Comprehensive utilization of urban wastewater sludge with production of technogenic soil

- 1 — Ph.D. Researcher Empress Catherine II Saint Petersburg Mining University ▪ Orcid ▪ Scopus

- 2 — Ph.D. General Director OOO NPK EcoDrive ▪ Orcid

- 3 — Ph.D. Associate Professor Empress Catherine II Saint Petersburg Mining University ▪ Orcid ▪ Scopus

- 4 — Researcher Empress Catherine II Saint Petersburg Mining University ▪ Orcid ▪ Scopus

Abstract

The article presents the analysis of the existing approach to wastewater sludge treatment and justifies the selection of the most promising management technology that allows maximum use of wastewater sludge resource po-tential. To obtain a useful product (biocompost) suitable for use as part of technogenic soil, experimental studies of aerobic stabilization of organic matter of dehydrated urban wastewater sludge with the addition of other waste by using passive composting technology were carried out. The technology is included in the list of best available technologies (BAT). The selection of the most optimal components for the mixture was based on the results of determining the C and N content, humidity and pH of the components used that ensured the composting of organic waste. The results of laboratory studies of the obtained biocompost according to the main agrochemical and sanitary-epidemiological indicators are presented. Testing was carried out according to the criterion of toxicity of the biocompost’s aqueous extract. The assessment of the technogenic soil was performed when using biocompost in its composition for compliance with existing hygienic requirements for soil quality in the Russian Federation. Based on the results of the vegetation experiment, optimal formulations of the technogenic soil were determined, i.e., the ratio of biocompost and sand, under which the most favorable conditions for plant growth are observed according to a combination of factors such as the number of germinated seeds, the maximum height of plants and the amount of biomass. The conducted research makes it possible to increase the proportion of recycled urban wastewater sludge in the future to obtain soils characterized by a high degree of nutrient availability for plants and potentially suitable for use in landscaping, the biological stage of reclamation of technogenically disturbed lands, as well as for growing herbaceous plants in open and protected soil.

Funding

The work was carried out as part of the state assignment of the Ministry of Science and Higher Education of the Russian Federation (FSRW-2024-0005)

Introduction

According to the officially published data based on the results of the last All-Russian Population Census in 2020, there is continued growth of the population combined with urbanization of society: between 2010 and 2020, the population increased by 1.4 % (147.2 million people), and 74.8 % of the total population of the Russian Federation are urban residents. (In 2010, the ratio of urban and urban the rural population was 73.5 and 26.5 %, respectively). The growth of the urban population, in turn, leads to an increase in the amount of the generated wastewater flowing to urban wastewater treatment plants. For example, the annual intake of water in Russia from natural water sources, including the water used for household needs, increased from 54523 million m3 to 56531 million m3 between 2020 and 2022.

Wastewater generated as a result of human economic and industrial activities enters wastewater treatment plants, where the process of removing mechanical impurities and pollutants using various technologies is organized, as well as further discharge or use of treated wastewater [1-3]. It should be noted that urban wastewater treatment plants often receive mixed wastewater instead of household wastewater in its pure form. It comprises a mixture of household, industrial and stormwater in various proportions. The composition of these waters has a wide range of insoluble and soluble pollutants [4, 5].

The classical wastewater treatment method includes the stages of mechanical, chemical, physicochemical and biological treatment, as well as measures for the treatment, neutralization and disposal of wastewater sludge. Mechanical cleaning is usually a preparatory stage and is used to remove insoluble impurities mainly using gratings, sand traps, grease traps, oil traps, etc., as well as settling tanks, where suspended solids settle under the influence of gravitational forces and light substances float to the surface [6, 7]. Chemical and physicochemical treatment ensures the removal of most pollutants and includes a variety of approaches, such as the addition of reagents for the deposition of pollutants, coagulation, flocculation, sorption, as well as ion exchange and reverse osmosis [8, 9]. Special attention has recently been paid to technologies using alternative sorbents that are effective from an environmental and economic point of view [10, 11]. The final stage is biological treatment, the essence of which is the mineralization of organic pollutants of wastewater in the form of finely dispersed undissolved and colloidal substances, as well as in a dissolved state, using aerobic biochemical processes [12-14].

The adoption of a particular treatment method depends on many factors and requires consideration depending on the specifics of the generated wastewater. For example, for industrial wastewater, the key stage is often chemical and physicochemical treatment aimed at removing dissolved chemical compounds and heavy metals. For urban wastewater treatment plants, it is biological treatment and disinfection, which is due to large amount of organic impurities in incoming household and sewage effluents.

Nevertheless, regardless of the adopted water treatment system, wastewater sludge occurs, which is a mixture of solid fractions of organic and mineral substances containing a significant number of pathogenic microorganisms and heavy metals formed during mechanical treatment, as well as excess activated sludge (a complex of microorganisms involved in the process of biological wastewater treatment and derived from the technological process) [15, 16]. According to data published on the portal on the practice of water supply and wastewater treatment of settlements and industry, in Russia the annual formation of wastewater sludge (by dry matter) is about 1.37-1.51 million tons, and the annual sludge from urban buildings with its average humidity of 96 % is more than 100 million m3, while the organic to mineral ratio is 80 : 20 [17, 18].

When handling wastewater sludge, there are two main stages: dehydration and further disposal of the dehydrated sludge. Dehydration is carried out by mechanical processing (filter pressing, centrifu-gation, vacuuming, filtration through geotubes, etc.) or in natural conditions on sludge pits [17, 19]. It should be noted that, despite the development and the introduction of mechanical dehydration technologies, sludge pits are still widely used today due to their ease of operation and low cost, however, this process is long-term and requires alienation of large territories. In addition, sludge pits are often overcrowded due to insufficient utilization of dehydrated sludge, which negatively affects the components of the environment due to the high content of pathogenic viruses and bacteria, gases and dangerous chemical compounds, including heavy metals [18, 19]. It is known that in Russia's million-plus cities alone there are more than 50 sludge pits with a total area of more than 1.5 thousand hectares. According to the state register of waste disposal facilities, the technology of sludge pits is used everywhere, regardless of natural and climatic conditions, including in the territories of the Arctic zones of the Russian Federation vulnerable to anthropogenic impact.

Concerning the methods of disposal of dehydrated wastewater sludge, it should be noted that the most common approaches today are heat treatment to obtain secondary waste in the form of solid residues that are further disposed of, and the production of fertilizers and soils [4, 16, 20].

Thermal disposal methods make it possible to neutralize sewage sludge against pathogenic viruses and bacteria. However, they lead to a concentration of non-volatile toxic substances, especially heavy metals, in solid residues, which limits the scope of their further application. In addition, these methods are associated with high economic costs [4]. Thus, the most common uses of solid residues in the form of combustion ash are the production of composite materials (concretes, asphalt concrete, expanded clay gravel, wall ceramics) [21, 22], and solid residues in the form of pyrolysis products are the production of carbonaceous materials (coal, semi-coke, or pyrocarbon) [23].

The development of technologies for obtaining fertilizers based on sewage sludge [24, 25] and soils [26, 27] is primarily due to the high content of organic substances in these wastes, which provides a supply of nutrients for plants. Unlike thermal recycling, the use of these technologies is cha-racterized by lower economic costs, minimal environmental consequences during implementation (there is no concentration of toxic compounds, including heavy metals), as well as the absence of secondary waste formation [4, 16]. It should also be noted that this approach makes rational use of the resource potential of sludge (as a fertile substrate for plants), which meets modern requirements for sustainable development in combination with the restoration of disturbed lands [28]. However, special attention should be paid to the sanitary and epidemiological assessment of the products obtained due to the presence of pathogenic microorganisms in urban wastewater sludge.

It thus becomes obvious that it is necessary to increase the options for the disposal of dehydrated urban wastewater sludge and intensify the processes of its introduction in order to avoid overflow of existing sludge pits and the need to alienate new territories for newly formed precipitation, which helps to minimize negative consequences for the components of the natural environment. At the same time, the purpose of this study is to obtain a product (technogenic soil) potentially suitable for use in greening of territories, the biological stage of reclamation of technogenically disturbed lands, as well as for growing herbaceous plants in open and protected soil.

Methods

To obtain a product containing urban wastewater sludge that would be safe in sanitary and epidemiological aspect, the technology of aerobic fermentation of organic matter of dehydrated sludge (passive composting) was selected, which is included in the list of the best available technolo-gies. According to some studies [29, 30] and regulatory documents, for the effective course of the composting process of organic waste, the following parameters must be observed:

- the optimal moisture content of the compostable material should be 60 %, but the process can also take place in the range from 40 to 70 %. With a moisture content above 70 %, the rate of organic de-composition decreases, anaerobic conditions are formed, and a putrid smell appears;

- the C/N ratio of the compostable material should be from 25 : 1 to 35 : 1. At a higher C/N ratio, the process speed decreases, and at a lower one, nitrogen loss occurs;

- the optimal pH levels of the compostable material range from 7.0 to 8.0. However, the composting process can also take place at a wider range of pH values (from 6.5 to 9.0 pH units).

The result of composting organic waste is a fermented mixture, which is a stabilized biocompost with a high nutrient content [31, 32]. Also, during the course of organic decomposition, the compostable material is self-heated (above 60 °C), which leads to the death of most pathogenic microorganisms dangerous to humans and plants, as well as weed seeds [29, 33].

Compliance with the optimal ranges of the parameters presented above was obtained by selecting the composition of the compostable mixture. The classical approach to obtaining fermented wastewater sludge consists in adding organic carbon-rich components (e.g. sawdust, straw, peat) during composting to compensate for the high nitrogen content in the sludge and obtain an optimal C/N ratio [26, 34, 35]. It should be noted that when selecting the composition of the compostable mixture in this study, the task was in organizing co-disposal of several types of waste, as well as choosing easily available additional materials for that, which is most effective from an environmental and economic point of view.

In addition to the selected classic and available components (sawdust and peat), the possibility of adding feed waste (residues of grain raw materials obtained during the cleaning of technological lines in the production of combined fodder) and soil waste during open excavation was considered. The availability of feed waste is due to the presence of 25 largest companies of the agro-industrial complex for the production of combined fodder in Russia with established logistics lines throughout the country, while recently there has been growth and development of this industry, including in the Arctic territories, which is associated with the intensification of the import substitution process. For example, in the Arkhangelsk region, abandoned lands are being developed for the cultivation of forage crops in order to further develop their own production of compound fodder. The advantage is that feed waste is characterized by a high content of organic carbon, nitrogen, protein, vitamins and trace elements, which makes it suitable for composting in order to obtain nutritious substrates for plants. The availability of soil waste is conditioned by the widespread carrying out of open excavations.

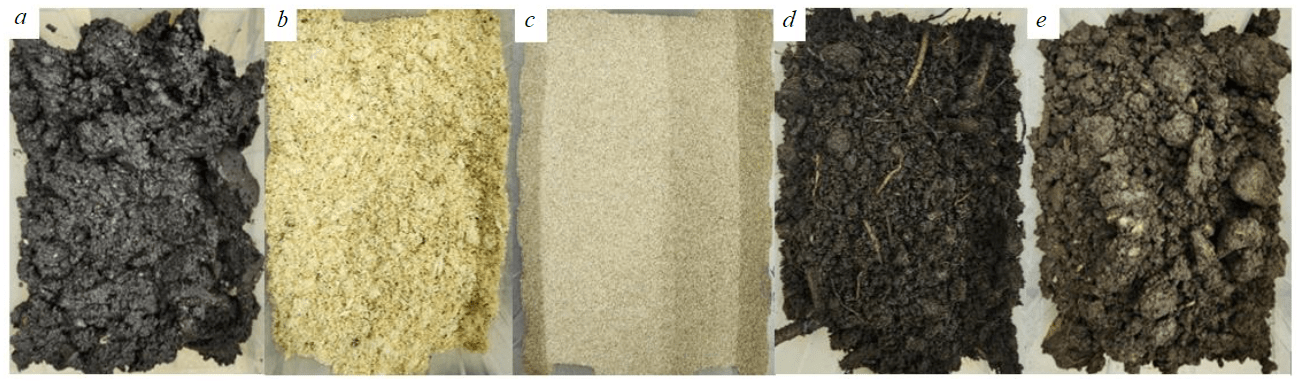

Thus, the following materials were used as components for the production of biocompost: wastewater sludge (waste from urban wastewater treatment plants from sludge pits), pure wood sawdust (waste from the woodworking industry), feed waste, peat and soil waste during open excavation. The appearance of the components is shown in Fig.1.

Fig.1. The appearance of the compostable mixture components: wastewater sludge (а), sawdust of pure wood (b), feed waste (c), peat (d), soil waste (е)

The ratio of components in the mixture to ensure the flow of the composting process was determined based on laboratory studies using the following indicators:

- humidity of the components (using the LECO TGA701 thermogravimetric analyzer in accordance with the user manual);

- carbon and nitrogen content in the components (using the LECO CHN-628C carbon, hydrogen, nitrogen analyzer in accordance with the user manual);

- actual and metabolic acidity – reaction of the medium (determination of the pH of the aqueous and salt extract from the components using the pH meter-ionomer Expert-001 in accordance with GOST 26423-85, GOST 26483-85, GOST 27979-88, GOST 11623-89).

The characteristics of the components according to the above indicators are presented in Table 1. The C and N contents are presented taking into account the moisture content of the components. It was found that with a mass ratio of components (wastewater sludge, sawdust of pure wood, feed waste, peat, soil waste) in the compostable mixture of 32.5 : 35 : 6.5 : 13 : 13, respectively, optimal conditions for the composting process are achieved: humidity – 61 %, C/N ratio – 25 : 1, the actual and metabolic acidity is 7.0 and 6.7 pH units, respectively. It has been established experimentally and computationally that with an increase in the proportion of sawdust of pure wood and/or peat, both the actual and metabolic acidity decreases (less than 6.5 pH units), while it is impossible to compensate for the pH level of the mixture by adding wastewater sludge, feed waste, and soil waste without reducing the C/N ratio beyond the optimal the range. With a decrease in the proportion of sawdust, the pH level is in the acceptable range. However, there is a need to reduce the proportion of wastewater sludge due to the high nitrogen content in them, which is impractical, since this type of waste is the main recyclable component.

Table 1

Characteristics of composting components according to the main indicators

|

Component |

C content, wt.% |

N content, wt.% |

C/N |

pHaq |

pHKCl |

Humidity, wt.% |

|

Wastewater sludge |

8.1 |

1.1 |

7:1 |

7.5 |

7.1 |

80 |

|

Pure wood sawdust |

26.1 |

0.02 |

1305:1 |

5.5 |

4.5 |

55 |

|

Feed waste |

41.5 |

2.3 |

18:1 |

8.0 |

7.5 |

13 |

|

Peat |

19.2 |

1.1 |

17:1 |

6.0 |

5.7 |

80 |

|

Soil waste |

3.7 |

0.3 |

12:1 |

7.0 |

6.1 |

35 |

The experimental clamp was laid on the territory of Saint Petersburg Mining University in the summer. The composting site was a fenced area protected from direct sunlight, intense wind load and precipitation (in order to avoid excessive evaporation of moisture and overmoistening of the compostable material). Preliminary preparation of the site was also carried out, which consisted in covering the place where the experimental clamp was laid with a layer of straw, which prevents premature cooling of the compostable material due to the relatively small volume (about 100 dm3).

The composting experiment lasted for 90 days to fully stabilize the biocompost. The compostable mixture was stirred occasionally (1 time every 10 days) in order to increase the air flow to eliminate the development of anaerobic processes. Also, temperature control inside the clamp was carried out using Thermochron portable loggers. Humidity control of the composted mixture was implemented by periodic sampling and using a MOS-120H moisture analyzer (in order to add water, if necessary, to maintain humidity at an optimal level of 60 %). The appearance of the experimental clamp in different time periods is shown in Fig.2.

After receiving the biocompost, its multifactorial assessment was carried out according to the main agrochemical and sanitary-epidemiological indicators, as well as testing according to the criterion of toxicity of aqueous extract. Laboratory studies of the biocompost and its quality assessment were carried out according to the relevant regulatory documents currently provided for soils, since on the basis of the resulting biocompost, the composition of technogenic soil was developed, the quality of which should meet modern environmental safety requirements.

Fig. 2. The appearance of an experienced clamp during the composting period

From the group of agrochemical indicators, the following laboratory studies were carried out in order to determine the fertility of the resulting product according to the degree of availability of nutrients (macronutrients) for plants:

- organic matter content (using the LECO TGA701 thermogravimetric analyzer in accordance with GOST 26213-2021);

- mineral nitrogen content – ammonium and nitrate (using the DR5000 spectrophotometer in accordance with GOST 26489-85 and GOST 26488-85);

- mobile phosphorus content (using the DR5000 spectrophotometer in accordance with GOST 54650-2011);

- exchangeable potassium content (using the Shimadzu AA-7000 atomic absorption spectrometer in accordance with GOST 54650-2011);

- actual and metabolic acidity – the reaction of the medium.

Laboratory studies were also conducted to determine the main indicators for assessing the sanitary and epidemiological condition in accordance with SanPiN 2.1.3684-21:

- content of gross forms of metals (mesoelements and trace elements), including heavy ones (using the Shimadzu AA-7000 atomic absorption spectrometer in accordance with M-MVI-80-2008);

- petroleum products content (using the liquid analyzer “Fluorat-02-3M” in accordance with PND F 16.1:2.21-98);

All of the above laboratory studies were carried out on the basis of the Scientific Center “Assessment of technogenic transformation of ecosystems” at Saint Petersburg Mining University. The study of the following sanitary and hygienic, bacteriological and parasitological indicators was carried out by the Federal State Budgetary Institution “Center for Hygiene and Epidemiology in Saint Petersburg and the Leningrad Region”:

- mass fraction of volatile phenols (in accordance with PND F 16.1:2.3:3.44-2005);

- cyanide content (in accordance with M 4-2017);

- coli-index of lactose-positive E. coli (in accordance with MUC 4.2.3695-21);

- coli-index of fecal enterococci (in accordance with MUC 4.2.3695-21);

- presence of pathogenic bacteria, including salmonella (in accordance with MUC 4.2.3695-21);

- presence of eggs and viable larvae of helminths (in accordance with MUC 4.2.2661-10, clause 4.2);

- presence of oocysts and cysts of intestinal pathogenic protozoa (in accordance with GOST R 57782, item 12);

- presence of larvae and pupae of synanthropic flies (in accordance with MU 2.1.7.2657-10,

paragraph III).

Additionally, testing was performed according to the toxicity criterion of the aqueous extract of the biocompost in accordance with PND F T 14.1:2:3:4.10-04 taking Chlorella vulgaris algae culture as a test object using a set of biotesting equipment: cultivator KV-05, multi-cell cultivator for algae KVM-05 and photoelectric colorimeter IPS-03.

The final stage of the laboratory research was the implementation of a vegetation experiment, which is the cultivation of plants in vessels filled with test and control substrates. At the same time, homogeneous conditions are provided (except for the studied factors), which eliminates accidental effects on plant growth and development. The value of vegetation experiments lies in the prompt receipt of information about the influence of various factors, which are selected depending on the objectives of the study [26, 36, 37].

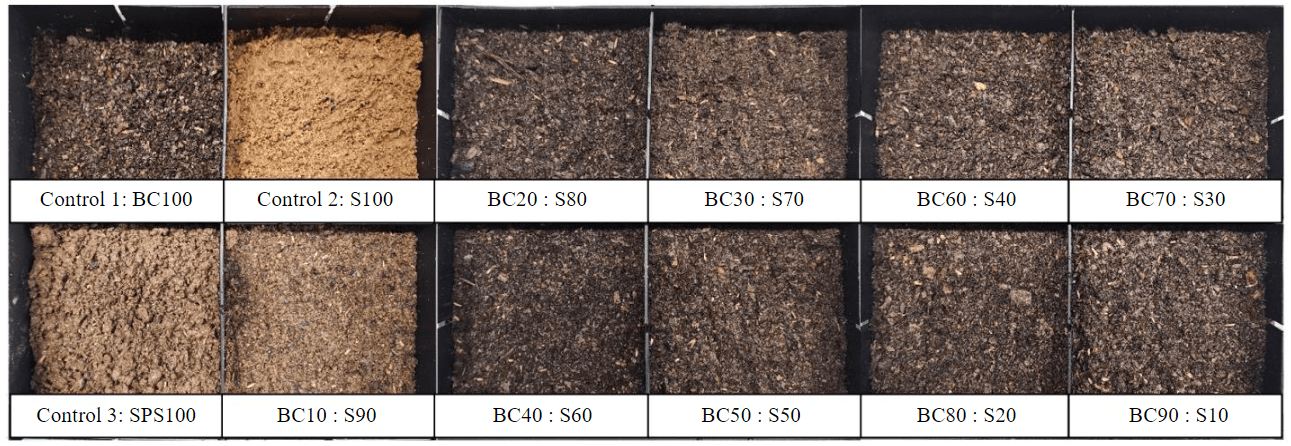

The main studied factor influencing the growth and development of plants was the composition of technogenic soil obtained by mixing biocompost with quartz sand in various mass ratios. Mixing of biocompost with sand in the production of technogenic soil is caused by the need to balance the mineral and organic parts (creation of a soil skeleton) to ensure optimal conditions for plant growth and development, while sand is chemically inert. It does not contain heavy metals, petroleum pro-ducts, nutrients, pathogenic microorganisms for humans and plants. The biocompost performs the function of a structure-forming agent when obtaining a ready-made technogenic soil: sand particles are packed into the pore space of the biocompost with stirring.

Before conducting the vegetation experiment, additional studies were conducted to determine the actual and metabolic acidity of the sand used in accordance with GOST 29234.6-91 and GOST 26483-85, as well as the volumetric (bulk) density of all prepared substrates in accordance with GOST 5180-84. The use of a standard for determining the exchange acidity in soils is due to the absence of an appropriate standard for sands.

During the experiment, lawn grass of the Lolium perenne family of grasses (perennial ryegrass) was used as a test object. The planting rate was determined according to the recommendations of the manufacturer of the seeds used. To create homogeneous growing conditions, the NLO 79-03-04 LD plant stand was used with the ability to adjust the power of LED phytolamps and the daily schedule, and the humidity of the substrates was maintained at 60 % of the total water capacity. Figure 3 shows the soil substrates studied during the vegetation experiment. Sod-podzolic soil, which is a subtype of podzolic soils common in the Leningrad region, was used as a control soil sample.

As a result of the vegetation experiment, results were obtained on seed germination (in percentage terms), as well as an assessment of the maximum height of lawn grass and the amount of its biomass. At the same time, the number of germinated seeds was determined on the 10th day of the experiment, which corresponds to the recommendations for determining the germination rate of pere-nnial ryegrass according to GOST 12038-84, and the maximum height of plants and the amount of biomass were estimated on the 21st day. The biomass was cut in an identical manner for all samples at a level of 2 cm from the surface.

Fig.3. Experimental substrates during the vegetation experiment

The figure corresponds to the mass fraction of the corresponding component in the substrate BC – biocompost, S – sand, SPS – sod-podzolic soil

Discussion of the results

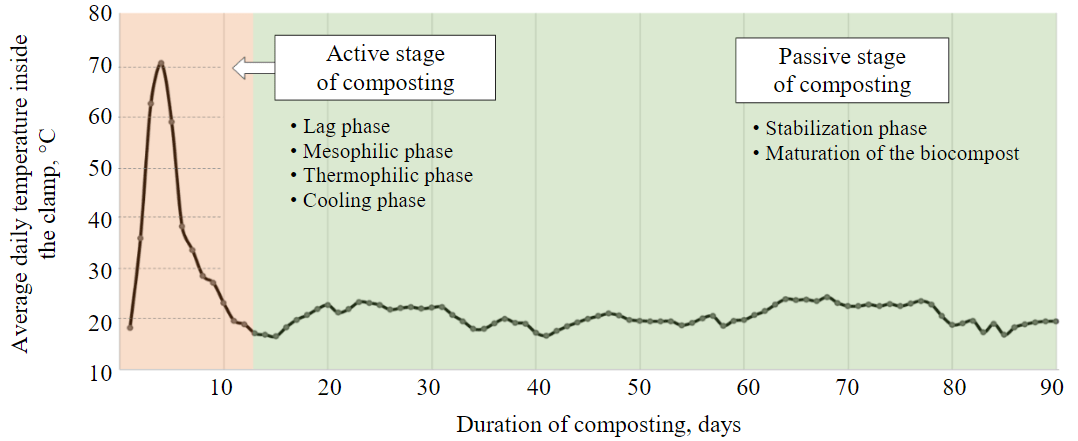

During the composting of the mixture using portable loggers, the moment when self-heating began (after 26-28 h) and the maximum temperature (on the 3rd day) were recorded, which was about 71 °C. That indicates the course of the process of thermal destruction of organic substances and the death of microorganisms pathogenic to humans and plants, as well as weed seeds. Figure 4 shows the change in the average daily temperature inside the experimental clamp and the composting stage. Minor fluctuations in the average daily temperature in the passive stage of composting are caused by fluctuations in atmospheric air temperature.

The finished biocompost is characterized by the absence of putrid, ammonia or hydrogen sulfide smell and has an earthy smell, which indicates the completion of the composting process. The results of determining the main agrochemical parameters of the finished biocompost: organic matter content 60 %; mineral nitrogen content (ammonium and nitrate) 145 mg/kg; mobile phosphorus content (in terms of P2O5) 3500 mg/kg; exchangeable potassium content (in terms of K2O) 1700 mg/kg; reaction of the medium (actual acidity) 7.3 pH unit, reaction of the medium (metabolic acidity) 6.8 pH unit. The biocompost has a very high supply of nutrients available to plants.

The results of determining the main sanitary and hygienic indicators of the finished biocompost are presented in Table 2. It was found that according to SanPiN 1.2.3685-21, there are no exceedances in the biocompost for any indicators for which the maximum permissible (MPC) or approximate permissible concentrations (APC) have been established to date, except for zinc. The ratio of the concentration of the element to APC was 1.2). However, this excess is neutralized by mixing the biocompost with sand when obtaining the final product (technogenic soil). There was also no excess in the content of petroleum products, the permissible level of which is 1000 mg/kg.

The results of determining the main bacteriological and parasitological parameters of the finished biocompost: lactose-positive E. coli (coli-forms)10 CFU/g; enterococci (fecal streptococci)10 CFU/g; pathogenic bacteria, including salmonella, eggs and larvae of helminths (viable), cysts of intestinal pathogenic protozoa, larvae and pupae of synanthropic flies – not detected. Based on the results obtained, it was found that according to MU 2.1.7.730-99, technogenic soil produced by mixing biocompost and sand belongs to the category of clean soils and can be used in the territories of recreation areas (parks, squares, etc.), sanitary protection zones of reservoirs, sanitary protection zones, etc.

Table 2

Characteristics of the biocompost according to the main sanitary and hygienic indicators (including the content of mesoelements and trace elements), mg/kg

|

Indicator |

Сi |

MPCi |

APCi |

C/MPC(APC) |

|

Zinc |

265 |

– |

220 |

1.2 |

|

Lead |

35 |

– |

130 |

0.3 |

|

Copper |

123 |

– |

132 |

0.9 |

|

Cadmium |

0.7 |

2.0 |

– |

0.4 |

|

Mercury |

Less than 0.02 |

2.1 |

– |

0.2 |

|

Manganese |

639 |

1500 |

– |

0.4 |

|

Molybdenum |

4.4 |

– |

– |

– |

|

Iron |

30900 |

– |

– |

– |

|

Aluminum |

48500 |

– |

– |

– |

|

Magnesium |

11200 |

– |

– |

– |

|

Calcium |

38700 |

– |

– |

– |

|

Petroleum products |

160 |

– |

– |

– |

|

Volatile phenols |

1.8 |

– |

– |

– |

|

Cyanides |

Less than 0.5 |

– |

– |

– |

Fig.4. Change in average daily temperature

When testing according to the toxicity criterion of an aqueous extract of a biocompost (biotesting using a culture of Chlorella vulgaris algae), it was found that there was no manifestation of toxicity. There was no decrease in the average optical density compared to the control variants by 20 % or more in the case of suppression of the growth of the test culture or its increase by 30 % or more in case of stimulation of the growth processes. The results of the bioassay are presented in Table 3.

Table 3

The results of bioassay of the aqueous extract of the biocompost

|

Sample number |

Dilution ratio |

Number |

D |

Daverage value |

I % |

Has/does not have an acute |

|

Control |

0 |

1 |

0.138 |

0.151 |

0 |

– |

|

2 |

0.152 |

|||||

|

3 |

0.156 |

|||||

|

4 |

0.158 |

|||||

|

1 |

1 |

1 |

0.195 |

0.188 |

–24.50 |

Does not have |

|

2 |

0.182 |

|||||

|

3 |

0.191 |

|||||

|

4 |

0.184 |

|||||

|

2 |

3 |

1 |

0.178 |

0.171 |

–13.25 |

Does not have |

|

2 |

0.169 |

|||||

|

3 |

0.170 |

|||||

|

4 |

0.167 |

|||||

|

3 |

9 |

1 |

0.171 |

0.162 |

–7.28 |

Does not have |

|

2 |

0.158 |

|||||

|

3 |

0.160 |

|||||

|

4 |

0.159 |

|||||

|

4 |

27 |

1 |

0.160 |

0.158 |

–4.64 |

Does not have |

|

2 |

0.147 |

|||||

|

3 |

0.166 |

|||||

|

4 |

0.159 |

|||||

|

5 |

81 |

1 |

0.149 |

0.153 |

–1.32 |

Does not have |

|

2 |

0.158 |

|||||

|

3 |

0.145 |

|||||

|

4 |

0.160 |

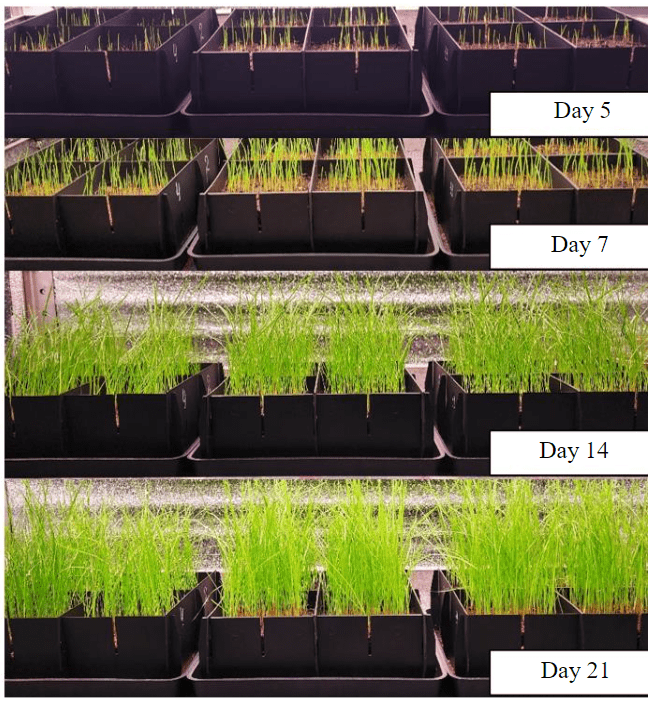

The vegetation experiment made it possible to evaluate the suitability of the obtained biocompost as a source of nutrients for plants in laboratory conditions and to determine the optimal ratios of biocompost and sand in technogenic soil. It should be noted that the first shoots of the test culture appeared on the 3rd day of the vegetation experiment already. Figure 5 summarizes the stages of biomass formation on experimental substrates during vegetation experiment.

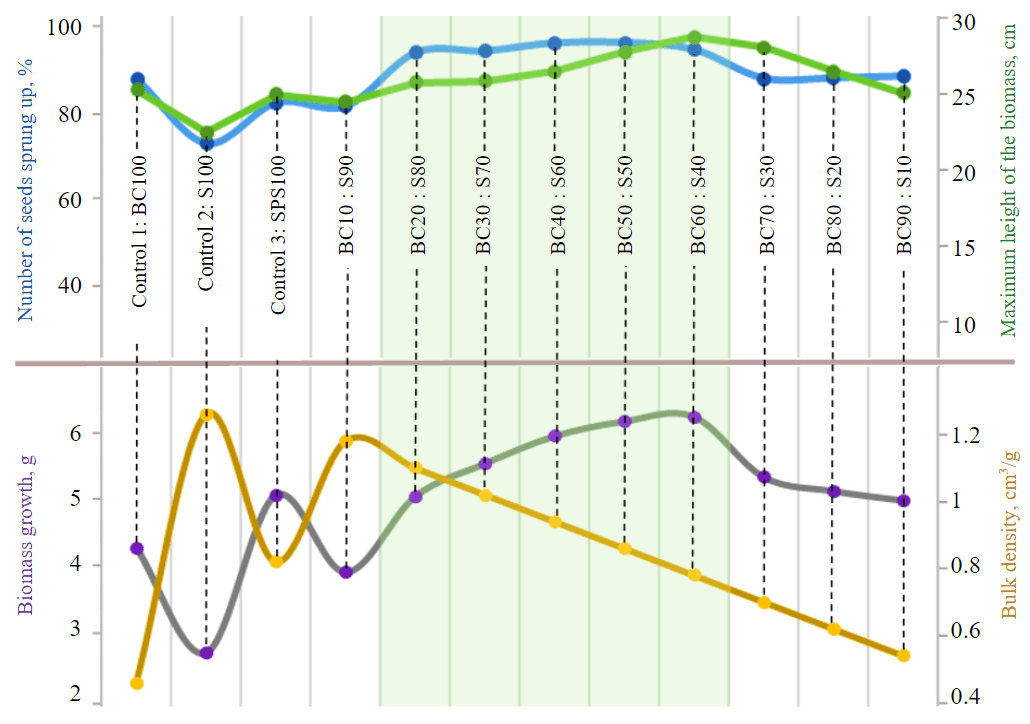

According to the obtained results of the vegetation experiment, optimal formulations of technogenic soil were identified, i.e. the ratio of biocompost and sand, in which the most favorable conditions for the growth of the test crop are observed based on the combination of all factors (Table 4, Fig.6). It should be noted that the actual and metabolic acidity of the sand used is 7.0 and 6.6 pH units, respectively. Therefore, the finished technogenic soil is neutral (pHKCl: more than 6.0 pH units) regardless of the ratio of biocompost and sand.

Fig.5. Stages of biomass formation on experimental samples of substrates for the entire period of the vegetation experiment

Thus, with a biocompost: sand mass ratio equal to (20-60) : (80-40), the following positive trends are observed: an increase in seed germination (over 95 %), the maximum height of lawn grass and the amount of its biomass compared with both control samples and samples with a higher or lower content of biocompost. These trends may be due to the influence of factors such as nutrient content and substrate density, both individually and in combination with each other. For example, with an increase in the biocompost content of more than 60 wt.% despite the increase in the amount of nutrients, there is a deterioration in the studied indicators, which may be due to a decrease in the density of substrates.

Table 4

The results of the vegetation experiment

|

Experimental substrate |

Number of seeds |

Maximum height |

Biomass amount, g |

Bulk density, cm3/g |

|

Control 1: BC100 |

89.1 |

25.3 |

4.31 |

0.46 |

|

Control 2: S100 |

74.6 |

22.5 |

2.74 |

1.26 |

|

Control 3: SPS100 |

83.8 |

25.0 |

5.09 |

0.82 |

|

BC10:S90 |

83.0 |

24.5 |

3.94 |

1.18 |

|

BC20 : S80 |

95.1 |

25.8 |

5.07 |

1.10 |

|

BC30 : S70 |

95.5 |

25.9 |

5.56 |

1.02 |

|

BC40 : S60 |

97.3 |

26.5 |

5.97 |

0.94 |

|

BC50 : S50 |

97.4 |

27.8 |

6.19 |

0.86 |

|

BC60 : S40 |

95.8 |

28.8 |

6.26 |

0.78 |

|

BC70 : S30 |

89.3 |

28.1 |

5.36 |

0.70 |

|

BC80 : S20 |

89.4 |

26.5 |

5.15 |

0.62 |

|

BC90 : S10 |

89.8 |

25.1 |

5.01 |

0.54 |

An insufficient amount of the mineral component (sand), which serves as the basis of the soil skeleton, critically affects the air and water regime, leads to violation of capillary bonds, leaching of macronutrients and trace elements, excessive evaporation of moisture, as well as instability in the formation of root systems.

With the biocompost content of less than 20 wt., in addition to reducing the amount of nutrients, substrate compaction can also play an important role. It complicates the formation of root systems, worsens the diet due to a decrease in the number of pores and capillary bonds, and impedes the circulation of soil air [38].

Fig.6. The results of the vegetation experiment

It has been experimentally established that the resulting technogenic soil can be stored in air-dry form, which greatly simplifies its transportation if necessary, and also eliminates the need to use insecticides, fungicides and/or preservatives. It is also possible to store and/or transport the biocompost separately with the further production of technogenic soil of the required composition directly at the site of its intended use, while available sandy soils can be used as a mineral part [38].

Conclusion

The conducted research and the presented results allow us to speak about the possibility of integrated utilization of urban wastewater sludge with sawdust of pure wood, feed waste, peat and soil waste. Moreover, the resulting useful product in the form of a biocompost is characte-rized by a high content of organic matter, nitrogen, phosphorus, and potassium in forms accessible to plants. When mixing biocompost with sand, optimal ratios are obtained, at which the most favorable conditions for the growth of herbaceous plants were revealed using the example of perennial ryegrass.

Increasing the options for recycling urban wastewater sludge will reduce the number of sludge pits, which in turn helps to reduce the negative impact on environmental components. However, it is important to take into account that, when implementing this method of disposal, it is necessary to monitor each batch of the resulting biocompost or the finished composition of technogenic soil according to sanitary, hygienic, bacteriological and parasitological indicators to confirm the safety of their use for various purposes in accordance with current regulatory documents.

To establish the suitability of using the resulting technogenic soil for a long-time during landscaping, the biological stage of reclamation of technogenically disturbed lands and the cultivation of herbaceous plants in closed or open ground conditions, it is advisable to conduct long-term vegetation experiments in laboratory conditions and pilot tests.

References

- Rui Du, Cong Li, Qingtao Liu et al. A review of enhanced municipal wastewater treatment through energy savings and carbon recovery to reduce discharge and CO2 footprint. Bioresource Technology. 2022. Vol. 364. N 128135. DOI: 10.1016/j.biortech.2022.128135

- Matveeva V.A., Alekseenko V.A., Karthe D., Puzanov A.V. Manganese Pollution in Mining-Influenced Rivers and Lakes: Current State and Forecast under Climate Change in the Russian Arctic. Water. 2022. Vol. 14. Iss. 7. N 1091. DOI: 10.3390/w14071091

- Mysin A.V., Kovalevskiy V.N., Kirkin A.P. Ensuring environmental safety of massive explosions in the combined development of coal deposits in Kuzbass. IOP Conference Series: Earth and Environmental Science. 2021. Vol. 848. N 012139. DOI: 10.1088/1755-1315/848/1/012139

- Kizgin A., Schmidt D., Joss A. et al. Application of biological early warning systems in wastewater treatment plants: Introducing a promising approach to monitor changing wastewater composition. Journal of Environmental Management. 2023. Vol. 347. N 119001. DOI: 10.1016/j.jenvman.2023.119001

- Matyushenko E.N. Phosphorus removal from return flows of a wastewater treatment plant. Water and Ecology: Problems and Solutions. 2019. N 2 (78), p. 40-49 (in Russian). DOI: 10.23968/2305-3488.2019.24.2.40-49

- Bilgin M., Yurtsever M., Karadagli F. Microplastic removal by aerated grit chambers versus settling tanks of a municipal wastewater treatment plant. Journal of Water Process Engineering. 2020. Vol. 38. N 101604. DOI: 10.1016/j.jwpe.2020.101604

- Kalachev D.A., Branner W. Mechanical treatment of wastewater. Water Supply and Sanitary Technique. 2021. N 12, p. 46-49 (in Russian). DOI: 10.35776/VST.2021.12.06

- Junaidi, Sudarno, Santoso R. Physical and Chemical Treatability Study in Wastewater Treatment Plant Design (Case Study: Leather Tanning Industry). IOP Conference Series: Earth and Environmental Science. 2023. Vol. 1268, N 012025. DOI: 10.1088/1755-1315/1268/1/012025

- Lasaki B.A., Sugio R., Maurer P., Schönberger H. Sustainable transformation: Unlocking energy positivity in municipal wastewater treatment through innovative advanced primary treatment configurations for maximum solids separation. Separation and Purification Technology. 2024. Vol. 342. N 127081. DOI: 10.1016/j.seppur.2024.127081

- Chukaeva M.A., Povarov V.G., Sverchkov I.P. Iron-Containing Metalworking Wastes as a Chemosorbent for Wastewater Treatment from Molybdenum Ions. Moscow University Chemistry Bulletin. 2020. Vol. 75. N 1, p. 36-42. DOI: 10.3103/S0027131420010058

- Cheremisina O., Litvinova T., Sergeev V. et al. Application of the Organic Waste-Based Sorbent for the Purification of Aqueous Solutions. Water. 2021. Vol. 13. Iss. 21. N 3101. DOI: 10.3390/w13213101

- Shihao Jia. Biological Treatment of Industrial Wastewater. Highlights in Science, Engineering and Technology. 2023. Vol. 69, p. 523-531. DOI: 10.54097/hset.v69i.12530

- Matveeva V.A., Bech J., Danilov А.S. Prospects of nitrogen removal from mine drainage by micro-algae in northern environments. Sustainable Development of Mountain Territories. 2023. Vol. 15. N 1, p. 134-142. DOI: 10.21177/1998-4502-2023-15-1-134-142

- Xiaojun Meng, Zhigui Huang, Guanghuan Ge. Upgrade and reconstruction of biological processes in municipal wastewater treatment plants. Desalination and Water Treatment. 2024. Vol. 317. N 100299. DOI: 10.1016/j.dwt.2024.100299

- Dubovets D.L. Waste management of wastewater sludge: main directions. Ekologiya na predpriyatii. 2023. N 5 (143), p. 27-35 (in Russian).

- Abdelfattah A., Ramadan H., Elsamahy T. et al. Multifaced features and sustainability of using pure oxygen in biological wastewater treatment: A review. Journal of Water Process Engineering. 2023. Vol. 53. N 103883. DOI: 10.1016/j.jwpe.2023.103883

- Valiev V.S., Ivanov D.V., Shagidullin R.R. Methods for urban wastewater sludge disposal (review). Russian Journalof Applied Ecology. 2020. N 4, p. 52-63 (in Russian). DOI: 10.24411/2411-7374-2020-10034

- Nasyrov I.A., Mavrin G.V., Shaikhiev I.G. Problems of utilization of sludge from wastewater treatment plants. Vestnik tekhnologicheskogo universiteta. 2015. Vol. 18. N 19, p. 257-259 (in Russian).

- Shashkin R.Yu. Modern sewage sludge treatment methods. Forum molodykh uchenykh. 2018. N 5/3 (21), p. 919-922(in Russian).

- Pashkevich M.A., Patokin D.A. Nitrocellulose containing chemical industry waste for mineral resources complex facilities: directions of use. Mining Informational and Analytical Bulletin. 2023. N 9-1, p. 215-230 (in Russian). DOI: 10.25018/0236_1493_2023_91_0_215

- Chulkova I.L., Smirnova O.E., Krasova A.V. Use of sewage sludge in concrete industry. The Russian Automobile and Highway Industry Journal. 2021. Vol. 18. N 5, p. 566-575 (in Russian). DOI: 10.26518/2071-7296-2021-18-5-566-575

- Litvinova T.E., Suchkov D.V. Lightweight ash-based concrete production as a promising way of technogenic product utilization (on the example of sewage treatment waste). Journal of Mining Institute. 2023. Vol. 264, p. 906-918.

- Kuzmina R.I., Kubasheva R.N., Kunasheva Z.K. Investigation of the properties of the solid residue of the pyrolysis of sewage sludge. Izvestiya of Saratov University. Chemistry. Biology. Ecology. 2023. Vol. 23. Iss. 3, p. 280-288 (in Russian). DOI: 10.18500/1816-9775-2023-23-3-280-288

- Kominko H., Gorazda K., Wzorek Z. Effect of sewage sludge-based fertilizers on biomass growth and heavy metal accumulation in plants. Journal of Environmental Management. 2022. Vol. 305. N 114417. DOI: 10.1016/j.jenvman.2021.114417

- Rudzish E.R., Petrova T.A. Application prospects for nonconventional improvers for vegetation cover in reclamation areas. Gornyi Zhurnal. 2023. N 9, p. 75-82 (in Russian). DOI: 10.17580/gzh.2023.09.1

- Kasatikov V.A., Shabardina N.P. Impact of soil based on municipal wastewater sedimentation on agrochemical pro-perties of soddy podzolic soil and yield of annual ryegrass. Vladimir agricolist. 2021. N 3 (97), p. 35-38 (in Russian). DOI: 10.24412/2225-2584-2021-3-35-38

- Smirnov Yu.D., Suchkov D.V., Danilov A.S., Goryunova T.V. Artificial soils for restoration of disturbed land productivity. Eurasian Mining. 2021. N 2, p. 92-96. DOI: 10.17580/em.2021.02.19

- Yurak V.V., Usmanov A.I. Disturbed land restoration in mountain ecosystems. Sustainable Development of Mountain Territories. 2023. Vol. 15. N 4, p. 901-911 (in Russian). DOI: 10.21177/1998-4502-2023-15-4-901-911

- Mironov V.V., Sedyh A.A., Mironov A.V., Paljutkin K.V. Biothermocomposting of organic waste. Journal of VNIIMZH. 2019. N 4 (36), p. 37-45 (in Russian).

- Sedyh A.A., Mironov V.V. To the question of the carbon – nitrogen ratio in straw-and-manure mixture at experiments designing. Journal of VNIIMZH. 2016. N 4 (24), p. 147-150 (in Russian).

- Malyukhin D.M., Bakina L.G., Mayachkina N.V. et al. Solid Waste Screening of SMW: Environmental, Chemical and Toxicological Characteristics Based on the Results of a Two-year Field Experiment. Ecology and Industry of Russia. 2023. Vol. 27. N 12, p. 62-68 (in Russian). DOI: 10.18412/1816-0395-2023-12-62-68

- Kovshov S.V. Effect of biohumus based on poultry waste on physico-chemical properties of sodpodzolic soils and cultivated plants. Sustainable Development of Mountain Territories. 2023. Vol. 15. N 2, p. 326-337 (in Russian). DOI: 10.21177/1998-4502-2023-15-2-326-337

- Mironov S.Yu., Protasova M.V., Protsenko E.P. et al. Technological directions for the processing of organic waste. Auditorium. 2017. N 1 (13). С. 30-42 (in Russian).

- Yashkina A.A., Fedorova O.A., Kirdishova E.A. The agrochemical properties of the composts based on the wastewater sludge with adding different fillings. Regional Environmental Issues. 2018. N 1, p. 45-49 (in Russian). DOI: 10.24411/1728-323X-2018-11045

- Singh A., Sawant M., Herlekar M. et al. Assessing feasibility of sewage sludge composting in rotary drum reactor. Bioresource Technology. 2024. Vol. 394. N 130219. DOI: 10.1016/j.biortech.2023.130219

- Chukaeva M.A., Pukhalsky Y.V., Loskutov, S.I. et al. Assessment of changes in the heavy-metal phytoextraction by Tagetes erecta from contaminated soils of Norilsk using humic additives. Arctic: Ecology and Economy. 2024. Vol. 14. N 1, p. 90-102 (in Russian). DOI: 10.25283/2223-4594-2024-1-90-102

- Khabarova T.V., Vinogradov D.V., Kochurov B.I. et al. Agroecological efficiency of sewage sludge and vermicompost in agrocenoses of cultivated oat. South of Russia: ecology, development. 2018. Vol. 13. N 2, p. 132-143 (in Russian). DOI: 10.18470/19921098-2018-2-132-143

- Sverchkov P., Bykova M.V., Smirnov Yu.D., Malyukhin D.M. Application for invention N 2024108705 of the Russian Federation. Technogenic soil. 02.04.2024 (in Russian).