One of the ways to increase the durability of the sectional pump balancing ring

- Ph.D. North-Eastern Federal University named after M.K.Ammosov ▪ Scopus

Abstract

The article presents the results of scientific research aimed at struggling the adhesive wear of parts of sectional pumps balancing ring, where the drainage units pumping equipment of the Russian Federation underground kimberlite mines was used as an object of research. It has been theoretically proven and experimentally confirmed that if there is data on the total operating time of a sectional pump in transient modes per day, using the constructed regression model, it is possible to calculate with high accuracy the average operating time of its balancing ring unit to failure. The constructed regression model is applicable only to sectional pumps of drainage units of underground kimberlite mines in the Russian Federation. It is possible to increase the durability of the balancing ring by reducing the acceleration and deceleration time of the sectional pump; for safe operation, it should be at least 10 s. Pilot tests carried out indicate the effectiveness of the proposed method for prompt identification of the critical axial displacement of the sectional pump rotor through the vibration of the discharge tube. The introduction of this method will reduce the cost of repair work to restore the performance of parts of the hydraulic foot to a minimum.

Introduction

Long-term experience of operating of sectional pumps in drainage systems of underground kimberlite mines of the Russian Federation indicates that this type of centrifugal pump is characterized by frequent failures of such a critical structural unit as a balancing ring [12, 28, 30]. The unit of the balancing ring (hydraulic balancing device) is one of the least reliable elements in the design of a sectional pump in terms of durability [1, 15, 20, 29].

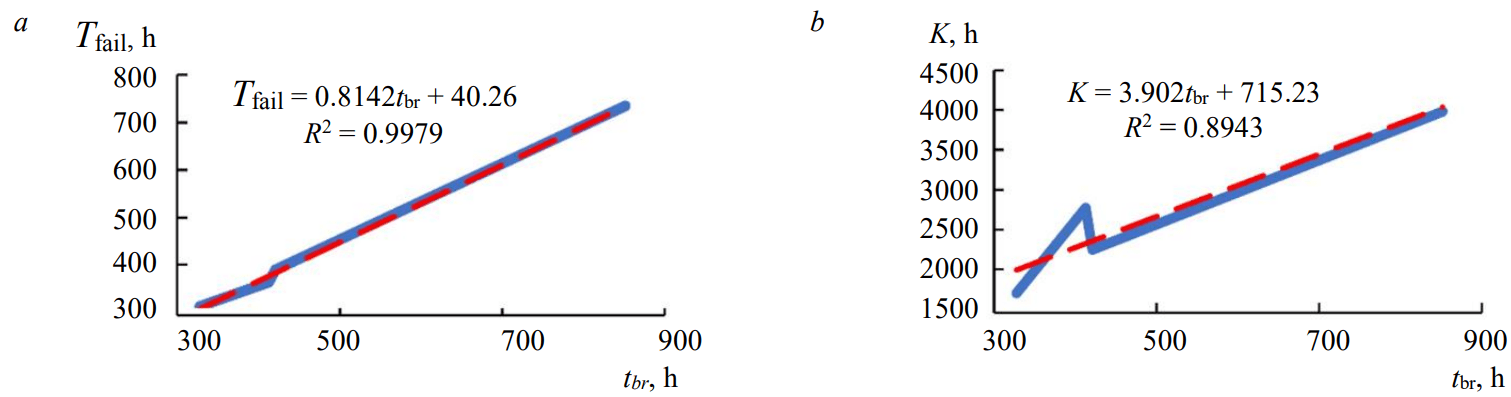

Currently, the problem of premature failure of balancing ring in sectional pumps used in domestic underground kimberlite mines is quite acute, since practice shows that such key indicators of pump reliability as the mean time between failures Tfail and the average resource between overhauls K are significantly the degrees are determined by the durability of the considered node tbr (Fig.1).

It is known that the low durability of flow path of centrifugal pumps parts is caused by extensive destruction of their surfaces, which is a consequence of the total impact on the metal of several types of wear: cavitation, hydroabrasive, corrosion and others [24, 26, 27, 33].

Fig.1. Dependences of the influence of the unitdurability on the mean time between failures (a) and the average resource between overhauls (b) and their approximation by a linear trend

The most common reasons for the premature wear of balancing ring parts are the operation of the sectional pump in the cavitation mode, as well as the ingress of air into its flow path [2, 13]. These negative processes are primarily characteristic of centrifugal pumps operating with a positive suction lift [10, 23].

In papers [5, 6, 9, 31] it is noted that frequent failures of flow path of sectional pumps parts can also be caused by their intense abrasion by suspended mechanical impurities contained in mine water.

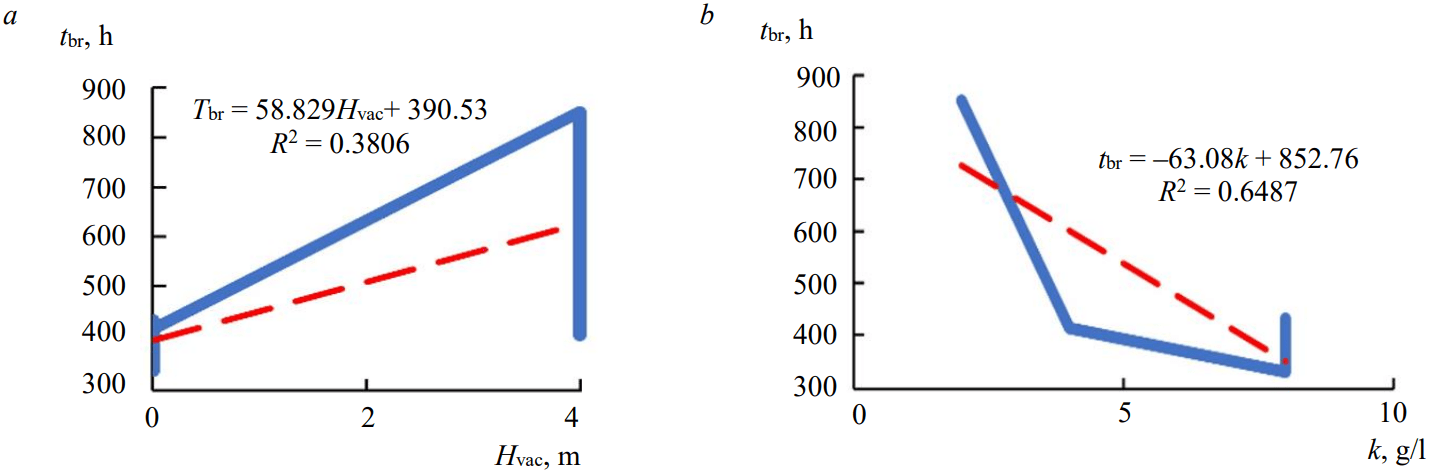

Mathematically processed practical material on the operation of sectional pumps of domestic underground kimberlite mines drainage facilities showed that cavitation and balancing ring wear types, expressed through the vacuum suction height Hvac and the concentration of mechanical impurities in mine water k, definitely affect the durability of the balancing ring, but none of them is prevalent (Fig.2).

Fig.2. Dependences of the vacuum gauge suction height influence and the concentration of mechanical impurities in mine water on the durability of the balamcing ring assembly (a) and their approximation by a linear trend (b)

Corrosion wear is also not typical for balancing rings, which is explained by the fact that most of the sectional pumps used in underground mining of mineral deposits are made of corrosion-resistant materials (SCPa, SCCP) [8, 16].

In papers [1, 20] it is noted that at the time of the output of the sectional pump for the first or next major overhaul, the axial force acting on its parts can increase by about 2-7 times compared to the initial value. This is dictated by an increase in the gaps in the gap seals of the impellers due to their gradual wear [7, 18].

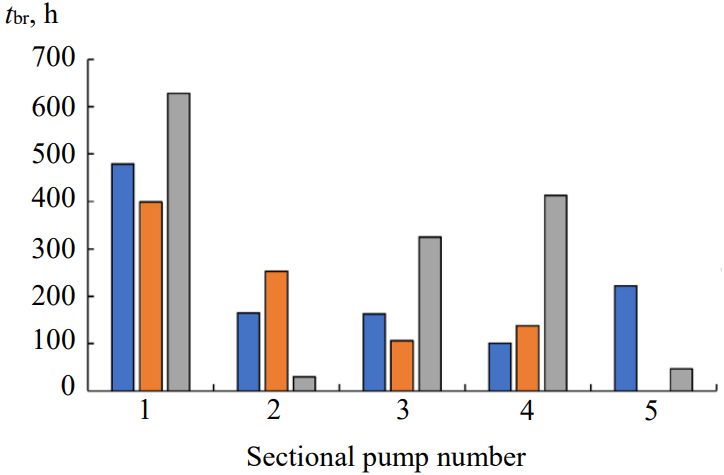

Due to the fact that the balancing ring can safely function only with an actual axial force not exceeding the calculated one by more than 30-40 %, then with an increase in the operating time of the sectional pump, the load on the balancing ring will gradually increase, leading to rubbing of its parts against each other [1, 14, 15]. This pattern is to a certain extent typical for sectional pumps operating in drainage systems of domestic underground kimberlite mines. As can be seen from Fig.3, with an increase in the operating time of sectional pumps, coupled with an increase in the clearances in the slotted seals of the impellers, in most cases, a decrease in the service life of a single balancing ring is clearly observed in comparison with the previous one (new or restored).

Fig.3. The dynamics of changes in the durability of balancing ring with an increase in the operating time of sectional pumps on the example of sectional pumps for the main drainage of the underground mine “Udachny”

The operating experience of sectional pumps used in underground mining of mineral deposits indicates that in transient operating modes, i.e. during acceleration and deceleration of the sectional pump, the parts of the balancing ring begin to actively touch each other due to the axial displacement of the pump rotor, thereby activating the process of adhesive wear [12, 14, 15]. Figure 4 clearly shows the consequences of balancing ring disk surfacesadhesivewear-depressions and craters. As the revisions of sectional pumps operating in the drainage facilities of domestic underground kimberlite mines show, such damage to parts of balancing ring is quite common.

Fig.4. Worn disk of the balancing ring of the JSH-200 sectional pump of the main drainage unit of the “Udachny” underground kimberlite mine

The process of friction of the balancing ring partsin transient modes of sectional pumpoperation a can be described by the wear model of Argard [21]:

where k – wear factor; P – contact pressure; νs – sliding speed of contact surfaces; H – material hardness.

As can be seen from formula (1), the rate of adhesive wear increases with a decrease in the hardness of the rubbed parts of the balancing ring. It is known that the hardness of metal products directly depends on their heating temperature [19, 21, 22]. In turn, the heating temperature of the rubbed parts of the balancing ring will increase until they stop actively touching each other. Thus, the rate of adhesive wear of balan-cing ring parts should largely depend on the operating time of the sectional pump in transient modes. The article is devoted to the study of the relationship between the durability of balancing ring of sectional pumps operating in underground kimberlite mines of the Russian Federation, and their acceleration and deceleration times [12].

Practice shows that each of the operating sectional pumps used in the drainage systems of underground kimberlite mines in the Russian Federation can be switched on and off up to three times a day. In this regard, instead of the acceleration and deceleration times of the sectional pump in research [12] as a variable, it is more expedient to use its total operating time in transient modes per day:

where n – the number of starts and stops of the pump per day; T – pump acceleration and deceleration times.

It can be concluded that it is possible to reliably predict and control the durability of the balancing ring unit by using a regression model obtained by mathematical processing of the operating time dependence of the unit under consideration tbr on the total pump operating time in transient modes per day.

In addition to the operation of the sectional pump in transient modes, the process of adhesive wear of balancing ring parts is strongly activated at a critical displacement of the pump rotor [30, 34, 35]. To protect the balancing ring parts of the sectional pump against intensive adhesive, it is recommended to install a vibration sensor on the unloading pipe, with the help of the data of which it is possible to quickly identify the critical axial displacement of the rotor, thereby reducing the cost of repair work to restore the operability of balancing ring parts to a minimum [10, 30]. The results of previous experiments indicate that with an increase in the initial level of vibration of the unloading pipe to 20 % and higher, the sectional pump must be taken out of operation for revision [30]. For practical application, the considered research results need to be tested in real operating conditions.

This article presents the results of scientific research on the construction of a regression model, which allows, with a high probability, to make a qualitative forecast of the functioning and manage the durability of the unit of the balancing ring of a sectional pump, as well as to test a method for the swift identification of the critical axial displacement of the sectional pump rotor based on the revealed patterns of the influence of the position of the rotor on the vibration discharge pipe level. The research is aimed at struggling the adhesive wear of parts of balancing ring of sectional pumps, where the pumping equipment of drainage units of underground kimberlite mines of the Russian Federation was used as the objects of research.

Methodology

To build a regression model, it is necessary to make sure that the collected material on the operation of sectional pumps is sufficient. To check the completeness of the volume of the collected material, the technique was used described in the article [17], according to which the volume of the collected material is considered acceptable for carrying out various kinds of statistical research only if the condition

where tfact, tcalc – actual and calculated observation time of the pumping equipment operation under study, respectively, h, is met.

The observation time is as follows:

where N – the number of failures of the hydraulic foot during the actual observation time tfact; Tmax – maximum operating time of the balancing ring to failure, h; d – objects of observationnumber; r – correction factor (for the confidence level γ = 0.8 and relative error δ = 0.1).

The durability of centrifugal pump flow path parts is in square dependence on the diameter of the part and in cubic dependence on the number of electric motor rotations [3, 4, 9]. In this regard, when conducting statistical studies, sectional pumps were taken as the object of research, which have similar sizes of wearing parts (i.e., similar in performance) and the speed of the electric motor.

As can be seen from the table, the collected material on the operation of 18 sectional pumps, the capacity of which lies in the range of 300-400 m3/h, and the rotational speed is equal to 1450 rpm, is quite sufficient for research.

The results of the check for completeness of the collected material

|

Pumping equipment for drainage system |

N |

Tmax |

d |

r |

Tfact |

tcalc |

|

KGV-2 |

34 |

1100 |

5 |

0.75 |

13955.2 |

9973.33 |

|

VNS-210 |

26 |

1450 |

5 |

0.75 |

22144.2 |

10053.33 |

|

KGVU, JSH-250 pumps |

57 |

1209 |

5 |

0.75 |

18673.2 |

18376.8 |

|

KGVU, SCPa 350-1100 |

17 |

914 |

3 |

0.7 |

7330.4 |

6905.77 |

When constructing the relationship between the average operating time of the balancing ring to failure and the total operating time of the sectional pump in transient modes per day, the weighted average values x of these parameters were used, which were calculated as follows [11, 12]:

where а1, а2…an – real numbers; w1, w2…wn – real weights.

The obtained results of statistical studies were necessarily checked for adequacy using the Fisher test.

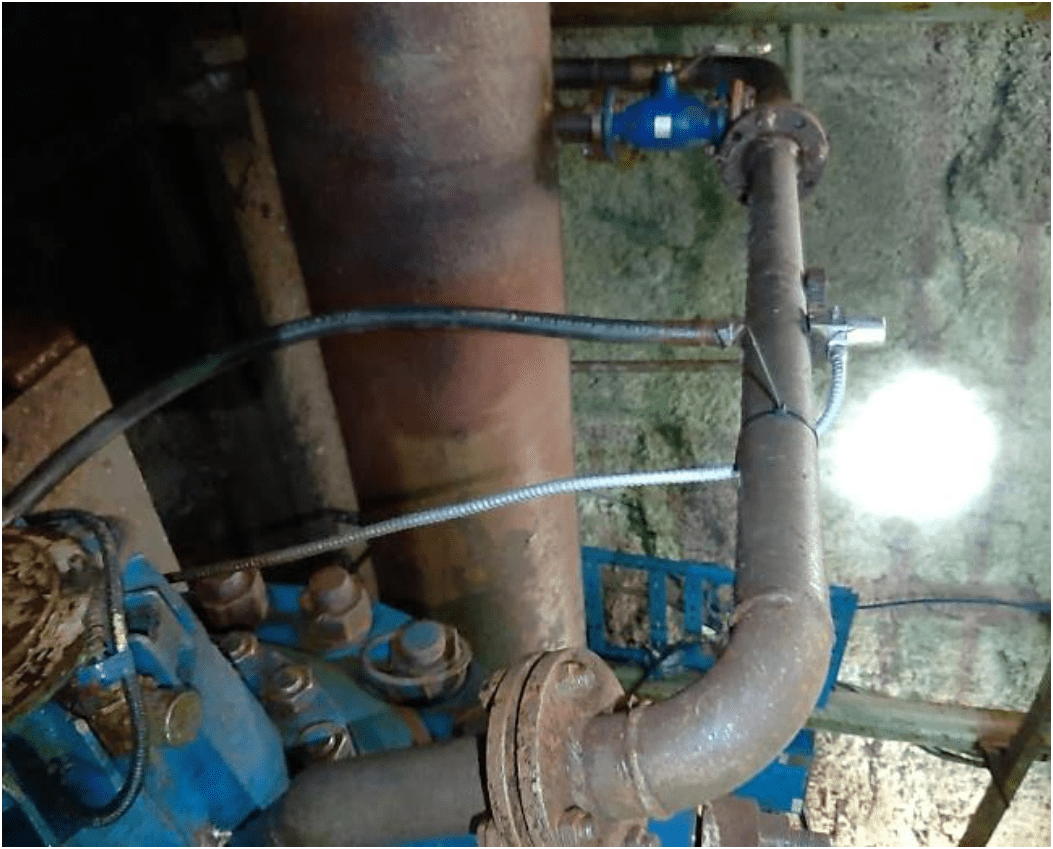

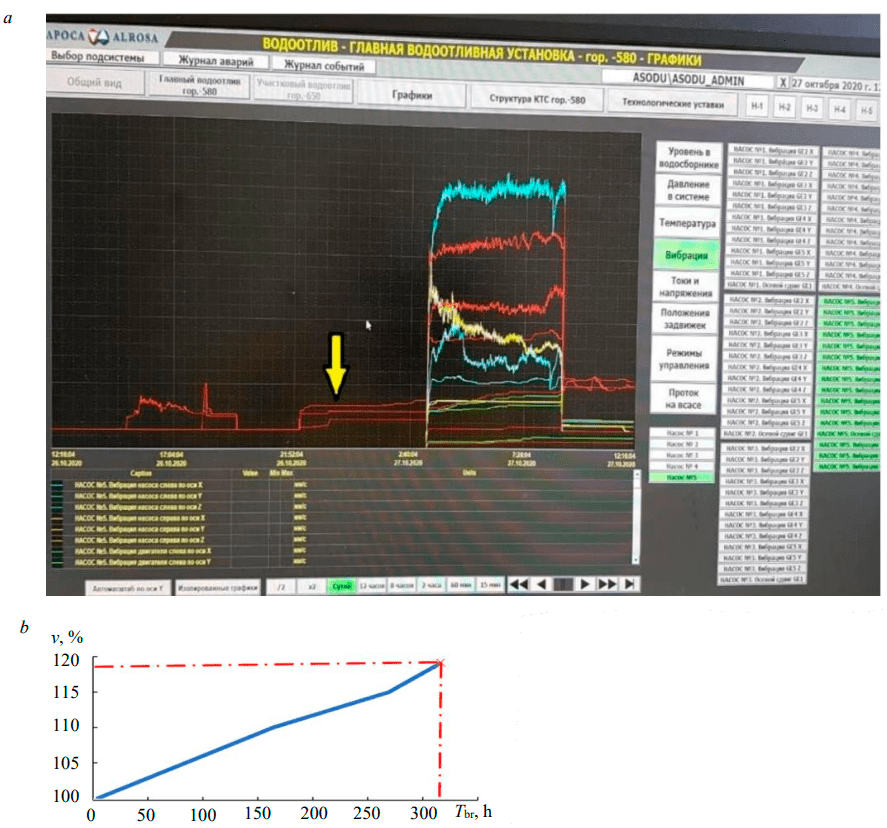

The method of operational identification of the critical axial displacement of the sectional pump rotor was tested on pump N 5 of the main drainage unit of the “Udachny” underground kimberlite mine, model JSH-200, using the Becker Mining Systems automation system operating at the mine (Fig.5). For better fixation of the vibration sensor, a plate was welded to the surface of the discharge pipe.

Discussion of research results

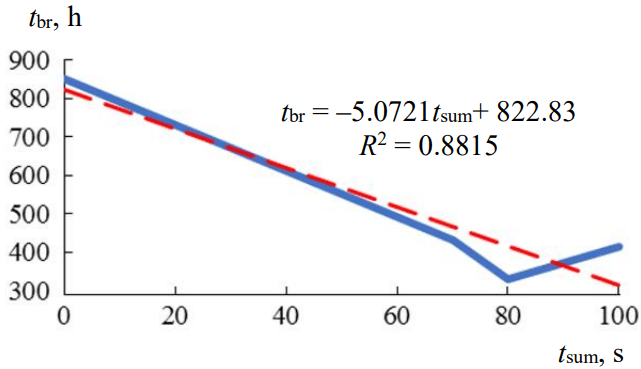

The obtained results of statistical studies have confirmed a strong relationship between the parameters tbrand tsum (Fig.6). The results are adequate, as evidenced by their verification by Fisher's criterion. The significance F of the constructed regression model tbr = –5.0721tsum + 822.83 is 0.02. Thus, it has been experimentally confirmed that in the presence of data on the total operating time of the sectional pump in transient modes per day, it is possible to accurately calculate the average operating time of the balancing ring unit to failure.

Fig.5. Industrial experimental tests

Fig.6. Dependence tbr = f(tsum) and its approximation by a linear trend

Practice shows that it is impossible to effectively control such a component of the tsum parameter as the number of starts and stops of the pump per day n (2), since the total operating time of sectional pumps per day that affects its value usually changes abruptly over time.

Provided that the electric motor of the sectional pump has a smooth start, it is possible to increase the durability of the balancing ring by reducing the pump acceleration and deceleration time. According to the recommendations of “Link Product” ltd., the ace-leration and deceleration time of the sectional pump should be at least 10 s [12]. With shorter acceleration and deceleration times, network overloads are possible due to a sharp jump in the starting current of the pump motor.

It is possible to reduce the rate of adhesive wear of balancing ring parts during operation of a sectional pump in transient modes by increasing their dimensions, as this leads to a decrease in contact pressure [25, 32, 34]. At the same time, the operating experience of sectional pumps of the main drainage unit of the “Udachny” underground kimberlite mine has shown that the use of factory-made balancing rings of increased diameter does not always have a positive effect on the efficiency of the pumps. As it turned out, the use of such modernized balancing rings can lead to a drop in the productivity of pumping equipment by 50-60 m3/h due to an increase in the flow of water through the discharge pipe. One of the consequences of a drop in the productivity of the pumping equipment of the drainage installation is the commissioning of the pumps in reserve. This negatively affects their reliability due to the increase in operating time in transient operating modes.

Experimental tests carried out on a sectional pump of the main drainage unit of the “Udachny” underground kimberlite mine confirmed the effectiveness of the method for prompt identification of the critical axial displacement of the rotor (Fig.7). It was found that the root-mean-square value of the vibration of the unloading pipe of the sectional pump increases along with the operating time of the balancing ring (Fig.7, b). During the tests, the balancing ring was replaced when the operating time Tbr = 315 h, which was accompanied by an almost limit, according to research [30], increase in the level of vibration of the discharge pipe v. At the time of replacement, the balancing ring was heavily worn, which confirms the effectiveness of the approved technical solution.

Conclusion

It has been theoretically proven and experimentally confirmed that if there is data on the total operating time of a sectional pump in transient modes per day, it is possible, using the constructed regression model, to calculate with high accuracy the average operating time of its balancing ring unit between failures. The constructed regression model is applicable only to sectional pumps of drainage units of underground kimberlite mines in the Russian Federation.

Fig.7. Dynamics of the change in the level of vibration of the unloading pipe (a) and its dependence on the operating time of the balancing ring (b)

It is possible to increase the durability of the balancing ring by reducing the acceleration and deceleration time of the sectional pump. To ensure safe operation, the pump acceleration and deceleration time must be at least 10 s.

Pilot tests carried out indicate the effectiveness of the proposed method for prompt identification of the critical axial displacement of the sectional pump rotor through the vibration of the discharge tube. The introduction of the method into production will reduce the cost of repair work to restore the operability of the balancing ring parts.