Lithification of leachate from municipal solid waste landfills with blast furnace slag

- 1 — Ph.D., Dr.Sci. Head of Department Empress Catherine ΙΙ Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus

- 2 — Postgraduate Student Empress Catherine ΙΙ Saint Petersburg Mining University ▪ Orcid

Abstract

The article presents an alternative method of utilization of blast furnace slag and leachate from solid municipal waste landfills, the formation of which occurs during the infiltration of atmospheric precipitation through the thickness of deposited waste. The method is based on the conversion of leachate from the liquid phase to the solid aggregate state by lithification using blast furnace slag as an astringent material. The hydraulic activity of slag, which depends on the amount of oxides contained in it, has been estimated. The investigated slag belongs to the 3rd grade, which confirms the possibility of its use as an astringent material. The filtrate was analyzed for the content of various elements, and the maximum permissible concentrations for each element were found to be exceeded. Chemical and biological oxygen demand were determined, and critically high values were installed (17200 mgO2/l and 4750 mgO2/l, respectively). The lithification process was divided into two stages. The first stage was to reduce the organic component in the filtrate using a coagulant, aluminum sulfate; the second stage was slag hydration. The optimum ratio of lithificate components in terms of mixture solidification rate was established at 1:0.03:1.25 (leachate, coagulant, blast furnace slag). The obtained material was analyzed for the solubility and content of various forms of metal. It is established that at infiltration of atmospheric precipitations through lithificate only 3 % of material will be washed out; concentrations of gross and mobile forms of heavy metals do not exceed the maximum permissible, except for the gross content of arsenic, mobile, and water-soluble forms of which were not found. The values of chemical (687 mgO2/l) and biological (173 mgO2/l) oxygen demand in the aqueous extract from lithificate decreased more than 25 times in comparison with the initial filtrate. According to the results of toxicological studies, lithificate was assigned an IV class of waste hazard, which confirms the possibility of its use as bulk material at landfills.

Funding

The work was carried out under the state assignment of the Ministry of Science and Higher Education of the Russian Federation (FSRW-2024-0005)

Introduction

Currently, the Russian Federation is experiencing steady growth in industrial production. According to Federal State Statistics Service, industrial production grew by 3.5 % in 2023 compared to the previous year. At the same time, the basic branch of the economy that provides life support was and remains the metallurgical industry, which annually becomes the leader of the positive dynamics of the rate of development, where the growth in 2023 amounted to 9.5 % compared to 2022 [1, 2]. The volume of pig iron smelting in Russia in December 2023 amounted to 4.4 million t, which is 3 % higher than in December 2022; over the year it increased by 5.8 % and reached 54.6 million t [3]. Non-alloy steel output in December 2023 increased by 13 % to 4.9 million t compared to the same period in 2022; total growth for the year was 7.9 % (60.2 million t).

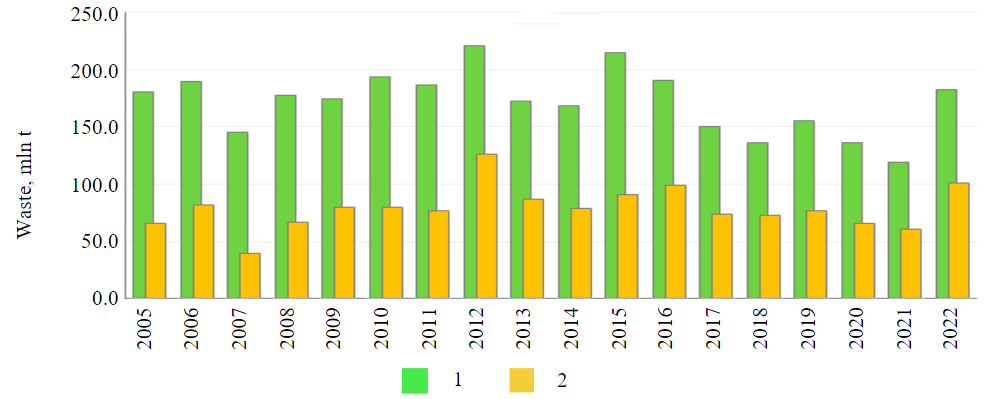

A negative factor in the development of industrial production is the increase in the volume of waste generation, which is especially characteristic of enterprises of mineral and raw materials complexes, where during the extraction and processing of minerals, multi-tonnage wastes are generated and accumulated – overburden, tailings, as well as processing wastes [4]. A significant position in the formation and accumulation of industrial waste is occupied by the metallurgical processing of iron and steel [5]. According to statistical data, currently less than half of the generated wastes from metallurgical production are utilized, which leads to their accumulation in the form of man-made massifs on the territories of industrial enterprises (Fig.1) [6].

Fig.1. Quantity of generated (1), utilized, and neutralized (2) wastes in the metallurgical production by years

The main wastes of ferrous metallurgy are slag from blast furnaces and steelmaking [7]. The output of blast furnace slag can reach 600 kg per 1 t of pig iron, and that of steelmaking slag is 200 kg per 1 ton of steel [8].

Slags formed during iron smelting are products of the interaction of initial components under the influence of a high-temperature regime – ore, fuel, and flux [9]. Fuel provides heating of charge materials up to temperatures of 1400-1600 ºC and is a catalyst for chemical reactions in ore melting. Coking varieties of hard coal – coke – are used as fuel [10, 11]. Waste rock from the ore part of the charge and ash from coke combustion are converted into slag by adding flux, a material that reduces heat consumption for the melting of some oxides [12]. The melting temperature of such oxides can be 1700 ºC and higher, which is impossible to realize in the conditions of blast furnace operation. At a certain ratio of oxides composing the main part of the ore waste rock (SiO2, Al2O3, CaO, and MgO), by adding flux, compounds with a melting point of 1300 ºC are formed, which makes it possible to separate the useful part from the waste part in the ore charge. Depending on the composition of the ore charge, one or another flux is used: basic, acidic, or alumina. In most cases, the ore mined contains acidic rock, which implies the use of basic flux, represented by limestone.

Thus, the composition and properties of the obtained slag depend on the chemical and mineral composition of iron ore, ash from coke combustion, added flux, and the operating condition of the blast furnace [13-15]. The chemical composition of blast furnace slag is mainly represented by such elements as silicon, calcium, aluminum, and magnesium, and, to a lesser extent, iron, manganese, and sulfur. The mass fraction of blast furnace slag components is, %: SiO2 – 33.0-44.0; CaO – 30.0-49.0; Al2O3 – 4.5-20.0; MgO – 1.5-15.0; FeO – 0.5-3.0; Fe2O3 – 0.3-0.8; MnO – 0.3-3.0; SO3 – 0.4-2.5.

One of the peculiarities of slag is its similarity in component composition to cement in terms of lime, silica, and alumina content. For this reason, the main methods of handling this waste can include its use as a binder material or aggregate in the production of cement and concrete, as well as in road construction [16-18]. Less frequently, slag is used in the production of slag wool as a thermal insulation material and mineral fertilizer [19, 20]. In this case, the amount of slag produced significantly exceeds the volume of utilization, which leads to its accumulation and, as a consequence, the formation of technogenic massifs. This determines the relevance of the search for new ways of utilizing the waste under consideration.

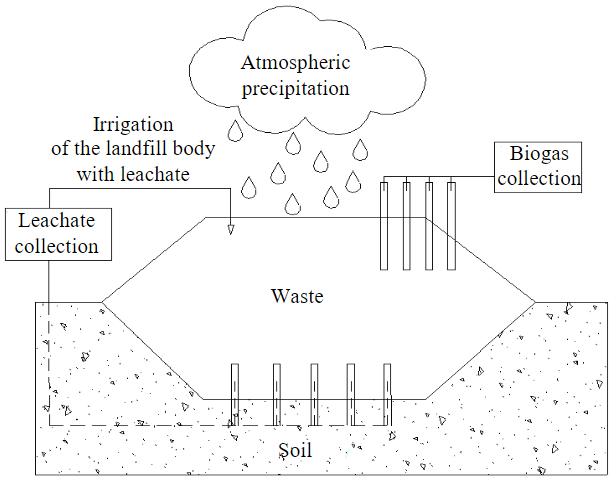

Fig.2. Scheme of landfill leachate formation

The article considers an alternative method of utilization of blast furnace slag together with the liquid waste of municipal solid waste (MSW) landfills – leachate, which is formed as a result of biological and physicochemical transformations in the body of the array under the influence of infiltrating precipitation (Fig.2) [21]. The composition of this leachate, characterized by diversity and variability, includes an extensive list of pollutants – compounds of various heavy metals and a number of toxic, hard-to-oxidize organic substances. The migration of landfill leachate outside the landfill causes irreparable damage to all components of the environment. There is pollution of surface and underground water bodies with salts of heavy metals and organic compounds coming from leachate, soil pollution, and, as a consequence, changes in their composition and reduction of plant communities [22, 23].

To treat leachate from landfills, it is possible to use various methods of effluent treatment – mechanical, physical-chemical, biological, and combined, which are insufficiently effective and economically inexpensive [24]. Therefore, leachate is often collected and used in the irrigation of the landfill body to accelerate the process of decomposition of accumulated waste, which leads to its re-accumulation.

One of the possible options for leachate utilization is the conversion from the liquid to the solid phase. This method of stabilization is called lithification of landfill leachate. Up to now, various methods of leachate lithification have been considered, in particular the method of mixing leachate with shale ash and ash from the incineration of MSW as a binding material [25-27]. The development of this direction is difficult due to the lack of sufficient quantities of binder material of anthropogenic origin (shale ash). The main disadvantage of using ash from the incineration of MSW remains the difficulty of continuous regulation of the composition of municipal waste incoming to incineration plants in order to control the concentration of heavy metals in the ash. The Saint Petersburg Mining University developed a formulation of technology from landfill leachate with the use of binding material based on steelmaking slag [28]. However, the volume of formed steelmaking slag is two times lower than the volume of blast furnace slag formation. At the same time, blast furnace slag has better hydraulic activity due to the increased content of CaO, which should lead to an increase in the strength characteristics of the resulting lithificate. Therefore, it seems promising to use blast furnace slag as a binding material.

Methods

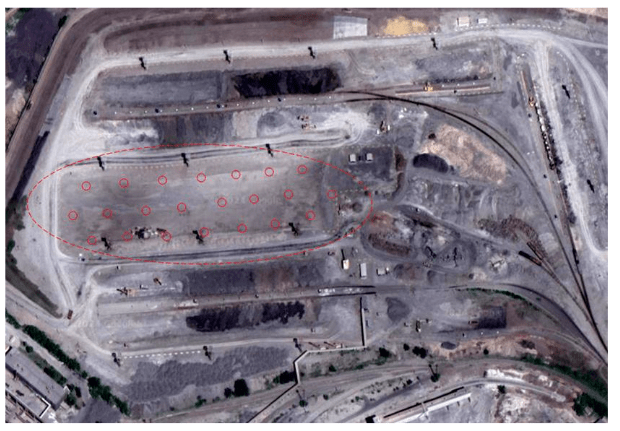

The object of the study is blast furnace slag from a metallurgical plant in the Lipetsk region. Hot liquid slag masses are discharged into trenches and cool down naturally [29]. Sampling was carried out in the area of slag discharge after its cooling on a uniform network according to PND F 12.4.2.1–99 “Waste of mineral origin. Recommendations on sampling and preparation of samples. General provisions”. The site is characterized as homogeneous by the composition, coarseness and moisture content of the material (Fig.3). Selected 22 point samples (marked in red on Fig.3) were combined into one and delivered for further analysis to the laboratory of Saint Petersburg Mining University.

Blast furnace slag as additives in cement production should meet the requirements of GOST 3476-2019 “Blast furnace slag and electrothermophosphorus granulated slag for cement production”. Assessment of slag hydraulic activity is carried out by the quality coefficient, which depends on the content of some oxides. At the content of magnesium oxide (MgO) of more than 10 %, the coefficient is determined by the formula

The component composition of slag was determined according to GOST 5382-2019 “Cements and cement production materials. Methods of chemical analysis” by X-ray fluorescence (XRF) method using a sequential wave dispersive X-ray fluorescence spectrometer XRF-1800 by Shimadzu [30]. A laboratory sample of blast furnace slag was selected for analysis. The material was crushed to particles less than 30 μm and then pressed into tablets.

Fig.3. Blast furnace slag sampling scheme at the primary processing site

The leachate was sampled at the landfill located in Gatchina district, Leningrad region. The leachate is collected by means of a drainage system, passing through the thickness of the deposited waste, and is further directed to a storage pond, from which it is used for irrigation of the body of the massif to accelerate the decomposition process of the deposited waste. In this case, there is a re-accumulation of leachate and an increase in concentrations of pollutants: heavy metals, hard-to-oxidize organics, etc. The content of metals and metalloids in the leachate was determined by atomic absorption spectroscopy according to the method M-02-2406-13 using an optical emission spectrometer with inductively coupled plasma Shimadzu ICPE-9000 (Japan). Mass concentrations of anions were measured by ion chromatography according to the method M-02-1805-09 using an ion chromatograph Shimadzu (Japan) LC-20 Prominence.

The normal process of slag hydration is hindered by the presence of a high content of organic substances in the leachate. To determine the content of organic substances in the leachate, chemical and biological oxygen demand (COD and BOD) were determined. COD was determined by the spectrophotometric method according to FR.1.31.2013.16588, and BOD was determined by the manometric method according to FR.1.31.2015.20690.

The lithification process is divided into two stages and consists of mixing leachate and blast furnace slag with the addition of a coagulant to activate the solidification process of the mixture by precipitating suspended solids and some organic compounds.

At the first stage of experimental studies, the selection of coagulant was carried out according to the highest rate of mixture solidification. For this purpose, different coagulants were added to four samples of filtrate in a ratio of 1:0.05 (200 ml of filtrate and 10 g of coagulant). The resulting solution was stirred until the gassing reaction was stopped. The most widely used reagents for wastewater treatment were used as coagulants: slaked lime, aluminum sulfate, iron (III) chloride, and iron (III) sulfate. At the end of the coagulation process, one part of slag (200 g) was added to the obtained mixture, after which the mixture was stirred to form a homogeneous mass. According to the curing time of the mixture, the best coagulant was determined. To determine the effectiveness of the coagulant, a comparison sample without the addition of coagulant was additionally prepared in a 1:1 ratio (200 ml of filtrate and 200 g of slag).

The second stage of research consisted of the selection of the optimal ratio of components – coagulant and blast furnace slag. For this purpose, the coagulant selected in the first stage was added to five samples of filtrate in the ratio of 1:0.05 and different amounts of slag parts: 1, 1.25, 1.5, 1.75, and 2 (200, 250, 300, 350, and 400 g).

After determining the optimum amount of slag introduced by the rate of solidification of the mixture, the determination of the minimum required amount of the selected coagulant was carried out. For this purpose, coagulant in the amount of 0.01 to 0.05 parts (2, 4, 6, 8, and 10 g) and the previously selected optimal amount of slag were added to five samples of filtrate.

The obtained lithificate was analyzed for solubility by the gravimetric method according to GOST 33135-2014 “Public roads. Viscous petroleum road bitumen. Method for determining solubility”. For this purpose, an aqueous extract of lithificate was prepared according to GOST 26423-85 “Soils. Methods of determination of specific electrical conductivity, pH, and dense residue of water extract”. The solubility was calculated by the formula

where m1 is the mass of the weighing cup with filter dried, g; m2 is the mass of the weighing cup with filter dried with sediment, g; msmpl is the mass of the lithificate sample taken for analysis, g.

Toxicological studies of the lithificate were carried out to establish its hazard class by biotesting on a testing culture of Chlorella vulgaris algae. For this purpose, the multiplicity of the dilution of water extract from the obtained waste, at which there is no harmful effect on hydrobionts, was determined. The study was carried out according to the method of PND FT 14.1:2:3:4.10-04 and consisted of recording the difference in optical density between the test culture of Chlorella algae grown in a medium containing no harmful substances (the control) and the test sample of water extract, which may contain harmful substances. An aqueous extract of lithificate was prepared, and dilutions of 10, 100, 1000, and 10,000 times were carried out according to the methodology for production and consumption waste. The toxicity criterion is considered to be a decrease in the value of optical density compared to the control variant (distilled water) by 20 % or more, as well as in algae growth stimulation by 30 % or more.

In cases of growth suppression by more than 20 %, the toxic dilution rate is calculated according to the formula

where Рh is the dilution rate (the highest) at which the percentage of deviation was below the toxicity criterion (20 %); Рl is the dilution rate (the lowest) at which the percentage of deviation was above the toxicity criterion; Ih and Il are the deviations from the control corresponding to these dilutions, shares.

In order to establish the degree of leachability of the organic component from the lithificate, COD and BOD were determined in the aqueous extract using the same methods as for the leachate.

The determination of the gross concentrations of metals and metalloids, as well as their mobile and water-soluble forms, in the lithificate was carried out by atomic absorption spectrometry. To determine the gross forms of elements, microwave decomposition of pre-crushed lithificate in a mixture of concentrated acids (nitric, hydrochloric, and hydrofluoric) For the determination of water-soluble forms, an aqueous extract was prepared according to GOST 26423-11 “Methods of determination of specific electrical conductivity, pH, and dense residue of aqueous extract”. For the determination of mobile forms, an extract from lithificate with an acetate-ammonium buffer solution with a pH of 4.8 was prepared according to RD 52.18.289.

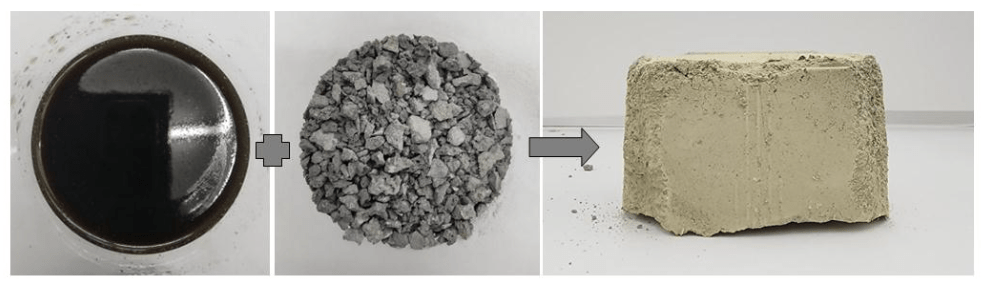

Fig.4. Landfill leachate, blast furnace slag, and lithification product obtained

Results

The presented method of utilization of blast furnace slag together with landfill leachate is based on the transition of leachate from a liquid aggregate state to a solid, stable form using crushed blast furnace slag with particle sizes up to 5 mm instead of cement as a binding material (Fig.4).

Blast furnace slag is well studied as a material used as a mineral additive to cement and concrete. It can be used as a binding component and as an aggregate instead of crushed stone [31, 32]. Its use as an additive solves two main environmental problems: the reduction of carbon dioxide emissions into the atmosphere during cement production as well as the partial utilization of waste and its recycling.

The composition of the investigated slag, as well as the quality coefficient calculated on its basis, are presented in Table 1. According to the data obtained, the studied slag belongs to the 3rd grade, which indicates its low activity and unsuitability for use as a binding material in the manufacture of cements and high-strength concrete [33, 34]. Thus, there is a need to find an alternative way of utilizing blast furnace slag. It is proposed to use it as a hydraulic binder for the stabilization of liquid waste from landfills.

Table 1

Chemical composition of blast furnace slag

|

Sample |

Mass fraction of components, % |

||||||||||

|

SiO2 |

CaO |

Al2O3 |

MgO |

Fe2O3 |

MnO |

SО3 |

TiO2 |

Cl |

K |

|

|

|

Norm for grade 3 |

n/r* |

n/r |

n/r |

Not more than 15.0 |

n/r |

Not more than 4.0 |

n/r |

Not more than 4.0 |

Not more than 0.1 |

Not less than 1.20 |

|

|

Blast furnace slag |

40.5 |

38.1 |

5.8 |

10.5 |

0.47 |

0.33 |

2.4 |

0.39 |

Less than 0.0001 |

1.30 |

|

* No regulation.

The composition of landfill leachate depends largely on the composition of stored waste and its storage conditions, climatic conditions and the time of landfill operation [35]. The composition of leachate used in this study is presented in Table 2.

Table 2

Indicators of leachate from landfills

|

Indicator |

Significance |

MAC |

|

рН |

7.8 |

6.0-9.0 |

|

Electrical conductivity, µSm/cm |

46,000 |

n/r* |

|

BOD5, mgO2/l |

4,750 |

2 |

|

COD, mgO2/l |

17,200 |

15 |

|

Solid residual, mg/dm3 |

13,405 |

1,500 |

|

Chlorides, mg/dm3 |

6,075 |

350 |

|

Sulfates, mg/dm3 |

252 |

500 |

|

Hydrocarbonates, mg/dm3 |

12,501 |

n/r |

|

Nitrates, mg/dm3 |

51.9 |

45.0 |

|

Nitrites, mg/dm3 |

13.8 |

3.0 |

|

Ammonium-ion, mg/dm3 |

1,894 |

1.5 |

|

Potassium, mg/dm3 |

1,266 |

n/r |

|

Sodium, mg/dm3 |

2,384 |

200 |

|

Calcium, mg/dm3 |

365 |

180 |

|

Magnesium, mg/dm3 |

168 |

50 |

|

Total iron, mg/dm3 |

9.8 |

0.3 |

|

Copper, mg/dm3 |

0.3 |

1.0 |

|

Cadmium, mg/dm3 |

0.267 |

0.001 |

|

Mercury, mg/dm3 |

<0.005 |

0.0005 |

|

Cobalt, mg/dm3 |

<0.05 |

0.1 |

|

Chromium, mg/dm3 |

2.31 |

0.05 |

|

Lead, mg/dm3 |

<0.1 |

0.01 |

|

Arsenic, mg/dm3 |

<0.01 |

0.01 |

|

Zinc, mg/dm3 |

6.5 |

5.0 |

|

Nickel, mg/dm3 |

0.40 |

0.02 |

|

Manganese, mg/dm3 |

0.2 |

0.1 |

|

Aluminum, mg/dm3 |

5.1 |

0.2 |

* No regulation.

Thus, exceedances of the maximum admissible concentration (MAC) established for water in underground and surface water bodies of economic and drinking water use are observed almost for each of the above indicators. Thus, the content of ammonium ions exceeded MAC more than 1,000 times.

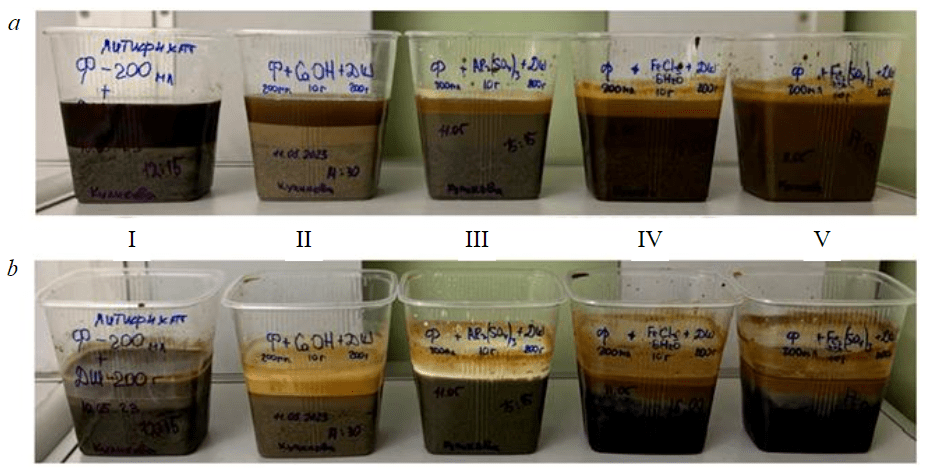

The high content of organic substances in leachate (COD = 17200 mgO2/l) slows down the process of blast furnace slag hydration. According to GOST 23732-2011 “Water for Concrete and Mortars: Specifications” the oxidizability of water used for the preparation of concrete mixtures should be no more than 15 mg/l. Therefore, the lithification process was divided into two stages. The first stage is represented by the process of particle coagulation [36, 37]. The high intensity of precipitation is visually observed when aluminum and iron (III) sulfates are used, which indicates their high coagulating ability (Fig.5). Aluminum sulfate was chosen for further studies due to its lower toxicity compared to iron (III) sulfate.

Fig.5. Selection of the optimal coagulant according to the speed of curing of the mixture: a – on the day of mixture preparation; b – on the 10th day of curing; I – without coagulant; II – Са(ОН)2; III – Al2(SO4)3; IV – FeCl3; V – Fe2(SO4)3

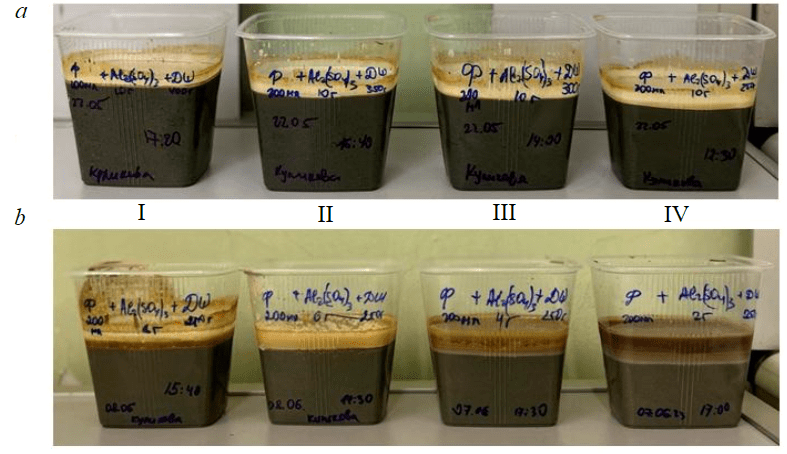

Fig.6. Selection of lithificate formulation: а – the optimal amount of slag introduced: I – 400 g; II – 350 g; III – 300 g; IV – 250 g; b – the optimal amount of coagulant added: I – 8 g; II – 6 g; III – 4 g; IV – 2 g

Preliminary coagulation triggers the second stage of lithification: the direct solidification of the mixture with the help of blast furnace slag. Based on the results of laboratory studies, the optimal formulation of lithificate in terms of solidification time was selected: 200 ml of filtrate, 6 g of aluminum sulfate, and 250 g of blast furnace slag (Fig. 6). The ratio of components – filtration, coagulant, and blast furnace slag – was chosen because, at the introduction of more slag, the rate of solidification does not change, and at a lower dosage of Al2(SO4)3, the coagulation process is not started. The complete solidification of the lithificate occurred after 14 days from the beginning of the experiment. The highest rate of strength gain of the mixture was noted for the slag fraction smaller than 1 mm.

Based on the results of experimental studies on the solubility of lithificate, it was found that only 3 % of the resulting material would be leached by the infiltration of precipitation through it.

The results of studies of the obtained lithificate for the content of gross, mobile, and water-soluble forms of metals and metalloids are presented in Table 3. The pH of the lithification salt extract was over 12. The determined concentrations were compared with MAC for loamy and clayey soils with a pH of salt extract greater than 5.5.

Table 3

Elemental content in lithifacate

|

Element |

Gross concentrations, mg/kg |

Concentrations of mobile forms, mg/kg |

Concentrations of water-soluble forms, mg/kg |

MAC in soil, mg/kg |

MAC of mobile forms of substances in soil, mg/kg |

|

Total iron |

2,531 |

146 |

0.9 |

n/r |

n/r |

|

Zinc |

3 |

0.3 |

0.1 |

220 |

23 |

|

Aluminum |

4,967 |

198 |

17 |

n/r |

n/r |

|

Chromium |

126 |

1.6 |

0.1 |

n/r |

6.0 |

|

Nickel |

55 |

1.6 |

0.4 |

80 |

4.0 |

|

Cadmium |

Less than 0.01 |

Less than 0.05 |

Less than 0.05 |

2.0 |

n/r |

|

Copper |

2.2 |

Less than 0.5 |

0.5 |

132 |

3.0 |

|

Manganese |

1,471 |

410 |

1.9 |

1,500 |

100 |

|

Lead |

Less than 0.05 |

Less than 0.5 |

Less than 0.5 |

130 |

6.0 |

|

Cobalt |

Less than 0.01 |

Less than 0.5 |

Less than 0.5 |

n/r |

5.0 |

|

Calcium |

223,963 |

75,728 |

3,528 |

n/r |

n/r |

|

Barium |

798 |

156 |

2.1 |

n/r |

n/r |

|

Magnesium |

31,374 |

7,200 |

48 |

n/r |

n/r |

|

Sodium |

7,036 |

2,500 |

1,687 |

n/r |

n/r |

|

Potassium |

8,132 |

2,091 |

967 |

n/r |

n/r |

|

Strontium |

525 |

318 |

16.2 |

n/r |

n/r |

|

Vanadium |

28 |

1.6 |

Less than 5.0 |

150 |

n/r |

|

Mercury |

Less than 0.01 |

Less than 0.005 |

Less than 0.005 |

2.1 |

n/r |

|

Arsenic |

31 |

Less than 0.05 |

Less than 0.05 |

10.0 |

n/r |

|

Titanium |

3,048 |

Less than 5.0 |

Less than 5.0 |

n/r |

n/r |

It follows from the obtained data that concentrations of gross content of heavy metals and their mobile forms in lithificate do not exceed MAC in the soils of settlements, except for the gross content of arsenic. According to the research conducted, mobile and water-soluble forms of arsenic in extracts from lithificate were not found. In the case of atmospheric precipitation impacting lithificate, arsenic migration into the natural environment does not occur [38].

The obtained values of COD (687 mgO2/l) and BOD (173 mgO2/l) for the aqueous extract from the lithificate water decreased more than 25 times compared to the same values in the leachate.

According to the results of toxicological studies, the toxic dilution multiplicity of aqueous extract from the obtained waste was established, at which the growth suppression occurs in comparison with distilled water by 20 % – 48.5 (Table 4). According to the order of the Ministry of Natural Resources of Russia at the dilution multiplicity of aqueous extract from 1 to 100, the waste can be referred to the IV class of danger.

Table 4

Biotesting on Chlorella algae culture (Chlorella vulgaris)

|

Multiplicity dilution |

Optical density after 22 h |

Medium optical density after 22 h of cultivation medium |

Deviation out |

Quality assessment |

|

Control |

0.048 |

0.048 |

– |

– |

|

1 |

0.016 |

0.015 |

76.1 |

Affects |

|

10 |

0.036 |

0.036 |

25.0 |

Affects |

|

100 |

0.040 |

0.040 |

17.7 |

Doesn't affect |

|

1000 |

0.042 |

0.042 |

13.6 |

Doesn't affect |

|

10000 |

0.044 |

0.044 |

9.4 |

Doesn't affect |

* Minus the optical density after the addition of chlorella before culturing.

Fig.7. Bulk material based on landfill leachate and blast furnace slag

Based on the results of studies of the composition and properties of lithificate, it is proposed to use it as a techno-soil (Fig.7) to create an insulating intermediate layer for waste storage in accordance with the instructions for the design, operation, and reclamation of landfills for solid municipal waste. Limestone waste, slag from TPPs, gypsum-containing waste, etc. are used as insulating materials at landfills for solid municipal waste storage. Other industrial waste in the IV class of hazards is allowed. Insulation with the material is carried out daily with a layer thickness of 0.15 to 0.25 m. Thus, the use of lithificate in the research as an alternative insulating material is relevant to the activity of landfills for solid waste [39-41].

Conclusion

As a result of the conducted research, the method of utilizing blast furnace slag together with landfill leachate was developed. The method is based on solidification of leachate by adding blast furnace slag as a binding material.

Before introducing the crushed slag, a coagulant is added to the liquid waste to reduce the high concentrations of organic compounds in it. Aluminum sulfate was chosen as a coagulant – a reagent with the highest coagulation ability compared to other tested compounds. The conducted experiments allowed us to establish the optimal dosage of coagulant and blast furnace slag introduction into the leachate in the ratio 1:0.03:1.25 (filtrate, aluminum sulfate, blast furnace slag). The formulation can be applied to other objects of the study. However, fluctuations in the composition of filtrate and blast furnace slag can slightly affect the lithification, which requires some adjustment of the doses of the introduced components.

The application of the obtained material was found to form an insulating layer in the filling of production and consumption wastes [42]. The IV class of hazard of the obtained lithified material was established, as well as the absence of mobile and water-soluble forms of toxic elements in it, which confirms the possibility of its use. As a result, the negative impact on the environment will be reduced due to the utilization of two types of accumulated waste at once.

References

- Aliev A.T., Zheltenkov A.V., Baldin K.V. Problem and Potential of Economic Development, Industrial Production and Innovation in Modern Russia. Bulletin of Moscow Region State University. Series: Economics. 2023. N 2, p. 48-58 (in Russian). DOI: 1018384/2310-6646-2023-2-48-58

- Govoruhin V.A., Kuchina E.V. Sustainable development of the metallurgical industry in the context ESG transformations. Bulletin of the South Ural State University. Series Economics and Management. 2023. Vol. 17. N 2, p. 92-100 (in Russian). DOI: 10.14529/em230207

- Bezhanov I.V. Ways of development of the metallurgical industry in Russia. Progressive Economy. 2023. N 10, p. 111-124 (in Russian). DOI: 10.54861/27131211_2023_10_111

- Ignatyeva M.N., Yurak V.V., Dushin A.V., Strovsky V.E. Technogenic mineral accumulations: problems of transition to circular economy. Mining Science and Technology (Russia). 2021. Vol. 6. N 2, p. 73-89. DOI: 10.17073/2500-0632-2021-2-73-89

- Katunin V.V., Zinoveva N.G., Ivanova I.M., Petrakova T.M. Basic indices of Russian steel industry operation in 2019. Ferrous metallurgy. Bulletin of scientific, technical and economic information. 2020. Vol. 76. N 4, p. 309-334 (in Russian). DOI: 10.32339/0135-5910-2020-4-309-334

- Scobelev D.O., Maryev V.A., Shubov L.Ya. et al. Wastes of the mining and metallurgy industry: the systematization of the technological decision of the ecological tasks. Part I. Ecological Systems and Devices. 2018. N 12, p. 29-37 (in Russian). DOI: 10.25791/esip.12.2018.305

- Riley A.L., MacDonald J.M., Burke I.T. et al. Legacy iron and steel wastes in the UK: Extent, resource potential, and management futures. Journal of Geochemical Exploration. 2020. Vol. 219. N 106630. DOI: 10.1016/j.gexplo.2020.106630

- Pechentsov I.M. Processing of Waste from the Metallurgical Industry for Stabilization and Reinforcemnet of Problematic Soils. Proceedings of Petersburg Transport University. 2023. Vol. 20. Iss. 4, p. 811-819 (in Russian). DOI: 10.20295/1815-588X-2023-4-811-819

- Kocheshkova І.M. International Experience in Generated and Use of Blast Furnace Slag. Economic Herald of the Donbas. 2020. N 2 (60), p. 181-186 (in Ukrainian). DOI: 10.12958/1817-3772-2020-2(60)-181-186

- Kharchenko A.S., Sibagatullina M.I., Kharchenko E.O. et al. Reduction of specific coke consumption in blast furnace by impact on thermal reverse zone. Izvestiya. Ferrous Metallurgy. 2023. Vol. 66. N 4, p. 394-402. DOI: 10.17073/0368-0797-2023-4-394-402

- Rudko V.А., Gabdulkhakov R.R., Pyagai I.N. Scientific and technical substantiation of the possibility for the organization of needle coke production in Russia. Journal of Mining Institute. 2023. Vol. 263, p. 795-809.

- Pavlov A.V., Spirin N.A., Beginyuk V.A. et al. Analysis of slag mode of blast furnace melting using model decision support systems. Izvestiya. Ferrous Metallurgy. 2022. Vol. 65. N 6, p. 413-420 (in Russian). DOI: 10.17073/0368-0797-2022-6-413-420

- Bazhin V.Yu., Ustinova Ya.V., Fedorov S.N., Shalabi M.E.Kh. Improvement of energy efficiency of ore-thermal furnaces in smelting of alumosilicic raw materials. Journal of Mining Institute. 2023. Vol. 261, p. 384-391.

- Petrova T.A., Epishina A.D. Anti-corrosion protection of pipelines at mining and processing enterprises. Obogashchenie rud. 2023. N 6, p. 52-58 (in Russian). DOI: 10.17580/or.2023.06.09

- Khobotova E.B., Ignatenko M.I., Storchak O.G. et al. Mineral composition of dump blast furnace slag. Izvestiya. Ferrous Metallurgy. 2019. Vol. 62. N 10, p. 774-781. DOI: 10.17073/0368-0797-2019-10-774-781

- Sakhapova T.S., Baranova K.O., Khusnutdinov M.I., Tikhonov V.A. Enterprise waste management practices: implementing a waste management system. Russian Mining Industry. 2021. N 5, p. 94-98 (in Russian). DOI: 10.30686/1609-9192-2021-5-94-98

- Chukaeva M.A., MatveevaV.A., Sverchkov I.P. Complex processing of high-carbon ash and slag waste. Journal of Mining Institute. 2022. Vol. 253, p. 97-104. DOI: 10.31897/PMI.2022.5

- Oge M., Ozkan D., Celik M.B. et al. An Overview of Utilization of Blast Furnace and Steelmaking Slag in Various Applications. Materials Today: Proceedings. 2019. Vol. 11. Part 1, p. 516-525. DOI: 10.1016/j.matpr.2019.01.023

- Ahmad J., Kontoleon K.J., Majdi A. et al. A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability. 2022. Vol. 14. Iss. 14. N 8783. DOI: 10.3390/su14148783

- Eremeeva A.M., Ilyashenko I.S., Korshunov G.I. The possibility of application of bioadditives to diesel fuel at mining enterprises. Mining Informational and Analytical Bulletin. 2022. N 10-1, p. 39-49. DOI: 10.25018/0236_1493_2022_101_0_39

- Shapovalov D.A., Kholin R.N., Skorobogatova U.E. Simulation and assessment of groundwater and surface water pollution by the filtrate of solid waste landfill. International Agricultural Journal. 2021. Vol. 64. N 2, p. 8-19 (in Russian). DOI: 10.24411/2588-0209-2021-10305

- Sarapulova G.I. Geochemical approach in assessing the technogenic impact on soils. Journal of Mining Institute. 2020. Vol. 243, p. 388-392. DOI: 10.31897/PMI.2020.3.388

- Matveeva V.A., Alekseenko V.A., Karthe D., Puzanov A.V. Manganese Pollution in Mining-Influenced Rivers and Lakes: Current State and Forecast under Climate Change in the Russian Arctic. Water. 2022. Vol. 14. Iss. 7. N 1091. DOI: 10.3390/w14071091

- Milyutina N.O., Politaeva N.A., Zelenkovskii P.S. et al. Review of purification methods of municipal solid waste landfills leachate. The Eurasian Scientific Journal. Vol. 12. N 3, p. 11 (in Russian). DOI: 10.15862/03NZVN320

- Prituzhalova O.A., Zhovanik I.A. Analysis of the study of landfill filtrate at Russian municipal solid waste landfills. Bulletin of Udmurt University. Series Biology. Earth Sciences. 2024. Vol. 33. N 4, p. 413-426 (in Russian). DOI: 10.35634/2412-9518-2023-33-4-413-426

- Hao Zhang, Zehua Ji, Yuxin Zeng, Yuansheng Pei. Solidification/stabilization of landfill leachate concentrate contaminants using solid alkali-activated geopolymers with a high liquid solid ratio and fixing rate. Chemosphere. 2022. Vol. 288. Part 2. N 132495. DOI: 10.1016/j.chemosphere.2021.132495

- Yazev A.V., Milyutina N.O., Averyanova N.A. et al. Lithification of MSW Landfill Leachate as a Way of its Disposal. Ecology and Industry of Russia. 2020. Vol. 24. N 6, p. 36-41 (in Russian). DOI: 10.18412/1816-0395-2020-6-36-41

- Matveeva V.A., Valiulin I.M., Chukaeva M.A., Smirnov Iu.D. Patent N 2807336 RU. Method for producing inert soil. Publ. 14.11.2023. Bul. N 32 (in Russian).

- Ponomarenko M.R., Kutepov Yu.I. Using the typification of mining-engineering facilities to substantiate deformation monitoring of opencast mining. News of the Ural State Mining University. 2020. Vol. 4 (60), p. 115-122. DOI: 10.21440/2307-2091-2020-4-115-122

- Sverchkov I.P., Gembitskaya I.M., Povarov V.G., Chukaeva M.A. Method of reference samples preparation for X-ray fluorescence analysis. Talanta. 2023. Vol. 252. N 123820. DOI: 10.1016/j.talanta.2022.123820

- Panova V.F., Panov S.A., Kambalina I.V. Aggregates and cements on the basis of secondary mineral resources. Vestnik Priamurskogo gosudarstvennogo universiteta im. Sholom-Aleikhema. 2016. N 1 (22), p. 72-77 (in Russian).

- Talapaneni T., Chaturvedi V. Proposing a suitable slag composition by estimating the fusion behavior, viscosity and desulphurization ability for blast furnaces running with high alumina. Materials Today: Proceedings. 2022. Vol. 67. Part 4, p. 558-565. DOI: 10.1016/j.matpr.2022.07.452

- Nizina T.A., Balykov A.S., Korovkin D.I. et al. Evaluation of physico-chemical efficiency of mineral additives of various compositions in cement systems. Expert: Theory and Practice. 2021. N 5 (14), p. 41-47 (in Russian). DOI: 10.51608/26867818_2021_5_41

- Blinov P.A., Shansherov A.V., Cheremshantsev D.M. et al. Analysis and selection of a grouting mixture, resistant to dynamic loads, in order to improve the support tightness quality in the annulus. Bulletin of the Tomsk Polytechnic University. Geo Assets Engineering. 2022. Vol. 333. N 11, p. 115-123 (in Russian). DOI: 10.18799/24131830/2022/11/3726

- Ashikhmina T.V., Kaverina N.V., Kuprienko P.S. Analysis of negative ecological effects caused by operation of solid municipal waste disposal facility. Regional Geosystems. 2020. Vol. 44. N 3, p. 343-358 (in Russian). DOI: 10.18413/2712-7443-2020-44-3-343-358

- Krasavtseva E.A., Zhilkin B.O., Makarov D.V. Wastewater treatment of the Lovozersky GOK LLC from fluorine ions by chemical coagulation. Trudy Fersmanovskoi nauchnoi sessii GI KNTs RAN. 2020. N 17, p. 297-301 (in Russian). DOI: 10.31241/FNS.2020.17.056

- Petrova T.A., Rudzisha E. Utilization of sewage sludge as an ameliorant for reclamation of technogenically disturbed lands. Journal of Mining Institute. 2021. Vol. 251, p. 767-776. DOI: 10.31897/PMI.2021.5.16

- Petrov D.S., Danilov A.S. Hydrochemistry and ecology of aquatic ecosystems in influence zones of mineral fertilizers production. Gornyi Zhurnal. 2023. N 9, p. 83-88 (in Russian). DOI: 10.17580/gzh.2023.09.12

- Moskoyani T.D., Vlasenko V.P. Reclamation of disturbed land on the example of a part of a land plot. Sovremennye problemy i perspektivy razvitiya zemelno-imushchestvennykh otnoshenii. Sbornik statei po materialam V Vserossiiskoi nauchno-prakticheskoi konferentsii, 20 April 2023, Krasnodar, Russia. Krasnodar: Kubanskii gosudarstvennyi agrarnyi universitet imeni I.T.Trubilina, 2023, p. 316-322 (in Russian).

- Shumilova L.V., Khatkova A.N., Razmakhnin K.K., Nomokonova T.T. Application of the best available technologies to improve environmental safety in the disposal of ash and slag waste. Transbaikal State University Journal. 2021. Vol. 28. N 8, p. 23-34 (in Russian). DOI: 10.21209/2227-9245-2022-28-8-23-34

- Pashkevich M.A., Patokin D.A. Nitrocellulose containing chemical industry waste for mineral resources complex facilities: directions of use. Mining Informational and Analytical Bulletin. 2023. N 9-1, p. 215-230 (in Russian). DOI: 10.25018/0236_1493_2023_91_0_215

- Yurak V.V., Usmanov A.I. Disturbed land restoration in mountain ecosystems. Sustainable Development of Mountain Territories. 2023. Vol. 15. N 4, p. 901-911 (in Russian). DOI: 10.21177/1998-4502-2023-15-4-901-911