Potential use of water treatment sludge for the reclamation of small-capacity sludge collectors

Abstract

In small settlements, collectors for the sludge produced during water treatment processes are small-sized and located in the vicinity of drinking water storage reservoirs or in coastal areas. Sludge removal is not economical. Besides, the relief depressions formed after sludge disposal are required to be reclaimed. In ore mining regions, where the main settlements of the Urals are located, sludge produced in water treatment has high contents of heavy metals typical of ore mining provinces. Consequently, places of sludge accumulation are potential sources of water pollution. The article discusses the possibility to mix sludge with slaked lime and local overburden with the help of special equipment. So far water treatment sludge in the region has been used to reclaim the surface of solid waste landfills by creating anaerobic conditions for waste decomposition. When placed inside the embankment dams as an independent object, sludge needs to be improved for the increase of its bearing capacity and the ability to bind heavy metals. The article aims at the substantiation of the composition and properties of the reclamation material made of the water treatment sludge mixed with local overburden and slaked lime (technosoil). For this reason the paper describes the composition of the sludge in a sludge collector, the composition and properties of the overburden rocks as a component of the mixtures with water treatment sludge, the composition and properties of the mixtures of water treatment sludge with overburden rocks and Ca(OH)2 as a component dewatering sludge and neutralizing toxicants. Furthermore, the research work provides the technology created for the optimal processing of the water treatment sludge in the process of the reclamation of a sludge collector. The research results and the experience obtained in reclamation of disturbed lands in the region have confirmed the possible use of technosoil for the reclamation of small-capacity sludge collectors. The analysis of the chemical composition and physical and mechanical properties of the mixtures under study has shown that the most economical and environmentally sound reclamation material is a mixture of water treatment sludge, loose overburden dump soils and Ca(OH)2 in a ratio of 60 : 30 : 10 %.

Introduction

Surface waters are the main source of domestic water supply. Their reactant purification is accompanied by coagulation and sedimentation of a significant amount of suspended material. Waste from water clarification includes high-moisture organic and mineral sludge consisting of suspended solids contained in the treated water and flocculent hydrolysis products called coagulants with adsorbed organic and mineral compounds [1-3].

The generation of such waste characterized by high moisture content (up to 99.9 %) and very low compaction (dehydration) ability is quite large scaled. For example, the USA generates about 10 million tons of water treatment sludge per year while the Russian Federation annually produces about 500 thousand tons of dry sludge or 100 million m3 of sludge with moisture content of 99.5 %. A water treatment plant with the capacity of 750 thousand m3 per day on average generates up to 12 thousand tons of dry sludge per year [4]. According to the Municipal Unitary Enterprise “Yekaterinburg Vodokanal”, the main water treatment station in Yekaterinburg – the Western Filtration Station – operates with the capacity of 400 thousand m3 per day. In accordance with the design scheme, about 60 thousand m3 of wash water generated during the water treatment process used to be discharged into the sludge collector. Due to a long-term water discharge, the sludge collector built in the 1970s overflowed, which led to excessive water discharge at the outlet [5].

The problem of environmentally safe storage and disposal of water treatment sludge is extremely relevant for Russia, where the main sources of centralized water supply are surface waters, whose share in the total volume of water intake accounts for 68 % [6]. The water supply of many large cities of the country (Moscow, Saint Petersburg, Saratov, Samara, Yekaterinburg, Chelyabinsk, Novosibirsk, etc.) is entirely based on surface water sources such as rivers and water storage reservoirs. Centralized water supply for half the cities with the population of over 100 thousand people is either entirely based on surface waters or accounts for more than 90 % of the water consumption balance. About 90 % of surface water coming into a water treatment plant is treated (most often by coagulation) to remove excess impurities and pathogenic microorganisms. At the same time, most water treatment stations neither process wash water nor dispose of the resulting sludge [7-9]. As a rule, water treatment sludge is stored in sludge collectors and on sludge beds [10-12]. The use of sludge ponds for storage and partial dewatering of sludge during its long-term gravitational compaction and drainage of clarified water has become widespread in many countries of the world [4, 13, 14].

Water treatment sludge is less dangerous for the environment and humans than, for instance, municipal wastewater sludge [15-17]. The presence of contaminants in sludge largely depends on the quality of wastewater coming for purification [18]. At the same time, water treatment sludge especially that formed during the purification of high-coloured, low-turbidity waters has higher filtration resistivity values and requires greater costs of thickening and dewatering [19, 20]. The storage of water treatment sludge in the sludge ponds or on the dewatering sites leads to the alienation of significant land areas withdrawn from economic use for many years to come. All this requires the search for optimal methods for environmentally safe waste disposal and reclamation of disturbed lands.

Currently, in Russia and abroad, water treatment sludge is mainly used as a component of building materials, as a sorbent for soil and water purification, as a raw material for the production of iron-containing powders, and as a soil component [6, 15, 21].

All these uses of water treatment sludge serve as a basis for the development of technologies for production of cement, mortar, concrete [15, 22, 23], brick [24-26], roofing tiles, and ceramics [15, 27, 28]. Due to its component composition, water treatment sludge can be used as a substitute for natural clay minerals in the production of terracotta ceramics [29]. Agricultural use of water treatment sludge is considered to be the most accessible and large-scale option for its disposal [15]. Other known alternatives for the disposal of water treatment sludge include the reuse of a coagulant or its use as an inexpensive adsorbent for heavy metals such as mercury, lead [30-32], selenium and arsenic [33].

The use of water treatment sludge is one of the effective ways to reclaim disturbed lands. In accordance with GOST R 54534-2011 “appropriately controlled sludge from water treatment, wastewater treatment and water use” can be used as a secondary material resource for the reclamation of disturbed lands. Water treatment sludge can be used either to fill quarry excavations at a technical stage of reclamation [34-36] or to create top soil of the earth and to reclaim contaminated and depleted soils at a biological stage of recultivation [32, 37].

The processing of water treatment sludge for the production of secondary products is rather expensive because big costs are required to determine the composition and properties of the sludge as well as to select and develop technologies for its utilization. When water treatment sludge is produced in big amounts, its utilization can have a beneficial economic impact on the enterprises of housing and communal services. In large cities, a significant part of the budget of organizations operating water treatment plants goes to the removal and deposition of sludge generated in large amounts [37]. In small towns where small amounts of water treatment sludge are generated, the use of sludge treatment technologies or its removal to specialized waste disposal sites is often economically ineffective.

In small settlements of Sverdlovsk region, water treatment sludge collectors are of small capacity (up to 100,000 m3), but they are commonly located in the vicinity of drinking water storage reservoirs or in coastal zones of surface water bodies. In ore mining regions, where the main settlements of the Urals are located, sludge produced during water treatment processes has increased contents of heavy metals typical of ore mining provinces. All this requires the reclamation of sludge collectors by means of inert material prepared for the reduction of the anthropogenic pressure on the environmental components.

For this reason one of the sludge collectors of the water intake station in Sverdlovsk region has been selected with the aim of studying the possibilities of its reclamation in situ and through the use of special equipment mixing sludge with slaked lime (Ca(OH)2) and local overburden soils for the increase of the bearing capacity of the resulting mixtures and the reduction of the environmental hazard from the sludge.

The study aims at the substantiating the composition and properties of the water treatment sludge as a material for the reclamation of the sludge collector. The analysis of the literature on the projects implemented in Russia and abroad and related to the disinfection and stabilization of the sewage sludge has shown that one of the economically feasible, technologically advanced, and relatively simple ways to reduce sanitary and environmental hazard from the sludge is the use of lime as the main reagent. Lime addition leads to the sludge dewatering and structuring, which contributes to the immobilization of heavy metals [12].

The research sets the task to describe the composition of the sludge accumulated in a sludge collector in its initial state; the composition and properties of the overburden rocks as a component of mixtures with water treatment sludge; the composition and properties of the mixtures of water treatment sludge with overburden rocks, and Ca(OH)2 as a component dewatering sludge and neutralizing toxicants. Moreover, the paper focuses on the creation of the technology for optimal processing of water treatment sludge during the reclamation of a sludge collector.

In order to develop a sludge disposal technology for obtaining an optimal sludge composition with characteristics for the reclamation of a sludge collector, several tests have been made. They have resulted in the selection of the technogenic soil composition and the main parameters of the technology for its production. The properties of the composition have made it possible not only to reclaim the sludge collector but also to ensure the safety of the resulting soil for the environment in accordance with regulatory documents.

Research object

The object of research is a sludge collector of the Chernoistochinskiy hydroelectric complex. It is used for the storage of water treatment sludge, that is, suspended solids resulted from washing water treatment facilities such as microfilters and filters, emptying and washing sedimentation tanks, washing the tanks of the reagent facilities of the Chernoistochinskiy hydroelectric complex, a structural division of OOO Vodokanal-NT (a limited liability company under the laws of the RF), which supplies the population and industrial enterprises of Nizhniy Tagil with drinking water.

The sludge collector is located on the border of the landscape reserve of regional significance “Chernoistochinskii pond with Ushakovskaya ditch and surrounding forests” within the water protection zone of Chernoistochinskii water storage reservoir and on the territory of the II and III belts of the sanitary protection zone of the Chernoistochinskii hydroelectric complex. The location of the waste disposal facility within the boundaries of the sanitary protection zone and the water protection zone determines the need for the reclamation of the sludge collector as well as the reduction of its negative impact on the environment.

The collector for the water treatment sludge is a pit consisting of one section up to 4.18 m in depth. It is filled with water treatment sludge. The total capacity of the sludge collector is 75900 m3. At the base of the sludge collector there are eluvial loams having thickness of more than two meters and filtration coefficients n equal to 10–7 cm/s.

The initial water treatment sludge accumulated in the sludge collector demonstrates slightly increased measured values of zinc, lead, arsenic, copper, nickel, and oil products in relation to background values for the soils in the area under study. Tentative allowable concentrations (TAC) of arsenic for soils are also exceeded (Table 1). Increased values are associated both with the natural processes of the sludge concentrating at the particulate surface water phases in complexes with organic substances and with technogenic processes during the sludge treatment at the Chernoistochinskii hydroelectric complex.

Table 1

Chemical composition of the water treatment sludge in the sludge collector

|

Indicator name |

Test result |

Background in the soil |

MAC/TAC for soils according toSanitary regulations and norms 1.2.3685-21 |

Norms of the GOST R 54534-2011 |

|

|

Technicalreclamation |

Biologicalreclamation |

||||

|

рН of the salt extract (рНsalt) |

6.4 |

– |

Not regulated |

5.0-8.5 |

5.0-8.5 |

|

Total nitrogen, % |

>0.6 |

– |

Not regulated |

Not regulated |

No less than 0.5 |

|

Total phosphorus, % |

2.1 |

– |

Not regulated |

Not regulated |

No less than 1.5 |

|

Dense residue of water extract, % |

0.30 |

– |

Not regulated |

– |

– |

|

Ash content, % |

91.0 |

– |

Not regulated |

Not less than 65 |

65-85 |

|

Exchange (mobile) aluminum, mmol/100 g |

0.072 |

– |

Not regulated |

– |

– |

|

Cadmium (g), mg/kg |

<0.8 |

<0.8 |

2 |

60 |

30 |

|

Chromium (g), mg/kg |

<10 |

<10 |

Not regulated |

2000 |

1000 |

|

Copper (g), mg/kg |

69 |

45 |

132 |

1500 |

750 |

|

Manganese (g), mg/kg |

76 |

632 |

1500 |

– |

– |

|

Nickel (g), mg/kg |

21 |

14 |

80 |

800 |

400 |

|

Lead (g), mg/kg |

23 |

<20 |

130 |

1000 |

500 |

|

Zinc (g), mg/kg |

83 |

81 |

220 |

7000 |

3500 |

|

Arsenic (g), mg/kg |

12 |

3.6 |

10 |

40 |

20 |

|

Mercury (g), mg/kg |

0.033 |

0.11 |

2.1 |

30 |

15 |

|

Petroleum products, mg/kg |

47.0 |

23.0 |

1000 |

– |

– |

|

Benzpyrene, mg/kg |

<0.005 |

<0.005 |

0.02 |

– |

– |

|

Class of danger |

V |

– |

– |

IV-V |

– |

The main macrocomponents of the water treatment sludge of the research object are inert oxide compounds of silicon (20.88 %), aluminum (14.58 %), iron (4.38 %), calcium (4.27 %), magnesium (4.14 %). They can be constituent elements of sand, clay and mineral particles. The rest components include organic substances, fertilizing macroelements (nitrogen, phosphorus, potassium) and microelements. According to the tests results, the content of exchange (mobile) aluminum in the sludge is 0.072 mmol/100 g, the mass fraction of total nitrogen is >0.6 %, the mass fraction of gross phosphorus is 2.1 %, the mass fraction of the ash content is 91.0 %, the dense residue of the water extract is 0.3 %. Water extracts of water treatment sludge samples are not toxic. They are attributed to the V class of danger according to the degree of their negative impact on the environment.

Methods

The properties of the water treatment sludge have been studied in laboratory conditions by means of standard techniques and engineering survey equipment. The same methods have been used to study the overburden rocks of local deposits and technosoil. Judging by plasticity index and flow index the water treatment sludge refers to fluid clays. Taking into account its granulometric composition, the water treatment sludge belongs to heavy clays. According to the studies, the maximum molecular moisture capacity of the sludge W equals to 206.4 %, total moisture capacity of the sludge W0 accounts for 720.4 %, and soil density is 1.07 g/cm3.

The strength properties of the soil have been studied in laboratory conditions using a non-consolidated-undrained shear scheme. The value of compression modulus of deformation of the sludge with natural moisture content is 0.4 MPa. Strength indicators of the sludge with natural moisture content С and φ account for 0.002 MPa and 9° respectively.

The main factors affecting the use of sludge for reclamation are high moisture content and, consequently, low values of strength and deformation properties, increased levels of arsenic (above the established maximum allowable concentrations (MAC) for soils); slightly increased values of zinc, lead, arsenic, copper, nickel, and petroleum products in relation to background values for soils in the area under study.

These tests results have influenced the development of a technology for processing (recycling) the sludge into artificial technogenic soil which can be subsequently used for the reclamation of disturbed lands by means of reducing the moisture content of the sludge, increasing the mechanical properties of the soil and lowering the concentrations of contaminants in the sludge to maximum allowable ones.

The soil from loose overburden dump of the Glavnyi quarry of the Vysokogorsk deposit is another material, whose chemical and granulometric compositions as well as moisture content have been studied. The soil can be used for reclamation as a filler for mixtures with water treatment sludge accumulated in the loose overburden dump located in the Glavnyi quarry of the Vysokogorsk iron ore deposit 20 km north of the sludge collector. The chemical, granulometric composition and soil moisture content of the dump of loose overburden of the Glavnyi quarry of the Vysokogorsk iron ore deposit, selected for use as a reclamation agent, have been studied. The article provides the study of the composition, chemical and physical-mechanical properties of the mixtures of water treatment sludge with overburden rocks of the Vysokogorsk deposit and calcium hydroxide Ca(OH)2 (slaked lime) as a component dewatering high moisture sludge and ecotoxicants (Table 2).

Table 2

Ratios of mixed components, wt.%

|

Water treatment sludge |

Calcium hydroxide Са(ОH)2 (slaked lime) |

Soil from the loose overburden dump of the Glavnyi Quarry of the Vysokogorsk deposit |

|

90 |

10 |

– |

|

70 |

30 |

– |

|

50 |

50 |

– |

|

70 |

– |

30 |

|

50 |

– |

50 |

|

30 |

– |

70 |

|

45 |

10 |

45 |

|

30 |

10 |

60 |

|

60 |

10 |

30 |

The prepared mixtures of water treatment sludge with overburden rocks of the Vysokogorsk deposit and Ca(OH)2 have the determined contents of gross and water-soluble forms of metals (Cu, Zn, Ni, Al, Mn) and arsenic as well as the determined pH of salt and water extracts. The list of chemical substances determined by the quantitative methods was made taking into account the geochemical specifics of the area under study. The quantitative chemical analysis was performed according to the standard techniques GOST 26483-85, RD 52.18.685-2006, PND F 16.1:2.2:3.17-98, GOST 26485-85, M-MVI 80-2008. The toxicity of mixtures was determined using the method of PND F T 16.1:2.3:3.8. The research was made in the testing laboratory of OOO Test-Expert in Yekaterinburg.

Laboratory tests of the physical and mechanical properties of the mixtures included determining density, moisture content, deformation modulus, angle of internal friction, and specific adhesion in accordance with GOST 30416-2020, GOST 5180-2015, GOST 12536-2014, GOST 12248-2020. The strength properties of the mixtures were studied under the conditions of non-consolidated undrained shear. The deformation properties were determined by the compression method. The studies were carried out in the testing laboratory of OOO Uralgeoproekt in Yekaterinburg.

The bearing capacity of technosoils composed of water-saturated organomineral and organic soils was determined in accordance with the paragraphs 5.1.9 and 5.7.5 of SP 22.133302016 with the calculation of the ultimate resistance of the base NU under vertical load on linear models.

Results and Discussion

The conducted research has shown that adding recultivants such as loose overburden rocks of the Vysokogorsk deposit and Ca(OH) 2 (slaked lime) to the water treatment sludge leads to the fact that the sludge is dewatered and the concentrations of ecotoxicants in it are reduced.

The studies of the chemical composition of the soils from the loose overburden dump of the Vysokogorskoye deposit reveal the following contents of elements and compounds in mg/kg: copper 107.0, zinc 114.0, lead less than 20, arsenic 3.8, nickel 27, mercury 0.097, cadmium less than 0.8, chromium less than 10.0, manganese 124.0, benzopyrene less than 0.005, petroleum products 14.0. The overburden rocks are characterized by a permissive category of contamination (Zc = 3.8); increased contents of metals and arsenic are not detected; the soils are not toxic.

The addition of slaked lime (Ca(OH)2) and overburden rocks to water treatment sludge changes the chemical composition of the material. The contents of water-soluble forms of metals and arsenic are significantly lower than those of their gross forms, which proves the binding of ecotoxicants in the form of complex poorly soluble and insoluble mineral and organomineral compounds (Table 3).

Table 3

Content of ecotoxicants in the mixtures

|

Sample characteristics |

рНaqu |

рНsalt |

Elements content |

|||||||||||

|

Cu |

Zn |

As |

Ni |

Al |

Mn |

|||||||||

|

Gross, mg/kg |

Water-soluble, mg/kg |

Gross, mg/kg |

Water-soluble, mg/kg |

Gross, mg/kg |

Water-soluble, mg/kg |

Gross, mg/kg |

Water-soluble, mg/kg |

Exchange (mobile),mmol/100 g |

Water-solubla, mg/kg |

Gross, mg/kg |

Water-soluble, mg/kg |

|||

|

Mixture of sludge + Cа(OН)2 (90 · 10 wt.%) |

10.2 |

9.7 |

143.0 |

26.0 |

120.0 |

<1 |

3.6 |

<1 |

25.0 |

1.3 |

0.26 |

<5 |

152 |

5.9 |

|

Mixture of sludge + Cа(OН)2 (70 · 30 wt.%) |

12.5 |

12.3 |

63.0 |

4.7 |

57.0 |

<1 |

0.3 |

<1 |

17.0 |

2.3 |

<0.05 |

<5 |

62.0 |

<1 |

|

Mixture of sludge + Cа(OН)2 (50 · 50 wt.%) |

12.4 |

12.4 |

53.0 |

<1 |

30.0 |

<1 |

1.7 |

<1 |

14.0 |

<1 |

<0.05 |

<5 |

41.0 |

<1 |

|

Mixture of sludge + soil (70 · 30 wt.%) |

9.8 |

8.2 |

317.0 |

<1 |

122.0 |

<1 |

6.6 |

<1 |

15.0 |

<1 |

<0.05 |

<5 |

950 |

14.0 |

|

Mixture of sludge + soil (50 · 50 wt.%) |

8.4 |

6.9 |

427.0 |

<1 |

131.0 |

<1 |

5.0 |

<1 |

14.0 |

<1 |

<0.05 |

<5 |

1225 |

12.0 |

|

Mixture of sludge + soil(30 · 70 wt.%) |

8.3 |

7.5 |

289.0 |

<1 |

135.0 |

<1 |

4.2 |

<1 |

<10 |

1.3 |

<0.05 |

<5 |

777 |

7.4 |

|

Mixture of sludge + soil + Cа(OН)2 (45 · 45 · 10 wt.%) |

12.4 |

12.4 |

275.0 |

11.0 |

109.0 |

<1 |

5.1 |

<1 |

20.0 |

<1 |

<0.05 |

<5 |

1479 |

1.7 |

|

Mixture of sludge + soil + Cа(OН)2 (30 · 60 · 10 wt.%) |

12.5 |

12.4 |

254.0 |

<1 |

118.0 |

<1 |

4.9 |

<1 |

12.0 |

<1 |

<0.05 |

<5 |

1220 |

4.0 |

|

Mixture of sludge + soil + Cа(OН)2 (60 · 30 · 10 wt.%) |

12.0 |

11.9 |

200.0 |

42.0 |

118.0 |

<1 |

0.9 |

<1 |

14.0 |

2.2 |

0.26 |

<5 |

847 |

16.0 |

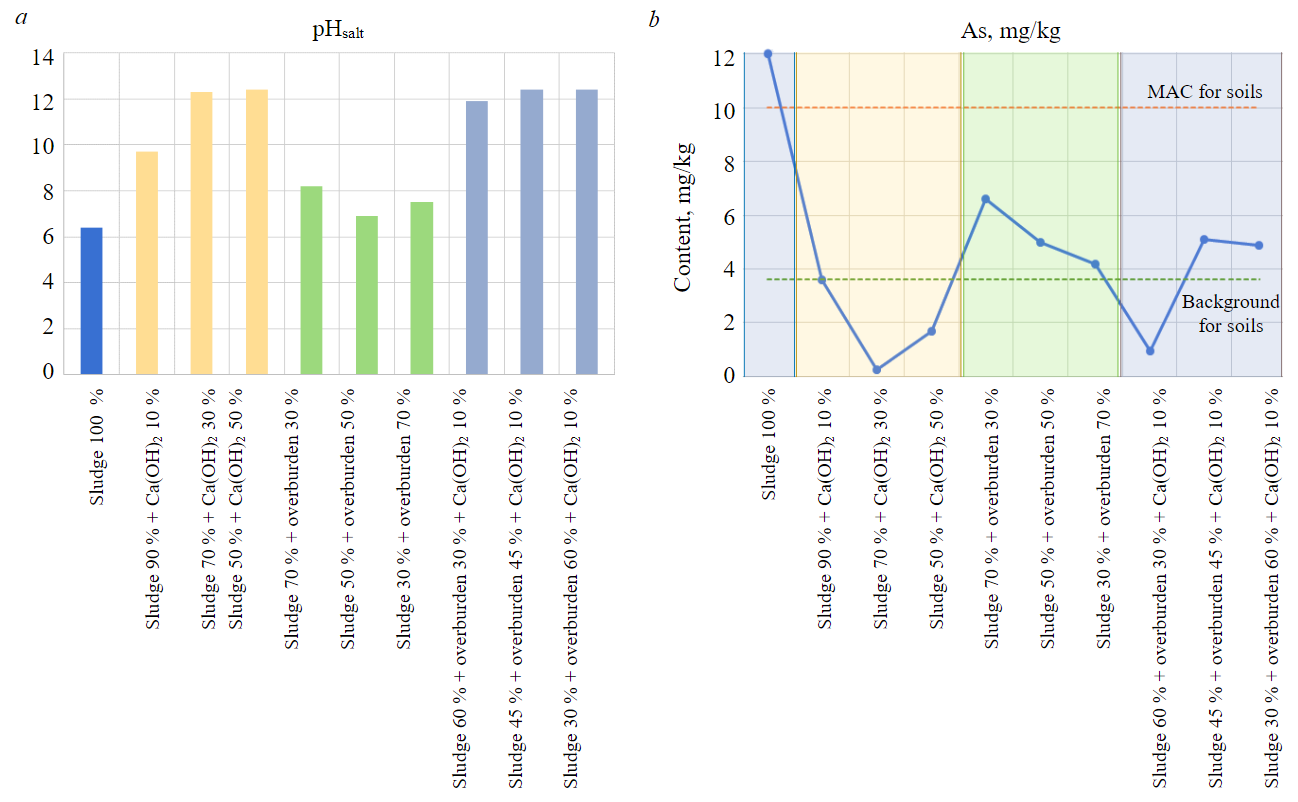

Fig.1. Change of рНsalt (а) and arsenic content (b) in the mixtures of water treatment sludge with Са(ОH)2 and overburden rocks

The addition of slaked lime increases the pH of aqueous extracts of the mixtures under the study to 9.7-12.4 and contributes to the decrease of the arsenic content (Fig.1)

The research results emphasize that the mixture of water treatment sludge, overburden rock and calcium oxide in a percentage ratio of 60 : 30 : 10 % proves to be the safest from the environmental point of view (with the arsenic content being below the relevant MAC). In this case, the most favorable conditions are created due to the absence of the components exceeding the maximum permissible concentrations for soils.

The addition of slaked lime and overburden rocks to the water treatment sludge changes physical and mechanical properties of the initial material. (Table 4).

According to the research results, the increase in the sludge density from 1.07 to 1.26 g/cm3 is observed with the addition of up to 50 % of Ca(OH)2; with further addition of Ca(OH)2, the density of the mixture almost fails to increase. When clay material is added, the density of the mixture increases up to 1.78 g/cm3.

With the addition of up to 50 % of Ca(OH) 2, the moisture content of the mixture decreases from 700 to 65 %. With the addition of up to 70 % of clay soil, the moisture content decreases even more from 700 to 47 %.

Table 4

Results of the study of physical and mechanical properties of the mixtures

|

Sample characteristics, % |

Natural moisture content W, % |

Soil density ρ, g/cm3 |

Deformation modulus Е, MPa |

Angle of internal friction φ, deg. |

Specific adhesion С, MPa |

|

Sludge 100 % |

700.0 |

1.07 |

0.4 |

9 |

0.002 |

|

Mixture of sludge + Cа(OН)2 (90 · 10 wt.%) |

249.6 |

1.20 |

0.7 |

10 |

0.003 |

|

Mixture of sludge + Cа(OН)2 (70 · 30 wt.%) |

135.3 |

1.25 |

0.8 |

20 |

0.023 |

|

Mixture of sludge + Cа(OН)2 (50 · 50 wt.%) |

64.4 |

1.26 |

2.9 |

35 |

0.035 |

|

Mixture of sludge + soil (30 · 70 wt.%) |

46.6 |

1.78 |

0.9 |

27 |

0 |

|

Mixture of sludge + soil (50 · 50 wt.%) |

89.8 |

1.50 |

1.3 |

16 |

0 |

|

Mixture of sludge + soil (70 · 30 wt.%) |

169.5 |

1.28 |

0.7 |

10 |

0 |

|

Mixture of sludge + soil + Cа(OН)2 (30 · 60 · 10 wt.%) |

46.7 |

1.68 |

1.3 |

36 |

0.004 |

|

Mixture of sludge + soil + Cа(OН)2 (45 · 45 · 10 wt.%) |

71.9 |

1.51 |

1.3 |

38 |

0.006 |

|

Mixture of sludge + soil + Cа(OН)2 (60 · 30 · 10 wt.%) |

113.8 |

1.35 |

0.9 |

29 |

0.008 |

The strength characteristics of the mixture with Ca(OH)2 are higher than those of the mixture with clay material. The decrease in the moisture content occurs more intensely with the addition of Ca(OH)2.

The assessment of the soil according to its bearing capacity for the reason of ensuring the movement of equipment during the reclamation activities has revealed that with an embankment width of up to one meter only the sludge mixed with 30 and 50 % of Ca(OH)2 satisfies the calculation of the bearing capacity. With a strip width of two meters, this condition is satisfied by the mixtures including overburden rocks in different proportions and 10 % of Ca(OH)2. This result imposes restrictions on the use of equipment. Thus, the formation of a dump from freshly prepared technosoil requires the use of the equipment exerting the least pressure on the ground (B10MB bulldozers with an increased width of tracks), and the choice of technology for placing technosoil in a sludge collector should be made in favour of that which does not suggest the need for dump trucks to drive onto the surface of a dump made from technosoil.

The analysis of the results of the chemical composition and physical and mechanical properties of the mixtures under study has provided the reasons why the mixture of water treatment sludge, overburden rock and Ca(OH)2 at a ratio of 60 : 30 : 10 % proves to be the most economical and environmentally friendly option for the preparation of the recultivation material for the reclamation of a sludge collector. The reasons are as follows:

- the initial sediment sample contained arsenic in an amount of 1.2 TAC;

- quantitative analysis of the overburden rocks of the Vysokogorskoe deposit showed that the contents of the gross forms of the metals did not exceed the established maximum permissible concentrations (MAC);

- in the sample containing overburden rocks (30 %), Ca(OH)2 (10 %), and sludge (60 %), the arsenic content decreases below the TAC; in the water extract the arsenic content is also below the MAC;

- the mixture is not toxic;

- according to physical and mechanical characteristics, the mixture in a ratio of 60 % sludge, 30 % overburden rock and 10 % Ca(OH)2 has a high load-bearing capacity for technological operations aimed at the reclamation of a sludge collector with a reclamation strip being of at least two meters wide.

The results of the research have formed the basis for setting up the regulations for the preparation of the technogenic soil recommended for the reclamation of the sludge collector of the Chernoistochinskii hydroelectric complex.

Technogenic soil (technosoil) is the water treatment sludge accumulated in a sludge collector and mixed with slaked lime and natural soil for the improvement of its bearing capacity and the reduction of the contaminant migration. To create technosoil, it is planned to use the entire volume of the accumulated sludge. The embankment formed by the techno-soil is expected to have a convex shape to ensure the drainage of the atmospheric precipitation from the territory of the reclaimed sludge collector.

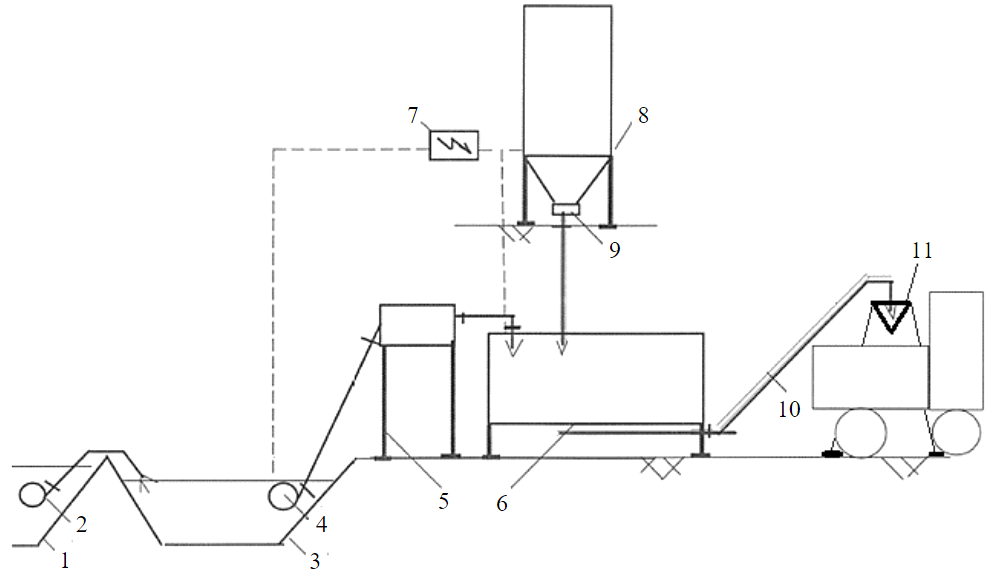

To avoid dusting, the sludge can be mixed with lime by means of a paddle mixer in the cement truck-mixer system or with soil on a kart freed from the sludge (Fig.2).

Fig.2. Scheme of equipment for mixing sludge with lime

1 – sludge collector; 2, 4 – sludge pumps; 3 – process unit; 5 – flow divider; 6 – mixer; 7 – control cabinet; 8 – silo – lime bunker; 9 – screw doser for feeding lime; 10 – screw for unloading mixture from the mixer; 11 – bunker device

Fig.3. Twin-shaft paddle mixer SMK-126

The work was carried out in a process unit of the sludge collector. The process unit, whose volume ranges from 900 to1300 m3, is located next to the technological platform where sludge disposal equipment is installed. The technological platform is situated on board the sludge collector and includes a site covered with reinforced concrete road slabs and two loading areas for the access of cement trucks used for loading lime into the silos and dump trucks used for unloading sludge mixed with lime. The sludge from other remote process sections is fed to the process unit with the help of a high-performance sludge pump. From the process unit the sludge by means of a sludge pump enters the flow divider and then goes through two channels to twin-shaft paddle mixers. Industrial enterprises usually use a twin-shaft paddle mixer SMK-126 for watering and mixing clay (Fig.3). Lime is fed using a screw doser. In the mixer, the sludge is constantly mixed with lime and moves from the inlet hatch to the unloading hatch into the lower part of the mixer. The movement of the entire mass is regulated by blades mounted on the shafts. All work is carried out in summer.

Technosoil resulting from the mixture of sludge and lime is moved to the overburden on the karts. After that the primary planning or leveling is done. The use of Ca(OH)2 has some disadvantages. For instance, the pH medium of the resulting technogenic soil can significantly change from neutral one (pH 6.4) to alkaline (up to pH 12.3), which prevents the restoration of local plant species in the reclaimed areas. This fact determines the need to use potentially fertile and fertile soil as the top layer.

Conclusion

Sustainable development of mining areas is associated with the reclamation of the lands disturbed as a result of industrial activities and their subsequent return to economic use. The increased content of pollutants (arsenic) and low bearing capacity of water treatment sludge accumulated in the sludge collector of the Chernoistochinskii hydroelectric complex have necessitated the search for methods and materials both for binding pollutants to avoid their leaching upon contact with surface waters, and for increasing the bearing capacity of the material for the reclamation of the facility under study.

The analysis of the results of the chemical composition and physical and mechanical properties of the mixtures under study has shown that the mixture of water treatment sludge, loose overburden dump soils and Ca(OH)2 in a ratio of 60 : 30 : 10 % proves to be the most economical and environmentally friendly for the preparation of the reclamation material.

The resulting technosoil with approved material specification 08.92.10-001-97921764-2020 will make it possible to reclaim facilities with small amounts of water treatment sludge and, consequently, to improve the environmental situation in the sanitary protection zone of the water supply source.

The rational use of water treatment sludge as a technogenic secondary raw material ensures environmentally safe waste disposal and reclamation of disturbed lands.

References

- Butko D.A. Modification of physical, chemical and rheological properties of waste waters processed at water treatment plants for the environmental load reduction. Rostov-na-Donu: Rostovskii gosudarstvennyi stroitelnyi universitet, 2014, p. 132 (in Russian).

- Apakashev R.A., Malyshev A.N., Lebzin M.S. Study of the physicochemical properties of water treatment residuals for “green” soil utilization. News of the Ural State Mining University. 2022. Iss. 3 (67), p. 117-124 (in Russian). DOI: 10.21440/2307-2091-2022-3-117-124

- Voronkevich S.D. Technical soil reclamation. Moscow: Akademicheskaya nauka, 2015, p. 244 (in Russian).

- Kalashnikov N.V., Solovyova A.V., Vasiliev V.S. Technology of Treating Rinse Waters Precipitate in Water Treatment Plants. Innovative Technologies in Water Supply and Drainage Systems. Proceedings of the International Scientific Conference, 24-25 October 2019, Cheboksary, Russia. Cheboksary: Sreda, 2019, p. 43-52 (in Russian).

- Mareninov A.Yu., Pomosova N.B. Practices in operating membrane technologies at water treatment facilities of the Municipal Unitary Enterprise “Vodokanal” in Yekaterinburg. Nailuchshie dostupnye tekhnologii vodosnabzheniya i vodootvedeniya. 2023. N 5, p. 18-28 (in Russian).

- Yurak V.V., Malyshev A.N., Lebzin M.S., Apakashev R.A. “Green” utilization of water treatment sludges: patents review. Science, Education, Production in Solving Environmental Problems (Ecology-2022): Materialy XVIII Mezhdunarodnoi nauchno-tekhnicheskoi konferentsii, 1-15 maya 2022, Ufa, Russia. In 2 volumes. Vol. 1. Ufa: Ufa State Aviation Technical University, 2022, p. 230-235 (in Russian).

- Nair A.T., Ahammed M.M. Coagulant recovery from water treatment plant sludge and reuse in post-treatment of UASB reactor effluent treating municipal wastewater. Environmental Science and Pollution Research. 2014. Vol. 21. Iss. 17, p. 10407-10418. DOI: 10.1007/s11356-014-2900-1

- Litti Y., Kovalev D., Kovalev A. et al. Increasing the efficiency of organic waste conversion into biogas by mechanical pretreatment in an electromagnetic mill. Journal of Physics: Conference Series. 2018. Vol. 1111. N 012013. DOI: 10.1088/1742-6596/1111/1/012013

- Lysov V.A., Butko D.A. Integrated use of sludge treatment and disposal facilities. Bulletin of Civil Engineers. 2020. N 1 (78), p. 156-161 (in Russian). DOI: 10.23968/1999-5571-2020-17-1-156-161

- Balashov A.M., Fedorovskaya L.A. Processing of sewage and water treatment sludge as a way of significant reduction of the environmental load on biogeocenoses. Rostovskii nauchnyi zhurnal. 2017. N 8, p. 92-98 (in Russian).

- Balashov A.M., Fedorovskaya L.A. Training of technical personnel under conditions of reindustrialization of the regional economy. Podgotovka kadrov tekhnologicheskogo profilya v usloviyakh reindustrializatsii ekonomiki regiona: Sbornik statei Vserossiiskoi nauchno-prakticheskoi konferentsii, 19-21 aprelya 2017, Novosibirsk, Rossiya. Novosibirsk: Novosibirskii gosudarstvennyi pedagogicheskii universitet, 2017, p. 21-29 (in Russian).

- Korolev V.I., Zvereva E.R. Russian experience in the use of chemical water treatment waste in economic activity: prospects for use in the treatment of sewage sludge (review article). Power engineering: research, equipment, technology. 2022. Vol. 24. N 6, p. 47-62 (in Russian). DOI: 10.30724/1998-9903-2022-24-6-47-62

- Yaqian Zhao, Ranbin Liu, Olumide Wesley Awe et al. Acceptability of land application of alum-based water treatment residuals – An explicit and comprehensive review. Chemical Engineering Journal. 2018. Vol. 353, p. 717-726. DOI: 10.1016/j.cej.2018.07.143

- Romanovskii V.I. Processing of water treatment waste in the Republic of Belarus. Nauka i tekhnologii – ZhKKh. 2019. N 1, p. 111-120 (in Russian).

- Kofman V.Ya. Water sludge: utilization in the production of construction materials and agriculture Alternative coagulants (a review). Water Supply and Sanitary Technique. 2020. N 6, p. 55-64 (in Russian). DOI: 10.35776/MNP.2020.06.08

- Kuts E.V., Vakhrusheva O.M. Processing and disposal of residual and filter sludge accumulated during water treatment processes. Obshchestvo. Nauka. Innovatsii (NPK-2017): Sbornik statei Vserossiiskoi ezhegodnoi nauchno-prakticheskoi konferentsii, 1-29 aprelya 2017, Kirov, Rossiya. Kirov: Vyatskii gosudarstvennyi universitet, 2017, p. 1402-1408 (in Russian).

- Litvinova T.E., Suchkov D.V. Lightweight ash-based concrete production as a promising way of technogenic product utilization (on the example of sewage treatment waste). Journal of Mining Institute. 2023. Vol. 264, p. 906-918.

- Schegolkova N.M. Waste of Water Treatment Plants and of Water Purification Plants: Problem or Business Project? WATER-Magazine. 2015. N 9 (97), p. 28-33 (in Russian).

- Nikolaenko E.V., Belkanova M.Yu. Methods to increase the water yielding capacity of natural water sludge. Vodosberezhenie, melioratsiya i gidrotekhnicheskie sooruzheniya kak osnova formirovaniya agrokulturnykh klasterov Rossii v XXI veke: Sbornik dokladov XVIII Mezhdunarodnoi nauchno-prakticheskoi konferentsii, 18 marta 2016, Tyumen, Rossiya. In 3 volumes. Vol. 1. Tyumen: Tyumenskii gosudarstvennyi arkhitekturno-stroitel'nyi universitet, 2016, p. 122-125 (in Russian).

- Boyko T. Possibility of using membrane technology for dewatering sludge from water treatment plants. FEFU: School of Engineering Bulletin. 2019. N 4 (41), p. 125-133 (in Russian). DOI: 10.24866/2227-6858/2019-4-13

- Turner T., Wheeler R., Stone A., Oliver I. Potential Alternative Reuse Pathways for Water Treatment Residuals: Remaining Barriers and Questions – a Review. Water, Air, & Soil Pollution. 2019. Vol. 230. Iss. 9. N 227. DOI: 10.1007/s11270-019-4272-0

- El-Didamony H., Khalil Kh.A., Heikal M. Physico-chemical and surface characteristics of some granulated slag–fired drinking water sludge composite cement pastesFootnote. HBRC Journal. 2014. Vol. 10. Iss. 1, p. 73-81. DOI: 10.1016/j.hbrcj.2013.09.004

- Balchugov D.V., Skolubovich A.Yu., Zavrazhin S.V., Shott A.A. Possible schemes of washing water treatment and sludge treatment at existing water treatment plants in small towns. News of Higher Educational Institutions. Construction. 2022. N 12 (768), p. 29-37 (in Russian). DOI: 10.32683/0536-1052-2022-768-12-29-37

- Smirnov Yu.D., Suchkov D.V., Danilov A.S., Goryunova T.V. Artificial soils for restoration of disturbed land productivity. Eurasian Mining. 2021. N 2, p. 92-96. DOI: 10.17580/em.2021.02.19

- Samuel De Carvalho Gomes, John L. Zhou, Wengui Li, Guangcheng Long. Progress in manufacture and properties of construction materials incorporating water treatment sludge: A review. Resources, Conservation and Recycling. 2019. Vol. 145, p. 148-159. DOI: 10.1016/j.resconrec.2019.02.032

- Chung-Ho Huang, Shun-Yuan Wang. Application of water treatment sludge in the manufacturing of lightweight aggregate. Construction and Building Materials. 2013. Vol. 43, p. 174-183. DOI: 10.1016/j.conbuildmat.2013.02.016

- Benlalla A., Elmoussaouiti M., Dahhou M., Assafi M. Utilization of water treatment plant sludge in structural ceramics bricks. Applied Clay Science. 2015. Vol. 118, p. 171-177. DOI: 10.1016/j.clay.2015.09.012

- da Silva E.M., Morita D.M., Lima A.C.M., Teixeira L.G. Manufacturing ceramic bricks with polyaluminum chloride (PAC) sludge from a water treatment plant. Water Science & Technology. 2015. Vol. 71. N 11, p. 1638-1645. DOI: 10.2166/wst.2015.132

- Yew Pei Ling, Ren-Haw Tham, Siew-Ming Lim et al. Evaluation and reutilization of water sludge from fresh water processing plant as a green clay substituent. Applied Clay Science. 2017. Vol. 143, p. 300-306. DOI: 10.1016/j.clay.2017.04.007

- Mikkonen H.G., Dasika R., Drake J.A. et al. Evaluation of environmental and anthropogenic influences on ambient background metal and metalloid concentrations in soil. Science of the Total Environment. 2018. Vol. 624, p. 599-610. DOI: 10.1016/j.scitotenv.2017.12.131

- Adagunodo T.A., Sunmonu L.A., Emetere M.E. Heavy metals’ data in soils for agricultural activities. Data in Brief. 2018. Vol. 18, p. 1847-1855. DOI: 10.1016/j.dib.2018.04.115

- Mishra M., Mohan D. Bioremediation of Contaminated Soils: An Overview. Adaptive Soil Management: From Theory to Practices. Singapore: Springer, 2017, p. 323-337. DOI: 10.1007/978-981-10-3638-5_16

- Hyun-Shik Yun, Min Jang, Won-Sik Shin, Jaeyoung Choi. Remediation of arsenic-contaminated soils via waste-reclaimed treatment agents: Batch and field studies. Minerals Engineering. 2018. Vol. 127, p. 90-97. DOI: 10.1016/j.mineng.2018.07.015

- Evdokimov S.I., Gerasimenko T.E., Dmitrak Yu.V. Elimination of accumulated environmental damage. Sustainable Development of Mountain Territories. 2019. Vol. 11. N 2 (40), p. 238-248 (in Russian). DOI: 10.21177/1998-4502-2019-11-2-238-248

- Abdelhadi K., Latifa O., Khadija B., Lahcen B. Valorization of mining waste and tailings through paste backfilling solution, Imiter operation, Morocco. International Journal of Mining Science and Technology. 2016. Vol. 26. Iss. 3, p. 511-516. DOI: 10.1016/j.ijmst.2016.02.021

- Olivier Vidal. Mineral Resources and Energy. London: ISTE Press, 2018, p. 170. DOI: 10.1016/C2017-0-00318-X

- Apakashev R.A., Guman O.M., Valiev N.G. Reclamation of disturbed lands by means of technogenic water treatment sludge. Sustainable Development of Mountain Territories. 2020. Vol. 12. N 2 (44), p. 229-236 (in Russian). DOI: 10.21177/1998-4502-2020-12-2-229-236