Analysis of experience in the use of preformed particle polymer gels in the development of high-water-cut production facilities in low-temperature oil reservoirs

- 1 — Ph.D., Dr.Sci. Professor Perm National Research Polytechnic University ▪ Orcid

- 2 — Ph.D. Researcher Perm National Research Polytechnic University ▪ Orcid ▪ Scopus

Abstract

Foreign practice of oil production in high-water-cut conditions suggests using the technology of injection of preformed particle gel (PPG) suspension into injection wells. After swelling, the polymer particles become elastic and are able to penetrate through highly permeable watered intervals into the remote reservoir zone, forming a polymer “plug”. Thus far, the domestic experience of application of this technology boiled down to testing foreign compounds. We have looked into the possibilities of PPG technology application in geological and technological conditions of high-water-cut fields of Perm Krai. The paper proposes PPG reagents effective in low-temperature reservoirs (20-35 °С) and at relatively high salinity of formation water (more than 200 g/l). The world experience of PPG technology application was analyzed to identify the principal scheme of reagent injection, to establish variants of sequence of injection of PPG particles of different sizes, as well as the possibility of regulating the morphological characteristics of polymer gel particles during synthesis depending on the porosity and permeability of the reservoir. A prerequisite for the technology is the ability to remove PPG particles after treatment from the bottom-hole zone of the formation; for this purpose, tests were carried out on a breaker compound based on sodium persulfate with synergizing additives. PPG technology is effective in reservoirs with high permeability heterogeneity. Two types of high-water-cut production facilities potentially promising for PPG realization have been identified for oil fields of Perm Krai. The first type includes carbonate Tournaisian-Famennian reservoirs with pronounced macrofracturing, in which the PPGs are used for colmatation of flushed large fractures. The second type is terrigenous Visean deposits with increased oil viscosity from 5 to 100 mPa∙s and high permeability of reservoirs (> 0.5 μm2). For both types of reservoirs, areas have been selected that are promising for the implementation of PPG technology.

Funding

The research was carried out with the financial support of the Ministry of Education and Science of Russia within the framework of implementation of the program of the world-class research and education center “Rational Subsoil Use”. A number of studies were carried out at the unique scientific installation “Complex for the study of the structure of the capacitive space of rocks” of the community center for filtration and capacitive properties of rocks of PNRPU.

Introduction

At a late stage of oil field exploitation, waterflooding of reservoirs results in formation of washed-out zones through which the injected water seeps. Consequently, production wells are prematurely watered out, while a part of residual recoverable oil reserves (ROR) from less permeable zones do not participate in the displacement process and remain undeveloped. This problem is most pronounced in oil deposits with highly heterogenour permeability and increased oil viscosity. It is especially urgent to reduce watercutting of well products in “old” oil and gas producing areas. The possibility of extending the life of well stock for late-stage fields would help intensify production and increase the final oil recovery factor. Rational development of such fields should be supported by tertiary enhanced oil recovery methods.

At present, the main method of increasing the efficiency of water injection in domestic fields is the technology based on the use of polymer solutions. As field experience shows, in conditions of high salinity of formation water the standard use of polyacrylamide (PAA) is ineffective. As polymers can be adsorbed by rock surface and interact with metal ions in water (such as Na+, Ca2+), the rheological characteristics of the injected PAA solution change greatly during treatment. Study [1] shows that due to adsorption of a part of the polymer dissolved in water by the formation rock, the polymer does not enter the anterior part of the displacing water front and the mobility of the water phase does not change significantly. As a result, the polymer front can significantly lag behind the front of oil displacement by water.

In order to influence the reservoir injectivity profile in fields at the late stage of exploitation, the world practice in recent years has been to use the technology of injecting a suspension of preformed particle gel (PPG) into injection wells. After swelling, the polymer particles become elastic and therefore can penetrate into highly permeable watered intervals, bypassing the bottom-hole zone (BHZ) to the remote formation zone (RFZ), and forming a polymer “plug” [2-4].

Problem statement

Russian experience in the application of technology based on preformed polymer gels mostly consists in testing the compounds produced abroad. Among the domestic developments, one should mention Temposcreen reagent based on water-soluble PAA cross-linked by ionizing irradiation and requires dedicated expensive equipment to be produced [5-7]. There is also a limited experience in the application of water-swelling AK-639 polymer, which swells at a temperature of 70 °С, and Ritin polymer gel, at oil fields [8-10].

For Perm Krai, applicability of the aforementioned polymers is limited by their low absorption capacity at low reservoir temperatures (20-35 °С) and increased formation water salinity (more than 200 g/l). In such geological conditions the absorption capacity of preformed particle gels tends to decrease, as particles remain rigid, which significantly reduces their ability to penetrate the RFZ. This process is explained by the Flory – Huggins theory, stating that in the presence of cations in aqueous medium, a double electric layer formed by negatively charged functional groups of the polymer and metal cations is formed on the surface of the polymer particle [11]. The described phenomenon leads to a decrease in the mobility of polymer chains in the pellet and, as a result, to a significant decrease in the absorption capacity.

Study [1] describes the experience of injection of preformed polymer systems at the Kalamkas field (Kazakhstan) and a number of fields in Perm Krai. In general, the geological and technical performance of PPG technology in wells of Yu1C formation of the Kalamkas field was 80 %. At the same time, the maximum technological efficiency was achieved in the zone of paleochannels (91 %), which in addition to increased density of oil reserves are characterized by the highest velocities of injected water. For Perm Krai fields, the analysis of waterflooding experience using standard polyacrylamide has shown low efficiency, as there is almost no residual resistance factor for water injected following the margin. Study [1] makes a conclusion on promising application of PPG technology at oil facilities of Perm Krai and recommends to carry out research work to adapt the properties of synthesized polymers for the geological and physical conditions of this territory.

Generalization of international research experience in application of preformed particle gels in the oil industry is made in review papers [12-14]. Notably, the industrial experience of PPG technology application abroad is much more extensive. Preformed particle gels have been developed and tested for selective blocking of reservoir interlayers with permeability more than 0.5 µm2 [15-17], along with microgels which aim at conformance control in wells with lower permeability of intervals treated with gel (up to 0.5 µm2) [18, 19]. Microgels are obtained by inverse emulsion synthesis; there are varieties of microgels that are water-swellable microspheres [20, 21], thermosensitive microgels with two types of cross-linking (stable and unstable) [22], pH-sensitive microgels [18] etc. The PPG technology has been tested at fields in China, USA, Canada, etc., where it is considered an effective method of conformity control of the displacement front of oil reservoirs with water cut from 50 to 95 %. Based on the analysis of scientific publications, we can summarize the experience of technology implementation.

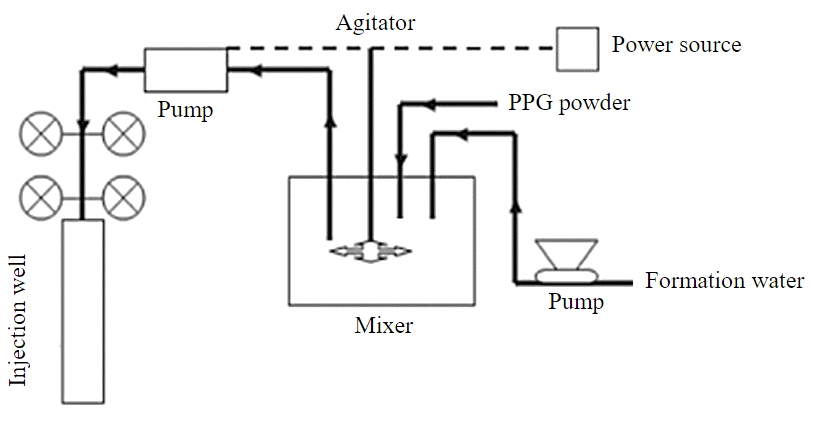

Figure 1 shows the basic scheme of PPG reagent injection [23], which involves preparing a suspension using produced water in a tank with an agitator. PPG suspension is pumped alternately with water. The recommended concentration of the reagent ranges from 2000 to 3500 mg/l, the volume of suspension for one treatment varies from 2500 to 4300 m3 on average. The required weight of PPG powder for treatment is 5-15 tons.

The advantage of using preformed particle polymer gels is low cost of the polymer, minimal expenditures on equipment for preparation of the suspension for injection into the well, as well as stability of its visco-elastic characteristics in reservoir conditions.

The PPG technology [24] was applied in a wide range of reservoir temperatures from 45 to 110 °С. Formation water with different salinity (up to 150 g/l and higher) was used for treatments. The gel was synthesized on the basis of polyacrylamide with addition of N,N′-methylene-bisacrylamide crosslinker. The absorption capacity of the obtained gel can vary from 10 to 200 g/g depending on the crosslinker concentration and formation water salinity.

The analysis of foreign experience shows that during treatment the volume of injected PPG suspension per well is 2000-4500 m3, the weight of dry PPG powder is from 5 to 15 tons of reagent. Duration of PPG treatment can be from 1.5 to 6 months. PPG technology application results in the following effects: increase of oil flow rate up to 10 tons per day; treatment effect of 120-250 tons per each ton of PPG powder (in dry form); reduction of water cut of production wells from 5 to 10 %. The technological effect from PPG treatment can last up to 12 months [25-27].

Methodology

The possibilities of PPG technology application are considered for the geological and technological conditions of the Volga-Ural oil and gas province (OGP) where most oil fields are at a late stage of operation. A typical example of prevalence of such mature fields is the territory of Perm Krai, where product water cut exceeds 75 % in more than 50 % of wells. In such geological and technological conditions there is a need for application of complex technologies aimed at conformity control and involvement of previously undeveloped reserves.

Formation conditions of Perm Krai fields are characterized by low temperatures (20-35 °С), which is generally typical for the Paleozoic sediments of the Volga-Ural Basin. Relatively high mineralization of formation water (200-230 g/l) is typical for Perm Krai. PPG reagents recommended for the study area should be adapted to the conditions of low-temperature formations with high formation water salinity.

Fig.1. PPG reagent injection scheme [23]

Due to low temperature and increased salinity of formation water, the absorption capacity drops significantly. That is why most imported PPG formulations are ineffective for the study area. The authors have developed an original formulation of PPG gel cross-linked with imide functional groups formed during synthesis between polyacrylamide chains [28]. Under the study conditions, the proposed composition has an absorption capacity of 35-40 g/g, which is twice higher than the available analogs. Optical microscopy has shown that the gel particles increase in size by 4-6 times during swelling. Tests to determine the strength of gel particles showed that they are able to compress and pass through holes 20 times smaller than the diameter of the swollen particle.

The authors have conducted filtration core tests of this reagent on carbonate fractured [29] and terrigenous reservoirs of pore type [30]. Using the X-ray tomography method [31] it was established that PPG suspension colmatizes fractures and highly permeable porous intervals of the core and promotes redistribution of filtration flows into low-permeable channels.

PPG treatment is controlled by three main parameters: injection rate, suspension concentration, and size of gel particles, which are determined, among other things, by permeability of the bottomhole formation zone and injectivity of injection wells. If at the initial stage of treatment there is an increase in pump outlet pressure, the first step is to reduce the injection rate and PPG concentration. The parameters are adjusted during treatment so that the injection pressure does not exced 80 % of the design rock fracture pressure.

The gel particle size is selected based on the void space characteristics, as well as gel characteristics (strength, absorption capacity). The most common algorithm for treatment involves injection of suspension starting with small PPG fractions, and if there is no change in injection pressure, increasingly larger PPG fractions are injected.

A different treatment option is used to treat reservoirs that have been determined to have fully flushed “superchannels”. In this case, injection starts with a larger PPG fraction to colmatize the reservoirs, and then gradually shifts to PPG with a smaller particle size.

During injection, PPG gel particles can adhere to the rock surface and form a crust [32, 33], so the necessary condition is the technological possibility to remove the reagent after treatment from the bottomhole zone. In [34] core studies it is shown that swollen PPG particles in the presence of hydrochloric acid can give away from 60 to 85 % water. Dehydration of PPG particles leads to their multiple shrinking and, consequently, to the restoration of permeability and porosity of the core. Analysis of the experience of the technology application shows that to restore BHZ injectivity, a breaker is usually injected into the injection well after treatment [35, 36].

Both enzymes and oxidizing agents were considered for the development of breakers (destructors) that destroy the structure of preformed gel. Enzymes are capable of effecting polymer chains, which leads to their breaking into shorter fragments of lower molecular weight. The use of enzymes as breakers is limited by their effectiveness in small temperature and pH intervals, as well as by their high cost. Therefore, it is more promising to use breakers that break polymer chains as a result of redox processes.

Study [35] describes tests of PPG breakers based on such oxidizing agents as sodium hypochlorite, calcium hypochlorite, and sodium persulfate, and concludes that the latter is more efficient. With this in mind, the authors tested a breaker based on sodium persulfate as part of the testing of the obtained reagent. During the research PPG particles were kept in model formation water (mineralization 200 g/l) up to the equilibrium absorption capacity, after which a 20 g gel sample was placed in the breaker solution. After 24 hours, the polymer was separated from the breaker solution by filtration. The fractions of dissolved polymer were calculated from the polymer mass values before and after interaction with the breaker. The test showed that 85 % of the PPG gel dissolved during interaction with the breaker within one day, which can be considered a satisfactory result.

One of the main conditions determining the final efficiency of the technology application is the correct choice of the development system section, including the injection and associated production wells. The necessary requirement for the injection well is its high injectivity factor. For successful introduction of the technology in the implementation area, the formation has to have a pronounced heterogeneity in terms of permeability (k) from 10–3 μm2 to single digits. There should be a stable hydrodynamic connection between the injection and production wells, which is most reliably substantiated by tracer studies.

Having summarized the analysis of experience of PPG technology implementation, we can formulate the following geological and technological conditions for selecting sites promising in terms of its effective application. Economic feasibility should be justified by the presence of sufficient residual recoverable oil reserves, which oil and gas producing companies currently estimate based on 3D digital geological and technological models. The site of technology implementation should be characterized by water cut of production wells more than 50 % and high injectivity of injection wells [13]. In this case, based on the methods of hydrodynamic studies of wells, well interference testing and tracing of labeled substances, stable hydrodynamic connection between the injection well and the neighboring producing wells should be established. Examples of evaluation of interference of production and injection wells based on complex analysis of hydrodynamic studies of wells, methods of hydraulic listening and tracing of labeled substances are given in [36].

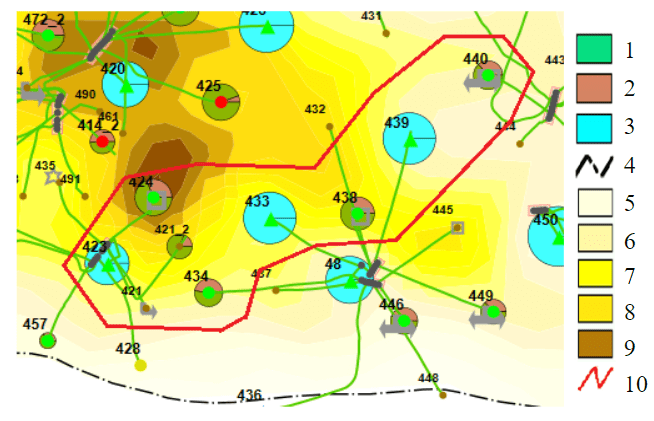

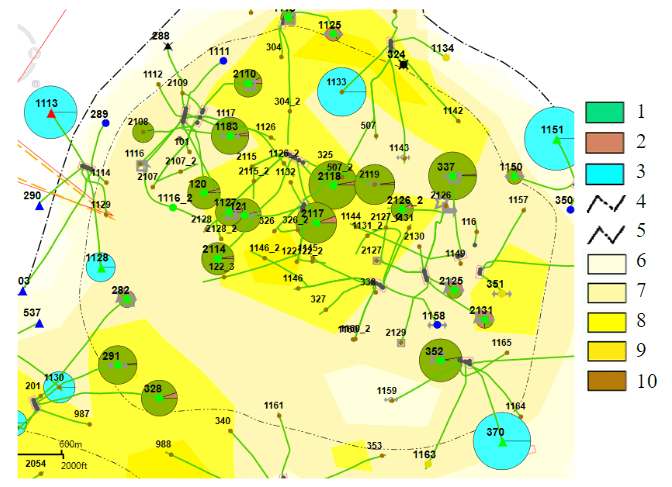

Fig.2. Example of a fractured reservoir development site.

Facility T. Opalikhinskoe oil field 1, 2 – current withdrawals, tons per day (1 – water flow rate, 2 – oil flow rate); 3 – injectivity, m3/day; 4 – outer oil bearing contour; 5-9 – density of reserves, t/m2 (5 – 0.03-0.17; 6 – 0.17-0.32; 7 – 0.32-0.46; 8 – 0.46-0.61; 9 – 0.61-0.75); 10 – PPG area

Effective application of PPG technology also requires high anisotropy of reservoir permeability both in height and in area. With this in mind, this technology can be effective for both fractured reservoirs and pore-type reservoirs with highly heterogeneous geological structure. For deposits with pronounced macrofracturing, the purpose of PPG is colmatization of washed-out large fractures. In Perm Krai, this type is mainly confined to carbonate reservoirs of Tournaisian-Famennian age (T, Fm) [37]. An example is the deposit of reservoir T of the Opalikhinskoe field, which is characterized by high-viscosity oil (μ = 82 mPa∙s) and reduced reservoir matrix permeability (k = 0.061 μm2). In this production facility with the current reserve recovery η = 46.8 %, more than 60 % of wells work with water cut of more than 50 %, which testifies to the expediency of application of tertiary methods of oil recovery.

An area of the deposit with increased density of oil reserves and water cut of all producing wells exceeding 50 % was selected as a promising area for implementation of PPG technology (Fig.2).

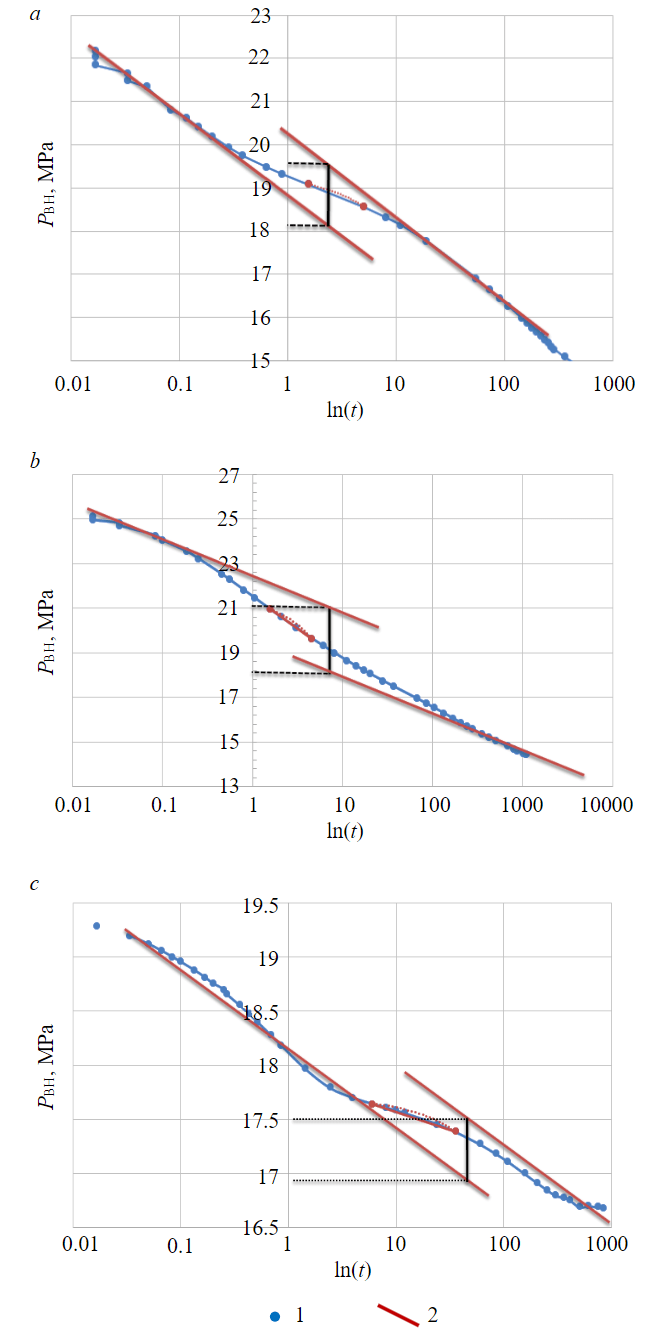

The choice of this area for implementation of a production trial is based, among other things, on the fact that it is well studied: apart from standard logging, hydrodynamic studies have shown high permeability of the reservoir (k > 0.5 μm2). At the same time, its injection wells N 423, 433, 439 have a characteristic bend on the pressure drop curves (Fig.3), which is interpreted as presence of fracturing in Warren – Root model [38, 39]. According to efficiency calculations, the average fracture openness over the thickness of the perforation interval ranges from 30 to 50 μm. The effect of PPG technology application should be colmatization of the most open cracks, and taking into account the change in particle size after swelling, the minimum size of PPG particles can be estimated at 250 μm.

Fig.3. Pressure drop curves for injection wells N 423 (а), 433 (b), 439 (c) 1 – pressure drop curve measurements; 2 – interpretation by Warren – Root model

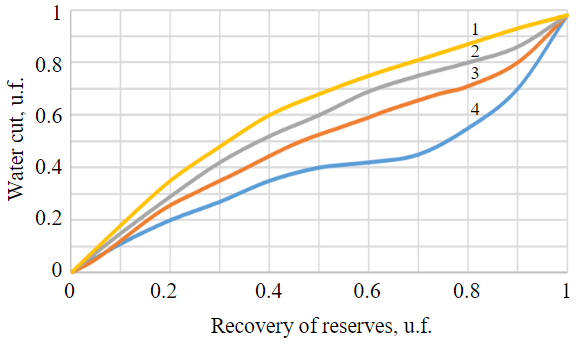

In a pore type of reservoir, the advanced waterflooding of wells is more pronounced in deposits with increased oil viscosity. Figere 4 shows examples of dependence of well product watercut on oil reserves recovery [40] for pore type reservoirs in different ranges of reservoir oil viscosity.

At µ < 2 mPa∙s only after recovery of η > 75 % reserves, the wells start to quickly become waterflooded. At low µ, the oil displacement front is uniform over the entire reservoir thickness, and water cut does not exceed 45 % during the main development period. Starting from µ > 5 mPa∙s, the water cut exceeds 50 % as early as at 40 % recovery. Thus, deposits with increased oil viscosity (μ ≥ 5 mPa∙s) in highly permeable pore reservoirs (k ≥ 0.5 μm2) are promising for PPG realization. The analysis of Perm Krai deposits shows that deposits of this type predominantly belong to terrigenous Visean strata (Tl, Bb, Ml – 41 facilities) of the platform part of Perm Krai. It should be noted that focal areas with k ≥ 0.5 μm2 might be present in deposits with lower average permeability, which may also become targets for PPG application.

The Tl-Bb reservoir of the Shagirtsko-Gozhanskoe field (μ = 38 mPa∙s, k = 1.2 μm2, η = 60.9 %) can be considered a promising pore-type facility for PPG technology. In this production facility as a whole, in pre-sence of sufficient ROR, the stock of producing wells operates with water cut of more than 80 % (Fig.5).

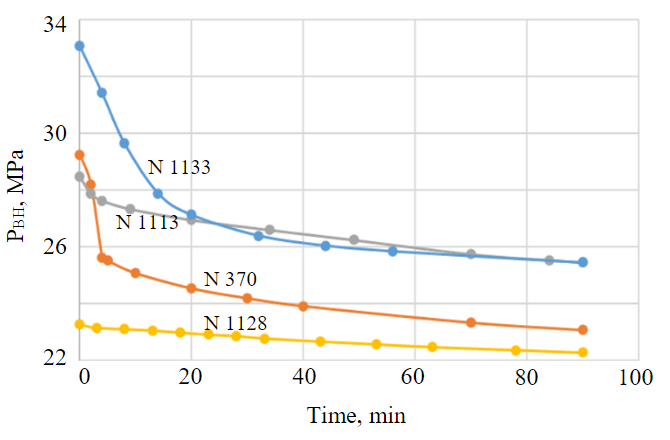

According to foreign practice, it is recommended to select candidate wells for injection of PPG reagents by calculating the PI (pressure index), which is plotted on a pressure drop curve with values taken at intervals of 5-10 min when the injection well is shut down for 90 min [14, 23, 41]. An index is calculated from the graph of pressure change over time

where P(t) is pressure change over time when the injection well is shut down; Т is well shutdown time.

Fig.4. Dependences of product water cut on recovery of reserves depending on different ranges of oil viscosity. Tl-Bb-Ml facilities. Perm Krai [40] 1 – μ < 2 MPa·s; 2 – μ = 2-5; 3 – μ = 5-20; 4 – μ > 20

Fig.5. Example of a pore reservoir development site. Tl-Bb facilities. Shagirtsko-Gozhanskoe field 1, 2 – current withdrawals, tons per day (1 – water flow rate, 2 – oil flow rate); 3 – injectivity, m3/day; 4 – inner oil bearing contour; 5 – outer oil bearing contour; 6-10 – density of reserves, t/m2 (6 – 1.23-3.97; 7 – 3.97-6.71; 8 – 6.71-9.44; 9 – 9.44-12.18; 10 – 12.18-14.92)

Fig.6. Pressure drop curves of injection wells N 370; 1113; 1128; 1133 for PI calculation

According to [14], injection wells with lower PI values deviating from the average value for the site by more than 5 MPa can be considered the first-priority candidates for PPG injection. According to the data of short-term measurements of efficiency (Fig.6) with participation of the authors, in [42] calculations of PI were carried out, according to which for wells N 370 – PI = 83.5 MPa; 1113 – PI = 104.8; 1128 – PI = 113.8; 1133 – PI = 78.9.

Thus, the considered development element is characterized by a high degree of heterogeneity (PI range of about 35 MPa) and can be recommended for selective isolation of highly permeable intervals. The lowest PI index was recorded for injection wells N 370 and 1133, which have a sharp downward trend of efficiency (Fig.6). Taking this into account, wells 370 and 1133 are prioritized for reagent injection when implementing PPG technology.

Conclusion

On the basis of the analysis of international experience of PPG technology application and research conducted for low-temperature oil deposits of Perm Krai, the authors have developed a composition cross-linked with imide functional groups formed during synthesis between poly-acrylamide chains This PPG reagent has an absorption capacity of 35-40 g/g, which is twice as high as available analogs. The effectiveness of colmatization of fractures and highly permeable porous intervals by the developed compound with redistribution of filtration flows into low-permeable channels is confirmed by the results of core filtration trials.

Optical microscopy studies have shown that swollen gel particles increase in size by 4-6 times. Tests to determine the strength of the gel particles show that they are able to compress and pass through holes 20 times smaller than the diameter of the swollen particle.

Two main areas of PPG technology application have been identified for high-water-cut oil production facilities in Perm Krai: in carbonate reservoirs with established fracturing and in terrigenous reservoirs with high heterogeneity of geological structure. For carbonate deposits, the effect of PPG technology application should consist in colmatization of the most open fractures. At one of the production facilities, based on the data of hydrodynamic studies of wells, the injection section with the established fracture openness of about 30-50 μm was identified, where injection of the reagent is recommended. Minimal size of PPG particles during treatment is estimated at 250 μm.

In terrigenous reservoirs, PPG technology is most effective for oil deposits with viscosity more than 5 mPa·s and permeability more than 0.5 μm2. The PI index was calculated for this type of reservoir when selecting injection wells for PPG injection using the pressure drop curve. It was found that the considered element of development is characterized by a high degree of heterogeneity (PI range of about 35 MPa). As a result of calculations, the wells with a sharp downward trend of the pressure drop curve were recommended for injection of the reagent.

The research has included trials of different types of breakers for PPG, with the conclusion that sodium persulfate is the most effective one. The experiments showed that 85 % of the PPG gel dissolved when interacting with sodium persulfate within one day.

Thus, as a result of the conducted research, a complex of necessary measures for effective application of PPG technology has been determined. The principal scheme of reagent injection was defined, effective scenarios of sequential injection of PPG particles of different sizes were established for various geological and technological conditions. Potentially promising areas of PPG implementation with fractured carbonate and pore terrigenous types of reservoirs were identified. The conducted studies allow singling out promising operational sites for implementation of preformed particle gel injection technology that could increase the period of profitable operation and ultimate oil recovery factor in mature fields in the long run.

References

- Mikhailov N.N., Zakenov S.T., Kiynov K.K. et al. The experience of implementation of polymer flooding technology in oil fields characterized by a high degree of salinity of reservoir and injected waters. Oil Industry Journal. 2019. N 4, p. 74-78 (in Russian). DOI: 10.24887/0028-2448-2019-4-74-78

- Elsharafi M.O., Bai B. Effect of Strong Preformed Particle Gel on Unswept Oil Zones/Areas During Conformance Control Treatments. EAGE Annual Conference & Exhibition incorporating SPE Europec, 10-13 June 2013, London, UK. OnePetro, 2013. N SPE-164879-MS. DOI: 10.2118/164879-MS

- Goudarzi A., Zhang H., Varavei A. et al. Water Management in Mature Oil Fields using Preformed Particle Gels. SPE Western Regional & AAPG Pacific Section Meeting 2013 Joint Technical Conference, 19-25 April 2013, Monterey, CA, USA. OnePetro, 2013. N SPE-165356-MS. DOI: 10.2118/165356-MS

- Zhang H., Bai B. Preformed-Particle-Gel Transport Through Open Fractures and Its Effect on Water Flow. SPE Journal. 2011. Vol. 16. Iss. 2, p. 388-400. DOI: 10.2118/129908-PA

- Barabanov V.L., Demyanovsky V.B., Kaushansky D.A. The study of rheological heterogeneity of the liquid systems in the instance of the water-swollen dispersed gels of polyacrylamide. Georesources, geoenergetics, geopolitics. 2016. N 1 (13) (in Russian). DOI: 10.29222/ipng.2078-5712.2016-13.art4

- Kaushansky D.A. Multipurpose innovative technology “Temposkrin-Lyuks” to increase OIL recovery from reservoirs at the late stage of development. Georesources, geoenergetics, geopolitics. 2014. N 1 (9) (in Russian).

- Kaushanskii D.A., Batyrbaev M.D., Duzbaev S.K., Demyanovskii V.B. Results of using Temposcreen technology in the fields of the Republic of Kazakhstan (on the example of PF Embamunaigas). Geology, geophysics and development of oil and gas fields. 2006. N 9, p. 51-58 (in Russian).

- Idiyatullin A.R. Ritin-10: A new effective reagent for reservoir recovery increase. Oil Industry Journal. 2007. N 2, p. 54-58 (in Russian).

- Sladovskaya O.Yu., Bashkirtseva N.Yu., Kuryashov D.A. et al. Application of colloidal systems for oil recovery enhancement. Vestnik Kazanskogo tekhnologicheskogo universiteta. 2010. N 10, p. 585-591 (in Russian).

- Shuvalov S.A., Vinokurov V.A., Khlebnikov V.N. Using polymeric agents for eor and waterproofing. Trudy Rossiiskogo gosudarstvennogo universiteta nefti i gaza imeni I.M.Gubkina. 2013. N 4 (273), p. 98-107 (in Russian).

- Hongbin Yang, Wanli Kang, Shuren Liu et al. Mechanism and Influencing Factors on the Initial Particle Size and Swelling Capability of Viscoelastic Microspheres. Journal of Dispersion Science and Technology. 2015. Vol. 36. Iss. 11, p. 1673-1684. DOI: 10.1080/01932691.2014.1000463

- Rozhkova Y.A., Burin D.A., Galkin S.V., Yang H. Review of Microgels for Enhanced Oil Recovery: Properties and Cases of Application. Gels. 2022. Vol. 8. Iss. 2. N 112. DOI: 10.3390/gels8020112

- Baojun Bai, Jia Zhou, Mingfei Yin. A comprehensive review of polyacrylamide polymer gels for conformance control.Petroleum Exploration and Development. 2015. Vol. 42. Iss. 4. DOI: 10.1016/S1876-3804(15)30045-8

- Yuzhang Liu, Baojun Bai, Yefei Wang. Applied Technologies and Prospects of Conformance Control Treatment in China. Oil & Gas Science and Technology – Revue IFP Energies nouvelles. 2010. Vol. 65. Iss. 6, p. 859-878. DOI: 10.2516/ogst/2009057

- Bai B., Liu Y., Coste J.-P., Li L. Preformed Particle Gel for Conformance Control: Transport Mechanism Through Porous Media. SPE Reservoir Evaluation & Engineering. 2007. Vol. 10. Iss. 2, p. 176-184. DOI: 10.2118/89468-PA

- Imqam A., Bai B., Delshad M. Preformed Particle Gel Propagation Through Super-K Permeability Sand and Its Resistance to Water Flow During Conformance Control. SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, 20-22 October 2015, Nusa Dua, Bali, Indonesia. OnePetro, 2015. N SPE-176429-MS. DOI: 10.2118/176429-MS

- Long Yu, Qian Sang, Mingzhe Dong. Enhanced oil recovery ability of branched preformed particle gel in heterogeneous reservoirs. Oil & Gas Science and Technology – Revue IFP Energies nouvelles. 2018. Vol. 73. Iss. 1. N 65. DOI: 10.2516/ogst/2018062

- Abdilbaki M., Huh C., Sepehrnoori K. et al. A critical review on use of polymer microgels for conformance control purposes. Journal of Petroleum Science and Engineering. 2014. Vol. 122, p. 741-753. DOI: 10.1016/j.petrol.2014.06.034

- Almohsin A., Ding H., Bai B. Experimental Study on the Transport and Improved Oil Recovery Mechanism of Submicron Particle Gel. SPE EOR Conference at Oil and Gas West Asia, 26-28 March 2018, Muscat, Oman. OnePetro, 2018. N SPE-190364-MS. DOI: 10.2118/190364-MS

- Meiqin Lin, Guiqing Zhang, Zhao Hua et al. Conformation and plugging properties of crosslinked polymer microspheres for profile control. Colloids and Surfaces A: Physicochemicsal Engineering Aspects. 2015. Vol. 477, p. 49-54. DOI: 10.1016/j.colsurfa.2015.03.042

- Chuanjin Yao, Guanglun Lei, Lei Li, Xuemei Gao. Selectivity of Pore-Scale Elastic Microspheres as a Novel Profile Control and Oil Displacement Agent. Energy Fuels. 2012. Vol. 26. Iss. 8, p. 5092-5101. DOI: 10.1021/ef300689c

- Ohms D., McLeod J., Graff C.J. et al. Incremental-Oil Success From Waterflood Sweep Improvement in Alaska. SPE Production & Operations. 2010. Vol. 25. Iss. 03. DOI: 10.2118/121761-PA

- Baojun Bai, Liangxiong Li, Yuzhang Liu et al. Preformed Particle gel for Conformance Control: Factors Affecting its Properties and Applications. SPE/DOE Symposium on Improved Oil Recovery, 17-21 April 2004, Tulsa, OK, USA. OnePetro, 2004. N SPE-89389-MS. DOI: 10.2118/89389-MS

- Baojun Bai, Mingzhen Wei, Yuzhang Liu. Injecting Large Volumes of Preformed Particle Gel for Water Conformance Control. Oil & Gas Science and Technology – Revue IFP Energies nouvelles. 2012. Vol. 67. Iss. 6, p. 941-952. DOI: 10.2516/ogst/2012058

- Daoyi Zhu, Jirui Hou, Xianxing Meng et al. Effect of Different Phenolic Compounds on Performance of Organically Cross-Linked Terpolymer Gel Systems at Extremely High Temperatures. Energy Fuels. 2017. Vol. 31. Iss. 8, p. 8120-8130. DOI: 10.1021/acs.energyfuels.7b01386

- Long Yu, Qian Sang, Mingzhe Dong. Enhanced oil recovery ability of branched preformed particle gel in heterogeneous reservoirs. Oil & Gas Science and Technology – Revue IFP Energies nouvelles. 2018. Vol. 73. Iss. 1. N 65. DOI: 10.2516/ogst/2018062

- Bo Wang, Meiqin Lin, Jinru Guo et al. Plugging properties and profile control effects of crosslinked polyacrylamide microspheres. Journal of Applied Polymer Science. 2016. Vol. 133. Iss. 30. N 43666. DOI: 10.1002/APP.43666

- Rozhkova Yu.A. Justification of the application of limited swelling polymer gels in the development of high-water-cut oil production facilities in Perm Krai: Avtoref. dis. … kand. tekhn. nauk. Perm: Permskii natsionalnyi issledovatelskii politekhnicheskii universitet, 2021, p. 19 (in Russian).

- Ketova Y.A., Bai B., Khizhnyak G.P. et al. Testing of preformed particles polymer gel technology on core filtration models to limit water inflows. Journal of Mining Institute. 2020. Vol. 241, p. 91-96. DOI: 10.31897/PMI.2020.1.91

- Ketova Y., Galkin S., Kolychev I. Evaluation and X-Ray tomography analysis of super-absorbent polymer for water management in high salinity mature reservoirs. Journal of Petroleum Science and Engineering. 2021. Vol. 196. N 107998. DOI: 10.1016/j.petrol.2020.107998

- Efimov A.A., Galkin S.V., Savitsky Y.V., Galkin V.I. Estimation of heterogeneity of Oil & Gas field carbonate reservoirs by means of computer simulation of Core X-Ray Tomography data. Ecology, Environment and Conservation. 2015. Vol. 21. November S, p. 79-85.

- Elsharafi M., Bai B. Minimizing Formation Damage for Preformed Particle Gels in Mature Reservoirs. SPE Asia Pacific Enhanced Oil Recovery Conference, 11-13 August 2015, Kuala Lumpur, Malaysia. OnePetro, 2015. N SPE-174645-MS. DOI: 10.2118/174645-MS

- Imqam A., Bai. B. Optimizing the strength and size of preformed particle gels for better conformance control treatment. Fuel. 2015. Vol. 148, p. 178-185. DOI: 10.1016/j.fuel.2015.01.022

- Imqam A., Bai B., Wei M. et al. Use of Hydrochloric Acid To Remove Filter-Cake Damage From Preformed Particle Gel During Conformance-Control Treatments. SPE Production & Operations. 2016. Vol. 31. Iss. 03. № SPE-172352-PA. DOI: 10.2118/172352-PA

- Ze Wang, Baojun Bai, Enze Zhou et al. Experimental Evaluation of Oxidizing Breakers for a Polyacrylamide-Based Re-Crosslinkable Preformed Particle Gel. Energy & Fuels. 2019. Vol. 33. Iss. 6, p. 5001-5010. DOI: 10.1021/acs.energyfuels.9b00709

- Martyushev D.A. Improving the geological and hydrodynamic model of a carbonate oil object by taking into account the permeability anisotropy parameter. Journal of Mining Institute. 2020. Vol. 243, p. 313-318. DOI: 10.31897/PMI.2020.3.313

- Cherepanov S.S. Integrated research of carbonate reservoir fracturing by Warren – Root method using seismic facies analysis (evidence from tournaisian-famennian deposit of Ozernoe field). Perm Journal of Petroleum and Mining Engineering. 2015. Vol. 14. N 14, p. 6-12 (in Russian). DOI: 10.15593/2224-9923/2015.14.1

- Fei Wang, Shicheng Zhang. Pressure-buildup analysis method for a post-treatment evaluation of hydraulically fractured tight gas wells. Journal of Natural Gas Science and Engineering. 2016. Vol. 35. N PA, p. 753-760. DOI: 10.1016/j.jngse.2016.09.026

- Mordvinov V.A., Martiushev D.A., Ladeishchikova T.S., Gorlanov N.P. Estimation of effects of natural reservoir fracturing on producing well performance. Perm Journal of Petroleum and Mining Engineering. 2015. Vol. 14. N 14, p. 32-38 (in Russian). DOI: 10.15593/2224-9923/2015.14.4

- Ilyushin P.Yu. Justification of oil reservoir water cut forecast using analog-statistical methods (on the example of development of Permian Prikamye fields): Avtoref. dis. … kand. tekhn. nauk. Saint Petersburg: Natsionalnyi mineralno-syrevoi universitet “Gornyi”, 2013, p. 20 (in Russian).

- Dongmei Wang, R.S. Seright, Zhenbo Shao, Jinmei Wang. Key Aspects of Project Design for Polymer Flooding at the Daqing Oilfield. SPE Reservoir Evaluation & Engineering. 2008. Vol. 11. Iss. 06. N SPE-109682-PA, p. 1117-1124. DOI: 10.2118/109682-PA

- Rozhkova Y.A., Gurbanov V.S., Efendiyev G.M., Galkin S.V. Assessment of applicability of preformed particle gels for Perm region oil fields. XIV Russian Conference on Petroleum and Mining Engineering, 09-12 November 2021, Perm, Russia. IOP Conference Series: Earth and Environmental Science, 2022. Vol. 1021. N 012073. DOI: 10.1088/1755-1315/1021/1/012073