Reproduction of reservoir pressure by machine learning methods and study of its influence on the cracks formation process in hydraulic fracturing

Abstract

Hydraulic fracturing is an effective way to stimulate oil production, which is currently widely used in various conditions, including complex carbonate reservoirs. In the conditions of the considered field, hydraulic fracturing leads to a significant differentiation of technological efficiency indicators, which makes it expedient to study in detail the crack formation patterns. For all affected wells, the assessment of the resulting fractures spatial orientation was performed using the developed indirect technique, the reliability of which was confirmed by geophysical methods. In the course of the analysis, it was found that in all cases the fracture is oriented in the direction of the development system element area, which is characterized by the maximum reservoir pressure. At the same time, reservoir pressure values for all wells were determined at one point in time (at the beginning of hydraulic fracturing) using machine learning methods. The reliability of the used machine learning methods is confirmed by high convergence with the actual (historical) reservoir pressures obtained during hydrodynamic studies of wells. The obtained conclusion about the influence of the formation pressure on the patterns of fracturing should be taken into account when planning hydraulic fracturing in the considered conditions.

Introduction

The oil and gas reserves contained in carbonate reservoirs are approximately 70 % of the world reserves, and proven recoverable reserves – approximately 50 % [1-3]. Compared to reservoirs represented by sandstones, carbonate rocks much differ in the characteristics of the geological structure and mechanisms of reserves development, which, of course, should be taken into account when choosing development methods [4-6]. In many articles [5, 7, 8] it is noted that during the exploitation of carbonate deposits, the initial levels of oil production can be high, but it is quite difficult to maintain them at a stable level. In these conditions, measures to stimulate oil production, such as acid hydraulic fracturing (AHF), play an important role in the effective development of complex carbonate reservoirs [9-11]. However, it should be noted that the application of this method in complex reservoirs, for example, in reef structures, is complicated by unstable results [12-14]. Thus, when conducting acid fracturing at the Famennsky development site of one of the oil fields confined to the Solikamsk depression (Perm Territory), there is a significant spread in the values of technological efficiency indicators: a number of wells achieved a very significant increase in production rate, which persists for a long period of time, on some wells, the increase in production rate is minimal (or not obtained) [15-17]. One of the probable reasons for the noted phenomenon may be the complex geological structure of the development object, including differences in the structure of the void space, a large range of variation in effective oil-saturated thicknesses, which ultimately can affect the formation of hydraulic fractures [18-20]. In this regard, it seems relevant to study the patterns of hydraulic fractures formation for further effective application of the considered method of stimulation [21-23].

There are a number of methods that allow assessing the direction of hydraulic fractures during the operation [24-26]. One of the common methods for assessing the parameters of a hydraulic fracture is microseismic monitoring (MSM), which has received practical application in many oil producing regions of Russia and abroad [27-29]. However, in areas with unfavorable seismo-geological conditions, it is not always possible to obtain conditioned material using seismic research methods. On the territory of the Perm Territory, the zone of unfavorable seismogeological conditions is widespread and has a significant area; a number of oil fields are located on its territory, including the one considered in this paper [30].

Another well-known tool for controlling the process of formation of hydraulic fractures is a geophysical method – sonic waveform logging (SWL-D) [31]. This method is also widely used in the oilfield business practice, including in the Perm region fields, however, mass use is also limited by economic and technological reasons. Therefore, the development of indirect methods for determining the direction of hydraulic fractures is especially relevant, and the existing actual experience of MSM and SWL can be used to assess the reliability of the results.

In papers [32, 33] describes a technique based on the field data analysis and confirmed by the results of hydraulic fracturing MSM at a number of wells in the Perm region fields. The essence of the technique is reduced to a comparative analysis of the mutual influence of wells within the element of the development system in which the well is located – the object of influence. As a measure of well mutual influence, it is proposed to use the correlation coefficient between fluid flow rates (injectivity in the presence of injection wells), a hypothesis about the direction of the fracture is put forward based on visual analysis and comparison of fields representing the distribution of the correlation coefficient between well flow rates in the area of the development system element. Despite the good agreement between the results of using the indirect technique with MSM, its practical application is hampered by the need and complexity of a comparative visual analysis of the fields of distribution of correlation coefficients, dependence on the so-called human factor. In this regard, it is advisable to adjust the methodology aimed at eliminating this shortcoming.

Reliable determination of the hydraulic fractures direction will allow to increase the detailing of the operations results analysis performed in complex carbonate reservoirs, to explore the probable patterns of this process. In turn, the identification of geological and technological factors that determine the patterns of the spatial arrangement of hydraulic fractures is a key tool in the management of the event, its use will significantly increase the efficiency of planning in the conditions under consideration [34, 35].

In the general list of geological and technological factors that probably affect the hydraulic fractures patterns formation in the reservoir, reservoir pressure should be highlighted. However, the discreteness and time difference of reservoir pressures actual measurements, despite the high coverage of the fund of the considered object by hydrodynamic studies (HDS), is a factor limiting the detailed analysis of this hypothesis, therefore it seems relevant to use indirect methods for determining reservoir pressure based on mathematical processing of the accumulated experience of hydrodynamic and field tests. research using artificial intelligence.

Currently, the methods of artificial intelligence and machine learning are widely used in all areas, including oil and gas engineering, and their application makes it possible to modernize existing technologies and processes [36-38]. Machine learning methods can be used to indirectly assess and predict the energy state of deposits [39-40].

At present, there are several types of machine learning:

- classical learning – includes such algorithms as classification, regression, clustering, generalization, association;

- reinforcement learning – used to create autopilots, robotic vacuum cleaners, computer games;

- ensemble methods – used in search engines, computer vision and all tasks where classical algorithms work;

- neural networks and deep learning – used in all of the above tasks, they represent a set of neurons and connections between them.

The choice of a machine learning method depends on the problem statement; a combination of methods is often used. For the effective use of elements of artificial intelligence, a well-prepared database is required, which is often a more time-consuming task than the process of building a model and training it. Taking into account innovative trends in the oil and gas industry and an extensive database of development objects, the use of machine learning methods to solve various analytical problems in this area is particularly relevant.

Methodology

This study proposes an improved approach to solving the problem. The direction of hydraulic fractures is still proposed to be assessed by changing the degree of interaction between wells, based on the assumption that as a result of hydraulic fracturing in the zone of fracturing, permeability changes, which, of course, affects the presence and degree of hydrodynamic communication between wells. A distinctive feature is the inclusion in the methodology of the stage of calculating the value of Δr, which is the change (in absolute value) of the correlation coefficient between well flow rates.

In the future, it is proposed to build not two fields, but one, reflecting the change in the value of Δr over the area of the development system element. The section of the element with the maximum value of Δr is proposed to be considered a probable direction of crack formation. Thus, the improved indirect technique involves the construction and analysis of only one field – the scheme for changing the value of Δr.

At the next stage, studies were carried out to assess the influence of geological and technological factors on the hydraulic fracture formation patterns. Identification of such factors will make it possible to successfully plan further hydraulic fracturing activities. It is obvious that as the factors that probably determine the hydraulic fractures formation patterns, parameters should be considered, the practical determination of which is not difficult.

To this end, for all wells within the elements of the development system, a large amount of geological and field data was involved, including bottomhole pressure, porosity coefficient values, belonging to the lithofacies zone, and calculations were carried out to determine the reservoir pressure values for each well of the element at one point in time corresponding to the beginning of hydraulic fracturing. When calculating reservoir pressures, two methods of machine learning were used – random forest and artificial neural network.

The machine learning method “random forest” has been widely used in many areas and is used to solve various kinds of problems [41, 42]. One of the few universal algorithms was first proposed by American mathematicians L.Bryman and A.Cutler, it allows solving problems of classification, regression, clustering, anomaly search, etc.

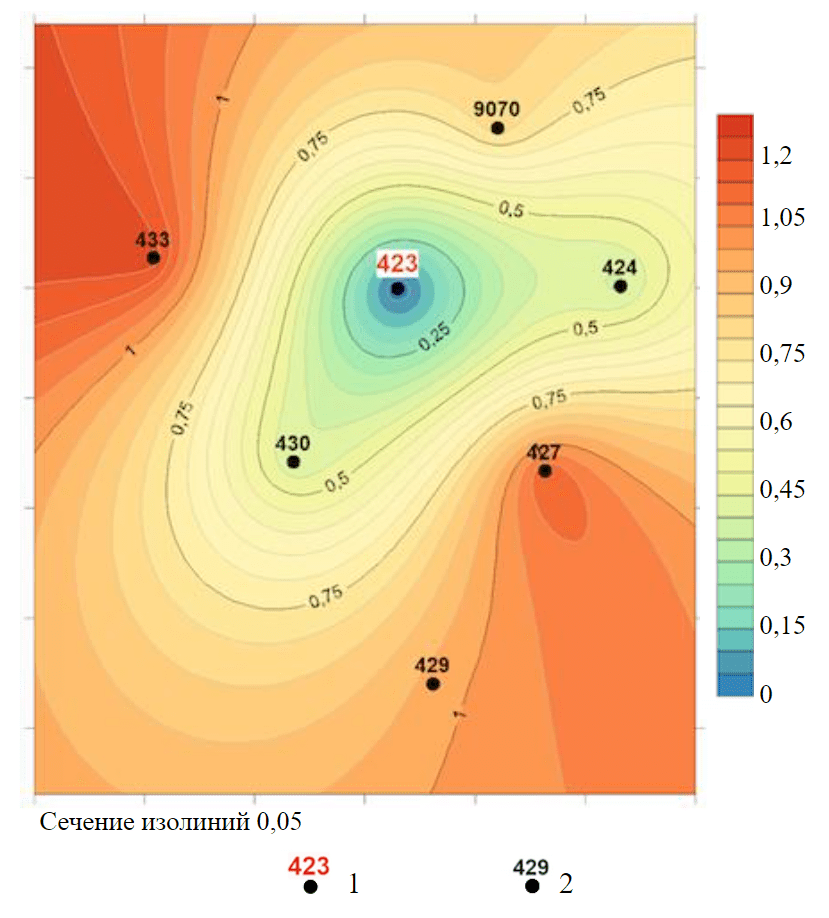

Fig.1. Scheme of changing the parameter Δr on the area of the development system element [44] 1 – hydraulic fracturing well; 2 – production well

An artificial neural network is also currently being successfully applied in the field of oil and gas engineering due to the use of a large amount of geological and field data. With proper training, a neural network can reliably predict the required parameters by defining complex non-linear relationships between input data.

When developing models for determining reservoir pressure using artificial intelligence methods (random forest and neural network), such parameters as fluid flow rates, as well as the operating factors of each well, were used as input data. In calculating reservoir pressures, a method was used that showed the best match between the calculated and actual values of the desired value [43].

Results

Figure1 shows the results of the practical application of the proposed methodology – assessment of the hydraulic fractures direction for one of the wells (N 423), which exploits the Famennian carbonate deposits, on which acid fracturing was performed with proppant fixation. The choice of this well is due to the availability of wave acoustic logging data, performed before and after hydraulic fracturing.

For all wells within a development system element that includes a well 423, the values of the correlation coefficients r between the fluid flow rates before and after hydraulic fracturing were calculated, their difference was determined, and a scheme was constructed for changing the parameter Δr over the area of the element (Fig.1).

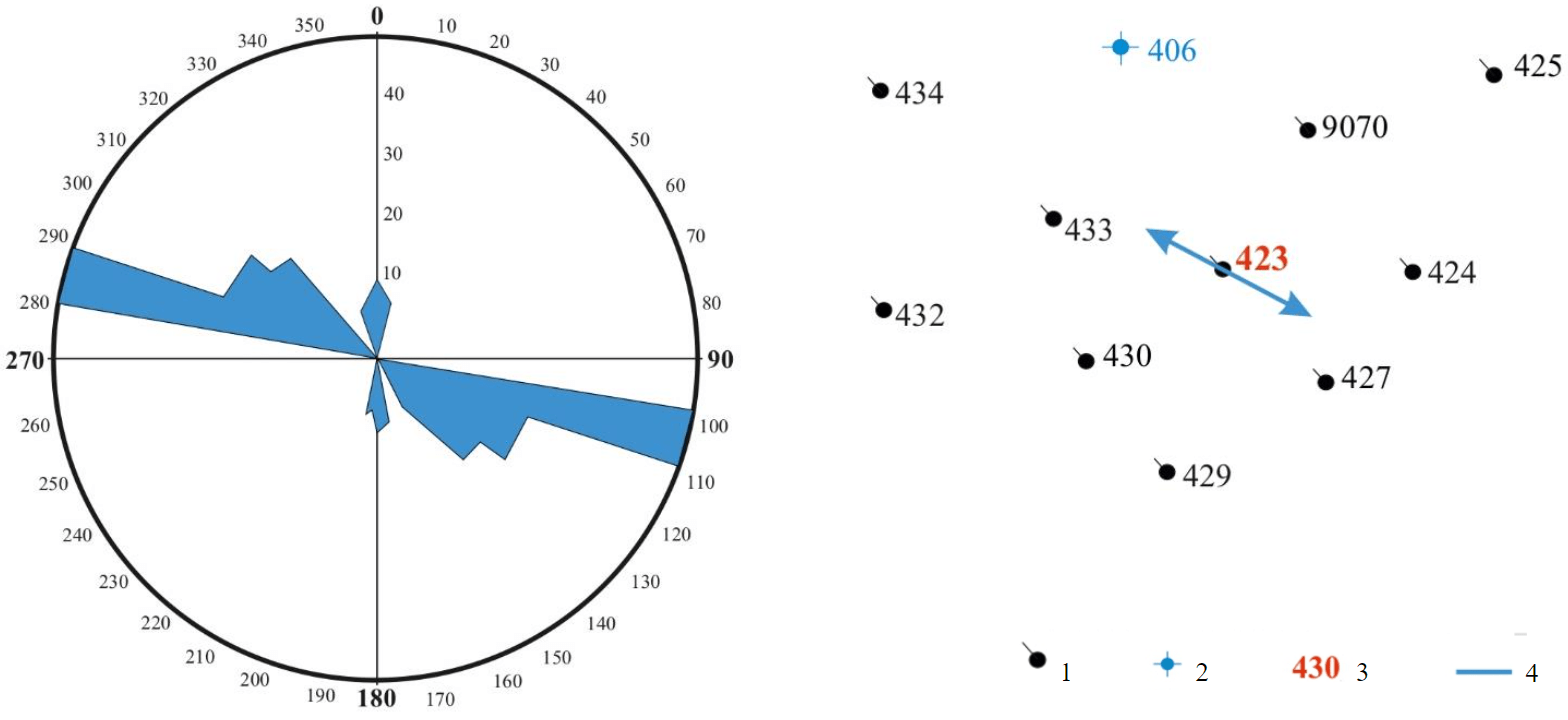

As follows from the analysis of Fig.1, the maximum change in the correlation coefficient between production rates is noted in the direction of the well 433 and 427, which is fully confirmed by the results of SWL (Fig.2).

Fig.2. Spatial position of hydraulic fracture according to SWL [44] 1 – operating production well; 2 – operating injection; 3 – well-fracturing facility; 4 – fracture direction after hydraulic fracturing

Comparison of correlation coefficients of actual and model reservoir pressures

|

Well |

Correlation coefficient value |

|

|

Random forest |

Neural network |

|

|

423 |

0.721 |

0.728 |

|

424 |

0.836 |

0.964 |

|

427 |

0.972 |

0.950 |

|

429 |

0.734 |

0.836 |

|

430 |

0.979 |

0.914 |

|

433 |

0.624 |

0.712 |

|

9070 |

0.806 |

0.806 |

|

Average |

0.810 |

0.844 |

In total, 26 hydraulic fracturing operations were performed at the object under consideration, and for each of them, the direction of hydraulic fractures was estimated. It should be noted that the obtained results are fully consistent with the SWL materials (for wells where hydraulic fracturing was accompanied by this control method).

The next stage of the work was to study the probable causes of the spatial orientation of the formed cracks. It has been established that the only factor (out of the total significant amount of information involved) that affects the location of fractures is reservoir pressure. As noted earlier, reservoir pressure values for all wells before hydraulic fracturing were determined using machine learning methods implemented as a module of a generalized software package, which was developed to solve a number of tasks for monitoring the oil fields development. This module allows you to perform retro- and prospective analysis of reservoir pressure in the extraction zones at any time. Reliability of reservoir pressure reproduction by each of the two methods is estimated by the criterion r – the correlation coefficient between the actual and model reservoir pressures (see table).

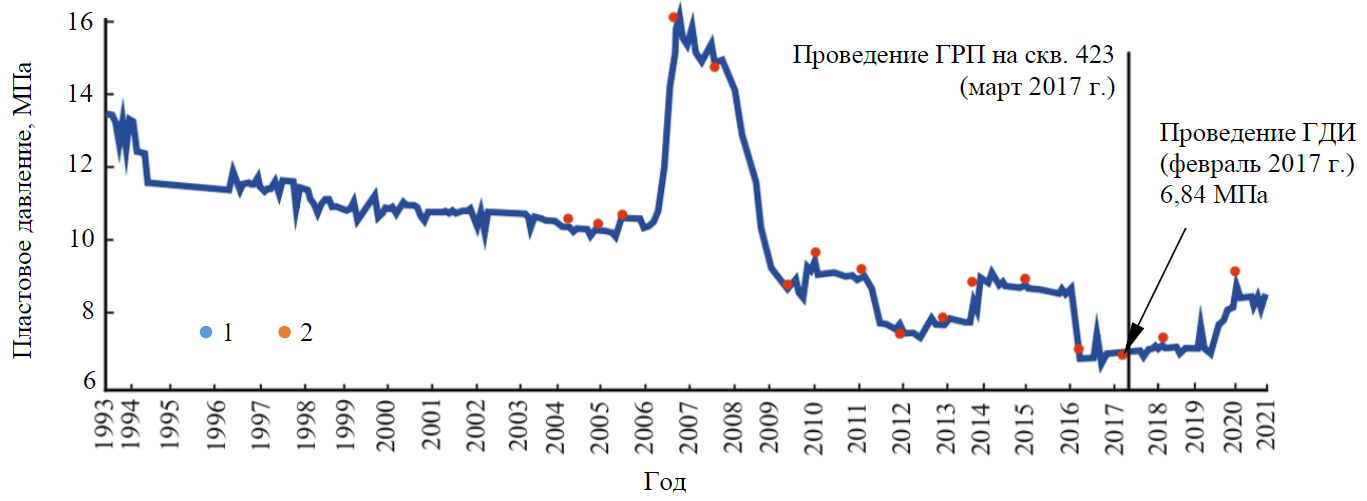

For the conditions of the considered development object, both the neural network and the random forest method demonstrate high reliability when reproducing historical data on reservoir pressure. Based on a slightly higher average value of the coefficient r, data obtained using a neural network were used for further research. The reproduction of historical data is also illustrated by a graph of reservoir pressure dynamics for one of the wells of the element – well 9070 (Fig.3). Visual analysis of the graph confirms the high reliability of the machine learning method used in reproducing reservoir pressure (a sharp increase in reservoir pressure (2007-2008) is associated with the introduction of a reservoir pressure maintenance system, and a subsequent significant change in the energy condition is due to a decrease in the injection of the agent into injection wells and active drilling of the deposit).

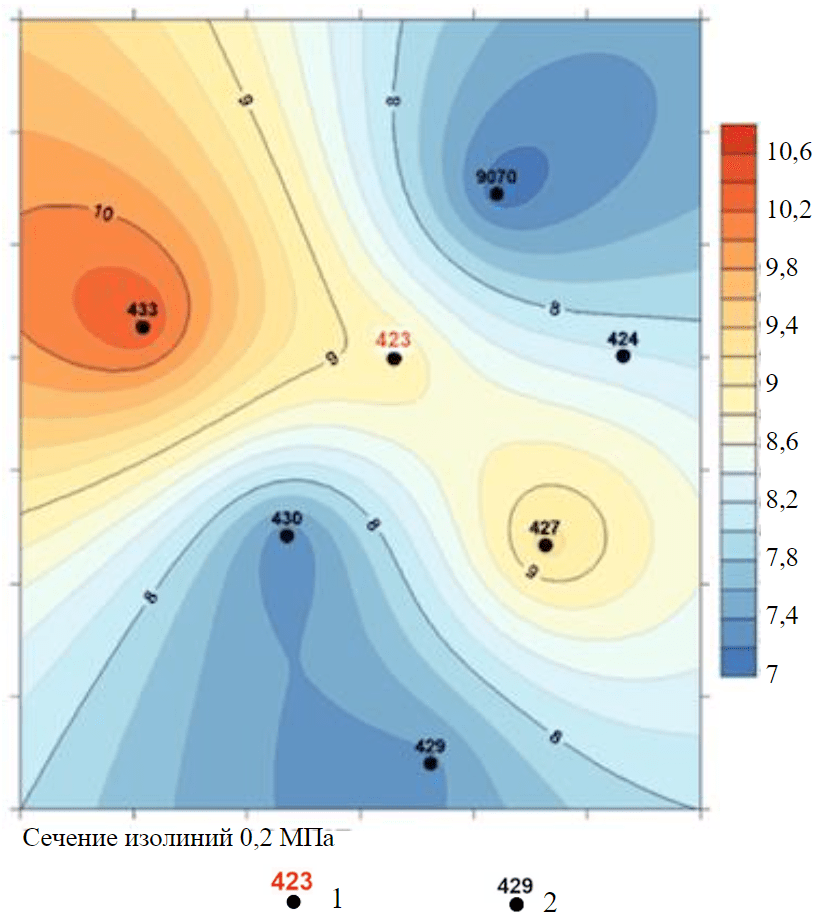

The high reliability of the used indirect method for determining reservoir pressure made it possible to assess the energy state of the development system element immediately before hydraulic fracturing in the well 423 located within this element. The calculations results are presented in the form of a reservoir pressure distribution scheme, a kind of analogue of the isobar map built for a reservoir fragment.

Fig.3. Dynamics of actual and model reservoir pressure during well 9070 operation [44] 1 – model reservoir pressure; 2 – actual (hydraulic well studies)

As follows from the analysis of the scheme presented in Fig.4, the maximum values of reservoir pressure are typical for well sampling zones 433 and 427. At the same time, it was in the direction of these wells that the priority development of cracks was established (see Fig.1, 2), i.e. within the considered section of the deposit, hydraulic fractures propagated in the direction of zones with maximum reservoir pressure.

Coincidences of the spatial distribution of hydraulic fractures and zones with the highest formation pressures (within the elements of the development system) were established for 25 out of 26 measures performed at the facility.

Fig.4. Reservoir pressure distribution scheme within the development system element before hydraulic fracturing [44]

Discussion

In the performed analysis course, it was found that within the limits of the Tournaisian-Famennian considered field oil deposit, as a result of hydraulic fracturing, cracks are formed in the reservoir, oriented to the zone with the maximum reservoir pressure for the area. This conclusion will allow more efficient planning of hydraulic fracturing, reducing economic and technological risks.

The establishment of this regularity became possible due to the complex use of two indirect methods – fracture formation direction assessment according to the comparative analysis of the correlation of well flow rates before and after hydraulic fracturing, as well as a method for determining reservoir pressure in any period of well operation, based on the use of machine learning methods.

It should be noted that the conclusion obtained in the work on the predominant impact direction in the area of increased formation pressures, to some extent, contradicts the known geomechanical concepts. Thus, in the works [14, 20, 45] based on analytical solutions, the authors made conclusions about the propagation of hydraulic fractures in the area of low pressures. Of course, this issue is debatable and requires further study.

In particular, the conclusion that a fracture propagates into a low-pressure zone contradicts the laws of fluid flow: it is known that the fluid moves from a higher pressure to a lower one, and it is not clear how the propagation of a fracture into a low pressure zone will ensure the influx of additional fluid volumes.

In any case, the issue of the hydraulic fractures spatial orientation has not been resolved. On the one hand, analytical solutions cannot take into account the complexity of the geological structure of carbonate deposits. On the other hand, the solution obtained and described in this article is valid only for the object under consideration and may be a particular, atypical case due to the peculiarities of the geological structure of the deposit itself, or it may describe the general trend in hydraulic fracturing. For example, the reservoir under consideration is a reef structure with a complex structure of void space, complicated by the presence of cracks and caverns. Within the reservoir, zones with different anisotropy of the reservoir permeability are distinguished, which, can affect the patterns of fracturing in the process of hydraulic fracturing. Therefore, similar studies will be carried out in the future, the objects of which will be oil deposits confined to terrigenous and carbonate pore reservoirs.

Conclusion

Hydraulic fracturing is a method of intensifying oil production, widely used not only in terrigenous, but also in complex carbonate reservoirs.

When analyzing the accumulated experience of AHF in the conditions of the Tournaisian-Famennian development site of one of the fields in the Perm region, represented by complex carbonate reservoirs, a significant differentiation of technological efficiency indicators was established: high production rates were obtained at some wells, while the planned effect was not achieved at others. In this regard, the task of a hydraulic fracturing accumulated experience detailed analysis, including the assessment of the direction of fracture formation and the identification of factors influencing it, is an urgent task.

To assess the direction of hydraulic fractures, an indirect technique based on the comparative correlation of well flow rates was used. The results of this technique are fully confirmed by the materials of geophysical surveys (SWL-D), the direction of fracturing is established for all wells – hydraulic fracturing objects.

The hypothesis about the probable influence of reservoir pressure on the hydraulic fracture’s formation direction is investigated. To check it for all wells, including those located in the immediate vicinity of wells – objects of influence, the materials of hydrodynamic studies with the determination of reservoir pressures were involved.

The difference in measurements of actual reservoir pressures necessitates the use of indirect methods that allow reproducing reservoir pressures in any period of well operation. In this work, machine learning methods are used – a promising direction that allows solving numerous problems of oil and gas engineering. With the use of machine learning methods (“random forest” and neural network), models were obtained, which, for convenience, were implemented as a software module. Reliability of calculations is confirmed by high convergence with actual historical data.

The constructed models are used to reproduce reservoir pressure values in the sampling zones of all wells immediately before hydraulic fracturing. At the same time, pressures were calculated both for wells – objects of influence, and for those located in the immediate vicinity.

A joint analysis of hydraulic fracture directions and reservoir pressure distribution patterns within the elements of development systems made it possible to obtain the most important conclusion that fractures propagate in the direction of zones with the highest reservoir pressures.

This conclusion can be both of the particular nature, applicable to the conditions of the object under consideration, and reflect the general pattern of this type of impact.

References

- Kresse O., Weng X. Numerical modeling of 3D hydraulic fractures interaction in complex naturally fractured formations. Rock Mechanics and Rock Engineering. 2018. Vol. 51. Iss. 12, p. 3863-3881. DOI: 10.1007/s00603-018-1539-5

- Qinghua Lei, John-Paul Latham, Chin-Fu Tsang. The use of discrete fracture networks for modelling coupled geomechanical and hydrological behaviour of fractured rocks. Computers and Geotechnics. 2017. Vol. 85, p. 151-176. DOI: 10.1016/j.compgeo.2016.12.024

- Jianchun Guo, Bo Luo, Cong Lu et al. Numerical investigation of hydraulic fracture propagation in a layered reservoir using the cohesive zone method. Engineering Fracture Mechanics. 2017. Vol. 186, p. 195-207. DOI: 10.1016/j.engfracmech.2017.10.013

- Galkin V.I., Ponomareva I.N. Study of reservoirs properties of fractured-porous Tournasian-Famennian productive formation within Solikamskaya depression. Neftyanoye khozyaystvo. 2016. N 11, p. 88-91 (in Russian). DOI: 10.24887/0028-2448-2019-8-122-125

- Martyushev D.A. Rock stress state in fluence on permeability of carbonate reservoirs. Bulletin of the Tomsk Polytechnic University. Geo Аssets Engineering. 2020. Vol. 331. N 8, p. 24-33 (in Russian) DOI: 10.18799/24131830/2020/8/2765

- Elmo D., Stead D. An integrated numerical modelling-discrete fracture network approach applied to the characterization of rock mass strength of naturally fractured pillars. Rock Mechanics and Rock Engineering. 2010. Vol. 43. Iss. 1, p. 3-19. DOI: 10.1007/s00603-009-0027-3

- Syed F.I., AlShamsi A., Dahaghi A.K., Neghabhan Sh. Machine Learning techniques to Model Geomechanics and Petrophysical Properties of Shale Reservoirs – A Systematic Literature Review. Petroleum. 2020. DOI: 10.1016/j.petlm.2020.12.001

- Li Yang, Kang Zhijiang, Xue Zhaojie, Zheng Songqing. Theories and practices of carbonate reservoirs development in China. Petroleum Exploration and Development. 2018. Vol. 45. Iss. 4, p. 669-678. DOI: 10.11698/PED.2018.04.12

- Zhukov V.S., Kuzmin Yu.O. Experimental evaluation of compressibility coefficients for fractures and intergranular pores of an oil and gas reservoir. Journal of Mining Institute. 2021. Vol. 251, p. 658-666. DOI: 10.24887/0028-2448-2020-8-50-53

- Parth Solanki, Dhruv Baldaniya, Dhruvikkumar Jogani et al. Artificial intelligence: New age of transformation in petroleum upstream. Petroleum Research. 2022. Vol. 7. Iss. 1, p. 106-114. DOI: 10.1016/j.ptlrs.2021.07.002

- Ning Qi, Guobin Chen, Lin Pan et al. Numerical simulation and analysis of fracture etching morphology during acid fracturing of dolomite reservoirs. Chemical Engineering Science. 2021. Vol. 229. N 116028. DOI: 10.1016/j.ces.2020.116028

- Galkin V.I., Koltyrin А.N. Investigation of probabilistic models for forecasting the efficiency of proppant hydraulic fracturing technology. Journal of Mining Institute. 2020. Vol. 246, p. 650-659. DOI: 10.31897/PMI.2020.6.7

- Ziyuan Cong, Yuwei Li, Jizhou Tang, Martyushev D.A. et al. Numerical simulation of hydraulic fracture height layer-through propagation based on three-dimensional lattice method. Engineering Fracture Mechanics. 2022. Vol. 264. N 108331. DOI: 10.1016/j.engfracmech.2022.108331

- Duan Wei, Zhiqian Gao, Tailiang Fan et al. Experimental hydraulic fracture propagation on naturally tight intra-platform shoal carbonate. Journal of Petroleum Science and Engineering. 2017. Vol. 157, p. 980-989. DOI: 10.1016/j.petrol.2017.08.016

- Raspopov A.V., Kondratiev S.A., Sharafeev R.R. Experience of hydraulic fracturing in oil fields of the Perm Region, the Komi Republic and the Nenets Autonomous District. Neftyanoye khozyaystvo. 2019. N 8, p. 48-51 (in Russian). DOI: 10.24887/0028-2448-2019-8-48-51

- Ali Al-Rubaye, Hisham Khaled Ben Mahmud. A numerical investigation on the performance of hydraulic fracturing in naturally fractured gas reservoirs based on stimulated rock volume. Journal of Petroleum Exploration and Production. 2020. Vol. 10, p. 3333-3345. DOI: 10.1007/s13202-020-00980-8

- Wan X., Rasouli V., Damjanac B., Pu H. Lattice simulation of hydraulic fracture containment in the North Perth Basin. Journal of Petroleum Science and Engineering. 2020. Vol. 188. N 106904. DOI: 10.1016/j.petrol.2020.106904

- Gabnasyrov A.V. Forecasting of the direction of a formation hydraulic fracturing based on the assessment of the rocks’ stress-strain state. Geology, geophysics and development of oil and gas fields. 2015. N 11, p.70-72 (in Russian).

- Kuznetsov M.A., Letko I.I., Ibragimov K.R. Algorithm design for locating fracture initiation during multistage refrac in horizontal wells by using iFrac technology. Neftyanoye khozyaystvo. 2020. N 4, p. 49-53 (in Russian). DOI: 10.24887/0028-2448-2020-4-49-53

- Zhifeng Luo, Nanlin Zhang, Liqiang Zhao et al. An extended finite element method for the prediction of acid-etched fracture propagation behavior in fractured-vuggy carbonate. Journal of Petroleum Science and Engineering. 2020. Vol. 191. N 107170. DOI: 10.1016/j.petrol.2020.107170

- Zhaohui Chong, Qiangling Yao, Xuehua Li. Effect of Joint Geometrical Parameters on Hydraulic Fracture Network Propagation in Naturally Jointed Shale Reservoirs. Geofluids. 2018. Vol. 2018. N 1852604, p. 1-23. DOI: 10.1155/2018/1852604

- Xiaowei Weng. Modeling of complex hydraulic fractures in naturally fractured. Journal of Unconventional Oil and Gas Resources. 2015. Vol. 9, p. 114-135. DOI: 10.1016/j.juogr.2014.07.001

- Jian Zhou, Yan Jin, Mian Chen. Experimental investigation of hydraulic fracturing in random naturally fractured blocks. International Journal of Rock Mechanics and Mining Sciences. 2010. Vol. 47. N 7, p. 1193-1199. DOI: 10.1016/j.ijrmms.2010.07.005

- Rabaev R.U., Bakhtizin R.N., Sultanov S.Kh. et al. Substantiation of application of the technology of acid hydraulic facing insea shelfgas condensate carbonate reservoirs. SOCAR Proceedings. 2020. N 4, p. 60-67 (in Russian). DOI: 10.5510/OGP20200400466

- Kaikai Zhao, Pengfei Jiang, Yanjun Feng et al. Numerical Investigation of Hydraulic Fracture Propagation in Naturally Fractured Reservoirs Based on Lattice Spring Model. Geofluids. 2020. Vol. 2020. N 8845990. DOI: 10.1155/2020/8845990

- Chunchi Ma, Yupeng Jiang, Huilin Xing, Tianbin Li. Numerical modelling of fracturing effect stimulated by pulsating hydraulic fracturing in coal seam gas reservoir. Journal of Natural Gas Science and Engineering. 2017. Vol. 46, p. 651-663. DOI: 10.1016/j.jngse.2017.08.016

- Zou Yushi, Zhang Shicheng, Zhou Tong. Experimental investigation into hydraulic fracture network propagation in gas shales using CT scanning technology. Rock Mechanics and Rock Engineering. 2016. Vol. 49. Iss. 1, p. 33-45. DOI: 10.1007/s00603-015-0720-3

- Pettitt W., Pierce M., Damjanac B. et al. Fracture network engineering for hydraulic fracturing. The Leading Edge. 2011. Vol. 30. Iss. 8, p. 844-853. DOI: 10.1190/1.3626490

- Zhiyuan Liu, Mian Chen, Guangqing Zhang. Analysis of the influence of a natural fracture network on hydraulic fracture propagation in carbonate formations. Rock Mechanics and Rock Engineering. 2014. Vol. 47. Iss. 2, p. 575-587. DOI: 10.1007/s00603-013-0414-7

- Ponomareva I.N., Martyushev D.A., Govindarajan S.K. A new approach to predict the formation pressure using multiple regression analysis: Case study from Sukharev oil field reservoir – Russia. Journal of King Saud University – Engineering Sciences. 2022. DOI: 10.1016/j.jksues.2022.03.005

- Hongpu Kang, Huawen Lv, Fuqiang Gao et al. Understanding mechanisms of destressing mining-induced stresses using hydraulic fracturing. International Journal of Coal Geology. 2018. Vol. 196, p. 19-28. DOI: 10.1016/j.coal.2018.06.023

- Galkin V.I., Ponomareva I. N., Cherepanov S.S. et al. New approach to the study of the results of hydraulic fracturing (on the example of Bobrikovsky deposits of the Shershnevsky field). Bulletin of the Tomsk Polytechnic University. Geo Аssets Engineering. 2020. Vol. 331. N 4, p. 107-114 (in Russian). DOI: 10.18799/24131830/2020/4/2598

- Ponomareva I.N., Martyushev D.A. Evaluation of hydraulic fracturing results based on the analysis of geological field data. Georesources. 2020. Vol. 22. N 2, p. 8-14 (in Russian). DOI: 10.18599/grs.2020.2.8-14

- Kulakov P.A., Kutlubulatov A.A., Afanasenko V.G. Forecasting of the hydraulic fracturing efficiency as components of its design optimization. SOCAR Proceedings. 2018. N 2, p. 41-48 (in Russian). DOI: 10.5510/OGP20180200349

- Cruz F., Roehl D., Vargas Jr. E. do A. An XFEM element to model intersections between hydraulic and natural fractures in porous rocks. International Journal of Rock Mechanics and Mining Sciences. 2018. Vol. 112, p. 385-397. DOI: 10.1016/j.ijrmms.2018.10.001

- Sergeychev A.V., Toropov K.V., Antonov M.S. et al. Automated intelligent assistant in the selection of well placement when developing hard-to-recover reserves. Oil Industry. 2020. N 10, p. 76-81 (in Russian). DOI: 10.24887/0028-2448-2020-10-76-81

- Akulich A.V., Zvyagin A.V. Numerical simulation of hydraulic fracture propagation. Vestnik Moskovskogo universiteta. Seriya 1: Matematika. Mekhanika. 2008. N 1, p. 43-49 (in Russian).

- Evsyutkin I.V., Markov N.G. Deep artificial neur al networks for fore casting debit values for production wells. Bulletin of the Tomsk Polytechnic University. Geo Аssets Engineering. 2020. Vol. 331. N 11, p. 88-95 (in Russian). DOI: 10.18799/24131830/2020/11/2888

- Chernikov A.D., Eremin N.A., Stolyarov V.E. et al. Application of artificial intelligence methods for identifying and predicting complications in the construction of oil and gas wells: problems and solutions. Georesources. 2020. Vol. 22. N 3, p. 87-96 (in Russian). DOI: 10.18599/grs.2020.3.87-96

- Kaikai Zhao, Doug Stead, Hongpu Kang et al. Investigating the interaction of hydraulic fracture with pre-existing joints based on lattice spring modeling. Computers and Geotechnics. 2020. Vol. 122. N 103534. DOI: 10.1016/j.compgeo.2020.103534

- Shady Galal Ramah, Mohamed Abdalla Othman, Ahmed Z.Nouh, Tarek El-Kwidy. Prediction of fold-of-increase in productivity index post limited entry fracturing using artificial neural network. Petroleum Research. 2022. Vol. 7. Iss. 2, p. 236-245. DOI: 10.1016/j.ptlrs.2021.09.002

- Khuzin R.R., Andreev V.E., Mukhametshin V.V., Kuleshova L.S., Dubinskii G.S., Safiullina A.R. Influence of hydraulic compression on porosity and permeability properties of reservoirs. Journal of Mining Institute. 2021. Vol. 251, p. 688-697. DOI: 10.31897/PMI.2021.5.8

- Zakharov L.А., Martyushev D.А., Ponomareva I.N. Predicting dynamic formation pressure using artificial intelligence methods. Journal of Mining Institute. 2022. Vol. 253, p. 23-32. DOI: 10.31897/PMI.2022.11

- Filippov E.V. Study and analysis of the process of fracturing during hydraulic fracturing of carbonate reservoirs: Avtoref. dis. … kand. tekhn. nauk. Perm': Permskii natsional'nyi issledovatel'skii politekhnicheskii universitet, 2022, p. 22 (in Russian).

- Bohu Zhang, Xiaopeng Tian, Binxiang Ji et al. Study on microseismic mechanism of hydro-fracture propagation in shale. Journal of Petroleum Science and Engineering. 2019. Vol. 178, p. 711-722. DOI: 10.1016/j.petrol.2019.03.085