Experimental ice drilling with organosilicon fluid using the KEMS-135 drill in borehole 5G (Vostok Station, Antarctica)

- 1 — Ph.D. Scientific Supervisor of the Laboratory Empress Catherine II Saint Petersburg Mining University ▪ Orcid

- 2 — Ph.D. Head of Department Empress Catherine II Saint Petersburg Mining University ▪ Orcid

- 3 — Ph.D. Assistant Lecturer Empress Catherine II Saint Petersburg Mining University ▪ Orcid

- 4 — Researcher Arctic and Antarctic Research Institute ▪ Orcid

Abstract

The article presents the results of experimental drilling of congelation ice in the branch hole 5G-5 at the Vostok Station (Antarctica) using the KEMS-135 coring drill in the PMS-3 organosilicon fluid. The studies were conducted during the 70th Russian Antarctic Expedition and were aimed at assessing the technology efficiency in deep glacier drilling and opening of subglacial reservoirs, as well as at determining rational drilling parameters. Borehole preparation included extraction of drilling fluid, a body of geophysical studies, and wellbore reaming. The PMS-3 was delivered to the bottomhole using a specialized device called “Slonik”. Experimental drilling of congelation ice was conducted by the KEMS-135 coring drill. Two drilling runs were performed with core sampling of 1.10 and 1.14 m long, drilling depth 3595.15-3597.39 m. The presence of PMS-3 at the bottomhole was monitored by geophysical studies and sampling. Particular attention was given to analysing drilling modes, including mechanical speed, cuttings properties, and the effect of PMS-3 on the drilling equipment elements. The results of experimental drilling showed an increase in the mechanical drilling speed in the PMS-3 organosilicon fluid environment by 15-20 % compared to the used drilling fluid (kerosene + dichlorofluoroethane), as well as the absence of crown plugging and improved lubricating properties of the fluid. The article describes the promising areas of further research related to the drill design optimization for operation in the PMS-3 environment and the study of the long-term impact on subglacial ecosystems.

Funding

The research was performed at the expense of the subsidy for the State assignment in the field of scientific activity for 2024 N FSRW-2024-0003.

Introduction

Subglacial lakes of Antarctica are unique natural reservoirs that preserve valuable geological, paleoclimatic, and potentially biological information [1-3]. Their study requires advanced drilling techniques that ensure minimal impact on fragile subglacial ecosystems [4-6].

Of particular scientific interest is Lake Vostok, the largest subglacial water body in Antarctica, isolated from the ambient by an ice sheet about 4000 m thick for millions of years [7-9]. Since 1970, the Saint Petersburg Mining University, in cooperation with the Arctic and Antarctic Research Institute (AARI), has been conducting systematic research at the Vostok Station located above the cognominal lake [10-12]. As a result, the researchers drilled five deep boreholes, obtained kilometres of ice core, and in 2012 and 2015, successfully opened the lake [13, 14]. In recent years, employees of the Mining University have been conducting research to create new and improve existing glacier drilling technologies, as well as studying subglacial environments [15-17].

Since 1990, the KEMS-135 electromechanical coring drill with a drilling fluid (DF) based on a mixture of Jet A-1 kerosene and dichlorofluoroethane (HCFC-141b) as a weighting agent has been used for drilling in borehole 5G [18, 19]. The density of such a mixture is regulated over a wide range and is usually close to the density of ice (0.92 g/cm3). Despite the proven reliability of this technology, its significant drawback is low environmental safety of the reagents used [20-22].

During the 70th Russian Antarctic Expedition (RAE), an experiment was conducted to replace traditional drilling fluid with organosilicon fluid PMS-3, which has a number of advantageous characteristics [23-25]: high environmental safety [26]; low crystallization temperature (–80 °C) [27]; excellent lubricating properties; chemical stability over a wide temperature range; bioinertness; ability to absorb gas emissions; optimal rheological properties [27].

The choice of the PMS-3 brand (manufacturer OOO Silan, TU 20.16.57-036-44216037-2023) for experimental drilling of the branch hole 5G-5 was due to its density being close to the density of ice under the borehole PT conditions and optimal rheological properties [28, 29]. During the work, the temperature-density characteristics of the fluid were studied in the atmospheric conditions of the Vostok Station.

Methods

Borehole 5G was prepared for experimental ice drilling in several stages:

- DF extraction from the upper horizons of the borehole;

- a body of geophysical studies of the borehole (barometry, thermometry, calliper logging);

- reaming (expansion) of the branch hole 5G-5;

- delivery of PMS-3 to the branch hole 5G-5 bottom;

- quality control of delivery.

Extraction of drilling fluid from the upper horizons of the borehole. DF extraction from the borehole lowered its level in order to create an optimal differential pressure of the “glacier – DF” system in the borehole when the drill was at the bottomhole [14].

The drilling fluid sampling device is a set of core pipes with a hole for collecting the fluid in the upper part and an electromagnetic valve for draining it at the lower end. The device with a closed electromagnetic valve is lowered into the borehole below the DF level, it fills the internal cavity of the core pipes through the hole in the upper part. Then the device is raised to the surface, the electromagnetic valve opens, and the fluid is drained into the tank. This device showed high reliability during repeated use and the ability to extract from 70 to 100 l of fluid per run. A total of five runs were made and 400 l of drilling fluid were extracted to the surface, while its level dropped from 51 to 70 m. The average volume of fluid extracted per run was 80 l.

Borehole geophysical studies (BGS) were conducted to assess the technical condition of borehole 5G after its re-entry. Such monitoring is performed annually at least twice a season – before the start and after the end of work [30, 31]. The last time BGS were conducted in January 2024 after the end of the seasonal work of the 69th RAE.

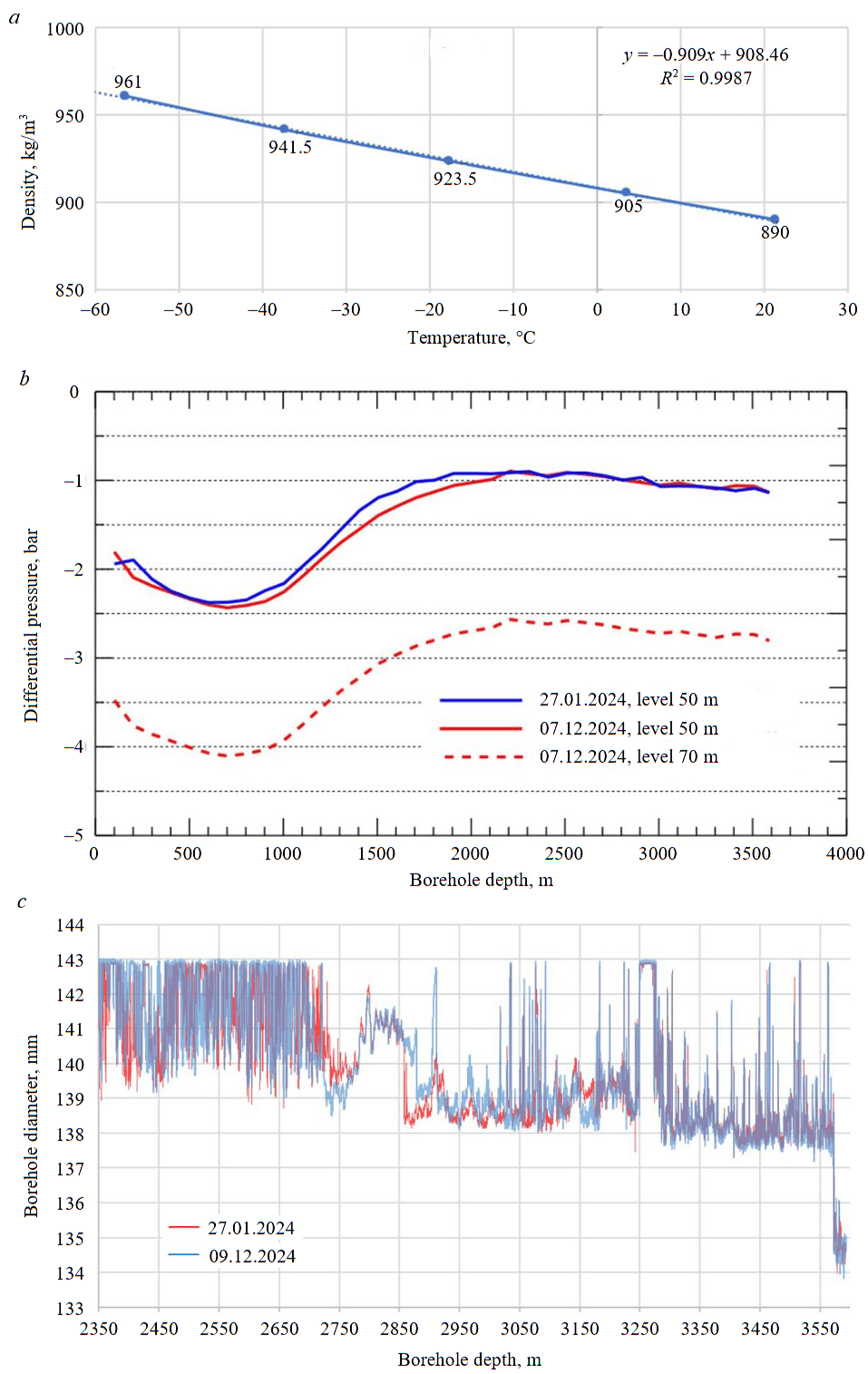

The pressure and temperature were measured using the KMT-009 device (a borehole pressure gauge-thermometer), manufactured and calibrated at NPP Grant (Ufa) and tested in the freezing chamber of the AARI Climate and Environmental Change Research Laboratory (LIKOS). In accordance with the documentation, the resolution of the KMT-009 temperature sensors is 0.002 °C, and the systematic measurement error does not exceed ±0.1 °C [30]. The measurements were carried out by the KMT-009 device lowered from the wellhead to the bottomhole with a step of 100 m (10 m in the bottomhole zone) and a stay of one minute, the lowering speed was 1000-3600 m/h. At each point, in addition to measuring pressure and temperature (Fig.1, a), the DF dynamic level as monitored in real time using a Sigma-Art echo-wave level metre with a resolution of 0.01 m manufactured by OOO Technopark-Sigma (Kazan). The DF level was defined by the time it took for the signal to pass to the “air – fluid” phase separation interface and back.

Based on the barometry and thermometry results with the DF level control, the differential pressure of the “glacier – DF” system was estimated, reduced to the level of 50 m (the drill is at the bottomhole) and 70 m (the drill is on the surface) in borehole 5G. The differential pressure graph (Fig.1, b) constructed by V.Ya.Lipenkov (LIKOS AARI) shows that the pressure in the bottomhole zone is the same as it was on 21 January 2024, at the end of the previous season. Therefore, maintaining the DF level of about 50 m when the drill is at the bottomhole allows work to be performed in the borehole without the risk of drill jamming due to the walls collapse. Additional delivery of dichlorofluoroethane weighting agent (HCFC-141b) to the borehole was not required.

Fig.1. Geophysical survey data during borehole preparation for experimental drilling: a – dependence of PMS-3 density on temperature; b – differential pressure reduced to depths of 50 and 70 m; c – calliperograms of 5G-5 branch hole in the depth range of 2350-3593 m

The calliper logging was made to identify narrowed sections of borehole 5G after a year of conservation. The borehole diameter was measured with a lever-type calliper developed at the Saint Petersburg Mining University. Comparison of the calliper log curves of 27.01.2024 (end of the 69th RAE season) and 09.12.2024 (beginning of the 70th RAE season) (Fig.1, c) allowed us to conclude that the borehole diameter did not change over the entire depth during the conservation period, i.e. it was possible to continue work with preliminary reaming (expansion) of the lower section of the branch hole 5G-5, starting from a depth of 3540 m to the bottomhole.

Reaming (expansion) of the branch hole 5G-5 was carried out in order to eliminate wall irregularities and increase the borehole diameter to reduce hydraulic resistance during bottomhole circulation of the DF and prevent accidents during drilling [32, 33].

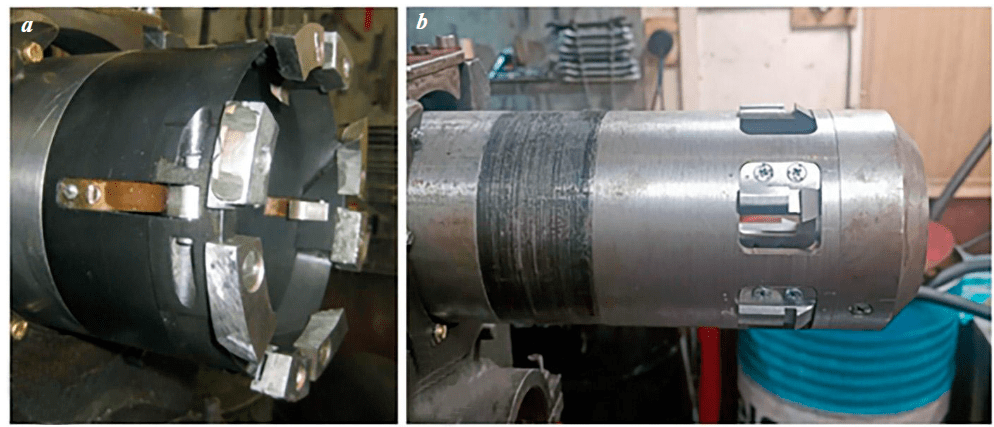

In the 70th RAE season, two rock-cutting tools were used for reaming: a four-cutter crown (Fig.2, a) and a six-cutter mechanical reamer MR-138 (Fig.2, b). The four-cutter crown with an outer diameter of 138 mm was previously used for drilling an additional fifth branch hole of 5G during the 64th RAE season (2018/19) [34]. Two runs were performed with it in the range of 3540.0-3584.5 m with a mechanical drilling speed of 10-12 m/h. The MR-138 reamer (outer diameter over cutters 137.5 mm), developed at the Saint Petersburg Mining University, underwent well tests this season. Two runs were performed in the range of 3584.6-3595.0 m with a mechanical drilling speed of 16 m/h. After testing, during a visual inspection of the MR-138 reamer, no cuttings were found on the cutters and flushing windows on the surface.

The borehole reaming with a crown and a reamer was stable and without troubles. However, a higher mechanical drilling (reaming) speed was achieved with the reamer and an increase in the cuttings size was noted, leading to an increase in the drilling progress per run. Well tests of the new MR-138 reamer were successful and revealed a number of advantages over the four-cutter crown. Its use in further drilling operations for reaming and expansion of borehole 5G is recommended.

PMS-3 delivery to the bottomhole of the branch hole 5G-5. The work was aimed at creating a PMS-3 column in the bottomhole zone of branch hole 5G-5, necessary for conducting experimental drilling operations.

The main idea of the method of delivering the drilling fluid was its step-by-step laminar injection to the bottomhole with a discrete lift of the well delivery device developed and manufactured at the Vostok Station by experts from the Saint Petersburg Mining University and the AARI, which was called “Slonik” (Little elephant) due to its design features. The device allows delivering a specified volume of fluid to the bottomhole zone of the borehole to the required depth. Its design includes the following elements: cable lock, electrical compartment, fluid tank, filter compartment, pump compartment, flow metre, electromagnetic valve unit, and dispenser. The “Slonik” device specification is as follows: outer diameter 127 mm; length 12.9 m; weight 210 kg; fluid tank volume 87 l.

Fig.2. Technical means for widening the branch hole 5G-5: a – four-cutter crown; b – new mechanical reamer MR-138

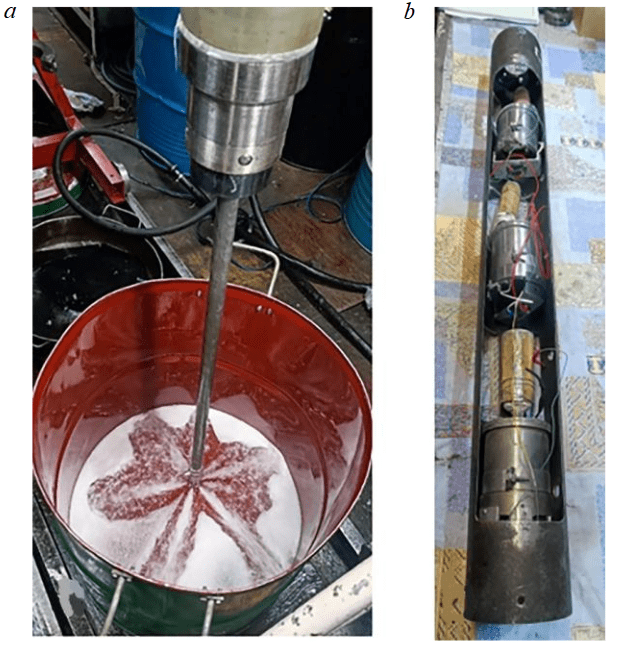

At the first stage, the device was tested on the surface, and then in the borehole at depths of 1250 and 3595 m. The tests (Fig.3, a) enabled to choose the optimal operating modes of the device. In particular, the performance of the ECN-91 electric centrifugal pump, the method for delivering the drilling fluid to the bottomhole was adjusted, and instructions for working with the device were written.

Fig.3. Technical means for working with organosilicon fluid: a – downhole delivery device “Slonik”; b – multi-section sampler

Three runs were made to deliver the PMS-3 to the bottomhole zone of the branch hole 5G-5. The volume of the delivered PMS-3 was 261 l, which made it possible to create a column 17.46 m high in the depth range of 3577.69-3595.15 m. During operation, the device pumped PMS-3 into the bottomhole zone of the borehole through the dispenser, and through the holes in the upper part of the tank, the drilling fluid was supplied to the device, thus replacing the drilling fluid with the PMS-3. After the device was pulled to the surface, DF samples were collected in sterile containers in 5 l increments with measurements of its density and temperature. A total of 58 fluid samples were collected, 43 of which were sent to the Saint Petersburg Mining University for chemical analysis.

Quality control of PMS-3 delivery to the bottomhole of branch hole 5G-5. To analyse the quality of PMS-3 delivery to the bottomhole, as well as for subsequent DF chemical analysis, it was necessary to determine the concentrations of PMS-3, kerosene, and freon in the DF in the bottomhole zone of branch hole 5G-5.

DF samples from deep horizons of the borehole were taken by a multi-section sampler (MS) with a forced-suction operation principle designed by prof. N.I.Vasiliev (Fig.3, b). The device controlled from the operator’s console allows for taking several DF samples of 400 ml at different depths in one run. Each MS section operates autonomously. The used device configuration had three sections, the total length was 1.1 m, and the outer diameter of the body was 127 mm.

Due to the 10-year mothballing of the MS, before starting work in the borehole, it was necessary to perform the following tests: full technical maintenance; surface bench tests to check the MS operability, determine the operating parameters of the built-in pumps and the filling time of each section (tests were carried out in a mixture of Jet A-1 kerosene and HCFC-141b dichlorofluoroethane weighting agent, as well as separately in PMS-3); well tests at depths of 1250 and 3590 m to determine the operating parameters and operability under conditions of high hydrostatic pressures and low temperatures.

The tests revealed that due to the great length of the load-carrying cable (4000 m), there is a drop in DC voltage by 91.2-91.4 %, which had to be considered when conducting borehole operations. Also, as a result of the tests, a number of changes were made to the design: check valves and some pumps were replaced, a mesh was installed throughout the interior of the MS body. A fine mesh with a diameter of 0.375 mm served to filter the fluid from mechanical impurities.

Five runs were made to collect DF samples from the branch hole 5G-5 bottomhole, including three runs before the PMS-3 delivery, one run after the PMS-3 delivery, and one run after the experimental drilling.

The samples from the MS were transferred on the surface to sterile containers, and then their density and temperature were measured for comparison with the original components of the fluid mixtures and thermobarometry interpretation. A total of 15 samples were collected.

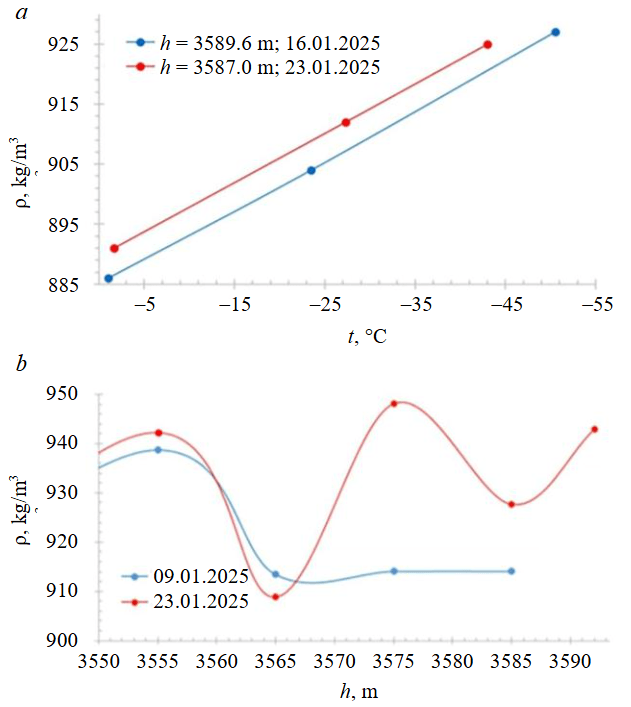

Figure 4, a shows the results of measuring the temperature-dependant density of fluids sampled by MS on 16.01.2025 from a depth of 3589.6 m (before the PMS-3 delivery) and on 23.01.2025 from a depth of 3587.0 m (after the PMS-3 deli-very). Each curve is constructed using three mea-surement points and has a linear dependence. The graph shows an increase in the DF density after delivery of PMS-3 to the bottomhole zone of the wellbore, measured at atmospheric pressure (the average annual pressure at the Vostok Station is 460 mm Hg), which indicates the presence of PMS-3 in the bottomhole zone. The obtained samples were sent to the Saint Petersburg Mining University for chemical analysis – determination of the PMS-3, Jet A-1 kerosene, and dichlorofluoroethane HCFC-141b concentrations, which will allow a final interpretation of the sampling data.

Fig.4. Results of organosilicon fluid delivery to the bottomhole: dependence of the DF samples density on the temperature at different depths (a) and the estimated DF density in the branch hole 5G-5 according to the barometry results (b) on 09.01.2025 (before PMS-3 delivery) and 23.01.2025 (after PMS-3 delivery)

After the PMS-3 was delivered to the bottomhole zone of borehole 5G, the pressure and temperature were measured. Unlike previous works, the descent and ascent speed at a depth of 3550-3594 m was 40 m/h. Such a low speed was adopted to prevent mixing of the PMS-3 with a mixture of Jet A-1 kerosene and HCFC-141b dichlorofluoroethane weighting agent. The results of wellbore barometry and thermometry taken before the PMS-3 was delivered to the bottomhole zone of the borehole (09.01.2025) and after (23.01.2025) are presented in Table 1. In the presence of a number of initial data on pressure, temperature, and the DF level in the borehole, obtained by direct measurements under the same conditions, a comparative analysis of densities was made.

Based on the barometry results, the average density of the fluid in the borehole was estimated at the measurement ranges using the following formula:

where Pn is the fluid pressure at the bottom of the n-th range, bar; g is the gravitational acceleration, m/s2; hn is the borehole depth at the bottom of the n-th range, m; Hn avg is the DF level from the wellhead, measured when the KMT-009 device was set at the bottom of the n-th range and estimated as the average over three measurements, m.

When analysing the DF density estimation in the branch hole 5G-5 based on the barometry before and after the PMS-3 was delived to the bottomhole zone (Fig.4, b), a noticeable increase in the DF density from a depth of 3570 m to the bottomhole was noted. The density extremum (ρ = 948.09 kg/m3) was at the level of 3575 m (the midpoint of the measurement range), corresponding to the upper interface of the created PMS-3 column. This allowed us to conclude that PMS-3 was present in the bottomhole zone of the branch hole 5G-5 and, consequently, that the technology and technical means for delivering PMS-3 were implemented successfully.

Table 1

Results of barometry and thermometry of the branch hole 5G-5 before and after delivery of PMS-3 to the bottomhole zone

|

Item N |

h, m |

Р1, bar |

t, °С |

Havg, m |

havg, m |

ρ, kg/m3 |

|

|

09.01.2025 |

|||||

|

1 |

3400 |

304.58 |

–10.75 |

48.68 |

||

|

2 |

3500 |

313.68 |

–8.68 |

48.06 |

3450 |

921.91 |

|

3 |

3550 |

318.20 |

–7.63 |

47.61 |

3525 |

913.23 |

|

4 |

3560 |

319.12 |

–7.39 |

47.62 |

3555 |

938.76 |

|

5 |

3570 |

320.02 |

–7.21 |

47.57 |

3565 |

913.47 |

|

6 |

3580 |

320.92 |

–6.99 |

47.54 |

3575 |

914.08 |

|

7 |

3590 |

321.82 |

–6.79 |

47.50 |

3585 |

914.08 |

|

|

23.01.2025 |

|||||

|

1 |

3400 |

305.06 |

–10.76 |

43.29 |

|

|

|

2 |

3500 |

314.16 |

–8.71 |

42.62 |

3450 |

921.45 |

|

3 |

3550 |

318.68 |

–7.64 |

42.10 |

3525 |

911.90 |

|

4 |

3560 |

319.60 |

–7.45 |

42.14 |

3555 |

942.22 |

|

5 |

3570 |

320.48 |

–7.19 |

42.27 |

3565 |

908.86 |

|

6 |

3580 |

321.38 |

–6.93 |

42.60 |

3575 |

948.09 |

|

7 |

3590 |

322.28 |

–6.77 |

42.71 |

3585 |

927.64 |

|

8 |

3594 |

322.65 |

–6.64 |

42.71 |

3592 |

942.92 |

Discussion

The objective of the experimental drilling in the branch hole 5G-5 using the KEMS-135 electromechanical core drill on a load-carrying cable in an organosilicon fluid environment was to determine the optimal drilling modes, identify the peculiarities of drilling warm congelation ice, and clean the bottomhole from cuttings. The standard KEMS-135 electromechanical core drill with a total length of 12.4 m is equipped with three cuttings pipes (4.95 m) with three filters and two core pipes (CP) (3.3 m).

Before the experimental drilling, the drill underwent a complete maintenance, and the tele-metry complex sensors – axial load, rotation, and power (current) measurement were repaired. The performance of the rotary pump installed in the drill was measured when pumping PMS-3 at a fluid temperature of –2 °C and a density of 903 kg/m3, which was 94 l/min. Two runs of core drilling in the branch hole 5G-5 were performed using KEMS-135 in the PMS-3 environment: N 22 (25.01.2025) and N 23 (26.01.2025).

When lowering the drill, a special drilling operation prevented mixing of the drilling fluids and ensured that the internal CP space and the cuttings collector were filled with PMS-3 fluid. In the range of 3570-3580 m, the lowering was at a speed of 30 m/h. Considering the rotary pump productivity and the internal diameter of the coring drills, a rational lowering speed of the KEMS-135 with the pump turned on in the range of 3580-3595 m was determined, which was 500 m/h. At this lowering speed, the speed of the fluid, which is sucked in by the pump and passes through the CP and the cuttings collector of the drill, relative to the borehole walls is zero. The drill replaces its own displaced volume considering the pumping, the DF fills all its internal cavities, and the drill passes through the DF without mixing it. Next, standard drilling was carried out with the CP rotating and the pump turned on; the descent to the bottomhole was at a speed of 8 m/h.

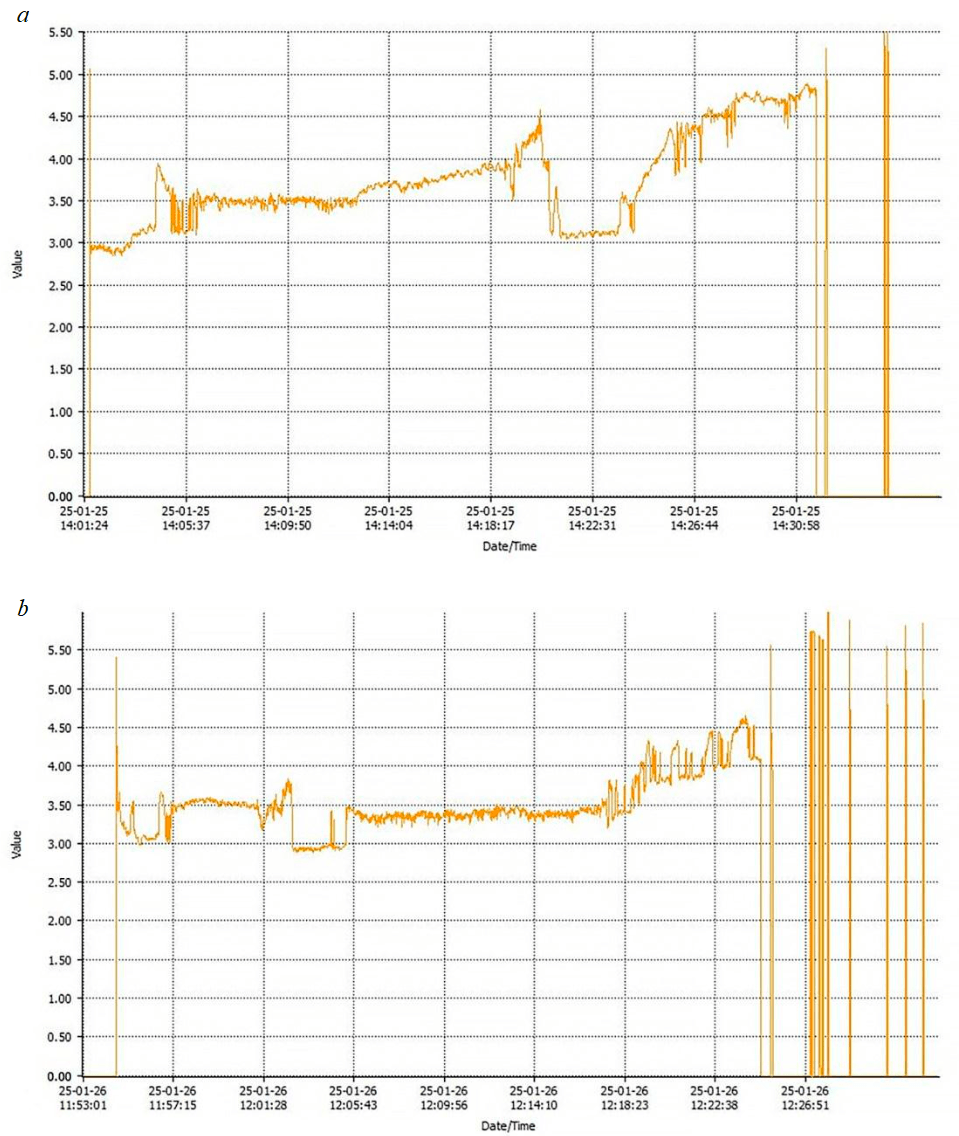

When setting to the bottomhole, the current on the driving electric motor (DEM) of the drill increased sharply, the drill feed was stopped until the current load stabilized (Fig.5, a). After the current stabilized, the borehole drilling began with the minimum possible mechanical drilling speed and its smooth increase to 2.1 m/h.

Fig.5. Current load on the drill engine during drilling: a – run N 22; b – run N 23

The bottomhole of run N 22 was at 3595.15 m, after 0.35 m of drilling, the mechanical drilling speed increased to 3 m/h, the drilling was stable. However, a smooth constant increase in the DEM current was noted, which is typical for filling the filters with cuttings, but with greater intensity than usual. After drilling 0.7 m, the DEM current reached more than 4 A. When drilling 0.9 m at a depth of 3596.05 m, the drill began to turn over, its feed was immediately stopped. After three minutes of downtime without feed, the drill turnover completely stopped, and drilling continued with a mecha-nical speed of 2.1 m/h. After drilling 0.05 m, the mechanical speed was reduced to 1.1 m/h, while the DEM current did not stabilize and was constantly increasing; drilling was stopped at a depth of 3596.35 m. The nature of the increase in the DEM current without returning to optimal modes indicated complete plugging of the filter system with cuttings.

Ice drilling (run N 23) began with the minimum possible drilling speed, which gradually increased to 2.5 and then 3 m/h. After drilling 0.3 m, the drill turned over at the bottomhole, which preceded by an obvious increase in the current load (Fig.5, b). The drill feed was immediately stopped, after three minutes the turnover ceased, and drilling continued at a speed of 2.1 m/h. The drilling was stable, after drilling 0.95 m, a ragged current load graph was noted, while the drilling speed was reduced to 1.7 m/h. Drilling was stopped after an intensive increase in the DEM current at a depth of 3597.5 m.

The core breakoff when drilling in the PMS-3 environment is similar to breakoff when drilling in kerosene with freon. In run N 22, the core broke off on the first try, and in run N 23 – on the third try, while in the second case the breakoff was not obvious, and an increased tension of the load-carrying cable was also noted, which is characterized by an increase in the winch current value to 80 A.

The drill was lifted from the bottomhole to a depth of 3570 m at a speed of 50 m/h to prevent mixing of the drilling fluids, then at maximum possible speed.

The data obtained during the experimental drilling runs with KEMS-135 in the PMS-3 environment are presented in Table 2.

Table 2

Results of experimental drilling with KEMS-135 in PMS-3 environment

|

Parameter |

Run number |

|

|

22 |

23 |

|

|

Drilling progress, m |

1.2 |

1.1 |

|

Drilling time, min |

25 |

26 |

|

Average mechanical drilling speed, m/h |

2.88 |

2.54 |

|

Maximum mechanical drilling speed, m/h |

3.00 |

3.00 |

|

Core length, m |

1.10 |

1.14 |

|

Run duration, hh:mm |

05:05 |

04:54 |

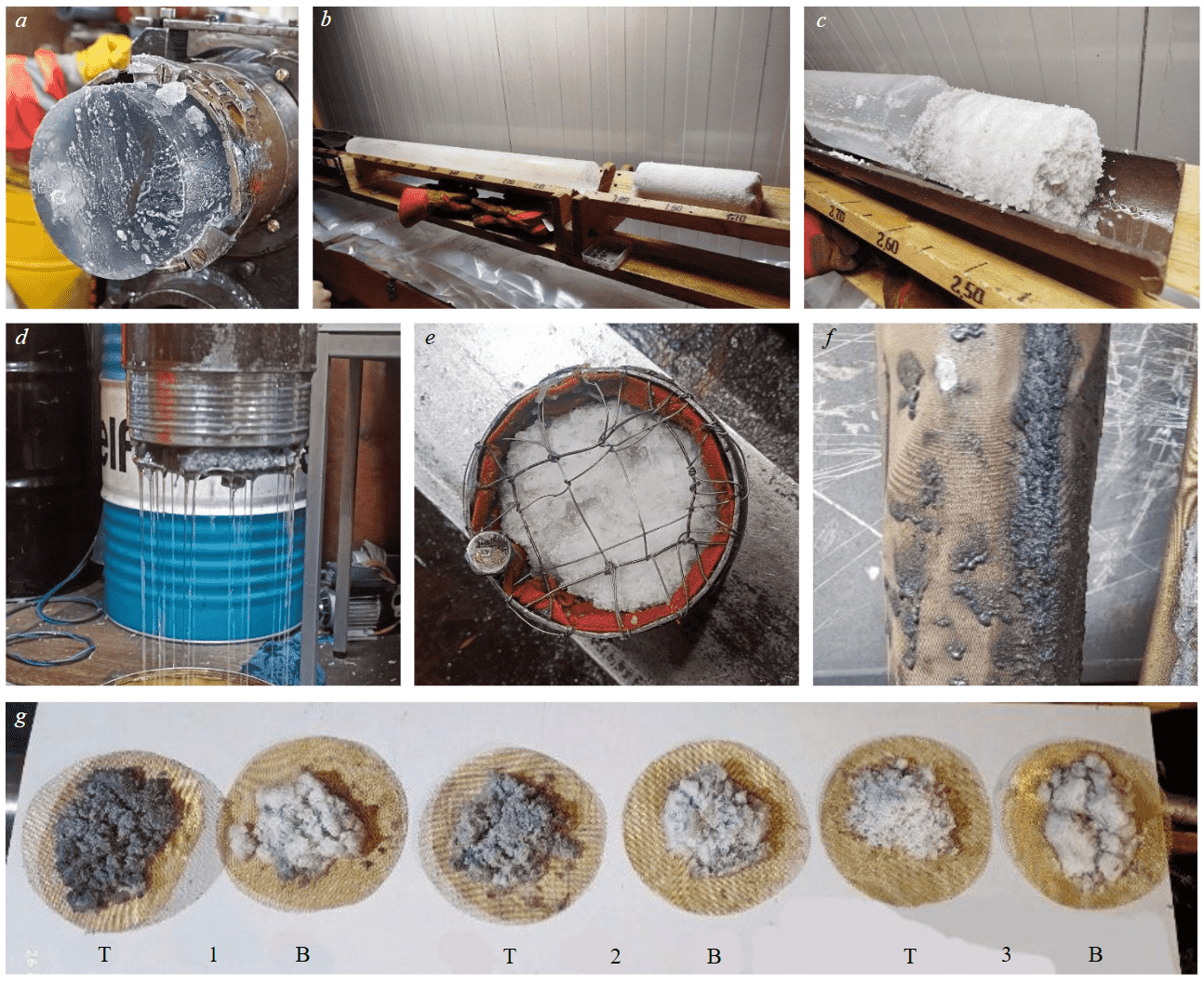

After both runs, when extracting the core from the coring drill (Fig.6, a), cuttings plugs were found above the core: 0.215 m long and 0.112 m in diameter (Fig.6, b) (run N 22), 0.15 m long and 0.107-0.109 m in diameter (Fig.6, c) (run N 23). The core obtained in run N 23 has grooves from the core-pulling knives (Fig.6, c), which happens when the core is not broken off the first time. No cuttings plugging of the crown and core-pulling knives was observed after drilling. The nature of the DF outflow from the cuttings collector changed during servicing the KEMS-135. Thin streams of DF were observed along the pipe perimeter (Fig.6, d), and the cuttings collector was completely filled with DF.

During the filter system disassembly, we discovered that the cuttings completely plugged the check valve (Fig.6, e), which remained open during the drill lifting from the borehole. This situation was observed after both runs.

Filter plugging with cuttings after run N 22 was as follows: the upper filter – 100, the middle filter – 70, the lower filter – 50 %. The lower filter after the run turned out to be very dirty (Fig.6, f). Mechanical impurities were on the outer side of the mesh, which characterizes an intensively contaminated bottomhole zone of the borehole. Filter plugging with cuttings after run N 23 was as follows: the upper filter 80, the middle filter 70, the lower filter 70 %.

During the drill maintenance, two DF samples were taken from the filter system and six cuttings samples from each run (Fig.6, g). Visually, an increase in the cuttings size was noted compared to drilling with kerosene and freon. All samples were sent to the Saint Petersburg Mining University for further laboratory studies.

During the drill maintenance after two runs in the organosilicon fluid environment, we found that the drive elements (gear wheels and bearings) were covered with a thin PMS-3 film (with lubricating ability), which has a positive effect on the mechanical operation of the drill.

Analysis of two core drilling runs into the borehole using KEMS-135 in an organosilicon fluid environment (PMS-3) showed the following: an increase in the mechanical drilling speed to 3 m/h; an increase in the cuttings size; no plugging of the crown and core-breaking knives; no sticking of the cuttings; stable flow of the drilling; a positive effect of the fluid lubricating properties on the drill drive elements.

Fig.6. Results of experimental drilling: core in the core pipe after the drill was removed from the borehole (a); core and cuttings plug from run N 22 (b); run N 23 (c); DF leakage from the cuttings collector during drill disassembly after run N 22 (d); check valve plugged with cuttings (e); lower filter after run N 22 (f); cuttings samples (g)

Conclusion

Experimental ice drilling in borehole 5G (Vostok Station, Antarctica) using organosilicon fluid (PMS-3) as a drilling fluid allowed us to obtain significant results confirming the prospects of this technology for deep glacier drilling. Based on the results, we can draw the following key conclusions.

Efficiency of use. The use of PMS-3 showed a number of advantages over the traditional mixture of Jet A-1 kerosene and HCFC-141b dichlorofluoroethane: increased mechanical drilling speed to 3 m/h; increased drilling progress per run; improved lubricating properties, which had a positive effect on the operation of the KEMS-135 drill drive elements; no cuttings plugging the crown and core knives, as well as no cuttings sticking, which indicates the drilling stability.

Environmental safety. PMS-3 is highly bioinert and low-toxic, which makes it environmentally preferable for work in the unique natural conditions of Antarctica. This is especially important for projects related to the study of subglacial lakes, where minimizing environmental pollution is a vital task.

Technology issues. Successful delivery of PMS-3 to the bottomhole using the “Slonik” device confirmed the possibility of creating a stable fluid column in the bottomhole zone. Quality control of delivery, including sampling with a multi-section sampler and barometry, showed high accuracy and reliability of the method. Wellbore reaming with the MR-138 reamer allowed to increase the drilling progress per run and reduce hydraulic resistance.

Features identified. An increase in the cuttings size was observed, which requires further study to optimize the operation of the drill filter systems. Intensive plugging of filters and the check valve indicates the need to modernize the drill design for operation in the PMS-3 environment.

Prospects for further research: development of a modernized drill adapted for operation with PMS-3, with an improved cuttings removal system; in-depth study of the interaction between PMS-3 and various types of ice, including basal and congelation ice; additional experiments to optimize drilling modes and assess the long-term stability of PMS-3 under high pressure and low temperature conditions.

The results of experimental drilling confirmed that PMS-3 is a promising alternative to traditional drilling fluids. Its use both increases the efficiency of drilling operations and complies with modern environmental standards. To implement this technology in deep drilling practice, it is recommended to conduct additional studies of fluids under various PT conditions, develop methodological guidelines for the use of PMS-3, and ensure monitoring of the fluid chemistry during long-term operation.

The work performed opens up new opportunities for the projects studying subglacial lakes and other unique natural features in Antarctica with minimal impact on the environment.

References

- Siegert M.J., Priscu J.C., Alekhina I.A. et al. Antarctic subglacial lake exploration: first results and future plans. Philosophical Transactions of the Royal Society A. 2016. Vol. 374. Iss. 2059. DOI: 10.1098/rsta.2014.0466

- Livingstone S.J., Yan Li, Rutishauser A. et al. Subglacial lakes and their changing role in a warming climate. Nature Reviews Earth & Environment. 2022. Vol. 3. Iss. 2, p. 106-124. DOI: 10.1038/s43017-021-00246-9

- Smith A.M., Woodward J., Ross N. et al. Evidence for the long-term sedimentary environment in an Antarctic subglacial lake. Earth and Planetary Science Letters. 2018. Vol. 504, p. 139-151. DOI: 10.1016/j.epsl.2018.10.011

- Priscu J.C., Kalin J., Winans J. et al. Scientific access into Mercer Subglacial Lake: scientific objectives, drilling operations and initial observations. Annals of Glaciology. 2021. Vol. 62. Iss. 85-86, p. 340-352. DOI: 10.1017/aog.2021.10

- Yan Zhou, Xiangbin Cui, Zhenxue Dai et al. The Antarctic Subglacial Hydrological Environment and International Drilling Projects: A Review. Water. 2024. Vol. 16. Iss. 8. N 1111. DOI: 10.3390/w16081111

- Talalay P.G., Xiaopeng Fan. Alternative clean approaches to accessing subglacial Lake Vostok. Arctic and Antarctic Research. 2024. Vol. 70. N 4, p. 499-513. DOI: 10.30758/0555-2648-2024-70-4-499-513

- Kapitsa A.P., Ridley J.K., Robin G. de Q. et al. A large deep freshwater lake beneath the ice of central East Antarctica. Nature. 1996. Vol. 381. Iss. 6584, p. 684-686. DOI: 10.1038/381684a0

- Popov S.V., Boronina A.S., Ekaykin A.A. et al. Remote sensing and mathematical modelling of Lake Vostok, East Antarctica: past, present and future research. Arctic and Antarctic Research. 2024. Vol. 70. N 4, p. 460-476. DOI: 10.30758/0555-2648-2024-70-4-460-476

- Lukin V.V., Markov A.N. Hypothesis of Tectonic Preglacial Genesis of the Basin and Water Body of Antarctica’s Lake Vostok. Geography and Natural Resources. 2024. Vol. 45. N 2, p. 192-201. DOI: 10.1134/S1875372824700264

- Lukin V., Bulat S. Vostok Subglacial Lake: Details of Russian Plans/Activities for Drilling and Sampling. Antarctic Subglacial Aquatic Environments. American Geophysical Union, 2011. Vol. 192, p. 187-197. DOI: 10.1002/9781118670354.ch11

- Litvinenko V. Foreword: Sixty-year Russian history of Antarctic sub-glacial lake exploration and Arctic natural resource development. Geochemistry. 2020. Vol. 80. Iss. 3. N 125652. DOI: 10.1016/j.chemer.2020.125652

- Gorelik G.D., Egorov A.S., Shuklin I.A., Ushakov D.E. Substantiation of optimal range of geophysical surveys to study deep structure of the Lake Vostok area. Gornyi zhurnal. 2024. N 9, p. 56-61 (in Russian). DOI: 10.17580/gzh.2024.09.09

- Vasiliev N.I., Talalay P.G., Bobin N.E. et al. Deep drilling at Vostok Station, Antarctica: history and recent events. Annals of Glaciology. 2007. Vol. 47, p. 10-23. DOI: 10.3189/172756407786857776

- Lipenkov V.Ya., Turkeev A.V., Ekaykin A.A. et al. Unsealing Subglacial Lake Vostok: Lessons and implications for future full-scale exploration. Arctic and Antarctic Research. 2024. Vol. 70. N 4, p. 477-498. DOI: 10.30758/0555-2648-2024-70-4-477-498

- Bolshunov A.V., Vasiliev N.I., Timofeev I.P. et al. Potential technological solution for sampling the bottom sediments of the subglacial lake Vostok: relevance and formulation of investigation goals. Journal of Mining Institute. 2021. Vol. 252, p. 779-787. DOI: 10.31897/PMI.2021.6.1

- Ignatiev S.A., Vasilev D.A., Bolshunov A.V. et al. Experimental research of ice cuttings transport by air while drilling of the snow-firn layer. Ice and Snow. 2023. Vol. 63. N 1, p. 141-152 (in Russian). DOI: 10.31857/S2076673423010076

- Shishkin E.V., Bolshunov A.V., Timofeev I.P. et al. Model of a walking sampler for research of the bottom surface in the subglacial lake Vostok. Journal of Mining Institute. 2022. Vol. 257, p. 853-864. DOI: 10.31897/PMI.2022.53

- Vasilev N.I., Dmitriev A.N., Lipenkov V.Ya. Results of the 5G borehole drilling at Russian Antarctic station Vostok and researches of ice cores. Journal of Mining Institute. 2016. Vol. 218, p. 161-171 (in Russian).

- Talalay P.G. Mechanical Ice Drilling Technology. Springer, 2016, p. 284. DOI: 10.1007/978-981-10-0560-2

- Alekhina I.A., Moskvin A.L., Ekaykin A.A., Lipenkov V.Ya. Phenol compounds in the borehole 5G, Vostok Station, after the unlocking of the subglacial lake. Ice and Snow. 2017. Vol. 57. N 3, p. 417-426 (in Russian). DOI: 10.15356/2076-6734-2017-3-417-426

- Lipenkov V.Ya., Ekaykin A.A., Alekhina I.A. et al. Evolution of climate, glaciation and subglacial environments of Antarctica from the deep ice core and Lake Vostok water sample studies (Key results of implementation of the Russian Science Foundation project, 2014-2016). Ice and Snow. 2017. Vol. 57. N 1, p. 133-141 (in Russian). DOI: 10.15356/2076-6734-2017-1-133-141

- Alekhina I.A., Vasilev N.I., Ekaikin A.A., Lipenkov V.Ya. Preliminary results of chemistry studies of water frozen in a borehole after opening Lake Vostok. Problemy Arktiki i Antarktiki. 2014. N 2 (100), p. 5-14.

- Triest J., Alemany O. Drill fluid selection for the SUBGLACIOR probe: a review of silicone oil as a drill fluid. Annals of Glaciology. 2014. Vol. 55. Iss. 68, p. 311-321. DOI: 10.3189/2014AoG68A028

- Alemany O., Talalay P., Boissonneau P. et al. The SUBGLACIOR drilling probe: hydraulic considerations. Annals of Glaciology. 2021. Vol. 62. Iss. 84, p. 131-142. DOI: 10.1017/aog.2020.79

- Litvinenko V., Trushko V. Modelling of geomechanical processes of interaction of the ice cover with subglacial Lake Vostok in Antarctica. Antarctic Science. 2025. Vol. 37. Iss. 1, p. 39-48. DOI: 10.1017/S0954102024000506

- Talalay P.G., Hong J. Perspectives for development of ice drilling technology: continuation of the discussion. Annals of Glaciology. 2021. Vol. 62. Iss. 84, p. 143-156. DOI: 10.1017/aog.2020.81

- Ning Liu, Huiwen Xu, Yang Yang et al. Physicochemical properties of potential low-temperature drilling fluids for deep ice core drilling. Cold Regions Science and Technology. 2016. Vol. 129, p. 45-50. DOI: 10.1016/j.coldregions.2016.06.004

- Talalay P., Cheng Yang, Pinlu Cao et al. Ice-core drilling problems and solutions. Cold Regions Science and Technology. 2015. Vol. 120, p. 1-20. DOI: 10.1016/j.coldregions.2015.08.014

- Litvinenko V.S., Leitchenkov G.L., Vasiliev N.I. Anticipated sub-bottom geology of Lake Vostok and technological approaches considered for sampling. Geochemistry. 2020. Vol. 80. Iss. 3. N 125556. DOI: 10.1016/j.chemer.2019.125556

- Lipenkov V.Ya., Turkeev A.V., Vasilev N.I. et al. Melting temperature of ice and total gas content of water at the ice-water interface above subglacial Lake Vostok. Arctic and Antarctic Research. 2021. Vol. 67. N 4, p. 348-367 (in Russian). DOI: 10.30758/0555-2648-2021-67-4-348-367

- Markov A., Talalay P., Sysoev M. et al. Borehole multi-functional logger for geophysical high-precision monitoring in Antarctic and Greenland ice sheets and glaciers. Annals of Glaciology. 2021. Vol. 62. Iss. 85-86, p. 374-384. DOI: 10.1017/aog.2021.17

- Motoyama H., Takahashi A., Tanaka Y. et al. Deep ice core drilling to a depth of 3035.22 m at Dome Fuji, Antarctica in 2001–07. Annals of Glaciology. 2021. Vol. 62. Iss. 85-86, p. 212-222. DOI: 10.1017/aog.2020.84

- Kern Z., Perșoiu A. A Review of Ice Core Drilling in Cave Environment – Challenges, Achievements and Future Directions. Frontiers in Earth Science. 2022. Vol. 9. N 720038. DOI: 10.3389/feart.2021.720038

- Turkeev A.V., Vasilev N.I., Lipenkov V.Ya. et al. Drilling the new 5G-5 branch hole at Vostok Station for collecting a replicate core of old meteoric ice. Annals of Glaciology. 2021. Vol. 62. Iss. 85-86, p. 305-310. DOI: 10.1017/aog.2021.4