Development of an algorithm for determining the technological parameters of acid composition injection during treatment of the near-bottomhole zone, taking into account economic efficiency

- 1 — Ph.D. assistant professor Perm National Research Polytechnic University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 2 — Ph.D. Senior Lecturer Perm National Research Polytechnic University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 3 — Laboratory Assistant Пермский национальный исследовательский политехнический университет ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

Abstract

Relevance of the research is due to the low proportion of successful hydrochloric acid treatments of near-bottomhole zones of carbonate reservoirs in the Perm region caused by insufficiently careful design and implementation of measures to stimulate oil production. Within the framework of this article, the development of a program is presented, which is based on an algorithm that allows determining the volume and rate of injection for an acid composition into a productive formation corresponding to the maximum economic efficiency during hydrochloric acid treatment. Essence of the proposed algorithm is to find the greatest profit from measures to increase oil recovery, depending on the cost of its implementation and income from additionally produced oil. Operation of the algorithm is carried out on the principle of enumerating the values of the volume and rate of injection for the acid composition and their fixation when the maximum difference between income and costs, corresponding to the given technological parameters of injection, is reached. The methodology is based on Dupuis's investigations on the filtration of fluids in the formation and the results of the experiments by Duckord and Lenormand on the study of changes in the additional filtration resistance in the near-well zone of the formation when it is treated with an acid composition. When analyzing and including these investigations into the algorithm, it is noted that the developed technique takes into account a large number of factors, including the lithological and mineralogical composition of rocks, technological parameters of the injection of a working agent and its properties, well design, filtration properties of the formation, properties of well products. The article provides an algorithm that can be implemented without difficulty using any programming language, for example, Pascal. Selection of the optimal values for the volume and rate of injection is presented in this paper, using the example of a production well at the Chaikinskoye oil field, located within the Perm region. Introduction of the developed algorithm into the practice of petroleum engineering will allow competent and effective approach to the design of hydrochloric acid treatments in carbonate reservoirs without a significant investment of time and additional funds.

Introduction

At present, there is a high proportion of carbonate reservoirs under development, characterized by low permeability and porosity properties [6], as well as high heterogeneity [28, 38]. Deteriorated state of the near-bottomhole zone (NBHZ) is a widespread problem in oil and gas production wells operating in formations composed of carbonate varieties [18, 22]. Limestones and dolomites [31] mainly represent these rocks in the lithological section. In order to improve the hydrodynamic connection between the formation and the well, various geological and technical measures (GTM) are used [9, 29].

Hydrochloric acid treatment (HCAT) is the most effective measure to stimulate oil flow in carbonate reservoirs [14, 40]. In addition, the authors of [26] note that acid treatment is the least costly and short-term technological operation at the oil field in comparison with other GTM. This method is widespread throughout the world [16, 30]. There is a large number of investigations devoted to acidic effects on carbonate reservoirs [7, 17]. However, despite the extensive experience in the application of the technology under consideration and its simplicity, the share of unsuccessful operations is about 50 % [12, 25]. This is associated with an insufficiently substantiated approach to the planning and design of NBHZ treatments [13, 37].

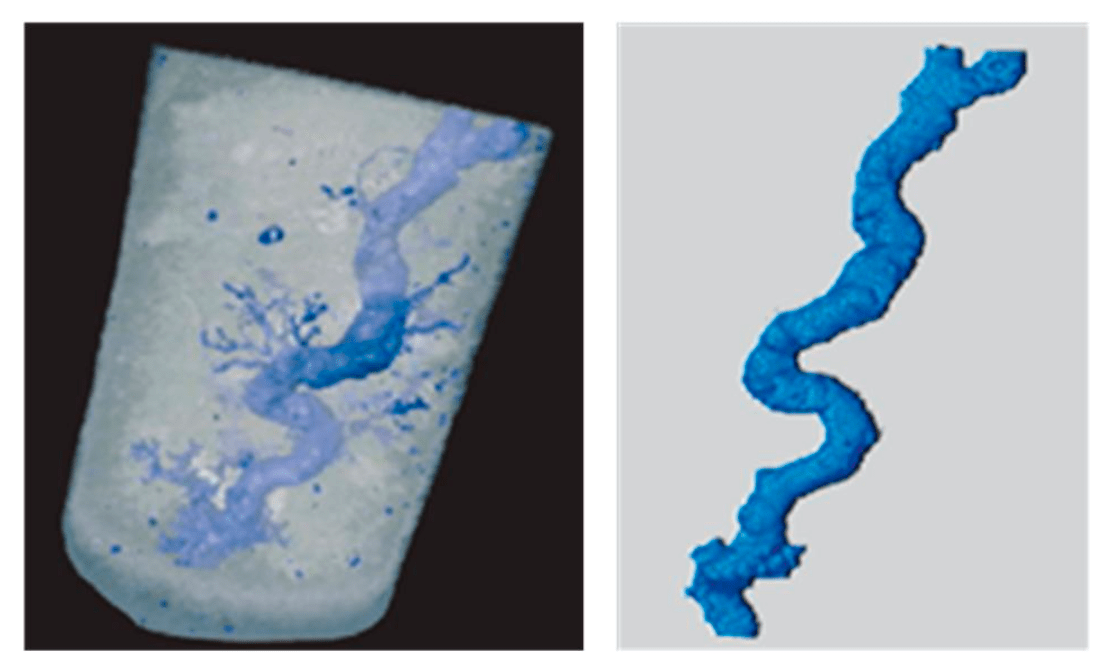

Fig.1. Wormhole imaging based on computer tomography

In order to determine the most effective acid composition (AC) and the technological parameters of its injection into the formation, laboratory filtration installations [2, 41] are now actively used. They allow creating highly conductive filtration channel (wormhole) [3, 21], presented for example in Fig.1 [11], and estimating the degree of change in permeability in a rock sample [32, 39]. It is customary to characterize this degree of change by the recovery factor, which is the ratio of the permeability coefficients of the rock sample after and before modeling the acid effect on the filtration installation [20, 35]. Based on the results of laboratory investigations, recommendations are formed on the choice of AC optimal volumes and rates of injection. However, the application of the results obtained in the HCAT design at a real object is limited due to the high anisotropy of the reservoir properties of carbonate reservoirs and the impossibility of accurate extrapolation of the results for filtration investigations with standard rock samples having a diameter and length of 30 mm to a real object.

It is also worth considering the existing models for the development of wormholes when exposed to an acid composition. They in their essence are the beginning for the development of projects for modeling HCAT. The most famous models currently include models of the transitional pore size, capillary tubes, pore space, numerical ones, correlation (semi-empirical), based on the Damkeler and Peclet numbers, but only the last three have practical application. Each of them has its own approach and includes individual parameters. They affect the development of the dissolution channel, but they also have different degrees of disadvantages. To predict changes in the skin factor using the theory of the Damkeler number, it is required to combine it with a physical model of wormhole growth, since this model does not have the ability to estimate the radius of wormhole development in the NBHZ. Correlation model allows predicting changes in the skin factor based on the results of filtration investigations. However, according to the authors of [19], application of correlation models for highly conductive filtration channels is only an approximate picture of changes in the structure of the pore space due to a high degree of unreliability and incorrectness of extrapolating results obtained on a standard rock sample 30 ´ 30 mm to formation conditions. The model that most closely describes the development of the dissolution channel in the NBHZ is the model based on the Peclet number, which is considered in this article.

Modeling of HCAT is an important and relevant trend of engineering in recent years, since it allows to more accurately predict acid treatment effectiveness and competently choose the implementation technology. Simulators that allow designing acid stimulation, based on the use of the correlation model of the wormhole, are presented in works [23, 33]. Considered modeling technologies simulate the change in the cavern space in the NBHZ at certain technological parameters of the AC injection. It provides the possibility of calculating the decrease in filtration resistance in the radial direction and assessing the increase in oil production. Also, these simulators include the functions of calculating the economic component of the projected design for the HCAT, which includes the accounting of profit due to the intensification of oil production and the cost of conducting an operation at the well. However, the accuracy of the results obtained using the software is questionable, since they contain a model that has a number of significant drawbacks. In addition, these simulators do not allow selecting the most efficient way to treat the NBHZ in an automated mode.

Currently, at the fields of the Perm Region, the process of designing the treatment of the NBHZ with acid compositions is carried out based on experience, i.e. the results of the treatments carried out at the analogue objects. Expected effects are predicted according to the same principle. Based on the review of the GTM results base over the past 10 years, a large proportion of the implemented HCAT operations do not achieve the planned results. This confirms the relevance of the development of methods for HCAT modeling in order to increase the effectiveness of this measure.

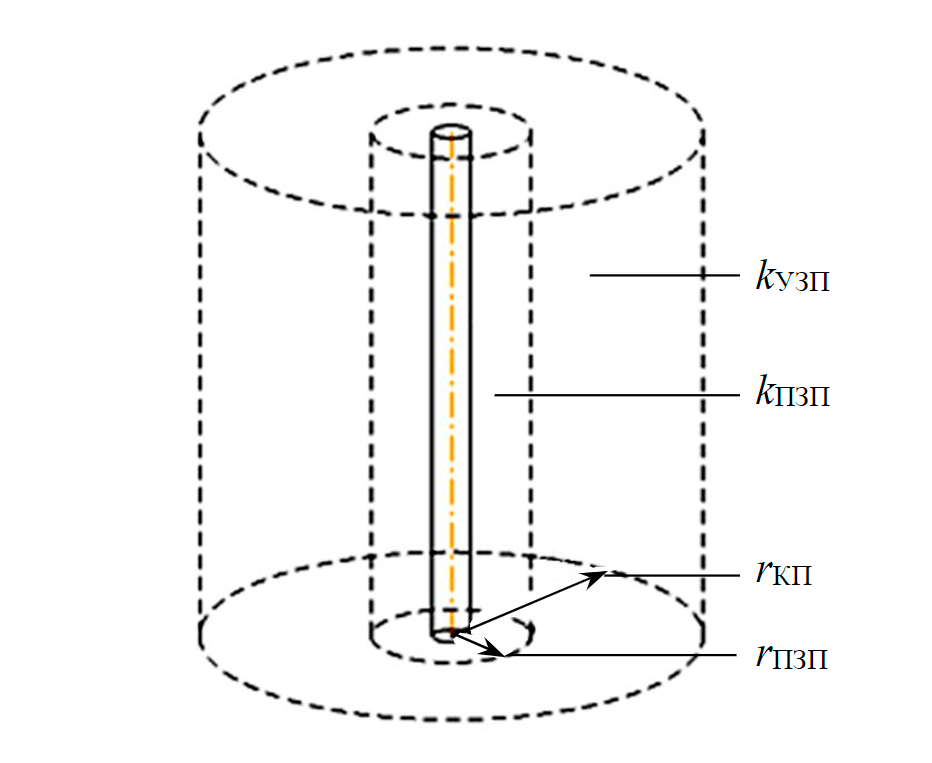

Fig.2. Scheme for near and remote zones of productive formation kNBHZ, kRBHZ – permeability of the near and remote zones of the formation, respectively; rNBHZ, rDR – radii of the near-bottomhole zone and the drainage area, respectively

Improvement of reservoir properties in the near-well zone (NWZ) can be analyzed by changing the skin factor, which characterizes the difference in filtration characteristics in the near and remote-bottomhole zones (RBHZ) [8, 27], schematically shown in Fig.2. According to the derived equations in these works, the skin factor value is directly proportional to the ratio of the permeabilities in the remote and near-bottomhole zones and the logarithmic dependence for the ratio of the NBHZ and well radii.

Currently, ways to improve the efficiency of HCAT are being actively studied. In order to increase efficiency, various laboratory investigations are carried out with rock samples and selected acid compositions. Modeling of the NBHZ treatment design is also used. However, use of existing technologies for HCAT does not allow reaching the planned indicators, which leads to an increase in the cost of oil production. In this regard, it became necessary to create a methodology that would allow competent design for the acid treatment technology, taking into account a preliminary assessment of the economic effect.

Materials and methods of the research

This study proposes a method for determining the optimal technological parameters of the AC injection during the treatment of the NBHZ. This allows achieving the maximum economic profitability. First, it is necessary to estimate the flow rate of the well, which is determined taking into account the additional filtration resistance to the flow of fluids in the NWZ according to the Dupuis formula [1, 4]:

where kp – ormation permeability, м2; h – perforated formation thickness, м; Pf – formation pressure, Pa; Pb – bottomhole pressure, bottomhole pressure, Pa; μf – dynamic viscosity of the fluid, Pa·s; bf – fluid compressibility factor, m3/m3; Rd – drainage area, m; rw – well radius, m; R – skin factor.

Filtration properties of the NBHZ improve after acidizing the formation. As a result, the value of the skin factor decreases. Taking into account this fact, the Dupuis formula after HCAT will take the following form [15]:

где S1 – скин-фактор до СКО; ΔS – изменение скин-фактора после проведения СКО.

Исходя из представленных выражений, можно выразить прирост дебита нефти после проведения мероприятия по интенсификации:

To determine the decrease in the parameter characterizing the NBHZ state, this technique includes the results of the experiments of Duckord and Lenormand. This allows assessing the change in the skin factor during HCAT [5, 24]:

where d – fractal dimension of the pore space structure formed in the NBHZ; Ac – acid number, units; $\mathrm{N_{P_{c}}}$ – Peclet number, units; b – constant taken equal to 1,7·104 md – 2; V – volume of the injected AC, m3; m – porosity, %.

This calculation of skin factor change uses a wormhole model called the Peclet number model. The method of assessing the change in additional filtration resistance was tested in [34, 36]. Results showed the effectiveness of using this model to predict changes in the skin factor and oil production. Technique for determining the parameters given in equation (4) is also presented in these works. Based on the results of investigations and transformations of this dependence, the authors have derived an equation that allows the most simplified determination of the change in the skin factor after NBHZ treatment:

where x, y – content of limestone and dolomite in the rock, respectively, %; Vh – volume of injected AC per meter of perforated formation thickness, m3/m; T – absolute temperature, К; μAC – AC dynamic viscosity, Pa·s; rp – radius of the AC diffusing particle, m; q – AC flow rate, m3/s.

Based on equation (5), it can be stated that this dependence takes into account a large number of factors reflecting the lithologic-mineralogical composition of reservoir rocks, the technological parameters of the AC injection and its properties, as well as the construction features of the well itself.

Calculation of the largest profit from the treatment is carried out by finding the maximum difference between the income from the increase in oil production at the well and the cost of carrying out the HCAT. This paper proposes the most simplified assessment of the profit from the method of oil production intensification, which will have an absolutely similar nature of change in relation to the results of the calculation, taking into account all the technical and economic indicators of the GTM. The idea for determining the income received is its calculation as the product of the numerical values for the obtained increase in the oil flow rate of the well and the cost of this product:

where ρoil – oil density, ton/m3; Coil – price for ton of oil, rub.

In order to determine the economic result, i.e. profit, it is important to estimate the costs of treatment implementation. This methodology introduces the assumption that the cost of carrying out the HCAT will vary only depending on the volume of the pumped AC, all other factors are unchanged for production investments. Due to this assumption, the costs will be expressed by the formula:

where CAC – price for 1 m3 of AC, rub./m3.

By taking into account equations (6) and (7), it is possible to express the conditional profit from the designed technology to increase the productivity of the well:

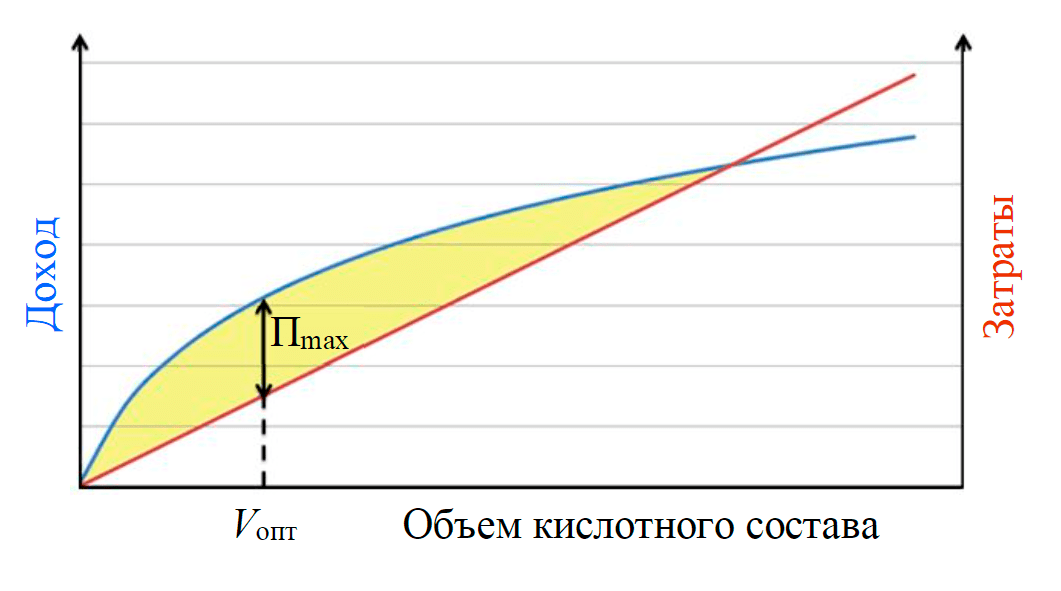

Analyzing the presented expressions, the nature of changes in income and costs, depending on the AC volume, can be examined in detail. Based on equality (7), the AC costs and volume are directly proportional and have a linear relationship. When assessing income, it is feasible to note that the increase in oil flow rate is inversely proportional to the change in the skin factor (3). It, in turn, changes according to the logarithmic law depending on the volume of the injected acid composition (5). Consequently, income tends to be logarithmic. Figure 3 shows the dependence of income and costs on the AC volume, where the zone of technological parameters for the HCAT design is painted in yellow, in case of going beyond which additional oil production will not cover the costs of implementing the HCAT technology.

Fig.3. Dependence of income and costs on the volume of injected AC

The authors of the article have developed an algorithm that allows determining the values of the AC volumes and rates of injection into the formation, at which the designed technology of a simple HCAT will have the maximum profit Pmax (Fig.3). To create an algorithm, it is necessary to get acquainted with the technical characteristics of the pumping units, which inject the AC into the productive horizon. The most commonly used unit is SIN-32, manufactured by Perm PA “Synergy”, the technical characteristics of which are given in the table.

Working characteristics of the SIN-32 unit on the Ural 4320 chassis

|

Gear |

Plunger diameter, mm |

|||

|

100 |

125 |

|||

|

Flow rate, l/s |

Pressure, MPa |

Flow rate, l/s |

Pressure, MPa |

|

|

II |

2.6 |

46.0 |

4.1 |

30.0 |

|

III |

5.0 |

24.0 |

7.9 |

15.4 |

|

IV |

7.6 |

15.7 |

12.0 |

10.0 |

|

V |

11.5 |

10.4 |

18.0 |

6.6 |

The values of productivity and pressure presented in the table are introduced into the algorithm in order to minimize errors. It should be noted that, based on the designs of wellhead equipment and production casing, there are a number of restrictions on the injection pressure during the HCAT operations. Therefore, it becomes necessary to include pressure restrictions in accordance with the data on the target well when applying the proposed method.

Algorithm for determining the optimal volumes and rates of injection for acid composition into the formation

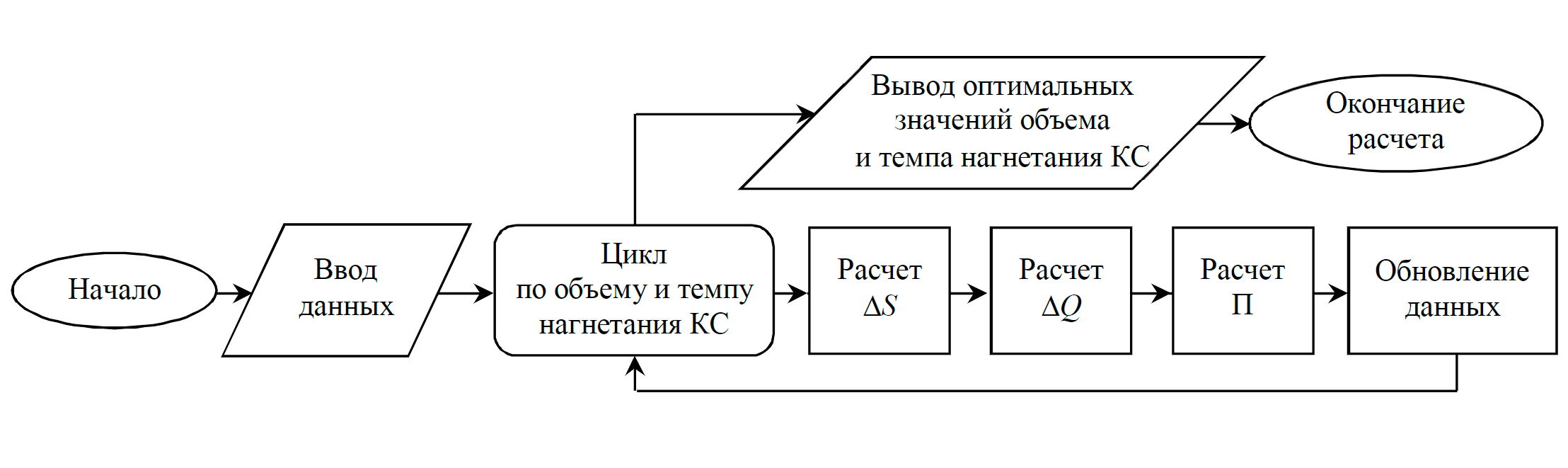

This article presents a developed program, which is based on an algorithm for determining the optimal AC volumes and rates of injection into the near-bottomhole zone of the carbonate formation. Taking into account all the described features, assumptions and dependencies, an algorithm was compiled that allows determining the maximum conditional profit when varying the values of the volume and rate of injection for the acid composition (Fig.4).

Developed algorithm has a number of advantages. It allows more competent design of productive formation acidizing without significant investment of time and money. To ensure the operation of the algorithm, it is necessary to enter data represented by the numerical values for the parameters of the properties and characteristics of the formation, produced fluid, acid composition and well design. Based on the entered data, a cyclic process is carried out. It consists in a step-by-step enumeration of the values for the AC volume and rate of injection into the formation and computational operations for each of them in order to find the optimal values.

This cycle occurs when the AC volume changes per meter of perforated thickness from the minimum threshold value calculated for the penetration of the reagent into the zone of NBHZ contamination, the radius of which must be preliminarily estimated (up to 5 m3/m [10] with a step of 0.01 m3/m). The variation of the AC injection rate is implemented according to the technical capabilities of the pumping unit, as well as when an important condition is met - the injection pressure must exceed the formation pressure.

Established series of calculations follow:

- Calculation of the change in the skin factor after the HCAT at the corresponding values of Vh and q according to equality (5).

- Estimation of the increase in the well flow rate at the calculated value of DS according to the equation (3).

- Determination of the specific profit based on the calculation of additional oil production and the volume of the injected AC into the formation, in accordance with the expression (8).

At the end of the calculation, the output data is updated if the calculated profit for the given values for the AC volume and rate of injection exceeds the previously obtained maximum value of this profit. After the comparison, the program moves to the next set values and repeats the cycle. Thus, this cycle scheme allows enumerating all possible options for HCAT implementation and determine the most cost-effective one.

At the end of the cycle chain, the conditions of the HCAT technology are saved in the program, which are displayed at the end of the program execution. Values for the AC volume and rate of injection correspond to the maximum specific profit from the designed measure with a pre-selected acid composition at a specific object. Its properties and characteristics are included in the initial data. Developed algorithm is easily implemented using the Pascal programming language. Therefore, its implementation into practice in oil and gas engineering will not cause difficulties and will be extremely useful in the design of the HCAT technology in wells with deteriorated filtration properties in the NBHZ.

Results

The target object for determining the optimal AC volumes and rates of injection into the formation is the oil production well of the Chaikinskoye oil field, associated with the oil and gas structure of the Perm region. Well under consideration penetrates the Tournaisian formation and produces low-viscosity oil with an insignificant water cut. Developed object is at the final stage of development; as a result, there is a low flow rate and a high additional filtration resistance in the NWZ. Using this object as an example, the operation of the algorithm proposed by the authors of the article is shown.

Fig.4. Algorithm for determining the optimal AC volumes and rates of injection into formation

Conducted hydrodynamic investigations for the analyzed well determined the following parameters: permeability is 0.027 μm2, current value of the skin factor is 2.5, which indicates a deteriorated condition of the NBHZ, radius of the drainage contour reaches 370 m, diameter of the well has a standard value of 146 mm, temperature at the borehole bottom is 27 °C.

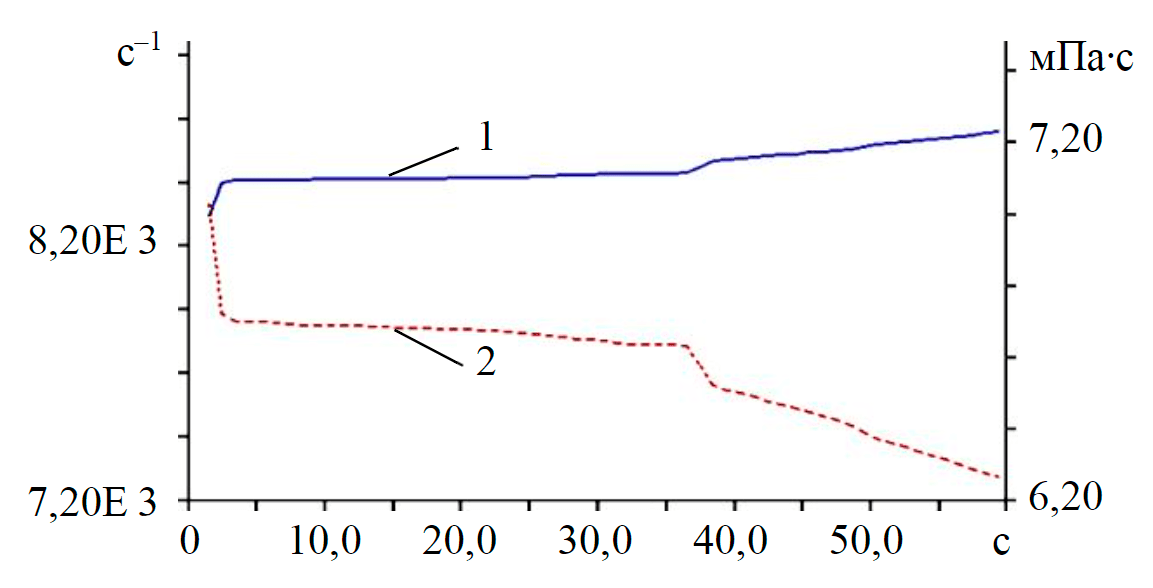

In order to determine the properties of oil, laboratory investigations were carried out. To determine the dynamic viscosity of oil corresponding to the formation temperature, a RheotestRN 4.1 rotary viscometer was used. Measurement results are shown in Fig.5. In the laboratory, using a densimeter, the density of the oil sample was determined to be 876 kg/m3.

Fig.5. Results of measuring the rheological properties of the sample oil taken on the target object carried out on a rotational viscometer RheotestRN 4.1 1 – function D(t); 2 – function h(t)

Investigations of the lithological and mineralogical composition of the rock were carried out using the KM-04M carbonate meter, which has a certificate of conformity N SSGP 01.1.1-194. The carbonatomer allows determining the percentage of calcite, dolomite and insoluble mineral residue. Investigations of rock samples taken from the well under consideration showed that content of calcite is 91.1 %, dolomite is 0.8 %.

Acid composition of the FLAXOCOR-210 brand of JSC “Poliex”, specializing in the field of chemical technologies and reagents for the intensification of oil and gas production, was selected as the injected agent. According to the results of the compatibility investigations for this composition with formation fluids, it was determined that this composition has no deviations, since during the research no formation of emulsions, flakes, clots was noted. Coefficient of AC dynamic viscosity was determined in accordance with GOST 33768-2015 using a Pinkevich viscometer (VPZh-4) mAC = 1.274 mPa∙s. Radius of a diffusing particle was determined as 1 micron using a binocular microscope “Mikmed-5”

Following data were obtained when substituting these values into the program proposed by the authors, written in Pascal: with AC volume per meter of perforated thickness of 0.64 m3/m and AC injection rate into the formation of 0.0041 m3/s, the maximum economic effect is expected from the implementation of this HCAT technology. When analyzing the data obtained, it is noted that at the indicated volume and rate, the skin factor will decrease by 2.87, which indicates a significant improvement in the filtration properties in the NWZ.

Conclusion

Proposed technique and its implementation in the program allow determining the most rational technology for hydrochloric acid treatment without much effort and time. Optimal volume and rate of injection of the acid composition into the productive formation, taking into account economic efficiency, are determined. This program is based on an algorithm regarding the equations of fluid filtration in the formation (Dupuis) and the results of investigations by Duckord and Lenormand on the change in additional filtration resistance to fluid flow in the near-bottomhole zone during acidizing. Essence of the developed methodology is to find the maximum value of the specific profit depending on income as a result of an increase in oil production after hydrochloric acid treatment at a production well and the cost of implementing this geological and technical measure. Search for the highest profitability is carried out by enumerating the values of the volume per meter of perforated thickness and the rate of injection for the acid composition into the oil-saturated formation. A block diagram of the algorithm is presented, according to which the calculation of variable parameters was made using the example of an oil production well in the Chaikinskoye field located in the Perm region. Application of the proposed algorithm in the oil industry will allow competent and effective approach to planning and design of the intensification of oil production and, thereby, to ensure an increase in the number of successful measures and save funds for the implementation of the measure.