Justification of a comprehensive technology for preventing the formation of asphalt-resin-paraffin deposits during the production of highlyparaffinic oil by electric submersible pumps from multiformation deposits

- 1 — Ph.D., Dr.Sci. professor Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Engineer Saint Petersburg Mining University

Abstract

Production of highly solidifying abnormal oils (with a paraffin content of over 30 % by mass) in the Far North is complicated by the intensive formation of asphalt-resin-paraffin deposits (ARPD) in the bottomhole zone of the productive formation, well and surface equipment. Existing methods and technologies for countering the formation of organic deposits in well equipment have many advantages. However, their application in the production of highly paraffinic oil does not fully prevent the formation of ARPD in the tubing string. This leads to a significant reduction in oil production, reduction of turnaround and intertreatment periods of production wells operation, an increase in specific operating expenses for paraffin removal. Results of theoretical and laboratory investigations presented in the article show that one of the promising ways to improve the operational efficiency of wells equipped with electric submersible pumps during extraction of highly paraffinic oil from multiformation deposits is the application of a new integrated technology based on the joint production of highly solidifying abnormal oil with oil, characterized by a lower paraffin content and manifestation of structural and mechanical properties, in conjunction with the regulation of the parameters for the electric submersible pump. Results of numerical modeling using the PIPESIM steady-state multiphase flow simulator, physical, chemical and rheological investigations show that with a decrease of highly paraffinic oil from the productive formation D2ef in a blend with Stary Oskol oil from the Kyrtaelskoye field, a decrease in the mass content of paraffin in the blend and the temperature of its saturation with paraffin, depth and intensity of the organic deposits formation in the tubing string, pour point, as well as the improvement of the rheological properties of the investigated structured dispersed systems is observed. Article describes a promising assembly of well equipment for the single tubing separate production of highly paraffinic oil from multiformation deposits of the Timan-Pechora province, providing separation of the perforation zones in two productive formations using a packer-anchor system at simultaneous-separate operation of the formations by a double electric submersible pump unit.

Introduction

Oil fields with a high paraffin content are widespread throughout the world [29, 32, 36]. Currently, development and implementation of advanced technologies for the extraction, treatment and transportation of highly paraffinic oils under complex natural and climatic conditions is of particular importance, since it forms an innovative potential for further development of deposits in the Arctic zone of the Russian Federation [27]. Oils are divided into three groups by paraffin content: low paraffinic (less than 1.5 % by mass), paraffinic (from 1.5 to 6.0 % by mass) and highly paraffinic (over 6.0 % by mass); by the content of resin-asphaltene substances: low resinous (less than 5.0 % by mass), resinous (5.0-15.0 % by mass) and highly resinous (over 15.0 % by mass) [14]. In the article [11], it is proposed to additionally classify oils with a paraffin content of more than 6.0 % by mass into the following subgroups: moderately paraffinic (6.0-10.0 % by mass), highly paraffinic (10.0-20.0 % by mass) and super-high paraffinic (over 20.0 % by mass). It is noted that the share of oil with a paraffin content of more than 6.0 % by mass accounts for about 27 % of world reserves, half of which are highly and super-high paraffinic oils.

More than 300 deposits of highly solidifying abnormal oils are known In Russia and the former USSR countries. The main reserves and production volumes of such oils in Russia are in the Timan-Pechora oil and gas province (OGP) [7, 26]. State balance of mineral reserves in the Timan-Pechora province accounts for 239 oil and gas fields as of 01.01.2019 (incl. 213 oil, 16 oil and gas condensate, 5 gas and oil, 5 oil and gas). Share of the North-West region in the structure of oil production in the Russian Federation is 5.4-6.2 %. Thus, oil production in 2019 amounted to 31.2 million tons [20]. Most of the oils in the Timan-Pechora OGP are abnormal – these are highly paraffinic oils, solidifying at positive temperatures, and heavy high-viscosity oils [8, 15, 35]. A distinctive feature of highly paraffinic oils is their high-temperature viscosity and tangible structural and mechanical (viscoplastic, thixotropic and viscoelastic) properties. This is due to the crystallization of paraffinic hydrocarbons and structure formation when the temperature drops to a level below the temperature of oil saturation with paraffin [6, 29, 31]. Thus, oils from productive sediments of the Middle and Upper Devonian in a number of fields (Kharyaginskoye, Kyrtaelskoye, Yuzhno-Lyzhskoye, Vostochno-Saratayuskoye, Vostochno-Kharyaginskoye, Zapadno-Saratayuskoye, Lekharyaginskoye, etc.), which are classified as medium and small in terms of initial recoverable reserves, are characterized by an extremely high paraffin content (over 20 % by mass) and pour points from 25 to 40 °C [12, 17]. Most of the fields have multiple formations [16, 18].

Complications associated with paraffinization of well equipment are most relevant in the production of highly paraffinic oil at the Kyrtaelskoye, Yuzhno-Lyzhskoye, Severo-Kozhvinskoye and Yuzhno-Kyrtaelskoye fields developed by the TPE “LUKOIL-Ukhtaneftegaz” [17, 30]. The main commercial oil and gas potential of the Kyrtaelsko-Pechorogorodsky oil and gas region, located in the southwestern part of the Pechora-Kolvinskaya oil and gas area, is associated with the Eiffelian, Stary Oskol and Dzhier sediments of the Middle Devonian-Frasnian subdomanic oil and gas structure containing 95.7 % of the recoverable oil reserves, 100 % of condensate and 97.8 % of gas. Small deposits of hydrocarbons and oil signs were found on the territory of the Pechora-Kozhvinsky mega-shaft in the sediments of the Domanik-Tournaisian, Lower-Upper Visean, Upper-Nevizian-Lower Permian and Middle-Upper Permian oil and gas structures [16, 22].

Statement of the problem

Significant number of methods and technologies for countering ARPD inside the well equipment have been developed to date in order to prevent the formation and remove already formed organic deposits [4, 5, 9]. The most widespread methods of countering organic deposits in well equipment are the methods of mechanical and thermal paraffin removal due to low costs and ease of implementation [12, 13, 23].

Physical and chemical properties and composition of well product, flow rate and well operation method, intensity and interval of paraffin formation, component composition of organic deposits are the most important factors determining the effectiveness of using certain methods of countering ARPD [13, 33, 34]. The main criteria for the technological efficiency of measures taken to prevent the formation and removal of organic deposits in well equipment are such indicators as intertreatment and turnaround periods of production wells. These indicators, on the one hand, characterize the operating conditions of wells (for example, the degree of intensity for paraffin formation processes), and on the other hand, the state and quality of work carried out for the selection, maintenance and repair of well equipment, including the effectiveness of measures to prevent the formation of organic deposits and their removal using various methods [24]. Field experience shows that the most preferable and effective is the use of integrated methods and technologies for preventing the formation of ARPD. This allows, taking into account the geological and physical conditions of the oil field development, to minimize the number of complications in the existing well number, to increase the intertreatment and turnaround periods of their work, and also to exclude the effect of the “sawtooth” change in the flow rate of the well in the case of periodic application of methods for removing ARPD [10].

Analysis of the accumulated experience for operating oil production wells at the Kyrtaelskoye field, equipped with electric submersible pumps (ESP), shows that the main complicating factors are:

- intensive formation of ARPD (paraffin content in oil of productive formations D2st and D2ef is 21.3 and 37.9 % by mass, respectively);

- high gas-oil ratio (average value for D2st and D2ef deposits is 231.4 and 87.1 m3/t, respectively);

- high-temperature viscosity (oil from the upper part of the Eifelian stage is characterized by high values of pour point – 38-40 °С, yield point and effective viscosity in the temperature range below the paraffin phase transition temperature in it) [17].

The main methods of countering ARPD at the Kyrtaelskoye field during the operation of wells equipped with ESP are:

- mechanical (cleaning of the inner surface of the tubing string is carried out mainly using stationary and mobile installations for paraffin removal with a semi-automatic drive with an average frequency of 2-4 times a day and, to a lesser extent, using mechanisms with an automatic drive – MDWA “Suleimanov” winches up to 6-8 times a day);

- thermal (hot oil flushing of well equipment and flow lines, application of heating cables with controlled heating, induction heaters of the manifold and a check valve of the wellhead equipment);

- application of tubing with a protective coating;

- paraffin removal in the tubing string without lifting well pumping equipment using coiled tubing, for a complicated number of production wells (D2ef reservoir), the optimal intertreatment period was experimentally established, equal to 10 days; between treatments of the tubing string using coiled tubing, additional heat treatments of well equipment and flow lines are carried out;

- combined methods – integrated application of tubing with silicate-enamel coating and heating cables with periodic measures for mechanical cleaning of lift pipes.

Analysis of the situation on paraffin removal in wells at the Kyrtaelskoye field shows that the measures taken to prevent the formation and removal of ARPD deposits in well oilfield equipment during the production of highly solidifying abnormal oil, despite certain progress in this direction, do not allow complete elimination of complications and minimize their consequences. Shutdowns of medium and high production wells due to paraffinization of the tubing string with its subsequent overhaul significantly reduce oil production rates, lead to a reduction in turnaround and intertreatment periods of production wells and an increase in specific operating costs for paraffin removal. In this regard, it is necessary to improve the existing and develop new methods and technologies for countering organic deposits, which are the most acceptable for the operation of wells equipped with ESP in multi-formation highly paraffinic oil fields of the Timan-Pechora province.

Methodology of the research

Oils from productive formations D2ef (upper part of the Eifelian stage) and D2st (Stary Oskol oil and gas condensate deposit – the main development object) of the Kyrtaelskoye field are classified as highly paraffinic in terms of paraffin content. Investigated oil dispersed systems (ODS) differ significantly both in the component composition and in the content of high molecular mass paraffinic hydrocarbons, which determines the difference in their physical, chemical and rheological properties. It is proposed to consider the possibility of using the technology of simultaneous-separate production of highly solidifying abnormal oil from the D2ef deposit together with the Stary Oskol oil, which is characterized by a lower paraffin content and manifestation of structural and mechanical properties.

Calculation was performed using the PIPESIM steady-state multiphase flow simulator in order to substantiate the effectiveness of the proposed technology for the simultaneous-separate production of highly paraffinic oil from the D2ef and D2st productive formations of the Kyrtaelskoye field. Numerical modeling is carried out taking into account the model of the two- and three-phase state of the fluid. Use of the Multiflash Wax module provides a detailed description of the paraffin formation process and the behavior of the liquid phase when changing temperature and pressure conditions based on the construction of a thermodynamic equilibrium model [2, 37].

Determination of the physical and chemical properties of wellhead anhydrous oil samples taken from a number of wells that drilled-in the Middle Devonian terrigenous deposits at the Kyrtaelskoye field was carried out in accordance with GOST R 51858-2002. The pour point of the studied highly paraffinic oils and their mixtures was determined according to GOST 20287-91 (method B). Determination of the group hydrocarbon composition of anhydrous oil samples was carried out in accordance with GOST 11851-85 (method A).

Study of the rheological properties for highly paraffinic oils from the Kyrtaelskoye field and their mixtures was carried out by the method of rotational viscometry according to standard and developed techniques [1, 19, 28]. Rheological investigations were carried out on a Rheotest RN 4.1 rotary rheometer using an H1 cylindrical measuring system. This system allows measuring the viscosity of a liquid in the recommended range of 10-105 mPa∙s at an adjustable shear stress and shear rate in the range of 0.2-2000 s–1. Required volume of liquid for testing is 35 ml. Regulation and maintenance of the temperature regime in the investigated range of 65-20 °C was carried out using a Julabo F25-ME circulation thermostat.

Value of the ultimate (static) shear stress for the studied highly paraffinic oils of the Kyrtaelskoye field and their mixtures at a given temperature was determined in the Controlled Shear Stress mode with a controlled increase in the shear stress from 0 to 10, 50, 100, and 150 Pa for 100, 200, and 400 s, respectively, in dependence on temperature and was equal to such a value of the shear stress at which the shear rate becomes non-zero. Determination of the flow curves and effective viscosity for the studied oils and their mixtures at a given temperature was carried out in the Shear Rate Ramp mode with a smoothly (linearly) variable shear rate in the range of 0-300 s–1 for 300 s. Value of the temperature corresponding to the onset of structure formation in the studied ODS during their cooling was indirectly estimated from the viscosity-temperature characteristics obtained for different flow regimes according to the method described in [1, 21]. Intersection point of two tangents to the constructed viscosity-temperature characteristic in semilogarithmic coordinates at a certain shear rate corresponds to the temperature for the beginning of structure formation.

Results

Based on the known component composition of formation oil (Table 1), using Multiflash Wax module, the phase equilibrium diagrams of the hydrocarbon system for the productive formations D2ef and D2st of the Kyrtaelskoye field were constructed.

Table 1

Component composition of formation oil in D2ef and D2st deposits [2, 37]

|

Element |

Value |

||

|

Deposit D2ef |

Deposit D2st |

||

|

Component composition of formation oil, % mol. |

|||

|

Methane |

24.44 |

9.77 |

|

|

Ethane |

8.71 |

3.19 |

|

|

Propane |

10.30 |

3.01 |

|

|

Iso-butane |

1.52 |

2.38 |

|

|

N-butane |

6.70 |

1.05 |

|

|

Iso-pentane |

2.23 |

0.71 |

|

|

N-pentane |

4.26 |

0.51 |

|

|

Hexane |

6.60 |

0.64 |

|

|

Heptane |

6.12 |

17.32 |

|

|

Octane |

7.43 |

25.80 |

|

|

С9+ |

20.53 |

35.23 |

|

|

Carbon dioxide |

0.13 |

0.10 |

|

|

Nitrogen |

1.03 |

0.29 |

|

|

Helium |

0.01 |

– |

|

|

Molar mass, g/mol |

147.97 |

232.60 |

|

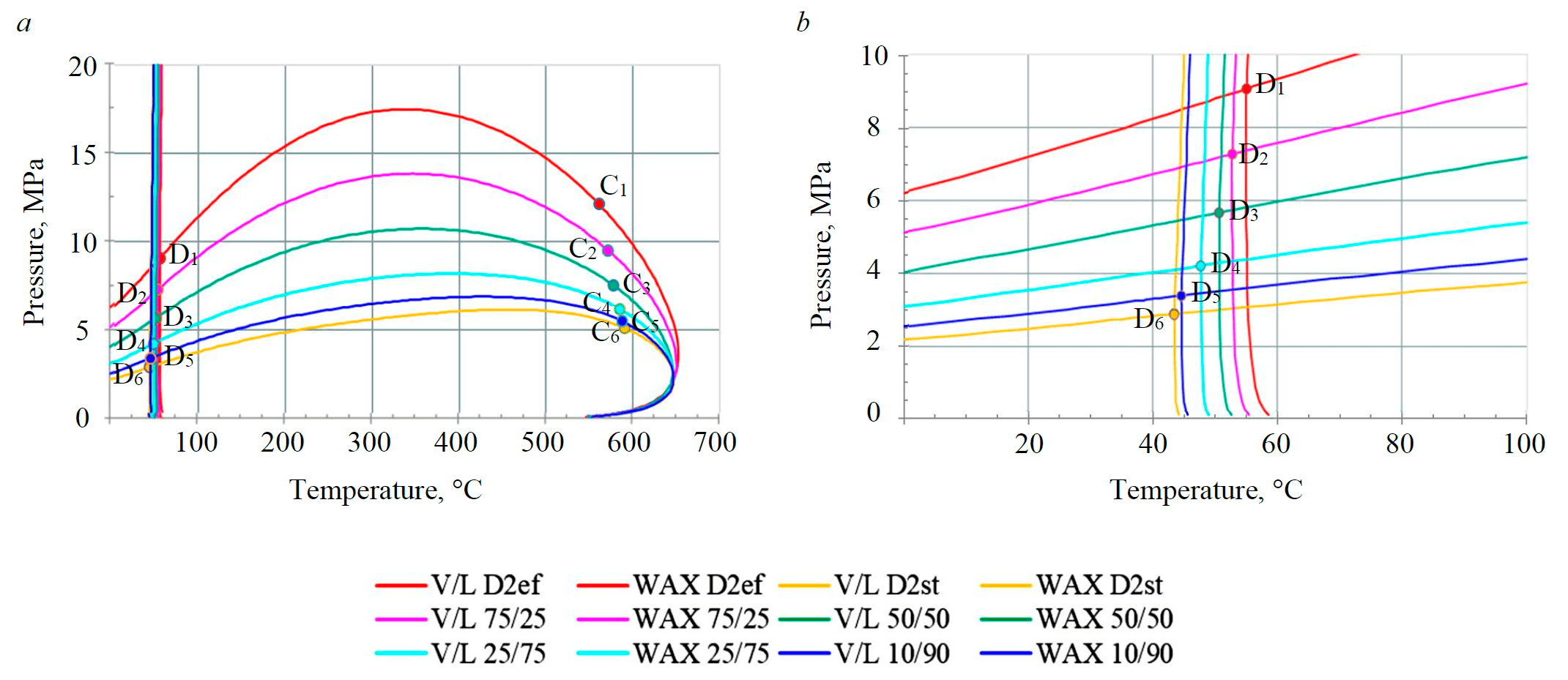

Fig.1. Phase equilibrium of hydrocarbon systems for D2ef and D2st deposits at the Kyrtaelskoye field and their mixtures (a) and the change in the saturation temperature of oil in the D2ef deposit with paraffin when mixed with Stary Oskol oil (b) in various ratios WAX – paraffin formation line; V/L – evaporation and saturation lines, separated by a critical point С

At the current stage, the solution to the problem was carried out using the Blend Fluid function in the Multiflash Wax module. It allows determining the phase behavior of the resulting blend with different ratios of its components from the known component composition of the initial oils. Figure 1 shows diagrams of the phase equilibrium for hydrocarbon systems in the D2ef, D2st deposits of the Kyrtaelskoye field and their blends in various ratios with the determination of the values of their saturation temperature with paraffin.

Analysis of the simulation results shows that the phase transition of paraffin in the Stary Oskol oil, as compared to the highly solidifying abnormal oil of the D2ef deposit, occurs at a lower temperature, which is confirmed by the results of experimental investigations. Thus, the saturation temperature of the studied oils with paraffin for the D2ef and D2st deposits at atmospheric pressure is 58.15 and 44.21 °C, and the paraffin content in oil is 28.53 and 12.08 % by mass, respectively. Significant difference between the obtained modeling results and experimental data on the paraffin content in the oil from the upper part of the Eifelian Stage may be due to the uneven distribution of paraffin over the D2ef deposit, which varies widely from 25.3 to 37.9 % by mass. It was found that with a decrease in the proportion of highly solidifying abnormal oil from the D2ef deposit in a blend with Stary Oskol oil, a significant decrease in the mass content of paraffin in the blend and the temperature of its saturation with paraffin is observed. This will contribute to a decrease in the depth and intensity of organic deposits formation in well equipment (Table 2).

Table 2

Change in the mass content of paraffin in the studied ODS and the temperature of their saturation with paraffin

|

Oil dispersed system |

Paraffin saturation temperature of oil at atmospheric pressure, °С |

Mass content of paraffin,% by mass |

|

Oil of upper Eiffel stage (D2ef deposit) |

58.15 |

28.53 |

|

Blend 75/25 |

55.42 |

25.58 |

|

Blend 50/50 |

52.57 |

21.00 |

|

Blend 25/75 |

48.92 |

17.51 |

|

Blend 10/90 |

45.54 |

14.59 |

|

Stary Oskol oil (D2st deposit) |

44.21 |

12.08 |

Results of experimental investigations of the physical and chemical properties of wellhead anhydrous oil samples taken from a number of wells that drilled-in the Middle Devonian terrigenous sediments at the Kyrtaelskoye field are presented in Table 3.

According to the physical and chemical properties oil from the Kyrtaelskoye field is classified as especially light, highly solidifying, highly paraffinic and resinous [14]. The main structure-forming components in the studied ODS are paraffinic hydrocarbons, the content of which in the oil of the D2ef and D2st deposits is 32.29 and 12.42 % by mass, respectively.

Results of determining the group hydrocarbon composition of the studied highly paraffinic oils and their blends are presented in Table 4.

Table 3

Physical and chemical characteristic of degassed oil from D2ef and D2st deposits

|

Parameter |

RD on MPI |

Value |

|

|

Deposit D2ef |

Deposit D2st |

||

|

Density at 20 °С, kg/m3 |

GOST R 51069-97 |

802.3 |

822.4 |

|

Pour point, °С |

GOST 20287-91 |

+40.0 |

+29.0 |

|

Group hydrocarbon composition, % by mass: |

|

|

|

|

paraffins |

GOST 11851-85 |

32.29 |

12.42 |

|

silica gel resins |

4.72 |

6.12 |

|

|

asphaltenes |

0.68 |

1.15 |

|

|

Melting point of paraffin, °С |

GOST 23683-89 |

+59.0 |

+52.0 |

Table 4

Group hydrocarbon composition of oils from the Kyrtaelskoye field and their mixtures

|

Oil dispersed system |

Content, % by mass |

||

|

Asphaltenes |

Silica gel resins |

Paraffins |

|

|

Oil of upper Eiffel stage (D2ef deposit) |

0.68 |

4.72 |

32.29 |

|

Blend 75/25 |

0.72 |

5.18 |

25.34 |

|

Blend 50/50 |

0.81 |

5.38 |

20.60 |

|

Blend 25/75 |

0.88 |

5.49 |

17.43 |

|

Blend 10/90 |

0.98 |

5.85 |

14.36 |

|

Stary Oskol oil (D2st deposit) |

1.15 |

6.12 |

12.42 |

It was found that with an increase in the share of Stary Oskol oil in the blend, first of all, there is a significant decrease in the content of paraffinic hydrocarbons in comparison with the original oil of the upper part of the Eifelian stage (D2ef deposit). Content of resins and asphaltenes when mixing the studied oils, in contrast to paraffinic hydrocarbons, changes insignificantly.

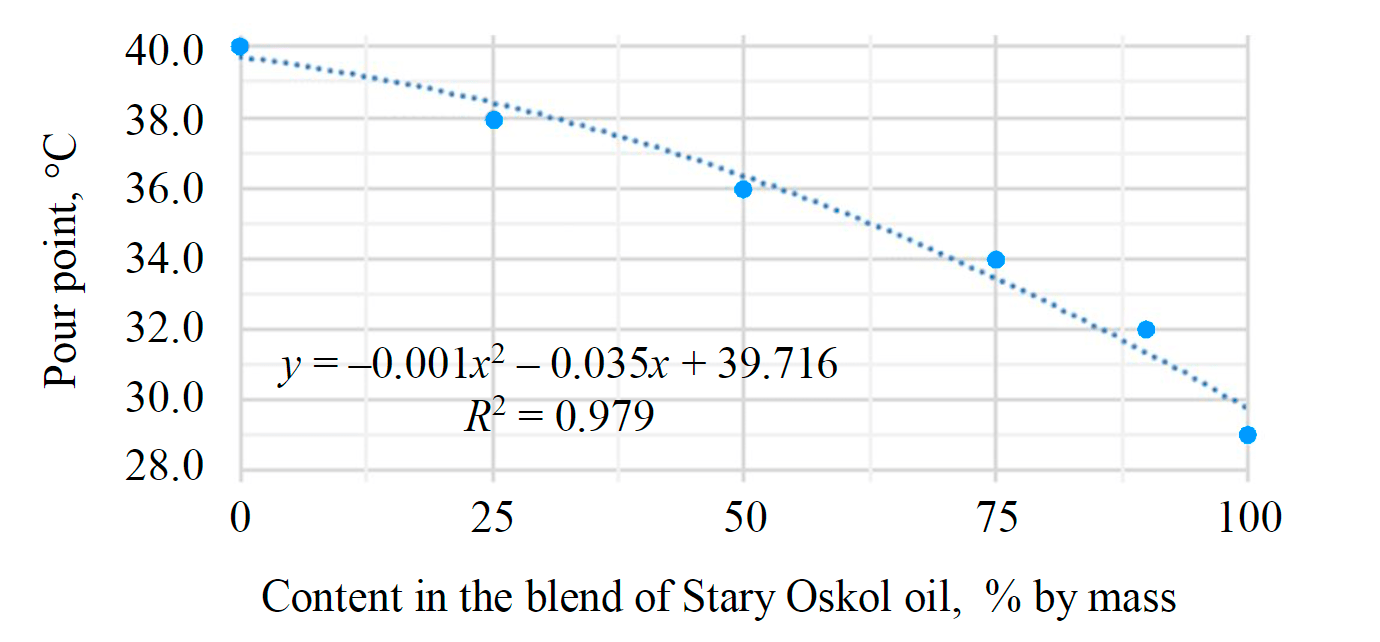

Fig.2. Change in pour point of highly paraffinic oil from D2ef deposit when mixed with Stary Oskol oil in different ratios

Results of experimental investigations describing the change in the pour point of highly solidifying abnormal oil from the D2ef deposit when it is mixed with the Stary Oskol oil (D2st deposit) in the ratios of 75/25, 50/50, 25/75 and 10/90 are shown in Fig.2. It was found that the dependence of the pour point of the investigated oil dispersed systems on the content of Stary Oskol oil in the blend from 25 to 90 % by mass is a quadratic function. Thus, with the content of Stary Oskol oil in the blend in the amount of 50 and 75 % by mass, the pour point decreases by 4.0 and 6.0 °C, respectively.

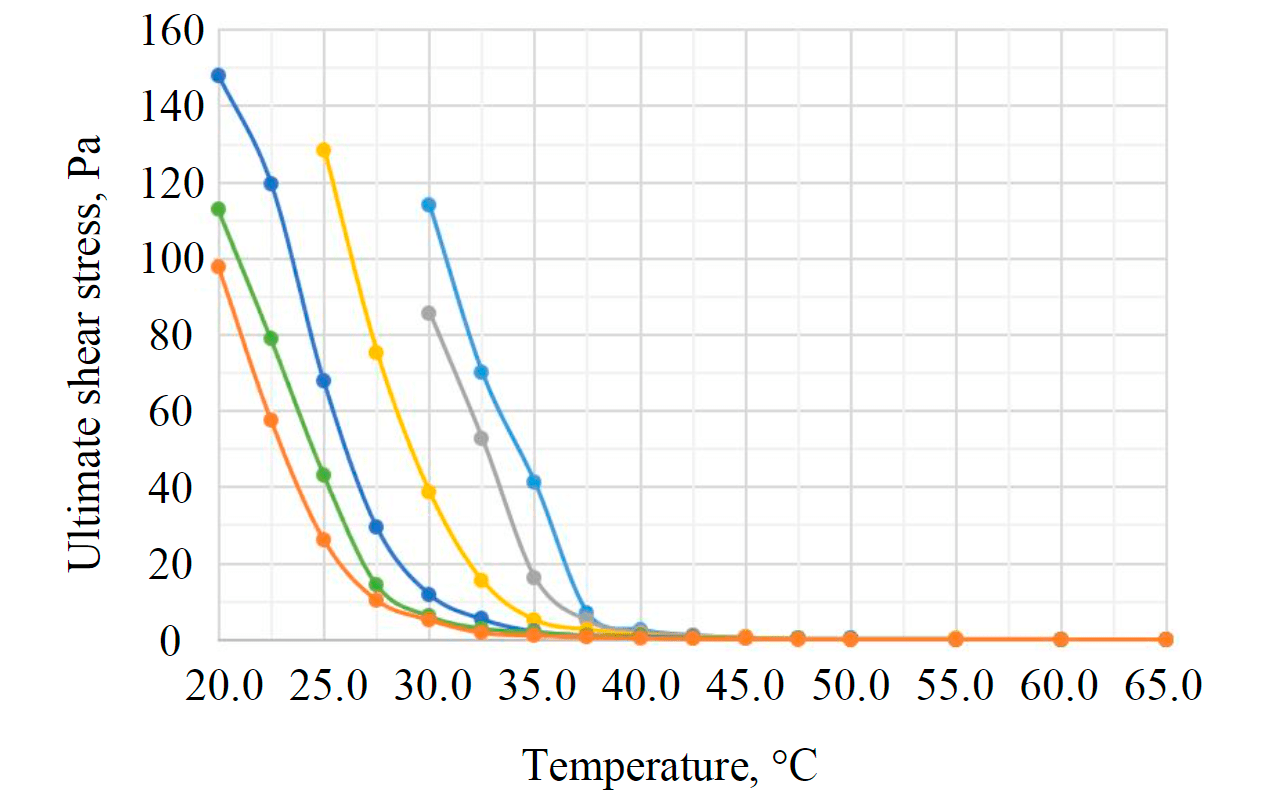

Multiple increase in the ultimate (static) shear stress of highly paraffinic oils from the D2ef and D2st deposits of the Kyrtaelskoye field is observed at temperatures below 40.0 and 32.5 °C, respectively, which indirectly indicates the beginning of the formation of a strong spatial structure in the studied ODS (Fig.3). With an increase in the content of the Stary Oskol oil in the blend from 50 to 75 % by mass, the temperature for the beginning of a strong spatial structure formation decreases by 5.0 °C, and the ultimate shear stress of the blend – up to 10 times compared with the highly solidifying abnormal oil in the upper part of the Eiffel stage.

Fig.3. Dependence of the ultimate shear stress of highly paraffinic oil from D2ef deposit when mixed with Stary Oskol oil in different ratios on temperature

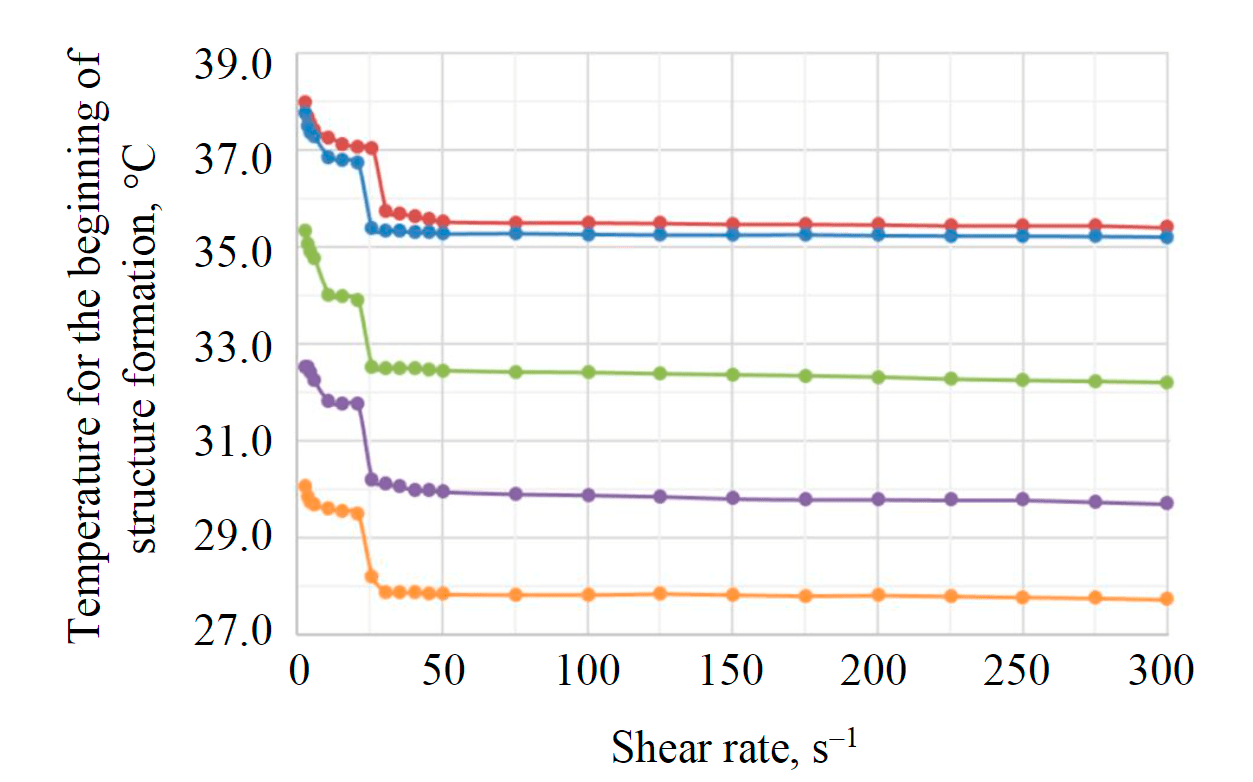

Fig.4. Dependence of the temperature for the beginning of structure formation for the studied highly paraffinic oils of the Kyrtaelskoye field and their blends on the shear rate

Obtained results of studying the rheological properties for blends of highly solidifying abnormal oil from the D2ef deposit with Stary Oskol oil in various ratios allowed estimating the temperature for the beginning of structure formation for the studied ODS based on processing their viscosity-temperature characteristics corresponding to a wide range of shear rates (Fig.4). It was found that the temperature for the beginning of structure formation in the investigated range of shear rates (0-300 s–1) decreases by 2.5 °C. For oils from productive formations D2ef and D2st of the Kyrtaelskoye field in the study area, the critical shear rate is conventionally distinguished, equal to 50.6 and 30.4 s–1, respectively, above which the temperature for the beginning of structure formation remains constant. Analysis of the viscosity-temperature characteristics of the studied ODS shows that with an increase in the content of Stary Oskol oil in the blend from 25 to 75 % by mass, a decrease in the temperature for the beginning of structure formation and the critical shear rate is observed in comparison with the highly solidifying abnormal oil of the D2ef deposit. Thus, when the content of Stary Oskol oil in the blend is 50 and 75 % by mass, the temperature for the beginning of structure formation in the studied range of shear rates decreases by 3.1 and 5.6 °C, respectively.

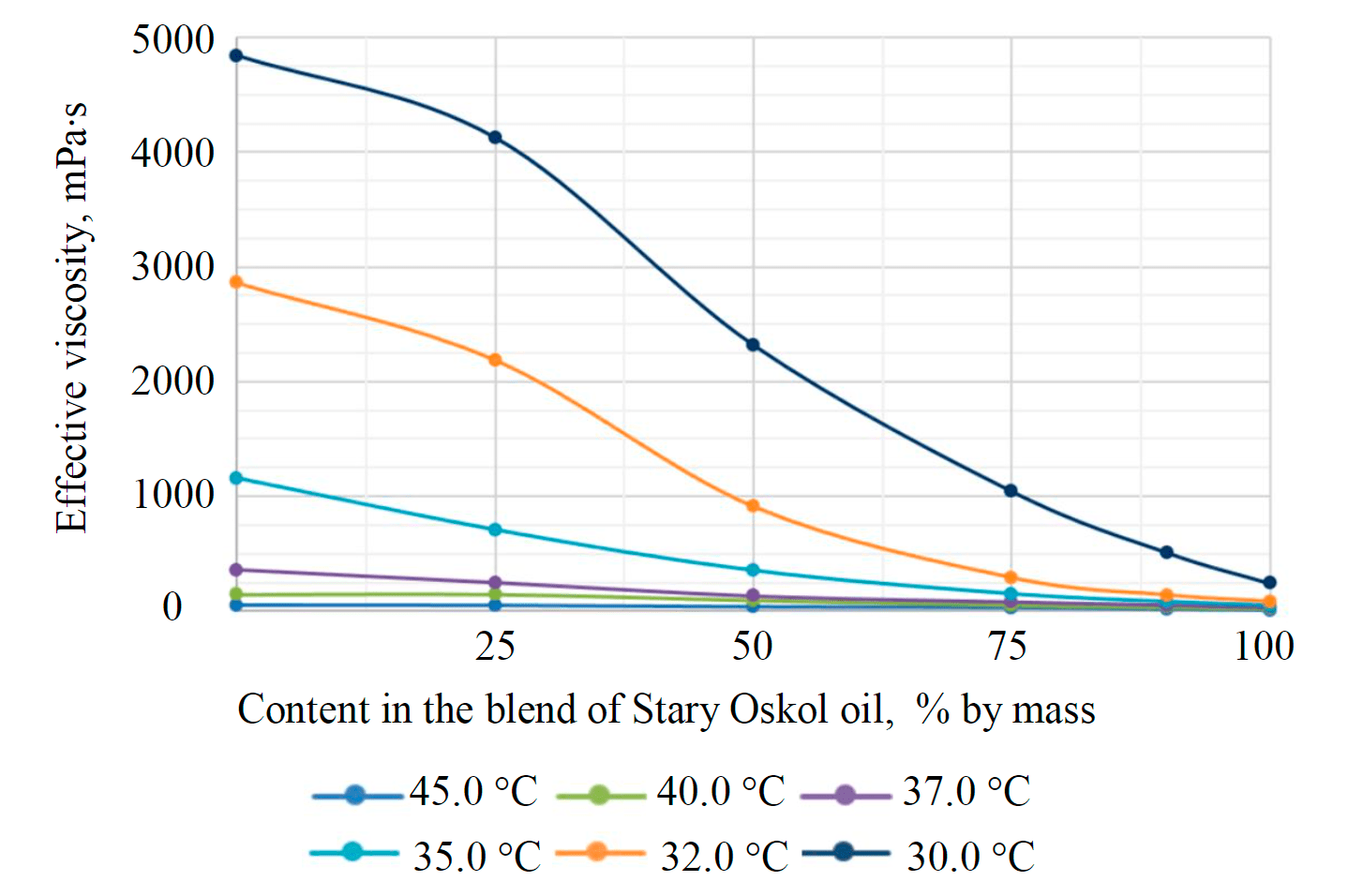

Figure 5 shows the dependencies describing the change in the effective viscosity for the studied highly paraffinic oils of the Kyrtaelskoye field and their blends on temperature. It was revealed that with an increase in the content of Stary Oskol oil in the blend from 25 to 90 % by mass, a multiple decrease in the values of the effective viscosity for the investigated oil dispersed systems is observed in the temperature range below 40.0 °C.

Fig.5. Change in effective viscosity of highly solidifying abnormal oil of the D2ef deposit when it is mixed in different ratios with Stary Oskol oil depending on temperature (at a shear rate of 10.8 s–1)

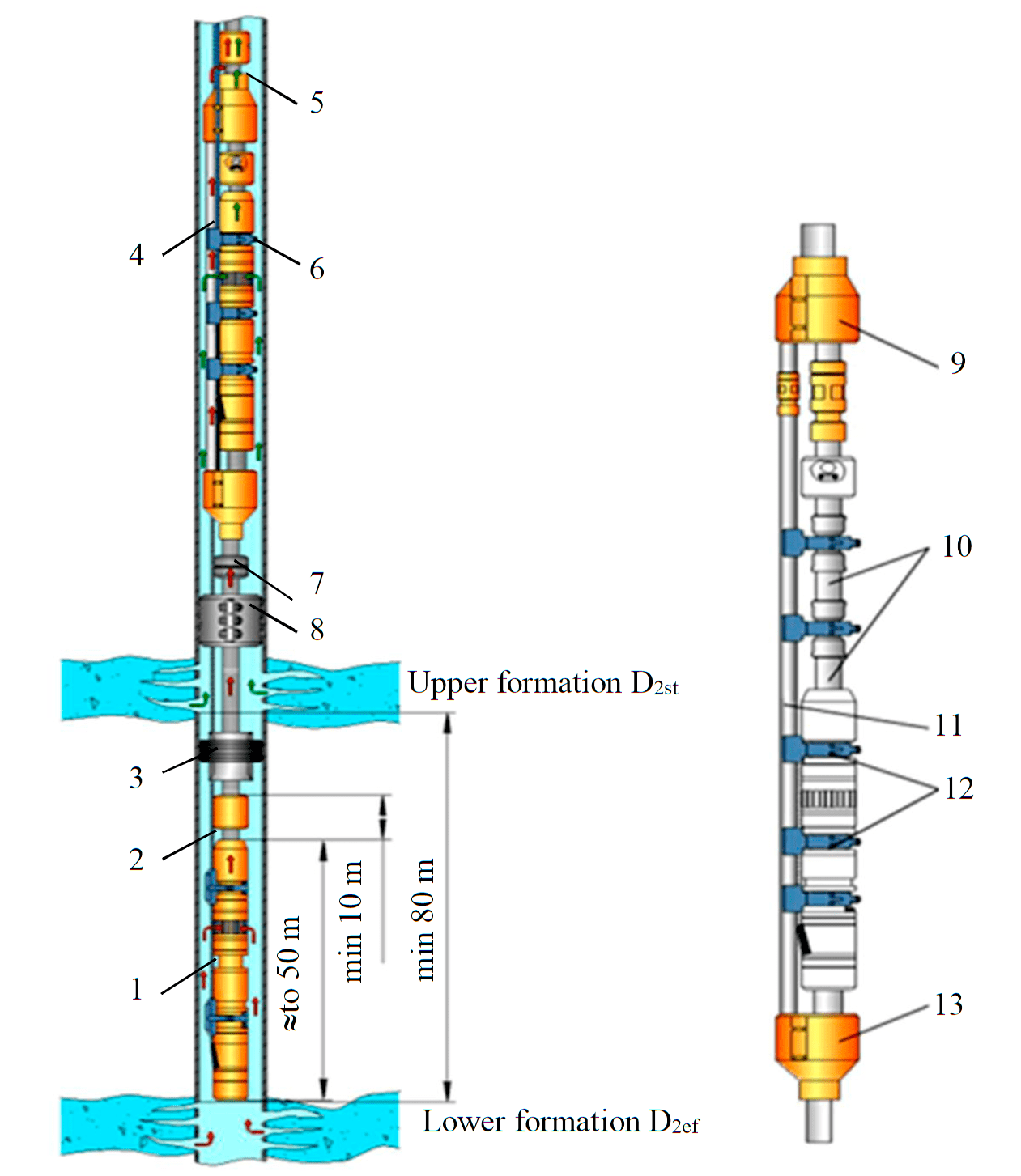

Successful pilot testing of the deve-loped integrated technology for preventing the formation of ARPD during the production of highly paraffinic oil from the productive formations D2ef and D2st of the Kyrtaelskoye field depends on a number of factors. First, for a complicated number of production wells, it is necessary to provide for the selection of promising assembly of well equipment, the reliability and efficiency of which has been confirmed by operating experience in a number of other multiformation fields. When implementing a system for joint development of productive formations, the key requirement is to provide individual control for each object and implement separate control of the operation for each formation in real time – with measurement of pressure, temperature and productivity of individual formations at the bottomhole of the wells [3]. Based on the conducted patent and literature review, an assembly of deep pumping equipment is proposed, which will allow the implementation of the single tubing separate production (STSP) technology for highly solidifying abnormal oil from the D2ef deposit together with the Stary Oskol oil under conditions of the Kyrtaelskoye field.

STSP assembly with the use of a dual system (JSC “Novomet-Perm”) is designed to separate the perforation zones of two productive formations using a packer-anchor system during the simultaneous-separate operation of formations by a double submersible electric centrifugal pumping unit.

The main advantages of the technology for simultaneous-separate operation with the use of dual systems are [25]: reduction of capital expenses for the construction of an additional well; operation in wells with casing strings with a diameter from 146 mm; isolated operation of two development objects and measurement of produced products for each formation; differential impact on each formation with the ability to control the withdrawal of liquids; efficient development of formations at large distances between them. Scheme of well assembly for simultaneous-separate oil production using a dual system is shown in Fig.6.

Fig.6. Well equipment layout diagram in case of single tubing separate production with the use of a dual system [25] 1 – lower unit; 2 – shear valve; 3 – cable packer; 4 – dual system with sealed bypass line; 5 – production strings with a diameter from 146 mm; 6 – upper unit; 7 – string disconnector; 8 – anchor; 9 – divarication; 10 – valve and pump connections; 11 – bypass line with sealed load-carrying pipes; 12 – clamp for fixing two cable lines; 13 – displacement unit for compensation of the installation length (for unit installation)

Installation of a gas separator should be considered as additional well equipment during pilot field tests for STSP of high-paraffin oil at the Kyrtaelskoye field in order to prevent the negative effect of free gas on the operation of the upper pumping unit.

Required ratio of produced oils in the blend is ensured by controlling the operating parameters of the lower and upper pumping units through the well control stations equipped with a frequency converter. Values of the recovered oil reserves at the Kyrtaelskoye field allow adhering to the recommended ratios for the joint production of highly solidifying abnormal oil from the D2ef deposit with the Stary Oskol oil (from 50/50 to 10/90, respectively).

Conclusion

Complications arising from the production of highly paraffinic oils lead to a significant decrease in oil production, a reduction in the turnaround and intertreatment periods for production wells, and an increase in the unit specific operating expenses for paraffin removal. Possessing many advantages, the existing methods and technologies for countering ARPD are not able to fully solve this problem, and the economic costs of measures to prevent the formation and removal of organic deposits in well equipment during the production of highly paraffinic oil remain very high.

Integrated technology proposed by the authors for preventing the formation of ARPD during production of highly solidifying abnormal oil (with a paraffin content of more than 30 % by mass) from multiformation deposits, based on the use of special well equipment for the simultaneous-separate operation of several productive formations and the selection of the well operation mode, taking into account the peculiarities for rheological behavior of highly paraffinic oils (manifestation of viscosity super anomalies and the presence of structural and mechanical properties) under different temperature conditions and flow regimes will reduce the risks of negative consequences associated with the intensive formation of organic deposits in well equipment, increase the intertreatment and turnaround periods of production wells with complicated stock. Results of theoretical and laboratory investigations show that with a decrease in the proportion of highly paraffinic oil from the productive formation D2ef in the blend with the Stary Oskol oil from the Kyrtaelskoye field, there is a decrease in the mass content of paraffin in the blend and the temperature of its saturation with paraffin, the depth and intensity of organic deposits formation in the tubing string, the pour point and improvement of rheological properties for the studied structured disperse systems.

Authors would like to express their sincere gratitude to V.I.Akshaev and A.V.Kulesh, as well as to the researchers, specialists and management of the “PermNIPIneft” branch of LLC “LUKOIL-Inzhiniring” in Perm: S.A.Lapshina, S.E.Bykov, R.M. Gabnasyrov, A.V.Mitroshin and N.A.Lyadova for their assistance, useful advice and remarks.

References

- Aleksandrov A.N., Rogachev M.K., Raupov I.R. Research of rheological properties of high-wax oil. Territoriya NEFTEGAZ. 2018. N 6, p. 52-62 (in Russian).

- Aleksandrov A.N., Kishchenko M.A., Rogachev M.K. Modeling the formation of solid organic particles in highly paraffinic formation oil. Inzhener-neftyanik. 2018. N 2, p. 42-49 (in Russian).

- Baryshnikov A.V., Yanin A.N. Regulation for the development of the Priobskoye field using the technology of simultaneous-separate water injection. Tyumen-Kurgan: Zaurale, 2013, p. 344 (in Russian).

- Glushchenko V.N., Silin M.A., Gerin Yu.G. Oilfield chemistry. Prevention and elimination of asphaltene-resin-paraffin depos-its. Мoscow: Interkontakt Nauka, 2009, p. 475 (in Russian).

- Golubev I.A., Golubev A.V., Laptev А.B. Practice of using the magnetic treatment devices to intensify the processes of prima-ry oil treating. Journal of Mining Institute. 2020. Vol. 245, p. 554-560. DOI: 10.31897/PMI.2020.5.7

- Devlikamov V.V., Kabirov M.M., Khabibullin Z.A. Abnormal oils. Мoscow: Nedra, 1975, p. 168 (in Russian).

- Dolgii I.E. Methods to enhance oil recovery in the process of complex field development of the Yarega oil and titanium deposit. Journal of Mining Institute. 2018. Vol. 231, p. 263-267. DOI: 10.25515/PMI.2018.3.263

- Zhuiko P.V. Development of principles for controlling the rheological properties of abnormal oils: Avtoref. dis. … d-ra tekhn. nauk. Ukhta: Ukhtinskii gosudarstvennyi tekhnicheskii universitet, 2003, p. 43 (in Russian).

- Zlobin A.A. Study of mechanism of oil magnetic activation in order to protect production wells from wax deposition. Vestnik Permskogo natsionalnogo issledovatelskogo politekhnicheskogo universiteta. Geologiya. Neftegazovoe i gornoe delo. 2017. Vol. 16. N 1, p. 49-63. DOI: 10.15593/2224-9923/2017.1.6 (in Russian).

- Ibragimov N.G, Tronov V.P., Guskova I.A. Theory and practice of methods for countering organic deposits at the late stage of oil field development. Мoscow: Neftyanoe khozyaistvo, 2011, p. 240 (in Russian).

- Iliin A.N., Polishchuk Yu.M., Yashchenko I.G. High paraffin oils: regularities of spatial and temporary changes their proper-ties. Neftegazovoe delo. 2007. N 1, p. 1-15 (in Russian).

- Kazakov A.A., Yunin Yu.G., Vishnyakov A.M. Results of implementation of kaskad technology for wells paraffin deposits removal at Kharyaginskoye deposit. Neftyanoe khozyaistvo. 2007. N 2, p. 117-119 (in Russian).

- Kamenshchikov F.A. Teplovaya deparafinizatsiya skvazhin. Мoscow-Izhevsk: Regulyarnaya i khaoticheskaya dinamika, 2005, p. 254 (in Russian).

- Classification of reserves and resources of oil and combustible gases: regulatory and methodological documentation. Мoscow: ESOEN, 2016, p. 323 (in Russian).

- Kondrasheva N.K., Baitalov F.D., Boitsova A.A. Comparative assessment of structural-mechanical properties of heavy oils of Timano-Pechorskaya province. Journal of Mining Institute. 2017. Vol. 225, p. 320-329. DOI: 10.18454/PMI.2017.3.320

- Kochkina Yu.V. Conditions for the formation of hydrocarbon deposits in the southern part of the Pechora-Kozhvinsky megashaft of the Timan-Pechora oil and gas-bearing basin: Avtoref. dis. … kand. geol.-mineral. nauk. Ukhta: Filial OOO “Gazprom VNIIGAZ”, 2017, p. 28 (in Russian).

- Krupin G.G. Integrated approach to the removal of ARPD in the production wells of the Kyrtaelskoye field. Inzhenernaya praktika. 2017. N 3, p. 16-17 (in Russian).

- Kuranov A.V. Unclaimed oil and gas objects of the Timan-Pechora province, their hydrocarbon potential and prospects for involvement in development: Avtoref. dis. … kand. geol.-mineral. nauk. Ukhta: OOO “Timano-Pechorskii nauchno-issledovatelskii tsentr”, 2015, p. 31 (in Russian).

- Malkin A.Ya., Isaev A.I. Rheology: concepts, methods, applications. St. Petersburg: Professiya, 2007, p. 560 (in Russian).

- Filimonova I.V., Nemov V.Yu., Provornaya I.V. et al. Oil and gas structure of Russia – 2019. Part 1. Oil industry – 2019: long-term trends and modern state. Novosibirsk: Institut neftegazovoi geologii i geofiziki im. A.A.Trofimuka Sibirskogo otdeleniya Rossiiskoi akademii nauk, 2020, p. 90 (in Russian).

- Aleksandrov A.N., Rogachev M.K., Lavrenchuk V.M. Certificate for state registration of the computer program N 2018615299 RF. Program for the automated processing of the viscosity-temperature characteristics of oil to assess the phase state of paraffins in it. Publ. 04.05.2018. Bul. N 5.

- Belonin M.D., Prishchepa O.M., Teplov E.L. et al. Timan-Pechora province: geological structure, oil and gas potential and development prospects. St. Petersburg: Nedra, 2004, p. 396 (in Russian).

- Turbakov M.S., Mitroshin A.V., Andreyev K.V. Study of the detergency effectiveness of chemical reagents for wax deposits removal in wells. Neftyanoe khozyaistvo. 2017. N 8, p. 104-107. DOI: 10.24887/0028-2448-2017-8-104-107 (in Russian).

- Turbakov M.S. Justification and selection of technologies for the prevention and removal of asphaltene-resin-paraffin depo¬sits in wells (on the example of oil fields in the Perm Kama region): Avtoref. dis. … kand. tekhn. nauk. St. Petersburg: Sankt-Peterburgskii gosudarstvennyi gornyi universitet, 2011, p. 20 (in Russian).

- Khudyakov D.A. STSP in wells using dual systems. Implementation and operation experience. Inzhenernaya praktika. 2012. N 6, p. 20-23 (in Russian).

- Chelintsev S.N. Increasing the efficiency of pipeline transportation of highly solidifying oils under difficult natural and climat-ic conditions: Avtoref. dis. … d-ra tekhn. nauk. Мoscow: Rossiiskii gosudarstvennyi universitet nefti i gaza im. I.M.Gubkina, 2002, p. 30 (in Russian).

- Cherepovitsyn A.E., Lipina S.A., Evseeva O.O. Innovative approach to the development of mineral raw materials of the arctic zone of the Russian Federation. Journal of Mining Institute. 2018. Vol. 232, p. 438-444. DOI: 10.31897/PMI.2018.4.438

- Shramm G. Fundamentals of practical rheology and rheometry. Мoscow: KolosS, 2003, p. 312 (in Russian).

- Zhang Jinjun, Yu Bo, Li Hongying, Huang Qiyu. Advances in rheology and flow assurance studies of waxy crude. Petrole-um Science. 2013. Vol. 10. Iss. 4, p. 538-547. DOI: 10.1007/s12182-013-0305-2

- Aleksandrov A.N., Kishchenko M.А., Nguyen V.T. Simulating the formation of wax deposits in wells using electric sub-mersible pumps. Advances in Raw Material Industries for Sustainable Development Goals. London: CRC Press, 2021, p. 283-295. DOI: 10.1201/9781003164395

- Adeyanju O., Oyekunle L. An experimental study of rheological properties of Nigerian waxy crude oil. Petroleum Science and Technology. 2012. Vol. 30. Iss. 11, p. 1102-1111. DOI: 10.1080/10916466.2010.498717

- Oliveira M.C.K., Teixeira A., Vieira L.C. et al. Flow assurance study for waxy crude oils. Energy & Fuels. 2012. Vol. 26. Iss. 5, p. 2688-2695. DOI: 10.1021/ef201407j

- Khaibullina K.S., Korobov G.Y., Lekomtsev A.V. Development of an asphalt-resin-paraffin deposits inhibitor and substantia-tion of the technological parameters of its injection into the bottom-hole formation zone. Periódico Tchê Química. 2020. Vol. 17. Iss. 34, p. 769-781.

- Khormali A. Asphaltene precipitation and inhibition in carbonate reservoirs. Petroleum Science and Technology. 2017. Vol. 35. Iss. 5, p. 515-521. DOI: 10.1080/10916466.2017.1295070

- Beloglazov I., Morenov V., Leusheva E., Gudmestad O.T. Modeling of heavy-oil flow with regard to their rheological prop-erties. Energies. 2021. Vol. 14. Iss. 2, N 359. DOI: 10.3390/en14020359

- Van Thang Nguyen, Rogachev M.K., Aleksandrov A.N. A new approach to improving efficiency of gas-lift wells in the con-ditions of the formation of organic wax deposits in the Dragon field. Journal of Petroleum Exploration and Production Technology. 2020. Vol. 10, p. 3663-3672. DOI: 10.1007/s13202-020-00976-4

- Aleksandrov A.N., Rogachev M.K., Van Thang Nguyen, Kishchenko M.A., Kibirev E.A. Simulation of organic solids for-mation process in high-wax formation oil. Topical Issues of Rational Use of Natural Resources. London: CRC Press, 2019. Vol. 2, p. 779-790. DOI: 10.1201/9781003014638-39