Technology of absorption elimination with cross-linking plugging material based on cement and cross-linked polymer

- 1 — Deputy Director “PermNIPIneft” Branch of OOO “LUKOIL-Inzhiniring” in Perm ▪ Orcid ▪ Elibrary

- 2 — Ph.D. Head of Department “PermNIPIneft” Branch of OOO “LUKOIL-Inzhiniring” in Perm ▪ Orcid ▪ Elibrary

- 3 — Ph.D. Associate Professor Perm National Research Polytechnic University ▪ Orcid

Abstract

The peculiarity of the geological structure of carbonate reservoirs is their complex permeability and porosity characteristics, reflecting the simultaneous presence of cavities variety (fractures, caverns, pores). Loss of circulation during penetration of fractured rock intervals significantly increases well construction time due to lack of efficient plugging isolation compositions. The main disadvantages of traditional compositions are high sensitivity to dilution in the process of their injection into the absorption zone, as well as insufficient structural strength to prevent the isolation composition from spreading during the induction period. For efficient isolation of catastrophic absorption zones in conditions of high opening of absorption channels a new cross-linking plugging isolation composition has been developed, which allows to exclude disadvantages of traditional isolation compositions. Application of the composition will allow to reduce the injection volume of the isolation composition and the time of isolation works due to its resistance to dilution and movement of formation water in the absorption interval.

Funding

The research was supported by the Ministry of Science and Higher Education of the Russian Federation (project N FSNM-2023-0005).

Introduction

At present, it is necessary to reduce well construction costs in order to ensure profitable hydrocarbon production. The solution to this task requires high-quality well construction with a multiple reduction in construction time [1]. At the modern level of technologies, it is not possible to exclude the costs of prevention [2-4] and elimination of complications during drilling [5-7]. Thus, on average 20-25 % of the calendar time of well construction is spent on elimination of complications. Absorption intensity is divided into three categories: filtration (less than 3 m3/h), partial (3-15 m3/h) and catastrophic (more than 15 m3/h) absorption [8]. The issue of catastrophic absorption zones isolation is especially relevant [9], which are characteristic for rocks with karst cavities, caverns, complicated by tectonic dislocations [1, 10]. The task of reducing the cost of eliminating complications associated with the absorption of technological liquids becomes more complicated when penetrating highly drained zones in the intervals of absorbing channels [11-13]. As a rule, when penetrating such zones, an increase in rate of penetration is observed, up to drilling tool dips, with subsequent loss of circulation. Isolation of fractured zones in carbonate formations with the use of bridging materials can be ineffective. To achieve the result, a large volume of isolation materials is used and a large number of repeated isolation works are carried out [14].

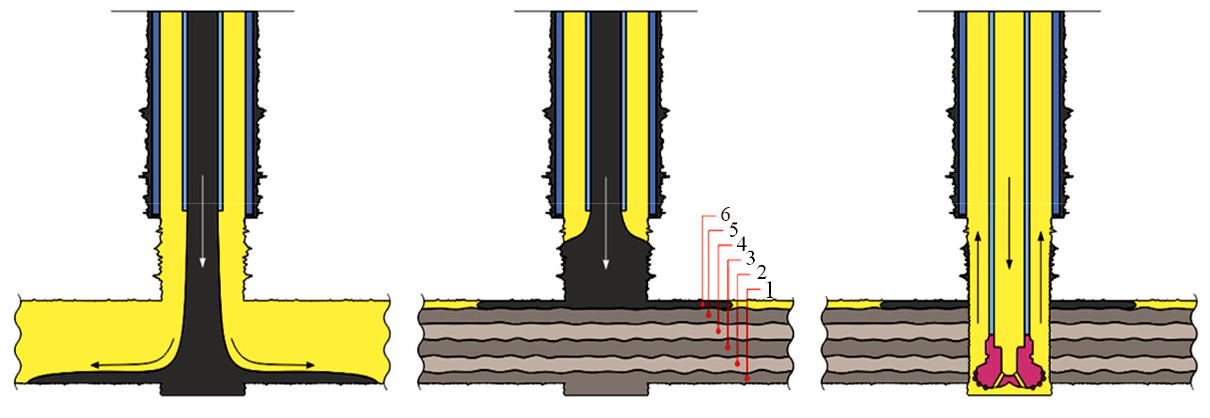

Fig.1. Mechanism of cavity space filling with conventional plugging compositions

1-6 – operation number

The practice of absorption zone isolation shows that low- and medium-intensity absorptions are successfully isolated using standard technologies accepted in drilling and service companies (bridging, sediment-forming compositions, instantaneous filtration compositions, plugging and foam-cement materials) [15]. Isolation of catastrophic absorption zones is achieved by gradual filling of the cavity space with the use of traditional plugging materials or by installing a profile blocker. In some cases, in agreement with the customer, the drilling contractor continues well construction without circulation output, taking measures to reduce flushing fluid consumption [16, 17], which allows to reduce the equivalent circulation density in the absorbing interval [18, 19]. Such a solution reduces the probability of fracture opening and drilling mud loss. This approach allows reaching the design bottomhole with a significant increase in well construction time, whereas drilling necessitates control of pressure in the annular space to prevent oil-and-gas influx or drill string sticking [18, 20]. Isolation of catastrophic absorption zones is mandatory in conditions of significant reduction of static fluid level in the well, which can provoke oil, gas and water influx (when penetrating the productive interval with high formation pressure).

Low efficiency of traditional plugging compositions is caused by the fact that in conditions of high opening of absorbing channels the cement solution moves along the most drained channels of maximum opening with subsequent spreading and bottom positioning under the effect of gravitational forces (Fig.1).

The isolation method is based on gradual filling of cavity space in the formation channel. A large number of operations is required to achieve a positive effect, the number of isolation operations can be reduced by adjusting the structural properties of the plugging composition.

Relevance of the problems in elimination of catastrophic absorptions during well construction

The problem of efficient solution for elimination of drilling mud absorption is relevant for the majority of oil and gas fields. At present, there are no unified approaches and technologies to eliminate absorption because there is no unified and generally recognized classification of absorption by intensity. At each field (area), different classifications of absorptions and technologies of absorption control based only on drilling experience are applied [21].

The efficiency of isolation works with the use of fillers depends on their proper selection (material, size and concentration) [22, 23]. High-intensity absorptions are counteracted by pumping large volumes of fillers into the well, with clay solution used as a carrier liquid. The plugging ability of the isolation material is determined by a properly selected particle size. It is believed that the plugging material should contain a certain number of particles with a size approximately equal to the diameter of perforations in the rock, as well as a set of smaller particles [24]. At high opening of absorbing channels, conditions are created when the maximum size of rigid bridging agent does not meet the requirements of formation isolation. In such cases, increasing the concentration and volume of the isolation composition cannot guarantee channel plugging.

The most common isolation material for absorption elimination is Portland cement plugging composition. Traditionally used methods for isolation of absorbing formations by injection of plugging compounds into the formation through the open end of pipes or with the help of packer do not always lead to isolation of the absorption interval [25]. Work mechanism of plugging compositions is based on gradual filling of cavity space in the formation channel. The composition moves in the opened channel of absorbing intervals not in a continuous and uniform flow, but along the most drained channels of the highest opening. Spreading far deep from the wellbore zone, it tends to take a bottom position in the formation under the effect of gravitational force. As a result, the most opened channels, being filled with plugging material for a short time, are subsequently “thinned”, as the resistance force in the channel is insufficient to fix the solution in it. The process is complicated by the fact that when moving down the wellbore below the drill pipes and in the formation, the solution inevitably mixes with the flushing fluid and loses its plugging properties [21].

To prevent spreading of isolation compositions, plugging compositions with high thixotropic properties are used, which consist of cement, suspension stabilizer and retarder [26]. Due to high thixotropic properties and flow resistance, the compositions should prevent spreading in the absorption zone with subsequent strength gain after hardening [27, 28]. The experience of isolation works has shown that structural and rheological properties of plugging compositions based on clay-cement, gel-cement are insufficient for isolation of zones with channel opening of more than 10 mm. Further increase of structure is possible only at reduction of water-cement ratio, which can lead to rapid growth of structural strength in the injection process, transitioning to the onset of setting.

In some cases, quick-setting compositions based on Portland cement [29] are used, the strength of the structure in which is achieved by introducing sulphuric acid salts into the composition. As a result of reaction between cement and these types of salts, gypsum is formed, which causes such behaviour of cement that after 10-12 min the plugging mixture thickens sharply. If such a sample of plugging solution is kept in motion for more than 20 min, the time of setting can be significantly increased from 30 min to 10 h. In this regard, the works on isolation of absorption zones using components based on gypsum binder should be carried out within 20 min from the moment of their preparation. If this condition is not fulfilled, the gypsum structure is destroyed [30].

High thixotropic properties, excluding the spreading of the isolation material, are characteristic for compositions based on cross-linked polymers [31-33]. In laboratory conditions, these compositions form an elastic gel without water loss with a “ringing” structure. The advantage of cross-linked systems is their ability to adapt to different channel volumes. At differential pressure, they penetrate into the absorbing interval and fill the channels without restrictions on opening and morphology. At the same time, the structurally high rheological characteristics prevent the composition from spreading after removal of the overpressure occurring in the injection process. This is because the presence of spatial structures prevents the internal movement of layers in the composition. The disadvantages include the occurrence of viscous flow at the appearance of external forces exceeding the value of the ultimate yield stress, at which the destruction of its structure occurs [34]. Isolation of catastrophic absorption involves injection of cross-linked polymer in the volume providing the reduction of filtration characteristics of the absorption zone with subsequent consolidation by hardening plugging composition based on Portland cement [35].

In conditions of highly fractured (channel opening of more than 10 mm) and karst rocks, the values of ultimate yield stress for compositions are significantly reduced. As a result, when fixing the plugging composition, the pressure is applied to the gel screen, at which viscous flow of isolation compositions into the absorption zone occurs that significantly reduces the efficiency of isolation works. To exclude viscous flow of cross-linked compositions it is necessary to increase the strength of the gel structure and its adhesion to the rock [36]. Catastrophic absorptions are often accompanied by a significant drop in the liquid level in the well (500 m and more). When filling the well with drilling mud after isolation works, excessive hydrostatic pressure equivalent to the static level value acts on the isolation composition from the well side. Thus, the necessary property of isolation materials for elimination of high-intensity absorptions is the ability to withstand rather high pressure drops (5 MPa and more). Therefore, cross-linked isolation compositions are not suitable for isolation of zones with high channel opening.

High efficiency for isolation of catastrophic absorption zones is achieved using local well wall support equipment [37-39]. The disadvantages of this technology include limited application in directional and horizontal wells, high cost and significant duration of work (7 days on average). At present, there is no effective technology for elimination of catastrophic absorption, where the absorption zone is complicated by fractured and cavernous rocks with reduced formation pressure.

It can be concluded that none of the isolation compositions provides effective isolation of high-intensity absorption zones, where the complication is confined to high opening of the absorption channel (presence of fractured rocks, paleokarst). It is necessary to develop an isolation composition capable of adapting to the morphology of the fracture space, combining the properties of cross-linked gel and cement solution, which will prevent the spreading of the isolation composition during the induction period and withstand the pressures arising during the resumption of the well construction process after the isolation works [30].

Methods

Technique for elimination of catastrophic absorptions during well construction

Attention should be paid to the necessity of developing an isolation composition capable of adapting to the morphology of the fracture space with the effect of complete filling of absorbing channels, as well as withstanding sufficiently high pressure drops (5 MPa and more) after the waiting for setting.

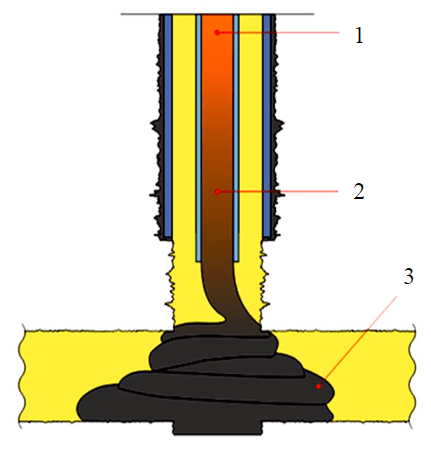

Fig.2. Mechanism of cavity space filling with CLPIM plugging compositions

1 – no cross-linking; 2 – beginning of cross-linking; 3 – end of cross-linking

To solve the problems of low efficiency for isolation of catastrophic absorption zones, the authors developed cross-linking plugging isolation material (CLPIM). The composition is a combination of cement and cross-linked polymer possessing transverse chemical bonds. After mixing, the composition undergoes three phase transitions from the linear gel stage to the cross-linked gel stage, with the final stage being crystallisation (solidification). The composition is pumped into the well as a linear liquid (Fig.2), the movement of the composition through the drill pipes is mainly in the liquid state. The concentration of cross-linking agent is selected so that cross-linking takes place in the lower part of the drill string. Thus, the composition enters the absorption zone in the cross-linked state, which prevents its spreading in the cavernous cavity of the absorbing formation. After completion of the injection, the well is left to wait for cement hardening to build up the strength of the isolation composition. The achieved strength allows the composition to withstand hydrodynamic pressure that occurs when the well construction process is resumed.

The required properties are ensured by using the basic composition (cement, mixing liquid, functional additives) and polymer. The composition is a stoichiometric mixture of oxides, carbonates, magnesium and calcium sulphates. When added to the magnesium chloride solution, it forms a cement mixture, that when entering the polymerisation reaction, forms an inorganic polyhydrate of magnesium hydroxysulphate/chloride, characterized by high compressive strength. The polymer from the group of heteropolysaccharides contained in the composition acts as a structure-forming agent and forms covalent chemical bonds of the polymer when interacting with the crosslinking agent. As a result, polymer chains are cross-linked with simultaneous increase in structural strength of the composition. The combination of reagents allows obtaining a homogeneous mixture, density and gelation time can be selected according to specific geological and technological conditions by adding conventional cement additives (retarding agents).

Laboratory tests were carried out at the laboratory base of “PermNIPIneft”, a branch of OOO “LUKOIL-Inzhiniring” in Perm. Gelation time and rheological characteristics of the isolation composition were determined.

The gelation time of the plugging material was determined by measuring its viscosity (consistency) on a consistometer in conditions close to wellbore parameters. Temperature, pressure, and rate of their gain were set according to geological and technical conditions of wells. Chandler 7322 high pressure and temperature sealed consistometer was used to determine the gelation time.

The rheological properties were determined on a modular rheometer MSR-102 manufactured by Anton Paar with a plane-to-plane measuring system (d = 50 mm), and gap size of 1 mm. The effective (dynamic) viscosity was determined at shear rates of 1-5 s–1 to minimize disruption of the composition structure and to avoid extrusion of the sample from the measuring system. To minimize the slipping effect of the sample in the measuring system, which leads to underestimation of the results, measurements were carried out under load (normal force 5 N).

Results

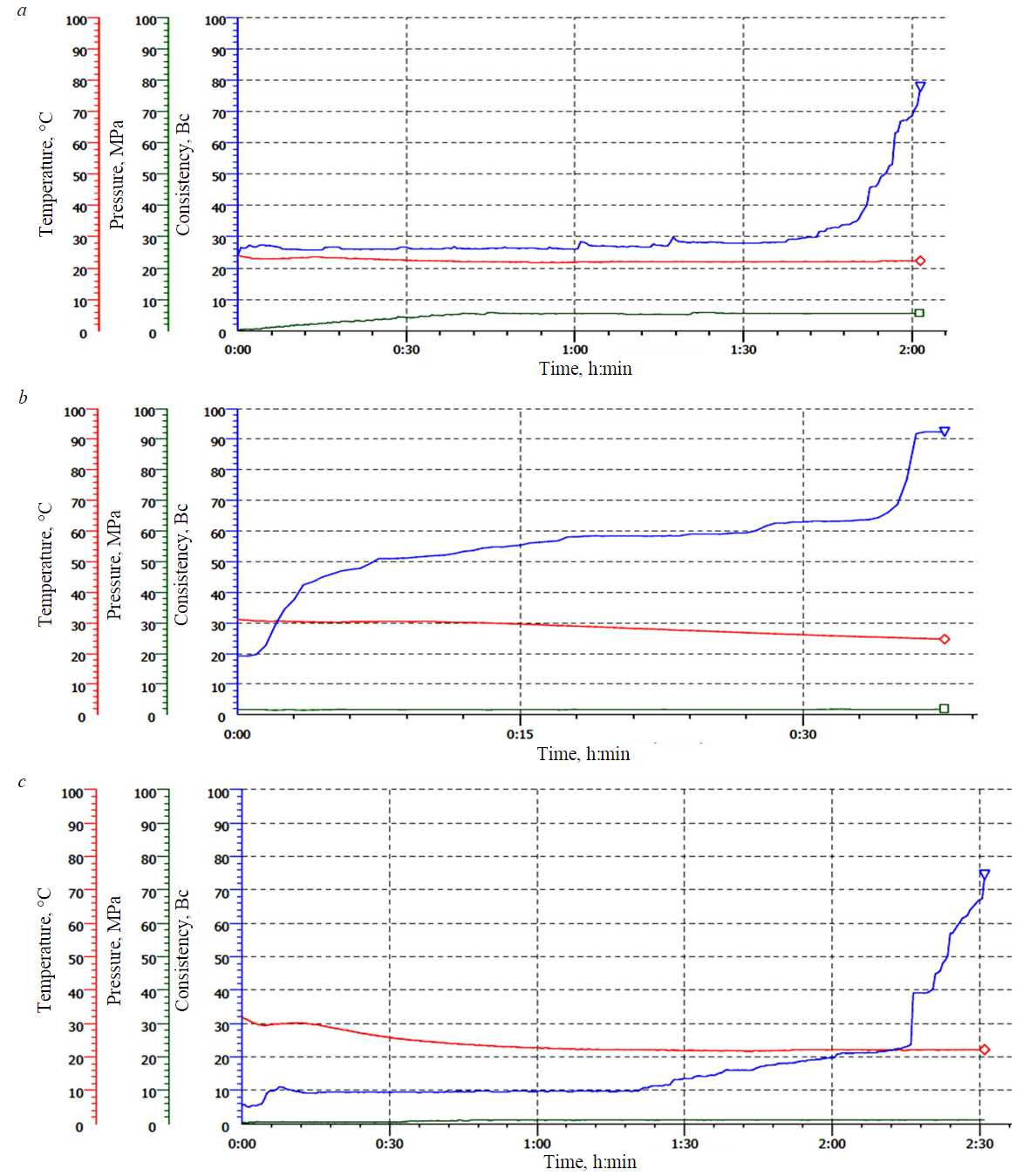

Fig.3 shows the consistency gain profiles (gelation time) of traditional magnesia binder-based isolation materials of fast-setting composition (FSC) without the effect of cross-linked gel stage and the proposed CLPIM composition with and without polymer. The traditionally used composition (FSC) is designed for bridge installation and absorption elimination. The composition is inert to hydrocarbon-based drilling muds, resistant to hydrogen sulphide aggression, has high adhesion characteristics, adjustable gelation time, fast strength gain, but has a number of disadvantages when isolating catastrophic absorption zones.

Graphs in Fig. 3 show that the technical result when using FSC is a sharp increase in the gelation time at the end of the induction period, short setting time (4-8 h), high thixotropic properties. Such result for carrying out isolation works in oil and gas wells is achieved by giving the plugging composition short setting and hardening times with provision of technological properties of injectability, simultaneous increase of compressive strength due to the use of caustic magnesite, stability regulator, bischofite, water, setting and hardening regulator (additives based on organophosphates) in the composition. The gelation time and consistency gain profile were determined on a consistometer at a pressure of 2-5 MPa and a temperature of 25-32 °С, the most typical for the fields of Perm region.

In the isolation compositions CLPIM and FSC, caustic magnesite is used as a binder, which includes functional additives that ensure its cross-linking. Cross-linking, which is expressed by a sharp increase in consistency, at maximum amount of additives occurs after 6-8 min (Fig.3, b), the time of the gelation beginning of the plugging part starts not earlier than 2.15 h (Fig.3, c).

When pumped into the cavernous cavities, the plugging compositions pass through a large volume of water and are diluted, which leads to deterioration of the isolation composition properties. Thus, a substantial part of the plugging compositions is spent on dilution. The technical result of the proposed composition is that the combination of components provides a shortened yield loss time due to internal cross-linking of the polymer. After the beginning of cross-linking the composition becomes resistant to degradation during its injection into the formation, it is not subject to dilution even in conditions of formation water movement. Contamination of the composition with well or formation fluids does not affect the process of strength gain, including in conditions of hydrogen sulphide aggression. Stability is confirmed by laboratory investigations in different environments. According to the results of investigations, it was concluded that polymer cross-linking inside the plugging composition makes the composition non-degradable.

Fig.3. Consistency gain profiles: а – fast-setting composition; b – CLPIM composition with maximum amount of polymer for gelation; c – CLPIM composition without polymer, regulating the gelation

In laboratory conditions, the composition after mixing for the first 15 min does not differ from conventional cement solutions and is in a liquid, flowing state, which allows the composition to be pumped into the well at minimum pressure. In 15 min after mixing, internal cross-linking takes place and the composition changes to an elastic gel state, but still flows. After 20 min, the composition is in a fully cross-linked state, withstands significant tensile forces and restores its shape after their removal. It should be emphasized that the proposed formulation of the composition after cross-linking provides low flowability while maintaining the conditions of injectability due to low adhesion to the well equipment. Thus, in the high pressure cell of a dynamic filter press the composition is pressed out at minimum pressure drop through a simulated model of a fracture with 10 mm opening.

In order to determine the safe time of operations with plugging compositions it is important to know the time of their gelation and setting. Two parallel processes – cement cross-linking and hydration – take place simultaneously in the proposed composition. When determining the gelation time, a consistency of 70 Bc (which characterizes the viscosity of a non-pumpable cement dough) will be reached at the time when polymer cross-linking starts (after 5 min). This is because when the polymer swells, a viscous linear gel is formed, which interacts with the cross-linking agent to form a three-dimensional elastic structure. The cross-linking process has no effect on the timing of the gelation onset - these are two independent processes. Consequently, the safe time of work can be determined by the gelation time of the base formulation without the addition of polymer.

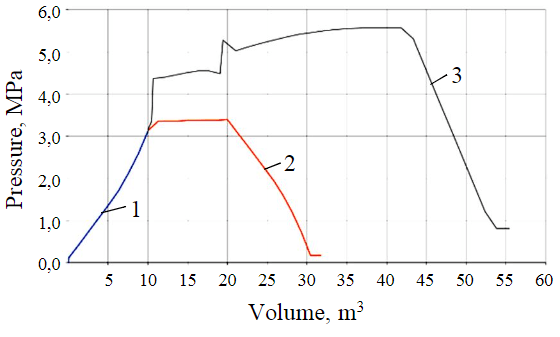

The development is currently being prepared for pilot field testing, and the risks associated with the pressure generated during the injection process have been identified. The safety of operations when using plugging compositions is a priority. In order to predict the pressure, to exclude the risks associated with the impossibility of pumping the isolation composition during the period of its cross-linking, a mathematical calculation for predicting the injection pressure at changing the rheological parameters of the isolation composition was performed. The calculation of pressure on the injection line was carried out in OptiCem module (LandMark) under the following conditions: static level before the start of works is 500 m, setting the open end of drill pipes above the absorption zone is 500 m, the depth of the absorption zone is 1 500 m, the volume of the injected composition is 20 m3, the flow rate (pumping rate) is 6 l/s, the composition is injected into the well with the open annular space. MSR-102 rheometer was used to measure the rheological characteristics of the cross-linked isolation composition, which allows obtaining highly accurate results of any viscous liquids, including cross-linked ones. Based on the obtained data, a graph of pressure dependence on the volume of injected CLPIM composition was plotted (Fig.4).

Fig .4. Injection pressure of the composition into the well

1 – injection of CLPIM into the pipe space; 2 – injection of CLPIM into the absorption zone; 3 – direct circulation

In conditions of high opening of the channels in the absorbing interval, the pressure during filling of the pipe space with the isolation composition and its injection into the formation will not exceed 3.5 MPa (lines 1 and 2). In case of low opening of the absorbing channels, when there are preconditions of the isolation composition movement into the annular space, it will be necessary to wash out the isolation composition by circulation. Movement of the cross-linked isolation composition through the annulus will be accompanied by higher values of wellhead pressure 4.5-5.0 MPa (line 3), in case of increasing the flow rate up to the design value the maximum pressure will increase up to 5.8 MPa. The injection technology implies setting the open end of the drill pipe above the absorption zone in such a way as to place 10-20 m3 of isolation composition in the open wellbore, i.e. no reaming and washing out of the isolation composition will be required. The risk associated with high pressure and the subsequent inability to pump the isolation composition in the designed volume at the specified flow rate is eliminated.

After injection of the isolation composition it is common practice to wash out the cement solution from the tool, there is an increase in hydrostatic pressure acting on the isolation composition, which may result in its viscous flow into the absorption zone. In order to increase the efficiency of isolation works, the test program at the object will recommend excluding the stage of tool washing, which may lead to clogging of drilling tools with cement solution. To exclude these risks, reagents have been added to the formulation of the composition to reduce adhesion in the pair of isolation composition – metal, thus minimizing adhesion of the composition to the inner surface of the tool. The tests show that after condensing a sample of CLPIM in a pressure and temperature regulated cell (HTHP) for 20 min after the start of cross-linking, the composition was pressed out through an opening of 10 mm with minimum pressure, the formation of “tongues” on the inner surface of the cell was not recorded.

The results of the tests indicate that there are no risks when CLPIM isolation composition passes through the bottomhole assembly during its gelling period. In the cross-linked state, the composition does not provide high hydraulic resistance, and adhesion-reducing reagents minimize adhesion of the composition to the inner surface of the tools.

Conclusion

The developed composition meets the requirements for isolation of catastrophic absorption zones complicated by high opening of absorption channels: shortened yield loss time due to internal cross-linking of the polymer; after the beginning of cross-linking the composition becomes resistant to degradation during its injection into the formation; the achieved strength allows the composition to resist hydrodynamic pressure occurring when the well construction process is resumed.

The use of magnesia binder in the formulation of the developed composition allows its destructuring by acid compositions during the development period, and also expands the area of application in conditions of hydrogen sulphide aggression. The advantages of the composition include short setting time and resistance to degradation in conditions of formation water movement. Parameters of density, gelation time, as well as the beginning of cross-linking can be selected in accordance with specific geological and technical conditions by adjusting the water-cement ratio, as well as by introducing retarders and cross-linking agents. At the first stage the area of application is limited by formation temperature (35 °C) as well as by the depth of the absorption zone (1500 m). After pilot tests the area of application can be expanded.

Tests of the developed technology are planned in order to assess the efficiency of eliminating catastrophic absorptions confined to formations with high opening of absorption channels. If the results of pilot tests are satisfactory, the use of CLPIM will significantly reduce the volume of injected isolation compositions, as well as the time of isolation works.

References

- Kumar A., Savari S., Whitfill D.L., Jamison D.E. Wellbore Strengthening: The Less-Studied Properties of Lost-Circulation Materials. SPE Annual Technical Conference and Exhibition, 19-22 September 2010, Florence, Italy. OnePetro, 2010. N SPE-133484-MS. DOI: 10.2118/133484-MS

- Rezaei A., Nooripoor V., Shahbazi K. Applicability of Fe3O4 nanoparticles for improving rheological and filtration properties of bentonite-water drilling fluids in the presence of sodium, calcium, and magnesium chlorides. Journal of Petroleum Exploration and Production Technology. 2020. Vol. 10. Iss. 6, p. 2453-2464. DOI: 10.1007/s13202-020-00920-6

- Ketova Y.A., Bai B., Khizhnyak G.P. et al. Testing of preformed particles polymer gel technology on core filtration models to limit water inflows. Journal of Mining Institute. 2020. Vol. 241, p. 91-96. DOI: 10.31897/PMI.2020.1.91

- Abdollahpour P., Tabatabaee Moradi S.S., Leusheva E., Morenov V. A Numerical Study on the Application of Stress Cage Technology. Energies. 2022. Vol. 15. Iss. 15. N 5439. DOI: 10.3390/en15155439

- Nikolaev N.I., Tyanle L. The modern technology of drilling and casing of well during the exploration of gas hydrates. Journal of Mining Institute. 2016. Vol. 218, p. 206-214 (in Russian)

- Blinov P.A., Dvoynikov M.V. Rheological and Filtration Parameters of the Polymer Salt Drilling Fluids Based on Xanthan Gum. Journal of Engineering and Applied Sciences. 2020. Vol. 15. Iss. 2, p. 694-697. DOI: 10.36478/jeasci.2020.694.697

- Chernyshov S.E., Galkin V.I., Ulyanova Z.V., Macdonald D.I.M. Development of mathematical models to control the technological properties of cement slurries. Journal of Mining Institute. 2020. Vol. 242, p. 179-190. DOI: 10.31897/PMI.2020.2.179

- Alsaba M., Al Dushaishi M.F., Nygaard R. et al. Updated criterion to select particle size distribution of lost circulation materials for an effective fracture sealing. Journal of Petroleum Science and Engineering. 2017. Vol. 149, p. 641-648. DOI: 10.1016/j.petrol.2016.10.027

- Razavi O., Vajargah A.K., Van O.E., Aldin M. Comprehensive analysis of initiation and propagation pressures in drilling induced fractures. Journal of Petroleum Science and Engineering. 2017. Vol. 149, p. 228-243. DOI: 10.1016/j.petrol.2016.10.039

- Elkatatny S., Gamal H., Ahmed A. et al. A Novel Solution for Severe Loss Prevention While Drilling Deep Wells. Sustainability. 2020. Vol. 12. Iss. 4. N 1339. DOI: 10.3390/su12041339

- Miller M.L., Scorsone J.T., Whitfill D.L. et al. The Development of a Geopolymer-Based Pill as an Engineered Solution to Lost Circulation. SPE Annual Technical Conference and Exhibition, 30 September – 2 October 2013, New Orleans, LA, USA. OnePetro, 2013. N SPE-166123-MS. DOI: 10.2118/166123-MS

- Alsaba M., Nygaard R., Hareland G., Contreras O. Review of Lost Circulation Materials and Treatments with an Updated Classification. AADE Fluids Technical Conference and Exhibition, 15-16 April 2014, Houston, TX, USA. 2014. № AADE-14-FTCE-25

- Matanovic D., Gaurina-Medimurec N., Simon K. Risk Analysis for Prevention of Hazardous Situations in Petroleum and Natural Gas Engineering. Hershey: IGI Global, 2014, p. 433.

- Savari S., Butcher J., Al-Hulail M. Managing Lost Circulation in Highly Fractured, Vugular Formations: Engineered Usage of High Fluid Loss Squeeze and Reticulated Foam Lost Circulation Materials. IADC/SPE International Drilling Conference and Exhibition, 3-5 March 2020, Galveston, TX, USA. OnePetro, 2020. N SPE-199635-MS. DOI: 10.2118/199635-MS

- Whitfill D.L. Lost Circulation Material Selection, Particle Size Distribution and Fracture Modeling with Fracture Simulation Software. IADC/SPE Asia Pacific Drilling Technology Conference, 25-27 August 2008, Jakarta, Indonesia. OnePetro, 2008. N SPE-115039-MS. DOI: 10.2118/115039-MS

- Budnikov V.F., Bulatov A.I., Peterson A.Ya., Shamanov S.A. Control and ways of improving well technical conditions. Moscow: Nedra, 2001, p. 305 (in Russian).

- Ruzhnikov A. Theoretical Aspects and Practical Implementation of Study of Drilling Fluid Level in the Annulus While Drilling with Total Losses. Abu Dhabi International Petroleum Exhibition and Conference, 9-12 November 2020, Abu Dhabi, UAE. OnePetro, 2020. N SPE-203454-MS. DOI: 10.2118/203454-MS

- Almetayev R., Hosani M.A., Ameri S.A. et al. First Nitrified Managed Pressure Drilling Application in United Arab Emirates. Abu Dhabi International Petroleum Exhibition and Conference, 12-15 November 2018, Abu Dhabi, UAE. OnePetro, 2018. N SPE-193025-MS. DOI: 10.2118/193025-MS

- Ali A.S., Dosunmu A., Anyanwu C. et al. Optimizing the Drilling HPHT/Deep Offshore Wells Using Managed Pressure Drilling Techniques. SPE Nigeria Annual International Conference and Exhibition, 5-7 August 2014, Lagos, Nigeria. OnePetro, 2014. N SPE-172349-MS. DOI: 10.2118/172349-MS

- Nugroho W.A., Hermawan S., Lazuardi B.H., Mirza R. Drilling Problems Mitigation in Geothermal Environment, Case Studies of Stuck Pipe and Lost Circulation. Asia Pacific Oil & Gas Conference and Exhibition, 17-19 October 2017, Jakarta, Indonesia. OnePetro, 2017. N SPE-186922-MS. DOI: 10.2118/186922-MS

- Kamenskikh S.V. Experience of Fight Against Absorption of Boring and Grouting Solutions at Construction of Wells. Scientific papers of donntu. Series: The Mining and Geology. 2016. N 2 (25), p. 36-51.

- Kang Y., Yu H., Xu C., Tang L. An optimal design for millimeter-wide facture plugging zone. Natural Gas Industry B. 2015. Vol. 2. Iss. 1, p. 113-119. DOI: 10.1016/j.ngib.2015.02.011

- Scott P., Redburn M., Nesheim G., Phillips C. A Pragmatic approach to Lost Circulation Treatments: What every Drilling Engineer Should Know. AADE Fluids Technical Conference and Exhibition, 14-15 April 2020, Houston, TX, USA. 2020. N AADE-20-FTCE-062.

- Liu H. Principles and Applications of Well Logging. Heidelberg: Springer, 2017, p. 356. DOI: 10.1007/978-3-662-54977-3

- Saragi R., Husien M., Sinaga A.L.M. et al. Successful Approach in Curing Lost Circulation in Depleted Aquifer Formations by Utilizing a Combination of Swelling Polymer & a Shear-Rate Rheology-Dependent Cement System; Case Study in UAE Land Operation. Abu Dhabi International Petroleum Exhibition and Conference, 15-18 November 2021, Abu Dhabi, UAE. OnePetro, 2021. N SPE-207416-MS. DOI: 10.2118/207416-MS

- Jadhav R., Patil S. Acid-Soluble Thixotropic Cement System for Lost Circulation Challenges. Abu Dhabi International Petroleum Exhibition and Conference, 12-15 November 2018, Abu Dhabi, UAE. OnePetro, 2018. N SPE-193168-MS. DOI: 10.2118/193168-MS

- Fomenkov A., Pinigin I., Mikliayev M., Fedyanin A. Using Thixotropic Cement Slurry for Lost Circulation Control: Case History, Volga-Urals Region. SPE Russian Petroleum Technology Conference, 22-24 October 2019, Moscow, Russia. OnePetro, 2019. N SPE-196813-MS. DOI: 10.2118/196813-MS

- Doutoum M.H.A., Alvarado R.F.B., Alaleeli A.R. et al. Advanced Light Weight Thixotropic Lost Circulation Cement Solution for Vugular and Natural Fractured Limestone Formations: UAE Offshore Case History. Abu Dhabi International Petroleum Exhibition and Conference, 15-18 November 2021, Abu Dhabi, UAE. OnePetro, 2021. N SPE-207264-MS. DOI: 10.2118/207264-MS

- Yuan B., Yang Y., Tang X., Xie Y. A starting pressure prediction of thixotropic cement slurry: Theory, model and example. Journal of Petroleum Science and Engineering. 2015. Vol. 133, p. 108-113. DOI: 10.1016/j.petrol.2015.06.005

- Yang J., Sun J. Status and Prospect of Drilling Fluid Loss and Lost Circulation Control Technology in Fractured Formation. Gels. 2022. Vol. 8. Iss. 5. N 260. DOI: 10.3390/gels8050260

- Mokhtari M., Ozbayoglu E.M. Laboratory Investigation on Gelation Behavior of Xanthan Crosslinked With Borate Intended to Combat Lost Circulation. SPE Production and Operations Conference and Exhibition, 8-10 June 2010, Tunis, Tunisia. OnePetro, 2010. SPE-136094-MS. DOI: 10.2118/136094-MS

- Jiang G., Deng Z., He Y. et al. Cross-linked polyacrylamide gel as loss circulation materials for combating lost circulation in high temperature well drilling operation. Journal of Petroleum Science and Engineering. 2019. Vol. 181. N 106250. DOI: 10.1016/j.petrol.2019.106250

- Leusheva E., Morenov V. Research of Clayless Drilling Fluid Influence on the Rocks Destruction Efficiency. International Journal of Applied Engineering Research. 2017. Vol. 12. N 6, p. 945-949.

- Ryltsev I.A., Ryltseva K.E., Shrager G.R. Kinematics of a Power-Law Fluid Flow in a Pipe with a Varying Cross Section. Vestnik Tomskogo gosudarstvennogo universiteta. Matematika i mekhanika. 2020. N 63, p. 125-138 (in Russian). DOI: 10.17223/19988621/63/11

- Luzardo J., Oliveira E.P., Derks P.W.J., Nascimento R.V. Alternative Lost Circulation Material for Depleted Reservoirs. OTC Brasil, 27-29 October 2015, Rio de Janeiro, Brazil. OnePetro, 2015. N OTC-26188-MS. DOI: 10.4043/26188-MS

- Bai Y., Liu C., Sun J. et al. High temperature resistant polymer gel as lost circulation material for fractured formation during drilling. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2022. Vol. 637. N 128244. DOI: 10.1016/j.colsurfa.2021.128244

- Timkin N. Liquidation of Disastrous Acquisitions with the Use of Equipment Local Well Casing (OLKS-295C) During Construction of the Well N 71 of Kovykta Field. Burenie & neft. 2016. N 2, p. 36-37 (in Russian).

- Park M., Teasdale P., Cowling M. Application of Uncemented Solid Expandable Liner for Combined Openhole Isolation and Casing Repair. SPE/IADC Drilling Conference and Exhibition, 17-19 March 2015, London, UK. OnePetro, 2015. N SPE-173134-MS. DOI: 10.2118/173134-MS

- Cameron J.R., Cooper B.S., Gusevik R.T. Expandable Solid-Steel Liner Applications in the Marcellus. SPE Eastern Regional Meeting, 20-22 August 2013, Pittsburgh, PA, USA. OnePetro, 2013. N SPE-165671-MS. DOI: 10.2118/165671-MS