Development of the drilling mud composition for directional wellbore drilling considering rheological parameters of the fluid

- 1 — Ph.D. Professor Ukhta State Technical University

- 2 — Ph.D. Associate Professor Saint Petersburg Mining University ▪ Orcid ▪ Elibrary ▪ Scopus ▪ ResearcherID

- 3 — Technologist LLC UK “Tatburneft”

Abstract

Article presents investigations on the development of a drilling mud composition for directional wells in an oil field located in the Republic of Tatarstan (Russia). Various rheological models of fluid flow and their applicability for drilling muds are analyzed. Laboratory experiments to measure the main rheological parameters of a solution, such as plastic viscosity, dynamic shear stress, as well as indicators of non-linearity and consistency are presented. On the basis of laboratory investigations, it was concluded that high molecular weight polymer reagents (for example, xanthan gum) can give tangible pseudoplastic properties to the washing fluid, and their combination with a linear high molecular weight polymer (for example, polyacrylamide) reduces the value of dynamic shear stress. Thus, when selecting polymer reagents for treating drilling muds at directional drilling, it is necessary to take into account their structure, molecular weight and properties. Combination of different types of reagents in the composition of the drilling mud can lead to a synergistic effect and increase the efficiency of the drilling process as a whole.

Introduction. Analysis of the scientific and technical references regarding complications and emergencies during construction of wells [1, 2, 7, 10], specifically, deviated and horizontal, shows that in order to predict the most common complications and emergencies, in the first place it is necessary to use drilling fluid of high quality that will meet the geological and technological requirements of drilling.

Rheological properties of drilling fluids affect almost every process and indicator associated with well drilling, that is why they are among the most important. In particular, rheological properties largely determine:

• cleaning degree of well bottomhole from sludge and cooling of rock-cutting tool, transporting ability of the washing fluid flow, hydraulic resistance in all parts of the circulation system in the well and hydrodynamic pressure on its walls and bottomhole during drilling;

• amplitude of pressure fluctuations during start-up and stop of the pumps, performing of tripping operations and development of the well with drilling string pacing;

• intensity of washing fluid enrichment with sludge, completeness of its replacement with cement slurry in the annular space between casing and walls of the well, etc. [6, 8, 11, 16, 17].

Regulation of solutions' rheological properties, continuously changing in the process of deepening, and maintaining them in accordance with requirements of drilling is one of the most important tasks of solution's chemical treatment. Rheological properties of solutions are affected by a large number of variable factors: temperature, pressure, component composition of the solution and concentration of each component, content of high-dispersed and colloidal fractions of clay, rate of shear deformations and thixotropic effects. Choice of a rheological model, by which rheological parameters will be determined, is also important. Analysis of scientific and technical literature on this issue [4, 5, 9, 11-15] showed that today there is no rheological model, which could give necessary accuracy of approximation over entire interval of shear rate changes, corresponding to drilling mud circulation in the well. Therefore, accuracy of calculated parameters will depend on both the correctly selected model and its applicability in a particular case.

Due to large number of variable factors affecting rheological properties of the drilling muds, it is rather difficult to predict their behavior. Therefore, study of this issue is relevant to improve drilling efficiency.

Purpose of this work is to justify and develop the composition of the drilling mud, which increases efficiency of drilling a horizontal section of the wellbore, taking into account rheological parameters of the drilling mud.

Drilling mud rheology. Drilling muds used at drilling of oil and gas wells exhibit nonNewtonian behavior: both shear thinning and shear solidification. It is usually believed that in such solutions there is a limiting shear stress and thixotropic effects are present [11]. The first rheological model used to describe rheological behavior of clay suspensions was Bingham – Shvedov or visco-plastic model. It describes substances that, at stresses below the critical value τо, called the ultimate shear stress or dynamic shear stress, do not deform, but flow at high stresses like viscous liquids [8].

Most drilling fluids are also characterized by the fact that their rheological properties depend both on magnitude of shear stress and on its duration. If viscosity is determined not only by shear rate, but also by shear duration, then such substances are called thixotropic. In thixotropic substances, with an increase in duration of the load, a decrease in viscosity is observed. After the end of deformation process and final rest time, substance regains its initial state.

Despite the fact that Bingham – Shvedov model can be used to describe the behavior of drilling muds during flowing inside the pipe at high shear rates, this model cannot be applied to all types of fluids. With appearance of various methods for processing water-based clay muds and with development of non-aqueous drilling fluids, limitations of Bingham model became increasingly apparent [15]. Behavior of such drilling muds lies between the boundaries described by Newtonian model and Bingham – Shvedov model. This behavior is called pseudoplastic. Relation between stresses arising in a fluid and the shear rate for pseudoplastic fluids is described by Ostwald – de Waele power-law model.

Like Bingham – Shvedov model, Ostwald – de Waele model does not provide an absolutely accurate characteristic of the drilling mud. However, its use is preferable if drilling mud is treated with polymers or is completely clayless and polymeric. If the fluid flow obeys a power-law model, then the yield and viscosity curves in logarithmic coordinates will be straight lines. In this model, drilling mud is a pseudoplastic fluid that does not have an ultimate dynamic shear stress. Thus, fluid begins to flow immediately after applying a shear load to it.

Each of mentioned above models is applicable only in individual cases. Bingham – Shvedov model includes an indicator of ultimate shear stress, but does not provide an accurate description of solution behavior at low deformation rates. Power-law model, on the contrary, more accurately describes behavior of solution at low shear rates, but due to absence of ultimate shear stress in the model, it cannot describe behavior of solution at extremely low shear rates close to zero. Therefore, behavior of typical drilling muds is between a viscoplastic and a pseudoplastic model.

There are also three-parameter models. Herschel – Bulkley model is obtained by combining a viscoplastic model with the Ostwald – de Waele model and takes into account dynamic shear stress[13]. This model is suitable for describing some of the low-solids drilling muds and solutions treated with polymer reagents. It covers a wider range of shear rates. However, determining the rheological parameters of solutions for this model and integrating the equations of their motion is quite difficult.

It seems more convenient and with acceptable accuracy to use simple Bingham and Ostwald – de Waele models with different rheological parameters for various intervals of shear rates. Often, in calculations, a pseudoplastic model is used with different values of consistency and non-linearity parameters in the shear rate ranges corresponding to the flow in annular space of the well and drilling string. In drilling bit nozzles, the drilling mud can be considered as Newtonian fluid.

Justification of necessary technological properties of the solution. Considered drilling mud is necessary for drilling a horizontal section of oil wellbore in the reservoir of an oil field located in the Republic of Tatarstan (Russia). Sandstones with mudstone interseams represent project horizon – Tula hard coal system. Sandstones are medium and coarse grained, of weak formation. Possible complications are rockslides and cavings. Temperature of the reservoir is 25 °С. Reservoir pressure is 12.1 MPa. Roof of project horizon is at a depth of 1196 m. According to well design, bottomhole is at a depth of 1208 m. Length of the wellbore is 1786 m. Application of a polymer solution with a low solid phase content (polymerbentonite) is necessary from a depth of 1486 m along the borehole at drilling for liner placement.

At a formation pressure of 12.1 MPa to ensure necessary backpressure at a given depth, drilling fluid must have a density of at least 1130 kg/m3.

Selection of optimal rheological properties of the solution is a difficult task. Given the experience of drilling horizontal wells, value of plastic viscosity η in this field should be no more than 20 mPa·s and no less than 7 mPa·s.

For a satisfactory hydrotransport of sludge to the day surface by laminar flow and prevention of weighting agent precipitation in surface circulation system, value of dynamic shear stress (DSS) should be from 1 to 8 Pa.

For timely control of viscosity at drilling site, relative viscosity (RV) is measured, which should be in the range of 30-50 s at rheological parameters indicated above.

An equally important parameter, characterizing the structural and mechanical properties of the solution is value of static shear stress (SSS). Usually it is enough that SSS10 ≤6 Pa, SSS1 ≤ 3 Pa. Thixotropy coefficient should be in range of 1-1.5

Water loss (filtration) during drilling in the formation must be minimal to preserve permeability of the reservoir and is in range of 4-6 cm3 . Absence of filtration (F) is also unacceptable, since in this case a filter cake, which will maintain stability of the reservoir and reduce the coefficient of friction, cannot form on walls of the well that is very important at drilling horizontal section. Thickness of clay cake (k) should be at least 1-1.5 mm and have low friction properties.

Performance of stabilizer chemicals is highly dependent on pH, especially in presence of inorganic inhibitors and mineralizers. Most of stabilizer inhibitor reagents are anionic or amphoteric, therefore, for their effective operation, it is necessary to maintain an alkaline environment in the drilling mud. In modern drilling fluids, pH is maintained in range of 8-10.

Thus, taking into account the geological conditions and drilling experience at this field, as well as recommendations from scientific and technical literature, necessary technological properties of the developed solution are acquired:

| Parameter | Density, kg/m3 | RV, s | SSS (1/10), Pa | DSS, Pa | η, mPa·s | F, sm3 | k, mm | pH |

| Recommended value | 1130 (+20) | 30-50 | 3/6 | 1-8 | 7-20 | 4-6 | 1-1,5 | 8-10 |

Research methodology. For research and modification, one of the basic formulations of a polymerbentonite solution with a density of 1140 kg/m3. used for drilling a horizontal section of the wellbore in a reservoir was selected. Basic composition of polymerbentonite solution: bentonit – 40, NaOH – 1, starch – 15, bactericide – 1, CMC-HV – 4, CMC-LV – 1, chalk – 185, lubricant – 25 kg/m3.

Study considers modifying the basic composition of washing fluid by replacing the polymer reagent with another or a combination of others, differing from carboxymethyl cellulose (CMC) by molecular weight, structure and properties, in order to improve rheological characteristics, while maintaining other technological parameters within required limits. To find optimal reagent or their combination it is necessary to study rheological parameters of the drilling mud. Composition, in which rheological parameters will be optimal (for example, such as low values of DSS and nonlinearity index), can be considered the most effective and appropriate for use in these conditions.

Effect exerted by polymer reagent depends primarily on its type, structure and molecular weight [3]. Therefore, various polymeric reagents were selected for study considering their origin and structure:

• with an average molecular weight (CMC, polyanionic cellulose (PAC)) and high (xanthan, polyacrylamide (PAA));

• synthetic (PAA) and natural (CMC, PAC, xanthan);

• anionic (CMC, PAC, xanthan) and manifesting amphoteric properties (PAA);

• with a linear structure (CMC, PAC, PAA) and branched (xanthan).

Rheological parameters of drilling muds depend not only on component composition, but also on the shear rate. Therefore, for a deeper analysis of rheological characteristics, their comparison and selection of optimal composition, it is necessary to measure rheological parameters, if possible, on a wider range of shear rates. Different rotation speeds of rotational viscometer correspond to different deformation rates of washing fluid: from low speeds at the beginning of circulation to very high speeds during passing through nozzles of the drilling bit. Measurements were carried out in following ranges of viscometer rotor speeds: 600-400, 400-300, 300-200, 200-100, 100-0 rpm. For each range, rheological parameters were determined using a viscoplastic and power-law solution model.

For research, Rheotest RN 4.1 rotational viscometer was chosen, which automatically registers viscosity and fluidity curves and allows deep rheological description of test medium in wide range of stresses and shear rates (Fig.1).

Measuring system with a cylinder of the viscometer is necessary to study rheological characteristics of substances with a viscosity of up to 100000 mPa·s. It consists of a stationary measuring cup and a cylindrical rotor, which is placed in this cup. To study the behavior of liquids at different temperatures, thermostated vessels are available..

Analysis of obtained rheological characteristics and selection of the optimal drilling mud formulation. Measurements of the rheological parameters of solution with composition presented earlier were made. Content of polymer reagent: high-viscosity CMC – 4 g/l, low-viscosity CMC – 1 g/l. Rheological parameters of solution 1:

| Rotation frequency, rpm | η, mPa·s | τо, Pa | n | k |

| 600-400 | 13,3 | 8,1 | 0,57 | 2,54 |

| 400-300 | 14,5 | 7,8 | 0,52 | 3,76 |

| 300-200 | 15,9 | 7,2 | 0,49 | 4,17 |

| 200-100 | 17,4 | 6,3 | 0,44 | 4,96 |

| 100-0 | 18,1 | 5,6 | 0,37 | 5,33 |

DSS τо и пластической вязкости n and plastic viscosity η are in the required range. With an increase in the shear rate, plastic viscosity of the solution decreases, and the non-linearity index n becomes higher, which indicates the effect of “shear thinning”. Experience of well construction and research of processes occurring during circulation of a drilling mud show that it is most advantageous to use pseudoplastic fluids as drilling fluids that have a nonlinearity index n < 0,3 [6, 7, 9, 13, 17]. Circulation of such a solution in the well provides effective removal of sludge, and resulting hydraulic resistance is minimal, which is very important during drilling-in of the reservoir by a horizontal wellbore. Non-linearity index of solution 1 has a rather low value n = 0,37.

Second analyzed composition was a solution with addition of another cellulose ether – polyanionic cellu lose. Like CMC, there are high-viscosity and low-viscosity brands. This polymer has a good inhibitory ability in clay rocks. It is widely used in the treatment of clay and clayless drilling muds. Content of polymer reagent: high-viscosity PAC – 4 g/l, low-viscosity PAC – 1 g/l. Rheological parameters of solution 2:

| Rotation frequency, rpm | η, mPa·s | τо, Pa | n | k |

| 600-400 | 14,1 | 8 | 0,55 | 2,82 |

| 400-300 | 15,5 | 7,2 | 0,51 | 3,39 |

| 300-200 | 17,4 | 0,51 | 0,44 | 3,54 |

| 200-100 | 18,7 | 6,7 | 0,4 | 3,96 |

| 100-0 | 19,3 | 6,1 | 0,36 | 5,74 |

Rheological parameters of the solution with addition of PAC were similar to the parameters of solution 1, all of them are in the required range. Similarity of the results is explained by the fact that these polymeric reagents have a similar linear structure, a slightly different molar mass, and both are anionic polymers.

Third analyzed composition was a solution with addition of xanthan gum as a polymer reagent. Content of xanthan – 4 g/l. Rheological parameters of solution 3:

| Rotation frequency, rpm | η, mPa·s | τо, Pa | n | k |

| 600-400 | 17,7 | 12,2 | 0,36 | 4,37 |

| 400-300 | 20,3 | 11 | 0,3 | 5,58 |

| 300-200 | 21,5 | 10,1 | 0,28 | 6,74 |

| 200-100 | 23,1 | 9,4 | 0,24 | 7,9 |

| 100-0 | 25,4 | 8,1 | 0,23 | 8,7 |

At the same concentration of the polymer reagent, viscosity of the solution was higher. Values of plastic viscosity and dynamic shear stress were higher than required values. However, nonlinearity index turned out to be 0.23, which indicates that this polymer gave the washing liquid more tangible pseudoplastic properties. These properties are also manifested by a more intensive decrease in plastic viscosity with an increase in shear rate. This is explained by the fact that xanthan gum has a strong difference in structure from cellulose ethers. Firstly, it has a large molecular weight and branched structure, rather than linear as in CMC and PAC. Flexibility of macromolecules in linear polymer is always higher than that of branched ones because branched polymers have a large number of short and frequently located side chains, which increase the rigidity of macromolecule due to reduced rotation possibility for individual units relative to each other. Secondly, presence of a larger number of functional groups makes it less mobile due to possible interactions. Such a solution will have higher carrying and cleansing abilities, but the value of hydraulic resistance during circulation will be higher.

Fourth analyzed composition was a solution with addition of PAA as a polymer reagent. Content of PAA – 1 g/l. Rheological parameters of solution 4:

| Rotation frequency, rpm | η, mPa·s | τо, Pa | n | k |

| 600-400 | 19,3 | 5,6 | 0,55 | 1,3 |

| 400-300 | 20,9 | 4,7 | 0,51 | 1,8 |

| 300-200 | 22,1 | 3 | 0,47 | 2,89 |

| 200-100 | 22,7 | 2,8 | 0,38 | 4,23 |

| 100-0 | 23,5 | 2,4 | 0,34 | 5,74 |

This composition has similar values of plastic viscosity and a non-linearity index with solutions 1 and 2, however, DSS value was significantly lower. This feature can be explained in terms of the polyacrylamide macromolecule structure. Functional groups in polyacrylamide are attached to the main chain, and are not connected with cyclic groups, like in starch or cellulose ethers, this makes the polyacrylamide macromolecule very flexible, therefore the resistance arising from initiation of washing liquid flow is less and, accordingly, initial shear stress is significantly lower.

Analysis of obtained data revealed that addition of PAA leads to a decrease in the initial shear stress, and addition of xanthan gum gives washing liquid more tangible pseudoplastic properties. Both of these qualities are favorable from a technological point of view. Pseudoplastic properties allow the solution to have high viscosity in the annulus and low viscosity during flowing in the pipe string and bit nozzles. Lower value of DSS will reduce the amplitude of pressure fluctuations during start-up and stopping of pumps and tripping operations, as well as the likelihood of stagnation zones' formation with accumulation of cuttings in them.

Therefore fifth analyzed composition was a solution with simultaneous addition of PAA and xanthan gum. Content of reagents: PAA – 0.5 g/l, xanthan – 2 g/l. Rheological parameters of solution 5:

| Rotation frequency, rpm | η, mPa·s | τо, Pa | n | k |

| 600-400 | 11,2 | 7,3 | 0,45 | 1,5 |

| 400-300 | 13,5 | 6,9 | 0,41 | 2,63 |

| 300-200 | 15 | 6,3 | 0,37 | 3,17 |

| 200-100 | 16,7 | 5,4 | 0,32 | 4,49 |

| 100-0 | 17,3 | 4,6 | 0,27 | 4,80 |

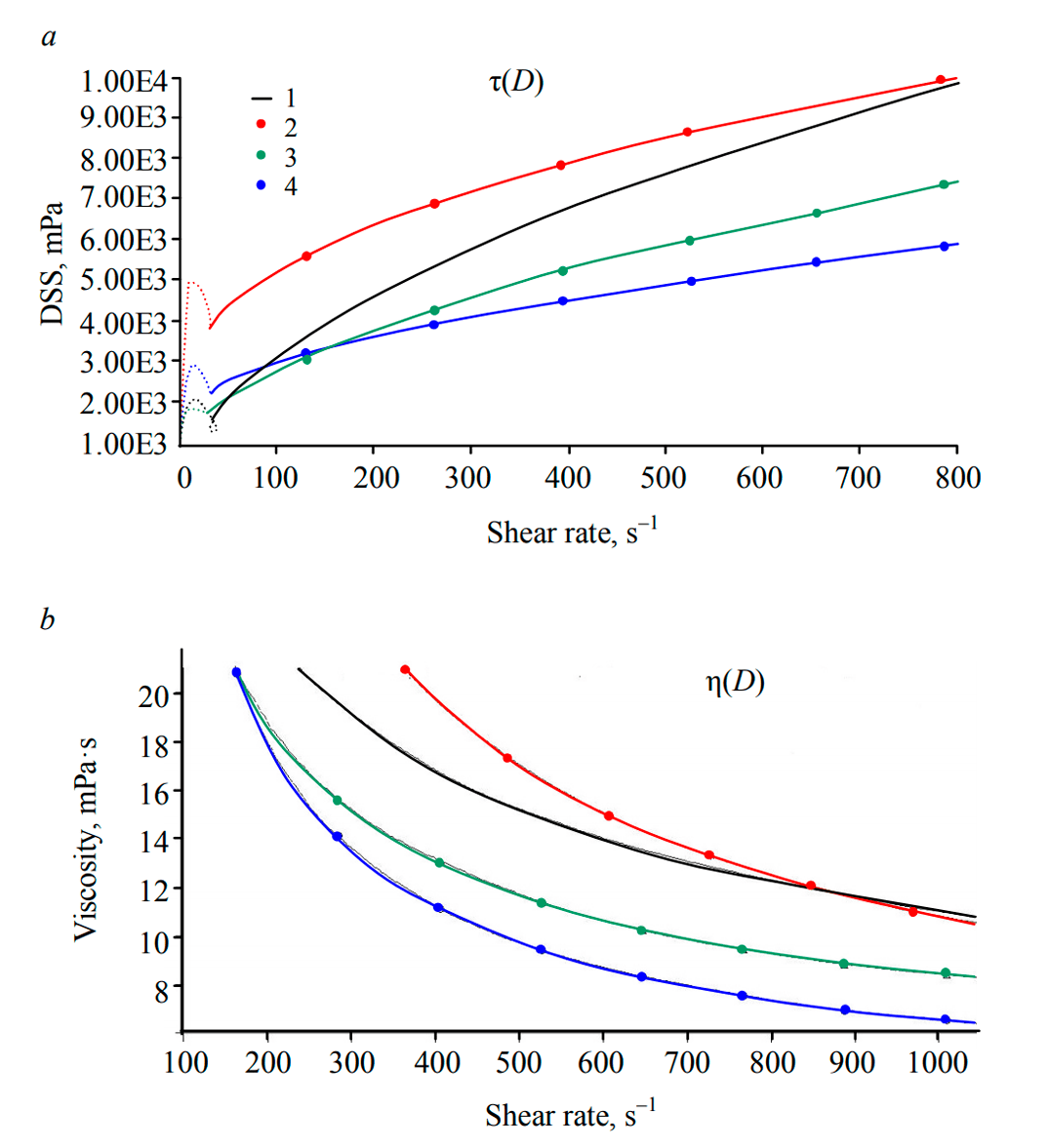

Thus, in solution 5, it was possible to simultaneously obtain lower DSS values and more tangible pseudoplastic properties compared to the basic formulation. For a visual representation of differences in rheological characteristics, they are presented on flow and viscosity curves (Fig.2). Viscometer software allows displaying up to 4 curves on one graph at a time. Therefore, base composition with CMC, solution 3 with xanthan, solution 4 with PAA, and solution 5 with PAA and xanthan are chosen for comparison.

Graphs in Figure 2 show that solution 5, which contains both PAA and xanthan, will create the least resistance during circulation. Solution 4 with PAA has the lowest initial shear stress, and solution 3 with xanthan, due to its higher molecular weight and branched structure, will thicken the solution more strongly than CMC at the same concentration and have more tangible pseudoplastic properties

SSS of drilling mud 5 was measured using the VSN-3 device. SSS1 = 2,3 Pa and SSS10 = 5,7 Pa. Compliance of remaining technological properties for the solution of considered formulation with the requirements mentioned above was also measured. Relative viscosity according to the results of three measurements was 34 seconds, which corresponds to the necessary requirements.

Filtration was measured using a filter press. For 30 minutes at an excess pressure of 0.7 MPa, amount of filtered liquid was 5 cm3. Filter cake formed strong and thin (about 1 mm).

Coefficient of friction for the filter cake was determined on a KTK-2 device. Angle was 4 degrees, and the tangent was 0.069, what is a low indicator, which means that resulting filter cake has good lubricity and will help reduce friction at the “steel-rock” interface. This is especially important during drilling directional and horizontal wells.

Level of pH is 9, which indicates alkaline medium in this drilling mud that is necessary for satisfactory operation of polymer and other reagents.

Technological properties of developed composition of the drilling mud:

| Parameter | Density, kg/m3 | RV, s | SSS (1/10), Pa | DSS, Па | η, mPa·s | F, cm3 | k, mm | pH |

| Recommended value | 1130 (+20) | 30-50 | 3/6 | 1-8 | 7-20 | 4-6 | 1-1,5 | 8-10 |

| Acquired value | 1140 | 34 | 2,3/5,7 | 4,6-7,3 | 11,2-17,3 | 5 | 1 | 9 |

Conducted study has shown that various polymer reagents have different effects on rheological properties of the washing fluid. This is due to the difference in their structure and functionality of elementary units. Branched polymer reagents give the washing fluid more tangible pseudoplastic properties. Pseudoplasticity is a necessary property of a modern drilling mud when it is necessary to reduce hydraulic resistance at a high deformation rate (bit nozzles and fluid movement in pipes) and increase the holding and transporting ability of the fluid at low shear rates in the annulus. Linear polymers, in which functional units are located at the main circuit, have greater flexibility and create less resistance at movement initiation, which is very important during start-up of pumps and resuming circulation after tripping operations. Performance of polymer reagents largely depends on mineralization of dispersion medium and formation fluids that are in contact with the drilling mud. Presence of functional groups in polymer reagents capable of interaction and dissociation creates the need to control this parameter. High mineralization can lead to the fact that electrostatic repulsion between functional groups is lost, which helps the main polymer chain to be in an extended state (globulization of the polymer reagent). Shape of the polymer reagent chain affects its performance. Reagents rolled into a coil or spiral are less effective.

As a result of the combination of polymer reagents with various properties, it was possible to obtain the composition of the washing liquid with optimal rheological characteristics: bentonite – 40, NaOH – 1, starch – 15, bactericide – 1, PAA – 0.5, xanthan – 2, chalk – 185, lubricant – 25 kg/m3.

General conclusions and recommendations. 1. Conducted laboratory study has shown that high-molecular polymer reagents (e.g., xanthan gum) can give flushing liquids tangible pseudoplastic properties, and their combination with a linear high-molecular polymer (e.g., PAA) can reduce DSS value. Thus, at selection of polymer reagents, it is necessary to take into account their structure, molecular weight and properties. Combination of different types of reagents can lead to a synergistic effect.

2. Optimal composition of the drilling mud for the conditions of an oil field located in the Republic of Tatarstan (Russia) includes xanthan gum and PAA as polymer reagents.