Evaluating the effectiveness of fine gold extraction technologies on the example of titanomagnetite beach placers of the western coast of Kamchatka

- Ph.D. Leading Researcher Scientific and Research Geotechnological Center of the Far Eastern Branch of the RAS ▪ Orcid

Abstract

The material on the gold content of coastal-marine deposits of the western coast of Kamchatka is analyzed and the resource potential is briefly characterized. A review of gold technological estimates obtained from the study of gold-bearing samples taken in promising areas of the coastal-marine strip, from the Bolshaya Vorovskaya River in the north to Cape Levashova in the south, is presented. Stock materials supplemented by our studies were used. Gold-bearing deposits with very fine (0.05-0.1 mm) and fine (0.1-1.0 mm) gold amounting to 94.6 % were tested, as well as samples with gold up to 2 mm and more in addition to fine gold The content of freely recoverable gold reached 91.9 %. In the case of significant gold reserves in placers, prospects for their commercial development open up. experiments on the enrichment of gold-bearing coastal-marine deposits of Western Kamchatka indicate the possibility of extraction of free gold and other valuable components from them. Gravity technologies and modern equipment developed by ОАО Irgiredmet and JSC ITOMAK are the most effective for their extraction. enrichment of gold-bearing formations with simultaneous extraction of several useful components from them, which is possible with the use of fluoride technology, can also become economically advantageous.

Introduction

The extraction of gold, diamonds, monazite, zircon, rutile, magnetite and other minerals from complex coastal-marine placers is growing in the world [4, 8, 17, 18]. Placer gold has been found on the coasts of the USA, Canada, Turkey, Panama, in the countries of South-West Africa, Australia, etc. [9, 16, 19, 21]. Research on the study and development of such placers, especially those located within the shelf zone, is relevant. In Russia, the potential reserve of gold is the reserves of small and fine-grained placer gold in the sediments of the coast of Western Kamchatka, which is gravity-recoverable. Due to the fact that Kamchatka in the 70-80s of the 20th century was not considered as another industrial area – a source of metal ores and precious metals – no objective assessment of the gold content of coastal-marine deposits was given. The study of promising sites for the identification of industrial placers was discontinued. But the revision of previous studies, supplemented with new ones, allows to reconsider the prospects for the development and extraction of gold in these areas.

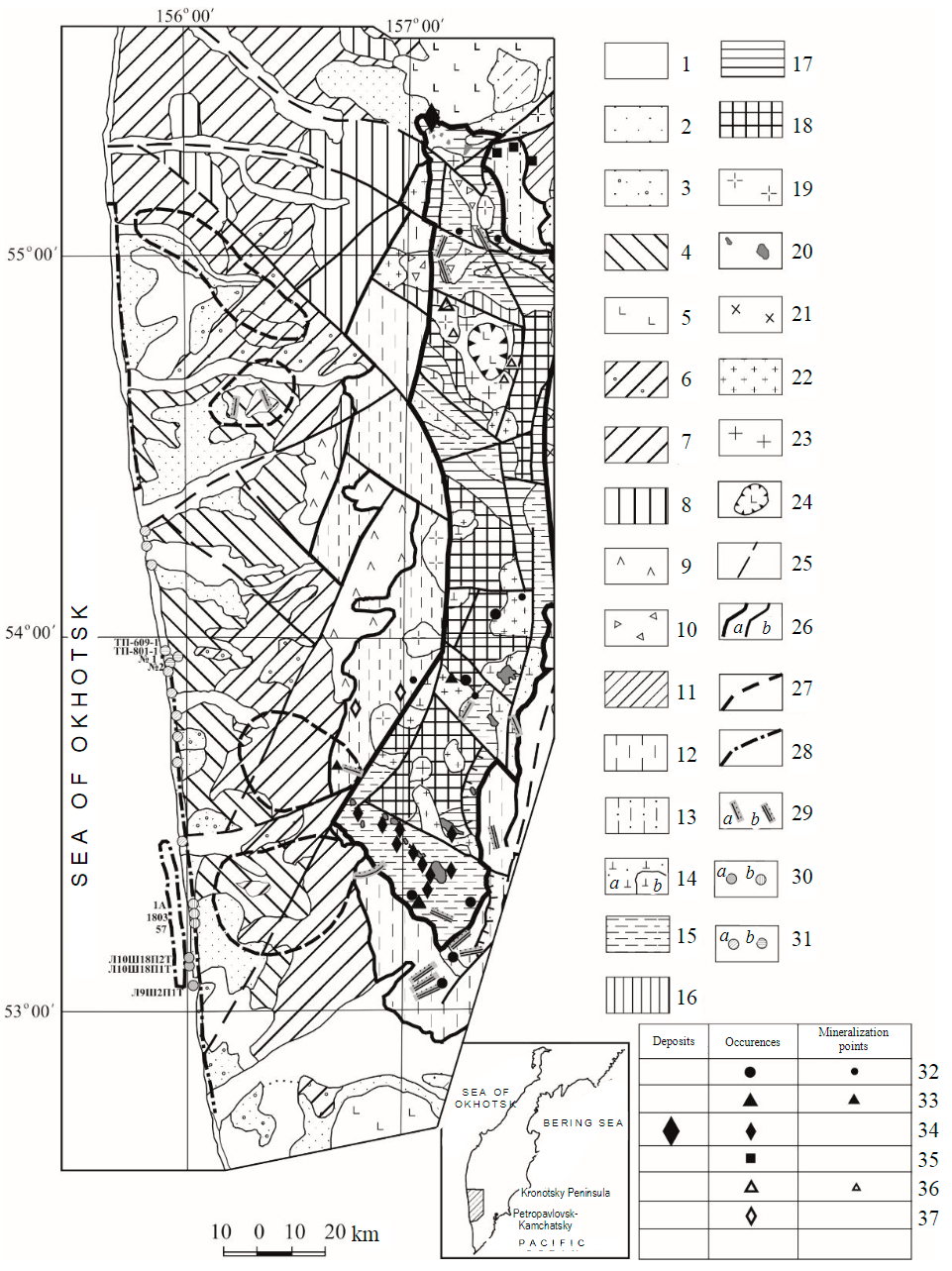

Fig.1. Schematic geological map of Western Kamchatka [13] 1-10 – Cenozoic: undifferentiated Holocene deposits – alluvial, proluvial, marsh, marine (1); upper quaternary – alluvial, lake-alluvial, marine, glacial (2); middle quaternary – glacial, fluvioglacial, marine (3); Upper Pliocene-Eopleistocene coastal-marine and alluvial-marine deposits (4); quaternary volcanites (5); Upper Neogene deposits (6); Lower Neogene deposits (7); Paleogene formations (8); Cherepanovsky volcanic complex of the Paleogene (9); tectonic-gravitational mixtites of the Eocene (10); 11 – Upper Cretaceous-Paleocene: Kirganik formation; 12 – Upper Cretaceous: Kvakhon, Khozgon and Kunun formations; 13 – Iruney formation; 14 – Alistora and Khimki formation (a) and sub-volcanic intrusions comagmatic to them (b); 15 – Heyvan formation; 16 – Andrianov formation; 17 – upper Proterozoic: Kamchatka series;18 – kolpakovskaya series; 19-23 – Intrusive complexes: Cenozoic granodiorite lacinski (19); Cortlandt-orthopyroxene-gabbro-norite dukuks (Paleocene-Eocene?) (20); upper Cretaceous leventinese (21); plagiogranite-granodiorite Kola (22); the lower Cretaceous krutogorovsky gneiss-granite (23); 24 – Caldera volcano Hangar; 25 – faults; 26 – the border: Kamchatka median mass (a) and of the upper Cretaceous rocks bordering Kamchatka median mass (b); 27 – areas of placer gold; 28 – placer gold halo Western Kamchatka coast and shelf; 29 – placer: nonindustrial (a), industrial (b); 30 – sampling sites and numbers of technological samples taken in 1998 (a) and 1967 (b), 31 – in 1969 (a) and 1985 (b); 32-37 – indigenous sources of gold (formational types): gold-quartz, low-sulphide (32); gold-quartz-sulfide (33); the gold-sulfide

Formulation of the problem

The Far East, including the western coast of the Kamchatka Peninsula, is a large reserve of promising geological objects. Most of them are easily accessible, which ensures the economic feasibility of their study and subsequent development. The object of research is the beach gold-bearing deposits of the southern part of the West Kamchatka coast (Fig.1).

Solving the problem of their effective development requires the allocation of promising areas, revision of available data and research to justify the choice of methods and devices for maximum metal extraction. According to Russian researchers, the development of placers with small and fine-grained gold can be cost-effective starting with free (recoverable) gold contents of 100 mg/m3 or more [12]. The issues of the application of existing technologies for the extraction of small and fine-grained gold using foreign and domestic devices of various designs are considered [1, 10, 14, 15, 20, 22].

The research is of practical importance – the creation of prerequisites for the re-evaluation of the object for the purpose of integrated development without causing serious damage to the environment, the organization of gold mining, as well as other related useful components – titanomagnetite, ilmenite, garnet – primarily on the south-western coast of Kamchatka.

Methodology

In 1997-2000, and then in 2015 and 2019 the Scientific and Research Geotechnological Center of the Far Eastern Branch of the RAS, together with specialists of the AmurKNII of the Far Eastern Branch of the RAS, carried out work to clarify the prospects and assess the industrial significance of coastal-marine gold-bearing formations from the standpoint of the possibility of using advanced technology for their processing. In 1967-1985, the staff of the gold sands enrichment laboratory of the Central Research Institute of Geological Prospecting for Base and Precious Metals (TsNIGRI) conducted studies of gross samples to determine the technological types of gold, the forms of its location, tested various methods of metal extraction, and proposed a technology for enriching beach gold deposits.

The accumulated experience is analyzed and possible options for the subsequent use of technologies are considered both during testing of titanomagnetite gold-bearing deposits of Western Kamchatka and during the extraction of valuable components.

The first studies on the development of methods for extracting small and fine-grained gold from beach and submarine sediments of the western coast of Kamchatka were conducted at the TSNIGRI gold sands enrichment laboratory. In 1967, three gross samples were studied, taken from submarine beach gold-bearing formations in the southern part of Western Kamchatka (Goryushkina S.Ya., 1969). Sampling site – prospect pits from the depth of 0.0-0.5 m; sample weight – 0.4-0.5 t. Gold is mainly in the –0.3+0.1 mm class, represented by fine-grained scales up to 10 microns thick. After processing, the gold content in the heavy fraction was 3850, 2480, 1970 mg/t. The concentration of gold in the sands in terms of the rock volume is about 2.56 g/m3. The obtained data can become the basis for the development of such gold-bearing formations, since in Australia a placer with an average content of 0.162 g/m3 is being developed [18], and in the USA, under favorable geological conditions, 0.055 g/m3 [17].

During the studies of the material of these samples, various methods of extracting useful components were compared (see Table).

Extraction of small and fine-grained gold from beach and submarine sediments of the western coast of Kamchatka

|

Indicators, % |

Methods of useful components extraction (weight 10 kg) |

||

|

Two diaphragm jigging machine (with vertical diaphragm): the size of the sieve cell is 0.59 mm, with a hematite bed with a size of –3+1 mm |

Narrowing sluice box: installation capacity 4 t/m2/h, degree of dilution S:L = 1:2, the angle of inclination of the sluice box 160° |

Spiral separator:capacity 40 kg/h,degree of dilutionS:L = 1:5 |

|

|

The content of the heavy fraction in the concentrate |

24-56 |

16-40 |

36 |

|

Extraction of heavy fraction into concentrate |

76 |

69-89 |

90 |

|

Middlings yield |

20 |

25 |

30 |

|

Concentrate yield |

7.9-20 |

8.5-28 |

12.5 |

|

Gold extraction from the sands |

67 |

70 |

63 |

Therefore, gold was extracted by 63-70 % on various apparatuses, but when the tails were cleaned, gold extraction into concentrate increased to 88 %.

In 1969, 10 gross samples weighing 0.5 t and one technological sample weighing 4 t were processed. In the enrichment study of beach sediments samples, the possibility of processing sands with preliminary separation of a productive class of –0.3 mm by screening and subsequent gravitational and flotation extraction of gold from the minus material product with simultaneous extraction of titanomagnetite and garnet was established.

The processing of the samples showed that the gold in them is small, finely scaled, up to 0.3 mm in size, which is sufficiently fully extracted by centrifugal separation (up to 95-96 %). The enrichment laboratory recommended using the POU-4 unit for processing samples in the field.

In the samples, it was determined: “free” gold captured by gravity enrichment methods – from 2.8 to 77 % (on average 35 %); “free thin” gold removed from gravity devices and captured only by amalgamation and cyanidation methods – from traces to 49.5 % (on average 10 %); “bound” gold located in closed accretions with waste rock – from 23 to 95 % (on average 55 %); “finely dispersed” gold evenly distributed in waste products of the drain, – traces.

With double centrifugal separation, 91.13 % of gold was released into the concentrate head. Gold extraction by centrifugal separation was 95-96 % of all free gold.

In 1985, four samples taken from the beach area near the mouth of the Kyakhta River were analyzed in the Tula branch of TsNIGRI (Astafyeva G.I., 1985) (Fig.1). The volume of samples is 0.2 m3 each. The enrichment was carried out on a mobile processing plant POU 4-2M, equipped with a drum disintegrator and two sequentially installed centrifugal separators (main and control). The sample material was easily washable.

The sieve analysis of the gold dressing showed the presence of small gold (10.75-13.41 %), very small (62.32-80.43 %), fine-grained (8.7-22.46 %) and pulverized (traces – 1.81 %) in samples (N 1 and 2) from submarine deposits. Very small gold prevailed and it could be extracted only in concentrators with centrifugal or vibrational fields or their combinations. The total gold content is 318 and 380 mg/m3, freely extracted – 9 and 28 mg/m3, free fine-grained gold – 59 and 72 mg/m3. At the existing level of development of technical means, it was not extracted, but at the same time, it was a reserve for gold mining for future. It was recommended to process similar samples during exploration according to a scheme involving screening, concentration in centrifugal or vibrating apparatuses.

Samples from proluvial-deluvial formations (TP 609-1 and 801-1) contained 14.94-44.5 % coarse gold, 6.86-8.03 % medium, 31.68-52.03 % small. The average grain weight was 0.595 and 0.979 mg, the sample was 950 and 920‰, the content was 2585 and 4764 mg/m3, including 91.9 and 91.6 % freely extracted. The sample material is easily enriched. Almost all the gold from the samples is extracted by gravity methods. In the case of significant gold reserves in placers represented by such samples, prospects for their industrial development open up. If necessary, the extraction of magnetite, ilmenite and garnet was recommended to be carried out by refinement methods: magnetic, electromagnetic and electric.

For the processing of exploration gold-containing samples in production conditions, it was recommended to use a mobile processing plant POU-4M to extract “free gold” in samples with repeated passage of the ethel fraction through a centrifugal separator.

In 2011, the laboratory of Russkaya Korona LLC conducted tests of gold-containing sands. As a result, 0.252 g of concentrate with a gold content ≥ 10 % was obtained from the initial sample weighing approximately 16 kg. It was proposed to use dry extraction technology, which allowed mining all year round. The method of dry sand enrichment included the classification of the sample with the separation of the –0.315 mm size classes and the separation of the non-magnetic fraction from them on a roll magnetic separator and the electrostatic separation of the non-magnetic fraction on the electrostatic separator SE-24/30.

Gold content is present in almost the entire territory of the West Kamchatka Plain, including the modern beach and the adjacent shelf (Fig.1) [6]. The main sources of gold are located within the Kamchatka median massif, adjacent to the lowlands from the east (Fig.1). These are mainly ore occurrences and mineralization points with relatively large gold (maximum gold content up to 65.4 g/t).

Often, industrial alluvial placers of gold lie at a short distance from them. Numerous gold halos have been traced along the watercourses – from the sources of the rivers to their confluence with the Sea of Okhotsk.

Glacial and water-glacial formations with relatively high metal concentrations (up to 365 mg/m3) [7], as well as alluvial deposits with gold contents of 280-460 mg/m3 are exposed in the coastal zone.

In modern coastal-marine sediments along the coast of Western Kamchatka, a gold dispersal halo is extended of about 300 km long and up to 40 m wide with a metal content from 30 mg/m3 to several grams per cubic meter (Fig.1).

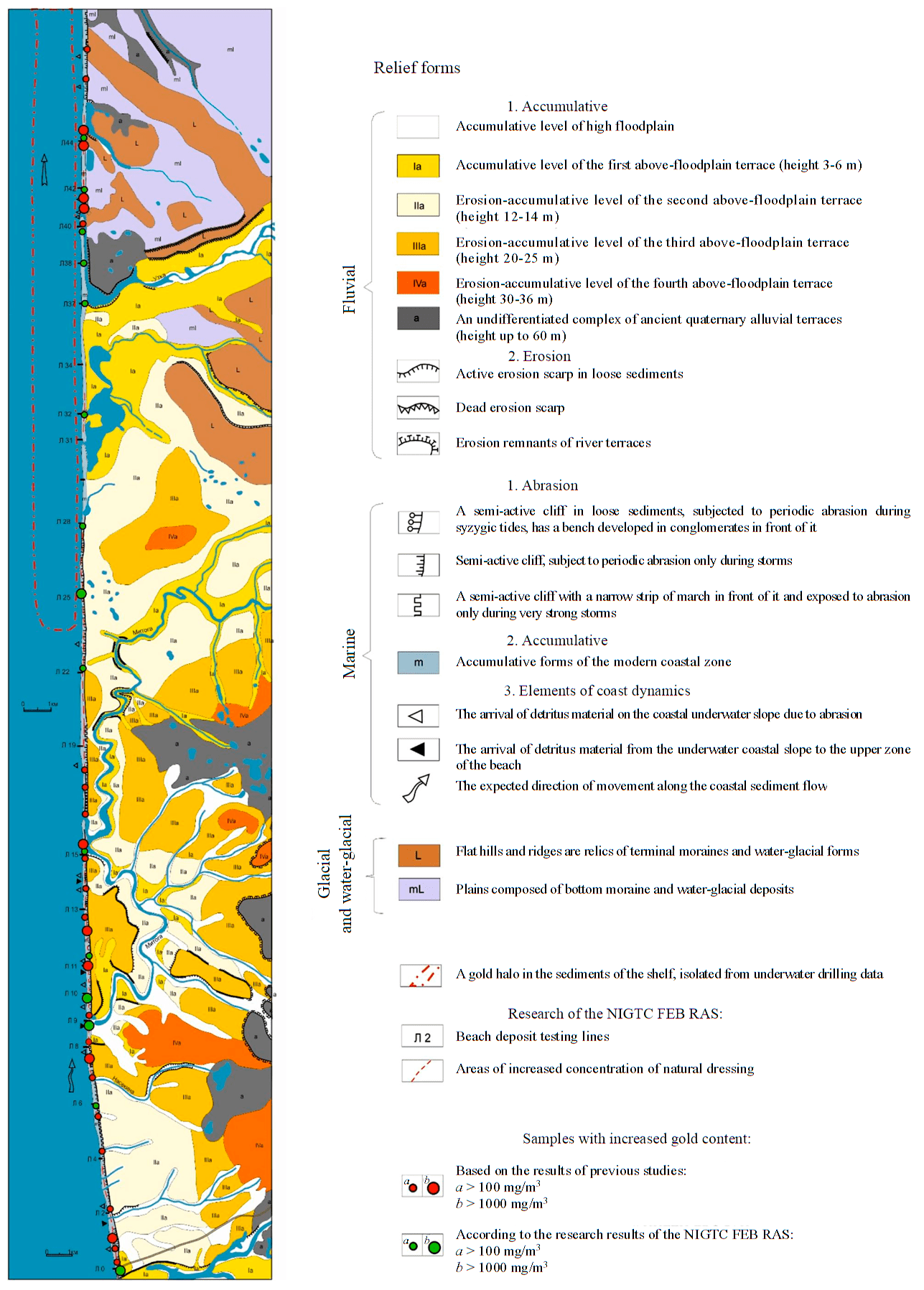

Small areas of a natural garnet-magnetite concentrate accumulation with the presence of gold were recorded on the surface of the beach (Fig.1-3):

- near the water edge in the form of spots 10-50 cm long, 1-5 cm wide with a gold content of 15-50 mg/m3;

- at the base of the second accumulative terrace in the form of strips up to 1 m wide, up to 10 m long with a gold content of 20 to 120 mg/m3;

- at the base of the cliff, where medium-fine-grained sands with magnetite-pyroxene-garnet association are developed, halos 2-3 m wide, up to a hundred meters long, 5-20 cm thick are recorded; the average gold content ranges from 40-190 mg/m3, reaching tens of grams per cubic meter in some samples (2695, 18275, 37821 mg/m3) (see Fig.2, 3) [6-8].

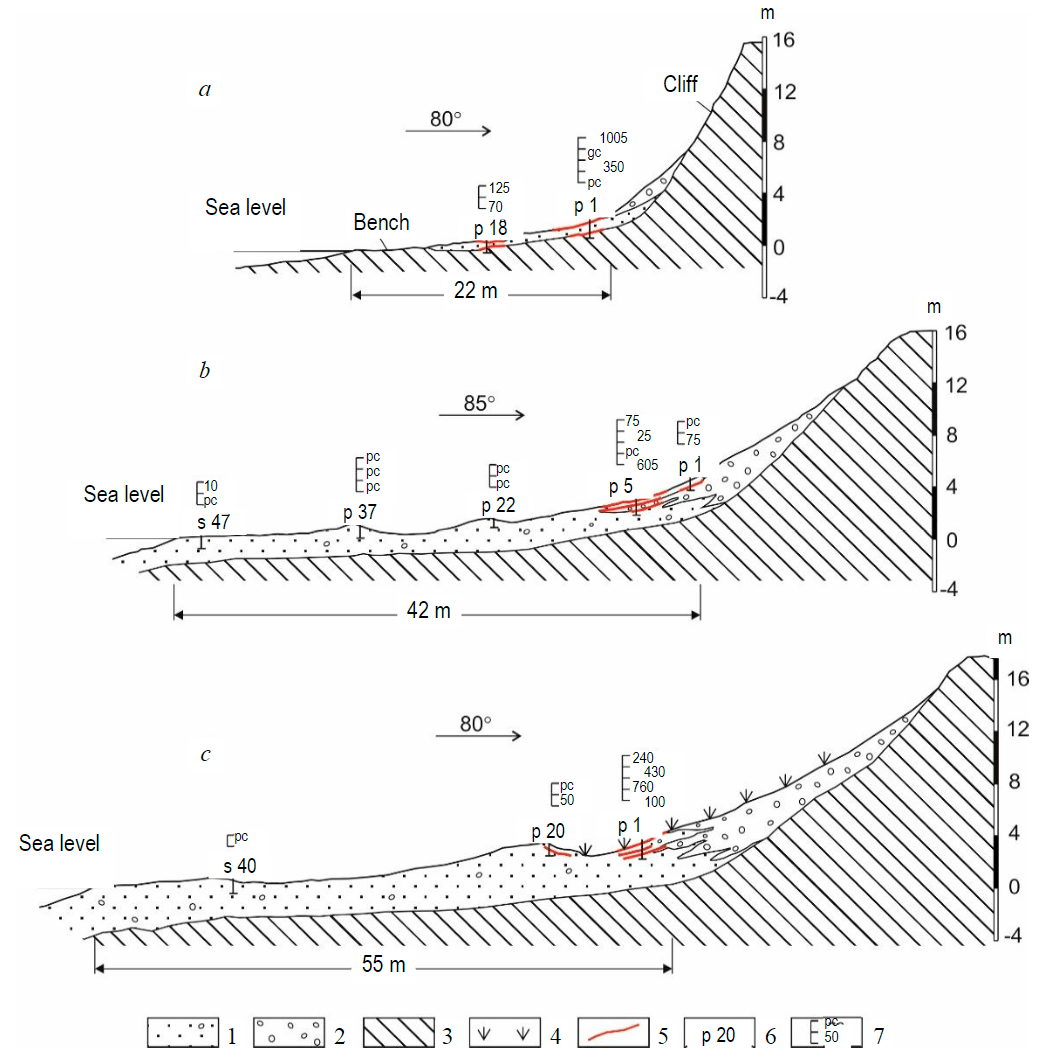

According to the degree of lithodynamic activity, several types of beaches are distinguished, which are characterized by different gold content. Narrow beaches up to 30 m wide (Fig.3, a) have a thickness of beach deposits from 0.1 to 1.5 m. At the base of the cliff, natural garnet-magnetite concentrates were observed both on the surface (with high gold contents – > 1000 mg/m3) (see Fig.2) and throughout the cut (up to the bedrock). In the samples taken after 0.25 m, gold was found from the signs to the first grams per cubic meter.

Beaches with a width of 30-50 m (Fig.3, b) have a thickness of beach deposits up to 3.0 m, are composed of often alternating layers (tens of centimeters thick) of well-sorted sands with gravel, pebbles, gravel-pebble deposits with lenses and low-power intermittent layers (from 1 to 4) of natural garnet-magnetite dressing with a capacity of 2-10 cm, which are associated with increased (tens and hundreds of milligrams per cubic meter) gold content concentrated in the near-bedrock part, represented by loams and siltstones. As a result of detailed exploration work carried out by the Kamchatka Party of the Primorskiy Geological Department, in one of the prospect pits (Sh-403), the gold content in the productive formation averaged 1029 mg/m3 (from 175 to 37821 mg/m3) per half-meter capacity. For the traced length of 6100 m (on the coast site between the Nasedkina and Mitoga rivers), the average gold content was 234 mg/m3 for the average thickness of the tested rock mass of 2.4 m.

Beaches with less lithodynamic activity have a width of up to 70 m, the thickness of beach deposits is up to 5 m, often with a narrow marching surface fixed by vegetation (Fig.3, c). The number of garnet-magnetite layers reaches nine, the gold content in them varies widely: from signs to the first grams per cubic meter. The gold-bearing formation with contents > 100 mg/m3 is most often located at a greater depth and is often confined to the base of the cut.

On the beaches of the full profile developed on the sites of accumulative shores, increased concentrations of gold are confined to the wave splash zone during severe storms, while the highest metal contents (up to 295 mg/ m3) tend to the bedrock part of the beach deposits, the thickness of which is more than 4-5 m.

The gold resources of the upper coastal zone are associated, as a rule, with deposits of the described beaches of incomplete profile (Fig.3) in the areas of development of abrasive shores and amount to > 500 kg with an average metal content of 150 mg/m3, placer width of 22-30 m and thickness of 2.0 m.

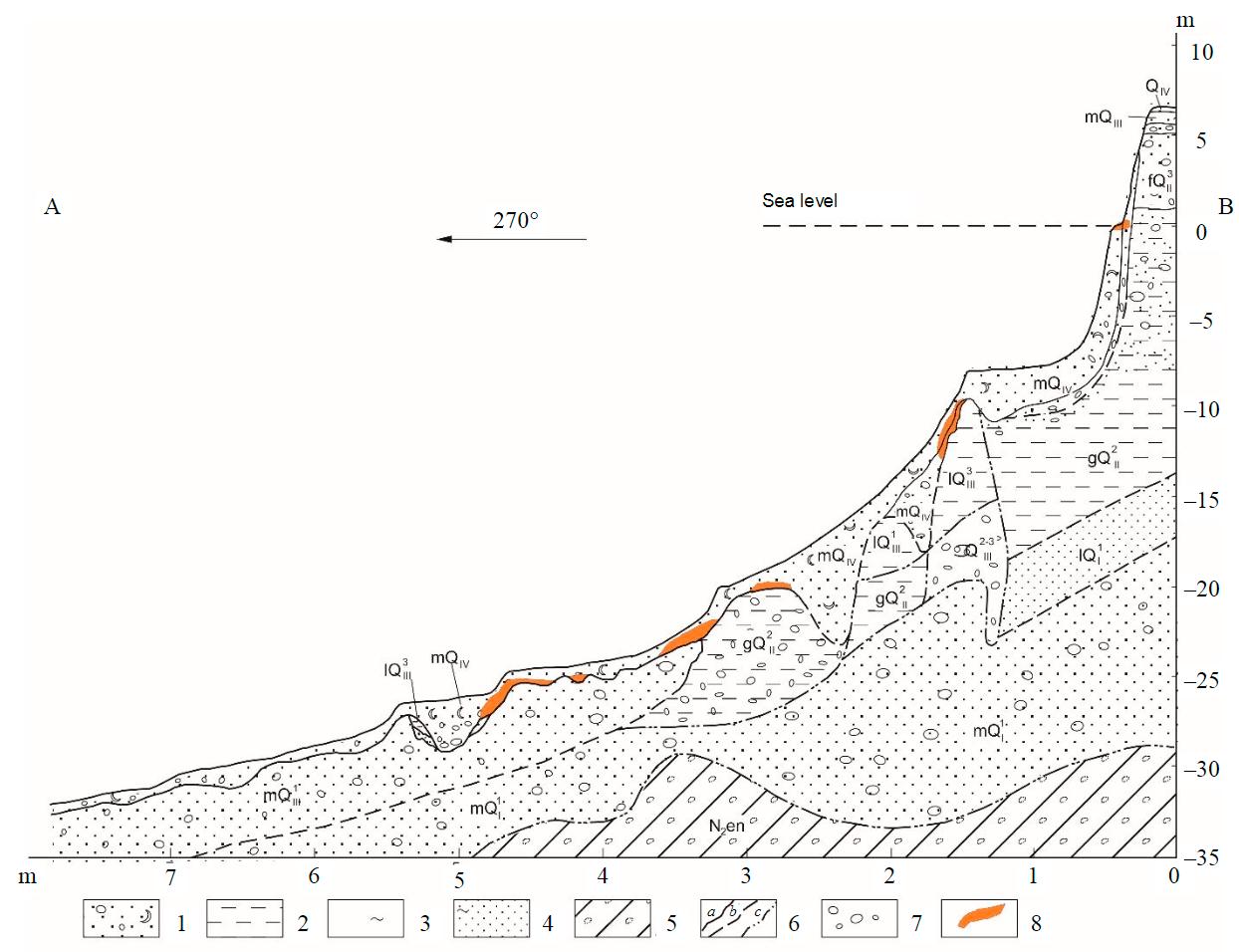

Fig.2. Geological and geomorphological scheme of a detailed research area of beach placers (according to Bondarenko I.V., 1979)

Fig.3. Typical schematic sections of beaches with an incomplete profile of various lithodynamic activity (the area of the coast between the mouths of the rivers Nasekina and Mitoga) 1 – beach deposits; 2 – slope deposits; 3 – raft rocks; 4 – vegetation on the march; 5 – layers of natural magnetite gold-bearing concentrate; 6 – number of working; 7 – gold content in mg/m3 (samples were taken after 0.25 m)

Promising for cost-effective mining are the areas in the southern part of the Western Kamchatka coast, the most accessible for development – between the rivers Utka – Khomutina, Nasekina – Mitoga (Fig.3-5). Proximity to the locality (village Ust-Bolsheretsk) ensures the efficiency of using modern technologies for extracting useful components.

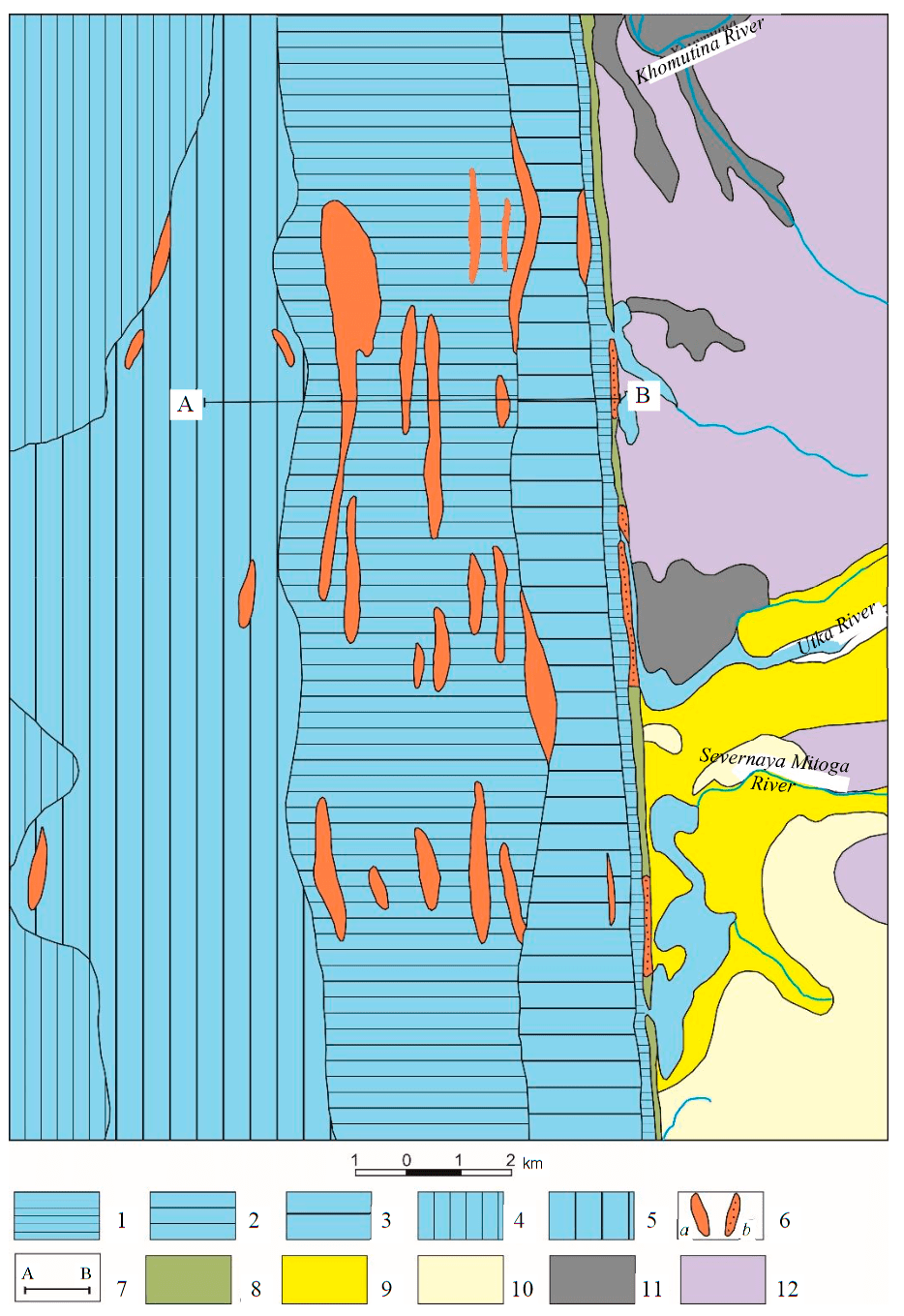

During the general and detailed exploration work on the shelf placers in the southern part of the western coast of Kamchatka in 1976-1978 (Bondarenko I.V., 1979) drilling from the ship revealed increased concentrations of gold (Fig.4, 5), confined to the rear zones of underwater sea terraces and the base of the active layer. In the northern part of the site, the maximum gold content was found in wells at depths: –8.6 m (579 mg/m3), –11.4 (183), –14.5 (220), –17.5 (167), –19.9 (1186), –23.2 (650); in the southern part: –8.5 m (134 mg/m3), –11.0 (212), –14.3 (120), –17.0 (311), –19.3 (60), –22.4 (87). The thickness of the active layer is from 3 m in the upper part of the underwater shore slope to the first tens of centimeters at its base; the tested sediment thickness is 0.1-3.6 m.

In addition to the gold content of beach deposits, in the zones of underwater terraces in bottom deposits, according to vibration drilling data (Fig.4, 5), halos are contoured with weight contents of gold, the distribution of which is extremely uneven. The total length of the gold halos in the tested zone of the underwater slope is 52.0 km (20 km long), the average width is 0.22 km, the thickness is about 2 m, the average gold content is 90 mg/m3. The estimated resources of gold are about 2 t (Bondarenko I.V., 1979). Since vibration drilling underestimates the content by at least 2-3 times, the real resources can be much higher.

Fig.4. The layout of gold halos on the underwater coastal slope (the coast between the rivers Severnaya Mitoga, Utka and Khomutina) 1-5 – slope values (tg of the slope angle): 0.025 (1), 0.0041 (2), 0.0031 (3), 0.0020 (4), 0.00043 (5); 6 – areas with gold content: > 60 mg/m3 on the underwater shore slope (a), > 100 mg/m3 on the beach (b); 7 – cut along the A–B line; 8-12 – beach deposits: modern marine (8), quaternary of the first above-floodplain terrace (9), second above-floodplain terrace (10), undifferentiated ancient quaternary terrace (11), water-glacial and glacial formations (12)

Significant (up to 5 g/m3) gold content in some areas in the sediments of the underwater shore slope on the surface and along the cuts of the beach, in conditions of high hydrodynamic activity, indicate the possible identification of buried placers, gold reserves, which may significantly exceed the estimated resources of placers of incomplete profile beaches. This long-term reserve of the mineral resource base is insufficiently studied and underestimated.

Fig.5. Schematic geological cut along the A–B line [4]

1-5 – lithological composition: sand-gravel-pebble formations with shell detritus (1); siltstones (2); loams (3); sand (4); gravel rocks, conglomerates, pebbles, gravel (5); 6 – age limits: established (a), assumed (b), seismoacoustic (c); 7 – gravel, pebbles; 8 – interval of increased gold content > 60 mg/m3 mQIV – modern marine deposits; lQ3III, mQ3III – upper quaternary: lake and marine, respectively; aQ2-3III – alluvial deposits of buried terraces; fQ3II, gQ2II – mid-quaternary sediments: water-glacial and glacial, respectively; mQ1I , lQ1I – lower quaternary marine and lacustrine sediments, respectively; N2en – Upper Neogene deposits of the Enemten formation

A correct assessment of the coastal zone sites can be given when detailing and before studying sedimentary formations within beaches, shallow shelf, as well as on adjacent land areas of the West Kamchatka Trough.

Discussion

The development of the technology for enriching the beach sands of the West Kamchatka coast continued in the field in 1998 by a team of employees of the NIGTC FEB RAS and AmurKNII FEB RAS. In 2015 and 2019, scientific research works (NIGTC FEB RAS) were carried out on the beach at sites of high concentrations of gold (see Fig.2, 3); a complex of mineralogical and technological studies was carried out. During the evaluation work on the beach site from Cape Levashov to the Utka River, 127 samples were taken along 24 search lines. According to the results of this assessment, promising (> 100 mg/m3) areas of the beach were identified for large-volume testing. Large-volume samples were taken from ditches oriented along the coastline. The width of the ditches on the surface was 1.2-2.0 m, the depth was determined by the results of evaluation work, and the length was determined by technical and physical capabilities. The material extracted from the ditches was calculated on the spot using a mobile screen. With wet screening, the horizontal position of the cellular tablet was the most effective. The total weight of the material selected at the initial stage was about 11 t. A fraction of more than 2 mm went into the dump, the total weight of which was approximately 6.75 t (on average, 61.4 % of the sample volume consists of a fraction > 2 mm).

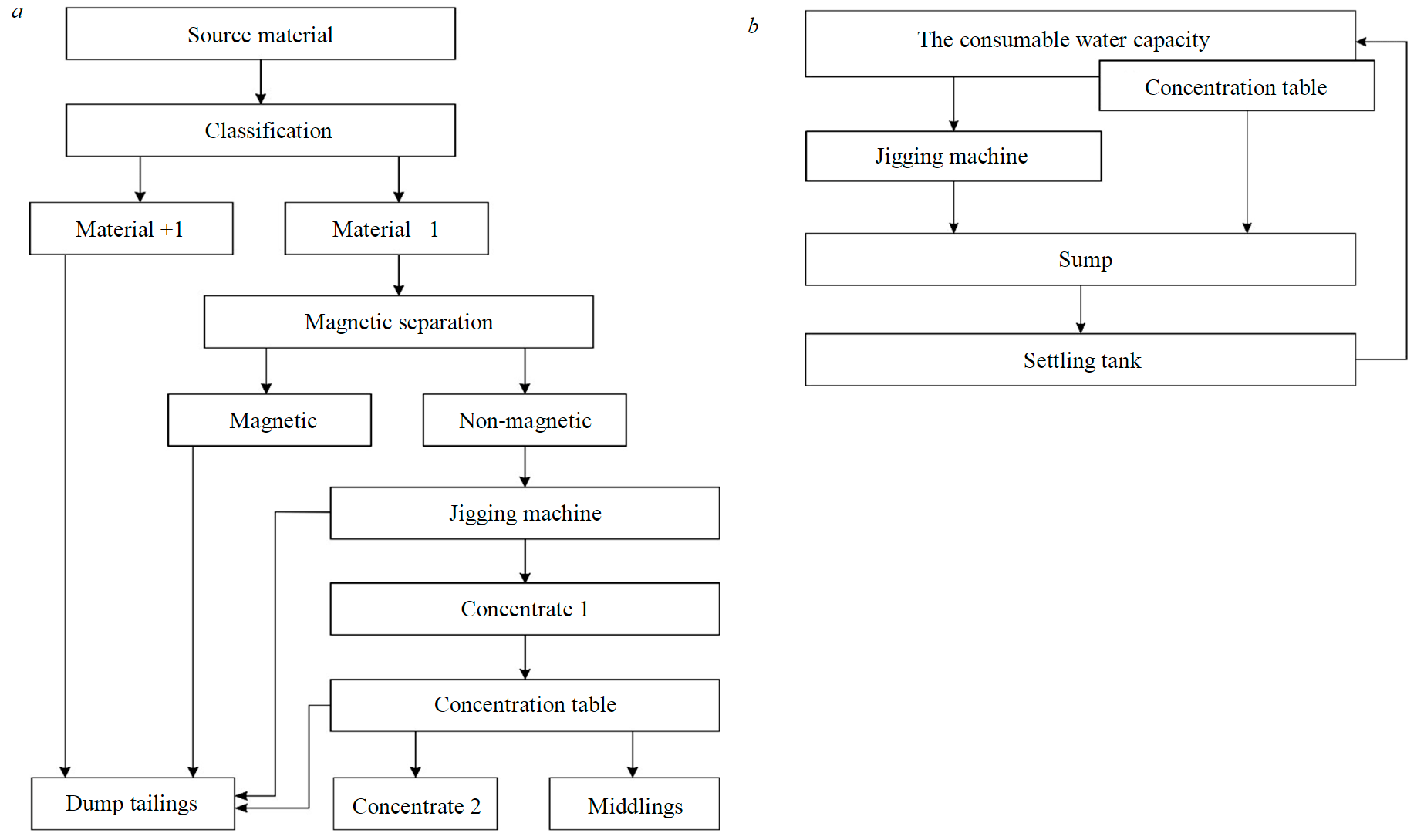

Concentrates were isolated from a fraction < 2 mm using a jigging machine and a concentration table, which were separated into magnetic, electromagnetic and non-magnetic fractions by magnetic and electromagnetic separation. The material composition of gravity concentrates was characterized by a high content of magnetic fraction. In surface natural dressings, this amount reaches 60-75 % of the mass of samples, and in individual samples – 80 %, non-magnetic – about 10 %. The main mineral of the magnetic fraction is magnetite, sometimes ilmenite. Magnetite contains a significant admixture of titanium (the average TiO2 content is 19.9 %) and belongs to titanomagnetites. The mineral in the samples occurs in the form of octahedral rounded crystals and their fragments. The maximum amount of titanomagnetite is contained in the class –0.3+0.1 mm; the average content in the mineral is Fe – 56.5, V2O5 – 0.35, Cr2O3 – 0.029, MnO – 0.60 %. The electromagnetic fraction is mainly represented by ilmenite and pyroxene. Ilmenite is found in the form of irregularly shaped grains and hexagonal crystals, concentrated in the class of –0.25+0.1 mm. Ilmenite crystals sprouted with filamentous magnetite secretions are observed. Ilmenite contains Fe – 52.5, TiO2 – 25.6, Cr2O3 – 0.046, MnO – 0.52, V2O5 – 0.35. Hematite and leucoxene are less common, garnet, martite, marcasite, chromite, sheelit, antimonite, arsenopyrite, anatase, brookite, tourmaline are present (less than 1 %). Garnets have the form of well-formed crystals of rhombododecahedra and irregularly shaped fragments: almandine predominates, in a subordinate amount – grossular and spessartine. The nonelectromagnetic fraction is represented by zircon and gold, sphene, rutile, spinel, barite, apatite, topaz are encountered.

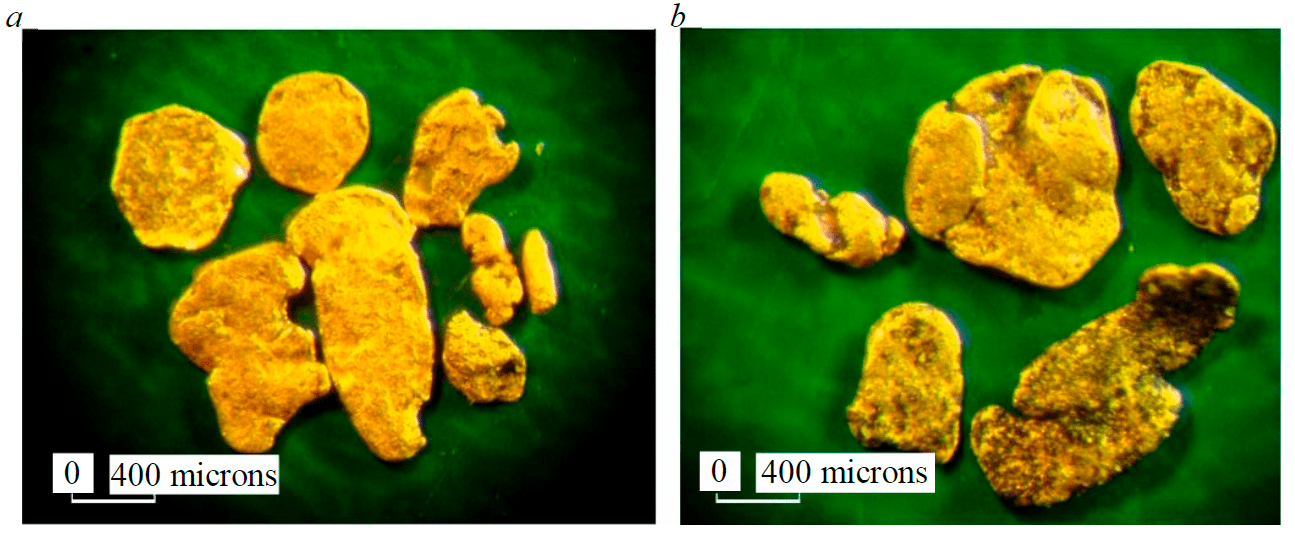

Fig.6. Gold of the beach coastal-marine placers of the south-western coast of Kamchatka: well-rounded lamellar, flat-shaped, scaled gold, elongated and lump-shaped grains with a finely-grained and slightly rough surface (a); gold with quartz inclusions, with a layer of iron hydroxides on the surface and in deepenings (b)

In parallel, a qualitative assessment of the gold sample material was carried out. The maximum established gold content in the beach deposits was 5 g/m3; 80 % of the gold is concentrated in the class –0.25-+0.1 mm. The sizes of gold in placers of the coastal-marine zone vary from < 0.07 to 2 mm (single 4-5 mm), the thickness ranges from 0.01 to 0.15 mm, the average weight is 0.015 mg. The shape of the gold grains is mostly flattened. These are lamellar, flat-shaped, scaly, wire-shaped, lump-shaped forms, as a rule, well-rounded (Fig.6). The gold sample varies from 656 to 972 [6], the distribution is polymodal, with the greatest extremes 770-810 and 920-950.

Of the technological properties, almost complete absence of clay minerals and good washability of sands should be highlighted. The number of fractions of 0.5 mm sand in different sites varies from 5 to 10 % of the total volume of the source material. Gold is characterized by high floatability.

Technological scheme of the sample material enrichment (Fig.7, a) and the schematic diagram of the water supply of the concentrating system (Fig.7, b) were compiled in the NIGTC FEB RAS. Recycled tap water was used during sample processing. The concentrate yield from processed samples is 6.9-24.0 %.

Taking into account the gold pieces dimension (average 0.30 mm) in the samples of the studied site of the coast, the content of a heavy fraction in them and the amount of material of class +1 mm (5.4 %), an optimal scheme for processing samples was developed: screening (2 mm); concentration on a centrifugal separator; drying of the material; magnetic and electromagnetic separation; blowing off gold; separation of gold under binoculars.

Fig.7. Schemes of sample processing (a) and water supply of the concentrating system (b)

The use of CVK-100M (capacity up to 200 l/h) and CVK-200 (capacity up to 3 m3/h) is recommended as centrifugal separators. Concentrators manufactured by AO Grant (Naro-Fominsk) allow obtaining high-density concentrates when extracting fine-grained gold into a concentrate of up to 98 %, and also allow extracting gold into a concentrate of up to 5 microns in size; they are distinguished by the ecological purity of the process.

Due to the ore gold deposits development in Kamchatka, further studies of the gold-bearing formations of the beach and work on the enrichment and extraction of valuable components from them were discontinued. Previously conducted experiments indicate the possibility of extracting not only gold from them. In order to develop a technology for the extraction of precious metal, as well as associated components, it is necessary to additionally test enlarged samples using modern equipment.

The Sea of Okhotsk is one of the main sources of seafood for Russia, therefore, technologies that can be used in the extraction of useful components from the gold-bearing titanomagnetite formations of the west coast should be environmentally safe. This requirement imposes a severe restriction on their choice, therefore leaching technologies are excluded, since today they are environmentally unsafe.

A group of environmentally friendly gold extraction technologies – electrostatic. They are classified depending on the type of discharge and the method by which the dispersed material is charged (corona and smoldering, triboadhesive, combined). Many designs of separators with low specific energy consumption and higher specific productivity, comparable only with the specific consumption and performance of magnetostatic separators, have been developed and created. Extracting a useful component requires 50 to 500 W of power. The SEP apparatus (electrostatic pneumatic separator) with a capacity of 60 m3/h, manufactured in Yekaterinburg by Russkaya Korona LLC*, consumes 500 W. The range of size classes of metal particles that they extract is wider than that of gravity devices, especially in the direction of fine-grained particles. The use of electrostatics for processing beach deposits will allow the fine particles extraction, which is not available for gravity technologies and devices (even rotary ones). The widespread introduction of electrostatic technologies into mining practice is hindered by the fact that they are dry [11]. The installation of powerful (up to 20 kW) electric heaters at the input of separators contributes to the dehydration and calcination of the supplied source material. This technique gives good results in deposits where the moisture content of the source material is low (Muruntau, Erdenet). But the material of the beach deposits contains a lot of water, its removal will require a significant amount of energy, which is why the use of electrostatic technologies may be on the verge of profitability.

It may be economically advantageous to enrich gold-bearing formations with simultaneous production of several useful components from them at once, which is possible using fluoride technology [5], which has been brought to perfection. Its use became possible in the production of many valuable metals (rare and rare-earth). Gold does not react with fluorine, and fluoride technology is not directly applicable for its extraction. If the gold-bearing material (sands) is processed with fluoride technology and several elements are obtained at once, then gold, in relation to the obtained elements, will remain in waste, its content will increase due to the reduction of the source material, therefore it will become easier to extract it. The technology can be applied in the development of a difficult-to-enrich material of complex composition, similar to the beach formations of the Sea of Okhotsk, with insignificant contents of valuable components. Its most important advantages are: high productivity, environmental friendliness, low energy consumption, complex extraction of almost all useful components from the source material, greater flexibility when switching to new raw materials. The use of this technology will make it possible to profitably extract most, and in future all the valuable mineral components contained in them. All standard and non-standard equipment for fluoride technology – flare reactors, electrolyzers, etc. – are manufactured in Russia; it has been repeatedly tested in large-scale production. In addition to the titanomagnetite gold deposits under consideration, there are many other objects in Kamchatka – titanomagnetite sands of the eastern coast (the Khalaktyrskoye deposit and three occurrences of beach titanomagnetite sands) containing titanium, iron, vanadium, manganese, magnesium, and cobalt.

The use of gravity technologies in the processing of clay and sludge deposits often leads to water pollution and silting of drains, but at the same time nothing extraneous gets into the water, and a band of turbid water quickly disappears after the operation of enrichment devices. Therefore, from the viewpoint of environmental safety, gravity technologies are the most acceptable in this case. But all gravity devices have an extraction characteristic showing which range of particle size classes it can extract well, and which classes are considered inaccessible to it. As a result, it turns out that during the processing of the deposit, it is proved that more than 90 % of gold is extracted, but after processing, a significant amount of metal turns out to be in the dumps. These particles are either larger or smaller than those to which the extraction devices were “tuned”. When it is said that 90 % of the metal is extracted, it is often not indicated in which range of size classes this occurs. In its “own” range, the device can extract more than 90 % of particles, but it can skip “non-native” ranges (both smaller classes and large ones) [2]. Because of this, most of the precious metal losses occur, due to which the development of the deposit is often on the verge of profitability. For processing with minimal metal losses, it is necessary to use not one gravity device, but their complex with approximately the same extraction characteristics in different size classes. The devices need to be selected so that their ranges of size classes overlap, and the productivity is approximately equal (such enrichment complexes are produced, for example, by the company ITOMAK*). The complex includes classification, gravity and finishing modules, which are equipped with modern and efficient equipment operating in a single technological line. The capacity of the complex is 70 m3/h. ITOMAK promises the most complete extraction of metal and works as well as NELSONS and FALCONS, but is much cheaper and easier to operate [3]. The basis of the complex consists of rotary concentrators KG-40, in which the extraction is 93-97 %, and the minimum size of the extracted metal is 0.075 mm.

It is possible to use field modular geological processing devices manufactured by ITOMAK. They differ from the processing complex in productivity, compactness and mobility. The device capacity is 4 m3/h, extraction and minimum size of the extracted metal is 93-97 % and 0.075 mm, respectively.

It is preferable to use mobile installations, since the beach formations of the western part of Kamchatka are a strip of gold-bearing sands up to 40 m wide, with a length of about 300 km. Gold is found throughout the coastal strip and further in the deposits of the shallow shelf.

The beach gold deposits have an interesting property – seasonal and tidal currents and storms restore the waste areas: over time, the metal appears again. If processing is carried out by one powerful stationary processing complex, then the delivery of material from the boundary parts of the deposit will become unprofitable. It is more convenient to use several mobile devices moving along the surf strip.

To extract gold from the surface natural gold-bearing titanium-magnetite concentrates from the beaches, a small-sized complex of MCTS produced by AO Grant is effective. It extracts up to 99.6 % of gold with a grain size of +20 microns from the concentrates, the productivity is 200 kg of gold in a season, it also has a low payback period (six months) and low energy consumption (0.08 kW).

Conclusion

The conducted research on the development of methods for extracting gold from the beach formations of Western Kamchatka gives reason to believe that their development is possible with further study. Since a significant part of the gold is small (–0.9+0.1) and very small (–0.1+0.05 mm), the evaluation and testing of gold-bearing formations should be repeated with the use of modern equipment. This will help to obtain positive results in the detection of placer gold deposits on promising coastal-marine areas of the beach, identified by previous work. By establishing their industrial significance, it is possible to proceed to the deployment of work on the shallow shelf using new mining and enrichment technologies.

Little attention is paid to the problem of cost-effective development of small low-productive placers. These formations are insufficiently studied, therefore they need to be investigated. Significant progress in gold extraction can contribute to a decrease in conditions and involve placers with low metal contents in operation.

Mobile concentrating units can be used for testing, such as ITEK-0.25 (Novosibirsk), the universal concentrating device POU4-3M (AO Tula NIGP), which are designed to meet high requirements for the extraction of gold from exploratory samples. It is also possible to use iCON IGR installations during gross testing, which will allow to get real data on the amount of metal extracted from mineral raw materials.

To extract valuable components from the gold-bearing titanomagnetite formations of Western Kamchatka, the most effective of all considered is modern equipment and gravity technologies developed by OAO Irgiredmet and JSC ITOMAK. They are successfully used not only in Russia, but also abroad, they allow extracting gold of any size without harming environment [1]. It is necessary to use a complex of gravity devices with approximately the same extraction characteristics in different classes of size. It is necessary to develop technological regulation with a scheme of enrichment and calculation of the set of equipment necessary for industrial operation and its capacity.

It may be economically advantageous to enrich titanium-magnetite deposits with simultaneous production of several useful components from them at once, which is possible using fluoride technology. It is technically possible to develop metallurgy in Kamchatka and extract non-ferrous and precious metals. The creation and deployment of a new metallurgy in the Kamchatka Region will lead to the emergence of a new industrial area in Russia.

References

- Afanasenko S.I. Modern technologies of fine gold mining. Zolotodobycha. 2010. N 139, p. 12-15 (in Russian).

- Bogdanovich A.V., Zarogatskii A.P., Korovnikov A.N. Modern equipment and technologies for highly efficient extraction of fine-grained gold from placer, ore and technological raw materials. Obogashchenie rud. 1999. N 4, p. 33-37.

- Bocharov V.A., Gurikov A.V., Gurikov V.V. Analysis of Gold-Containing Products Separation Processes in Knelson and Falcon SB Concentrators. Obogashchenie Rud. 2002. N 2, p. 17-21 (in Russian).

- Bykhovsky L.Z., Sporykhina L.V. Placer Deposits in the Resource Base and Mineral Mining. Mineral recourses of Russia. Economics and management. 2013. N 6, p. 6-17 (in Russian).

- Karelin V.A., Karelin A.I. Fluoride technology of processing concentrates of rare metals. Tomsk: Izd-vo NTL, 2004, p. 221 (in Russian).

- Kungurova V.E. Geological and genetic features of multistage formation of coastal-marine gold-bearing placers: Avtoref.

- dis. … kand. geol.-min. nauk. Мoscow: Institut mineralogii, geokhimii i kristallokhimii redkikh elementov, 2011, p. 26 (in Russian).

- Kungurova V.E. Gold-Bearing Coastal Marine Placers of the Coasts of South-Western Kamchatka And Alaska Peninsula. Mining informational and analytical bulletin. 2020. N S 46, p. 5-25 DOI: 10.25018/0236-1493-2020-12-46-5-25 (in Russian).

- Kungurova V.E. Revisiting the Placer Gold Mineralization of Coastal-Marine Zone of Kamchatka Southwest. Ores and Metals. 2014. N 5, p. 19-31 (in Russian).

- Lalomov A.V. Placer Deposits of the Russian Arctic and Ways of Development. Mineralogy. 2017. N 2, p. 30-42 (in Russian).

- Myazin V.P., Litvintseva O.V., Zakieva N.I. Technology of enrichment of gold-bearing sands. Mezhdunarodnyi zhurnal prikladnykh i fundamentalnykh issledovanii. 2012. N 9, p. 83-84 (in Russian).

- Olofinskii N.F. Electrical methods of mineral processing. Мoscow: Nedra, 1977, p. 519 (in Russian).

- Yushin A.A., Prisyazhnyi V.M., Kakaranza S.D. et al. Experience and problems of studying and searching with small and fine-grained gold in the sedimentary cover of the northwestern Black Sea region. Geologiya i poleznye iskopaemye Mirovogo okeana. 2008. N 2 (12), p. 34-52 (in Russian).

- Slyadnev B.I., Khasanov Sh.G., Krikun N.F. State Geological map of the Russian Federation on a scale of 1:1000000 (third generation). List N-57 (Petropavlovsk-Kamchatskii). St. Petersburg: KF VSEGEI, 2006 (in Russian).

- Kaikkonen L., Venesjärvi R., Nygård H., Kuikka S. Assessing the impacts of seabed mineral extraction in the deep sea and coastal marine environments: Current methods and recommendations for environmental risk assessment. Marine Pollution Bulletin. 2018. Vol. 135, p. 1183-1197. DOI: 10.1016/j.marpolbul.2018.08.055

- Burt R. The role of gravity concentration in modern processing plants. Minerals Engineering. 1999. Vol. 12. Iss. 11, p. 1291-1300. DOI: 10.1016/S0892-6875(99)00117-X

- Dill H.G., Goldmann S., Cravero F. Zr-Ti-Fe placers along the coast of NE Argentina: Provenance analysis and ore guide for the metallogenesis in the South Atlantic Ocean. Ore Geology Reviews. 2018. Vol. 95, p. 131-160. DOI: 10.1016/j.oregeorev.2018.02.025

- Garnett R.H.T., Basset N.G. Placer Deposits. Economic Geology: 100th Anniversary Volume. Society of Economic Geologists. 2005, p. 813-843. DOI: 10.5382/AV100.25

- Hou Baohong, Keeling J., Van Gosen B.S. Geological and Exploration Models of Beach Placer Deposits, Integrated from Case-Studies of Southern Australia. Ore Geology Reviews. 2017. Vol. 80, p. 437-459. DOI: 10.1016/j.oregeorev.2016.07.016

- Kirkpatrick L.H., Jacob J., Green A.N. Beachesand bedrock: How geological framework controls coastal morphology and the relative grade of a Southern Namibian diamond placer deposit. Ore Geology Reviews. 2019. Vol. 107, p. 853-862. DOI: 10.1016/j.oregeorev.2019.03.029

- Litvintsev V.S. Ponomarchuk G.P., Banshchikova T.S. Gold content in the gold production-generated silt-and-clayey formations in the Far East area of Russia. Journal of Mining Science. 2010. Vol. 46. N 5, p. 575-581.

- Moufti A.M.В. Opaque mineralogy and resource potential of placer gold in the stream sediments between Duba and Al Wajh, Red Sea coast, northwestern Saudi Arabia. Journal of African Earth Sciences. 2014. Vol. 99. Part 1, p. 188-201. DOI: 10.1016/j.jafrearsci.2013.10.011

- Wills B.A., Napier-Munn T.J. Mineral processing technology. Oxford: Butterworth-Heinemann, 2006, p. 456.