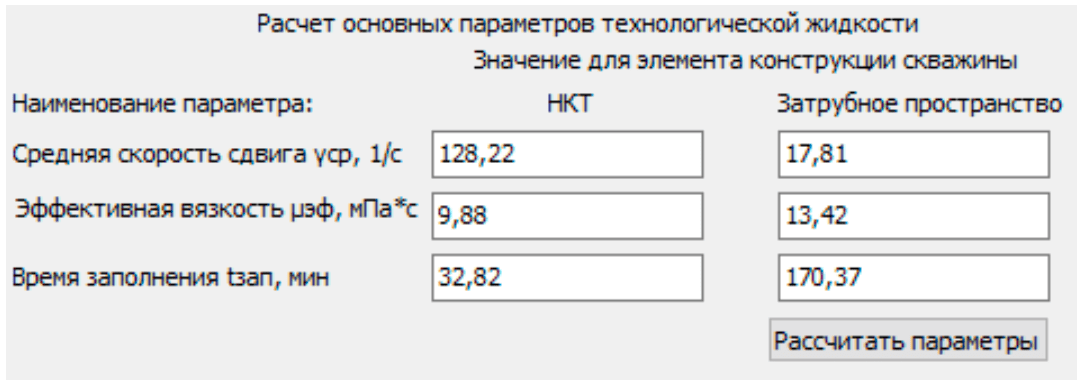

After selecting a suitable rheological model to describe the flow curves, the average shear rate, effective viscosity of the polymer composition and filling time are calculated for the different elements of the well design (Fig.5).

Knowledge of the rheological properties of liquids for different elements of the well design is important for predicting liquid behaviour and preventing possible complications when flowing through the wellbore. Such complications include the inability to flow due to excessively high viscosity [37].

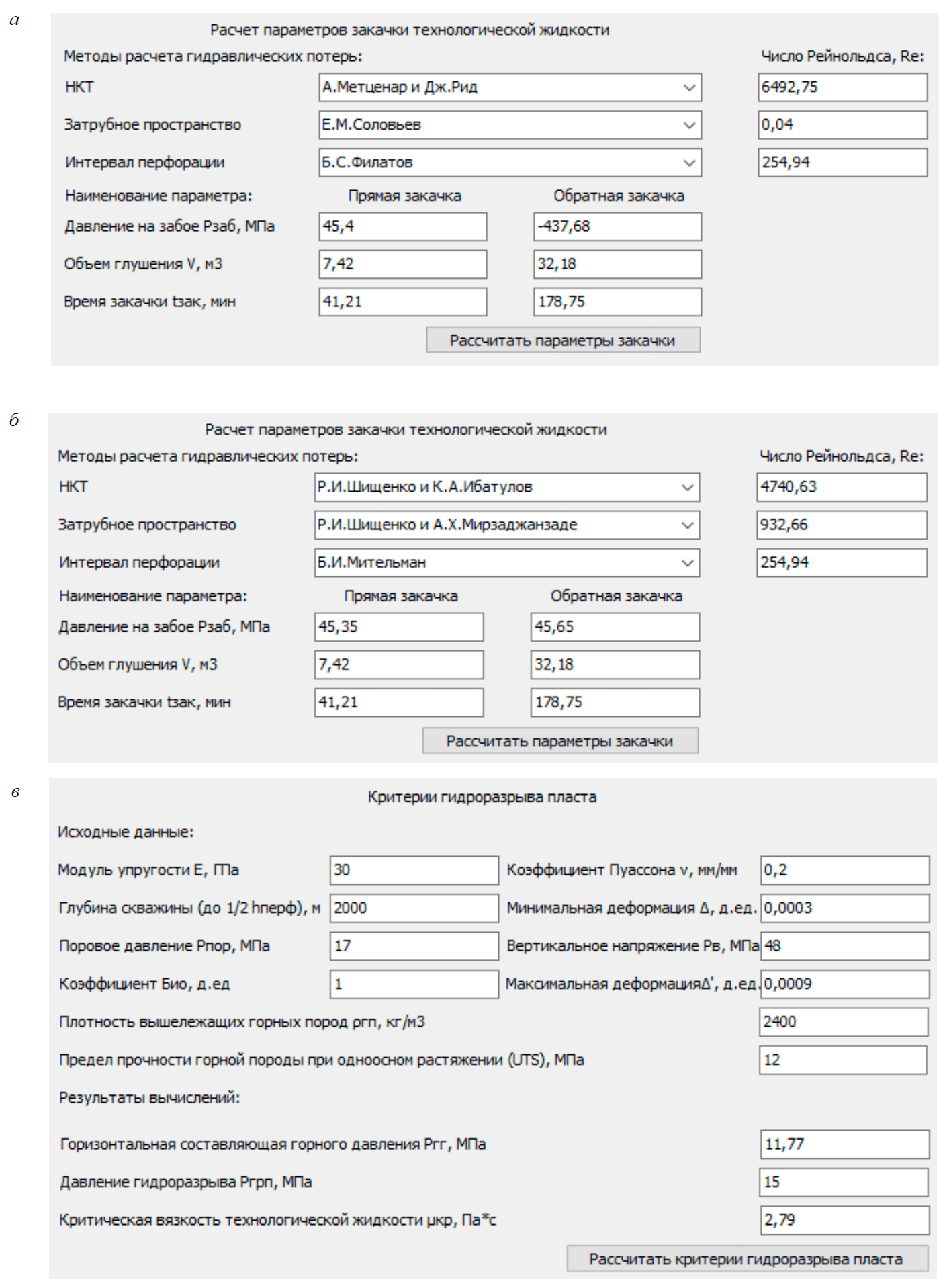

The next step is to calculate injection parameters of the polymer composition (Fig.6, a, b). For this purpose, methods of calculation of hydraulic resistance coefficient for tubing and annular space of well are selected beforehand (Table 3).

When analyzing the obtained results (Fig.6, a), it can be seen that the Reynolds number for tubing is too high in relation to the Reynolds number calculated for the annulus and perforation interval. This indicates incorrect selection of methods for calculating hydraulic resistance coefficient, which leads to errors, for example, in determining bottomhole pressure (–437.7 MPa). Changing the calculation methods for the hydraulic resistance coefficient results in correct values of polymer injection parameters (Fig.6, b).

At the last stage, to determine the hydraulic fracturing pressure and the critical viscosity of the polymer composition, the values of stresses, strains, elastic and durability properties of the rock (Fig.6, c) are set [38, 39]. The calculated value of hydraulic fracturing pressure (27 MPa) turned out to be lower than the value of bottomhole pressure (45 MPa) (Fig.6, b) when injecting polymer composition. In this case, there is a high risk of hydraulic fracturing [40, 41].

The resulting critical viscosity value serves as an upper limit for the viscosity of the technological liquid, above which a technogenic fracture as a result of an autohydraulic fracture may occur, so the current viscosity value must be compared with the specified limit value [42].

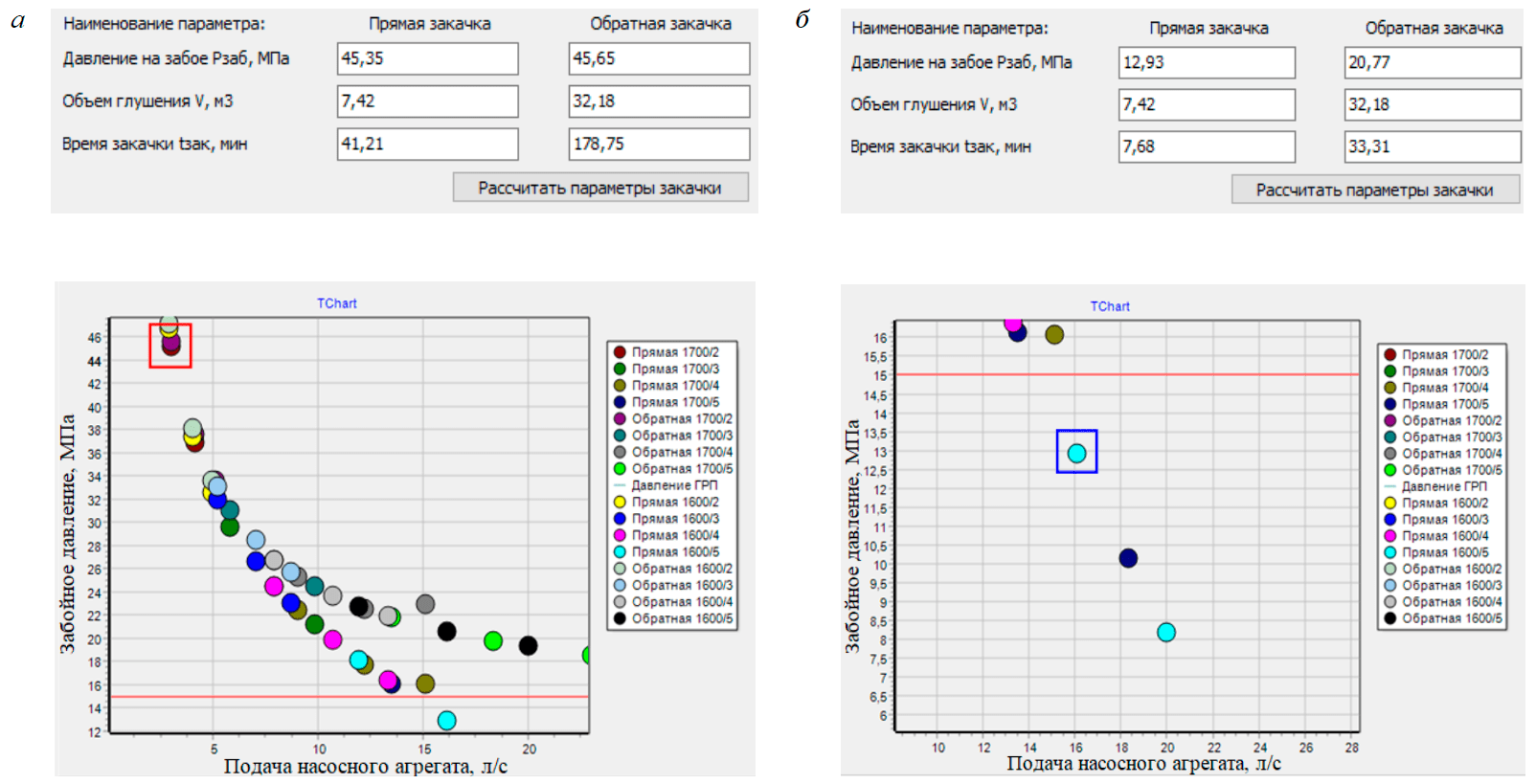

In order to visually assess whether the current bottomhole pressure exceeds the hydraulic fracturing pressure, a graph of bottomhole pressure dependence on the pumping unit flow rate is constructed. In the graph (Fig.7), bottomhole pressure is represented as points corresponding to different injection methods and technical conditions of the pumping unit operation, while fracturing pressure is marked with a red horizontal line. The graph can be used as an aid in selecting the optimum pumping unit characteristics. In this case, direct injection means filling the wellbore with TL through the tubing string. Reverse injection means that the liquid enters the wellbore through the annular space.

The current bottomhole pressure, marked with a red square (point 1700/2, where 1700 is the crankshaft rotation frequency and 2 is the gearbox value), is above the hydraulic fracturing pressure (Fig.7, a).

In practice, the following methods are used to prevent hydraulic fracturing when injecting a polymer composition into a well: changing the technological parameters of liquid injection into the well and changing the concentration of the components in the polymer composition [43].

Fig.6. Parameters for polymer composition injection (a, b) and hydraulic fracturing criteria (c)

The results of this calculation, e.g. when changing the technological characteristics of the pump unit, are shown in Fig.7, b. The resulting current bottomhole pressure, marked with a blue square (point 1700/4, where 1700 is the crankshaft rotation frequency and 4 is the gearbox value), is below the hydraulic fracturing pressure (Fig.7, b).

Fig.7. Bottomhole pressure (a) and hydraulic fracturing pressure (b) graph

The results of the investigation have shown that application of this program will allow a specialist to considerably accelerate obtaining information about basic parameters for the process of liquid injection into a well in the course of workover. This information is necessary for making regulations when planning preparatory and workover operations at a well.

The results of laboratory and theoretical investigations described in this work are important in modeling such processes in oil production as injection of polymer composition into the well, including killing of oil wells during their workover. When carrying out technological operations related to the injection of polymer compositions into a well, there is a need to obtain reliable viscosity values depending on geological and thermobaric conditions of the formation. The lack of consideration of the influence of the considered physical parameters on the viscosity or its incorrect determination can lead to negative results, such as uncontrollable formation of high-conductive fracture [44-46].

Conclusion

The algorithm developed by the authors involves calculation of the main parameters for the liquid injection process based on information about the design of the vertical well, pump operation modes, as well as the rheological characteristics of non-Newtonian liquid.

The software will allow optimizing the liquid injection mode. Namely, when calculating the critical viscosity, upon reaching which hydraulic fracturing is possible, the decision is made to change technological parameters of non-Newtonian liquid injection and/or its composition (components content, chemical base). The formation of fractures as a result of an autohydraulic fracturing can lead to catastrophic absorptions and, consequently, to an increased risk of bottomhole zone bridging and increased consumption of technological liquids pumped into the well during workover. Furthermore, there is an increased risk of uncontrolled gas breakthrough through highly conductive channels.

The proposed software prevents unintentional fracturing caused by hydraulic fracturing, reduces the high costs of downtime and possible post-repair complications, and increases the efficiency of well interventions by injecting polymer compositions.

References

- Akimov O.V. Improving well killing technologies for intensifying the development of low-permeability terrigenous reservoirs: Avtoref. dis. … kand. tekhn. nauk. Ufa: Ufimskii gosudarstvennyi neftyanoi tekhnicheskii universitet, 2011, p. 23 (in Russian).

- Rogachev M.K., Strizhnev K.V. Countering complications in oil production. Moscow: OOO “Nedra-Biznestsentr”, 2006, p. 295 (in Russian).

- Rogov E.A. Study of the well near-bottomhole zone permeability during treatment by process fluids. Journal of Mining Institute. 2020. Vol. 242, p. 169-173. DOI: 10.31897/PMI.2020.2.169

- Leusheva E., Morenov V., Tabatabaee Moradi S. Effect of carbonate additives on dynamic filtration index of drilling mud. International Journal of Engineering. 2020. Vol. 33. N 5, p. 934-939. DOI: 10.5829/ije.2020.33.05b.26

- Blinov P.A., Dvoynikov M.V. Rheological and Filtration Parameters of the Polymer Salt Drilling Fluids Based on Xanthan Gum. Journal of Engineering and Applied Sciences. 2020. Vol. 15. Iss. 2, p. 694-697. DOI: 10.36478/jeasci.2020.694.697

- Bakirova A.D., Shaliapin D.V., Dvoynikov M.V. Reseach of viscoelastic composition as a well-killing fluid. Academic Journal of West Siberia. 2018. Vol. 14. N 4, p. 44-45 (in Russian).

- Bondarenko A.V., Islamov Sh.R., Mardashov D.V. Potential for effective use of oil and gas wells killing liquids. Materialy Mezhdunarodnoi nauchno-prakticheskoi konferentsii “Dostizheniya, problemy i perspektivy razvitiya neftegazovoi otrasli”. 2018. Vol. 1, p. 216-221 (in Russian).

- Zharikov M.G., Li G.S., Kopylov A.I. et al. Development and testing of hydrocarbon-based killing liquids and blocking compositions for workover of gas wells at the Urengoyskoye OGCF. Stroitelstvo neftyanykh i gazovykh skvazhin na sushe i na more. 2018. N 1, p. 20-23 (in Russian).

- Kondrashev A.O., Rogachev M.K., Kondrashev O.F. Water shut-off polymer composition for low-permeable reservoirs. Neftyanoe khozyaistvo. 2014. N 4, p.63-65 (in Russian).

- Nutskova M.V., Rudyaeva E.Yu. Justification and development of compositions for the rapid elimination of flushing fluid absorption. Stroitelstvo neftyanykh i gazovykh skvazhin na sushe i na more. 2018. N 9, p. 15-20 (in Russian). DOI: 10.30713/0130-3872-2018-9-15-20

- Quintero L., Ponnapati R., Felipe M.J. Cleanup of Organic and Inorganic Wellbore Deposits Using Microemulsion Formulations: Laboratory Development and Field Applications Offshore Technology Conference, May 2017. Houston, Texas, USA. N OTC-27653-MS. DOI: 10.4043/27653-MS

- Jouenne S., Klimenko A., Levitt D. Tradeoffs Between Emulsion and Powder Polymers for EOR. Oil Recovery Conference, Tulsa, Oklahoma, USA, April 2016. SPE-179631-MS. DOI: 10.2118/179631-MS

- Wagle V., Al-Yami A.S., Al Safran A. Designing invert emulsion drilling fluids for HTPT conditions. SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, April 2018. SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition. 2018, p. 13. SPE-192192-MS. DOI: 10.2118/192192-MS

- Raupov I.R. Technology for intraformation water shut-off in terrigenous reservoirs using polymer compositions and optical process control: Avtoref. dis. … kand. tekhn. nauk. St. Petersburg: Sankt-Peterburgskii gornyi universitet, 2016, p. 20 (in Russian).

- Mardashov D.V. Justification of technologies for regulating the filtration characteristics of the near-bottomhole zone during workover: Avtoref. dis. … kand. tekhn. nauk. St. Petersburg: Sankt Peterburgskii gosudarstvennyi gornyi institut im. G.V.Plekhanova (tekhnicheskii universitet), 2008, p. 20 (in Russian).

- Eoff L.S., Dalrymple E.D., Eijden J. van, Vasquez J.E. Shallow Penetration Particle-Gel System for Water and Gas Shut-Off Applications. SPE Russian Oil and Gas Technical Conference and Exhibition, October 2008. Moscow, Russia, SPE Annual Technical Conference and Exhibition. 2008. Vol. 1, p. 532-538. SPE-114886-MS. DOI: 10.2118/114886-MS

- Litvinenko V.S., Nikolaev N.I. Development of the weighted biopolimer drilling mud for workover Journal of Mining Institute. 2012. Vol. 199, p. 375-378. (in Russian).

- Elkatatny S.M. Determination the Rheological Properties of Invert Emulsion Based Mud on Real Time Using Artificial Neural Network. SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, April 2016. SPE-182801-MS. DOI: 10.2118/182801-MS

- Gumerova G.R., Yarkeeva N.R.Technology of application of crosslinked polymeric compositions. Oil and Gas Business. 2017. N 2, p. 63-79 (in Russian). DOI: 10.17122/ogbus-2017-2-63-79

- Vinogradov G.V., Malkin A.Ya. Rheology of polymers. Moscow: Khimiya, 1977, p. 440 (in Russian).

- Dandekar A.Y. Petroleum reservoir rock and fluid properties. Boca Raton: CRC press, 2013, p. 544.

- Leusheva E.L., Morenov V.A. Study on rheological properties of clayless drilling fluids influenced by fractional composition of carbonate weighting agents. IOP Conference Series: Materials Science and Engineering. 2020. N 921, p. 10. DOI: 10.1088/1757-899X/921/1/012013

- Raupov I.R., Bondarenko A.V., Mardashov D.V. Patent N 2020615617 RF. Software for calculating the technological parameters of fluid injection into the well based on rheological data. Publ. 27.05.2020. Bul. N 6 (in Russian).

- Gumerov K.O., Rogachev M.K. Investigation of rheological properties of water-in-oil emulsions. Life Science Journal. 2014. Vol. 11. N 6s, p. 268-270.

- Raupov I.R., Shagiakhmetov A.M. The results of the complex rheological studies of the cross-linked polymer composition and the grounding of its injection volume. International Journal of Civil Engineering and Technology. 2019. Vol. 10. N 2, p. 493-509.

- Kirsanov A.E., MatveenkoV.N. Non-Newtonian behaviour of structured systems. Moscow: Tekhnosfera, 2016, p. 384 (in Russian).

- Ponomarev S.V., Mishchenko S.V., Divin A.G. Theoretical and practical aspects of thermophysical measurements: Monografiya. V 2 kn. Kniga 1. Tambov: Izd-vo Tambovskogo gosudarstvennogo tekhnicheskogo universiteta, 2006, p. 204 (in Russian).

- Shagiakhmetov A.M., Podoprigora D.G., Terleev A.V. The study of the dependence of the rheological properties of gelforming compositions on the crack opening when modeling their flow on a rotational viscometer. Periódico Tchê Química. 2020. Vol. 17. N 34, p. 933-939.

- Orlov A.I. Probability-statistical models of correlation and regression. Scientific Journal of KubSAU. 2020. N 160, p. 130-162. DOI: 10.21515/1990-4665-160-011

- Shramm G. Basics of practical rheology and rheometry. Moscow: KolosS, 2003, p. 312 (in Russian).

- Zhelonin P.V., Mukhametshin D. M., Archikov A.B. et al. Justification of the algorithm for selecting well killing technologies. Nauchno-tekhnicheskii vestnik PAO “NK “Rosneft” 2015. N 2 (39), p. 76-81 (in Russian).

- Galimkhanov A., Okhotnikov D., Ginzburg L. et al. Successful Implementation of Managed Pressure Drilling Technology Under the Conditions of Catastrophic Mud Losses in the Kuyumbinskoe Field. SPE Russian Petroleum Technology Conference, Moscow, Russia, October 2019. SPE Russian Petroleum Technology Conference. 2019. 14 p. SPE-196791-MS. DOI: 10.2118/196791-MS

- Bulatov A.I. System analysis of viscoplastic fluid flow investigations – clay and cement solutions (Part 1). Burenie i neft. 2016. N 3, p. 18-23 (in Russian).

- Xiaochun Jin, Subhash N. Shah, Jean-Claude Roegiers, Bing Hou. Breakdown Pressure Determination – A Fracture Mechanics Approach. SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, USA, September 2013. SPE-166434-MS. DOI: 10.2118/166434-MS

- Zoback M.D. Reservoir geomechanics. California: Cambridge University Press, 2007, p. 449.

- Osadchiy V.K., Ilina G.F. Approach to hydraulic fracturing characteristics calculations on the example of producing oil well in West Siberia. Readings name of A.I.Bulatov. 2017. Vol. 2, p. 192-197. (in Russian).

- Dvoynikov M.V., Budovskaya M.E. Development of a hydrocarbon completion system for wells with low bottomhole temperatures for conditions of oil and gas fields in Eastern Siberia. Journal of Mining Institute. 2022, p. 1-11 (Online first). DOI: 10.31897/PMI.2022.4

- Tabatabaee M.S., Nikolaev N.I., Chudinova I.V., Martel A.S. Geomechanical study of well stability in high-pressure, high-temperature conditions. Geomechanics and Engineering. 2018. Vol. 16. N 3, p. 331-339. DOI: 10.12989/gae.2018.16.3.331

- Sudarikov S.M., Yungmeister D.A., Korolev R.I., Petrov V.A. On the possibility of reducing man-made burden on benthic biotic communities when mining solid minerals using technical means of various designs. Journal of Mining Institute. 2022. Vol. 253, p. 82-96. DOI: 10.31897/PMI.2022.14

- Legkokonets V.A., Islamov Sh.R., Mardashov D.V. Multifactor Analysis of Well Killing Operations on Oil and Gas Condensate Field with a Fractured Reservoir. Proceedings of the International Forum-Contest of Young Researchers: Topical Issues of Rational Use of Mineral Resources. United Kingdom: London: CRC Press/Balkema, Taylor & Francis Group, 2019, p. 111-118.

- Islamov S., Grigoriev A., Beloglazov I. et al. Research Risk Factors in Monitoring Well Drilling – A Case Study Using Machine Learning Methods. Symmetry. 2021. Vol. 13. N 1293, p. 19. DOI: 10.3390/sym13071293

- Sultanbekov R.R., Beloglazov I.I., Ong M.C. Exploring of the Incompatibility of Marine Residual Fuel: A Case Study Using Machine Learning Methods. Energies. 2021. Vol. 14. N 8422. 16 p. DOI: 10.3390/en14248422

- Fedorov A.S., Kazakov Y. A., Fadeev D.V. Parameters of the screw press mouthpiece on the basis of requirements to the peat formed products. Gornyy informatsionno-analiticheskiy byulleten. 2020. N S , p. 3-15. DOI: 10.25018/0236-1493-2020-3-9-3-15

- Buslaev G., Tsvetkov P., Lavrik A et al. Ensuring the Sustainability of Arctic Industrial Facilities under Conditions of Global Climate Change. Resources. 2021. N 10. DOI: 10.3390/resources10120128

- Bykowa E., Dyachkova I. Modeling the Size of Protection Zones of Cultural Heritage Sites Based on Factors of the Historical and Cultural Assessment of Lands. Land. 2021. Vol. 10. N 1201. DOI: 10.3390/land10111201

- Yungmeister D.A., Isaev A.I., Korolev R.I., Yacheikin A.I. Choice of materials and justification of the parameters for the over-bit hammer. Journal of Physics Conference Series. 2020. Vol. 1582(1). N 012097. DOI: 10.1088/1742-6596/1582/1/012097