Scientific experimental bases for dry beneficiation of mineral ores

- 1 — Ph.D., Dr.Sci. Head of Laboratory N.V.Chersky Mining Institute of the North, Siberian Branch of the RAS ▪ Orcid

- 2 — Ph.D. Senior Researcher N.V.Chersky Mining Institute of the North, Siberian Branch of the RAS ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 3 — Junior Researcher N.V.Chersky Mining Institute of the North, Siberian Branch of the RAS ▪ Orcid ▪ Elibrary ▪ Scopus

- 4 — Junior Researcher N.V.Chersky Mining Institute of the North, Siberian Branch of the RAS ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

Abstract

The article presents the results of research on the development of processes and equipment for ore preparation and pneumatic dry beneficiation of mineral ores. The methods of crushing and grinding before enrichment of minerals have been considered, dry enrichment of geomaterials is investigated. Highly efficient prototypes of beneficiation equipment are developed and tested: crushers of multiple dynamic impact RD-MDV-900, DKD-300, centrifugal grinders CMVU-800 and VCI-12, pneumatic separator POS-2000. Fundamental designs are created, and a number of new ore preparation and pneumatic beneficiation instruments are being designed. The efficiency of approbation of an autonomous dry beneficiation complex with new safe environmental standards for the processing of gold-bearing ores, which makes it possible to fully release and extract free gold with a particle size from 10,000 to 100 µm, is shown. The introduction of the dry beneficiation method is very promising for the mining industry. It will allow to reduce capital costs for the construction of stationary beneficiation plants, completely or partially withdraw from the use of process water, the construction of a water supply system, a traditional tailing dam, etc.

Introduction

Currently, the beneficiation complex of the mining industry has an increasing interest in the use of dry beneficiation of mineral raw materials, which is a promising direction. It is known that some developments of dry technologies and equipment have been applied in various industries [1, 2], including in magnetic separation of iron ores [3-5]. In the beneficiation of mineral raw materials, this is primarily the absence of the need to use process water, filtration, thickening and drying of beneficiation products, which leads to savings in financial resources and energy costs [6, 7]. The relevance of the direction under study is associated with the high consumption of process water in mineral beneficiation, which in the conditions of the Russian North is fraught with excessive costs and increased environmental impact and is confirmed by the experience of operating beneficiation plants in Yakutia.

The purpose of the article is to review the development of dry beneficiation technology related to design and experimental research in the field of ore preparation and pneumatic dry beneficiation of mineral ores, including based on the author's investigations.

The main problem of ore preparation lies in the excessive cost and inefficiency of mineral release, and that of wet beneficiation – in the high consumption of process water (4-5 m3/t and more). Studies in the field of ore preparation revealed that the impact (dynamic) method of destruction is the most rational for the preliminary preparation of material before beneficiation and has a number of advantages in terms of the degree of crushing, energy consumption, and most importantly, in the release of useful components. The main goal is not only to reduce the particle size of the crushed material, but also to maximize the possible release of the useful component from the ore mass, which occurs in the main mode of disintegration along the weakest intergranular and intermineral bonds of complex in texture ore polymineral natural complexes (aggregates) [8-10]. This phenomenon is defined in the technical literature as the selective release of certain mineral components due to the selective nature of the destruction of rocks that are complex in composition and texture.

The following researchers devoted their work to the study of the destruction of rocks, to the basics of designing crushing and grinding equipment: P.Rittinger, V.A.Maslennikov, V.A.Kirpichev, Yu.A.Muizemnek, F.Bond, F.Kick, A.K.Rundkvist, R.A.Rodin, L.A.Vaisberg, M.M.Protodyakonov, L.I.Baron, L.F.Bilenko, P.M.Sidenko, P.A.Rebinder and others. N.E.Bauman, E.I.Levdansky, B.V.Klushantsev were engaged in the upgrading and development of impact grinding equipment. V.I.Revnivtsev made a huge contribution to the study of rocks destruction. He developed and comprehensively substantiated the concept of selective disintegration of ores and the notions of geometric and energy selectivity of rock disintegration, which actually means destruction along the interfaces of phases with minimal energy consumption. Revnivtsev studied the basic principles for the rational organization of the release of mineral aggregates in the preparation of ore raw materials for beneficiation. According to them, for the effective destruction of the material it is necessary to apply multiple dosed loads and use various methods of ore softening, which reduce the contact strength of unlike components and facilitate selective release of aggregates. Such conditions are possible in impact centrifugal mills, given that their design will provide multiple dynamic impacts on the crushed material.

In the field of grinding, equipment with an impact principle of operation is characterized by relatively low specific energy costs [11, 12]. The efficiency of grinding depends on the specific method of mechanical action and the design features of the mill [13-15]. Abroad [16, 17] (Metso Outotec, Acrowood Corp., Metso Minerals) and in the Russian Federation (ZAO New Technologies, NPO Centre, TECHPRIBOR plant) centrifugal plants based on the impact destruction of geomaterials are actively developing [18, 19]. The most common serial centrifugal impact units are presented in Table 1.

Table 1

Technical parameters of centrifugal units

|

Parameters |

Tribokinetika 3050 |

Titan M-63 |

Titan M-125 |

Barmac B3100SE VSI |

|

Productivity, t/h |

1-4.5 |

1-3 |

3-10 |

5-9 |

|

Feed particle size, mm |

to 20 |

to 30 |

to 40 |

to 20 |

|

Particle size of the crushed product, mm |

0.063-1.25 0.01-0.063 |

0.04-0.3 |

0.05-0.5 |

0.01-2 |

|

Installed power, kW |

60.2 |

110 |

205 |

11 |

|

Overall dimensions, m |

5.8×5.4×3.8 |

5.5×3.0×7.6 |

7.6×4.2×15.3 |

1.3×0.9×1.2 |

|

Weight, t |

3.9 |

8 |

12 |

1.2 |

Even the most modern grinding equipment, when switching to deep grinding of geomaterials, still remains quite energy-intensive, especially where the task is bulk grinding or size reduction. Often, for the grinding of stronger particles of waste rock (for example, quartz), a lot of energy is consumed. Its level increases significantly when moving to the stages of fine grinding.

Research methodology

The conditions for a significant intensification of impact crushing and grinding are found. They consist in the possibility of providing multiple dynamic effects on lumpy geomaterials in the working zone of destruction, implemented in new units, where instantaneous volumetric stress transfer through mechanical bonds throughout the entire volume of the material is determined. This ultimately leads to its fatal destruction in the mode of disintegration with advanced selective release of mineral forms, including useful components [20, 21]. The effect is fully consistent with the golden rule of ore dressers: “Do not crush anything superfluous”.

The article uses a comprehensive research method: analysis and generalization of literature and patent sources, experimental laboratory studies of the dry disintegration of rocks in the developed multiple dynamic impact mills (DKD-300 crusher, CMVU-800 grinder), pilot tests, standard and non-standard methods for determining the process properties of initial geomaterials (strength according to the Protodyakonov method) and processing products of beneficiation of quartz-vein gold-bearing ores from deposits Nezhdaninskoye, Duet, Sarylakh, Maltan, Nagornoye, Yakutskoye, Vyun, Malo-Tarynskoye (Yakutia) , Gurbey (Irkutsk region), particle size and fractional methods for analysing the products of crushing, grinding, pneumatic separation (laboratory vibrating screen Gr-50, vibration-type mill ChMV-1), methods for planning experiments, statistical and analytical processing of the results of experimental studies (diffractometer D8 Discover Bruker, spectrum meter SRS-3400 Bruker). Also, a method was developed for determining the degree of disintegration. It enables to analyse the ore preparation (disintegration, mechanical destruction) in determining the particle size composition of a crushed product with characteristic modal features. The method is based on isolating the share of the area of their predominant accumulation (modes) from the total particle size composition of the crushing products. It is described as a log-normal distribution that depends on the energy of mechanical impact and is responsible for the direct mechanical destruction of the geomaterial. The degree of disintegration is determined by the proportion of material released by disintegration (spontaneous dispersion) during crushing and grinding. It is formed by subtracting the share of the geomaterial (in %) destroyed directly by mechanical destruction from the total amount of the particle size distribution.

Discussion

The studies enabled to establish the patterns of rock disintegration under intense mechanical impacts, develop the methods for the destruction of lumpy geomaterials by multiple dynamic impacts in the disintegration mode, selective advancing release of monomineral useful components, which served to develop a number of promising ore preparation devices: dry crushing and grinding. This area is covered by 34 patents of the Russian Federation.

A characteristic effect was obtained when testing various ore geomaterials in a DKD-300 combined impact crusher. Destruction of lumpy ore materials in this crusher occurs due to multiple dynamic impacts, formed not only by the action of the working bodies, but also by the interaction (collision) of the pieces with each other. Tests of this unit during crushing of diamond-bearing kimberlites of the Zarnitsa pipe in comparison with the crushing results of the Nordberg NP-1007 impact crusher, tested under similar conditions, showed that the degree of crushing in the DKD-300 multiple impact crusher at four performance indicators is higher (Table 2).

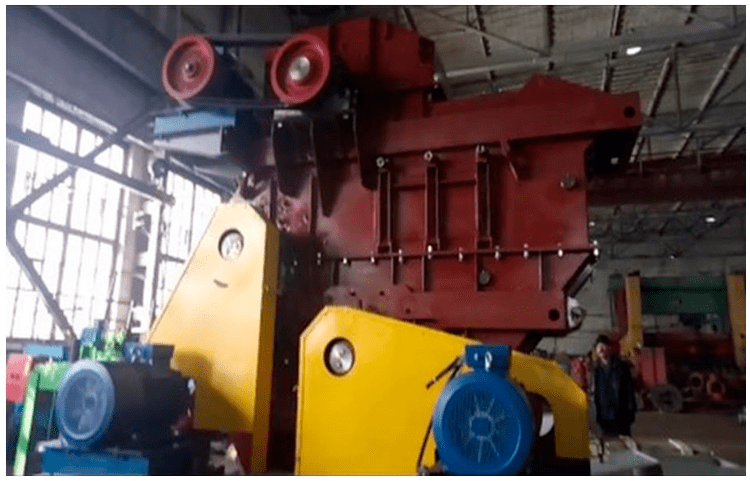

Along with a high degree of crushing, data were obtained on the high safety of diamond crystals in comparison with a wet AG mill of the Cascade type by a factor of three [22]. These results allow us to conclude that the DKD-300 crusher can be used for crushing kimberlite ores. At present, a high-performance rotary crusher RD-MDV-900 has been developed (Fig.1), using the same principle of crushing by multiple dynamic impacts, differing from the DKD-300 crusher not only in higher productivity to 120 t/h, but also in the presence in the design of a calibration grate, thanks to which it is possible not only to remove fine fractions in a timely manner without their regrinding, but also to control the upper size class of the crushed material. It is undoubtedly an important function that excludes the accumulation of critical size classes in the process circuits of ore preparation and the need to form circulating loads or intercycle stage of crushing. The use of a high-performance multiple dynamic impact crusher RD-MDV-900 will reduce the cost of metal consumption and energy efficiency in comparison with AG mills at enterprises processing diamond-bearing kimberlite ores. The full implementation of this crusher in the ore preparation circuits at diamond processing plants will eliminate the wet part of pulping. Therefore, there is no need to place ore preparation processes in buildings with a heated circuit. This, in turn, in the harsh conditions of the North is a significant factor in reducing the cost of processing and in general beneficiation of kimberlite ores.

Table 2

Particle size compositions of the crushing products of kimberlite ores from the Zarnitsa pipe

|

Size class, mm |

Yield, % |

|||

|

NP-1007 |

DKD-300 |

|||

|

Productivity, t/h |

||||

|

89 |

5.8 |

12.2 |

15.2 |

|

|

−1.6+0 |

7.9 |

28 |

21.3 |

18.90 |

|

−5+1.6 |

25 |

38 |

33 |

30.00 |

|

−10+5 |

21 |

18.7 |

21.5 |

22.70 |

|

−20+10 |

35 |

13 |

20.5 |

23.50 |

|

−35+20 |

9.9 |

2.2 |

3.7 |

4.50 |

|

−50+30 |

1.2 |

0.1 |

– |

0.40 |

|

Degree of crushing |

3.3 |

6.8 |

5.3 |

4.8 |

The increased effect of selective release of useful ore components with multiple impacts was proven in the processing of gold-bearing ores. Tests of the DKD-300 crusher made it possible to estimate the level of free gold release for a number of gold-bearing ores from various deposits.

The results of tests of gold-bearing ore from the Gurbey deposit in the Irkutsk region as part of the dry beneficiation testing are characteristic. During the disintegration of gold-bearing schistose ore of biotite-quartz composition in the DKD-300 crusher, which uses the principle of multiple impact, to 47 % of gravity-recoverable gold with a particle size of more than 100 µm is released in one stage of crushing. The degree of gold release is confirmed by instrumental studies using a TESCAN electron microscope with the TIMA analyser [23]. The subsequent extraction of released gold is associated with obtaining a primary gold concentrate.

Fig.1. General view of RD-MDV-900 crusher

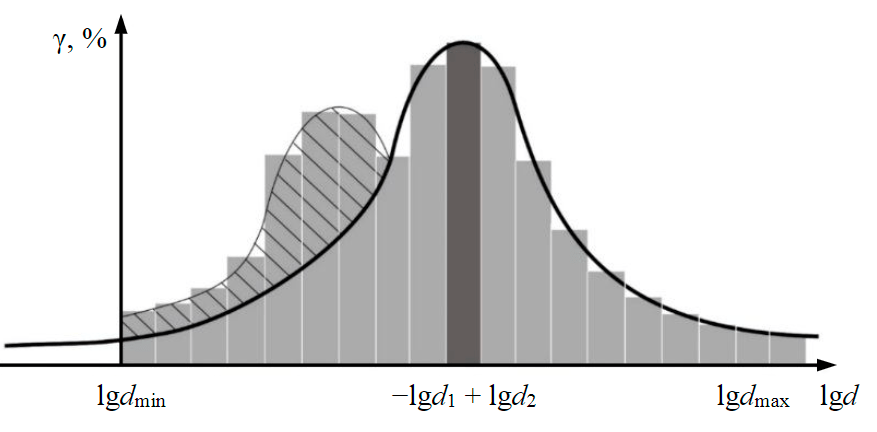

For a more accurate quantitative determination of the disintegration effect, a method for determining the degree of geomaterials disintegration was substantiated [24]. The method makes it possible to separate two processes simultaneously occurring in ore preparation: proper mechanical destruction of lumpy ore geomaterials and the accompanying disintegration, i.e., release of weaker mechani-cal bonds due to textural features of ore natural samples. Graphically, the method for calculating the degree of disintegration is shown in Fig.2, where the particle size characteristic of the crushing products of gold-bearing ores of the gold-quartz type, as a rule, has conditionally two characteristic modes: one in the region of small classes and the second, of large ones. The mode in the region of larger fractions has the shape of a log-normal distribution, and the shaded part represents the proportion of material destroyed due to disintegration, i.e., spontaneous dispersion of the weakest part of the geomaterial, depending on textural features. Thus, the ratio of the shaded area to the total mass of crushed material represents the degree of disintegration, and the calculation of the degree of disintegration is based on determining the proportion of products as a result of mechanical action and separating crushed products from the total particle size composition.

Fig.2. Method for determining the degree of disintegration

The calculation part of the method is as follows. The parameters of the mode region in the area of large fractions, limited by lgd1 and lgd2, and the yield value γmax are revealed. The area is determined

From the condition SI = f(x), equated to the log-normal distribution function,

The value of δ is determined, then the area under the log-normal distribution function is calculated

Degree of disintegration

Table 3 presents the results of calculations of the degree of disintegration for ores with various textures using the impact crushing method in the DKD-300 unit. The degree of disintegration depends not only on the texture and mineral composition of the geomaterial, but also on the crushing intensity. The proposed method for determining the degree of disintegration of lumpy geomaterials during crushing using dynamic impacts can indeed give a quantitative description of disintegration as an integral process of ore preparation by crushing and grinding. And the degree of disintegration can be an important process characteristic of both the target of ore preparation of mineral raw materials and the crushing and grinding unit, regardless of the used method and standard size.

Table 3

The degree of disintegration of ores with various textures in the DKD-300 crusher

|

Ore |

Productivity, t/h |

Degree of disintegration |

|

Quartz-antimonite banded texture |

6 |

0,49 |

|

Antimonite with quartz veins |

6 |

0,68 |

|

Quartz-antimonite vein texture |

6 |

0,56 |

|

Quartz massive texture |

6 |

0,35 |

|

Biotite quartz schistose texture |

6 |

0,52 |

|

Basalt massive texture |

6 |

0,43 |

|

Kimberlite |

5,8 |

0,85 |

| 12,2 |

0,74 |

|

| 15,2 |

0,71 |

A method was developed for grinding by multiple dynamic impacts with the possibility of increasing the impact energy (the velocity of particles collision with each other and with the surface of the working bodies). To implement this method, grinders with multiple dynamic impacts with original design solutions were created, in particular, impact centrifugal mills with different constructive shapes of working bodies (stepped, conical, disk).

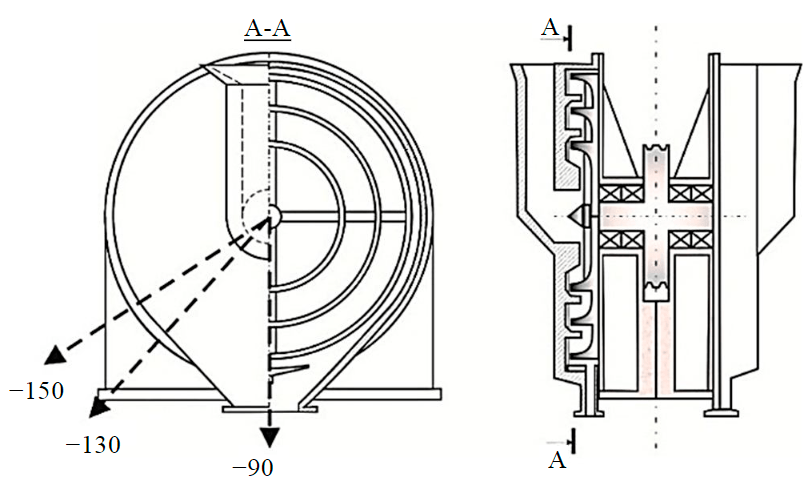

Such a first development is the CMVU-800 centrifugal step mill, which was designed, manufactured, and tested. A general view of the semi-industrial version of the CMVU-800 centrifugal step mill is shown in Fig.3. Technical specifications: productivity to 6 t/h; power 7 kW; feed size to 20 mm; product size 0.05-1 mm; overall dimensions – 1.4x1.3x1.2 m; weight 0.9 t.

With a stepped shape of working bodies, the crushed particles at each step receive an increase in velocity as they move in the working chamber of the mill to peripheral unloading, due to which the grinding efficiency increases, the degree of grinding is to 21 %.

Fig.3. General view of the CMVU-800 mill

Fig.4. Design of a centrifugal vertical grinder with the ability to adjust the unloading angle

One of the latest developments, based on the grinding by multiple dynamic impacts, is a vertical centrifugal grinder VCI-12 [25] with increased productivity to 12 t/h. Technical specifications: productivity to 12 t/h; power 30 kW; feed size to 30 mm; diameter of the inner disk 1200 mm; intake opening dimensions – 280x160 mm; outlet tray dimensions 210x220 mm; number of revolutions of the inner disk 760 rpm; weight 6662.5 kg; weight without electric motor 6512.5 kg.

In contrast to the known impact and abrasive grinders, in the proposed centrifugal vertical grinder VCI-12, there is an additional possibility to control the grinding process by adjusting the angle of unloading the crushed material and the rational gap between the working bodies (discs), which eliminates the ejection of under-grinded particles from the working area of the grinder with the possibility of obtaining a controlled fineness of grinding of disintegration products.

Figure 4 shows the possibility to adjust the height of the unloading unit at a certain angle re-lative to the central axis of the body and the axis of rotation of the grinder working bodies.

Preliminary experimental studies confirmed the possibility of controlling the grinding process by the proposed method. Based on the results obtained, it was found that at an unloading angle of −150°, the particle size composition of the grinding products is the most uniform with the highest content of small classes. This is explained by the fact that it is at this most rational value of the unloading angle that the removal of the smallest and lightest fractions from the grinding zone occurs.

In the mining industry, both in Russia and abroad, modern technologies and equipment are being developed for dry methods of processing and beneficiation of minerals, which is undoubtedly a promi-sing direction. The development and application of pneumatic separation expands the range of methods for dry beneficiation of mineral raw materials [26-28]. Classifying grinding complexes are widely applied, using air separation to separate single-component minerals by size when grinding them for the production of building mixtures [29, 30]. Using air separation for separation by density difference, researchers of OOO Promobogachenie achieved reliable results in pneumatic separation when creating the SEPAIR installation. It uses the principle of separation by the different density of minerals in the ascending air flow created in the installation nozzle above the moving perforated belt, on which the separated minerals are located [31-33].

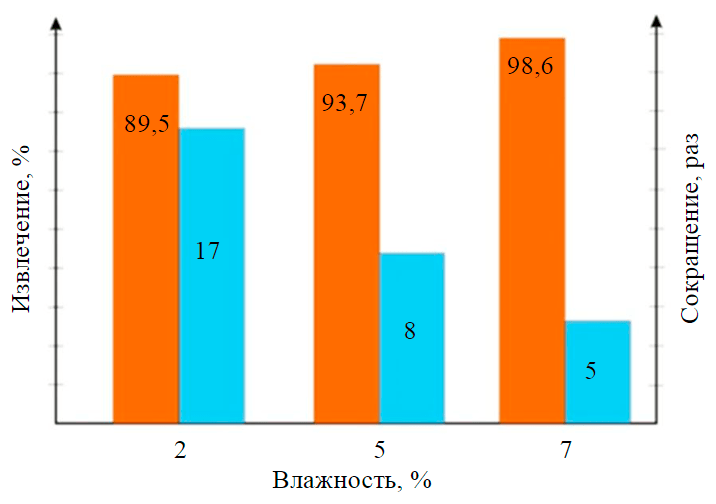

Fig.5. Histogram of recovery and reduction of medium density minerals as a function of moisture

Fig.6. POS-2000 pneumatic separator

In dry beneficiation, the foundations for the separation of minerals from crushed material by migration ability in an artificially created mineral-air flow were worked out. It is a significant deve-lopment in the field of pneumatic beneficiation methods, specifically for the beneficiation of minerals with high and medium density of mineral mixtures in artificially created aerodynamic flows. The development of theoretical and experimental studies made it possible to build a pneumatic screw separator, intended mainly for finishing operations for the beneficiation of minerals with high and medium density (gold, platinum, diamonds, zircon, ilmenite, etc.). In the screw pneumatic separator, the removed poor materials (tailings) and the heavy minerals passing into the accumulator move in the opposite direction. This minimizes the collision of oppositely directed grains of light minerals and minerals with high density, which makes it possible to achieve a high degree of extraction and reduce the feed material [34, 35].

The results of studies on the heavy minerals extraction are presented in Fig.5. The highest extraction of 89.5 % and reduction by 17 times at 2 % humidity was achieved at an air flow rate of 10 m/s.

The obtained research results make it possible to evaluate the area of effective separation of bulk material on a screw separator and the possibility of using it to achieve higher values of extraction, deg-ree of concentration, and reduction of the feed material.

All developed and manufactured equipment has passed various stages of implementation, including pilot tests on ores currently mined at gold deposits in the Republic of Sakha (Yakutia).

The developed and manufactured POS-2000 pneumatic separator (Fig.6) passed pilot tests at the Odolgo deposit (Amur region), the ore of which has a high proportion of free gold relatively coarse-grained gold. Technical specifications of POS-2000: productivity 6 t/h; power 5 kW; reduction of feed material (for gold ores) to 16 times; weight 2100 kg; fan performance 500-1500 m3/h.

POS-2000 pneumatic separator was tested in combination with the developed ore preparation devices (DKD-300 crusher, CMVU-800 centrifugal grinder). The results are shown in Table 4.

At the Zaderzhninskoye ore gold deposit, during pneumatic separation of finely ground material of −2 mm class at POS-2000, a reduction of 14-16 times was achieved, effective pneumatic separation was found without a significant loss in productivity and gold recovery, which is provided at a moisture content of up to 7 %.

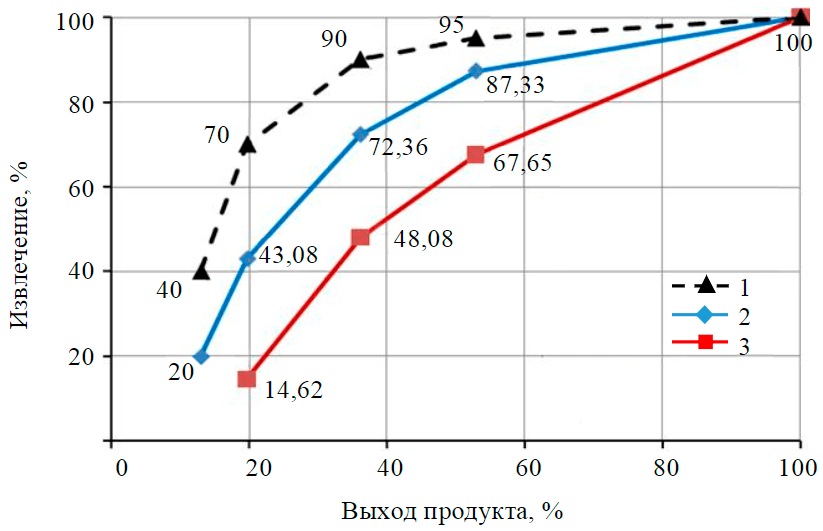

The pneumatic separator was also tested during the beneficiation of medium-density minerals, in particular, fluorite (Fig.7). A regularity was established: with a decrease in fluorite content in the ore entering the pneumatic separation, there is an increase in fluorite extraction into the concentrate. Thus, with a fluorite content in the ore of 35 %, the extraction into a 56 % concentrate is 67.65 %, with a decrease in the fluorite content to 9.8 %, an increase in extraction to 87.33 % is observed.

Fig.7. Dependence of fluorite extraction on the product yield at contents, %: 9.8 (1); 35 (2); estimated recovery at grade < 1 (3)

Table 4

Summary results of POS-2000 beneficiation for ore gold

|

Process indicators |

Content, g/t |

Material |

Degree of |

Recovery, % |

|

Tailings |

0.63 |

16 |

– |

1.36 |

|

Concentrate |

732 |

1 |

1159.28 |

98.64 |

|

Ore |

43.65 |

17 |

1 |

100 |

For ores with a low content of fine gold from pneumatic separation concentrates, it is possible, for example, to use flotation [36, 37], bacterial-chemical leaching [38], which are widely used in the mining industry.

The next stages in the development of pneumatic separation are associated with the increased efficiency of separation of mineral mixtures formed into aerodynamic flows under the influence of various physical fields in order to increase the degree of reduction and concentration. The conducted studies prove that both the methods under development and the developed methods of pneumatic separation can be used in the beneficiation of useful components (minerals) with medium and high density.

Conclusion

Highly efficient prototypes of beneficiation equipment were developed and tested: multiple impact crushers RD-MDV-900, DKD-300, centrifugal crushers CMVU-800 and VCI-12, pneumatic separator POS-2000. Fundamental designs were developed and a number of new devices for ore preparation and pneumatic beneficiation are being designed. The highest degree of crushing for the new high-performance crusher RD-MDV-900 with a value of 12 was established. The effective approbation of an autonomous complex for dry beneficiation with new safe environmental standards for the processing of gold-bearing ores is shown. It allows to completely release and extract free gold with a particle size from 10,000 to 100 µm.

In particular, this was confirmed by the example of the processing of gold-bearing ores from a number of deposits: Nezhdaninskoye, Duet, Sarylakh, Maltan, Nagornoye, Yakutskoye, Vyun, Malo-Tarynskoye (Yakutia), Gurbey (Irkutsk region), where results were obtained confirming the efficiency of dry beneficiation of ores with free gold.

The prospects for using dry beneficiation in the mining industry are remarkably high. For example, its implementation will allow in the future to withdraw from the construction of large beneficiation plants, completely or partially from the use of process water, the construction of a water supply system, a traditional tailing dump, etc.

References

- Yusupov T.S. Improvement of Dissociation of Rebellious Minerals. Journal of Mining Science. 2016. Vol. 52. N 3, p. 559-564. DOI: 10.1134/S1062739116030825

- Sotoudeh F., Nehring M., Kizil M.S., Knights P. Integrated underground mining and pre-concentration systems; a critical review of technical concepts and developments. International Journal of Mining, Reclamation and Environment. 2020. Vol. 35. Iss. 3. P. 153-182. DOI: 0.1080/17480930.2020.1782573

- Chelgani S.C., Neisiani A.A. Dry Mineral Processing. Cham: Springer, 2022. 156 p. DOI: 10.1007/978-3-030-93750-8

- Krasnogorov V.O., Tupikov D.Yu., Tupikov A.D. New developments in the field of electrical beneficiation of ores and pla-cers. Gornaya promyshlennost'. 2020. N 5, p. 30-31.

- Lakshmanan V.I., Ojaghi A., Gorain B. Beneficiation of Gold and Silver Ores. Innovations and Breakthroughs in the Gold and Silver Industries. Switzerland: Springer, 2019, p. 49-77. DOI: 10.1007/978-3-030-32549-7_4

- Nunna V., Hapugoda S., Eswarappa S.G. et al. Evaluation of Dry Processing Technologies for Treating Low Grade Lateritic Iron Ore Fines. Mineral Processing and Extractive Metallurgy Review. 2022. Vol. 43. Iss. 3, p. 283-299. DOI: 10.1080/08827508.2020.1837127

- Tripathy S.K., Banerjee P.K., Suresh N. et al. Dry high-intensity magnetic separation in mineral industry – a review of present status and future prospects. Mineral Processing and Extractive Metallurgy Review. 2017. Vol. 38. Iss. 6, p. 339-365. DOI: 10.1080/08827508.2017.1323743

- Gong D., Nadolski S., Sun C. et al. The effect of strain rate on particle breakage characteristics. Powder Technology. 2018. Vol. 339, p. 595-605. DOI: 10.1016/j.powtec. 2018.08.020

- Mamonov S.V., Zakirnichny V.N., Dresvyankina T.P. et al. Promising Dissociation Technologies for Preparation of Minerals to Flotation. Journal of Mining Science. 2019. Vol. 55. N 5, p. 839-848. DOI: 10.1134/S1062739119056210

- Wen-tao Zhou, Yue-xin Han, Yong-sheng Sun et al. Multi-scale impact crushing characteristics of polymetallic sulphide ores. Transactions of Nonferrous Metals Society of China. 2019. Vol. 29. Iss. 9, p. 1929-1938. DOI: 10.1016/S1003-6326(19)65100-9

- Khopunov E.A. A New Look at the Technology of Mineral Processing. Modern technics and technologies. 2015. N 3. URL: http://technology.snauka.ru/2015/03/5944 (accessed 18.04.2015) (in Russian).

- Nied R. Rotor Impact Mills. Handbook of Powder Technology. Amsterdam: Elsevier, 2007. Vol. 12, p. 229-249. DOI: 10.1016/S0167-3785(07)12008-X

- Lomovskiy I., Bychkov A., Lomovsky O., Skripkina T. Mechanochemical and Size Reduction Machines for Biorefining. Molecules. Vol. 25. Iss. 22. N 5345. DOI: 10.3390/molecules25225345

- Ballantyne G.R., Powell M.S. Benchmarking comminution energy consumption for the processing of copper and gold ores. Minerals Engineering. 2014. Vol. 65, p. 109-114. DOI: 10.1016/j.mineng.2014.05.017

- Neikov O.D. Mechanical Crushing and Grinding. Handbook of Non-Ferrous Metal Powders. Amsterdam: Elsevier, 2009, p. 47-62. DOI: 10.1016/B978-1-85617-422-0.00002-1

- Dey S.K., Dey S., Das A. Comminution Features in an Impact Hammer Mill. Powder Technology. 2013. Vol. 235,p. 914-920. DOI: 10.1016/j.powtec.2012.12.003

- Hee Chan Cho, Kwan Ho Kim, Hoon Lee, Dong Jun Kim. Study of residence time distribution and mill hold-up for a continuous centrifugal mill with various G/D ratios in a dry-grinding environment. Minerals Engineering. 2011. Vol. 24. Iss. 1, p. 77-81. DOI: 10.1016/j.mineng.2010.10.013

- Vaitekhovich P.E., Borovskii D.N., Grebenchuk P.S., Tabolich A.V. Determination of the Basic Parameters of Impact Interaction of Abrasive Particles Against the Blades of the Rotor Accelerator of a Centrifugal Mill. Chemical and Petroleum Engineering. 2018. Vol. 56, p. 156-160. DOI: 10.1007/s10556-018-0455-6

- Bardovskiy A.D., Gorbatyuk S.M., Keropyan A.M., Bibikov P.Ya. Assessing Parameters of the Accelerator Disk of a Centrifugal Mill Taking into Account Features of Particle Motion on the Disk Surface. Journal of Friction and Wear. 2018. Vol. 39, p. 326-329. DOI: 10.3103/S1068366618040037

- Urakaev F.K., Shumskaya L.G., Kirillova E.A., Kondrat’ev S.A. Improvement of Fine Milling Technology for Mining Waste Based on Proportioned Stage-Wise Disintegration. Journal of Mining Science. 2020. Vol. 56. N 5, p. 828-837. DOI: 10.1134/S1062739120057178

- Lvov E.S., Matveev A.I. Studying the Formation of Particle Size Distribution and Disclosure of Minerals in Ore Crushing Mill Using Multiple Dynamic Action DCD-300. Mining Informational and Analytical Bulletin. 2014. N 10, p. 112-116 (in Russian).

- Matveev A.I., Lvov E.S., Osipov D.A. Substantiation for the use of the DKD-300 combined impact crusher in the circuit of dry beneficiation of kimberlite ores from the Zarnitsa pipe. Journal of Mining Science. 2013. N 4, p. 107-115.

- Matveev A.I., Lvov E.S., Zaikina A.V. Dissociation of Gold Ore from Gurbey Deposit under Impact Effects. Journal of Mining Science. 2021. Vol. 57. N 2, p. 307-315. DOI: 10.1134/S1062739121020150

- Matveev A.I., Lvov E.S. Disintegratability Procedure for Geomaterials in Multiple Impact Crushing. Journal of Mining Science. 2020. Vol. 56. N 2, p. 283-287. DOI: 10.1134/S1062739120026769

- Matveev A I., Vinokurov V.R., Grigor'ev A.N. Patent N 2746502 В02С 7/00. Vertical centrifugal grinder. Publ. 14.04.2021. Bull. N 11.

- Tripathy S.K., Singh V., Murthy Y.R. et al. Influence of process parameters of dry high intensity magnetic separators on separation of hematite. International Journal of Mineral Processing. 2017. Vol. 160, p. 16-31. DOI: 10.1016/j.minpro.2017.01.007

- Sedinkina N.V., Gorlova O.E., Gmyzina N.V., Degodya E.Yu. Study of a possibility of enrichment of fine-crushed magnetite ore by dry magnetic separation. Ferrous Metallurgy. Bulletin of Scientific, Technical and Economic Information. 2019. Vol. 75. N 5, p. 564-571. (in Russian). DOI: 10.32339/0135-5910-2019-5-564-571

- Pelevin A.E., Sytykh N.A., Cherepanov D.V. Particle size impact on dry magnetic separation efficiency. Mining Informational and Analytical Bulletin. 2021. N 11-1, p. 293-305 (in Russian). DOI: 10.25018/0236_1493_2021_111_0_293

- Shelenin A.V. Patent N 2699287 RU. Device for dry beneficiation of gold ores. Publ. 04.09.2019.

- Bauman A.V., Stepanenko A.I., Stepanenko A.A. The working knowledge and prospects for dry concentration of ores and nonmetallic materials by pneumatic separation. Gornyi Zhurnal. 2019. N 3, p. 40-44 (in Russian). DOI: 10.17580/gzh.2020.03.07

- Chenlong Duan, Chenyang Zhou, Liang Dong et al. A novel dry beneficiation technology for pyrite recovery from high sulfur gangue. Journal of Cleaner Production. 2018. Vol. 172, p. 2475-2484. DOI: 10.1016/j.jclepro.2017.11.162

- Jingfeng Hea, Qiang Bai, Tianye Du. Beneficiation and upgrading of coarse sized low-grade bauxite using a dry-based flui-dized bed separator. Advanced Powder Technology. 2020. Vol. 31. Iss. 1, p. 181-189. DOI: 10.1016/j.jclepro.2017.11.162

- Baawuah E., Kelsey C., Addai-Mensah J., Skinnera W. Assessing the performance of a novel pneumatic magnetic separator for the beneficiation of magnetite ore. Minerals Engineering. 2020. Vol. 156. N 106483. DOI: 10.1016/j.mineng.2020.106483

- Honaker R.Q., Saracoglu M., Thompson E. et al. Upgrading Coal Using a Pneumatic Density-Based Separator. International Journal of Coal Preparation and Utilization. 2008. Vol. 28. Iss.1, p. 51-67. DOI: 10.1080/19392690801934054

- Matveev A.I., Lebedev I.F., Nikiforova L.V., Yakovlev B.V. Modeling of Motion of Particles in the Screwed Version of Air Separator. Mining Informational and Analytical Bulletin. 2014. N 10, p. 172-178.

- Aleksandrova T.N., Elbendari A.M. Increasing the efficiency of phosphate ore processing using flotation method. Journal of Mining Institute. 2021. Vol. 248, p. 260-271. DOI: 10.31897/PMI.2021.2.10

- Aleksandrova T., Elbendari A., Nikolaeva N. Beneficiation of a low-grade phosphate ore using a reverse flotation technique, Mineral Processing and Extractive Metallurgy Review. 2022. Vol. 43. Iss. 1, p. 22-27. DOI: 10.1080/08827508.2020.1806834

- Kioresku A.V. Intensification of Bacterial-Chemical Leaching of Nickel, Copper and Cobalt from Sulfide Ores Using Mic-rowave Radiation. Journal of Mining Institute. 2019. Vol. 239, p. 528-535. DOI: 10.31897/PMI.2019.5.528