Influence of technogenic brines on the strength characteristics of rocks in the productive strata of the Palashersky section of the Verkhnekamskoe potassium-magnesium salt deposit

- 1 — Head of Laboratory LLC ProTech Engineering ▪ Orcid

- 2 — Engineer LLC ProTech Engineering ▪ Orcid

- 3 — Ph.D., Dr.Sci. Professor Empress Catherine II Saint Petersburg Mining University ▪ Orcid

- 4 — Chief Specialist LLC ProTech Engineering ▪ Orcid

Abstract

The study examines the relationship between the weakening factors of the potassium-magnesium salt massif in the Palashersky section of the Verkhnekamsk deposit – specifically, the content of clay material in the form of halopelitic interlayers and the impact of technogenic brines on the strength characteristics of rocks in the productive strata during backfilling operations in mined-out areas. The results of laboratory studies on the influence of insoluble residue content and moisture on the strength properties of salt rocks are presented. Dependencies of changes in strength, moisture, and ultimate deformations on the duration of exposure to brines were established. Based on the test results, it was found that saturated brine does not significantly affect the compressive strength of sylvinite and rock salt but influences the intensity of deformability.

Introduction

At all active sections of the Verkhnekamsk potassium-magnesium salt deposit (VPMSD), a chamber mining system with the retention of rib pillars is employed. The geological structure of the deposit has been extensively studied by specialists N.M.Dzhinoridze and A.I.Kudryashov. General issues of potash salt mining at the Verkhnekamsk deposit were discussed in sources [1-5], where improving mining efficiency under conditions of compliance with safety measures was a key focus. Due to the presence of water-bearing horizons in the overlying strata and the need to maintain the integrity of the waterproofing layer [6], the primary task in determination of mining system parameters is calculating the load-bearing capacity of rib pillars. The high variability of factors affecting pillar stability (rock strength and granularity, fluctuations in layer depth and thickness, micro- and macro-folding, rheological properties of salts, rock moisture, and technogenic impacts such as hydraulic backfilling of mined-out voids) makes the selection of optimal mining parameters highly complex. The design of rib pillar widths during mine planning accounts for a weakened zone due to brine influence when designing hydraulic backfilling for specific sections. It is assumed that the width of the weakened edge zone of inter-chamber pillars should be 0.3 m [7].

Thus, accurately calculating the load-bearing capacity of inter-chamber pillars, which depends on the strength characteristics of the productive strata and roof rocks while considering multiple additional factors, is essential for determining mining parameters. Therefore, comprehensive studies of the physical-mechanical proper ties of salt rocks under various conditions and the influence of diverse factors – such as structural-textural features, stress-strain state, environmental conditions, and interaction with natural and technogenic brines of varying saturation levels [8-12] – are critical. Data from such studies are actively used in complex analyses, geological-lithological rock typing, and deposit modeling. Methods based on integrated geophysical and geomechanical approaches are proposed in sources [9, 13-15]. Many studies focus on rock behavior under specific factors. A methodology for laboratory studies of salt deformation under volumetric multistage loading is presented in the work of I.L.Pankov and I.A.Morozov [16].

During backfilling, moisture enters the mined-out voids, condenses on walls, and accumulates in depressions. The volume of brines interacting with the rock depends on the backfilling method and type. Brine impact on salt rock can be divided into two types: leaching and moistening. The first type depends directly on brine temperature and composition and occurs when the brine is unsaturated with the salts it contacts. The second type involves changes in the physical and mechanical properties of rocks due to increased moisture. The prerequisites for deviations in rock strength parameters during moistening due to adsorption processes were formulated by P.A.Rehbinder. The Rehbinder effect – adsorption-induced strength reduction – arises from the physicochemical influence of the environment, reducing the specific free surface energy of the body, which facilitates the formation of new surfaces during deformation and failure. This effect is only possible under the combined influence of the medium and a specific stress state [17-19]. During failure, liquid atoms penetrate the crack initiation zone and interact at the moment of bond rupture or rearrangement. Adsorption can either enhance damage or inhibit it – experiments measuring forces show both the disruption of interatomic interactions at crack tips and the slowing of failure due to new force bond formation [17, 20].

It was on ionic crystals, including rock salt, that P.A.Rebinder established and investigated the phenomenon of adsorption strength reduction. In salt polycrystals, grain boundaries, possessing excess free energy and in the absence of environmental influence, become the primary path for crack propagation. In the presence of such influence, they serve as adsorption sites for surface-active impurities during crystal growth from solution or diffusion [21].

A review of research on adsorption processes in natural salts was conducted by Z.N.Skvortsova [22]. According to [23, 24], the yield strength and compressive strength of rock salt and sylvinite samples decrease in the presence of a saturated salt solution. Experiments [25, 26] describe the merging of halite lenses along contacts in the presence of brine.

The presence of liquid layers along grain boundaries alters the elastic, rheological, and strength properties of rocks. These inclusions likely contribute significantly to elastic wave attenuation and serve as mass transfer pathways during dissolution-reprecipitation [19].

In their studies, V.G.Zilberschmidt, V.V.Zilberschmidt, and O.B.Naymark noted an increase in rock moisture after prolonged exposure (9-15 days) to brines before testing. A “moisture – uniaxial compressive strength” relationship was established based on studies of rocks from the central part of the VPMSD. According to the data, a 0.7-0.9 % increase in moisture reduces the compressive strength of salt rocks by 25-45 %. However, the study does not provide the dynamics of sample moisture change over brine exposure time, making it impossible to assess the rate and nature of moisture absorption by salt samples during the experiment [27].

In laboratory studies by B.A.Borzakovsky and L.M.Papulov samples with a diameter of 43 mm were used, and moistening occurred through contact with clay-salt slurry. The experiments showed that sample moisture initially increases and then stabilizes. Significant moisture fluctuations within and between batches were noted: 0.05-0.58 % over 0.5 months, 0.59-1.16 % over 1.5 months, and 0.22-1.05 % over 6-8 months. Additionally, an experiment with cubic monoliths (0.2 m edge length) placed in slurry under mine conditions was conducted. Over five years, moisture reached 0.36 %, with monolith moisture generally lower than that of 43 mm diameter samples. The absence of strength reduction in samples after prolonged moistening was attributed to possible crack healing effects upon contact with saturated brine.

Another characteristic feature of the VPMSD is the significant variability in the geological-lithological structure of the entire strata from the central to peripheral areas due to internal salt tectonics, geological history, and sedimentation features. For example, due to continuous clastic input from the eastern basin shore throughout salt sedimentation, insoluble residue content increases in the southeastern direction. In sylvinite layers, this is expressed as the appearance of new and increased thickness of existing seasonal and perennial clay interlayers. Halopelites contain minerals such as anhydrite, quartz, potassium feldspar, carbonates, and clay minerals (primarily chlorite and illite). The clay mineral content in insoluble residues varies spatially and increases upward in the section: 19.5 % for the layer above KrII, rising to 34.6 % above layer AB, and reaching 41.5 % above layer B [28].

In the study [29] on the typification of salt rocks at the Verkhnekamsk deposit, the determination of sylvinite content in petrographic thin sections was rejected due to sedimentation features creating complex layered textures in the massif. Instead, chemical composition analysis was used to evaluate the distribution of each element, including insoluble residue, which is also a component of lithological typification.

Analysis of the research results [30-33] highlights the significant influence of interlayers and inclusions of foreign material in salt strata on the strength and deformation properties of the massif, as well as the nature of sample deformation and failure. Clay material in salt rocks exists in various forms: as inclusions in crystals, in intergranular spaces, or as halopelitic interlayers of consistent or inconsistent thickness. The form of clay material determines the degree of strength reduction in the sample. According to sources [34, 35], dispersed clay and discrete inclusions do not affect mechanical properties, whereas the presence of clay chains or interlayers reduces strength by 24-34 % on average. The geometry of interlayers – their position in the sample, consistency, inclination angle, and contact type with salt – also significantly influences property changes. N.M.Proskuryakov et al. recorded a 30 % strength reduction when clay content increased from 1 to 3 %. Study [32] also emphasizes the weakening effect of insoluble residue (I.R.) on the strength parameters of halogenic rocks.

The primary objectives of this study on the influence of technogenic brines on the strength characteristics of these structures are to measure the natural moisture content of each rock type, determine their tendency to absorb water from brines, and establish trends in strength changes.

Previous research on this topic primarily evaluated the influence of moisture or clay interlayers on the strength characteristics of salt rocks. This study presents a comparative analysis of the simultaneous impact of both factors. The research was conducted for a mine field section where salt rocks interacted with technogenic brines during backfilling operations.

Methods

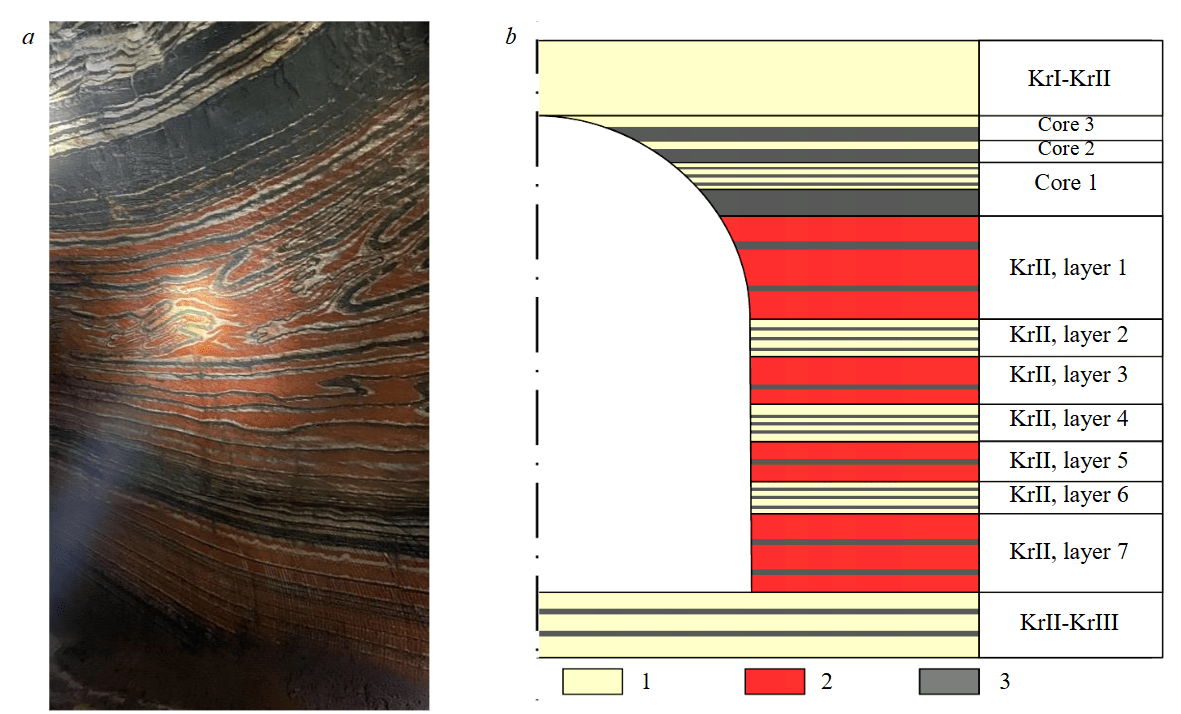

The Palashersky section is located in the southern part of the deposit. Its eastern and southeastern areas are characterized by increased clay content in the KrII layer, ranging from 8 to 18 %, compared to the average 3-5 % in the central part of the deposit. The productive strata's balance reserves consist of alternating layers of sylvinite ore and rock salt, systematically separated by halopelitic interlayers. The average thickness of clay interlayers varies from a few millimeters to 2-3 cm, except for the core part of the KrI-KrII layer, where halopelitic deposits reach 0.5-0.6 m (Fig.1). Due to high clay content, diverse forms of its distribution, and location within the strata, the physical-mechanical properties of rocks are heterogeneous even within conventionally uniform layers.

Fig.1. Photo of the excavation wall (а) and a typical section of the productive strata of the industrial KrII layer (b) for the 1st Southeastern panel of the Palashersky section

1 – rock salt; 2 – sylvinite; 3 – clay

For experimental studies, salt rock samples collected from the section were used. Cylindrical samples were prepared using a lathe, with auxiliary sample processing performed on a stone-cutting machine. After side surface treatment, the ends were ground to achieve the required dimensions, determined based on the height-to-diameter ratio h/d = 2.0, and a diameter exceeding ten times the grain size at the end. Accordingly, all prepared samples had the following dimensions: h = 84.00±0.10 mm, d = 42.00±0.10 mm. The samples were required to be free of natural or technogenic disturbances and visually consistent in composition, structure, and texture. Samples were grouped by lithotype, layer, and visual consistency to form representative sets. All tests were conducted at 24-25 °C without air mass transfer. For each sample, the uniaxial compressive strength (σ) was determined under automatic loading at a rate of 1 MPa/s, with dry friction at the sample-platen contact. Additionally, moisture content W was measured by drying to constant mass, and chemical composition was analyzed.

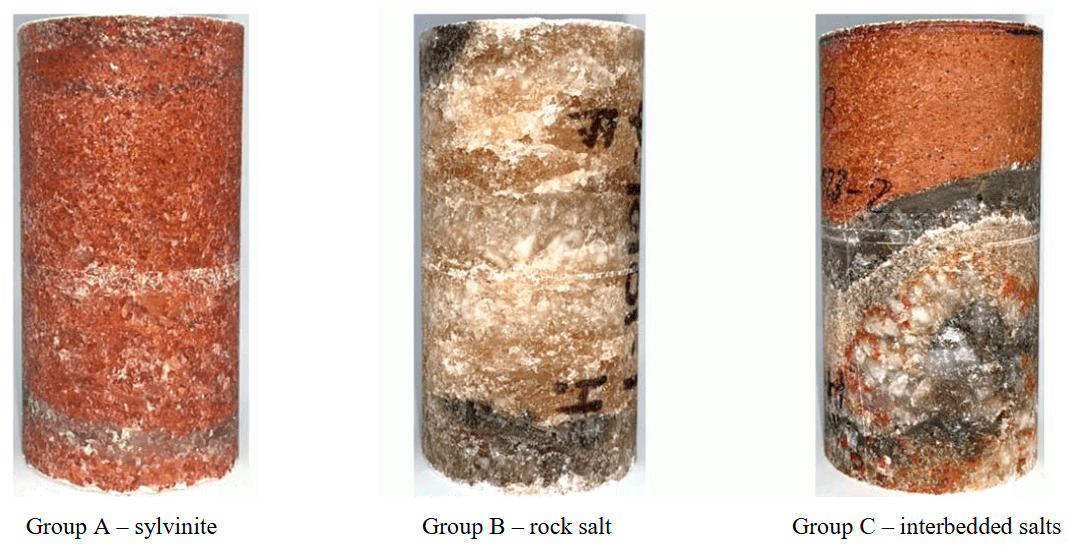

Fig.2. Types of samples used to determine physical-mechanical characteristics

The study was divided into two stages. The first stage examined the influence of moisture and insoluble residue content on rock strength under uniaxial compression. The second stage compared the deformation of salt rocks after exposure to brine.

Influence of clay content on salt rock moisture. To establish the relationship between rock moisture and clay content, 69 samples with varying clay content were prepared, including pure clay samples (i.e., clay interlayers without sylvinite or rock salt inclusions) collected interlayer “Core 1” of the KrII-KrI rock salt in the southeastern part of the mine field of LLC EuroChem Usolskiy, located at the edge of the VPMSD. Due to the inability to extract halopelitic material by coring, samples of this lithological composition are typically represented by lumps. For each sample, compressive strength, moisture content, and chemical composition were determined to quantify insoluble residue content.

Dependence of rock strength on brine contact duration. To determine moisture changes in samples of varying composition after exposure to potassium- and sodium-saturated brine, the experiment was designed as follows. Samples were divided into three groups: Group A included 37 sylvinite samples without visible clay inclusions and 37 rock salt samples; Group B comprised 38 rock salt samples without formed clay interlayers or nests; Group C consisted of 20 mixed-type salt samples characterized by interbedded layers of rock salt and sylvinite with clay interlayers. Typical samples from each group are shown in Fig.2. Within the groups, samples were further divided into four subgroups based on brine exposure duration: 1, 7, and 14 days (based on prior research). Test results included uniaxial compressive strength, deformations at the point of ultimate strength (ultimate deformations δult), and final moisture content for each sample. Uniaxial compressive strength is defined as the maximum uniaxial compressive stress at which sample failure occurs. The relative deformation at ultimate strength corresponds to the ultimate deformation.

Prepared samples were placed in cylindrical containers for brine exposure. Although the brines were saturated with NaCl and undersaturated with KCl, no significant dissolution of potassium grains with cavity formation was observed.

For samples pre-exposed to brine, testing was conducted immediately after extraction. Before testing, surface moisture was removed to ensure dry contact with the platen.

Correlation dependencies of moisture and insoluble residue effects on mechanical properties were plotted. The Pearson correlation coefficient was used to assess variable relationships.

Research Results

The study identified dependencies between the moisture content of salt rocks and clay content based on laboratory tests of 69 salt rock samples with varying clay content and clay samples subjected to uniaxial compression.

It was found that the average compressive strength of rock salt samples with I.R. content < 3 % is 24.37 MPa, while for sylvinite, it is 27.19 MPa.

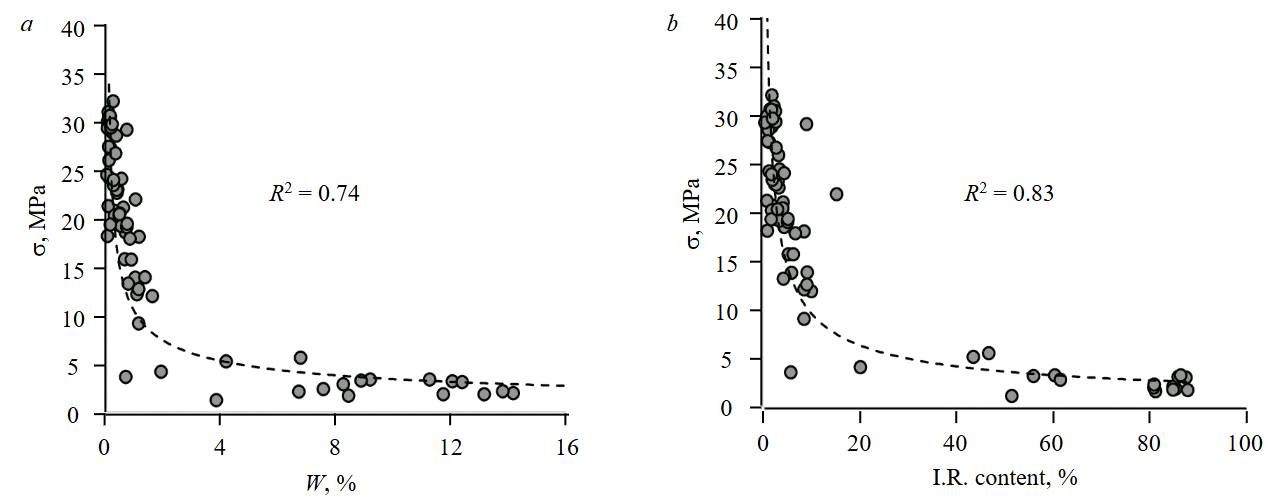

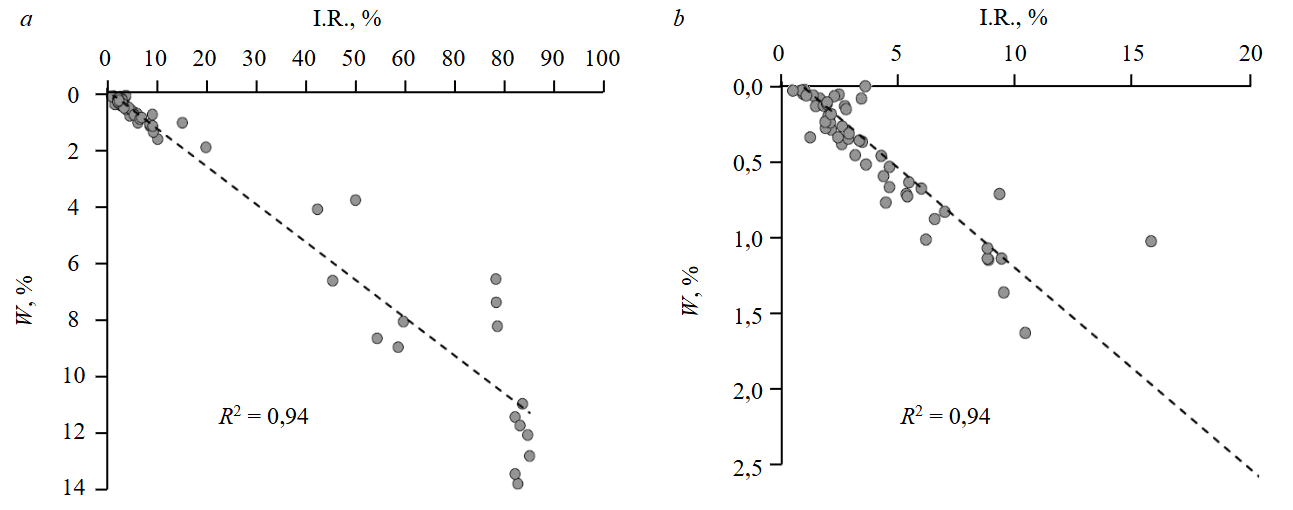

Based on the analysis of compressive strength, moisture content, and chemical composition, dependencies of strength changes on moisture and insoluble residue content were established (Fig.3), presented in a combined form by normalizing relative strength to the average value for rock salt and sylvinite. This approach does not provide precise dependencies for each lithotype but generalizes data regarding the influence of each factor. The graph of strength versus insoluble residue content shows value concentrations in the ranges of 0-10 %, 40-60 %, and 80-90 % I.R. The formation of stable, thick halopelitic interlayers at 10-40 % I.R. significantly complicates sample collection and preparation.

A power function was chosen for approximation. The Pearson correlation coefficient is higher for the strength versus insoluble residue dependency, suggesting that strength and sample moisture are indirectly related.

To determine the dependency of rock strength on brine contact duration, 95 tests on sylvinite, rock salt, and interbedded salts of varying types were analyzed. Numerical results for each subgroup are presented in the table.

Fig.3. Dependencies of uniaxial compressive strength on moisture (а) and insoluble residue content (b)

Average values of physical-mechanical properties of halogenic rocks at different brine exposure durations

|

Rock type |

Parameter |

No soaking |

Brine exposure duration |

|||

|

1 day |

7 day |

14 day |

||||

|

Sylvinite |

σ, МПа |

28,86 / 21,20-32,36 (15 pc.) |

27,02 / 21,97-31,90 (7 pc.) |

30,03 / 27,56-32,68 (7 pc.) |

30,47 / 26,31 - 35,14 (8 pc.) |

|

|

εпр, % |

2,66 / 1,65-3,93 (15 pc.) |

3,41 / 2,25-4,35 (7 pc.) |

3,45 / 2,27-4,38 (7 pc.) |

3,89 / 3,22-5,35 (8 pc.) |

||

|

W, % |

0,14 / 0,04-0,34 (6 pc.) |

0,06 / 0,03-0,13 (7 pc.) |

0,11 / 0,04-0,18 (7 pc.) |

0,04 / 0,00-0,08 (8 pc.) |

||

|

Rock Salt |

σ, МПа |

22,54 / 18,44 - 33,91 (15 pc.) |

23,72 / 18,82-28,46 (8 pc.) |

24,60 / 19,46 - 32,04 (9 pc.) |

23,59 / 17,86 - 24,42 (6 pc.) |

|

|

εпр, % |

1,43 / 0,87 - 2,21(15 pc.) |

2,10 / 1,24 - 3,05 (8 pc.) |

2,23 / 1,47 -2,55 (9 pc.) |

2,18 / 1,73 - 2,72 (6 pc.) |

||

|

W, % |

0,40 / 0,09-0,59 (10 pc.) |

0,24 / 0,02 -0,45 (8 pc.) |

0,30 / 0,17 - 0,51 (9 pc.) |

0,27 / 0,08-0,43 (6 pc.) |

||

|

Interbedded Salts |

σ, МПа |

17,98 / 13,83 - 21,46 (8 pc.) |

13,28 / 11,60 - 15,23 (8 pc.) |

12,90 / 12,82 - 12,98 (2 pc.) |

12,60 / 9,51 - 14,90 (5 pc.) |

|

|

εпр, % |

1,02 / 0,63 - 1,74 (8 pc.) |

1,50 / 0,89-2,24 (8 pc.) |

1,45 / 1,36 - 1,54 (2 pc.) |

1,65 / 0,98 - 2,20 (5 pc.) |

||

|

W, % |

0,87 / 0,49 - 1,56 (8 pc.) |

1,15 / 0,94 - 1,64 (8 pc.) |

1,16 / 1,16 - 1,16 (2 pc.) |

1,43 / 1,11-1,90 (5 pc.) |

||

Note.Numerator – average value; denominator – range of parameter variation.

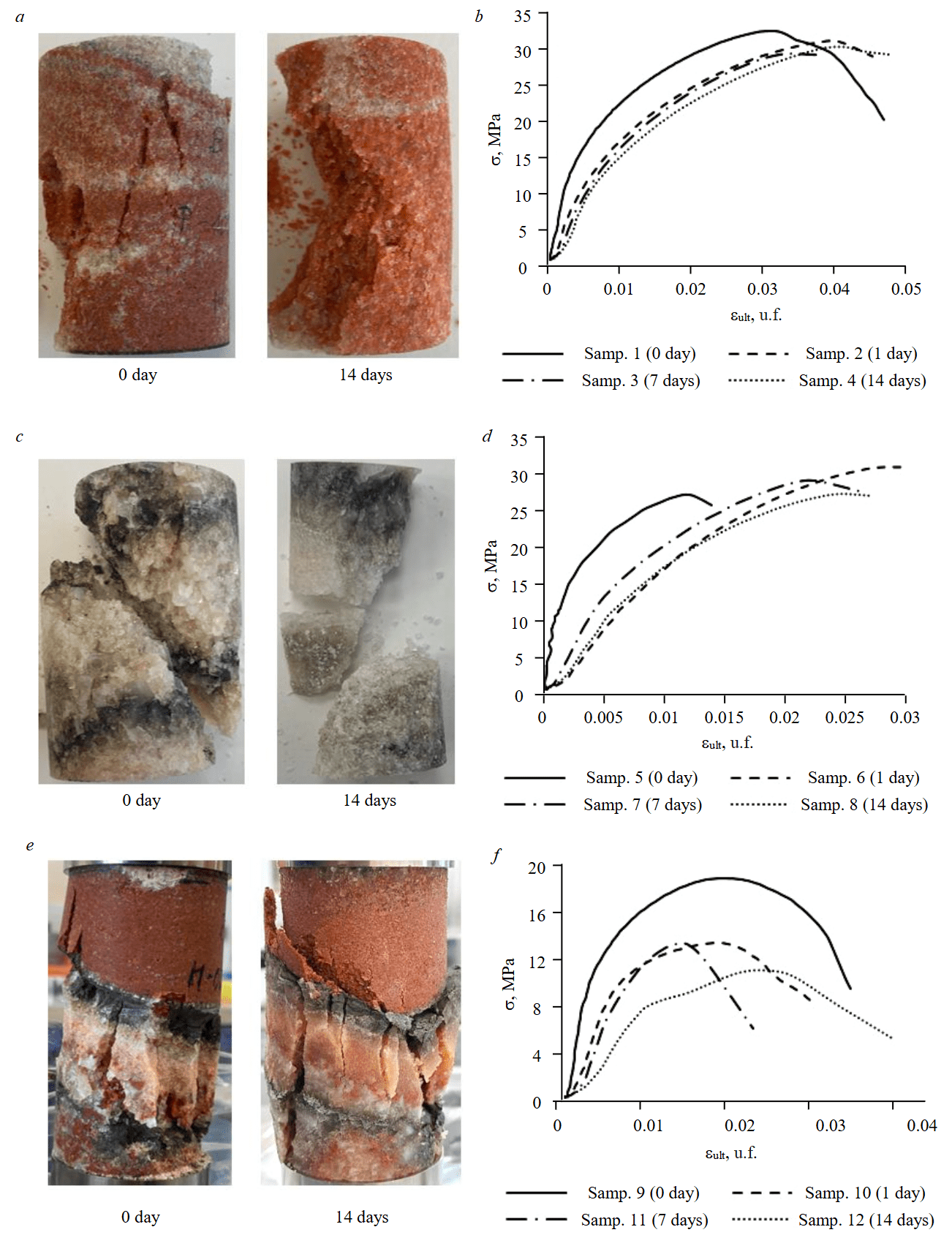

Characteristic failure modes of samples from each group under natural moisture (no brine exposure) and after 14-day brine exposure are shown in Fig.4, a, c, e. The typical outcome of uniaxial compression for rock samples with a height-to-diameter ratio of 2:1 and friction at the sample-platen contact is failure along a conical surface, formed by shear along planes of maximum tangential stress in the sample [7]. For both sylvinite and rock salt under natural conditions, failure does not always occur along cones; it may follow diagonal cracks or a combined pattern – with one cone and a crack. After 14-day brine exposure, the failure configuration under instantaneous loading at ultimate strength does not change.

A different pattern is observed for samples with distinct clay interlayers. In the central part of multilayered monoliths composed of rock salt interlayers, subvertical shear cracks form, evolving into tensile cracks due to the separation of stiffer salt along clay interlayers. Under increasing load, interlayers deform first, while the rock above and below the interlayers experiences both vertical axis loading and tangential stresses in the weakening plane, accelerating failure and reducing strength. In such samples, material fragmentation along weakening zones is noticeable, while cracks in the salt portion of the sample are subvertical, without crystal fragmentation along crack walls. No fundamental difference in failure patterns between naturally moist and brine-exposed samples was observed.

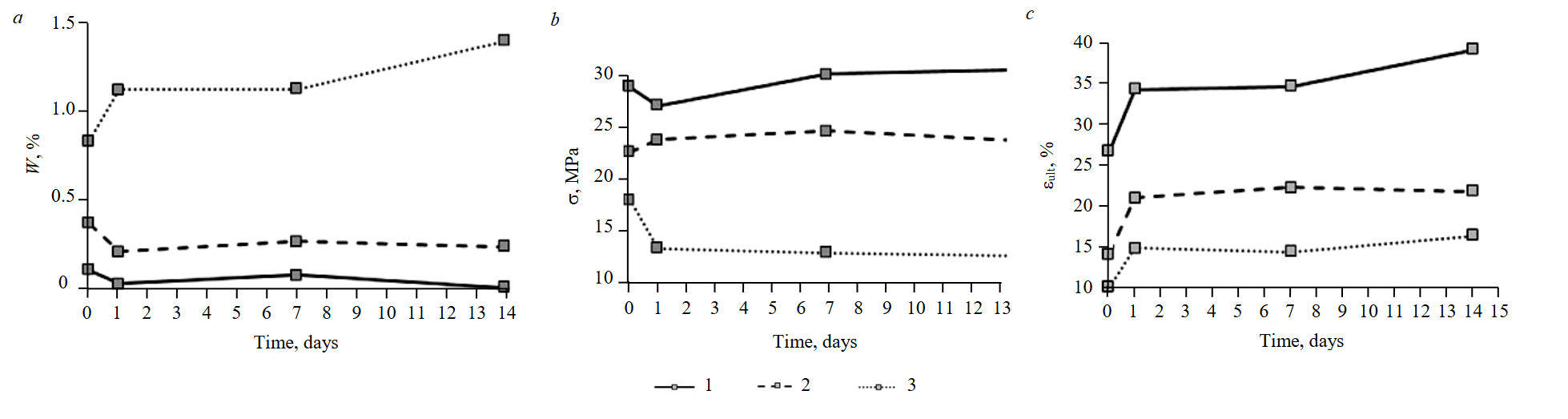

Analysis of uniaxial compression tests on sylvinite showed that under natural moisture, its average compressive strength is 28.86 MPa; after 1-day brine exposure, 27.02 MPa; and after 14-day exposure, 30.47 MPa. These strength values are in the natural variation range (10-15 %), suggesting minimal influence of soaking duration on sylvinite strength. Conversely, for ultimate deformation, soaking time has a noticeable effect, with deformation increasing with brine exposure duration (Fig.4, b).

Fig.4. Characteristic failure modes of samples before and after soaking and deformation curves for different brine exposure durations: a,b – sylvinite (Group A); c, d – rock salt (Group B); e, f – interbedded salts (Group C)

A similar analysis was conducted for rock salt. Under natural moisture, the average compressive strength is 22.54 MPa; after 1-day brine exposure, 23.72 MPa; and after 14-day exposure, 23.59 MPa. These values are in the natural variation range, indicating no significant influence of soaking duration on rock salt strength. However, like sylvinite, ultimate deformation increases with brine exposure – deformation curves shift left along the OX axis (Fig.4, d).

Both sylvinite and rock salt exhibit more brittle failure after brine exposure, manifesting as instantaneous failure at ultimate strength, often accompanied by fragment scattering and the opening of radial deformation sensor fixtures attached to the sample.

Unlike pure salt rocks, mixed-composition samples show strength reduction within the first day of brine exposure (17.98 MPa under natural moisture vs. 13.28 MPa after 1 day), with no further significant changes. No clear increase in relative deformations was observed, so deformation curves do not shift along the deformation axis (Fig.4, f).

Discussion of Research Results

Based on prior research, an increase in rock moisture after prolonged exposure to saturated brine was expected. However, as test results show, neither sylvinite nor rock salt samples without visible clay inclusions exhibited significant moisture changes (fluctuations relative to average values were < 0.1 % for sylvinite and < 0.2 % for rock salt). Moisture increase in samples occurred due to halopelite absorption. The average moisture of samples with clay interlayers increased from 0.66 % (no soaking) to 1.24 % after 14-day brine exposure, with individual samples reaching nearly 3 %, depending on interlayer thickness, configuration, composition, and natural moisture. Notably, maximum moisture absorption occurred within the first day, with no significant further increase. Significant deviations from the general moisture trend primarily occurred in samples with high insoluble residue content. This effect may be attributed to initially more moisture-saturated clay samples being more susceptible to external factors during collection, transportation, and preparation.

Fig.5. Dependency of sample moisture on clay content across the full range of I.R. (а) and for 0-20 % I.R. 0-20 % (b)

The obtained dependencies of strength on moisture and insoluble residue content are similar, and the correlation between rock moisture and clay content is high (correlation coefficient 0.94, Fig.5). Thus, a hypothesis of a linear relationship between insoluble residue content and rock moisture can be proposed. Salt, in the absence of discontinuities, is a low-porosity rock, making significant moisture absorption from brine unlikely. In contrast, halopelitic interlayers, which include active clay minerals, readily absorb moisture when exposed to liquid. For assessing instantaneous strength and deformation characteristics of salt rocks, evaluating dependencies on insoluble residue content is more accurate, as moisture is a derivative characteristic.

As shown in Fig.6, the uniaxial compressive strength for “sylvinite” and “rock salt” sample groups, regardless of brine exposure duration, fluctuates within 6.4 and 9.1 %, respectively, relative to control group averages. Conversely, “interbedded salt” samples with clay interlayers exhibited a 26.2 % strength reduction within the first day of brine exposure (from 17.98 to 13.28 MPa), with no further significant changes – strength reduction after 14-day exposure was 29.9 %.

Fig.6. Changes in moisture (a), strength (b), and ultimate deformation (c) over brine exposure duration

1 – sylvinite; 2 – rock salt; 3 – interbedded salts with halopelites

After brine exposure, the deformation behavior of sylvinite and rock salt changes – ultimate deformation increases, and brittle failure tendency rises, making it impossible to obtain stress-deformation curves beyond ultimate strength for brine-exposed samples without clay. A hypothesis regarding brine influence on deformation characteristics of salt rocks can be proposed. Further detailed studies, including long-term tests to determine the extent of this factor's influence on salt rock rheological properties, are needed.

Conclusion

The study presents laboratory results on the strength of salt rock samples with varying moisture content. Key findings include:

- Rocks composing the industrial layer (sylvinite and rock salt with clay interlayers) exhibit varying natural moisture levels, with halopelite moisture significantly higher. The study confirmed that higher insoluble residue content correlates with increased salt rock moisture. No moisture changes were observed in samples without visible halopelitic inclusions after exposure to saturated brine. The strength-moisture relationship should be considered indirect; further studies should focus on “strength – insoluble residue content” dependencies.

- Saturated brine over 14 days does not significantly affect the compressive strength of sylvinite and pure rock salt but alters their deformation behavior, suggesting a notable influence of brines on long-term strength properties of salts. Further detailed studies are needed to assess massif behavior at each stage of brine contact.

- Brine exposure reduces the strength of rocks with distinct clay accumulations or interlayers by 29.9 %, a critical factor in mining planning.

Given the complexity of the environment and its numerous components, accurate calculations of rib pillar load-bearing capacity should account for both individual weakening factors and their combined effects. Clay content – insoluble residue percentage, distribution type, concentration form, and interlayer thickness – significantly impacts massif strength. Additionally, halopelites are most susceptible to moistening, making clay interlayers the primary focus for studying weakened zones in rib pillars interacting with brines.

References

- Baryakh A.A., Smirnov E.V., Kvitkin S.Y., Tenison L.O. Russian potash industry: Issues of rational and safe mining. Russian Mining Industry. 2022. N 1, p. 41-50 (in Russian). DOI: 10.30686/1609-9192-2022-1-41-50

- Zubov V.P., Kovalski E.R., Antonov S.V., Pachgin V.V. Improving the safety of mines in developing Verkhnekamsk potassium and magnesium salts. Mining Informational and Analytical Bulletin. 2019. N 5, p. 22-33 (in Russian). DOI: 10.25018/0236-1493-2019-05-0-22-33

- Litvinenko V. Advancement of geomechanics and geodynamics at the mineral ore mining and underground space development. EUROROCK2018: Geomechanics and Geodynamics of Rock Masses: Proceedings of the 2018 European Rock Mechanics Symposium, 22-26 May 2018, Saint Petersburg, Russia. CRC Press, 2018. Vol. 1, p. 3-16. DOI: 10.1201/9780429462078

- Dzhinoridze N.M. Upper Kama deposit of lower permian potash-magnesium salts; peculiarities of halogenesis, tectonic development and mineral transformation. Prace Panstwowego Instytutu Geologicznego. 1997. N 157. Part 3, p. 69-70.

- Kovalski E.R., Kongar-Syuryun Ch.B., Petrov D.N. Challenges and prospects for several-stage stoping in potash minining. Sustainable Development of Mountain Territories. 2023. Vol. 15. N 2 (56), p. 349-364 (in Russian). DOI: 10.21177/1998-4502-2023-15-2-349-364

- Belyakov N.A., Belikov A.A. Prediction of the integrity of the water-protective stratum at the Verkhnekamskoye potash ore deposit. Mining Informational and Analytical Bulletin. 2022. N 6-2, p. 33-46 (in Russian). DOI: 10.25018/0236_1493_2022_62_0_33

- Basov I.G., Luzgin Yu.N. On determining rock strength under uniaxial compression. Izvestiya Tomskogo ordena Trudovogo Krasnogo Znameni politekhnicheskogo instituta im. S.M.Kirova. 1968. Vol. 158, p. 62-67 (in Russian).

- Ilinov M.D., Korshunov V.A., Pospekhov G.B., Shokov A.N. Integrated experimental research of mechanical properties of rocks: Problems and solutions. Gornyi zhurnal. 2023. N 5, p. 11-18 (in Russian). DOI: 10.17580/gzh.2023.05.02

- Kovalski E.R., Gromtsev K.V., Petrov D.N. Modeling deformation of rib pillars during backfill. Mining Informational and Analytical Bulletin. 2020. N 9, p. 87-101 (in Russian). DOI: 10.25018/0236-1493-2020-9-0-87-101

- Kuranov A.D., Bagautdinov I.I., Kotikov D.A., Zuev B.Yu. Integrated approach to safety pillar stability in slice mining in the Yakovlevo deposit. Gornyi zhurnal. 2020. N 1, p. 115-119 (in Russian). DOI: 10.17580/gzh.2020.01.23

- Liang W., Yang C., Zhao Y. et al. Experimental investigation of mechanical properties of bedded salt rock. International Journal of Rock Mechanics and Mining Sciences. 2007. Vol. 44. Iss. 3, p. 400-411. DOI: 10.1016/j.ijrmms.2006.09.007

- Gospodarikov A.P., Kirkin A.P., Trofimov A.V., Kovalevsky V.N. Determination of physical and mechanical properties of rocks using anti-burst destress measures. Gornyi zhurnal. 2023. N 1, p. 26-34 (in Russian). DOI: 10.17580/gzh.2023.01.04

- Belikov A.A., Belyakov N.A. Method of predicting the stress-strain state of interchamber pillars lined with a compliant rope fastener. Mining Informational and Analytical Bulletin. 2023. N 4, p. 20-34. DOI: 10.25018/0236_1493_2023_4_0_20

- Rybak J., Khayrutdinov M.M., Kuziev D.A. et al. Prediction of the geomechanical state of the rock masswhenmining salt deposits with stowing. Journal of Mining Institute. 2022. Vol. 253, p. 61-70. DOI: 10.31897/PMI.2022.2

- Ilyinov M.D., Petrov D.N., Karmanskiy D.A., Selikhov A.A. Physical simulation aspects of structural changes in rock samples under thermobaric conditions at great depths. Mining Science and Technology. 2023. Vol. 8. N 4, p. 290-302. DOI: 10.17073/2500-0632-2023-09-150

- Pankov I.L., Morozov I.A. Salt Rock Deformation under Bulk Multiple-Stage Loading. Journal of Mining Institute. 2019. Vol. 239, p. 510-519. DOI: 10.31897/PMI.2019.5.510

- Schukin E.D. Influence of the active environment on the mechanical stability and damageability of the surface firm body. Vestnik Moskovskogo universiteta. Seriya 2. Khimiya. 2012. Vol. 53. N 1, p. 50-72 (in Russian).

- Rebinder P.A., Shchukin E.D. Surface phenomena in solids during the course of their deformation and failure. Soviet Physics Uspekhi. 1973. Vol. 15. N 5, p. 3-42. DOI: 10.1070/PU1973v015n05ABEH005002

- Traskin V.Yu. Rehbinder Effect in Tectonophysics. Izvestiya, Physics of the Solid Earth. 2009. Vol. 45. N 11, p. 952-963. DOI: 10.1134/S1069351309110032

- Kornev V.M. Quantitative description of the Rehbinder effect (brittle and quasi-brittle solids): from fracture retardation to spontaneous dispersion. Fizicheskaya mezomekhanika. 2003. Vol. 6. N 3, p. 9-18 (in Russian).

- Malkin A.I. Regularities and mechanisms of the Rehbinder’s effect. Colloid Journal. 2012. Vol. 74. N 2, p. 223-238. DOI: 10.1134/S1061933X12020068

- Skvortsova Z.N. Deformation by the Mechanism of Dissolution–Reprecipitation as a Form of Adsorption Plasticization of Natural Salts. Colloid Journal. 2004. Vol. 66. N 1, p. 1-10. DOI: 10.1023/B:COLL.0000015048.05161.0b

- Stavrogin A.N. Studies of rheological soils. Leningrad: Ehnergiya, 1968. Iss. 38, p. 44-46 (in Russian).

- Urai J.L., Spiers C.J., Zwart H.J., Lister G.S. Weakening of rock salt by water during long-term creep. Nature. 1986. Vol. 324. Iss. 6097, p. 554-557. DOI: 10.1038/324554a0

- Hickman S.H., Evans B. Kinetics of pressure solution at halite-silica interfaces and intergranular clay films. Journal of Geophysical Research: Solid Earth. 1995. Vol. 100. Iss. B7, p. 13113-13132. DOI: 10.1029/95JB00911

- Hickman S.H., Evans B. Experimental pressure solution in halite: the effect of grain/interphase boundary structure. Journal of the Geological Society. 1991. Vol. 148. N 3, p. 549-560. DOI: 10.1144/gsjgs.148.3.0549

- Borzakovskii B.A., Shilov A.V. Salt leaching processes during flooding of the BKPRU-1 mine. Mining Informational and Analytical Bulletin. 2010. N 9. p. 136-143 (in Russian).

- Moloshtanova N.E. The mineral composition of the insoluble residue of halopelites from the “cores” of the Verkhnekamskoye deposit. Geologiya i poleznye iskopaemye Zapadnogo Urala. 2011. N 11, p. 49-50 (in Russian).

- Chaikovskii I.I. Chemical and genetic typification of primary salt rocks of the Verkhnekamskoye deposit. Gornoe ehkho. 2020. N 1, p. 27-31 (in Russian). DOI: 10.7242/echo.2020.1.6

- McBeck J., Mair K., Renard F. Linking macroscopic failure with micromechanical processes in layered rocks: How layer orientation and roughness control macroscopic behavior. Tectonophysics. 2019. Vol. 750, p. 229-242. DOI: 10.1016/j.tecto.2018.11.016

- Tijani M., Hadj-Hassen F., Rouabhi A. et al. Effect of insoluble materials on salt behavior during creep tests. Mechanical Behavior of Salt VII: Proceedings of the 7th Conference on the Mechanical Behavior of Salt, 16-19 April 2012, Paris, France. CRC Press, 2012, p. 97-103. DOI: 10.1201/b12041

- Yinping Li, Wei Liu, Chunhe Yang, Daemen J.J.K. Experimental investigation of mechanical behavior of bedded rock salt containing inclined interlayer. International Journal of Rock Mechanics and Mining Sciences. 2014. Vol. 69, p. 39-49. DOI: 10.1016/j.ijrmms.2014.03.006

- Basalaeva P.V., Kuranov A.D. Influence of dip angle of lithologically nonuniform interburden on horizontal mine opening stability during driving. Mining Informational and Analytical Bulletin. 2024. N 3, p. 17-30 (in Russian). DOI: 10.25018/0236_1493_2024_3_0_17

- Kablinov O.S., Chaikovskii I.I. On the effect of the form of separation of clay material on the strength of rock salt. Gornoe ehkho. 2021. N 2 (83). p. 3-6 (in Russian).

- Chaikovskii I.I., Kablinov O.S. On the geological causes affecting the strength of salt samples from the Verkhnekamskoye deposit. Strategy and Processes of Mastering of Georesource: Materials of annual scientific session of Mining Institute of Ural Branch of the Russian Academy of Sciences, 20-24 April 2009. Perm: Mining Institute of Ural Branch of the Russian Academy of Sciences, 2009, p. 5-7 (in Russian).