Specifics of geotechnical risk control in the design of underground structures

- 1 — Ph.D., Dr.Sci. Professor National University of Science and Technology NUST “MISIS” ▪ Orcid

- 2 — Ph.D. Associate Professor National University of Science and Technology NUST “MISIS” ▪ Orcid

- 3 — Engineer Mosinzhproekt OAO ▪ Orcid

Abstract

The underground space development is associated with the emergence of complex and dangerous situations, often leading to accidents. The condition for their development is the potential geotechnical risks. High-quality execution and analysis of design work at all the stages of design, starting from the early stages, is one of the effective ways to control risks. Clarification of the characteristics and features of the rock mass adjacent to the projected underground structure makes it possible to identify the potential cause of the occurrence of an adverse event with a certain probability during the construction and operation of an underground structure. The purpose of a qualitative risk analysis is to identify risk factors in underground construction. The value of the total geotechnical risk, expressed by the sum of each of the possible risks, should be numerically estimated at the design stage of a specific underground facility. At the same time, it is extremely important to develop a methodology for managing geotechnical risks, which would make it possible to assess their probability of development at an early stage of project preparation and propose measures to reduce or prevent them. This technique is given in the article. The results of the study conducted in accordance with the presented methodology showed that geotechnical risk control proved an effective method in preventing accidents during underground construction.

Introduction

The safety of underground facilities during construction and operation depends on the risk assessment of a potential emergency [1-3], as well as on the possibility of preventing the cause of its occurrence [4]. Emergencies are caused by specific engineering-geological, hydrogeological and urban planning conditions for the placement of underground facilities: the presence of a thick layer of man-made and karst soils; dense urban development and cramped conditions; high groundwater activity; suffusion manifestations; technogenic impacts on the geological component of the city, complicating the conditions of construction and operation of underground structures; involvement in the construction process of a large number of non-core specialists and organizations. These risk factors determine the need for their identification and accounting during the entire life cycle of an underground structure, which is designed to optimize the choice of the location of the object and the appropriate protective measures.

The studies of many Russian scientists address the issues of the development of aerological [5, 6], geoecological and geotechnical risks [7, 8], their quantitative assessment [9, 10], risk management [11, 12], however, do not take into account the specifics of risks dynamics in the conditions of the underground space development of the city. Basically, the issues of mining are considered where the risk is caused by the processes of mining. A number of works [13-15] are directly related to risks in underground construction. Foreign authors either focus on purely geotechnical risks [16, 17] or consider risk minimization methods also applied to mining [18, 19]. The weak point of all these studies is the lack of a unified regulatory and methodological approach to risk assessment and control.

An analysis of the domestic and international regulatory framework on risks, based on more than 30 national and international standards, industry rules, norms, recommendations and guidelines, allows drawing the following conclusions.

- The increasing complexity of risks manifestation in the world practice of tunnelling requires the creation of codes, standards, instructions and manuals that serve as a kind of “best practice” of how risk control should be built. However, these normative and methodological materials are scattered, there are no connections, sources of the used information, and the scope and technical requirements between them. The variety of approaches to formalization, description, definition and risk assessment create conditions for the development of the important categories for this research area, such as classifications, terms and definitions used in practice.

- Regulatory and legal approaches to risk control in Russia are determined by two aspects: operating with reference literature, containing terminology, information on risk identification, the procedure for their analysis and control on the one hand, and following state legal documents in the form of federal laws, departmental and other rules, requirements, orders, as well as translated international risk management standards and Bank of Russia documents, on the other hand.

- All the regulatory documents on risk control, available in the world practice, are focused mainly on compliance with commercial or financial interests, while the technological, organizational and managerial side is practically not affected.

- There is no concept of “geotechnical risk” in the regulatory and technical documentation of the Russian Federation on the construction of technically complex and hazardous production facilities.

- Due to the variability of the conditions for conducting underground construction work [20], the risk control should provide for the formation of an organizational infrastructure fixed in the standard, the functions of which would include an analysis of the internal and external situation for risk assessment.

- A new approach to the industry component of risk control is needed, taking into account the trends of financial policy and regulation of individual elements of organizations activities when implementing measures to prevent or minimize risk in underground construction. At the same time, risk control should take into account all the best that has been created in world practice, but be based on the management culture that has developed in our country. Strict requirements should be imposed on management personnel, who should equally have the high art of developing the best risk control strategy in a particular case and possess special knowledge in the field of tunnel construction.

When constructing underground structures, one of the main types of risks is construction risk [10, 21]. During construction, an emergency arises due to two independent negative events: an external non-project impact [22] and an event related to errors in projects [23]. Errors at the design stage and during construction determine the dynamics of risk development at subsequent stages. The leading role in determining the nature of the manifestation of one of the types of construction risks – geotechnical – belongs to a competent assessment of the engineering and geological conditions of mining operations [24].

Geotechnical risks have a huge impact on the occurrence of adverse factors due to the inherent heterogeneity of the rock mass [25], which contributes to significant variability of geotechnical parameters. This entails economic damage, reduces the safety, and quality of construction work [13]. Since underground mining is characterized by the joint work of mining equipment and people, the combination of the limited working space with the uncertainty of geotechnical data leads to an inevitable increase in the risk of accidents. For example, at metro facilities, 10 % of accidents are associated with survey deficiencies; 6 % – with violations of technological regimes, rules and regulations; 8 % – improper and untimely preventive inspections; 14 % – with design flaws or incorrectly selected materials; about 30 % – with deviations from the passport of work [14]. The remaining causes of accidents are due to the underestimation of the nature of the interaction of the underground structure and the environment.

A formal risk assessment is its definition as the product of the probability of the considered danger and the consequences caused by adverse events. This assessment implies [26] determining the amount of data for risk assessment and identifying the hazards in this volume. To determine the probability of the development of this event and its consequences, it is necessary to conduct a comparative qualitative and quantitative assessment [11]: as a result, we obtain risk-forming factors [27] and their total number. Thus, it becomes possible to assess the actual probability and consequences of the danger [16]. The development of a risk management methodology allows controlling them during construction [28].

Methodology

There are many methods for assessing geotechnical risk: Monte Carlo, Delphi, the analysis of failure tree, events, malfunctions, inspection reports, reliability block diagram, qualimetric assessment, analogy method, etc. The choice of the method depends on how fully it takes into account the objectives and evaluation criteria, the possibility of obtaining information, the level of acceptable risk, the type of system being analyzed, the nature of emerging hazards, the availability of material, financial and labor resources to perform the work, etc. The chosen method should be scientifically justified, reliable and effective in terms of assigning measures to minimize risk. To choose a risk management method, a plan is drawn up.

- Selection of the main controlled parameters of underground works:

– design – caused by the imperfection of the project materials, incorrect interpretation of the initial data, overestimated estimated cost, misunderstanding by the customer and contractors of the goals and objectives of the project, etc.;

– engineering-geological – caused by the manifestation of geological risks, including those developing under the influence of man-made factors;

– constructive – caused by design flaws and the choice of materials with the characteristics unsuitable for these conditions;

– geoecological – heat and mass transfer, aggressive environment and others, i.e. factors influencing the choice of technology for the construction of an underground facility and environmental safety;

– technological – factors affecting the quality of the object under construction and operation;

– factors affecting the safety of the surrounding buildings and communications in the construction area.

These parameters are closely related to each other and are integral parts of geotechnical risk, the assessment of which can be carried out by scoring or expert methods.

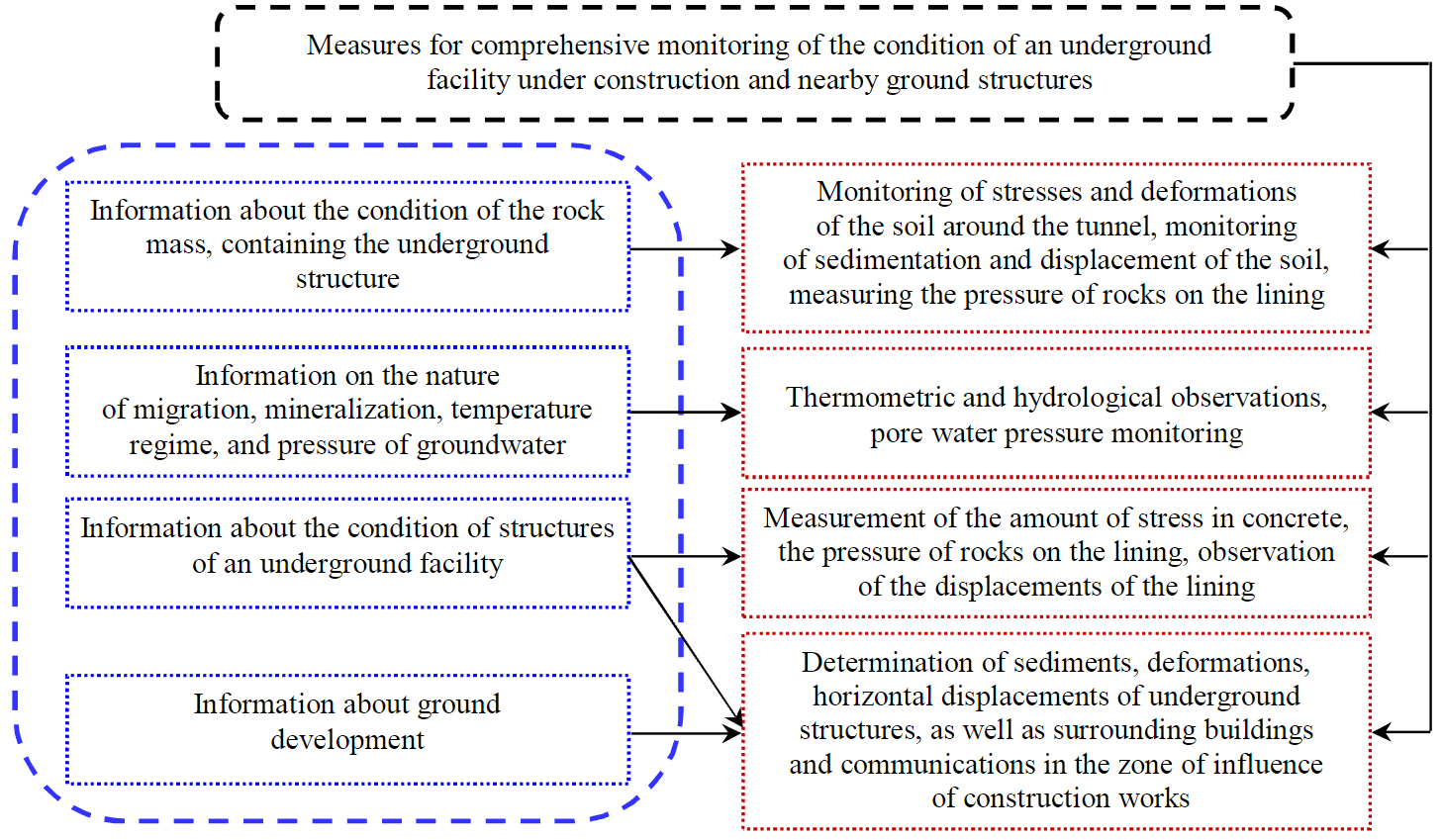

- Justification of measures for a comprehensive monitoring system for the condition of an underground facility under construction and nearby ground structures (Fig.1).

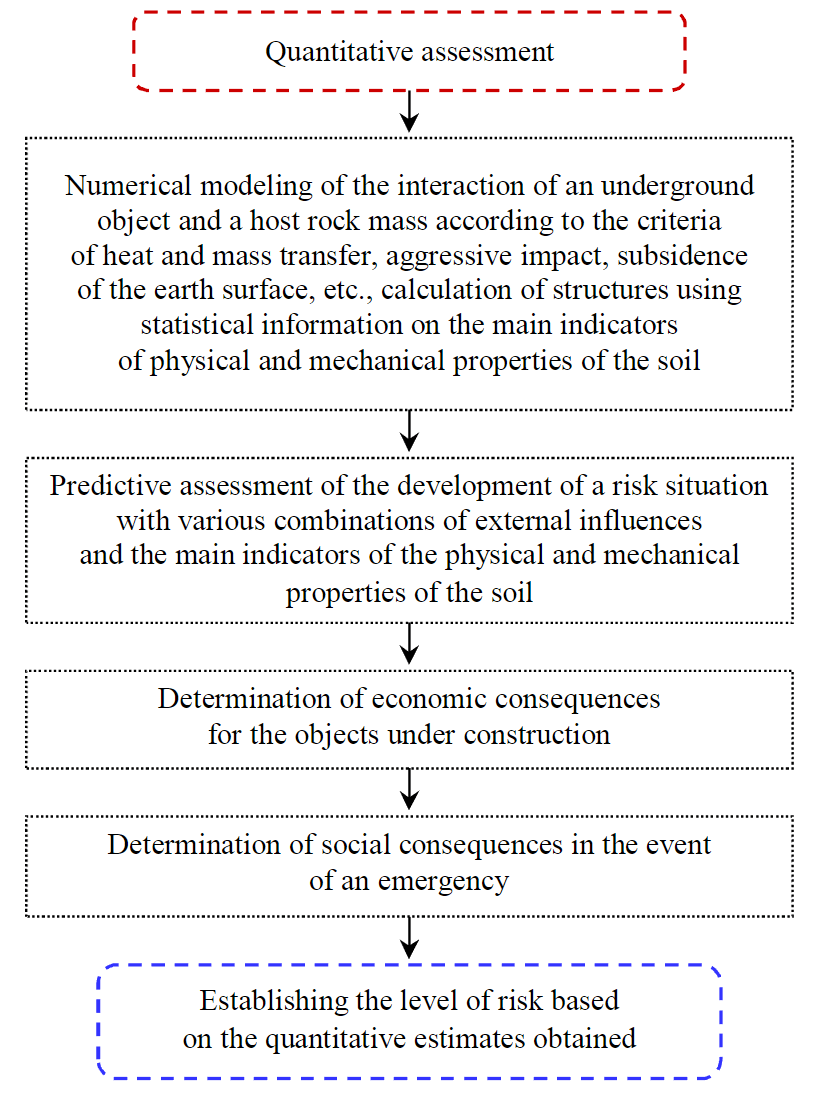

- Choosing a risk assessment method. The scoring that takes into account the qualitative characteristics of the factors of influence (Fig.2) and is based on the accounting of correction coefficients, allows the expert group to find variations of solutions depending on the information availability and the specifics of technologies and methods of underground construction.

Fig.1. Measures to monitor the condition of the object under construction

Fig.2. Quantitative risk assessment

The criterion of geotechnical risk on the site of an underground facility during its construction and operation, proportional to the magnitude of the score, is the frequency of accidents, which is directly related to the specific technology of underground space development. For underground tunnel-type structures, in accordance with the expected emergency, the length of each section of the route is varied, according to which the specific risk indicators are estimated. Thus, at each site it is possible to clarify information about the technical condition of the underground structure and predict the local frequency of potential accidents.

The technical condition of the underground structure for the n-th section can be determined based on scoring estimates according to the following dependence [29]:

where pi – the share of the i-th group of factors; qij – the share of the j-th factor in the i-th group; Bij – evaluation of the Fij factor , formalized in scores; B* – the average score of the underground structure along the entire length, obtained on the basis of the score of each section.

The local frequency of the accident ln can be determined as [29]:

where – the average frequency of accidents at this underground facility, the number of accidents /(km⋅year).

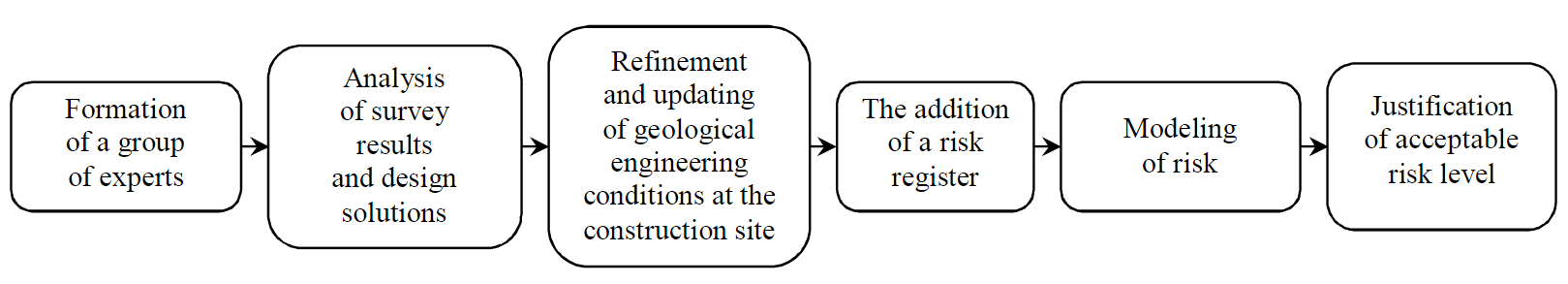

We can define the value of the coefficient of influence Kinf as the ratio of the local frequency of accidents ln on the site to its average value If, as a result of calculations, it’s not possible to obtain a representative amount of statistical data, then the risk is evaluated using expert assessments of non-numerical etiology with the assignment of a risk level (high, low, etc.). Processing the results implies an analysis of the probability of potential inaccuracies in engineering and geological surveys that complicate the choice of technologies, and the reliability of the results of geotechnical and geomechanical surveys of buildings and structures on the surface. Complexity of geotechnical conditions in the construction area [30] determines the development of adverse risk events, which should be taken into account in the proposed methodology. Carrying out measures to systematize materials characterizing the construction area [31], including their analysis, is an important stage in the geotechnical risk management system, since with their help it is possible to identify the causes of the development of an adverse event during the construction of an underground facility, and subsequently proceed to a quantitative risk assessment [32] (Fig.3).

Fig.3. Measures for the systematization and analysis of materials of construction area

Experts play a key role in identifying and systematizing the causes of geotechnical risks during the construction of underground structures, as well as in quantifying risks when determining the biggest possible damage from the occurrence of a risky event. The magnitude of the expected damage from construction work can be established by identifying geotechnical risks that are included in the registration statement, which provides a basis for their quantitative assessment. The task facing the experts is divided into several stages: determining possible adverse events, ranking them, identifying the magnitude of potential damage at the appropriate stage of construction work, assigning technological, constructive and organizational measures aimed at minimizing risks.

One of the stages of quantitative assessment consists of determining the combination of the probability of occurrence of a risk event and the expected damage. An important stage for experts is to determine the construction time or the cost of work compared with the same indicators laid down in the project in percentage terms. Numerical values of the degree of risk are distinguished: a very high level of risk (5 points) is characterized by a frequency of 0.6-1 and a probability of occurrence of an event of 70; a high level (4 points) – 1-10–1 with a probability of 50-70; average (3 points) – 10–1-10–2 and 30-50; for low (2 points) – 10–2-10–3 and 10-30; for very low (1 point) – less than 10–3 with a probability of less than 10. Data on the expected damage in quantitative terms: 10 % – 5 points; 8-10 % – 4 points; 4-8 % – 3 points; 1-4 % – 2 points; 1 % – 1 point.

With the help of system analysis [27], an expert assessment is processed according to probabilistic and statistical methods, after which a numerical value of the degree of risk is established. In order to assess the level of an adverse event and the degree of the need to make decisions to prevent it, a scale of the numerical value of the risk is built based on the analysis of the magnitude of the expected damage (see the table).

Quantitative risk assessment and identification of measures to minimize emergencies

|

Level of risk |

Measures to reduce the probability of an adverse event |

|

Very low 1-5 |

Missing |

|

Low 6-10 |

Minor structural and strengthening transformations |

|

Average 11-15 |

Making constructive or other changes to the project without additional financial investments |

|

High 16-20 |

Termination of construction work until the stabilization of undesirable changes and reduction of the degree of risk, additional financial investments are required |

|

Very high 21-25 |

Project implementation ban |

After the first stage of determining the quantitative assessment of risks, experts begin to re-evaluate the degree of manifestation of adverse events and enter new results into the registration statement, taking into account the measures already taken.

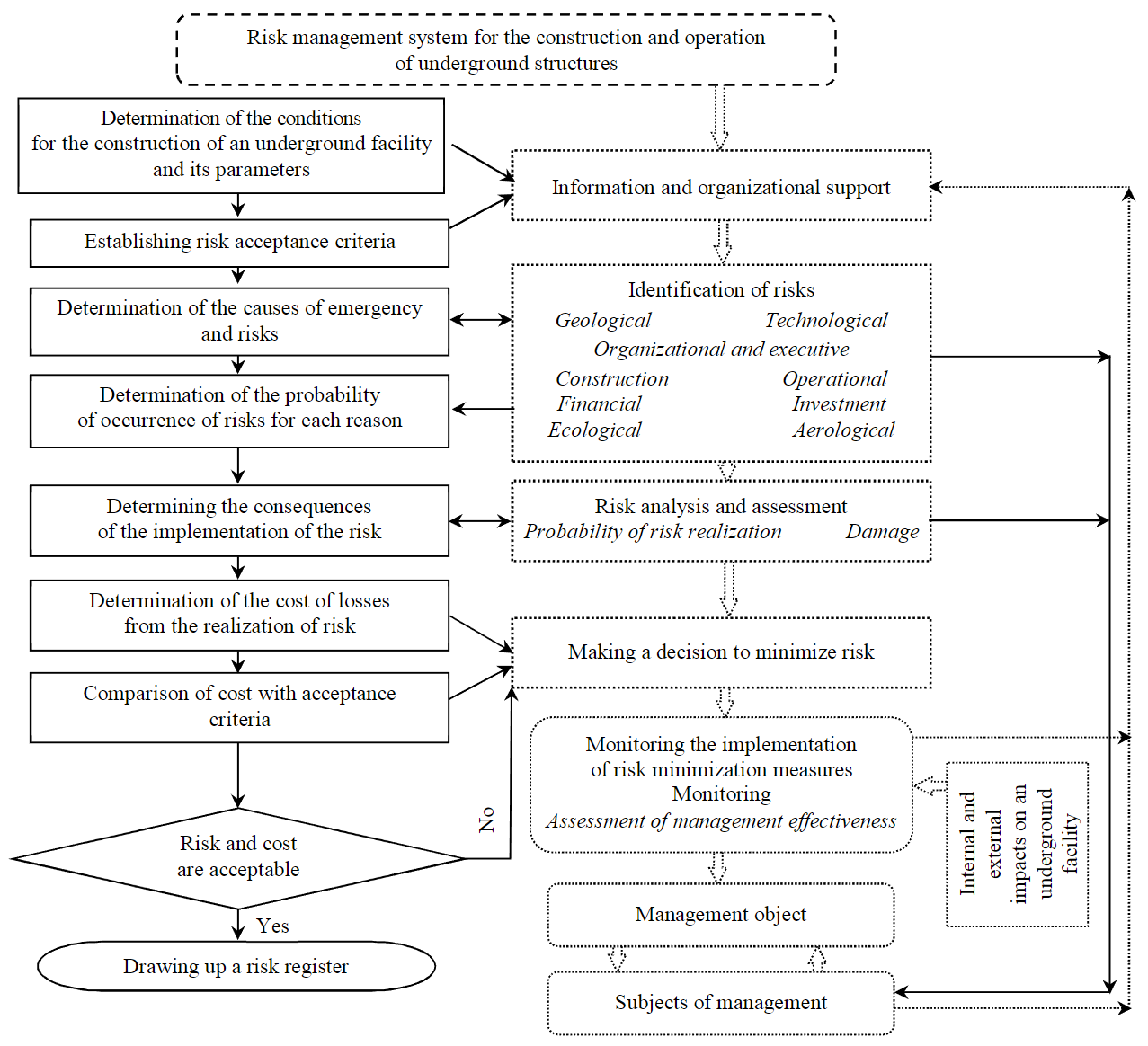

- Drawing up a risk management algorithm for the construction of underground facilities (Fig.4).

Fig.4. General risk control algorithm in underground construction

Results

According to the methodology described above, a study was conducted during the design and construction of the Sheremetyevo Airport terminal-to-terminal crossing. The object of the study is a group of structures consisting of the northern and southern station complexes and a tunnel section between them passing under the runway of the current Sheremetyevo airport. The transport section of the facility under the runways includes: single-track tunnels of an automated passenger and baggage transportation system; three technological cross passages; a drainage installation chamber. The construction of one of the tunnels is combined with the dismantling and construction of the structures of the projected terminal B, the second one – with the unification of terminals D and E and an aboveground pedestrian gallery between them. Two main line single-track tunnels are constructed in a closed manner using tunnelling mechanized complexes from the northern station complex to the southern one. To organize the passage of subway tunnels, an assembly-shield chamber is provided in the pit from the northern station complex side, and a dismantling-shield chamber from the southern one. At the inset and exit of the shields, the soil is strengthened by the method of jet cementation. To ensure the stability of the pits [23], the station complexes are constructed by “wall in the ground” method [31]. Due to the large width and length of the pit, their fastening is carried out by anchors and belts made of I-beams. The tunnels are mainly based on medium-sized sands and semi-solid loam. Within the construction site, four aquifers are found to the investigated depth of up to 80 m. During the construction of the tunnel section of the closed method of work, precast reinforced concrete lining was used. To ensure its full contact with the surrounding soil, the device of a jacket made of grouting solution is provided when installing blocks. Technological cross passages are provided for communication between the transport and baggage tunnels. The construction of structures is carried out in a closed way in the opening of the rings of subway tunnels with shielding by pipes. The lining of the cross passages has a rectangular outline. The structure is designed in monolithic reinforced concrete with internal metal insulation, which is protected from corrosion by a layer of shotcrete solution applied on the grid. The structure of the enclosure of the excavation of the northern station complex is adopted from a monolithic “wall in the ground”. The fastening of the fence is carried out using an anchor-bracing system. To transfer the load [33] to the anchors and struts, a longitudinal belt is arranged from two I-beams, as well as buntons and struts. For the lining of structures erected in an open way, waterproofing of PVC membrane is provided. Waterproofing on the coating is protected by a layer of fine-grained concrete reinforced with two reinforcing grids.

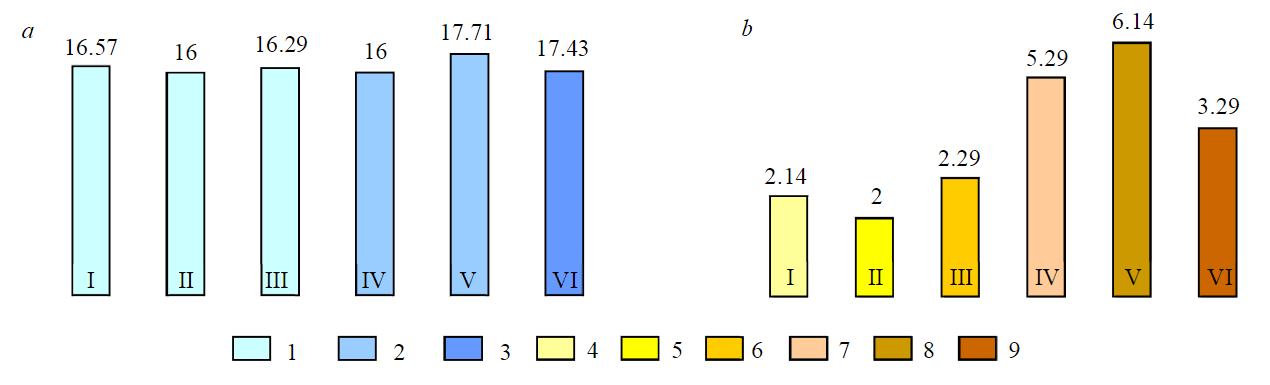

Fig.5. The level of risk of an adverse event and expected damage, depending on the cause of their occurrence (a), and emergency after preventive measures (b) I – errors in calculations of load-bearing and enclosing structures; II – incorrect design of joints of struts and strapping belts; III – errors in the design of ground anchors; IV – the imposition of troughdeformations of the surface due to nearby tunnels; V – runway base suffusion with the formation of voids under it; VI – entry of tonnel boring machine into the lens of water-saturated sand 1 – insufficient load-bearing capacity of load-bearing and enclosing structures, which will lead to their unacceptable deformations, as well as to deformations of surrounding buildings; 2 – additional subsidence of the surface, which will lead to a violation of the operability and operational reliability of airfield coverings and infrastructure; 3 – additional subsidence of the airfield surface due to the uncertainty of geological conditions along the tunnel route (lenses of water-saturated sandy soil, boulders, unaccounted communications), which will lead to deformation of the hull and shell of the shield, jamming of the rotor or to failures on the surface; 4 – carrying out verification calculations by an independent organization in a certified geotechnical software package; 5 – carrying out geotechnical expertise of project documentation and geotechnical monitoring; 6 – carrying out verification calculations by an independent organization in a certified geotechnical software package, monitoring anchors, preliminary testing of anchors; 7 – compensation of deformations due to strengthening of the soil mass; 8 – geophysical studies of the foundation of runway, filling voids before sinking under the runway, geotechnical monitoring; 9 – exploratory drilling and geophysical surveys before sinking dangerous areas

All the listed data were thoroughly examined, and a study was conducted on their basis. According to the results of the study, the risks attributed to the high ones were described (Fig.5, a).

In addition to high risks, the probability of occurrence of medium and 18 low risks was revealed. The risks classified as average and their level: underestimation of filtration and consolidation properties of the soil mass – 12.57; opening of unaccounted engineering water-carrying communications during the development of the pit – 13.86; underestimation of technological subsidences from trench development during the construction of a “wall in the ground” – 14.14; unclosed construction seams filtering water – 14.14; the flow of water into the pit through the soil inclusions in the “walls in the ground” formed during the production of concreting works – 11.71; poor quality of work in the installation of attachment points for buntons – 11.71; the inconsistency with the design of the geometric parameters of the “wall in the ground” structure, the binding belts, the distribution system – 12.57; flooding of the rock mass during the breakthrough of water-carrying communications – 13.86; fuel leakage in the tunnel during the breakthrough of fuel pipelines – 12.14; poor-quality waterproofing device of structures nearby tunnels – 13.57; fallout on the portal sections of the tunnel – 12.14; poor–quality installation of blocks – 11.71; injection of insufficient volume of grouting solution into the tunnel sealing space – 14.43; untimely fixing tamponage – 12.29.

To prevent high-level risks, the recommendations aimed at minimizing them are proposed: carrying out verification calculations by an independent organization in a certified geotechnical software package; geophysical studies of the runway base; filling voids [24] before sinking under the runway; exploration drilling and geophysical studies before sinking dangerous areas. To minimize the risks of medium and low levels, measures are needed that do not require additional costs, after which the risk assessment is carried out again (Fig.5, b).

When carrying out construction work, the priority is to preserve the health and life of workers, therefore planning construction work with a high or medium level of risk is unacceptable. Based on the results of the risk analysis, it is possible to react faster to the probability of an emergency. When the level of potential risk tends to medium or high values, it is necessary to take timely measures to reduce it, prevent accidents, personnel injuries, equipment losses, etc. In accordance with the proposed methodology, after the measures carried out, the level of occupational injuries can be reduced by 63.15 %. From Fig.5, b it follows that when additional measures are taken to prevent risks, their level is significantly reduced and ranges from small to very small.

Discussion

The complexity of the underground space development in modern conditions and the instability of engineering-geological and technological conditions entail the development of emergency situations. It is necessary to choose such a risk assessment methodology, where each risk will be considered individually in a comprehensive risk assessment system specific to a particular construction object, which will allow taking into account their specific features and developing effective ways of control and management. The proposed methodology is effective in assessing geotechnical risks and predicting adverse situations that reduce the safety of construction work and increase their cost indicators, since it includes a whole complex of flexible management characterized by interactive connection of the technological process and its control aimed at reducing the probability of risk. An algorithm for risk management in underground construction has been developed.

The methodology based on a risk-oriented approach allows identifying a weak link in the selection of technology and organization of construction; choose a tool for monitoring the vulnerability of elements of the natural and technical geosystem underground structure – rock mass – technology – environment and measures to eliminate the emerging instability. The main advantages of the proposed approach are:

- minimization and timely elimination of errors in the design of an underground facility;

- early identification of geotechnical risks and risk-forming factors;

- improving the efficiency of underground construction;

- the possibility of modeling the dynamics of risk development at a specific underground facility based on archival, operational, and forecast data;

- determination of optimal measures to minimize geotechnical risks based on the most complete information about the object;

- the possibility of flexible response to vulnerability indicators of the elements of the natural and technical geosystem;

- in-depth analytics on all elements of the formed natural and technical geosystem at all stages of its life cycle, including analysis of the causes and relationships between risks. Such analytics becomes a tool for building complex risk models and templates for more accurate forecasts of the development of the emergencies.

The disadvantages of the approach are the difficulties of forming a group of highly qualified experts. Prospects for the development of such risk management methods in the implementation of technological processes in underground construction – the creation of a Big Data bank and the introduction of the building information modeling BIM-technologies. This will make possible to achieve proactive management of geotechnical risks before their full development by identifying signs of the onset of a negative event at an early stage of its development and reducing the response time to the factors of the manifestation of an emergency.

Conclusion

The specifics of geotechnical risk control in underground construction are: the need for a thorough analysis of the variability of the engineering and geological condition of the rock mass containing the underground structure, which may lead to an erroneous design or technical solution for the construction of this facility; clarification of geotechnical data at all stages of project preparation and in the process of its implementation. The study conducted in accordance with the proposed methodology showed that with timely response to the occurrence of abnormal and emergency during the development of underground space, high-quality construction and installation work and additional measures, the risk level can be significantly minimized. This can be achieved with an integrated approach to geotechnical risk management at all stages of the life cycle of an underground structure.

A general algorithm for risk management in underground construction has been synthesized, which provides for the selection of the main controlled parameters of underground work, systematization and analysis of materials in the construction area, justification of measures for a comprehensive system of monitoring the condition of an underground facility under construction and nearby ground structures.

A well-chosen methodology for assessing geotechnical risks determines the effectiveness of their management and the correctness of measures for the safe implementation of construction works. The methodology presented in the article, based on the example of risk assessment during the construction of the Sheremetyevo airport terminal crossing, allowed raising the question of creating flexible risk management systems in underground construction based on expert assessment, timely and effective monitoring methods and varying the pass coefficient and impact coefficient.

It has been established that, in relation to the interterminal crossing of Sheremetyevo Airport, significant potential risks are due to insufficient load-bearing capacity of structures, leading to unacceptable deformations of these structures and surrounding buildings with additional subsidence of the earth’s surface in the area of construction and the airfield itself, entailing a violation of the operability and operational reliability of airfield coverings and infrastructure due to the uncertainty of geological conditions along the tunnel route (lenses of water-saturated sandy soil, boulders, unaccounted communications), which, in turn, will provoke deformations of shield hull and shell, jamming of the rotor or will lead to failures on the surface. Therefore, the in-depth analysis of all risk development factors at the design stage becomes a tool for building complex risk models and templates for more accurate forecasts of the growth of emergency. This makes it possible to design urban underground facilities in a new way in the conditions of hidden construction conditions, unreliability or insufficiency of the survey and analytical database.

References

- Konyukhov D.S. Analysis of mechanized tunneling parameters to determine the overcutting characteristics. Gornye nauki i tekhnologii. 2022. Vol. 7. N 1, p. 49-56 (in Russian). DOI: 10.17073/2500-0632-2022-1-49-56

- Volokhov E.M., Mukminova D.Z. Deformations assessment during subway escalator tunnels construction by the method of artificial freezing of soil for the stage of ice wall formation. Journal of Mining Institute. 2021. Vol. 252, p. 826-839. DOI: 10.31897/PMI.2021.6.5

- Karasev M.A., Sotnikov R.O. Prediction of the Stress State of the Shotcreting Support under Repeated Seismic Load. Journal of Mining Institute. 2021. Vol. 251, p. 626-638. DOI: 10.31897/PMI.2021.5.2

- Potapova E.V. Typology of metro structures for the tasks of geotechnical risk classification. Mining Science and Technology. 2021. Vol. 6. N 1, p. 52-60. DOI: 10.17073/2500-0632-2021-1-52-60

- Balovtsev S.V., Skopintseva O.V. Assessment of the Influence of Returned Mines on Aerological Risks at Coal Mines. Mining informational and analytical bulletin. 2021. N 2-1, p. 40-53 (in Russian). DOI: 10.25018/0236-1493-2021-21-0-40-53

- Skopintseva O.V., Balovtsev S.V. Evaluation of the influence of aerodynamic aging of production on aerological risks on coal mines. Mining informational and analytical bulletin. 2020. N 6-1, p. 74-83 (in Russian). DOI: 10.25018/0236-1493-2020-61-0-74-83

- Kulikova A.A., Kharlamova T.A., Khabarova E.I., Kovaleva A.M. On the Issue of Assessing the Impact of Microbiological Biocenoses on the Geoecological and Geotechnical Risks of Mining Enterprises. Ugol'. 2022. N 4, p. 67-71 (in Russian). DOI: 10.18796/0041-5790-2022-4-67-71

- Chunyuk D.Yu. Ensuring safety and reducing risks in geotechnical construction. Vestnik Moskovskogo gosudarstvennogo stroitelnogo universiteta. 2008. N 2, p. 107-111 (in Russian).

- Deineko A.V., Serova E.A., Chunyuk D.Yu. The specifics of quantitative analysis of geotechnical risk. Vestnik Moskovskogo gosudarstvennogo stroitelnogo universiteta. 2010. N 4, p. 369-373 (in Russian).

- Kulikova E.Yu. Methods of forming an integral risk assessment in mine and underground construction. Mining informational and analytical bulletin. 2021. N 2-1, p. 124-133 (in Russian). DOI: 10.25018/0236-1493-2021-21-0-124-133

- Kuznetsova M.O. Risk Management Implementation Practices in Russian Industrial Companies: Results of an Empirical Study. Strategic decisions and risk management. 2019. Vol. 10. N 4, p. 410-423 (in Russian). DOI: 10.17747/2618-947X-2019-4-410-423

- Merkin V.E., Zertsalov M.G., Konyukhov D.S. Geotechnical risk management in underground construction. Metro i tonneli. 2013. N 6, p. 36-39 (in Russian).

- Konyukhov D.S. Criteria Analysis of Contemporary Technologies of Underground Construction. Geotechnics. 2021. Vol. XIII. N 1/2021, p. 40-55 (in Russian). DOI: 10.25296/2221-5514-2021-13-1-40-54

- Kulikova E.Yu., Balovtsev S.V. Risk control system for the construction of urban underground structures. IOP Conference Series: Materials Science and Engineering. 2020. Vol. 962. Iss. 4. N 042020. DOI: 10.1088/1757-899X/962/4/042020

- Potapova E.V. Expert-statistical approach to the analysis of geotechnical risks in the construction of metro facilities. IOP Conference Series: Materials Science and Engineering. 2020. Vol. 962. Iss. 4. N 042052. DOI: 10.1088/1757-899X/962/4/042052

- Clayton C.R.I. Managing geotechnical risk: time for change? Geotechnical Engineering. 2001. Vol. 149. Iss. 1, p. 3-11. DOI: 10.1680/geng.2001.149.1.3

- Mishra R.K., Rinne M. Geotechnical Risk Classification for Underground Mines. Archives of Mining Sciences. 2015. Vol. 60. N 1, p. 51-60. DOI: 10.1515/amsc-2015-0004

- Hebblewhite B.K. Geotechnical risk in mining methods and practice: critical issues and pitfalls of risk management. Proceedings of the First International Conference on Mining Geomechanical Risk, 9-11 April 2019, Perth, Australia. Perth: Australian Centre for Geomechanics, 2019, p. 299-308. DOI: 10.36487/ACG_rep/1905_17_Hebblewhite

- Mishra R.K., Janiszewski M., Uotinen L.K.T. et al. Geotechnical Risk Management Concept for Intelligent Deep Mines. Procedia Engineering. 2017. N 191, p. 361-368. DOI: 10.1016/j.proeng.2017.05.192

- Trushko V.L., Protosenya A.G. Prospects of Geomechanics Development in the Context of New Technological Paradigm. Journal of Mining Institute. 2019. Vol. 236, p. 162-166. DOI: 10.31897/PMI.2019.2.162

- Carlsson M. Management of geotechnical risks in infrastructure projects: an introductory study. Stockholm: KTH, 2005, p.156.

- Poddubnyi V.V. Justification of engineering solutions for the effective development of the underground space of the big and mega cities: Avtoref. dis. … kand. tekhn. nauk. Ekaterinburg: Uralskii gosudarstvennyi gornyi universitet, 2008, p. 20 (in Russian).

- Ignatyev S.A., Sudarikov A.E., Imashev A.Z. Modern Mathematical Forecast Methods of Mainte-nance and Support Conditions for Mining Tunnel. Journal of Mining Institute. 2019. Vol. 238, p. 371-375. DOI: 10.31897/PMI.2019.4.371

- Sultanov K.S., Loginov P.V., Ismoilova S.I., Salikhova Z.R. Quasistaticity of the process of dynamic strain of soils. Magazine of Civil Engineering. 2019. N 1 (85), p. 71-91. DOI: 10.18720/MCE.85.7

- Demenkov P.A., Goldobina L.A., Trushko O.V. Method for Forecast of Surface Deformation during Excavation Operations in Restraint Urban Conditions Using the Slurry Trench Technique. Journal of Mining Institute. 2018. Vol. 233, p. 480-486. DOI: 10.31897/PMI.2018.5.480

- Kulikova E.Yu., Potapova E.V. Synthesis of managerial decisions to the effect of underground construction safety. Mining informational and analytical bulletin. 2022. N 2, p. 62-69 (in Russian). DOI: 10.25018/0236_1493_2022_2_0_62

- Yajie Xu, Xiangsheng Chen. Quantitative analysis of spatial vitality and spatial characteristics of urban underground space (UUS) in metro area. Tunnelling and Underground Space Technology. 2021. Vol. 111. N 103875. DOI: 10.1016/j.tust.2021.103875

- Zinovieva O.M., Kuznetsov D.S., Merkulova A.M., Smirnova N.A. Digitalization of Industrial Safety Management Systems in Mining. Mining informational and analytical bulletin. 2021. N 2-1, p. 113-123 (in Russian). DOI: 10.25018/0236-1493-2021-21-0-113-123

- Kulikova E.Yu., Korchak, A.V., Levchenko A.N. Analysis of risk factors in the construction of urban underground structures. Mining informational and analytical bulletin. 2004. N 4, p. 5-11 (in Russian).

- Tidlund M., Spross J., Larsson St. Observational method as risk management tool: the Hvalfjörður tunnel project, Iceland. Georisk: Assessment and Management of Risk for Engineered Systems and Geohazards. 2022, p. 1-15. DOI: 10.1080/17499518.2022.2046784

- Bourget A.P.F., Chiriotti E., Patrinieri E. Evolution of risk management during an underground project’s life cycle. Tunnels and Underground Cities: Engineering and Innovation meet Archaeology, Architecture and Art. London: CRC Press, 2019, p. 4375-4385. DOI:10.1201/9780429424441-463

- Proprenter М., Lenz G. Risk Management in Tunneling – A Joint Approach of all Involved. Proceedings of the World Tunnel Congress, 21-26 April 2018, Dubai, UAE. 2018, p. 439-450.

- Lebedev M.O. Validation of choice of stress-strain analysis method for support and lining in traffic tunnels. Mining informational and analytical bulletin. 2020. N 1, p. 47-60 (in Russian). DOI: 10.25018/0236-1493-2020-1-0-47-60