Study of the composition and properties of the beneficiation tailings of currently produced loparite ores

- 1 — Junior Researcher Laboratory of Nature-Inspired Technologies and Environmental Safety of the Arctic ▪ Orcid

- 2 — Junior Researcher Laboratory of Nature-Inspired Techno-logies and Environmental Safety of the Arctic ▪ Orcid

- 3 — Researcher Geological Institute, Kola Science Centre of the RAS ▪ Orcid

- 4 — Engineer of the 1st Category I.V.Tananaev Institute of Chemistry and Technology of Rare Elements and Mineral Raw Materials, Kola Science Centre of the RAS

- 5 — Ph.D. Head of Centre Institute of North Industrial Ecology Problems, Kola Science Centre of the RAS ▪ Orcid

- 6 — Ph.D., Dr.Sci. Chief Researcher Institute of North Industrial Ecology Problems, Kola Science Centre of the RAS ▪ Orcid

- 7 — Ph.D., Dr.Sci. Director Institute of North Industrial Ecology Problems, Kola Science Centre of the RAS ▪ Orcid

Abstract

The increase in demand for rare earth metals and the depletion of natural resources inevitably causes the need to search for alternative unconventional sources of rare metal raw materials. The article presents the results of a study of the composition and properties of the beneficiation tailings of currently produced loparite ores. Sieve, mineralogical, chemical, and radionuclide analyses were carried out. The average content of loparite in tailings was determined. Using scanning electron microscopy, minerals-concentrators of rare earth elements in the loparite ore beneficiation tailings were diagnosed. The distribution of valuable components and thorium in the tailings was determined depending on the particle size class. The radium-thorium nature of radioactivity was established, the values of the effective specific activity of the samples were calculated. We concluded that it is necessary to develop an integrated technology for processing the beneficiation tailings of loparite ore, due to the complex and heterogeneous mineral and chemical composition of the tailings material.

Introduction

Rare earth elements (REE) are widely used in high technology as a raw material for the production of superconductors, automotive catalytic converters, camera and telescope lenses, powerful magnets used in computer technology and the production of wind turbines, X-ray scanning systems and many other industries [1, 2]. Obtaining rare-metal raw materials is mainly based on the processing of complex ores with small dissemination of valuable components. The application of widely used magnetic and gravity separation at the first stages of beneficiation cannot ensure the complete extraction of heavy minerals, which leads to significant losses of valuable components with tailings [3, 4].

The depletion of the raw material base, the insufficient efficiency of existing beneficiation circuits, and the dynamics of supply and demand in the world metal markets increase interest in the search for unconventional and alternative sources of rare metal raw materials [5]. In recent years, the possibility of extracting REE from permanent magnets, fluorescent lamps, and electronics waste has been actively explored [6-8]. A large number of works are devoted to the processing of industrial waste: metallurgical production – phosphogypsum, bauxite residue (red mud), metallurgical slag and industrial and processing residues from thermal treatment facilities (coal ash, ash from waste incine-ration plants), wastewater from mining enterprises [4, 9-12].

The development of technologies for the extraction of rare earth elements from tailings of rare metal ore beneficiation has a number of advantages: processing of tailings can be carried out on the basis of the existing infrastructure using part of the equipment installed at the dressing plants, the need for crushing large pieces of ore is eliminated, which makes it possible to reduce grinding costs. As is known, grinding and classification of ore by size classes using mills and crushers is a significant part of the cost in ore processing circuits [13-15].

In addition to the significant energy and material consumption during production, waste from the beneficiation of ores containing REE can have a significant impact on the biosphere [16]. Stored solid mineral wastes are a source of serious pollution in the atmosphere, soils, surface and ground waters with a wide range of pollutants [17-19] due to dusting of loose dumps and tailings and migration of soluble forms of pollutants with natural waters [20, 21]. Special attention is drawn to storage facilities for wastes of rare metal ores due to the content of radioactive thorium in the tailings, which isomorphically replaces rare earth elements.

Thus, the involvement of final tailings in processing with the extraction of rare earth minerals can become a way to obtain a valuable commercial product, while simultaneously reducing the environmental hazard. The purpose of the work was to substantiate the prospects for the development of technology for the additional extraction of rare earth elements from the beneficiation tailings of currently produced loparite ores.

Methodology

The only enterprise in Russia that develops a deposit of loparite ores is in the central Kola Peninsula. At the mine, ore is extracted and beneficiated to obtain loparite concentrate. Beneficiation of loparite ores occurs in three stages: gravity separation, flotation recleaning, electromagnetic and electrostatic separation. The total accumulated volume of loparite ore tailings reaches 18 Mt with an annual increment of about 400-450 Kt, the average content of loparite varies from 0.64 to 0.96 % [22].

As previously noted, the differentiation of tailings material by particle size and material composition occurs already at the stage of storage [23], therefore, for this study, samples of tailings were taken from the sump at the dressing plant.

The particle size distribution in the tailings was determined using a Shimadzu SALD 201V laser particle size analyser. Samples were analysed in accordance with the international standard ISO 13320-1:1999 “Particle size analysis – Laser diffraction methods”. The silicate and mineralogical analyses were carried out in accredited laboratories of JSC “Kola Geological Information Analytical Centre” according to the established methods.

The qualitative composition of the samples was diagnosed by X-ray phase analysis (DRON-2.0 diffractometer, CuKa radiation, PDF2 database) and scanning electron microscopy (SEM LEO-420 (Carl Zeiss), Aztec Oxford Instruments system) at the Geological Institute of the Kola Science Centre of the Russian Academy of Sciences.

The content of light rare earth elements in the tailings was determined by inductively coupled plasma mass spectrometry at the Centre for Collective Use of the Institute of North Industrial Ecology Problems, Kola Science Centre of the Russian Academy of Sciences (ELAN 9000, PerkinElmer, USA). An average sample of tailings and samples sieved on sieves with a mesh size of 0.071, 0.1, 0.25, and 0.5 mm were submitted for analysis.

Radionuclide analysis using a scintillation γ-spectrometer with the “Progress” software was carried out for an average sample of tailings, finely dispersed material, and sieved fraction of +0.071 mm at the I.V.Tananaev Institute of Chemistry and Technology of Rare Elements and Mineral Raw Materials, Kola Science Centre of the Russian Academy of Sciences. The values of the specific activities of 226Ra, 232Th and 40K in tailings samples were calculated in accordance with GOST 30108-94 “Construction materials and products. Determination of specific effective activity of natural radionuclides”.

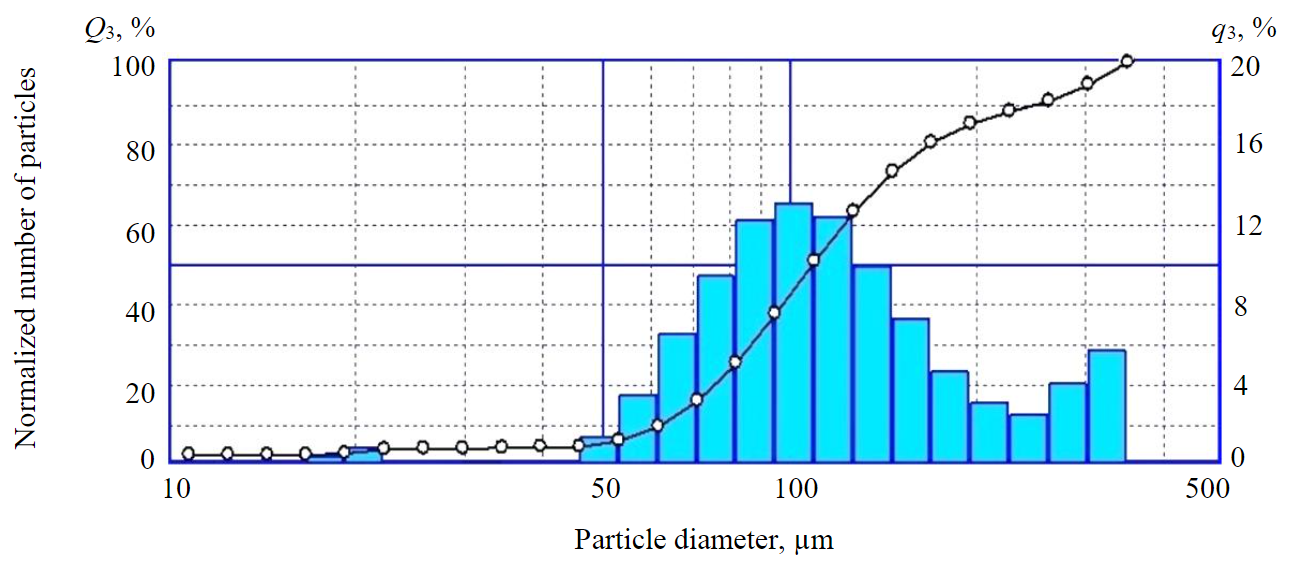

Fig.1. Particle size composition of the beneficiation tailings of currently produced loparite ores

Discussion of the results

Graphical results of the analysed particle size composition of the bene-ficiation tailings of currently produced loparite ores are shown in Fig.1.

According to the lithological classification, tailings belong to fine and medium-grained sands, the predominant fractions are 0.05-0.1 and 0.1-0.25 mm.

Chemical composition of the tailings in the current production, wt.%: SiO2 – 48.53, ТiO2 – 1.35, Al2O3 – 22.40, Fe2O3 – 5.12, FeO – 0.66, MnO – 0.25, CaO – 1.42, MgO – 0.38, K2O – 4.24, Na2O – 13.43, P2O5 – 0.68, SrO – 0.35, F – 0.08, SO3 – 0.11.

In the tailings, the predominant minerals are nepheline (Na,K)AlSiO4 (62.2 %), feldspars (Na,K)AlSi3O8 (16.5 %), and aegirine NaFe3+(Si2O6) (18.7 %). Apatite Ca10(PO4)6(OH, F, Cl)2 (1.03 %), lomonosovite Na10Ti4(Si2O7)2(PO4)2O4 (0.19 %), sodalite Na4Si3Fl3O12Cl (0.17 %), and lamprophyllite (Sr, Ba)2(Na, Ti)4Ti2O(Si2O7)2(O, OH, F)2 (0.15 %) were also found. The average content of loparite (Na, Ce, Ca, Sr, Th)(Ti, Nb, Fe)O3 was 0.98 %.

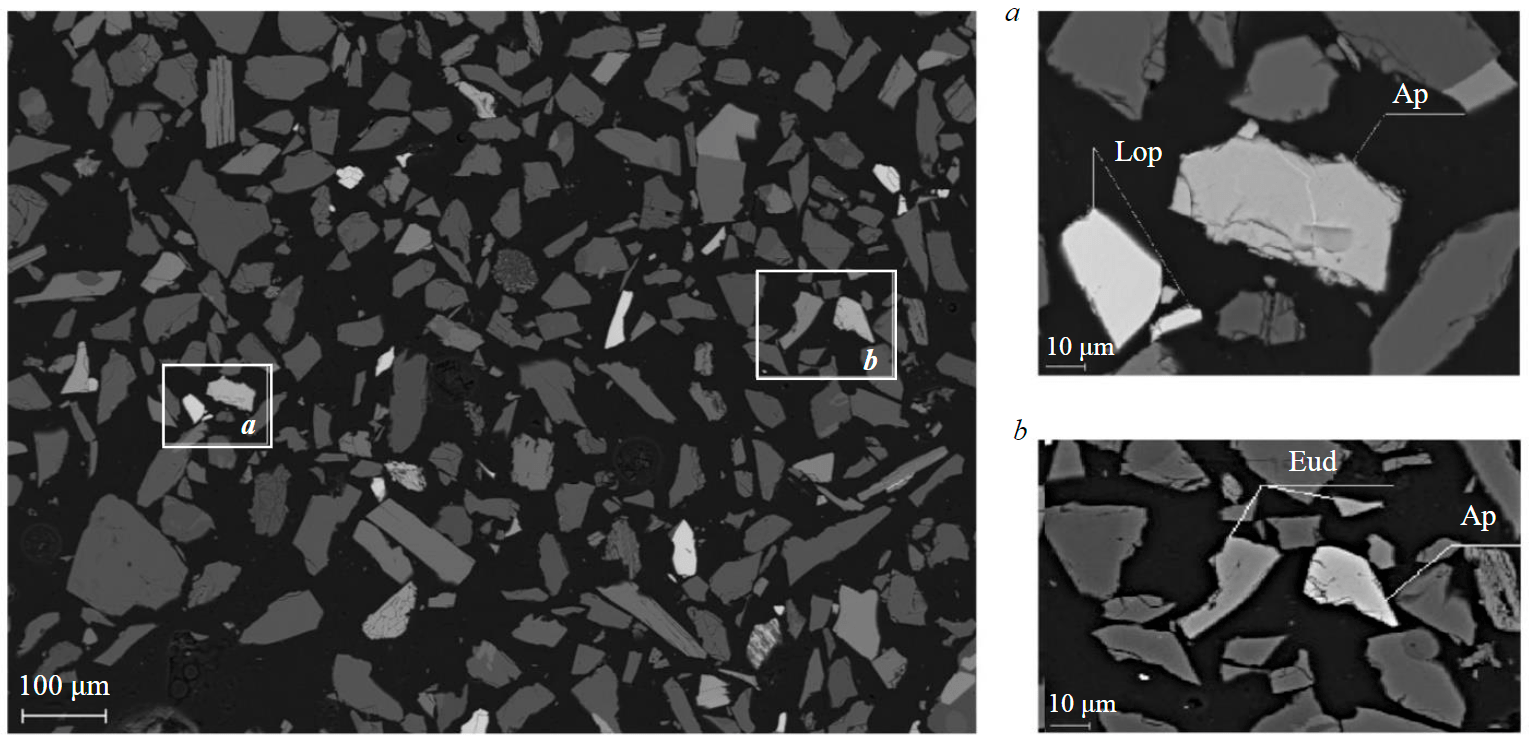

Fig.2. Micrograph of a sample of current production tailings: a – Lop (loparite), Ap (strontium apatite); b – Eud (eudialyte)

X-ray phase analysis is consistent with the established mineral composition of tailings. Fig.2 shows a micrograph of a sample of current production tailings. Samples of strontium apatite, loparite, and eudialyte are distinguished separately.

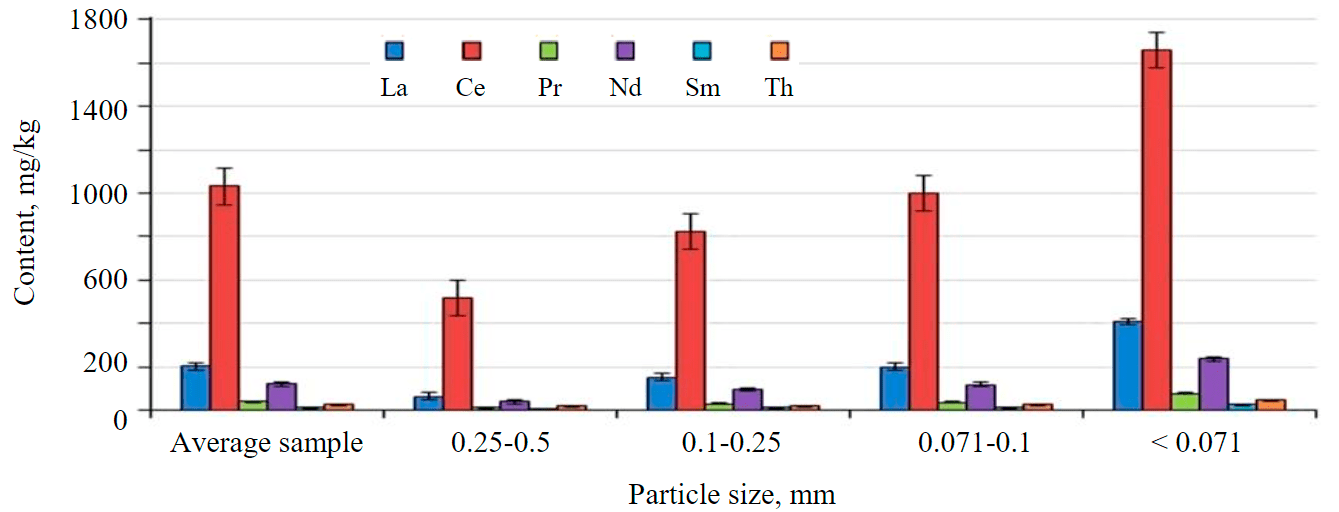

Fig.3. Distribution of light rare earth elements and thorium in the tailings material by size classes

The main REE concentrating minerals in tailings are: loparite, strontium apatite ((Sr, Ca)5(PO4)3(OH, F), eudialyte Na4(Ca, Ce, Fe, Mn)2Zr, Si6O17(OH, Cl)2. Vitusite (Ce) (Na3(Ce, La, Nd)(PO4)2 was also diagnosed. Substitution of calcium by strontium in the composition of strontium apatite leads to an increase in the unit cell parameters of Sr-apatite due to the larger ionic radius of strontium and a higher specific weight of Sr-apatite in comparison with pure apatite [24]. Particles of minerals containing rare-earth elements mainly have a smaller grain size than particles of aegirine, apatite, and potassium feldspars.

Thus, valuable minerals are mainly represented by hard-to-recover oxides (loparite), silicates (eudialyte), and phosphates (Sr-apatite, Ce-vitusite, etc.).

Results of the chemical analysis of the average sample and sieved fractions of the loparite ore tailings are shown in Fig.3.

One can note an increased content of light REE and thorium in the –0.071 mm fraction, which naturally exceeds the average content in the Earth's crust (lanthanum 30-35 mg/kg, cerium

64-66 mg/kg, praseodymium 7.1-9.1, neodymium 26-40, samarium 4.5-7) [25, 26]. The distribution of REE contents correlates with the Oddo-Harkins rule, the concentrations of elements with even ordinal numbers of the periodic table are higher than elements with odd ones [27].

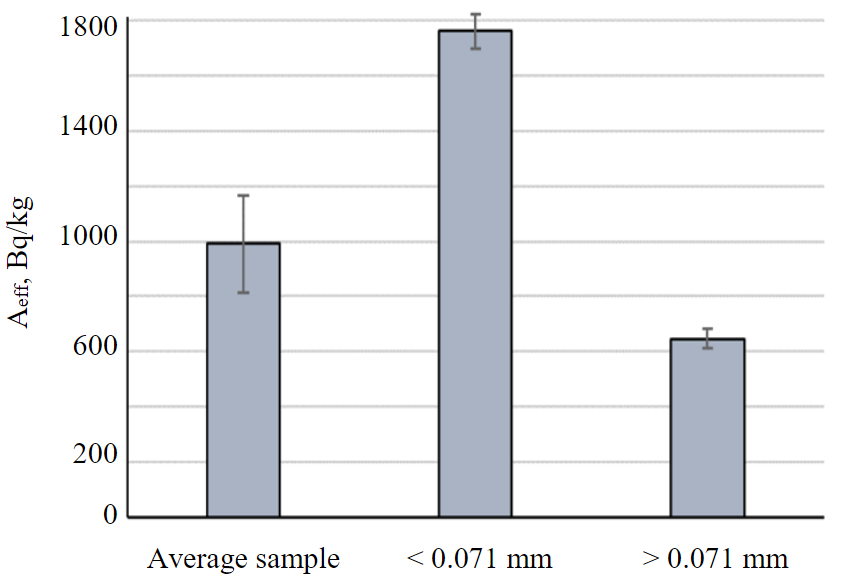

Fig.4. Effective specific activity of samples, Bq/kg

Comparison of the content of valuable components in the loparite ore tailings with similar sites in the world showed commensurate results with stored ore beneficiation tailings in China and the USA. Thus, in the tailing dam in Ganzhou, Jiangxi Province in southern China, the concentration of the total rare earth elements is 747±50 mg/kg, in the Mountain Pass mine tailings, the content of rare earth oxides reaches 5 % [4, 28, 29]. A higher REE content was noted for ore processing waste from the Bayan-Obo deposit, where a significant amount of REE and niobium was lost due to the imperfect processing cycle, which led to a low recovery factor (about 10 %) of REE [29].

Radionuclide analysis of the currently produced loparite ore tailings (Fig.4) established the radium-thorium nature of radioactivity, which is consistent with the pre-viously determined for stale beneficiation tailings [29].

Effective specific activity (Aeff) of na-tural radionuclides in the studied average tai-lings samples varies from 814 to 1168 Bq/kg, which makes it possible to classify tailings as waste category I with a calculated value of Aeff less than 1500 Bq/kg in accordance with clause 6.2. SanPiN 2.6.1.2800-10 “Hygienic requirements to limit public exposure due to natural sources of ionizing radiation”. Industrial wastes in category I can be sent for disposal to industrial waste disposal sites without restrictions on the radiation factor. According to clause 5.3.4. NRB 99/2009 building materials, as well as industrial waste used for the manufacture of building materials and finished products with Aeff of natural radionuclides more than 740 Bq/kg, but less than 1500 Bq/kg can be used in road construction outside settlements (III class building materials according to Aeff). According to SanPiN 2.6.1.2800-10 (clause 5.2), the feedstock belongs to II class materials according to Aeff and is a mineral raw material with increased content of natural radionuclides.

In samples of finely dispersed tailings material (–0.071 mm), Aeff is in the range of 1697-1825 Bq/kg. As beneficiation tailings, –0.071 mm fraction samples belong to waste category II (Aeff more than 1500, but less than 10,000 Bq/kg) in accordance with clause 6.2. SanPiN 2.6.1.2800-10. According to clause 6.4. SanPiN 2.6.1.2800-10, industrial waste of category II is sent for disposal to specially designated areas in industrial waste disposal sites. As a stock for building materials, fine tailings belong to class IV. According to clause 5.3.4. NRB 99/2009, the issue of using materials with Aeff of natural radionuclides more than 1500 Bq/kg, but less than 4000 Bq/kg is decided in each case separately based on the sanitary and epidemiological conclusion of the federal executive body authorized to carry out state sanitary and epidemiological surveillance.

In samples of screened tailings with a fraction of +0.071 mm, Aeff is in the range of

613-681 Bq/kg. As beneficiation tailings, +0.071 mm fraction samples belong to waste category I (less than 1500 Bq/kg) in accordance with clause 6.2. SanPiN 2.6.1.2800-10, as stock for building materials, they belong to class II. According to clause 5.3.4. NRB 99/2009, building materials, as well as industrial waste used for the manufacture of building materials and finished products with Aeff of natural radionuclides more than 370 Bq/kg but less than 740 Bq/kg (Class II), can be used in road construction within settlements and zones of promising development, as well as during the construction of industrial facilities. According to clause 4.5.2. SanPiN 2.6.1.2800-10, the use of materials and products in communal conditions and everyday life, except for building materials and materials containing only natural radionuclides with an effective specific activity of less than 740 Bq/kg, is allowed without restrictions on the radiation factor.

In general, the REE extraction consists of three main stages: mining and grinding, beneficiation (gravity separation, magnetic and electrostatic separation, flotation, etc.), and hydrometallurgical methods for extracting metals, including leaching, neutralization and precipitation, separation and purification methods [30]. The development of technology for the processing of current beneficiation tailings is associated with the selection of optimal methods that allow levelling the negative impact of the high content of the silicate component in the tailings, the presence of radioactive elements, the presence of target components in the composition of hard-to-recover rare-earth oxides and phosphates, the need for targeted extraction of components with a high content of interfering impurities in the productive solution.

The use of widespread treatment of tailings with inorganic acids and their mixtures, due to the high content of aluminosilicates in the tailings, in particular nepheline and feldspar, leads to the formation of silicic acid sols in the solution, which greatly complicates further processing of the productive solution. This factor can be overcome in several ways. In [31, 32], the interfering effect of silicic acid is eliminated by preliminary alkaline recovery of silicates and removal of silicon by aqueous leaching of soluble alkali metal silicates. Extraction of the total REE associated with the aluminosi-licate glassy phase from the finely dispersed residues of coal combustion [31] increased from 20 % when leaching with inorganic acids (HCl, H2SO4, HNO3) without pre-annealing to 79 and 89 % when annealing with NaOH and Na2CO3, respectively. Removal of dissolved silicates is possible by coagulation with polyacrylamide. In [33], purification of the productive solution during the processing of black aluminium slag by coagulation with polyacrylamide made it possible to obtain aluminium hydroxide of 99 % purity and achieve complete removal of silicates from the solution.

In the studies [34, 35] devoted to the processing of apatite-nepheline production tailings similar in material and particle size composition, nepheline was separated according to the flotation-magnetic circuit. Nepheline was separated by reverse flotation from deslimed tailings, then the flotation concentrate entered the wet two-stage electromagnetic separation, strong magnetic minerals, mainly titanomagnetite, were removed in a strong field, and aegirine was removed in a weak field. The circuit used [34] made it possible to obtain a nepheline concentrate with a content of 28.5-29.2 % Al2O3 from the wastes of the apatite-nepheline factories ANOF-1 and ANOF-2, while extracting from the initial raw material at the level of 57.7-71 %.

Jigging of nepheline and potassium feldspars from the loparite ore tailings can also be carried out using the gravity-magnetic technology proposed in [36], which includes size classification, screw separation to separate mainly large aggregates of aegirine and loparite, table concentration and electromagnetic separation. The proposed technology was tested on the Karnasurt plant tailings with the production of a nepheline concentrate containing 28.3-28.5 % Al2O3 with an extraction of 86.9 %, and on the Umbozero plant tailings with the production of a nepheline concentrate with an Al2O3 content of about 25 %. An obstacle to obtaining a higher quality concentrate was the high content of feldspars in the sample [36]. It was noted in [37, 38] that the use of gravity and magnetic methods of preconcentration can remove a significant part of gangue minerals, increasing the selectivity of REE extraction and reducing the consumption of reagents for both flotation and subsequent leaching.

Promising reagents for the subsequent flotation of a preconcentrated rare metal product is a class of complexing agents based on hydroxamic acids, which makes it possible to efficiently carry out the joint flotation of loparite and aegirine [35, 39]. The effect of exposure to hydroxamic acids was tested [35] during the flotation of slime products of loparite ore beneficiation, making it possible to obtain a 3.7 % concentrate of niobium oxide with an initial content of 0.17 % in slimes.

During hydrochemical conversion, thorium, which isomorphically replaces rare earth elements in a number of minerals, will inevitably pass into the productive solution along with ions of rare earth elements. Considering the diverse mineral composition of the ores mined in the Lovozero massif [40], it can be assumed that thorium will be mainly concentrated in Na-Th silicates, vitusite-(Ce), and loparite. In addition, a significant presence of thorium can be found in minerals of the rhabdophane group, titanite [41], pyrochlore, stensrupine, apatites (belovite-(Ce), fluorine- and strontioapatites), etc. Selective leaching of thorium is a complex technical problem due to the close properties of thorium and REE. The classical option of coprecipitation of thorium and REE from acidic solutions by adding oxalic acid is possible [42, 43]. The resulting oxalates of tetravalent cerium and thorium are subjected to ignition, repeated acid treatment, and extraction with tributyl phosphate. Dissolved rare earth elements remain in the aqueous solution, and thorium in the organic solution. According to [43], 30 % concentrated oxalic acid precipitates 99 % thorium and 98 % REE at 30 °C.

The multi-stage and complexity of the loparite ore tailings processing requires the use of new innovative technologies and further in-depth study of the tailings material, however, interest in this topic does not weaken. Recent technologies for bioleaching [44], flotation agents, etc. are being developed. Improvement in the technology of tailings pre-concentration and subsequent hydrometallurgical processing will reduce the number of necessary stages and the resources expended. Involvement of tailings in the processing can not only reduce the amount of accumulated waste and the damage they cause to the environment, but also obtain an additional commercial product, implementing the principle of transition to a sustainable economy in the mining industry.

Conclusion

The study investigated the composition and properties of the beneficiation tailings of currently produced loparite ores. The predominant fractions are 0.05-0.1 and 0.1-0.25 mm. The average content of loparite in the tailings is 0.98 %. Considering the volume of waste accumulated over the years of operation of the enterprise, the loparite ore tailings are of interest as a source of rare metal raw materials.

Using the method of scanning electron microscopy, REE concentrating minerals in the loparite ore tailings were diagnosed: loparite, eudialyte, strontium apatite. An analysis of the sieved fractions revealed the concentration of REE and thorium in the finely dispersed material of the beneficiation tailings. Based on the radionuclide analysis, the values of the effective specific activity of samples were calculated and the radium-thorium character of radioactivity was established.

The features of loparite ore beneficiation waste considered in this article are of immense importance in the development of modern economically and environmentally feasible processing technologies. Thus, the concentration of light REE and thorium in the fine tailings fraction, confirmed, among other things, by the higher effective specific activity of the fraction of less than 0.071 mm, provides for the inclusion of the stages of gravity-magnetic and flotation separation in the developed technology. This fact attracts attention in connection with the increased migration activity of the silty fraction of the tailings, which leads to an increase in the level of environmental risk for the areas adjacent to the tailing dams. A commodity product obtained at the initial stage of processing can be nepheline and potassium-spar concentrate, used as a raw material for the production of alumina, cement, potash, soda. The crude REE-containing concentrate can be further processed by the hydrometallurgical method. The productive solution is subjected to precipitation with the output of the total REE and thorium, or extraction with organic solvents to obtain individual metals. However, the separation of thorium, which provides the main part of the material radioactivity, remains the least developed issue. The introduction of the stage of thorium separation from REE at the current level of technology development will lead to a noticeable increase in production costs and an increase in the volume of associated waste. Finding an effective way to overcome this problem will entail a significant increase in the range of applications for waste from the loparite ore processing.

Considering tailings as manufactured deposits with a low content of valuable components, but a significant amount of material leads to the need to develop specific treatment procedures that provide not only a valuable commercial product, but also reduce environmental damage.

The authors thank Senior Researcher A.V.Svetlov and Junior Researcher A.A.Goryachev for assistance in sampling the loparite ore tailings, Engineer M.Yu.Sidorov for making samples for SEM.

References

- Kyung Taek Rim, Kwon Ho Koo, Jung Sun Park. Toxicological evaluations of rare earths and their health impacts to workers: A Literature Review. Safety and Health at Work. 2013. Vol. 4. Iss. 1, p. 12-26. DOI: 10.5491/SHAW.2013.4.1.12

- Goodenough K.M., Wall F., Merriman D. The rare earth elements: demand, global resources, and challenges for resourcing future generation. Natural Product Research. 2018. Vol. 27, p. 201-216. DOI: 10.1007/s11053-017-9336-5

- Jordens A., Ying Ping Cheng, Waters K.E. A review of the beneficiation of rare earth element bearing minerals. Minerals Engineering. 2013. Vol. 41, p. 97-114. DOI: 10.1016/j.mineng.2012.10.017

- Binnemans K., Jones P.T., Blanpain B. et al. Towards zero-waste valorisation of rare-earth-containing industrial process residues: A critical review. Journal of Cleaner Production. 2015. Vol. 99, p. 17-38. DOI: 10.1016/j.jclepro.2015.02.089

- Abaka-Wood G.B., Ehrig K., Addai-Mensah J., Skinner W. Recovery of Rare Earth Elements Minerals from Iron-Oxide-Silicate-Rich Tailings: Research Review. Eng. 2022. Vol. 3. Iss. 2, p. 259-275. DOI: 10.3390/eng3020020

- Abaka-Wood G.B., Zanin M., Addai-Mensah J., Skinner W. Recovery of rare earth elements minerals from iron oxide-silicate rich tailings – Part 1: Magnetic separation. Minerals Engineering. 2019. Vol. 136, p. 50-61. DOI: 10.1016/j.mineng.2019.02.026

- Binnemans K., Jones P.T., Blanpain B. et al. Recycling of rare earths: A critical review. Journal of Cleaner Production. 2013. Vol. 51, p. 1-22. DOI: 10.1016/j.jclepro.2012.12.037

- Tunsu C., Petranikova M., Gergorić M. et al. Reclaiming rare earth elements from end-of-life products: A review ofthe perspectives for urban mining using hydrometallurgical unit operations. Hydrometallurgy. 2015. Vol. 156, p. 239-258. DOI: 10.1016/j.hydromet.2015.06.007

- Lokshin E.P., Tareeva O.A. Recovery of lanthanides from extraction phosphoric acid produced by the dihydrate process. Russian Journal of Applied Chemistry. 2010. Vol. 83, p. 951-957. DOI: 10.1134/S1070427210060042

- Abhilash, Sinha S., Sinha M.K., Pandey B.D. Extraction of lanthanum and cerium from Indian red mud. International Journal of Mineral Processing. 2014. Vol. 127, p. 70-73. DOI: 10.1016/j.minpro.2013.12.009

- Franus W., Wiatros-Motyka M.M., Wdowin M. Coal fly ash as a resource for rare earth elements. Environmental Science and Pollution Research. 2015. Vol. 22, p. 9464-9474. DOI: 10.1007/s11356-015-4111-9

- Delgado J., Pérez-López R., Galván L. et al. Enrichment of rare earth elements as environmental tracers of contamination by acid mine drainage in salt marshes: a new perspective. Marine Pollution Bulletin. 2012. Vol. 64. Iss. 9, p. 1799-1808. DOI: 10.1016/j.marpolbul.2012.06.001

- Stanujkic D., Zavadskas E.K., Karabasevic D. et al. An approach to solving complex decision-making problems based on IVIFNs: A case of comminution circuit design selection. Minerals Engineering. 2019. Vol. 138, p. 70-78. DOI: 10.1016/j.mineng.2019.04.036

- Cleary P.W., Delaney G.W., Sinnott M.D. et al. Advanced comminution modelling: Part 1 – crushers. Applied Mathematical Modelling. 2020. Vol. 88, p. 238-265. DOI: 10.1016/j.apm.2020.06.049

- Owusu K.B., Karageorgos J., Greet C., Zanin M. et al. Predicting mill feed grind characteristics through acoustic measurements. Minerals Engineering. 2021. Vol. 171. N 107099. DOI: 10.1016/J.MINENG.2021.107099

- Wall F., Rollat A., Pell R.S. Responsible sourcing of critical metals. Elements. 2017. Vol. 13. Iss. 5, p. 313-318. DOI: 10.2138/gselements.13.5.313

- Derome J., Lindroos A.J. Effects of heavy metal contamination on macronutrient availability and acidification parameters in forest soil in the vicinity of the Harjavalta Cu-Ni smelter, SW Finland. Environmental Pollution. 1998. Vol. 99. Iss. 2, p. 225-232. DOI: 10.1016/s0269-7491(97)00185-1

- Xiuwu Zhang, Linsheng Yang, Yonghua Li et al. Impacts of lead/zinc mining and smelting on the environment and human health in China. Environmental Monitoring & Assessment. 2012. Vol. 184, p. 2261-2273. DOI: 10.1007/s10661-011-2115-6

- Jie Liang, Chunting Feng, Guangming Zeng et al. Spatial distribution and source identification of heavy metals in surface soils in a typical coal mine city, Lianyuan, China. Environmental Pollution. 2017. Vol. 225, p. 681-690. DOI: 10.1016/j.envpol.2017.03.057

- Csavina J., Field J., Taylor M.P. et al. A review on the importance of metals and metalloids in atmospheric dust and aerosol from mining operations. Science of the Total Environment. 2012. Vol. 433, p. 58-73. DOI: 10.1016/j.scitotenv.2012.06.013

- Zhen Cheng, Jingkun Jiang, Fajardo O.A. et al. Characteristics and health impacts of particulate matter pollution in China (2001-2011). Atmospheric Environment. 2013. Vol. 65, p. 186-194. DOI: 10.1016/j.atmosenv.2012.10.022

- Krasavtseva E.A., Makarov D.V., Maksimova V.V. et al. Studies of Properties and Composition of Loparite Ore Mill Tailings. Fiziko-texhnicheskiye problemy razrabbotki poleznykh iskopaemykh. 2021. N 3, p. 190-198 (in Russian). DOI: 10.15372/FTPRPI20210318

- Goryachev A., Krasavtseva E., Lashchuk V. et al. Assessment of the Environmental Hazard and Possibility of Processing of Refinement Tailings of Loparite Ores Concentration. Ecology and industry of Russia. 2020. Vol. 24. N 12, p. 46-51 (in Russian).DOI: 10.18412/1816-0395-2020-12-46-51

- Ogorodnikov V.N., Polenov Yu.A., Savichev A.N., Kisin A.Yu. Rare-earth composition of apatite for the purposes of facies analysis and search for high-purity quartz. Trudy Instituta geologii i geokhimii im. akademika A.N.Zavaritskogo. 2020. N 167, p. 122-128 (in Russian).

- Taylor S.R., McLennan S.M. The continental crust: its composition and evolution. Oxford: Blackwell Scientific Publications, 1985, p. 312.

- Greenwood N.N., Earnshaw A. Chemistry of the Elements. Oxford: Butterworth-Heinemann, 1997, p. 1359.

- Kotelnikova A.D., Rogova O.B., Stolbova V.V. Lanthanides in the Soil: Routes of Entry, Content, Effect on Plants, and Genotoxicity (A Review). Eurasian Soil Science. 2021. Vol. 54. N 1, p. 117-134. DOI: 10.1134/S1064229321010051

- Hailong Tang, Xiaojing Wang, Weitao Shuai, Yangsheng Liu. Immobilization of Rare Earth Elements of the Mine Tailings Using Phosphates and Lime. Procedia Environmental Sciences. 2016. Vol. 31, p. 255-263. DOI: 10.1016/j.proenv.2016.02.034

- Bo Zhang, Chengjun Liu, Chunlong Li, Maofa Jiang. A novel approach for recovery of rare earths and niobium from Bayan Obo tailings. Minerals Engineering. 2014. Vol. 65, p. 17-23. DOI: 10.1016/j.mineng.2014.04.011

- Lim B., Alorro R. Technospheric Mining of Mine Wastes: A Review of Applications and Challenges. Sustainable Chemistry. 2021. Vol. 2. Iss. 4, p. 686-706. DOI: 10.3390/suschem2040038

- Pan J., Vaziri Hassas B., Rezaee M. et al. Recovery of rare earth elements from coal fly ash through sequential chemical roasting, water leaching, and acid leaching processes. Journal of Cleaner Production. 2021. Vol. 284. N 124725. DOI: 10.1016/j.jclepro.2020.124725

- Kuppusamy, V. K., Holuszko, M. Sulfuric acid baking and water leaching of rare earth elements from coal tailings. Fuel. 2022. Vol. 319. N 123738. DOI: 10.1016/j.fuel.2022.123738

- Thi Thuy Nhi Nguyen, Man Seung Lee. Purification of the Sodium Hydroxide Leaching Solution of Black Dross by Removal of Silicate (IV) with Polyacrylamide (PAM). Mineral Processing and Extractive Metallurgy Review. 2021. Vol. 42. Iss. 1, p. 9-16. DOI: 10.1080/08827508.2019.1657862

- Mitrofanova G., Chernousenko E., Artemyev A. Chnogenic Deposits of the Murmansk Region as Prospective Sources of Mineral Raw Materials. Mine Surveying and Subsurface Use. 2020. N 3(107), p. 9-16 (in Russian).

- Mitrofanova G.V., Chernousenko E.V., Kameneva Yu.S., Vishnyakova I.N. Testing of a Complexing Reagent on the Basis of Hydroxamic Acids by Floating Transition Metal Minerals. Vestnik Kol'skogo nauchnogo tsentra RAN. 2019. Vol. 11. N 2, p. 95-104 (in Russian). DOI: 10.25702/KSC.2307-5228.2019.11.2.95-104

- Rakaev А.I., Chernousenko Ye.V., Rukhlenko Ye.D., Alekseeva S.А. Production of Nepheline Concentrate From Final Tailings of the Lovozyorsky Mining Complex Concentrating Plants. Obogashchenie rud. 2007. N 1, p. 8-11 (in Russian).

- Marion C., Grammatikopoulos T., Rudinsky S. et al. A mineralogical investigation into the pre-concentration of the Nechalacho deposit by gravity separation. Minerals Engineering. 2018. Vol. 121, p. 1-13. DOI: 10.1016/j.mineng.2018.02.008

- Faris N., Ram R., Tardio J. et al. Characterisation of a ferruginous rare earth bearing lateritic ore and implications for rare earth mineral processing. Minerals Engineering. 2019. Vol. 134, p. 23-36. DOI: 10.1016/j.mineng.2019.01.019

- Chernousenko E.V., Perunkova T.N., Artemiev A.V., Mitrofanova G.V. Improvement of flotation technologies for the Kola Peninsula ore. Gornyi Zhurnal. 2020 N 9, p. 66-72 (in Russian). DOI: 10.17580/gzh.2020.09.09

- Bochneva A., Lalomov A., LeBarge W. Placer mineral deposits of Russian Arctic zone: Genetic prerequisites of formation and prospect of development of mineral resources. Ore Geology Reviews. 2021. Vol. 138. N 104349. DOI: 10.1016/j.oregeorev.2021.104349

- Huber M., Kamiński D., Czernel G., Kozlov E. Optical and Spectroscopic Properties of Lorenzenite, Loparite, Perovskite, Titanite, Apatite, Carbonates from the Khibiny, Lovozero, Kovdor, and Afrikanda Alkaline Intrusion of Kola Peninsula (NE Fennoscandia). Crystals. 2022. Vol. 12. Iss. 2. N 224. DOI: 10.3390/cryst12020224

- Deqian Li, Yong Zuo, Shulan Meng. Separation of thorium (IV) and extracting rare earths from sulfuric and phosphoric acid solutions by solvent extraction method. Journal of Alloys and Compounds. 2004. Vol. 374. Iss. 1-2, p. 431-433. DOI: 10.1016/j.jallcom.2003.11.055

- García A.C., Latifi M., Amini A., Chaouki J. Separation of Radioactive Elements from Rare Earth Element-Bearing Minerals. Metals. 2020. Vol. 10. Iss. 11. N 1524. DOI: 10.3390/met10111524

- Sarker S.K., Haque N., Bhuiyan M., Bruckard W., Pramanik B.K. Recovery of strategically important critical minerals from mine tailings. Journal of Environmental Chemical Engineering. 2022. Vol. 10. Iss. 3. N 107622. DOI: 10.1016/j.jece.2022.107622