Development of parameters for an industry-specific methodology for calculating the electric energy storage system for gas industry facilities

- Ph.D. Senior Lecturer Empress Catherine II Saint Petersburg Mining University ▪ Orcid

Abstract

The issue of determining the main parameters of electric energy storage systems – power and energy intensity – is being considered, the determination of which is a fundamentally important task when introducing such devices into the power supply systems of enterprises for both technical (technological) and economic reasons. The work analyzes problems that can be solved by installing electricity storage systems at gas industry facilities. An industry-wide methodology has been developed for calculating the parameters of an electricity storage system based on traditional methods and methods aimed at minimizing the standardized cost of electricity with adaptation to the conditions of the gas industry. A distinctive feature of the presented methodology is the ability to determine the power and energy intensity of electricity storage systems when performing several functions. The methodology was tested at a typical gas industry facility – the Yarynskaya compressor station of OOO Gazprom Transgaz Ukhta, a characteristic feature of which is an autonomous power supply system. An example is given of calculating the electricity storage normalized cost using an improved LCOS indicator, which takes into account the effect of changing the fill factor of the electrical load schedule on the amount of gas consumption by a power plant for its own needs. To confirm the economic efficiency of introducing electricity storage systems calculated using the above methodology, calculations of the integral effect, net present value and efficiency index are presented.

Introduction

One of the main problems of energy supply to autonomous facilities and technological complexes in the gas industry is the autonomous power supply systems technical and economic efficiency insufficient level [1], associated with the need to simultaneously ensure reliability and uninterrupted power supply, stability and electrical energy sources operation efficiency, especially in cases of creating systems for power supply to consumers widely separated from each other or consumers with sharply variable schedule of electrical loads (in accordance with the Concept for the development of energy supply to production facilities of PAO Gazprom for the period up to 2030).

The solution to this problem may be the use of an electrical energy storage system (ESS). The development of electricity storage technologies makes it possible to seriously consider these devices as the main element of power supply systems [2-4]. A distinctive feature of electricity storage systems, which stimulates their widespread implementation, is the ability to perform several functions with one device [5]. Even without taking into account the functional features of the ESS when integrating renewable energy sources (RES) [6-8] the use of these devices in centralized and autonomous systems allows the following:

- reduce the payment for installed capacity by covering load peaks with ESS means;

- reduce capital investments in the creation and operating costs of power plants for own needs by reducing the number of operating units and covering peak loads with ESS;

- improve the regularity of power supply and power quality;

- reduce the costs of ensuring the required level of categorization by eliminating the loaded (rotating) reserve for electrical units and replacing it with ESS means;

- reduce the rapidly changing load on motor drive of power plants negative impact by covering the variable part of the load with ESS means.

When considering the ESS as the main element of the power supply system, it is necessary to calculate its physical parameters: rated energy intensity, rated power, maximum number of complete charge/discharge cycles, dependence characteristics of the maximum number of charge/discharge cycles on their depth, efficiency, self-discharge constant, specific energy intensity, etc. At the same time, given the wide functionality of electricity storage systems, determining its parameters becomes labor-intensive, since it comes down to multi-criteria optimization, when it is necessary to simultaneously consider a set of several incommensurable, contradictory objective functions [9-11].

Despite active work to determine the criteria that have the greatest impact on the ESS parameters choice, currently there is no single established methodology for calculating the ESS main parameters of power and energy intensity. In the works [12-14] the methods were developed based on the power supply systems with renewable energy sources functioning characteristics; in the article [15] the methodology is aimed at calculating the parameters of ESS for use in microgrids. In paper [16] the methodology is based on empirical expressions aimed at determining the energy intensity of an electrical energy storage device for energy recovery of traction rolling stock. In the article [17] the metho-dology for calculating the optimal parameters of the ESS based on the available power of the technological connection is described, and is supplemented with the maintaining a certain voltage in the busiest network node criteria. In the source [18] it is proposed to calculate the parameters of electricity storage systems using linear filtering, which consists of analyzing the harmonic composition of the load diagrams of generating units and determining those harmonics that are subject to suppression. In the article [19] an alternative method for selecting ESS parameters according to the conditions for limiting the depth of voltage dips is presented.

The use of these methods to solve problems in the gas industry is very difficult, since they either are focused on another industry and are practically not adaptable, or are aimed at solving only one problem, which, in turn, affects the final effect of the implementation of the ESS. Therefore, the purpose of this study is to generalize and formulate a universal methodology for determining the main parameters of the energy saving system for gas industry facilities with an autonomous power supply system [20-22].

Methods

To formulate a methodology for determining the parameters of the ESS, promising tasks for autonomous power supply systems in the gas industry have been formulated – replacing the rotating reserve of a power plant for its own needs and ensuring stable operation or changing the installed capacity of generating units by aligning electrical load schedules.

The ESS implementation will reduce the cost of maintaining the unit in operating condition, which in turn will reduce fuel consumption and increase the service interval. It is also expected to ensure a more uniform loading of electrical units with energy accumulation during the hours of least consumption and energy release during the hours of highest consumption. If necessary, it is possible to reduce the power of the technological connection to the external power system by reducing consumption from it during peak hours [23, 24].

Taking into account the identified tasks and the analysis of already developed methods for calculating the parameters of the ESS, the most suitable are the traditional (classical) method [25] and a methodology aimed at minimizing the standardized cost of electricity [26]. However, they require additional adaptation to the peculiarities of the gas industry.

The traditional calculation method is simple, but does not take into account the economic component of the implementation of such systems; only technical and technological aspects appear in the calculations. According to the adapted traditional methodology, the power of the EES is determined from several components:

- The power required to cover the generation capacity in the event of an emergency shutdown of one of the generators, which is calculated by determining the power of the rotating reserve unit being replaced, equal to the product of the generating unit installed capacity and the load factor (without taking into account derating):

where Punit – estimated power of the unit being replaced, kW; kload – unit load factor, p.u.

The unit load factor depends on the number of operating units and is determined by internal regulatory documents, for example STO Gazprom 2-6.2-208-2008, STO Gazprom 2-6.2-1028-2015.

- Power required for uniform loading of electrical units. The need to limit the power consumed by the load has technical and organizational conditions related to the number of operating electrical units.

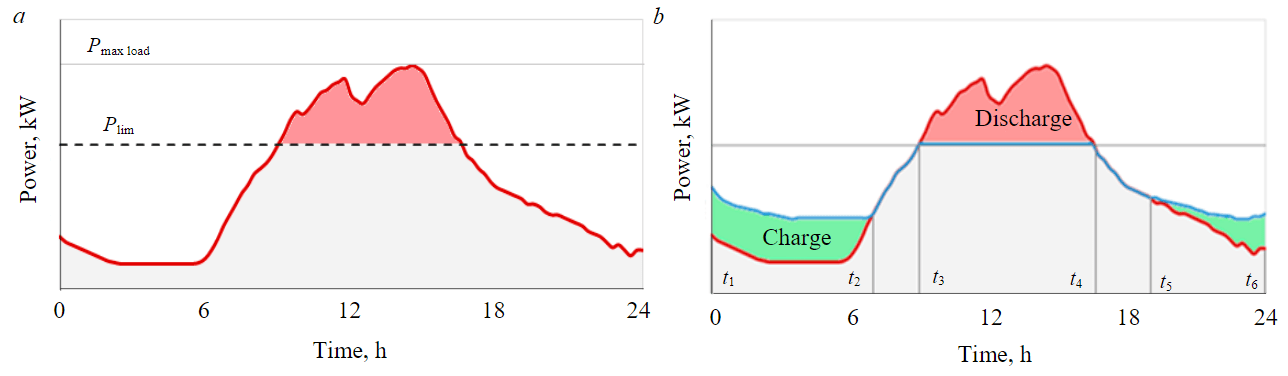

Figure 1, a shows the load graph as an example. Let us say, it is the required that the power to supply the load received from electrical units does not exceed the limit value Рlim, determined by the number of operating units. The area in which the load exceeds the maximum power marked with red. The ESS is designed to ensure the elimination of this imbalance.

Figure 1, b shows the same load graph with the installed ESS. When the load power exceeds the maximum power, the energy storage system switches to the electricity supply (discharge) mode and eliminates the imbalance. In this case, the calculated power of the ESS should correspond to the following inequality:

where Pmax load – maximum load power, kW.

Electricity consumption of the ESS (charging) occurs during periods when the load power does not exceed the maximum – such areas are shown with green in Fig.1, b. In this case, the total area of the charge zones must be greater than the area of the discharge zones by η2 times to ensure energy balance for a given period of time (η is the equivalent efficiency of the ESS elements – matching transformer, filter and inverter, according to GOST R 58092.2.1-2020, GOST R 58092.3.1-2020).

In addition, in order to more accurately determine the estimated power of the ESS, it is necessary to take into account the safety factor established by the requirements of the facility:

where ksaf – safety factor, p.u. (determined by regulatory documents); if there are no requirements for stock availability, then ksaf = 1.

The ESS energy intensity calculation using an adapted traditional methodology, consisting of several stages, must begin with the calculation of the energy intensity required to start up the backup unit (the time before start-up is 15 min – the maximum possible time):

Determining the energy intensity required to limit the electrical units load, it should be divided into the following subtasks, solved sequentially:

- exchange energy intensity determination – the amount of energy that the ESS exchanges with the power system in the process of power control when performing the stated functions;

- storage subsystem minimum energy intensity determination.

The exchange energy calculation using the example of the graph (Fig.1, b) should begin with the energy produced by the storage subsystem calculation, which is numerically equal to the red zone area divided by the ESS efficiency:

where Pcurrent (t) – current power, kW; Pdem (t) – demanded power, kW.

The energy accumulated by the storage subsystem is equal to the area of the green zone multiplied by the efficiency of the energy storage system:

In the considered daily time interval, the ESS produces the same amount of energy as it accumulates (EESS prod = EESS acc). However, various options for the configuration of the load schedule and, accordingly, the ESS charge/discharge schedule are possible, when the power output modes or consumption in the period under consideration alternate – one mode is replaced by another for a short time [27, 28]. In this case, it is necessary to take an individual approach to analyzing the load schedule and calculating energy intensity, based on the above approach.

Rules for determining exchangeable energy intensity:

- If in order to achieve the demanded P(t) dependence it is necessary to output some Edem (determined by integration), the accumulation subsystem should be able to output the value Edem/η (a larger value).

- If to achieve the demanded P(t) dependence it is necessary to consume some Edem, the storage subsystem must be able to consume a value of Edemη (smaller value).

Fig.1. Electrical load (a) and load with operating ESS (b) daily graph

To determine the minimum energy intensity of the storage subsystem, the following data is required: the required exchange energy intensity of the storage subsystem, taking into account losses on the Eex elements; required service life (years) of the battery or required service life number of charge/discharge cycles [29]; parameters of the batteries used (number of available cycles on the depth of discharge dependence) [30].

Based on the specified data, the of the service life in cycles on the energy storage device depth of discharge dependence is constructed. Using interpolation and extrapolation methods and having knowledge of the approximate number of charge/discharge cycles, it is possible to determine the ESS depth of discharge limiting value (DoD, p.u.). After determining the estimated discharge depth, the final energy capacity of the ESS is calculated. Next, the obtained energy intensity value is used to select the layout of the storage subsystem according to the formula

However, in the traditional method, when calculating ESS parameters, attention is focused only on the technical aspects of solving the problem; the economic component of the project does not appear in the calculations, which is fundamentally important when implementing such systems [31, 32].

Taking into account the economic component will allow the use of a methodology based on minimizing the specific cost of energy storage Levelized Cost of Storage – LCOS [33-35]. This indicator is an alternative to the levelized cost of electricity indicator Levelized Cost of Electricity – LCOE [36] and allows comparing different energy storage systems and alternative solutions, for example, as is done when planning the power plants construction. A detailed state analysis of LCOS indicator calculation, as well as adaptation of this indicator for the tasks solved during the implementation of the ESS in the electrical complexes of the gas industry, is presented in the article [37].

A distinctive feature of the proposed method for calculating LCOS [37] is the ability to take into account the versatility of the ESS, which also corresponds to the purpose of the study:

where Capital – capital costs, thousand rub.; t – operation year number; T – lifetime; OMt – operating and maintenance costs for the year, thousand rub.; i – inflation rate, p.u.; Auxt – electricity cost for ESS's own needs per year, thousand rub.; e –annual change rate in the cost of electricity, p.u.; Amt – annual depreciation costs, thousand rub.; r – discount rate, p.u.; P – estimated power of the unit being replaced, kW; k2 – unit load factor; h – backup unit start-up time, s; n – number of emergency launches per year; MWht – amount of energy supplied by the ESS to level the load curve, MWh; ∆S – reduction in fuel costs, thousand rub.

For the first time, an indicator that allows us to correlate the state of electrical load schedule leveling and changes in fuel consumption by generating equipment has been introduced:

where γ – load curve fill factor (load curve density); γlevel – load graph fill factor after leveling (load graph density); С0 – total fuel costs per year, thousand rub.

The formula (6) allows us to take into account the effect of replacing the rotating reserve and leveling the electrical load schedule, which, in turn, allows us to more accurately calculate the LCOS value.

The generalized methodology for calculating ESS parameters based on adapted traditional methods and methods based on minimizing the specific cost of electricity storage is the following sequence of actions:

- Calculation of the ESS parameters for replacing the rotating reserve using formulas (1), (3).

- Calculation of ESS parameters for leveling the electrical load graph at γlevel = 1 using formulas (2), (4).

- Calculation of the LCOS indicator using an improved method (5).

- If the LCOS indicator exceeds the value allowing a positive effect (according to the concept of the development of the market for electricity storage systems in the Russian Federation – 36 rubles / kWh), it is necessary to recalculate the ESS parameters to align the graph of electrical loads at γlevel < 1. However, the value of the load graph fill factor after leveling should ensure that the condition for the minimum LCOS value (min {LCOS}) is met.

- If the LCOS indicator provides a potential positive economic effect, then the ESS parameters used in the calculation can be taken into account for further detailed feasibility study of the use of the selected system.

- If it is not possible to achieve the minimum LCOS value, it is necessary to abandon a number of functions performed by the ESS and recalculate this indicator. If even in this case the LCOS value exceeds the minimum permissible value that ensures a positive economic effect, then the use of these devices should be abandoned.

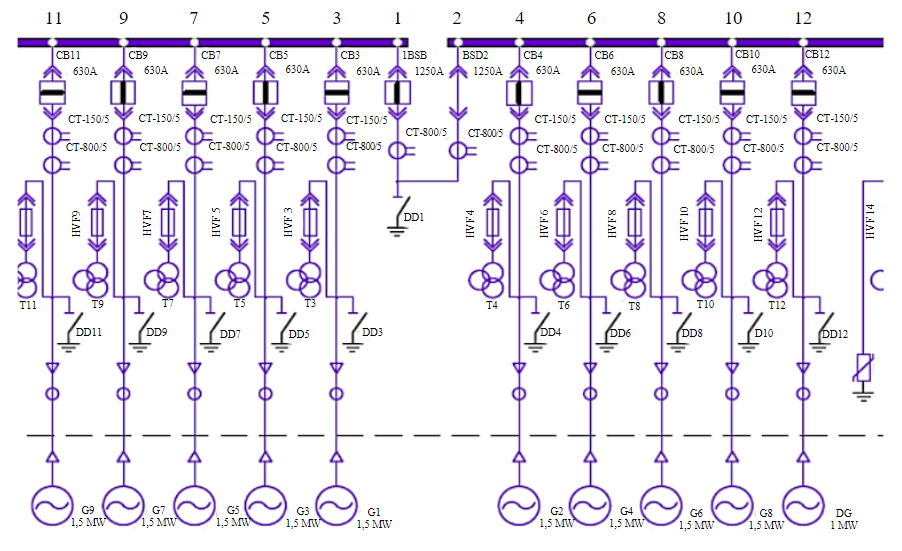

Fig.2. The power plant self-needs operation design scheme

CB – circiut braker; BSB – bus-section breaker; BSD – busbar section disconnector; CT – current transformer; HVF – high-voltage fuse; T – voltage transformer; DD – disconnecting device; DG – diesel-generator stand-by set; G – generator

To test the presented methodology, the ESS parameters are calculated using the example a real facility in the gas industry – a standard compressor station “Yarynskaya” of OOO Gazprom Transgaz Ukhta, an element of the design diagram of which is presented in Fig.2. The compressor station (CS) is a modern high-tech gas transportation facility that ensures gas transportation along the northwestern corridor of the PAO Gazprom gas trunkline system. The main electricity consumers at the Yarynskaya CS are gas air cooling units and gas pumping units with gas turbine drives. The power system of this compressor station is completely autonomous, and electricity is supplied from an auxiliary power plant based on nine gas-piston electric units with a capacity of 1.5 MW with an average load of 3-4 MW. Such a load requires the constant use of at least four power units to provide a rotating reserve, and in the event of a shutdown of one of the power units, the distribution of the load among the remaining units without stopping the technological process.

Results discussion

To confirm the ESS implementation economic efficiency, calculated using the given methodology, the integral effect is used – net present value (NPV) and efficiency index. Due to the introduction of an electricity storage system, it is planned to change the number of constantly operating units from four, with load of 70 %, to three, with load 90 %, and also achieve an additional effect from leveling the electrical load schedule by reducing gas consumption.

As a result of the scientific sources [2, 3, 5] analysis it can be concluded that the electrochemical type storage subsystem based on lithium-ion batteries is most promising for use as part of an energy storage system to solve the problems posed in the study, since it allows you to control both the operating modes of electrical grid equipment and network parameters. In this case, the ESS is not just a local buffer of electrical energy, but an active element that directly affects the energy efficiency of power supply.

The following functions can be implemented when using ESS based on lithium-ion batteries – ensuring power quality, managing power consumption, shifting consumption peaks, leveling the load curve, cold reserve – which are fully consistent with the objectives of this study.

Despite the fact that the limiting factor for the drives of this type use was their high cost, it is expected that by 2030 the drives of this type cost will be reduced by four times compared to 2018.

The main parameters of the ESS are calculated according to points 1 and 2 of the proposed methodology. If calculating the ESS power and energy intensity to replace the spinning reserve does not cause difficulties (unit power 1.5 MW; load factor 0.8; start-up time 15 min), then to calculate the parameters for regulating the load schedule, a detailed analysis of the electrical loads of the selected facility is required.

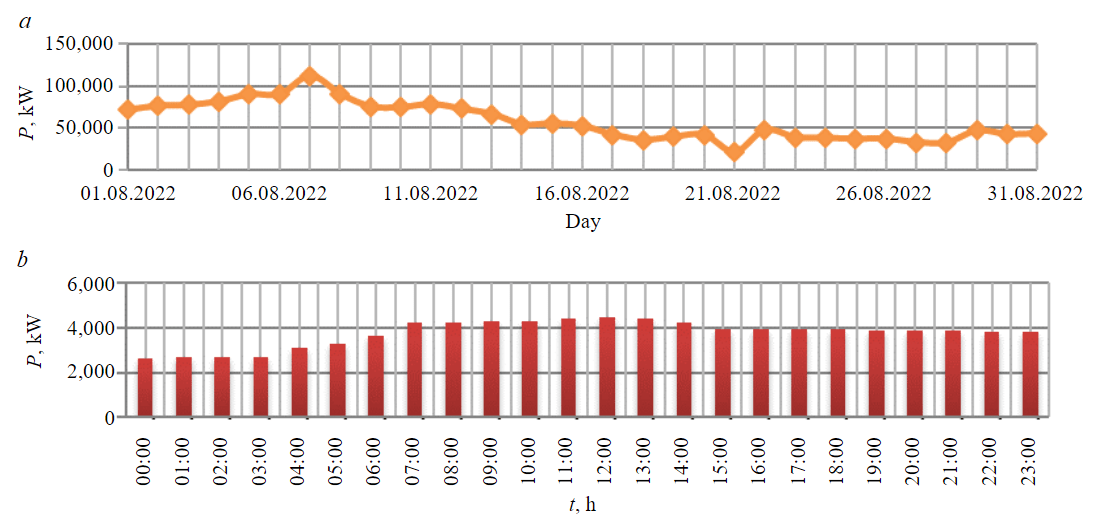

When analyzing the electrical loads of the Yarynskaya CS, it was found that the busiest month is August (Fig.3, a), and the busiest day is August 7 (Fig.3, b). The averaging period for the electrical load schedule is determined based on the conditions and method of solving the problem. In the case under consideration and for the unification of calculations, the averaging period is taken to be equal to six heating time constants for cable lines with voltages up to 6 kV and higher, supplying workshop transformer substations and distribution devices, which correspond to one hour. At the same time, the specified averaging interval does not contradict the conditions for using the ESS to solve the problem of leveling the electrical load graph – the averaging interval of the load graph should be longer than the battery response time and the discharge time of the minimum battery charge level, but should not exceed the discharge time of the current battery charge level. These conditions ensure that the energy stored in the battery is available to complete the task at hand.

Fig.3. Electrical load schedule of the Yarynskaya CS: a – the busiest month (August); b – busiest day (August 7)

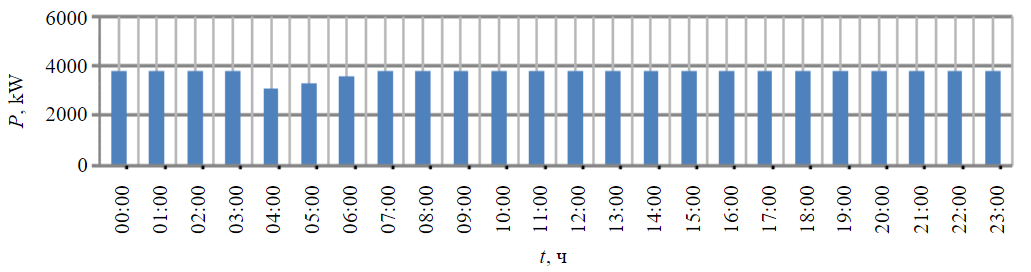

The load graph (Fig.3, b) shows that during peak hours of the day, electricity consumption exceeds 4,000 kW/h, which leads to the launch of an additional generator and, accordingly, additional consumption of resources. This can be avoided by redistributing excess energy to the morning minimum hours. Then the ESS produces the same amount of energy as it accumulates (EESS prod = EESS acc), while, according to the electrical load schedule, the power should not exceed 4,000 kW. Power and minimum permissible energy intensity are calculated using formulas (2) and (4), and a load graph is plotted after regulation (Fig.4).

Fig.4. Daily load schedule of the Yarynskaya CS after regulation using the ESS

The use of ESS to regulate the electrical load schedule makes it possible to achieve a change in the schedule density from 0.83 to 0.86 with a storage energy intensity of 800 kWh. However, even such a small difference in density will allow gas savings of up to 2,000,000 rubles per year, according to calculation using formula (6).

Next, it is necessary to calculate an improved indicator of the levelized cost of energy storage. Initial data for calculating LCOS: total capital costs (Capital), cost of energy saving energy (including the cost of transportation to the facility), installation, commissioning and testing – 119,541.65 thousand rubles; costs of operation and maintenance (O&M), maintenance and repair – 796 thousand rubles; the cost of electricity for the auxiliary subsystem is 6364.872 thousand rubles; the amount of electricity that the ESS produced over the estimated service life is 6,714 kWh; design power of the ESS – 1,600 kW; calculated energy intensity of the ESS – 2,745 kW∙h; ESS efficiency – 94 %; calculated lifetime – 20 years; discount rate – 0.08 p.u.; annual correction factor for the cost of electricity – 0.06 p.u.; annual inflation – 0.077 p.u.; reduction in fuel costs per year – 23,000 thousand rubles. The initial data for calculating capital costs, installation costs and the cost of the ESS are determined based on the operating experience of similar systems by the ESS manufacturer.

Using formula (5), the LCOS indicator was calculated as 20.68 rubles/kWh, which confirms the effectiveness of combining several functions for one ESS and allows us to predict a positive economic effect from the project.

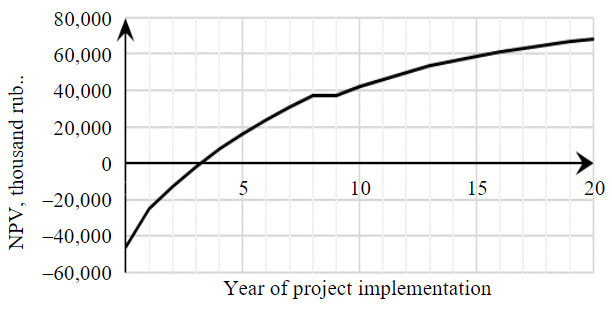

As a result of calculating the indicators of the integral effect without taking into account the reduction in capital repair costs and indicators of depreciation deductions and property taxes, the following values were obtained: NPV – 68.207 million rubles; NPV payback period is three years; internal rate of return – 23 %. The graph of changes in NPV depending on the year of project implementation is presented in Fig.5.

The implementation of the ESS that is calculated using the presented methodology will be cost-effective, since the amount of the integral effect is positive, the payback period according to the NPV will be three years.

Conclusion

The conducted research confirms the possibility of power supply system parameters calculation – power and energy intensity – using the proposed industry methodology, during the development of which previous experience in studying the issue of calculating the parameters of electricity storage systems was generalized and adapted to the peculiarities of gas industry facilities autonomous power supply system functioning.

A distinctive feature of the presented methodology is an attempt to take into account the ESS multifunctionality from a technical and economic point of view when implementing such systems.

Selecting the improved LCOS minimization as the objective function provides stakeholders with the following options:

- selection of the most effective combinations of ESS functions when determining system parameters, especially power and energy intensity;

- comprehensive analysis of technical, economic and financial changes impacts on the energy saving energy systems introduction into the enterprise's power supply system;

- domestic and foreign technologies comparison, determination of various electricity storage technologies competitive advantages.

The LCOS indicator does not limit the calculation to any framework and can become infinitely more complicated by introducing additional coefficients and variables that allow you to take into account a larger number of factors and thereby increase the accuracy of the calculation. Also, in favor of the presented methodology is that the number of tasks associated with the implementation of the ESS will increase every year, so it is advisable to use the LCOS calculation model as a key criterion for determining the ESS composition and the functions performed.

The LCOS indicator should be of an industry nature, since in two identical storage systems ope-rating at different facilities, with different technological processes, the electrical loads nature, and the power supply system type, it will take different values. The calculation of components that influence the LCOS value, such as the initial capital investment and, especially, the exchange energy intensity of the electricity storage system, should always be adapted to the considered power supply system characteristics.

References

- Baburin S., Turysheva A.V., Kovalchuk M.S. Algorithm for the choice of power supply system rational structure of gas pumping stations. Journal of Physics: Conference Series. 2021. Vol. 1753. N 012009. DOI: 10.1088/1742-6596/1753/1/012009

- Ping-Chang Tsai, Jia-Zhang Jhan, Samuel Sin-Shuan Tang, Cheng-Chien Kuo. Estimation of Energy Storage Requirements in an Independent Power System from an Energy Perspective. Applied Sciences. 2024. Vol. 14. Iss. 2. N 814.

- DOI: 10.3390/app14020814

- Zyryanov V., Kiryanova N., Korotkov I. et. al. Energy storage systems: russian and international experience. Energy Policy. 2020. N 6 (148), p. 76-87 (in Russian). DOI: 10.46920/2409-5516_2020_6148_76

- Tokarev I.S., Yugay V.F., Tolmachev V.N. et al. Use of electric power storage systems as part of power generating equipment of PJSC Gazprom production facilities power supply systems. Gas Industry. 2023. N S3 (853), p. 34-40.

- Das C.K., Bass O., Kothapalli G. et al. Overview of energy storage systems in distribution networks: Placement, sizing, operation, and power quality. Renewable and Sustainable Energy Reviews. 2018. Vol. 91, p. 1205-1230. DOI: 10.1016/j.rser.2018.03.068

- Fotopoulou M., Pediaditis P., Skopetou N. et al. A Review of the Energy Storage Systems of Non-Interconnected European Islands. Sustainability. 2024. Vol. 16. Iss. 4. N 1572. DOI: 10.3390/su16041572

- Alsalman A.S., Alharbi T., Mahfouz A.A. Enhancing the Stability of an Isolated Electric Grid by the Utilization of Energy Storage Systems: A Case Study on the Rafha Grid. Sustainability. 2023. Vol. 15. Iss. 17. N 13269. DOI: 10.3390/su151713269

- Mercier P., Cherkaoui R., Oudalov A. Optimizing a Battery Energy Storage System for Frequency Control Application

- in an Isolated Power System. IEEE Transactions on Power Systems. 2009. Vol. 24. Iss. 3, p. 1469-1477.

- DOI: 10.1109/TPWRS.2009.2022997

- Nesterenko G., Zyryanov V., Neshta A. et al. Methodology for designing electrical energy storage system parameters

- to reduce enterprise energy costs. Elektroenergetika glazami molodezhi: Materialy XI Mezhdunarodnoi nauchno-tekhnicheskoi konferentsii, 15-17 September 2020, Stavropol, Russia. V 2 t. T. 2. Stavropol: North-Caucasus Federal University, 2020, p. 175-178 (in Russian).

- Senchilo N.D., Ustinov D.A. Method for Determining the Optimal Capacity of Energy Storage Systems with a Long-Term Forecast of Power Consumption. Energies. 2021. Vol. 14. Iss. 21. N 7098. DOI: 10.3390/en14217098

- Dobush V.S., Belsky A.A., Skamyin A.N. Electrical Complex for Autonomous Power Supply of Oil Leakage Detection Systems in Pipelines. Journal of Physics: Conference Series. 2020. Vol. 1441. N 012021. DOI: 10.1088/1742-6596/1441/1/012021

- Nian Shi, Yi Luo. Energy Storage System Sizing Based on a Reliability Assessment of Power Systems Integrated with Wind Power. Sustainability. 2017. Vol. 9. Iss. 3. N 395. DOI: 10.3390/su9030395

- Sioshansi R., Madaeni S.H., Denholm P. A Dynamic Programming Approach to Estimate the Capacity Value of Energy Storage. IEEE Transactions on Power Systems. 2014. Vol. 29. Iss. 1, p. 395-403. DOI: 10.1109/TPWRS.2013.2279839

- Sokolnikova T.V., Suslov K.V., Lombardi P. Determining optimal energy storage parameters for renewable energy sources integration in isolated energy systems with active consumers. Proceedings of Irkutsk State Technical University. 2015. N 10 (105),

- p. 206-211 (in Russian).

- Fossati J.P., Galarza A., Martín-Villate A., Fontan L. A method for optimal sizing energy storage systems for microgrids. Renewable Energy. Vol. 77, p. 539-549. DOI: 10.1016/j.renene.2014.12.039

- Stepanenko V.P. Design of energy storage units for compound propulsion systems. Mining Informational and Analytical Bulletin. 2016. N 8, p. 166-174 (in Russian).

- Gusev Y.P., Subbotin P.V. Novel method for sizing and placement of energy storage systems in distribution grids. Bulletin of South Ural State University. Series “Power Engineering”. 2019. Vol. 19. N 2, p. 48-61 (in Russian). DOI: 10.14529/power190206

- Baluev D.Yu., Zyryanov V.M., Kiryanova N.G., Prankevich G.A. Experimental load diagram-based methods of calculating main parameters of energy storage devices. Proceedings of Irkutsk State Technical University. 2018. Vol. 22.N 5 (136), p. 105-114. DOI: 10.21285/1814-3520-2018-5-105-114

- Bakhteev K., Fedotov A., Chernova N., Misbakhov R. Methodological approaches to the choice of energy storage and optimization of their parameters to improve the electric power quality in various types of electric power systems. 10th International Scientific Symposium on Electrical Power Engineering (Elektroenergetika 2019), 16-18 September 2019, Stara Lesna, Slovakia. Stara Lesna: Technical University of Kosice – Department of Electric Power Engineering, 2019, p. 488-493.

- Shpenst V.A., Belsky A.A., Orel E.A. Improving the efficiency of autonomous electrical complex with renewable energy sources by means of adaptive regulation of its operating modes. Journal of Mining Institute. 2023. Vol. 261, p. 479-492.

- Abramovich B.N., Bogdanov I.A. Improving the efficiency of autonomous electrical complexes of oil and gas enterprises. Journal of Mining Institute. 2021. Vol. 249, p. 408-416. DOI: 10.31897/PMI.2021.3.10

- Belsky A.A., Glukhanich D.Y. Standalone power system with photovoltaic and thermoelectric installations for power supply of remote monitoring and control stations for oil pipelines. Renewable Energy Focus. 2023. Vol. 47. N 100493. DOI: 10.1016/j.ref.2023.100493

- Zhukovskiy Y.L., Kovalchuk M.S., Batueva D.E., Senchilo N.D. Development of an Algorithm for Regulating the Load Schedule of Educational Institutions Based on the Forecast of Electric Consumption within the Framework of Application of the Demand Response. Sustainability. 2021. Vol. 13. Iss. 24. N 13801. DOI: 10.3390/su132413801

- Lavrik A., Zhukovskiy Y., Tcvetkov P. Optimizing the Size of Autonomous Hybrid Microgrids with Regard to Load Shifting. Energies. 2021. Vol. 14. Iss. 16. N 5059. DOI: 10.3390/en14165059

- Bachurin P.A., Gladkov D.S., Zyryanov V.M. et al. Testing of the energy storage system industrial prototype SNE-10-1200-400 working together with the GPU as part of an experimental power system. Elektroenergiya. Peredacha i raspredelenie. 2020. N 2 (59), p. 18-24.

- Dulout J., Jammes B., Alonso C. et al. Optimal sizing of a lithium battery energy storage system for grid-connected photovoltaic systems. 2017 IEEE Second International Conference on DC Microgrids, 27-29 June 2017, Nuremberg, Germany. IEEE, 2017, p. 582-587. DOI: 10.1109/ICDCM.2017.8001106

- Bardanov A.I., Vasilkov O.S., Pudkova T.V. Modeling the process of redistributing power consumption using energy storage system with various configurations to align the electrical loads schedule. Journal of Physics: Conference Series. 2021. Vol. 1753. N 012013. DOI: 10.1088/1742-6596/1753/1/012013

- Ustinov D.A., Khomiakov K.A. Determination of Dynamic Characteristics for Predicting Electrical Load Curves of Mining Enterprises. Electricity. 2022. Vol. 3. Iss. 2. N 162-181. DOI: 10.3390/electricity3020010

- Belskii A.A., Dobush V.S. Russian lithium-ion batteries characteristics analysis. Promyshlennaya energetika. 2019. N 9,

- p. 25-32.

- Kuchak S.V., Brovanov S.V. Investigation of Impulse and Continuous Discharge Characteristics of Large-Capacity Lithium-Ion Batteries. Processes. 2022. Vol. 10. Iss. 12. N 2473. DOI: 10.3390/pr10122473

- Fedotov A.I., Fedotov E.A., Abdullazyanov A.F. Use of electrochemical energy storage systems in autonomous power supply systems to reduce fuel consumption of power installations. Power engineering: research, equipment, technology. 2021. Vol. 23. N 1, p. 3-17 (in Russian). DOI: 10.30724/1998-9903-2021-23-1-3-17

- Castro M., Alcanzare., Esparcia Jr.E., Ocon J. A Comparative Techno-Economic Analysis of Different Desalination Technologies in Off-Grid Islands. Energies. 2020. Vol. 13. Iss. 9. N 2261. DOI: 10.3390/en13092261

- Moradi-Shahrbabak Z., Jadidoleslam M. A new index for techno-economical comparison of storage technologies considering effect of self-discharge. IET Renewable Power Generation. 2023. Vol. 17. Iss. 7, p. 1699-1712. DOI: 10.1049/rpg2.12704

- Castro M.T., Esparcia Jr. E.A., Ocon J.D. A Comparative Future Levelized Cost of Storage of Static Electrochemical and Mechanical Energy Storage Technologies in 1-MW Energy and Power Applications. Chemical Engineering Transactions. 2022. Vol. 94, p. 355-360. DOI: 10.3303/CET2294059

- Melnikov V.D., Nesterenko G.B., Lebedev D.E. et al. Problems, aspectsofapplicationandthemethodofcalculatingthe levelized cost of storage. Vestnik Kazanskogo gosudarstvennogo energeticheskogo universiteta. 2019. Vol. 11. N 4 (44), p. 30-36 (in Russian).

- Prokhorov D.A., Semenov E.V. Comparison of the LCOE index of nuclear power plants and thermal power plants on the example of VVER-TOI & PGU-410 power units. Vestnik nauki. 2023. Vol. 4. N 6 (63), p. 964-970 (in Russian).

- Tokarev I.S., Vasilkov O.S., Shklyarskiy Ya.E. et al. Selection of parameters of an electricity storage system based on the criterion of an improved indicator of levelized cost for high-power facilities of Gazprom PJSC. Scientific Works of the Kuban State Technological University. 2024. N 2, p. 170-184 (in Russian). DOI: 10.26297/2312-9409.2024.2.15